Abstract

Electric vehicle sales are growing globally in response to the move towards a greener environment and a reduction in greenhouse gas emissions. As in any machine, grease lubricants will play a significant role in the component life of these new power plants and drivetrains. In this paper, the role of grease lubrication in electric vehicles (EVs) and hybrid vehicles (HVs) will be discussed in terms of performance requirements. Comparisons of grease lubrication in EVs and HVs for performance requirements to current internal combustion engines (ICEs) will be reviewed to contrast the major differences under different operating conditions. The operating conditions for grease lubrication in these EVs and HVs are demanding. Greases formulated and manufactured to meet specific performance specifications in EVs and HVs, which will operate within these specific electrification components, will be reviewed. Specifically, the thermal and electrified effects from the higher operating temperatures and electromagnetic fields on lubricant degradation, rheology, elastomer compatibility, and corrosion protection of the grease need to be evaluated to accurately meet the performance requirements for EVs and HV. The major differences between EVs and conventional ICEVs can be grouped into the following technical areas: energy efficiency, noise, vibration, and harshness (NVH), the presence of electrical current and electromagnetic fields from electric modules, sensors and circuits, and bearing lubrication. Additional considerations include thermal heat transfer, seals, corrosion protection, and materials’ compatibility. The authors will review the future development trends of EVs/HVs on driveline lubrication and thermal management requirements. The future development of electric vehicles will globally influence the selection and development of gear oils, coolants, and greases as they will be in contact with electric modules, sensors, and circuits and will be affected by electrical current and electromagnetic fields. The increasing presence of electrical parts in EVs/HVs will demand the corrosion protection of bearings and other remaining mechanical components. Thus, it is imperative that specialized greases should be explored for specific applications in EVs/HVs to ensure maximum protection from friction, wear, and corrosion to guarantee the longevity of the operating automobile. Low-viscosity lubricants and greases will be used in EVs to achieve improvements in energy efficiency. However, low-viscosity fluids reduce the film thickness in the driveline application. This reduced film thickness increases the operating temperature and reduces the calculated fatigue life of the bearings. Bearing components for EVs/HVs will be even more crucial as original equipment manufacturers (OEMs) specify these low-viscosity fluids. The application of premium bearing components using low-viscosity grease will leverage materials, bearing geometries, and surface topography to combat the impact of low-viscosity lubricants. In addition, EVs and HVs will create their own NVH challenges. Wind and road noise are more prominent, with no masking noise from the ICE. Increasing comfort, quality, and reliability issues will be more complicated with the introduction of new electrified powertrain and E-driveline subsystems. This paper elaborates on the current development trends and industrial test standard for the specified grease used for electrical/hybrid driveline lubrication.

1. Introduction

Due to the amount of wear and friction present in an automotive vehicle, lubricants are essential for the longevity and function of cars. Greases, which are boundary lubricants, are essential to the protection of car parts, preventing them from breaking down. Not only are they formulated specifically for the purpose of preventing wear, but they are also made to withstand the conditions of a car in action. Greases prevent rusting and accumulation of debris on surfaces by forming a protective layer; in addition, greases’ many properties such as their ability to flow at high temperatures while also being excellent at dissipating heat are what make them valuable and widely used [1]. A vast majority of applied greases will last throughout the entire lifetime of vehicles and do not need to be reapplied.

Greases are commonly derived from petroleum or synthetic materials. Synthetics are often preferred as they can typically function over a wider range of temperatures compared to those made from petroleum [2]. Furthermore, different types of vehicles can operate under different conditions and with either a higher or lower number of variables. For example, vehicles operating under higher/lower moisture, extreme loads, and having high speed bearings will all require different grease specifications to properly protect against corrosion and wear. This can be done through the usage of thickeners and additives such as rust inhibitors and anti-wear and friction-reducing agents [3].

In electrical vehicles (EVs), greases need to be formulated for new factors, the major ones being the increased presence of electricity, electrical currents, and noise in an EV due to the absence of an internal combustion engine (ICE) [4]. Due to the increased number of electrical components such as electric modules and sensors, the greases must be formulated to be unreactive with electricity. Usually, the noise of an engine will mask the creaks and rattles of a car, but as an EV is silent, any noise from the lack of lubrication and contact of surfaces will become much more apparent. Furthermore, a larger amount of grease must be used in an EV than in an internal combustion engine vehicle (ICEV) as the need for lubrication is higher in an EV. To further the understanding of the need of greases in EVs, this perspective paper will focus on the new variables that are present in EVs that necessitate a specified formulation of greases.

2. Greases in Automotive

2.1. Types of Greases and Their Usages

The most common types of greases are soaps, of which different options are shown in Table 1 along with their properties and applications. Lithium greases are widely used for their lubricity, shear stability, and thermal resistance [3,5]; calcium-based ones have better water resistance but worse thermal resistance, and sodium greases have high dropping points but cannot operate above 120 [6]. These greases are created through the blending of base oils and thickeners through intense mixing until the mixture becomes gelatin-like [3,7]. Overall, lithium grease has been shown to impart the advantages of high adherence, non-corrosiveness, available at high pressures, and moisture resistance, making it compatible with several OEM applications such as EVs/hybrid vehicles (HVs) [8,9]. Other types of greases include polyuria (PU), clay, and silica. PU greases’ high operating temperature, oxidative protection properties, and low bleed features make them useful for permanent sealing applications [10]. Clay greases are inert and favored in the food industry [3]. Although silica-based greases are a strong thickener, they are very sensitive to heat.

