Abstract

This paper presents a study on the effect of the mixed volume fraction of Jatropha curcas Oil (JCO) and Olea europea or extra virgin olive oil (EVOO) on the physical properties of the oil, especially viscosity, density and water content. This study also presents the mechanical properties examination result, especially its effect on the wear rate of the pin on disc tribometer results on ST 41 steel specimens, using optical microscopy. The independent variables used were variations of the oil mixture: 0, 20, 40, 60, 80 and 100% EVOO. With the increase in the percentage of the EVOO mixture in JCO, the density decreases. The result of water content in a higher percentage of JCO, the higher the water content value of 0.1217%. Pure JCO has the higher viscosity value of 1.9084 m2/s. The higher the percentage of JCO, the lower the wear rate value obtained. In the tribometer test, the pin on disk mixture of pure JCO has the lower wear value of 5.09 m2/s.

1. Introduction

Bio lubricant is mainly made from vegetable oils such as sunflower, coconut, Jatropha, rapeseed, and palm, while fuel oil is also acceptable for biolubricant production. Synthetic esters and petroleum products that fulfil biodegradability and toxicity criteria can also be used to manufacture biolubricants [1]. Jatropha curcas Linn oil (JCO) has a high percentage of FFA so that it can be produced to make bio lubricants, it was found that the bio lubricant produced is comparable to the ISO VG-46 commercial standards for light and industrial gears applications and other plant based bio lubricant [2]. Because of the fatty oil content, JCO may also be used as metal working fluid [3]. In previous study, superior seeds of Jatropha curcas Linn—which are drought resistant, have high productivity, and contain relatively free fatty acid FFA <4%—were developed and cultivated [4]. The physicochemical properties of JCO are a viable alternative in metal cutting fluids compared with others edible oils. The physicochemical properties and better flash point and viscosity value of JCO oil were found to be suitable properties for coolant-lubricant applications [5]. It was also applied on steel ST41 with the ratio of the mixture of Jatropha Curcas Oil (JCO) with mineral lubricants, namely 90:10, 80:20, and 70:30. The optimum result obtained is at a ratio of 70:30 where the wear rate of 9.61 m2/s [6]. When JCO mixed with the potential of carrier oil, it gave the result that EVOO (extra virgin olive oil) and SFO (sunflower oil) have the potential to be used as carrier oil in the pre-treatment process of JCO as lubricant. This is because, the results of the viscosity and density of the mixture of JCO with the two oils that are used as carrier oil make the density and viscosity of JCO also decrease [7]. The modernization of Pongamia and Jatropha curcas oil (JCO) as direct cutting fluids has great potential for use as environmentally friendly and biodegradable metal cutting fluids [8]. JCO provides excellent lubrication reducing the coefficient of friction [9]. The lubrication capacity is important for friction between the tool and the work piece and hence affects the tool wear behavior and the surface quality of the work piece just as JCO can be used as metalworking fluids [10]. It was observed that the Jatropha vegetal cutting oil presented the best results in relation to requirements for lubrication, superficial mean roughness (index Ra) and shape errors in relation to the other oils in both the techniques to apply fluid which were tested [11].

Lubrication is one of the complementary systems on a vehicle or production tool with the aim of regulating the lubricant to the moving parts of the engine. Mangas stated that the term “lubricants” refers to a wide variety of products characterized by hundreds of basic chemicals and additives [12]. Lubricating oils can be mineral based or synthetic. Mineral based oils are more widely used than synthetic oils. Lubricants are one of the factors that can reduce wear on the surface of the material. Wear is defined as the loss of material from the surface of a solid object as a result of mechanical motion. “Wear and tear” is generally a loss of material that arises as a result of the mechanical interaction of the two sliding moving surfaces. This is a normal phenomenon that occurs when two surfaces rub against each other, then there will be wear or displacement of the material. Wear and tear can be affected by the load factor, lubrication, the length of the track, and the properties of the material. So far, the most widely used lubricant is mineral oil, which is a mixture of several types of petroleum; besides that, it can also be used as a base lubricant type of vegetable oil, or synthetic oil derived from petroleum or vegetable oil. Mineral lubricants from petroleum will one day run out, so we need to find alternative lubricants from renewable sources. Lubricants made from vegetable oil from Jatropha, palm oil, corn, soybeans and others can be used as renewable lubricants. In this study, Jatropha plant was used with a mixture of olive oil as an alternative lubricant. Jatropha curcas (Jatropha curcas Linn) is a woody shrub that is commonly found in the tropics. Although it has long been known as a medicinal and toxic agent, nowadays it is gaining increasing attention as a source of biofuels for diesel engines and lubricants due to its oil content [13]. Olive oil is oil that is extracted from the fruit of the olive tree, (Olea europea L.). Olive oil is almost unique among vegetable oils in that it can be consumed without refining treatment. Their moderate degree of unsaturation is considered nutritious is preferable to the high saturation or unsaturation level of many other vegetable fats and oils [14].

2. Materials and Methods

This study used JCO which extracted from seed of JCUMM5, a superior variety of Jatropha curcas Linn (JCL) cultivated by researchers from University of Muhammadiyah Malang (UMM), as a based oil, which is drought resistant, high productivity, and contains free fatid acid (FFA) <4% [4]. Directly, the availability of these varieties is used as a source of seeds and seeds from crosses in the Jatropha restoration program. Jatropha is an energy crop, grows seed with high oil contents, provide high oil yield, and provides oil of high quality [15]. In addition, Jatropha oil has a potential as a basic lubricant over other energy sources. Talib [16] stated that the viscosity of oils affects the coefficient of friction and wear scar diameter. Moreover, Talib described that the machining performance of modified Jatropha oil (MJO) was comparable with synthetic ester (SE) in terms of cutting force and maximum cutting temperature. It concluded that MJO significantly improved the lubricating effect, thus it becomes a suitable candidate to substitute synthetic ester as a machining lubricant. This allows Jatropha oil which includes vegetable oil to be used as an alternative to basic lubricants, as well as being used as bioethanol and a diesel fuel capable of providing specific fuel consumption figures [17] (specific fuel consumption) higher than that given by standard bio solar [18].

Olea europea or extra virgin olive oil, called EVOO, consists of the glycerol fraction (90–99% from olives) and non-glycerol (0.4–5% from olives) containing phenolic compounds. EVOO’s glycerol fraction consists of monounsaturated fatty acid (MUFA), polyunsaturated fatty acid (PUFA), and saturated fatty acid (SFA), while the non-glycerol fraction consists of phenolic compounds (hydroxytyrosol, oleuropein, caffeic acid, coumaric acid, vanillic 13 acid), α-tocopherol, squalene, chlorophyll (color pigment), and β-carotene which function as antioxidants [19].

