Investigation of Effects of Strip Metals and Relative Sliding Speeds on Friction Coefficients by Reversible Strip Friction Tests

Abstract

:1. Introduction

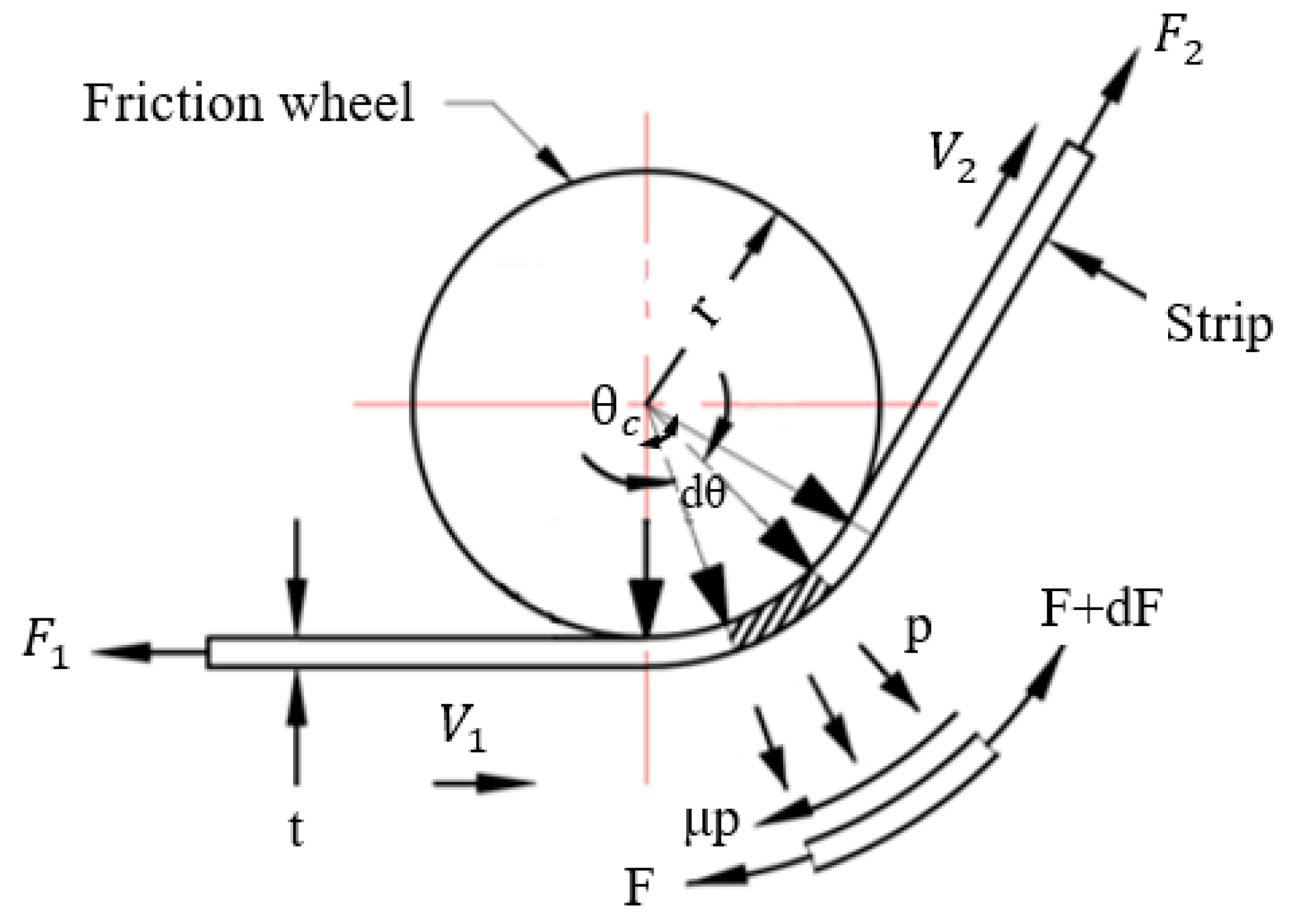

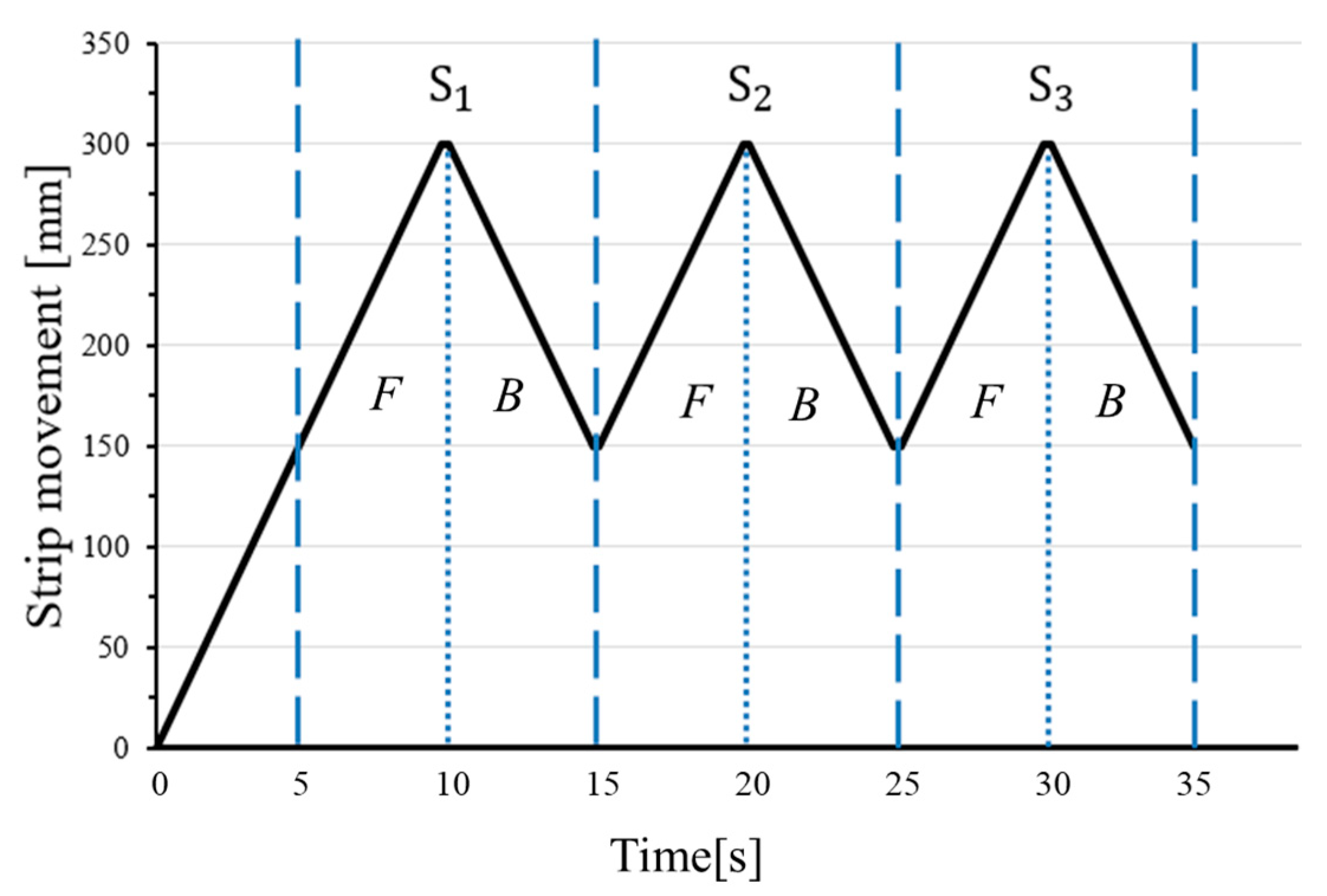

2. Determination of Friction Coefficient

3. Experimental Apparatus and Friction Test Conditions