Table 1.

Greases containing mineral oil (soaps) (Adapted from [8]).

Overall, approximately six different types of greases are present in a vehicle system—the majority of which are soap greases. Lithium greases are present in car hinges to gears. White greases are used for water sealing and surface adhesion. Aluminum greases are often used in wheel bearings, and copper greases are used in exhaust assemblies and battery pole connections. Finally, red rubber greases are present in areas with O-rings and hydraulic systems, and brake greases are used in drum and disc brakes [11].

2.2. Load

Viscosity does play a critical role in determining load-carrying capacity in fluid film hydrodynamic bearings. Load-carrying capacity is directly proportional to viscosity and operating speed and inversely proportional to the square of film thickness.

For EHL (ElastoHydrodynamic Lubrication) conditions, due to the nature of the contact of the roller elements and the race—Hertzian by nature—the elastic deflection of mating surfaces significantly influences the load being driven by the material properties of the bearing vs. the viscous-elastic properties of the oil phase in grease. For a Newtonian oil, the following equations govern the film thickness [12,13]:

where viscosity is contained within the Speed Parameter (U) and load is contained within the Load Parameter (W). In EHL conditions, the film thickness is minimally affected by the load, as seen by the magnitude of the powers for each W shown in the equations.

LINE CONTACT: (ho/R) = (2.65 G0.54 U0.7)/W0.13 (Dowson, 1970)

POINT CONTACT: (ho/Rx) = 3.63 U0.68 G0.49 W−0.073 (1 − e−0.68k)

2.3. Viscosity

Generally, the selection of viscosity is determined by bearing speed, operating temperature, bearing dimensions, and race surface finish. For roller element bearings, the focus will be on EHL conditions, which covers many of the conditions these bearings operate in.

The previous equations relate the variables needed to arrive at the optimal viscosity by determining film thickness. More specifically, they relate surface speed and required viscosity to determine the minimum EHL film thickness needed to match the composite surface roughness in the loaded contact area. From our previous discussion on load, we will focus on these variables given that the contribution of load to this determination is minimal under EHL conditions. There are graphical relationships that relate viscosity and speed to determine the optimal viscosity.

The next step is to determine the correct viscosity at the bearing operating temperature. Using the readily available viscosity curves, the ISO grade for the application can be determined.

Final confirmation of the correct operating viscosity is determined by calculating the specific film thickness:

where h = film thickness from the previous equations and

The choice of the correct viscosity minimizes asperity contact in the element load zone. Specific Film Thickness confirms the chosen viscosity, estimated from bearing speed and temperature, and yields the film thickness for the specific bearing surface finish characteristics. Lambda can have a significant effect on bearing fatigue life.

Lambda values below 1.5 reflect a dramatic loss of bearing fatigue life. Under this condition, the film thickness is not high enough to cover the average asperity height, leading to excessive friction and wear of the race and roller element surfaces. Lambda values between 1.5 and 3.0 contribute to an increased fatigue life, reflecting the ability of the film to cover load zone asperities. Lambda values above 3.0 exhibit increasing but diminishing improvements in fatigue life.

Determination of the correct viscosity is followed by determination of the National Lubricating Grease Institute (NLGI) grade needed for the application. The next step is determining the temperature range at which the grease will work. Care must be taken so as to not over- or underestimate the operating range, as catastrophic failure can occur. Therefore, it is always advised to measure the temperatures of the components if possible. Oftentimes, multiple greases can be found suitable to a particular application, at which point it should come down to the costs unless the item is already on hand [8].

2.4. Grease Formulation Issues

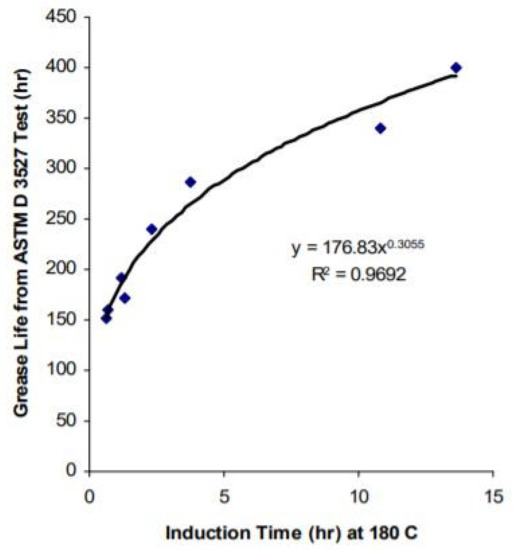

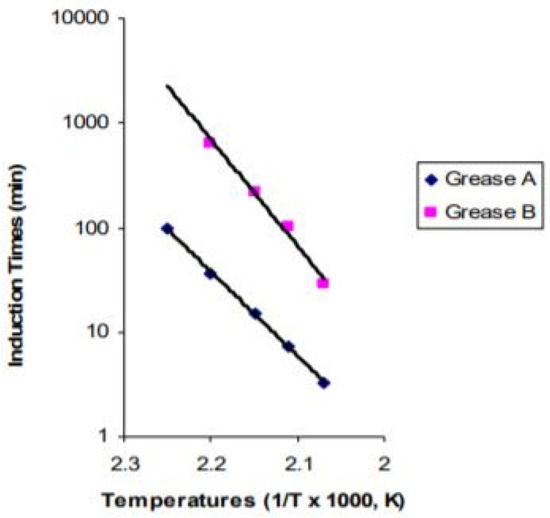

Since greases are formulated to operate within a specific range of conditions, operating outside those conditions or prolonged exposure to high temperatures will have a negative impact on the longevity of said grease. Figure 1 shows a correlation between induction time and the grease life—data obtained from the ASTM D 3527 test. A relationship is noticeable in that as the induction time increases, so does the life of the grease. Further testing in Figure 2 shows that an increase in temperature also leads to a decrease in induction time, thereby reducing the life of the grease. This is because greases with longer induction times achieve higher oxidative stability [14].