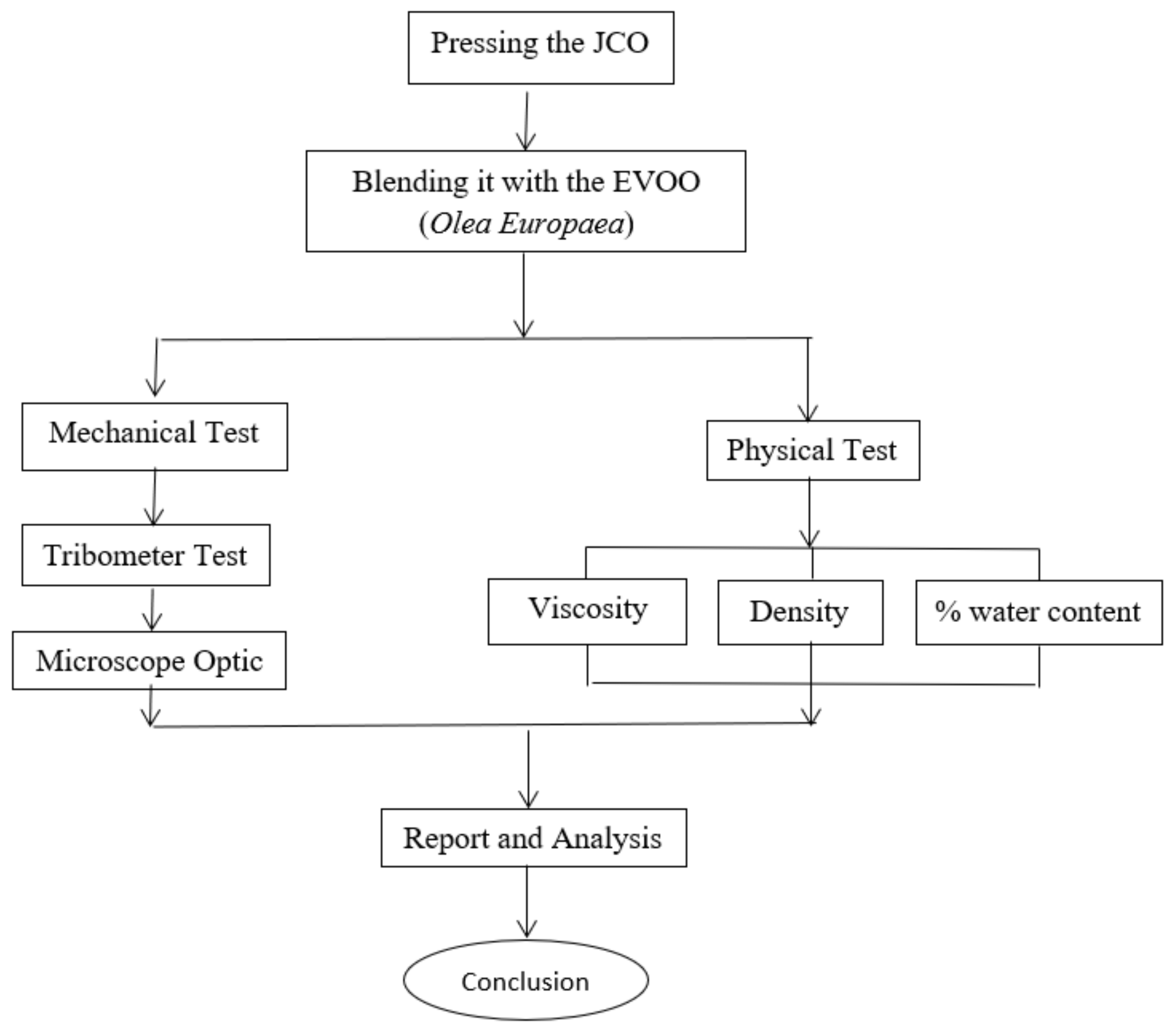

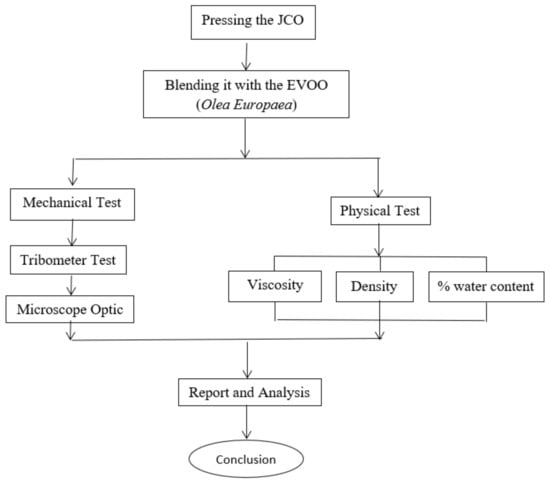

This study conducted a mixed JCO and EVOO in a composition of 0%, 20%, 40%, 60%, 80% and 100% followed by physical and mechanical testing. Physical testing includes tests for density, viscosity and percent water content. Mechanical tests are carried out using a tribometer test and then a microscope observation is carried out to calculate the wear rate. A detailed of the physical and mechanical testing is presented in Figure 1.

Figure 1.

Research flowchart.

To acquire physical properties of the blend, several tests were conducted. Viscosity of the blend was measured by using an Ostwald viscometer. The viscometer was heated to 100 °C for 2 h. After it was cooled off then the viscometer was set up. When the set up was ready, then oil blend was measured for its viscosity. Density was determined thru pycnometer. At first, the pycnometer was dried up by heating up to 70 °C for 30 min. After it was cooled off, the pycnometer was put on analytical scale. The blended oil then poured into pycnometer and the weight was measured. Water content was obtained by analysis of moisture thru evaporating water in the oil by heating in the oven. The heating process took 24 h to make sure all of water was evaporated. By comparing weight of oil before heating and after at room temperature, the water content can be acquired. The viscosity and density, the measurement was replicated 3 (three) but for water content test only had one measurement.