4. Friction Test Results and Discussion

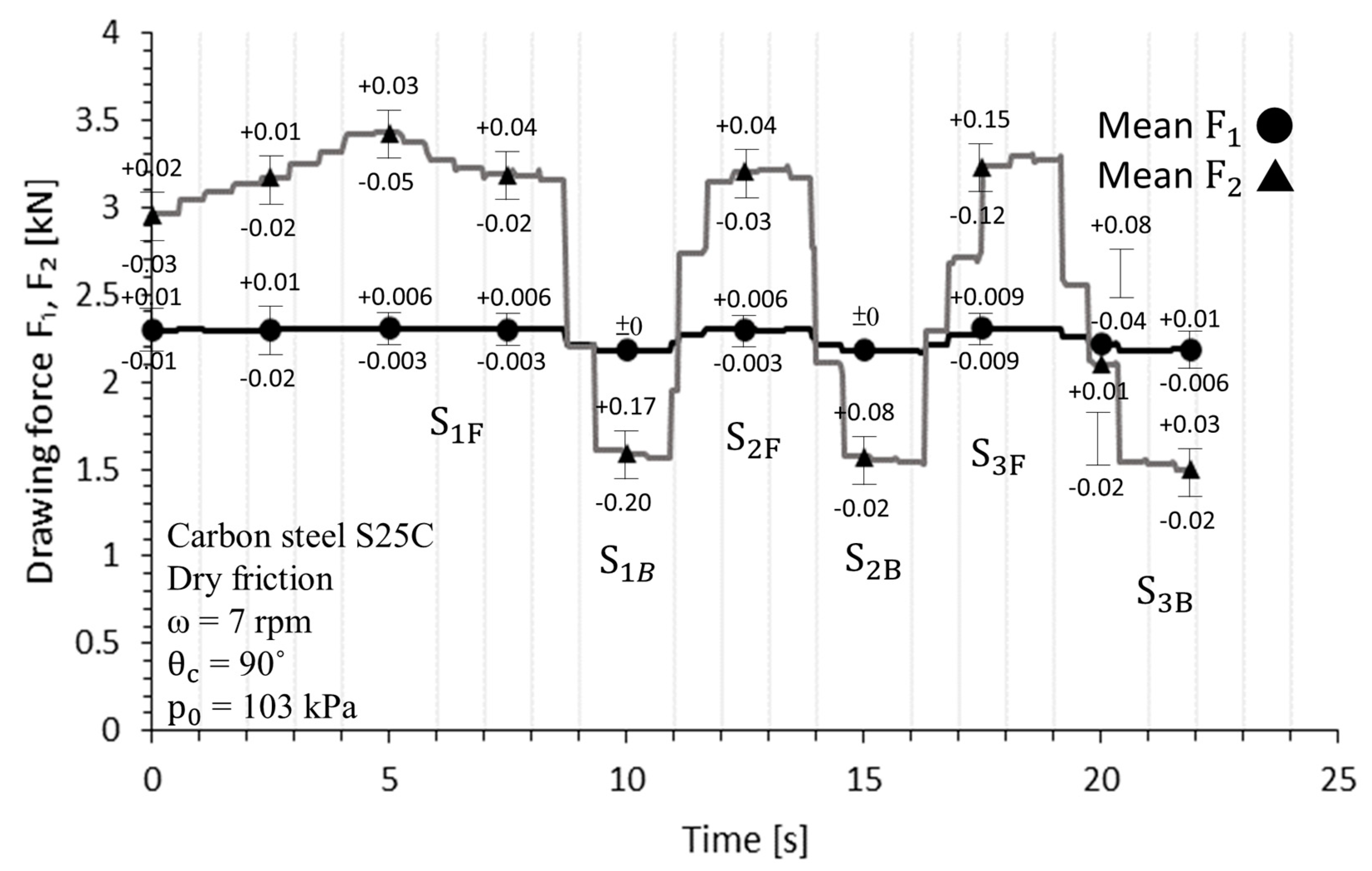

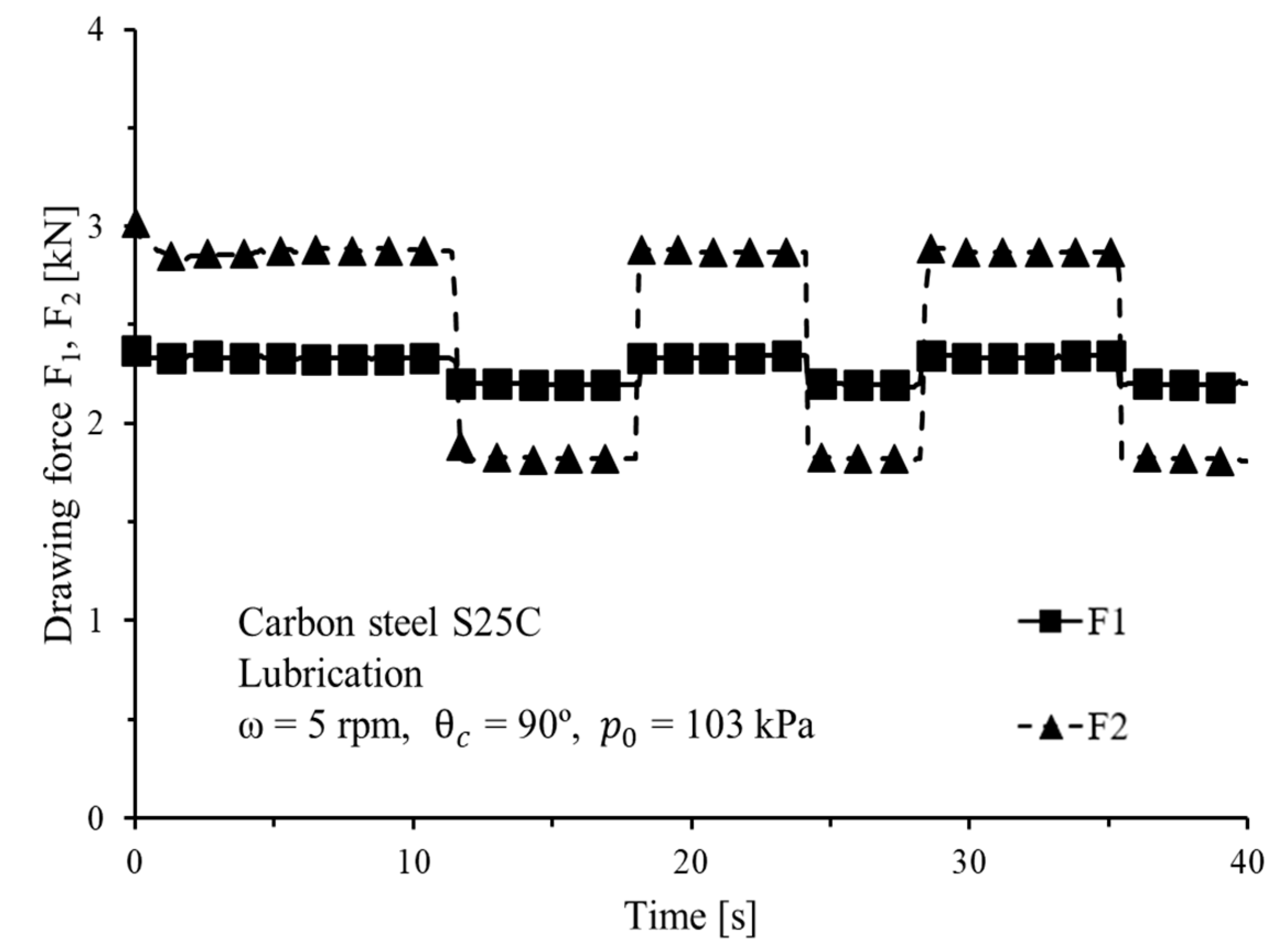

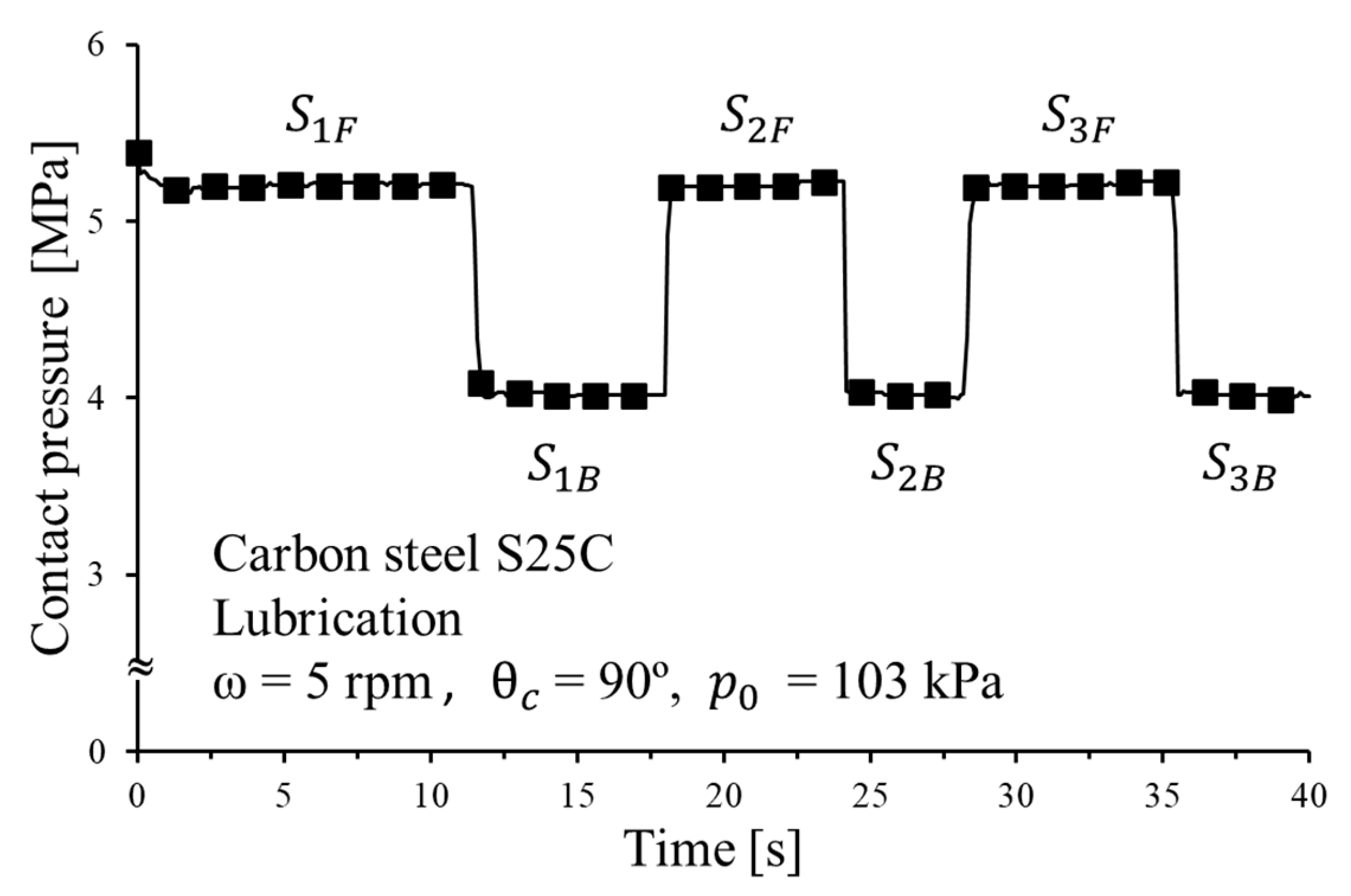

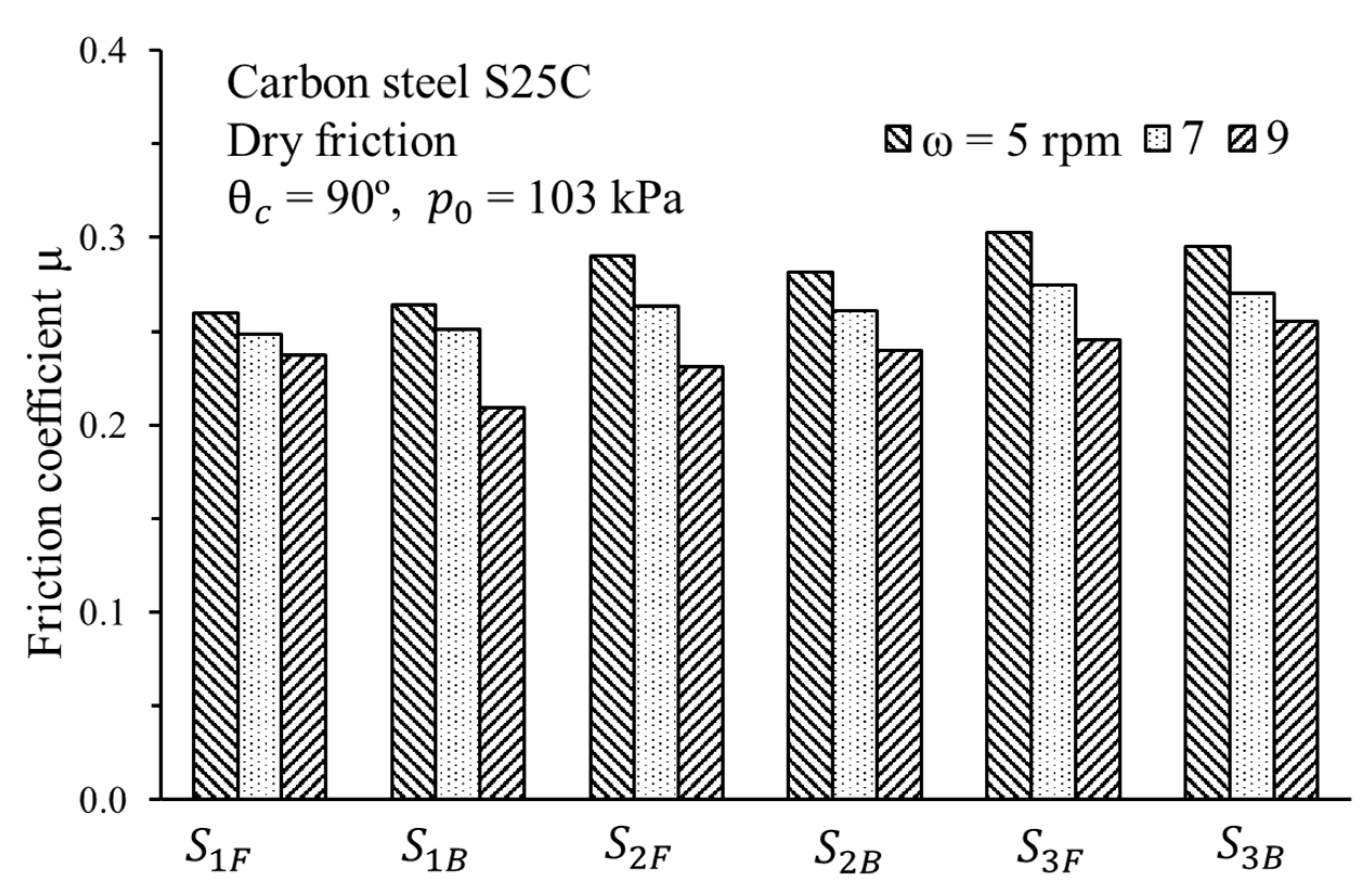

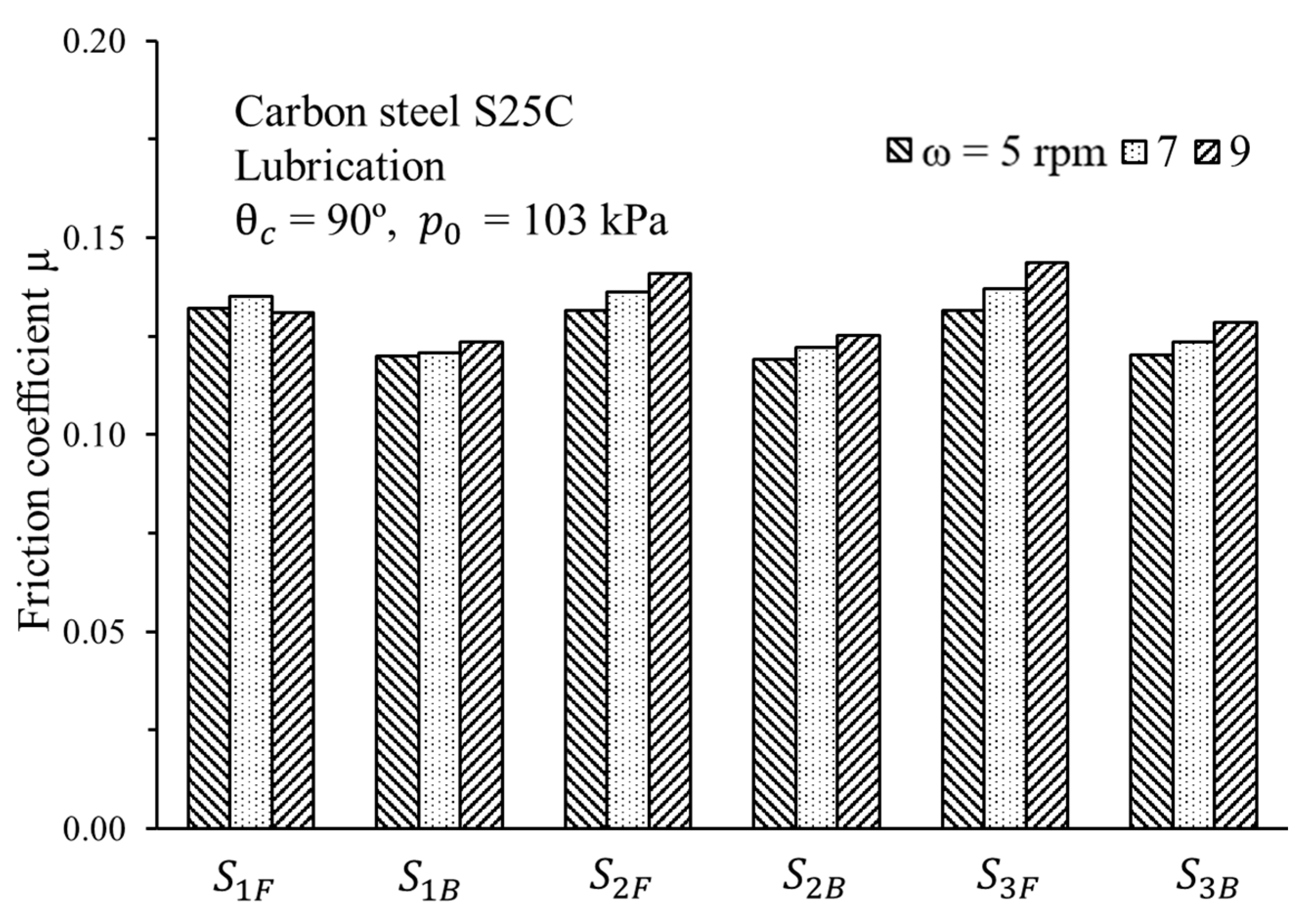

4.1. Friction Tests of Carbon Steel S25C Strip

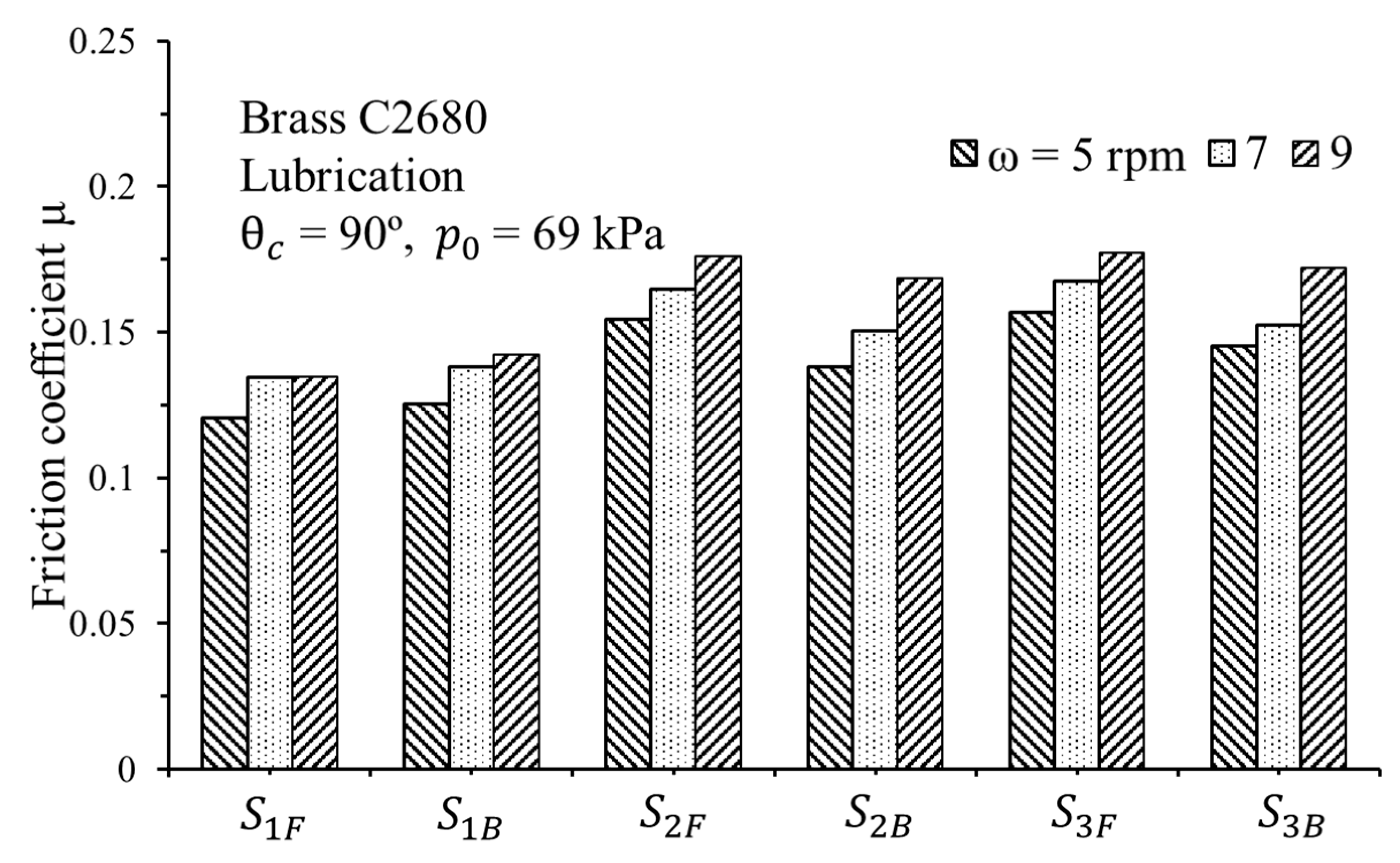

4.2. Friction Tests of Brass C2680