Figure 1.

Induction time vs. grease life (ASTM D 3527 Test) [14].

Figure 2.

Temperature effects on induction time [14].

3. Performance Requirements for Grease Used in EVs and HVs

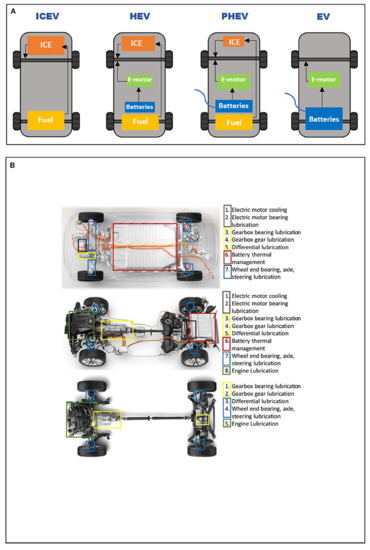

In EVs/HVs, a new configuration was designed to use an electrical motor combined with a battery module system for generating energy power. Instead of an engine, which is lubricated with oil and transfers power to a transmission and from there to the wheels, a battery module system powers an electric motor that drives the wheels. When designing EVs, lubrication engineers must select gear oils, coolants, and greases to meet new driveline requirements. The EV/HV configuration design has created substantial impact on driveline lubrication and thermal cooling requirements in the areas of electrical and thermal transfer characteristics, energy efficiency, and the presence of electric currents and magnetic fields. In addition, more system-related requirements such as noise, vibration, and harshness (NVH), seals, and materials’ compatibility are also being considered for important performance characteristics.

3.1. Electrical and Thermal Characteristics for Grease Used in EVs and HVs

In many HV or EV advanced system designs, automotive lubricants such as drivetrain fluids or grease lubricating encounter the integrated electric motor (e-motor) and thermal management devices. This leads to the addition of electrical and thermal properties which must be considered on top of conventional lubricant properties. The introduction of electrification components has been targeted for energy efficiency and long-term durability. Automotive industries have asked for the implementation of specialized automotive lubricants or driveline fluids to allow for appropriate thermal cooling specifications, to present bearing protection, to ensure corrosion protection, and to offer oxidation and sludge control.

Recently Tung, Woydt, and Shah published a paper related to the future trends of HV/EV driveline lubrication and thermal management [9]. They also reported that grease specifically designed for driveline lubrication of HVs and EVs should include appropriate electrical properties to guarantee protection from corrosion and be well suited with insulating materials [9,15,16]. There are two additional considerations on electrical conductivity and thermal conductivity of fluids. If the electrical conductivity of the liquids exceeds a certain value, current leaking can occur. However, if it is too low, degradation of the oil can occur because of lubricant oxidation, a direct outcome of electrical arcing in oil, and leads to a decrease in the protective ability of the fluid. Lubricants are not conductive but rather dissipative, though additives can affect the level of electrical conductivity. Conductivity might increase, however, as oxidation causes an oil to deteriorate. Additive suppliers suggested that lubricants susceptible to oxidation are potentially problematic. They also need to have appropriate thermal transfer characteristics, offer high-speed bearing protection, and provide oxidation and sludge control.

3.2. Electric Field Interactions with Driveline Lubricant or Grease Used in EVs/HVs

To understand driveline lubrication under the electric field is very crucial for EV/HV applications by automotive and lubricant suppliers. In a recent publication by Chen, Liang, and co-authors [15], they pointed out that lubricant properties under electric field interaction must be investigated. These important properties can be described as the electrostatic interaction, the electric charge distribution, the formation of transfer film/structural change, and the chemical–physical property changes. It has been found that lubrication is aided by weak electrostatic interactions. Static charges and the transient polarized charges on surfaces, which may be induced and strengthened by the externally applied field, enhance electrostatic interactions. They also claimed that at low electric potential, wear is adhesive-type dominated, while it is abrasive-type dominated when the potential is high. DC has been observed to enhance friction while the friction is reduced by AC. This interaction mechanism is due to vibration induced by the electrostatic force which is fluctuating under electric field. Structural change/oxidative transfer film formation in some material combinations (e.g., graphite–graphite, graphite–copper) has been found responsible for increased wear and reduced friction under the application of the external electric field [9,15].

In addition, Rhee, Yan, He, Xie, and Luo [14,15,16] indicated that chemical reactions and physical absorption occur at material interfaces under the influence of an external electric field, leading to a change in surface friction and lubrication behavior. Electric carrier (or electron–hole) charge distribution through the formation of localized quantum dots and electron–hole recombination affects interfacial mobility and surface friction properties [14,15,16].