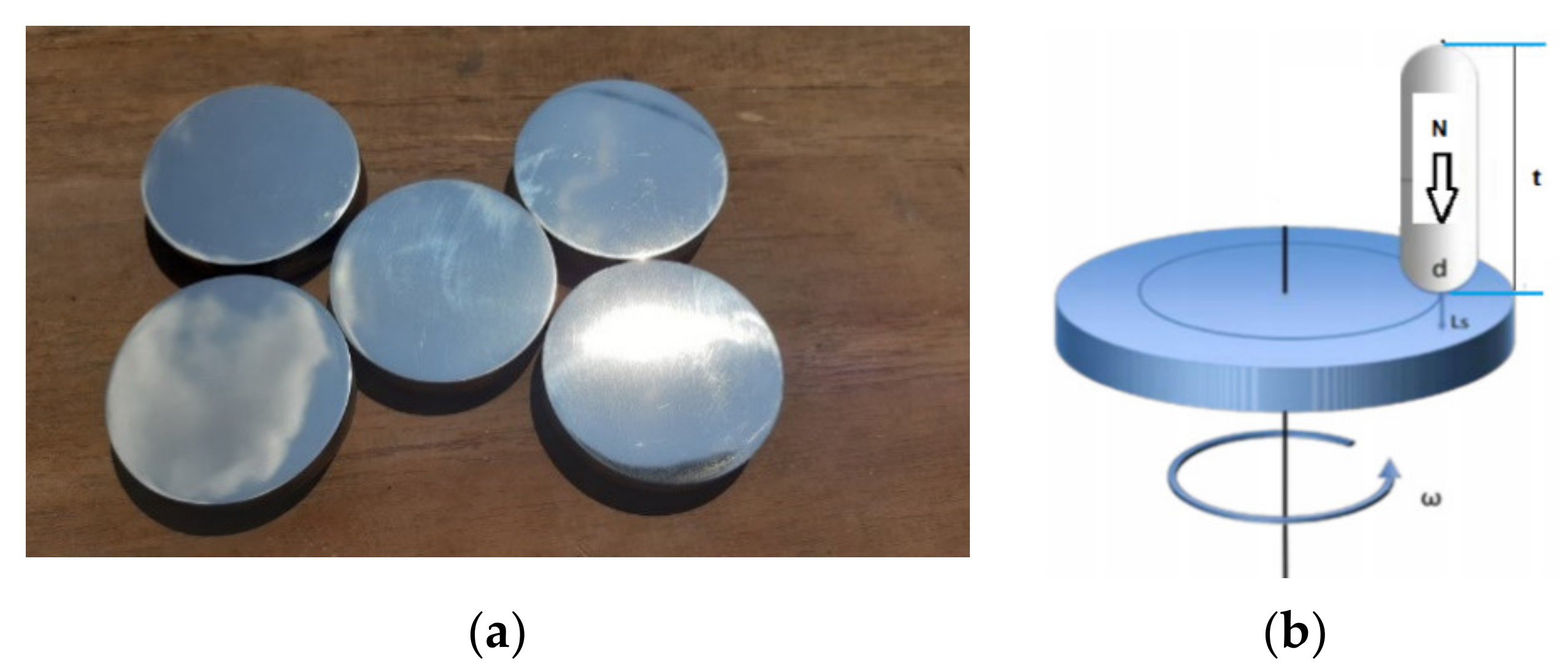

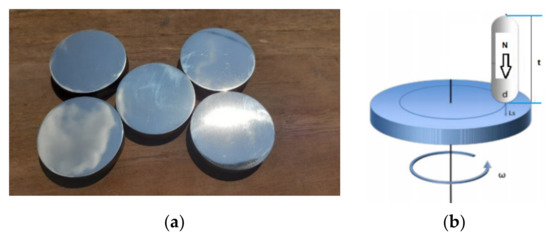

Tribometer test was conducted by pin-on-disk tribometer. Specimen was coated by 0.5 mL of blended oil every 5 min. The load applied for the test was 5 N, sliding speed was 1.0 m/s and the sliding time for the test was 10 min, track radius (R) and turning speed (ω) were constant. The wear track then examined and photographed. ST41 (Ra < 0.4 µm) samples of 90 × 90 mm2 and thicknesses 2.0 mm were selected as disk, seen in Figure 2. Track measurement was replicated 5 (five) times. For the research, the JCO was freshly squeeze from the seed but EVOO was purchased from the market.

Figure 2.

(a) ST41 disks and (b) the motion diagram.

3. Results

The physical properties of bio-oil mixture between JCO and EVOO were investigated, such as water content, kinematic viscosity, and density. The oil mixture then applied to the pin on disc tribometer test. Furthermore, the result of wear track was observed using an optical microscope.

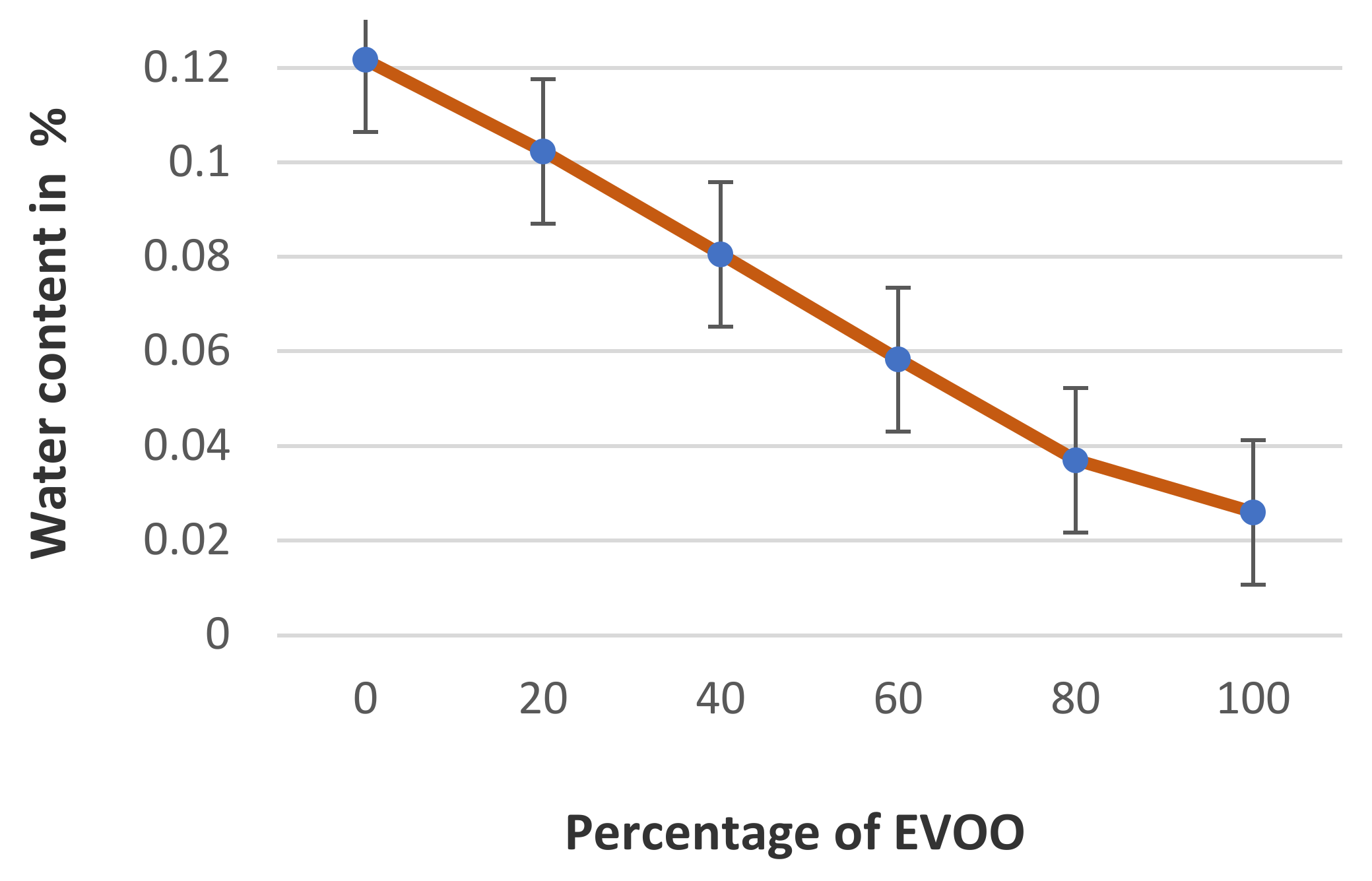

3.1. Water Content

Water content is the difference between the weight of the bio-oil before and after heating. When placed in open air, its water content will balance with the humidity of the surrounding air [20]. In determining the water content uses the drying method or it can be called the oven method, where this method is to remove water in the test material by heating it in an oven with a temperature reaching 105 °C [21] The formula used to determine the value of the water content is:

The results from testing the water content of the oven or drying method, with a temperature of 100 °C for 24 h is following formula above, the resulting data is presented in Table 1.