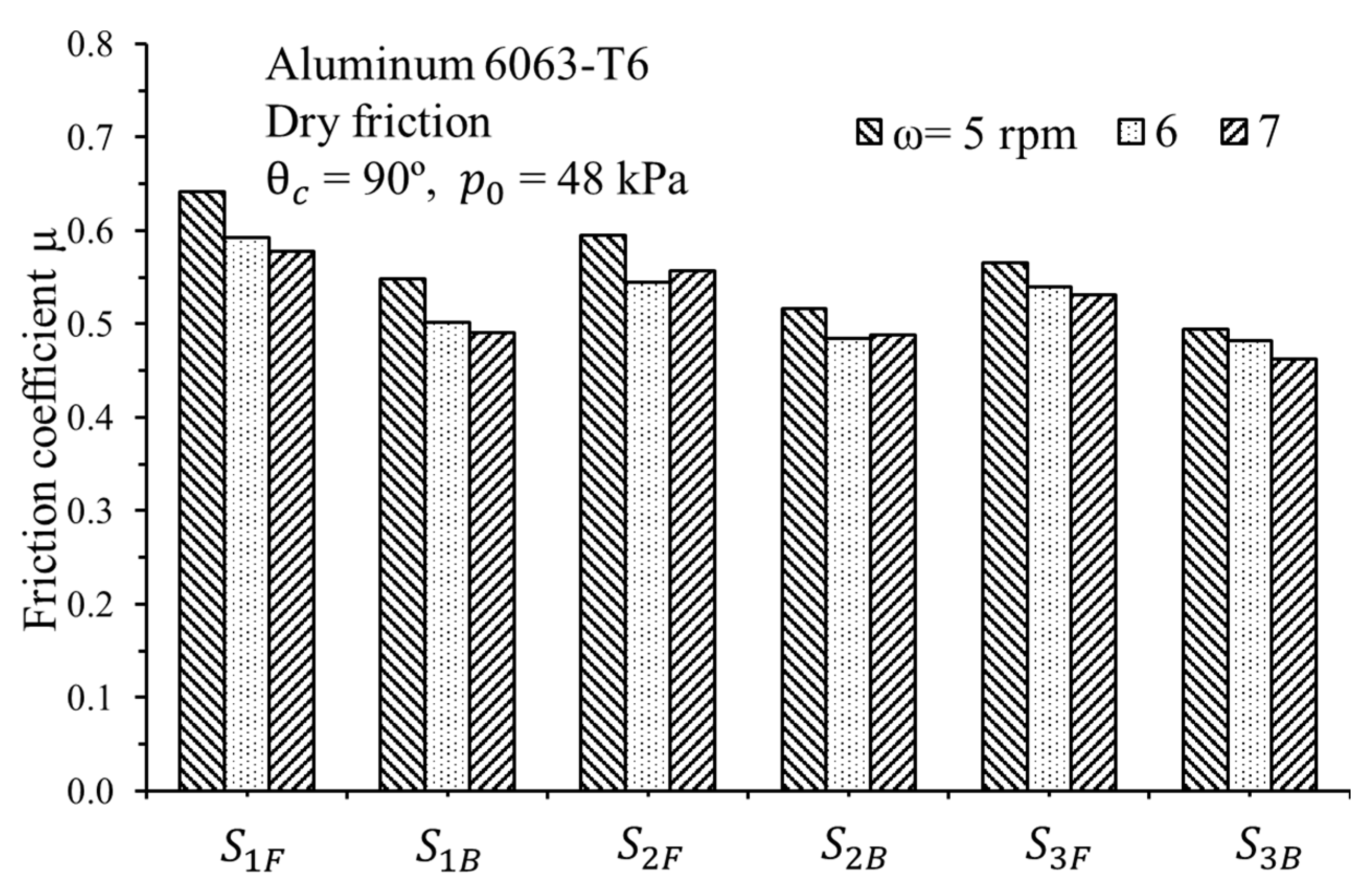

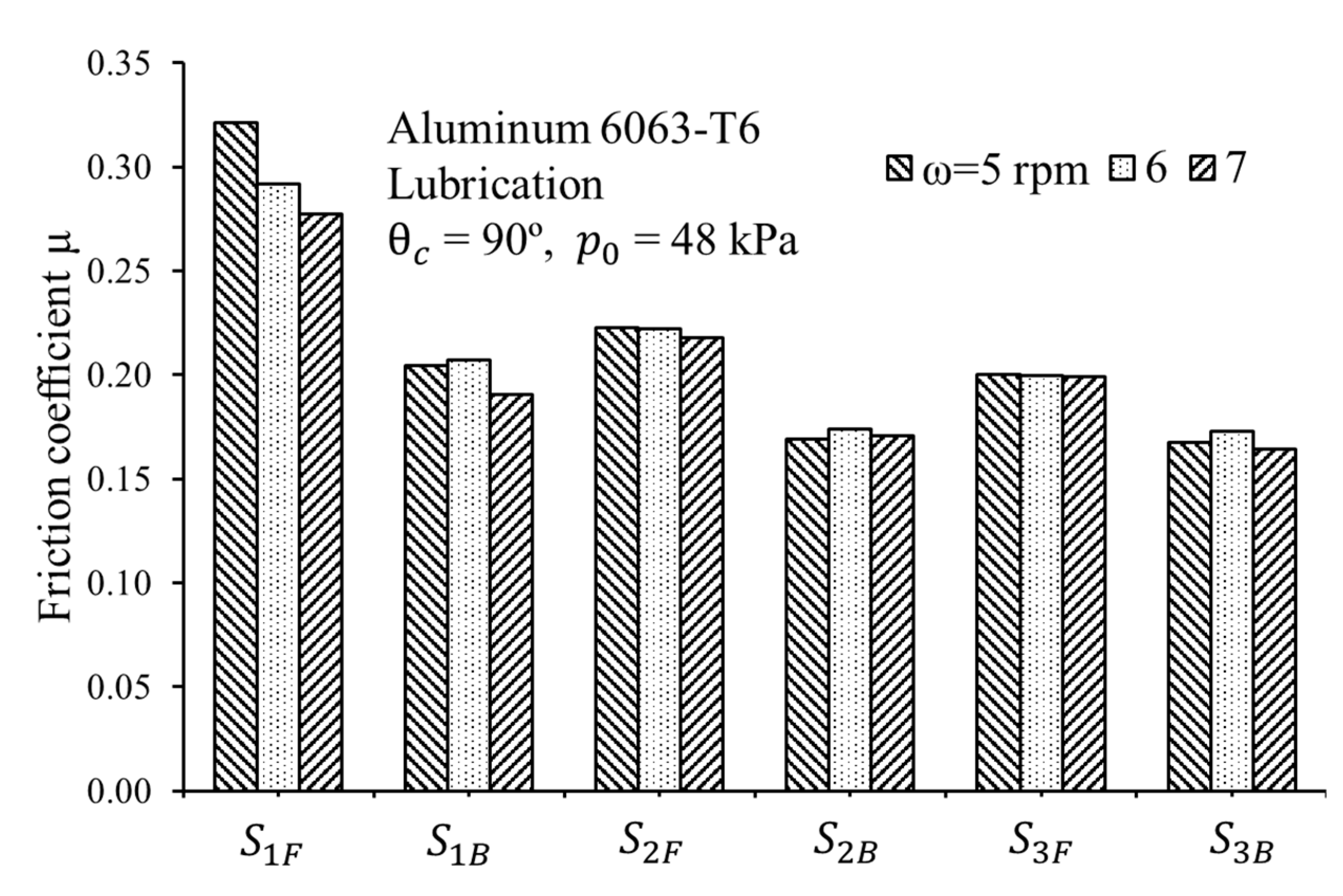

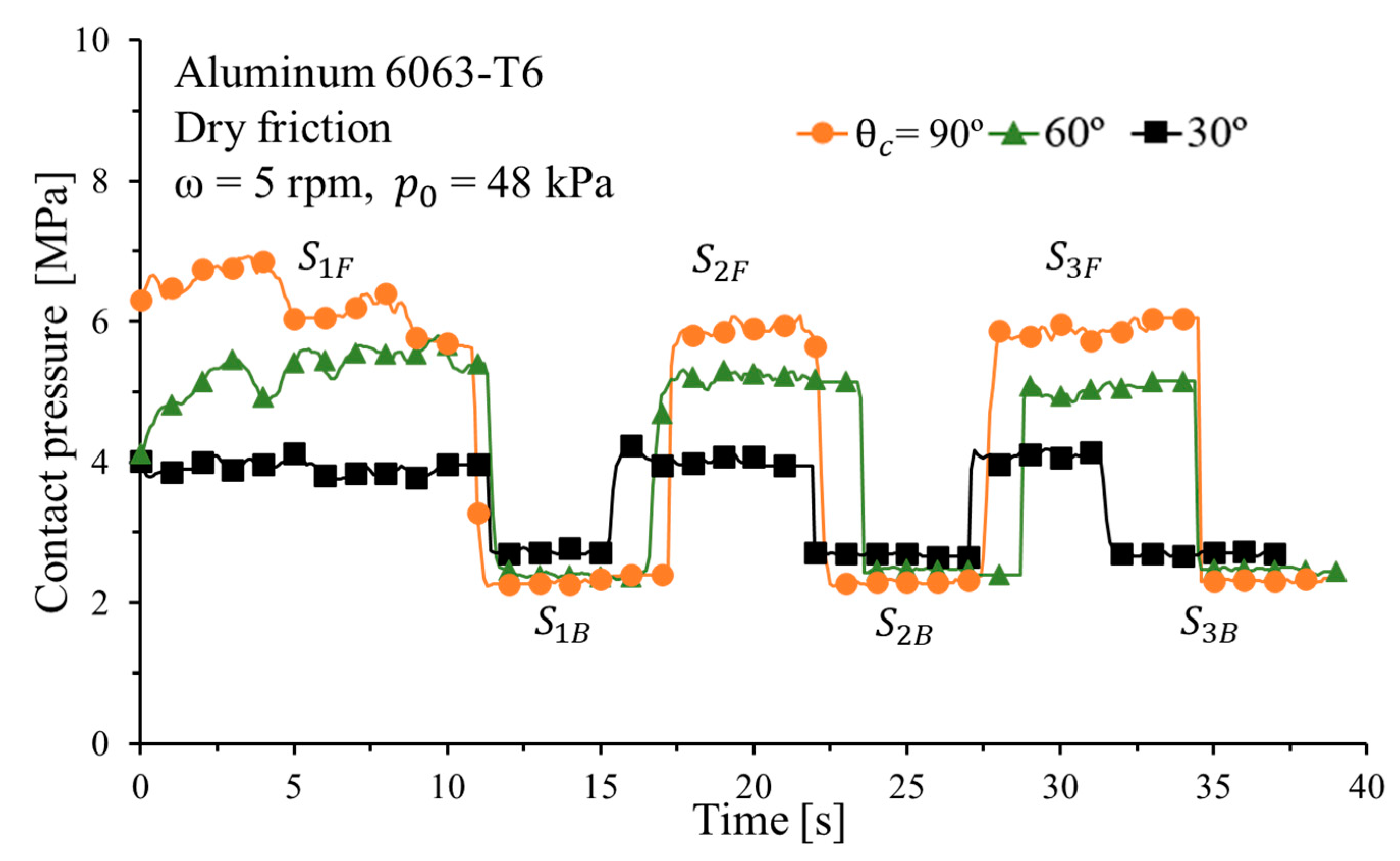

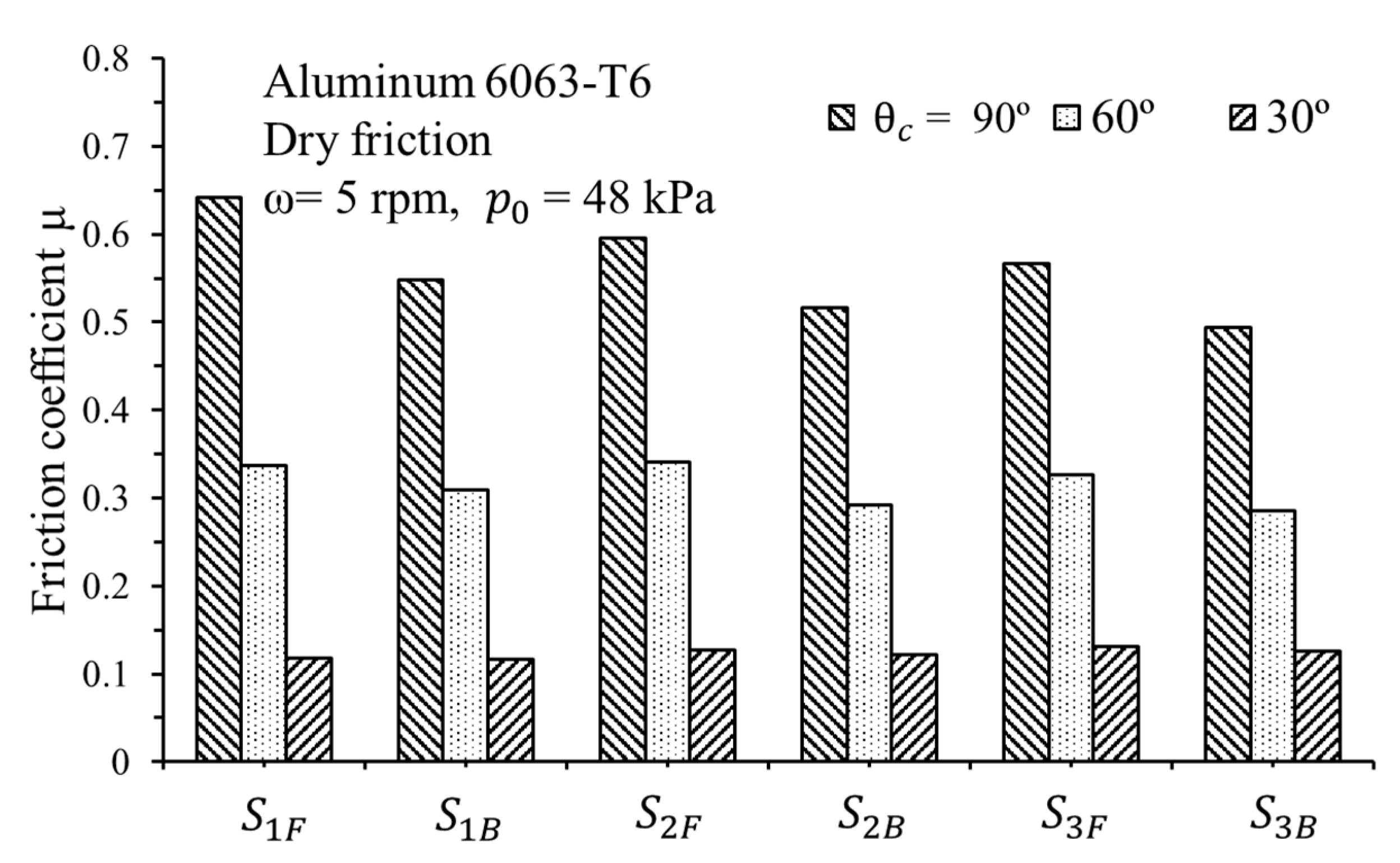

4.3. Friction Tests of Aluminum 6063-T6

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Tamai, Y.; Fuzita, T.; Inazumi, T.; Manabe, K. Effects of contact pressure, sliding velocity