3.3. Electric Breakdown Mechanisms of Lubricants and Grease

Besides the electrical properties of driveline lubricants or lubricating grease described in the above section, automotive R&D scientists [9,15,16,17,18] have reported that a highly fluctuating charged environment requires specially tailored lubricants to avoid component damage and premature failure due to improper lubrication. Major lubrication failure mechanisms explored can be classified into lubricant degradation, microbubble formation, and electrowetting. In the lubricant degradation mechanism, the lubricant base oil and thickeners undergo chemical oxidation to form carboxyl compounds. Lubricity is lost on account of the formation of highly viscous and acidic degradation products and agglomeration of additives. Heat generation causes faster base oil evaporation. Local overheating in EV/HV lubricants can lead to microbubble formation, which may then be driven by viscous drag, pressure gradient, and dielectrophoretic forces. The formation of these microbubbles, which are unstable and coalesce, tends to destabilize lubrication upon electrical breakdown. The microbubbles form more rapidly in conditions of electrode insulation. In addition, the electric field induces interfacial stress on a non-polar lubricant confined between two metallic surfaces in the electrowetting mechanism. Due to differing dielectric properties, a two-phase dispersion of lubricant may also destabilize this mechanism and can lead to the spread and breakdown of the lubricant when the electrostatic stress is too high.

3.4. Thermal Cooling Requirements for Lubricants and Grease Used in Electrical/Hybrid Systems

The heat generation rates in engine power controllers, computer chips, and optical devices/systems are on the rise because of future development trends that favor higher speeds and smaller features for increased performance for engine components, microelectronic devices, and brighter beams for optical devices [9]. Thermal cooling has become one of the main focuses of advanced industries such as microelectronics, transportation, manufacturing, and metrology. Electric hybrid and fuel cell vehicles use power electronics to control their electric motor. Power electronics require their own cooling loop including a heat exchanger, pump, and radiator. Power densities exceeding 100 W/cm2 while needing to maintain a temperature below 125 °C may eventually exceed 250 W/cm2. Conventional cooling methods to promote heat rejection rates apply increased surface areas such as fins and microchannels for heat dissipation. However, current thermal cooling designs have already reached their threshold. For HVs or EVs, the cooling requirements are more stringent than IC engines, especially in the case of fast charging and heavy consumption. Lithium-ion batteries and EV motor systems need to maintain the correct temperature range by cooling means. If they exceed this range, the batteries will face a “runaway”, not deliver the same power, and, more importantly, they will degrade quickly. Power electronics are also very susceptible to heat, especially during recharging. Heat sinks are used to draw away heat. Solutions for the thermal management of EVs or HVs have been described in the recent publication [9] by Tung, Woydt, and Shah. For example, advanced thermal management approaches such as microchannels for cooling batteries or fast-charging cables or immersion of battery cells in a dielectric fluid have been commercialized in energy and automotive industries.

Thermal Management and Measurement of Thermal Conductivity of Driveline Grease

The future development of thermal management technologies is encumbered by the urgent demand for thermal protection and cooling of electrification components. The traditional method for thermal cooling can no longer be progressed. New requirements have been enforced for high-performance cooling in electrical vehicles, batteries, motors, and power electronics [9]. New developments in thermal management of EVs/HVs are helping to extend the driving range and lifetime requirement. Global research activities using advanced coolants have the scientific merits and high potential for application in thermal cooling technologies. To meet these thermal management requirements, automakers are using combinations of cooling fluids and advanced thermal cooling devices throughout the electrical/hybrid propulsion system to improve overall energy efficiency and coolant compatibility with electrification components. In the next few sections, the authors will review the state-of-the-art thermal management technology used for meeting thermal cooling and extended driving range requirements of EVs/HVs.

Recently, lubricant industrial researchers [18,19,20,21,22,23] have investigated the thermal properties of lubricants or grease operated under tribological sliding conditions. Pettersson and Callen [18,19] have shown the fundamental phenomenon that the base oil molecular structure determines the thermal capacity and thermal conductivity of a lubricant [18]. The higher the number of the rotational and vibrational quantum states, the higher the thermal capacity [19]. When there are multiple vibrational and rotational states, it takes a higher energy input to increase the averaged kinetic energy, e.g., the temperature. In addition, Gedde and Jin [20,21] have indicated that the thermal conductivity of base oil was correlated to the molecular diffusivity in the fluid. The more easily the molecules of a lubricant pass through each other, the higher the lubricant thermal conductivity. This also means that there is a relationship between the lubricant viscosity and lubricant thermal properties because both the molecular quantum state density and the diffusivity closely correlate to the lubricant viscosity. This correlation can restrict the selection of the lubricant when both the tribological working condition and thermal management are considered. When tribological working conditions take a higher priority, it is difficult to change the base oil thermal properties. Thus, it is quite desirable to change the lubricant thermal property with some additives.

Jin, Shaikh, and Barbés have found out that driveline lubricants can significantly increase the thermal conductivity and thermal capacity of a lubricant by adding nanoparticles to the lubricant [21,22]. Essentially, adding those dispersed nanoparticles increased the carriers of thermal energies. Adding 0.8 vol% of silica nanoparticles can double the thermal conductivity of a lubricant [21]. Polyalphaolefin (PAO) containing 0.5 vol% carbon nanotubes has a more than 50% thermal conductivity compared to neat PAO. However, nanoparticles also lower the specific heat of the lubricant [23]. In addition, Chen and Dai and colleagues also investigated the synergistic effects of nano-lubricant additives [24,25]. They indicated that this nano-lubricant additive can be used to optimize the thermal property of a lubricant to fit any specific powertrain cooling design. Moreover, the nanoparticle additive improves the tribological performance of lubricants. They have shown substantial experimental evidence using this nano-lubricant additive which can dissipate heat extremely fast in EV/HV cooling processes.