Table 1.

Result of water content test.

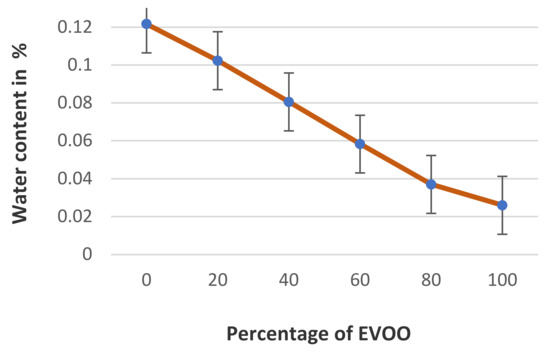

According to Figure 3, it can be seen that the water content reduced from 0.0226–0.1217. At 100% JCO, there is a fairly high water content of 0.1217 and the lowest is at 100% EVOO. The higher the oven temperature, the faster the material needs to evaporate. The decrease in water content is proportional to the oven time, the longer the oven time, the less water content in the material [21]. It is also described that, an oil that has been processed at a certain temperature still has water in it, and this water content can affect the storage life and viscosity of the oil. Water content may also be affected by moisture from the air when storage of an oil is not maintained properly.

Figure 3.

Water content of mixed Jatropha curcas oil (JCO) and extra virgin olive oil (EVOO).

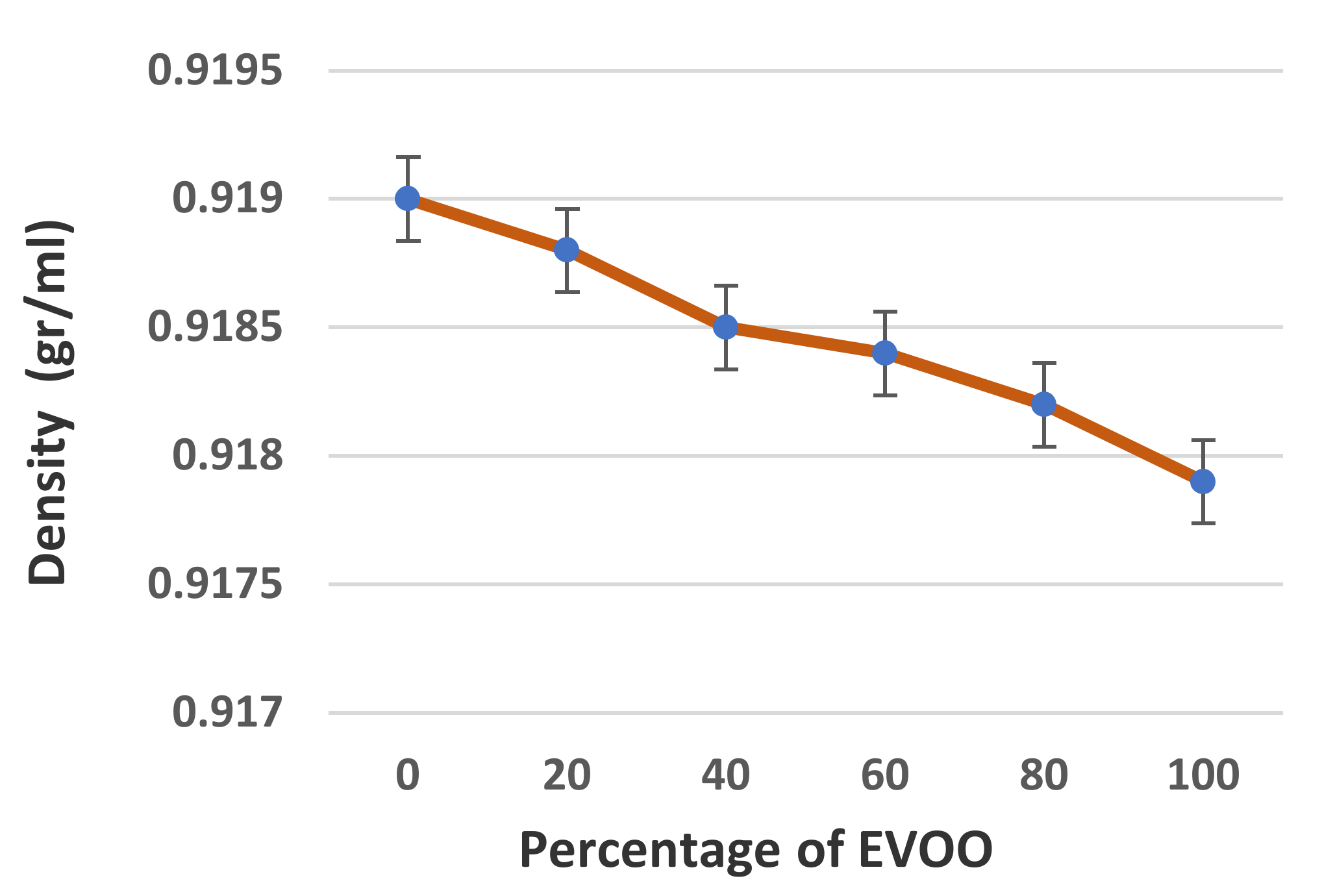

3.2. Density

The specific gravity and density measure were performed according to American Society for Testing and Materials (ASTM) standard test methods ASTM D 369 and D 891 for pycnometer [22]. A pycnometer is a tool used to measure the density value or density of the fluid. The formula used is:

where ρ is density (g/mL), m is mass (g), and v is volume (mL). The result of density test is presented in Table 2.

ρ = m/v

Table 2.

Result of density test.

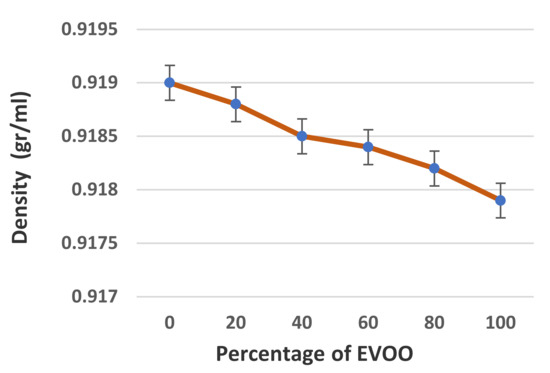

According to Figure 4, it can be concluded that each oil has a different density. The highest density value was pure JCO 0.9190 gr/mL with the lowest was pure EVOO 0.9179 g/mL. According to [23] that density is also influenced by a temperature and viscosity contained in an oil, because the characteristics of each oil are different. In addition, the study reported and concluded that the decrease in density on the graph is due to the effect of the viscosity of the oil. Compared data for density as a function of temperature measured by Noureddini, for a number of vegetable oils (crambe, rapeseed, corn, soybean, milkweed, coconut, lesquerella), as well as eight fatty acids in the range C8 to C22 at temperatures from above their melting points to 110 °C (230 °F), it found that density of pure JCO in between both coconut and lesquerella in the room temperature [22].