and sliding length on friction behavior of high-tensile-strength steel sheets. J. JSTP 2012, 54, 537–541. [Google Scholar]

- Hwang, Y.M.; Huang, L.S. Friction tests in tube hydroforming. Proc. IMechE Part B J. Eng.Manuf. 2005, 219, 587–594. [Google Scholar] [CrossRef]

- Fratini, L.; Lo Casto, S.; Lo Valvo, E. A technical note on an experimental device to measurefriction coefficient in sheet metal forming. J. Mater. Process. Technol. 2006, 172, 16–21. [Google Scholar] [CrossRef]

- Tamai, Y.; Inazumi, T.; Manabe, K. FE forming analysis with nonlinear friction coefficient model considering contact pressure, sliding velocity and sliding length. J. Mater. Process. Technol. 2016, 227, 161–168. [Google Scholar] [CrossRef]

- Weinmann, K.; Bhonsle, S.; Gerstenberger, J. On the determination of the coefficient of friction and the friction factor by the strip-tension friction test. CIRP Ann. 1990, 39, 263–266. [Google Scholar] [CrossRef]

- Saha, P.K.; Wilson, W.R. Influence of plastic strain on friction in sheet metal forming. Wear 1994, 172, 167–173. [Google Scholar] [CrossRef]

- Hsu, T.C.; Kuo, S.G. Boundary friction model in punch friction test. J. Mater. Process. Technol. 1994, 45, 601–606. [Google Scholar] [CrossRef]

- Kim, H.; Hwang, B.; Bae, W. An experimental study on forming characteristics of pre-coated sheet metals. J. Mater. Process. Technol. 2002, 120, 290–295. [Google Scholar] [CrossRef]