In the lubricant industry, the most common experimental method for measuring the thermal conductivity of a lubricant is called the transient hot-wire method [26,27]. The transient hot-wire experimental set-up was simple to perform and had high accuracy. This method used a Pt or Ni wire which was sealed inside a cylindrical pressure vessel filled with lubricant. The wire was heated up for a short amount of time electrically, and its temperature was monitored simultaneously by its electric resistance. The thermal conductivity and the thermal capacity of the lubricant can be calculated from the temperature change of the wire. In general, this measurement can be modeled as an axisymmetric thermal transportation problem [26]. It has an additional advantage when used to characterize lubricants, as the lubricant thermal properties are highly correlated with its pressure, and the pressurized transient hot-wire method is easy to achieve.

3.5. The Other Requirements for Grease Used in EVs and HVs

Another three major issues that are present in EVs or HVs are energy efficiency, noise, and electrification components [28]. Another important aspect of an EV is the increased presence of electrification components and how the greases will be affected by the electromagnetic fields and electrical currents. These place an even higher emphasis on corrosion prevention as the electrical currents will corrode the metallic components at a faster rate as compared to those in a regular ICE. In this perspective paper, we will discuss these important areas and their specific requirements used in EVs/HVs in the following sections.

3.5.1. Energy Efficiency

While EVs are extremely efficient in energy consumption, reports have shown that as much as 57% of the energy used by the car is for overcoming frictional losses [29]. The main components considered to make up the large frictional loss include motor, tires, steering system, wheel bearings, joints, suspensions, and a few others [29]. Friction losses observed in electrical motors (EMs) are attributed to the heat produced by rotors, vibration, wear, and going against wind resistance. In rolling bearings, the main sources of friction loss are from churning, sliding, which is the source of the greatest friction loss of bearings, rolling, and seal sliding friction [30]. For these, a good lubricant or grease is expected to properly offset the frictions. To improve the energy efficiency of grease in these bearing applications, synthetics, primarily polyalphaolefins (PAOs), are used. Given the mix of sliding and rolling contact in the load zone of point contact bearings (ball and spherical roller bearings), PAO-formulated greases have improved traction properties compared to mineral oil-formulated greases. Greases are mainly used in bearings and gears due to them being more of a solid than oil lubricants, as they will not leak out of components and cause damage. Since the usage of greases is much easier with bearings and gears, about 85% of all bearings are lubricated with grease. As increasing energy efficiency is a big focus in the EV industry, all opportunities to reduce friction will help achieve the goal of reaching a range of up to 400 miles [31].

Energy efficiency can be correlated to lubricating film thickness. Thinner lubricants reduce viscous friction, allowing more energy to be conserved. However, greases will reduce lubricating film thickness at high temperatures and bring their own challenges on wear protection of sliding surfaces. A thinner lubricating film will be closer to the mixed and boundary lubrication regimes where wear is a concern. Striking a balance between the capability to remain in a full film lubrication regime and the wear protection towards thinner lubricating films is a crucial turning point that enhances energy efficiency using low-viscosity lubricant or grease. Several papers have emphasized that a new approach using either surface coatings or lower-roughness surfaces will ensure a thin lubricating film to separate surfaces and mitigate wear.

One of the most significant challenges for EVs is to extend the driving range besides energy efficiency. This challenge also imposes the infrastructure of wide-spread recharging stations. Without recharging infrastructure, all passengers must be prepared to give up the 300- to 400-mile ranges they are accustomed to in a conventional vehicle. Automotive engineers are looking for innovation approaches to improve energy efficiency by making vehicles lighter and by reducing torque in all components.

3.5.2. Electrification Components

The projected growth of EVs and HVs in the automotive industries has made evolutional changes in propulsion system electrification components. Powertrain and driveline components will be enhanced by electric motors and E-drive configuration. Electrification components including electric motors or regenerative brake components will be integrated in this advanced configuration with thermal management systems for cooling applications. Electric motors and power electronics will be in contact with the cooling fluids. Coolants are required to cool motors and power electronics by removing heat for thermal management. In addition, automotive lubricants for electrified propulsion systems must function as effective coolants and reduce the corrosion of copper windings, on top of needing composites and rare earth magnetic materials while upholding wear and oxidation protection and energy efficiency.

Dr. Kuldeep K. Mistry [28] at The Timken Co. in Ohio also indicated that the development of electric vehicles will influence the selection and development of gear oils, coolants, and greases, because the lubricating oils or greases will be in contact with electric modules, sensors, and circuits. It will be affected by electrical current and electromagnetic fields. Soon, the number of electrical connections is expected to quadruple. In this context, one of the key life-limiting considerations will be corrosion.