Figure 4.

The density of mixed JCO and EVOO.

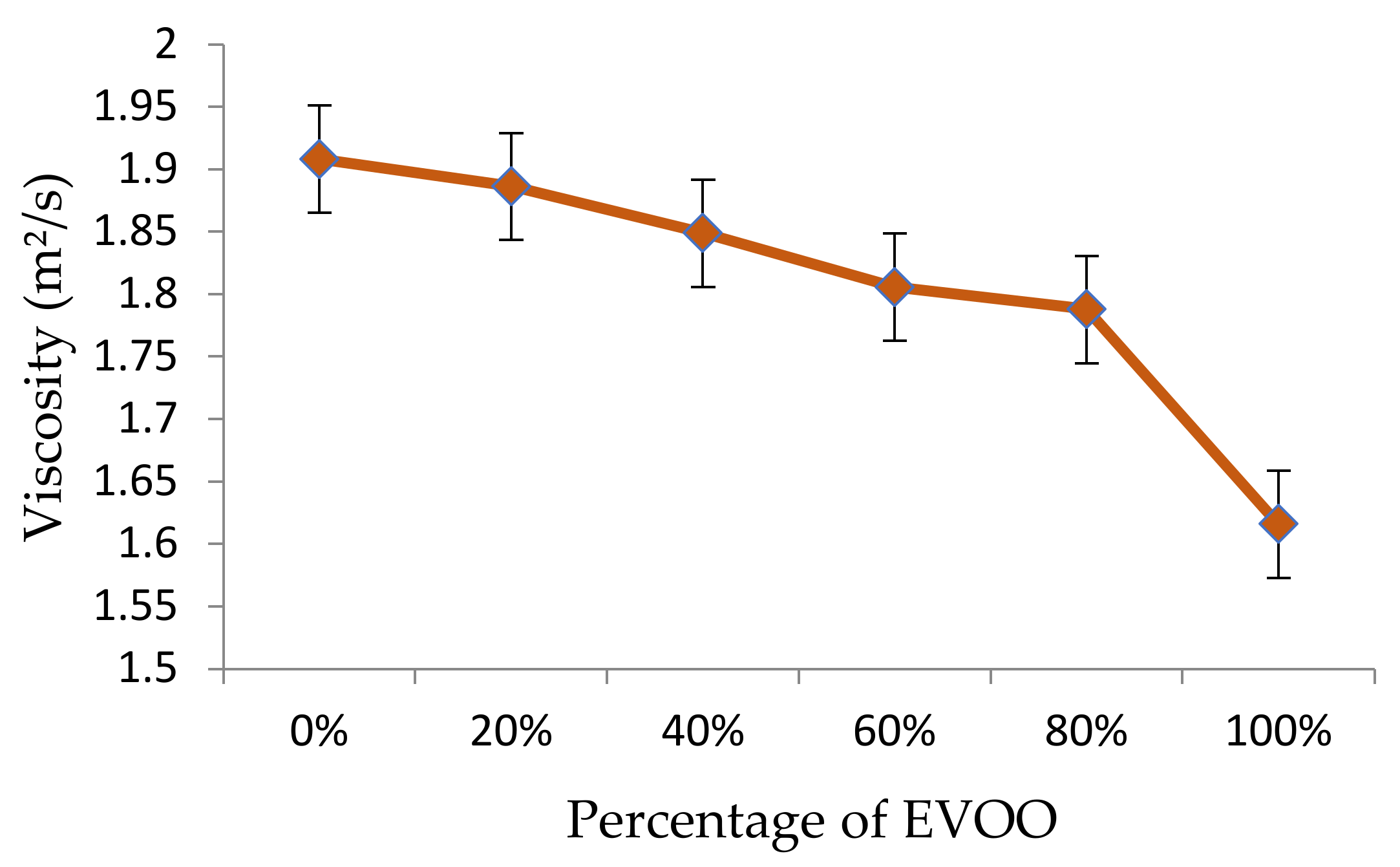

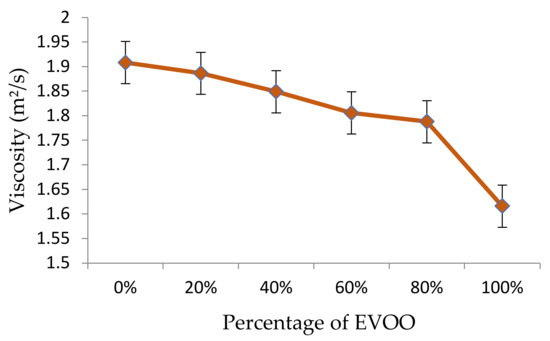

3.3. Viscosity

For such a purpose, there are many measurers of oil viscosity, e.g., the coriolis, positive displacement type turbine measurers and also the simple Ostwald viscometer [23]. Determination of viscosity using the Ostwald viscometer is done by measuring the time required for a fluid or liquid to flow in the capillary tube from point A (higher point) to point B (lower point). From the theory [24], the viscosity formula uses the following:

where η2 is kinematic viscosity (m2/s), η1 is viscosity comparison (m2/s), ρ1 is density comparison (gr/mL), ρ2 is density of sample measured (gr/mL), t1 is time comparison (s), and t2 is time of sample measured (s).

η2 = (η1 × ρ2 × t2)/(ρ1 × t1)

The results of the viscosity test using the Ostwald viscometer, the temperature used was 40 °C. This test is to determine the time taken at line A to B as an input for calculation in Equation (3) to obtain the kinematic viscosity value. The results of the calculation is presented in Table 3.

Table 3.

Result of kinematic viscosity test.

According to Figure 5, the highest viscosity value at 40 °C is pure JCO with a time of 3.26 s with a viscosity of 1.9084 m2/s (Cst) and the lowest is pure EVOO of 2.77 s with a viscosity of 1.6159 m2/s (Cst) with a low to high concentration of EVOO, the viscosity value decreases. In the level of wear and tear, a lubricant with a high viscosity value is needed because the viscosity value is a dominant role in lubricants. According to [25] viscosity is the most important property for lubricants because it is to determine the amount of friction to be faced between two friction surfaces and to reduce wear. Lubricants with greater viscosity result in a greater viscosity ratio and lower wear rates. A similar strong effect of lubricant viscosity has also been observed previously for surface fatigue life. According to studies [26] that the wear rate is closely related to the viscosity of lubricants. This is also due to an increase in temperature which forms an oxide layer at a higher friction rate which protects it from wear. Lubricant is spread evenly on the surface it will fill the space between the two surfaces so that a layer is formed that can help the surfaces to move with each other, thereby reducing wear rates [27]. JCO and EVOO each have different kinematic viscosity values. Although the basic bond between the two is the same, namely triglycerides, both oils have different macromolecular and micromolecular components. JCO contains more macromolecules than EVOO, so that the viscosity value of JCO can be seen to be higher than EVOO. The mixture of both JCO and EVOO, according to the percentage specified above will create a mixture of macromolecules and micromolecules. So, the mixing resulted a lower kinematic viscosity when compared to the pure viscosity of JCO.