- Lemu, H.G.; Trzepiecinski, T. Numerical and experimental study of frictional behavior in bending under tension test. Stroj. Vestn. J. Mech. Eng. 2013, 59, 41–49. [Google Scholar] [CrossRef]

- Ramezani, M.; Neitzert, T.; Pasang, T.; Selles, M.A. Dry sliding frictional characteristics of ZE10 and AZ80 magnesium strips under plastic deformation. Tribol. Int. 2015, 82, 255–262. [Google Scholar] [CrossRef]

- Fridman, H.D.; Levesque, P. Reduction of static friction by sonic vibrations. J. Appl. Phys. 1959, 30, 1572–1575. [Google Scholar] [CrossRef]

- Chowdhury, M.A.; Khalil, M.K.; Nuruzzaman, D.M.; Rahaman, M.L. The effect of sliding speed and normal load on friction. Mechatron. Eng. 2011, 11, 45–49. [Google Scholar]

- Saha, P.K. Factors affecting the accuracy and control of the sheet metal forming simulator. Trans. NAMRI/SME 1994, 22, 47–54. [Google Scholar]

- Adamczak, S.; Zmarzły, P. Research of the influence of the 2D and 3D surface roughness parameters of bearing raceways on the vibration level. J. Phys. Conf. Ser. 2019, 1183. [Google Scholar] [CrossRef]

- Ali, M.K.A.; Xianjun, H.; Elagouz, A.; Essa, F.A.; Abdelkareem, M.A.A. Minimizing of the boundary friction coefficient in automotive engines using Al2O3 and TiO2 nanoparticles. J. Nanopart. Res. 2016, 18, 377. [Google Scholar] [CrossRef]

- Escosa, E.G.; García, I.; Damborenea, J.J.D.; Conde, A. Friction and wear behaviour of tool steels sliding against 22MnB5 steel. J. Mater. Res. Technol. 2017, 6, 241–250. [Google Scholar] [CrossRef]

- Wu, Z.; Xing, Y.; Huang, P.; Liu, L. Tribological properties of dimple-textured titanium alloys under dry sliding contact. Surf. Coat. Technol. 2017, 309, 21–28. [Google Scholar] [CrossRef]

- Hwang, Y.M.; Yu, H.P.; Chen, C.C. Study of friction tests of strips with variant relative speeds, Tube Hydroforming Technology. In Proceedings of the 9th International Conference On Tube Hydroforming, Kaohsiung, Taiwan, 18–21 November 2019; pp. 178–183. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

| Strip Material | Vickers Hardness (HV) | Rotation Speed ω (rpm) | (°) | Interface Condition | ||

|---|---|---|---|---|---|---|

| Case 1 | Carbon steel S25C (t = 1.1 mm) | 130 | 5, 7, 9 | 90 | Oil lubrication/Dry friction | 103 |

| Case 2 | Brass C2680 (t = 0.5 mm) | 128 | 5, 7, 9 | 90 | Oil lubrication/Dry friction | 69 |

| Case 3 | Aluminum 6063-T6 (t = 1.3 mm) | 83 | 5, 6, 7 | 90 | Oil lubrication/Dry friction | 48 |

| Case 4 | Aluminum 6063-T6 | 83 | 5 | 30, 60, 90 | Dry friction | 48 |

| Dry Friction | Lubrication | |||

|---|---|---|---|---|

| Friction Coefficient μ | Friction Coefficient μ | |||

| 0.288 | 0.120 | |||

| 0.292 | 1.4% | 0.154 | 22.1% | |

| 0.298 | 2.0% | 0.157 | 1.9% | |

| Material | Carbon Steel S25C | Al6063-T6 | Brass C2680 | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Rotation Speed (rpm) | 5 | 7 | 9 | 5 | 5 | 5 | 6 | 7 | 5 | 7 | 9 |

| Contact angle | 90 | 90 | 90 | 30 | 60 | 90 | 90 | 90 | 90 | 90 | 90 |

| 0.248 | 0.248 | 0.238 | 0.191 | 0.478 | 0.642 | 0.593 | 0.578 | 0.288 | 0.183 | 0.161 | |

| [0.132] | [0.135] | [0.131] | [0.321] | [0.292] | [0.277] | [0.120] | [0.135] | [0.135] | |||

| 0.264 | 0.251 | 0.209 | 0.191 | 0.407 | 0.548 | 0.501 | 0.491 | 0.269 | 0.209 | 0.186 | |

| [0.120] | [0.121] | [0.124] | [0.204] | [0.207] | [0.190] | [0.125] | [0.138] | [0.142] | |||

| 0.29 | 0.263 | 0.231 | 0.209 | 0.434 | 0.595 | 0.544 | 0.557 | 0.292 | 0.244 | 0.226 | |

| [0.131] | [0.136] | [0.141] | [0.223] | [0.222] | [0.218] | [0.154] | [0.165] | [0.176] | |||

| 0.282 | 0.261 | 0.24 | 0.198 | 0.373 | 0.517 | 0.484 | 0.489 | 0.29 | 0.243 | 0.219 | |

| [0.119] | [0.122] | [0.125] | [0.169] | [0.174] | [0.171] | [0.138] | [0.150] | [0.168] | |||

| 0.303 | 0.275 | 0.246 | 0.214 | 0.412 | 0.566 | 0.54 | 0.531 | 0.298 | 0.27 | 0.234 | |

| [0.131] | [0.137] | [0.144] | [0.200] | [0.199] | [0.199] | [0.157] | [0.168] | [0.177] | |||

| 0.295 | 0.271 | 0.255 | 0.205 | 0.361 | 0.494 | 0.483 | 0.463 | 0.304 | 0.261 | 0.221 | |

| [0.120] | [0.124] | [0.128] | [0.168] | [0.173] | [0.164] | [0.145] | [0.152] | [0.172] | |||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hwang, Y.-M.; Chen, C.-C. Investigation of Effects of Strip Metals and Relative Sliding Speeds on Friction Coefficients by Reversible Strip Friction Tests. Metals 2020, 10, 1369. https://doi.org/10.3390/met10101369

Hwang Y-M, Chen C-C. Investigation of Effects of Strip Metals and Relative Sliding Speeds on Friction Coefficients by Reversible Strip Friction Tests. Metals. 2020; 10(10):1369. https://doi.org/10.3390/met10101369

Chicago/Turabian StyleHwang, Yeong-Maw, and Chiao-Chou Chen. 2020. "Investigation of Effects of Strip Metals and Relative Sliding Speeds on Friction Coefficients by Reversible Strip Friction Tests" Metals 10, no. 10: 1369. https://doi.org/10.3390/met10101369

APA StyleHwang, Y.-M., & Chen, C.-C. (2020). Investigation of Effects of Strip Metals and Relative Sliding Speeds on Friction Coefficients by Reversible Strip Friction Tests. Metals, 10(10), 1369. https://doi.org/10.3390/met10101369