Although grease oils will prevent moisture from reaching the surfaces, thus preventing rust, the presence of electromagnetic fields will create another challenge. Electromagnetic fields can propagate without the need for a solid medium. The amount of energy transferred is dependent on the intensity of the field, the frequency of its oscillation, and the dielectric properties of the material. The more energy the object absorbs, the more quickly the object will be heated. The object will gain heat as the frequency of the electromagnetic field increases. However, if the temperature diffusion rate is slower than the rate at which the electromagnetic field releases its energy, the temperature will increase rapidly [31]. As electric motors produce electromagnetic fields, there is a chance for the premature degradation of greases. The electrical discharge and free radicals will react with the oxygen in greases, creating hydrogen peroxide and continuing the chain of free radical reactions. This leads to the oxidation of base oils and thickeners, which causes a loss in lubricity. In addition, components within the grease will start to separate and the thermal effects from the electrical discharge will cause certain parts to evaporate and eventually cause grease failure [18,31]. To this degree, experiments have shown that a conductive lubricant will help with its corrosion prevention. This is because non-conductive greases will trap the energy from electrical currents and electromagnetic fields, leading to a sudden release and causing great damage [18,31]. However, if the material is conductive, then while the electrical currents will pass through, it will be in a much smaller amount and cause less damage.

3.5.3. Noise

The absence of an ICE to mask vibrations, harshness, squeaks, and rattles will trigger more problems such as NVH and buzz, squeak, and rattle (BSR). Chad Chichester has reported, in a recent Society of Tribologists and Lubricant Engineers (STLE) publication [28,29], that NVH and BSR can affect sensors that are increasingly used in vehicle safety and guidance. The choice of greases used in EVs/HVs is different from those available on the market today and can reduce or eliminate noise which will help make vehicles safe.

3.6. Future Development Trends for Grease Used in EVs/HVs

As EVs are different from ICEs, it is important to know their different future requirements. Of the multitude of greases on the market, lithium greases are a top choice because of their high adherence, non-corrosiveness, and moisture resistance—all of which allow them to be compatible with and protect components [28,29]. Lithium grease has shown to impart the advantages of high adherence, non-corrosiveness, and moisture resistance, making them compatible with several OEM applications such as EVs/HVs. Aluminum and urea greases perform well too; however, their production is associated with hazardous processing and constraints on process balance.

It is predicted that the use of eco-friendly and bio-degradable greases will increase. Additionally, corrosion protection, low-temperature performance, and water resistance, among others, will rise in interest [29,30,31]. It is also important to consider that it is more favorable to produce a grease with low torque functionality through thickeners, base oils, and additives while ensuring that the properties of the electrical and surfaces remain unaltered. In the future, it is likely that instead of general greases for all types of EVs, custom-made ones will be favored due to the variabilities in EV designs and the factors they will bring into the formulation of greases [18,32]. While PU greases are currently not commonly used in EVs, they might be of interest in the future due to their lifelong sealing functions, long-life properties at high temperatures, and low noise characteristics. PU grease formulations have inherent oxidation inhibition chemistry as part of the thickener, leading to long life at elevated temperatures. When coupled with PAO stocks, these products can contribute to significant improvements in grease life at elevated bearing temperatures. Furthermore, improved filtration practices and thickener reaction control have contributed to lower noise properties by controlling particles’ size and overall particle contamination. This leads to quieter noise levels in rotating bearings.

Desired lubricant properties in EVs/HVs [15,33,34] have been grouped into a table as shown in Table 2. All the required lubricant properties that need to test their performance characteristics are compared with the conventional lubricants used in the ICEs. This table indicates that these newly developed tests such as electrical conductivity, thermal conductivity, extreme speed, and bearing protection capability are crucial performance characteristics to meet HV or EV performance requirements.

Table 2.

Desired lubricant properties in electric vehicles (EVs)/hybrid vehicles (HVs) compared with in internal combustion engine vehicles (ICEVs) (adapted from [15,33,34]).

Figure 3.

(A) Comparison of battery and ICE sizes and (B) an image of the main areas where lubrication is required in an EV (Tesla), hybrid electric vehicle (HEV) (Volkswagen NetCarShow), and ICEV (Subaru Forester showroom), respectively [15].

3.7. ASTM Standard Test Development for Grease Used in EVs or HVs

Various ASTM standard tests [34] have been developed to ensure the required performance specifications for grease operation in EVs or HVs. Among these ASTM standard tests, the most important test parameters are shown in Table 3. For example, oil viscosity is developed according to the load, speed, and operating temperature of the application [32]. While viscosity should be reduced to minimize friction loss, too low of a viscosity hinders durability and causes the lubricant to leak out of the bearings. This brings into play oxidation properties and dropping point when in extreme temperatures. Oxidation, enhanced by spark discharges, deteriorates the oil and increases the chances of sludge buildup, which hinders thermal control from the motor. Additives are added to modify these properties, but some may be counterintuitive and shorten the life span of the grease. Lastly, the lubricant must maintain electrical properties such as volume resistivity, dissipation factor, and dielectric strength to avoid electrical losses in the system [32]. Overall, the lubricant must be formulated to balance all these requirements. Table 4 depicts specific grease properties that must be tested today for operation in EVs or HVs.+

Table 3.

Laboratory test specifications for electrical properties (adapted from [34]).

Table 4.

ASTM laboratory test specifications for functional driveline fluids or greases (adapted from [34]).

In addition, ASTM Corrosion Tests [32] for grease have been developed such as the ASTM D4048 Copper Corrosion from Grease, D5969 Corrosion of Grease in Sea Water, and D1743—Corrosion Preventive Properties of Lubricating Greases. ASTM offers other basic lab test methods for specific properties related to electric fields and thermal cooling conditions, which have yet to be reviewed and assessed for greases used in EVs or HVs. A future publication for further standard test methods will be addressed.