Figure 5.

Kinematic viscosity of mixed JCO and EVOO bio-oil.

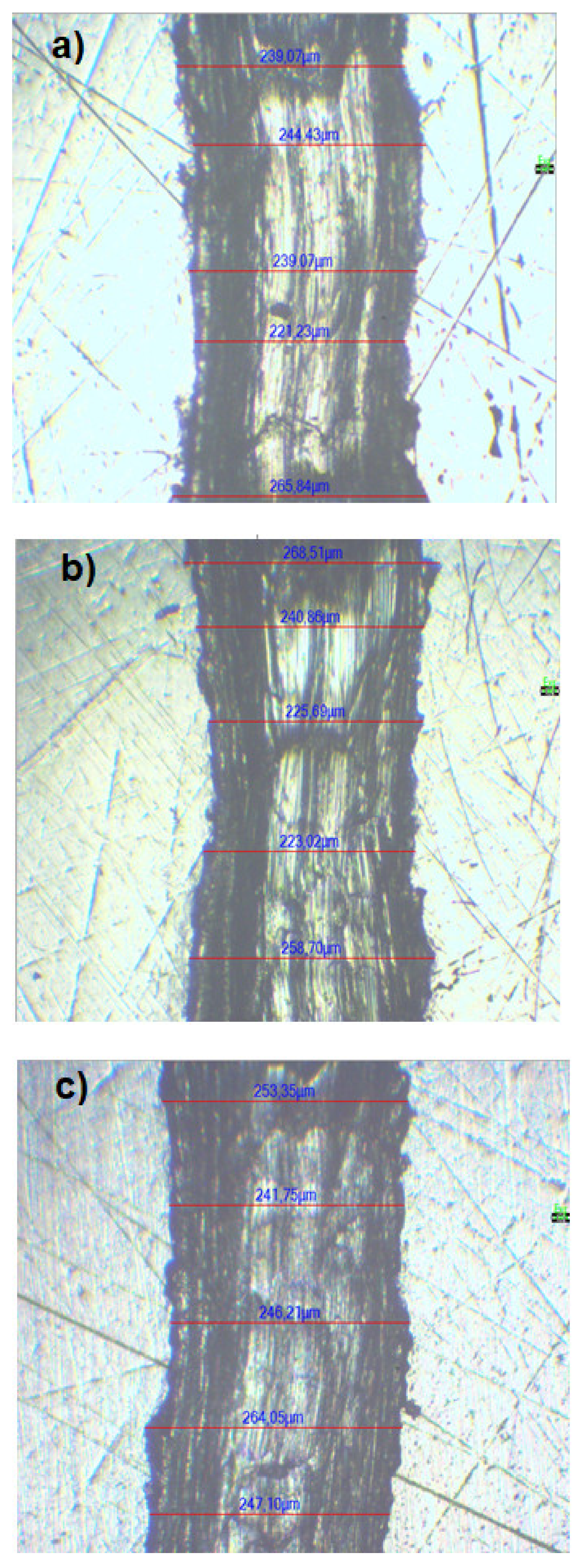

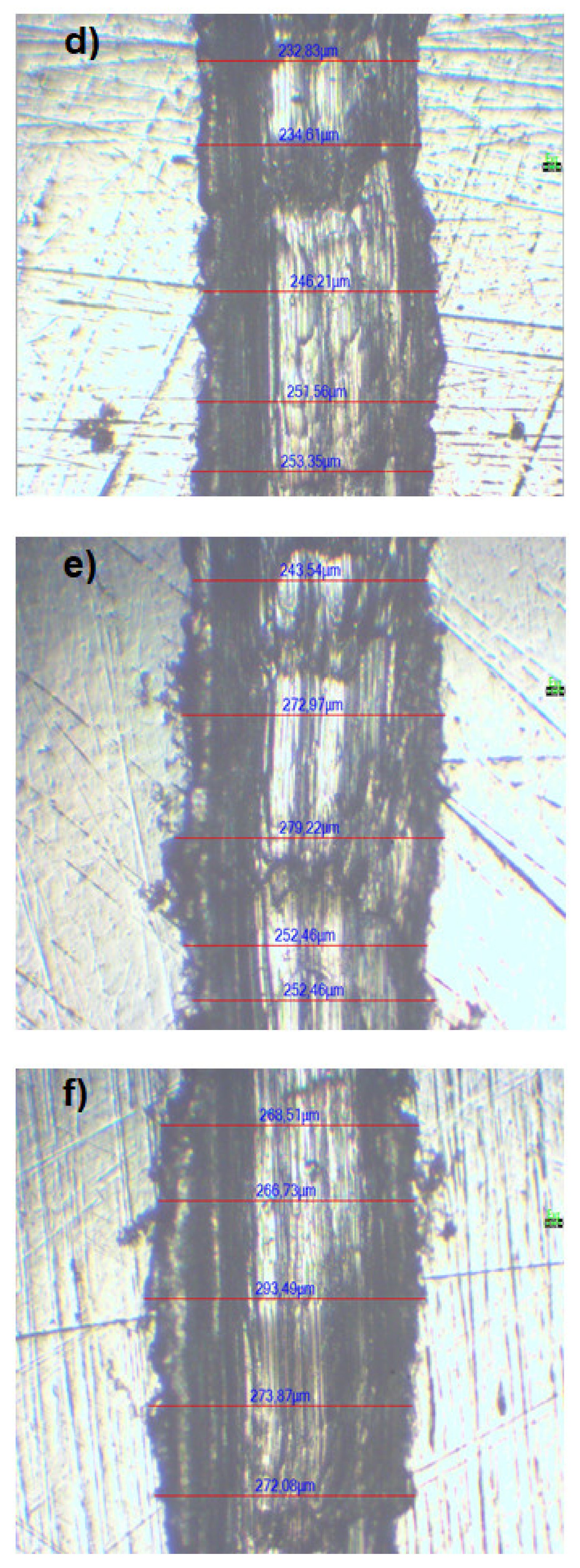

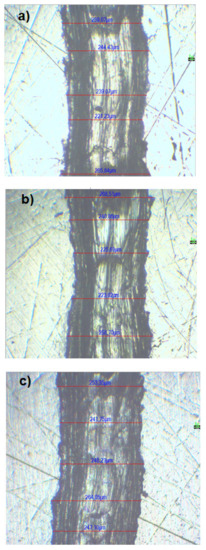

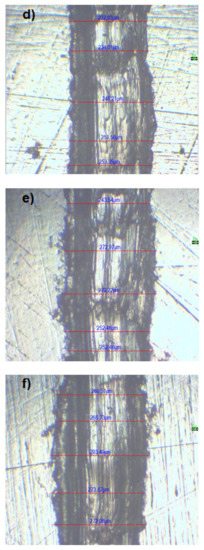

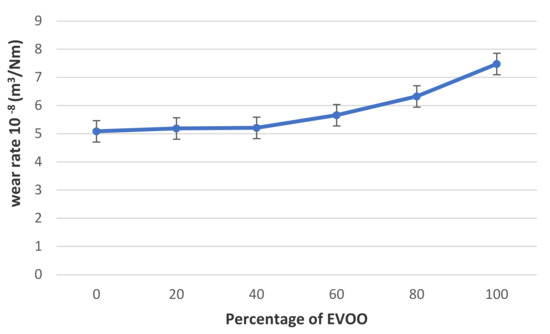

3.4. Tribometer Pin on Disk

The tribometer is a tool used to determine the wear and tear of a material between two contact surfaces. In the last research shows the wear on the material and is usually used to determine the strength and longevity of an object in contact [28]. In this case the disc refiner material is a type of corrosion wear, where corrosion wear is a type of wear that occurs due to friction that occurs in corrosive environments [29]. The wear resistance test [30] was obtained by the Ogoshi–Reiken method and expressed in Equation (4):

where Ws is wear rate surface (mm3/kg), B is the disc width of the wearer (mm), b is the width of the scratch on the test object (mm), r is wear disc radius (mm), Po is compressive load at the time of wear (kg), lo is long distance of scratch process (mm), Io = L × n × t, L is circumference (L = 2 × π × r), n is number of rotation, and t is time.

Ws = (B × b3)/(8 × r × Po × Io) (mm3/kg)

To determine wear by calculating the scratch width, which measured using an optical microscope, as presented in Figure 6. Table 4 presented the track width obtained then put into Equation (4), the result present in a table of the relationship between the wear rate and the ratio of the lubricant mixture as presented in Table 5.

Figure 6.

The track width of tribometer test resulted from lubrication of. (a) 0%, (b) 20%, (c) 40%, (d) 60%, (e) 80% and (f) 100% of EVOO.

Table 4.

Track width measurement result.

Table 5.

Result of wear rate.

According to Figure 7, it can be seen that with the increasing of EVOO percentage in the JCO, it increases the wear rate. In addition, the pure 100% JCO, has the lower wear rate is in accordance with the viscosity rate. This is because when applying force to the pin, the force touches the disc is one of the factors causing wear, the wear rate decreases with increasing friction coefficient, it will affect the height of the pin touching of the rotating disk [31,32].

Figure 7.

The wear rate of tribometer test result.

In tribometer testing research, the characteristics of wear are related to the hardness value of the specimen. The higher hardness has less abrasive material characteristic. The wider the wear marks, the higher the volume of material released from the test object. Less abrasive material means that it has high wear resistance. The impact of these wear traces can be reduced by providing lubrication on the surfaces of objects that are in contact or rubbing against each other, as well as the data obtained from the results of this study. According to [33] generally the viscosity of lubricating oil affects the power loss caused by friction and the amount of wear, to increase the anti-wear characteristics, it is better to choose lubricating oil that has high viscosity. However high viscosity can cause excessive power losses with the addition of additives increasing the service life and imparting additional performance characteristics to the lubricant, such as better flow, modified friction, and resistance to oxidation, extended pressure or temperature stability [34]. Compared to the polyalkylene glycol (PAG) oil, a commercial lubricant commonly used for conventional compressor in which it wear rate was 10−9 (mm3/Nm) [35], the performance of the examined bio-lubricant still need to be improved in order to be worthy as an alternative lubricant and the goal to reduce dependency on petroleum-based products can be reached.

4. Conclusions

A study on an alternative bio-lubricant, JCO, has been presented. The study includes the physical properties and wear rate. It is found that with the increase in the percentage of the EVOO mixture in JCO, the density of JCO decreases. The result of water content in a higher percentage of JCO is the higher water content value. The more the percentage of EVOO mixture in JCO, the lower the viscosity value. The higher the percentage of JCO, the lower the wear rate value obtained. This proves that viscosity is the most important property for lubricants because it is to determine the amount of friction to be faced between two friction surfaces and to reduce wear. Lubricants with greater viscosity result in a greater viscosity ratio and lower wear rates.

Author Contributions

Conceptualization, M.M.; methodology, I.S.A. and D.K.; formal analysis, I.S.A.; resources, M.M.; data curation, D.A. and D.K.; writing—original draft preparation, I.S.A.; writing—review and editing, W.C., A.G., K.O. and H.L.; visualization, I.S.A.; supervision, W.C.; funding acquisition, W.C., A.G. and I.S.A. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by RistekDikti, grant number B/1176/E.3/RA.00/2020 and The UBD research grant was funded by UBD/RSCH/1.3/FICBF(b)/2019/007.

Institutional Review Board Statement

Not Applicable.

Informed Consent Statement

Not Applicable.

Data Availability Statement

Not Applicable.

Acknowledgments

The first Author wish to thanks to the Ministry of Research Technology and Higher Education (RistekDikti) for financial support under grant PDUPT for the year of 2021 granted through University of Muhammadiyah Malang, Indonesia. The second Author would like to thank to Universiti Brunei Darussalam for the partial financial support of this study through the research grant number UBD/RSCH/1.3/FICBF(b)/2019/007.

Conflicts of Interest

The authors declare no conflict of interests.

References

- Hossain, M.; Mohamad, E.N.; Masjuki, H.H.; Kalam, M.; Al Mahmud, K.A.; Habibullah, M.; Ashraful, A.M. The prospects of biolubricants as alternatives in automotive applications. Renew. Sust. Energy Rev. 2014, 33, 34–43. [Google Scholar] [CrossRef]

- Bilal, S.; Nuhu, M.; Kasim, S.A. Production of biolubricant from Jatropha curcas seed oil. J. Chem. Eng. Mater. Sci. 2013, 4, 72–79. [Google Scholar] [CrossRef]

- Ravi, G.S.; Palani, B.; Kak, P.D.; Bapat, D. Water Based Metal Working Fluid Composition. U.S. Patent US20160053193A1, 25 February 2016. [Google Scholar]

- Zainudin, A. In Vitro selection of jatropha curcas linn. hybrids using polyethylene glycol to obtain drought tolerance character. Procedia Chem. 2015, 14, 239–245. [Google Scholar] [CrossRef][Green Version]

- Murad, M.N.; Sharif, S.; Rahim, E.A.; Abdullah, R. Comparative evaluation of physicochemical properties of jatropha curcas seed oil for coolant-lubricant application. AIP Conf. Proc. 2017, 1885, 020186. [Google Scholar] [CrossRef]

- Aisyah, I.S.; Widyawati, Y.I.; Kurniawati, D.; Sewoyo, T.; Tanaman, P.V. Investigasi potensi Jarak pagar sebagai. Pros. SENTRA 2018, 4, 167–173. [Google Scholar]

- Kurniawati, D.; Aisyah, I.S. The potent of carrier oil on pretreatment of crude jatropha curcas oil. J. Energy Mech. Mater. Manuf. Eng. 2020, 5, 45–52. [Google Scholar] [CrossRef]