4. Conclusions

Greases have been used in manufacturing and automotive industries and have been rapidly evolving in recent decades to meet the demands of modern automobiles. While some greases have specific niche applications, the most common ones are those that are versatile and can be used in a wide variety of situations. Lithium-based greases, for example, are some of the most popular greases on the market due to their wide temperature tolerance and high dropping point. The reason for their popularity is due to the effective solution for a major cause of grease failure—high temperature. Greases operating at high temperatures and loads for ICEVs’ components cannot be applied for EVs. EVs or HVs, while they also produce heat, prefer to operate in cooler conditions, requiring specific greases that can function at those temperatures as well.

Furthermore, one important aspect of EVs or HVs not present in ICEVs is the specific performance requirements of electrification components. These create electromagnetic fields and electrical currents, leading to potential issues as the field can transfer energy without the need for a physical medium. It became common for greases—especially thermally and electrically non-conductive ones—to absorb too much of the energy and eventually degrade due to oxidation and evaporation. The difference in operating conditions leads to a difference in requirement of lubricants in the two vehicles. The preferred cooler temperature of EVs leads to the pursuit of both a lower viscosity and density of lubricants while the opposite is true for ICEVs. While ICEVs are abundant today, EVs will undoubtedly become the future and their lubrication and grease components will be a focal point.

The major differences between EVs and conventional ICEVs can be grouped into the following technical areas: energy efficiency, noise, vibration, and harshness (NVH) issues and the presence of electrical current and electromagnetic fields from electric modules, sensors and circuits, and bearing lubrication. Additional considerations include thermal transfer, seals, corrosion protection, and materials’ compatibility. The authors will review the future development trends of EVs/HVs on driveline lubrication and thermal management requirements. The future development of electric vehicles will globally influence the selection and development of gear oils, coolants, and greases, as they will be in contact with electric modules, sensors, and circuits and will be affected by electrical current and electromagnetic fields.

The increasing presence of electrical parts in EVs/HVs will demand the corrosion protection of bearings and other remaining mechanical components. Thus, it is imperative that specialized greases should be explored for specific applications in EVs/HVs to ensure maximum protection from friction, wear, and corrosion to guarantee the longevity of the operating automobile.

Author Contributions

Conceptualization, R.S., R.C., S.T. and R.M.; literature review and formal analysis, R.C. and S.T.; writing—original draft preparation, S.T. and R.C.; writing—review and editing, R.S., S.T. and R.M.; revisions and supervision, R.S., S.T. and R.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data from reference [14] (Figures 1 and 2) and reference [15] (Table 2 and Figure 3) are publicly available from https://www.semanticscholar.org/paper/Decomposition-Kinetic-of-Greases-by-Thermal-Rhee/80d4d8f1ac0213173967ad1b6b4d15c3689f9026 (accessed on 2 March 2021) and https://doi.org/10.3389/fmech.2020.571464 (accessed on 2 March 2021), respectively. Data from Table 1 (reference [8]) and Tables 3 and 4 (reference [34]) have restricted access. Data from [8] is available at https://www.elsevier.com/books/the-tribology-handbook/neale/978-0-7506-1198-5 (accessed on 2 March 2021) and [34] is available at https://www.astm.org/DIGITAL_LIBRARY/MNL/PAGES/MNL6220121208809.htm (accessed on 2 March 2021).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Ahmed, N.; Nassar, A. Lubrication and Lubricants. Available online: https://www.intechopen.com/books/tribology-fundamentals-and-advancements/lubrication-and-lubricants (accessed on 9 December 2020).

- Greases for Your Vehicle. Available online: https://thelubepage.com/amsoil-magazine-articles/magazine-articles/articles/grease-for-your-vehicle (accessed on 10 December 2020).

- Wright, J. Grease Basics. Available online: https://www.machinerylubrication.com/Read/1352/grease-basics (accessed on 10 December 2020).

- Shah, R.; Wong, H.; Law, A.; Woydt, M. The New Age of Lubricants for Electric Vehicles. Available online: https://www.electrichybridvehicletechnology.com/features/the-new-age-of-lubricants-for-electric-vehicles.html (accessed on 3 December 2020).

- Farfan-Cabrera, L. Tribology of Electric Vehicles: A Review of Critical Components, Current State and Future Improvement Trends. Available online: https://www.sciencedirect.com/science/article/pii/S0301679X19303433?via%3Dihub (accessed on 10 December 2020).

- Choosing the Right Grease Thickening System. (n.d.). Available online: https://www.nyelubricants.com/choosing-the-right-grease-thickening-system (accessed on 10 December 2020).

- Klamann, D. Schmierstoff und Verwandte Produkte; VCH-Verlag: Weinheim, Germany, 1982. [Google Scholar]

- Neale, M.J. C4—Greases. In The Tribology Handbook, 2nd ed.; Butterworth-Heinemann: Oxford, MA, USA, 1995; pp. C4.1–C4.4. [Google Scholar]

- Tung, S.C.; Woydt, M.; Shah, R. Global Insights on Future Trends of Hybrid/EV Driveline Lubrication and Thermal Management. J. Front. Mech. Eng. Tribol. 2020, 6, 74. [Google Scholar] [CrossRef]

- Noria Corporation. Advantages of Using Polyurea Grease. Available online: https://www.machinerylubrication.com/Read/31367/using-polyurea-grease (accessed on 15 December 2020).

- Monkey, G. Complete Grease Guide—Workshop Greases. Available online: https://www.greasemonkeydirect.com/blogs/news/complete-grease-guide-workshop-greases (accessed on 15 December 2020).

- Dowson, D. ‘Elastohydrodynamic Lubrication,’ Interdisciplinary Approach to the Lubrication of Concentrated Contacts; NASA Spec. Pub-237; National Aeronautics and Space Administration: Washington, DC, USA, 1970; p. 34.

- Hamrock, B.J.; Dowson, D. Isothermal Elastohydrodynamic Lubrication of Point Contacts, Part III, Fully Flooded Results. ASME J. Lubr. Technol. 1997, 99, 264–276. [Google Scholar] [CrossRef]

- Rhee, I. Decomposition Kinetic of Greases by Thermal Analysis. In Proceedings of the 74th NLGI Annual Meeting, Scottsdale, AZ, USA, 27 April 2007. [Google Scholar]

- Chen, Y.; Jha, S.; Raut, A.; Zhang, W.; Liang, H. Performance Characteristics of Lubricants in Electrical and Hybrid Vehicles: A Review of Current and Future Needs. J. Front. Mech. Eng. Tribol. 2020, 6, 82. [Google Scholar]

- He, F.; Xie, G.; Luo, J. Electrical bearing failures in electric vehicles. Friction 2020, 8, 4–28. [Google Scholar] [CrossRef]

- Chau, K.T.; Chan, C.C. Emerging Energy-Efficient Technologies for Hybrid Electric Vehicles. Proc. IEEE 2007, 95, 821–835. [Google Scholar] [CrossRef]

- Pettersson, A. High-performance base fluids for environmentally adapted lubricants. Tribol. Int. 2007, 40, 638–645. [Google Scholar] [CrossRef]

- Callen, H.B. Thermodynamics and an Introduction to Thermostatics; Wiley: New York, NY, USA, 1985. [Google Scholar]

- Gedde, U. Polymer Physics, 1st ed.; Springer Science & Business Media: Dordrecht, The Netherlands, 1995. [Google Scholar]

- Jin, H.; Andritsch, T.; Tsekmes, I.A.; Kochetov, R.; Morshuis, P.H.; Smit, J.J. Properties of mineral oil based silica nanofluids. IEEE Trans. Dielectr. Electr. Insul. 2014, 21, 1100–1108. [Google Scholar]

- Shaikh, S.; Lafdi, K.; Ponnappan, R. Thermal conductivity improvement in carbon nanoparticle doped PAO oil: An experimental study. J. Appl. Phys. 2007, 101, 064302. [Google Scholar] [CrossRef]

- Barbés, B.; Páramo, R.; Blanco, E.; Pastoriza-Gallego, M.J.; Pineiro, M.M.; Legido, J.L.; Casanova, C. Thermal conductivity and specific heat capacity measurements of Al2O3 nanofluids. J. Therm. Anal. Calorim. 2013, 111, 1615–1625. [Google Scholar] [CrossRef]

- Chen, Y.; Renner, P.; Liang, H. Dispersion of nanoparticles in lubricating oil: A critical review. Lubricants 2019, 7, 7. [Google Scholar] [CrossRef]

- Dai, W.; Kheireddin, B.; Gao, H.; Liang, H. Roles of nanoparticles in oil lubrication. Tribol. Int. 2016, 102, 88–98. [Google Scholar] [CrossRef]

- Håkansson, B.; Andersson, P.; Bäckström, G. Improved hot-wire procedure for thermophysical measurements under pressure. Rev. Sci. Instrum. 1988, 59, 2269–2275. [Google Scholar] [CrossRef]

- Nagasaka, Y.; Nagashima, A. Simultaneous measurement of the thermal conductivity and the thermal diffusivity of liquids by the transient hot-wire method. Rev. Sci. Instrum. 1981, 52, 229–232. [Google Scholar] [CrossRef]

- Andrew, J.M. The future of lubricating greases in the electric vehicle era. Tribol. Lubr. Technol. 2019, 75, 38–44. [Google Scholar]

- Tung, S.C. The Impact of Advanced Propulsion System on Thermal Management and Lubrication Requirements. In Proceedings of the China International Lubricants Conference and Technology Exhibition (INTEX) Keynote Speaker, Guangzhou, China, 21–23 August 2019. [Google Scholar]

- Tung, S.C. Overview of Energy Innovation Technology and Future Development Trends Responding to Improving Energy Efficiency Requirements and Green Environmental Opportunities. Invited Speaker. In Proceedings of the SAE China International Congress, Beijing, China, 25 October 2019. [Google Scholar]

- Brodie, G. Energy Transfer from Electromagnetic Fields to Materials. Available online: https://www.intechopen.com/books/electromagnetic-fields-and-waves/energy-transfer-from-electromagnetic-fields-to-materials (accessed on 15 December 2020).

- Suzumura, J. Prevention of electrical pitting on rolling bearings by electrically conductive grease. Q. Rep. RTRI 2016, 57, 42–47. [Google Scholar] [CrossRef]

- Peskoe-Yang, L. Electric vehicles make grease’s future uncertain. Tribol. Lubr. Technol. 2020, 76, 24–25. [Google Scholar]

- Tung, S.C.; Totten, G. Chapter 9—Testing of Evaluation of Lubricating Grease for Rolling Element Bearings of Automotive System. In Automotive Lubricants and Testing; ASTM International: West Conshohocken, PA, USA, 2012; pp. 137–156. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).