- Jeevan, T.P.; Jayaram, S.R. Performance evaluation of jatropha and pongamia oil based environmentally friendly cutting fluids for turning AA 6061. Adv. Tribol. 2018, 2018, 1–9. [Google Scholar] [CrossRef]

- Figueroa, M.; García, E.; Hernández, E.A.G.; Vite-Torres, M. Friction and wear of Jatropha curcas oil using a four balls tester. Adv. Mater. Res. 2014, 902, 76–81. [Google Scholar] [CrossRef]

- Winter, M.; Öhlschläger, G.; Dettmer, T.; Ibbotson, S.; Kara, S.; Herrmann, C. Using Jatropha Oil Based Metalworking Fluids in Machining Processes: A Functional and Ecological Life Cycle Evaluation; Springer: Berlin, Germany, 2012. [Google Scholar] [CrossRef]

- Bork, C.A.S.; Gonçalves, J.F.S.; Gomes, J.O. The Jatropha curcas vegetable base soluble cutting oil as a renewable source in the machining of aluminum alloy 7050–T7451. Ind. Lubr. Tribol. 2015, 67, 181–195. [Google Scholar] [CrossRef]

- Mangas, I.; Sogorb, M.A.; Vilanova, E. Lubricating oils. In Encyclopedia of Toxicology; Elsevier: Amsterdam, The Netherlands, 2014; pp. 670–676. [Google Scholar]

- Carels, N. Chapter 2 Jatropha curcas. A Review. Adv. Bot. Res. 2009, 50, 39–86. [Google Scholar] [CrossRef]

- Kiritsakis, A.; Markakis, P. Olive oil: A review. Adv. Food Res. 1988, 31, 453–482. [Google Scholar] [CrossRef]

- Bindraban, P.S.; Brandenburg, W.A. Claims and facts on Jatropha curcas L. Plant. Res. Int. B.V. 2007, 158, 1–67. [Google Scholar]

- Talib, N.; Rahim, E.A. Performance evaluation of chemically modified crude jatropha oil as a bio-based metalworking fluids for machining process. Procedia CIRP 2015, 26, 346–350. [Google Scholar] [CrossRef]

- Aisyah, I.S. Performance of four stroke one cylinder ic engine with dual spark plugs using 94–100% Ethanol. J. Energy Technol. Policy 2016, 6, 13–17. [Google Scholar]

- Kurniawati, D. Effect of Alkaline metal catalyst to transesterification of jatropha curcas oil. J. Energy Mech. Mater. Manuf. Eng. 2018, 3, 31–42. [Google Scholar] [CrossRef]

- Tripoli, E.; Giammanco, M.; Tabacchi, G.; di Majo, D.; Giammanco, S.; la Guardia, M. The phenolic compounds of olive oil: Structure, biological activity and beneficial effects on human health. Nutr. Res. Rev. 2005, 18, 98–112. [Google Scholar] [CrossRef] [PubMed]

- Carneiro, J.; Nogueira, R.M.; Martins, M.A.; Valladão, D.M.; Pires, E.M. The oven-drying method for determination of water content in Brazil nut. Biosci. J. 2018, 34, 595–602. [Google Scholar] [CrossRef]

- Xiong, Z.; Wang, Y.; Syed-Hassan, S.S.; Hu, X.; Han, H.; Su, S.; Xu, K.; Jiang, L.; Guo, J.; Berthold, E.E.; et al. Effects of heating rate on the evolution of bio-oil during its pyrolysis. Energy Convers. Manag. 2018, 163, 420–427. [Google Scholar] [CrossRef]

- Noureddini, H.; Teoh, B.C.; Clements, L.D. Densities of vegetable oils and fatty acids. J. Am. Oil Chem. Soc. 1992, 69, 1189–1191. [Google Scholar] [CrossRef]

- Damasceno, M.A.; Penha, J.K.d.; Junior, N.F.d.; Felipe, R.N.B.; Felipe, R.C.T.d.S.; de Medeiros, G.G. Influence of the temperature, pressure and viscosity on the oil measurement with turbine type measurers. Braz. Arch. Biol. Technol. 2006, 49, 65–72. [Google Scholar] [CrossRef]

- Viswanath, D.S.; Ghosh, T.K.; Prasad, D.H.L.; Dutt, N.V.K.; Rani, K.Y. Viscosity of Liquids: Theory, Estimation, Experiment, and Data; Springer: New York, NY, USA, 2007. [Google Scholar]

- Habibullah, M.; Masjuki, H.H.; Kalam, M.A.; Ashraful, A.M.; Habib, M.A.; Mobarak, H.M. Effect of bio-lubricant on tribological characteristics of steel. Procedia Eng. 2014, 90, 740–745. [Google Scholar] [CrossRef]

- Okrent, E.H. The effect of lubricant viscosity and composition on engine friction and bearing wear. ASLE Trans. 1961, 4, 97–108. [Google Scholar] [CrossRef]

- Basha, S.M.; Dave, H.K.; Patel, H.V. Experimental investigation of jatropha curcas bio-oil and biodiesel in electric discharge machining of Ti-6Al-4V. Mater. Today Proc. 2021, 38, 2102–2109. [Google Scholar] [CrossRef]

- Noorawzi, N.; Samion, S. Tribological effects of vegetable oil as alternative lubricant: A pin-on-disk tribometer and wear study. Tribol. Trans. 2016, 59, 831–837. [Google Scholar] [CrossRef]

- Tabrett, C.P.; Sare, L.R. The effect of heat treatment on the abrasion resistance of alloy white irons. Wear 1997, 203, 206–219. [Google Scholar] [CrossRef]

- Zuan, A.M.S.; Syahrullail, S.; Arif, M.D.; Kamitani, S. Tribological performance of palm kernel oil at various load using pin-on-disk tribotester. J. Mech. Eng. 2017, 1, 91–102. [Google Scholar]

- Ruggiero, A.; D’Amato, R.; Merola, M.; Valášek, P.; Müller, M. On the tribological performance of vegetal lubricants: Experimental investigation on Jatropha curcas L. oil. Procedia Eng. 2016, 149, 431–437. [Google Scholar] [CrossRef]

- Singh, Y.; Singh, A.K.; Singla, A.; Upadhyay, A.K. Development and tribological characteristics of bio-based lubricant from Jatropha curcas oil. Energy Sources Part A Recovery Util. Environ. Eff. 2017, 39, 1725–1732. [Google Scholar] [CrossRef]

- Ku, B.C.; Han, Y.C.; Lee, J.E.; Lee, J.K.; Park, S.H.; Hwang, Y.J. Tribological effects of fullerene (C60) nanoparticles added in mineral lubricants according to its viscosity. Int. J. Precis. Eng. Manuf. 2010, 11, 607–611. [Google Scholar] [CrossRef]

- Maleque, M.A.; Masjuki, H.H.; Haseeb, A.S.M.A. Effect of mechanical factors on tribological properties of palm oil methyl ester blended lubricant. Wear 2000, 239, 117–125. [Google Scholar] [CrossRef]

- Jeon, H.G.; Lee, Y.Z. The evaluation of wear life based on accelerated test through analysis of correlation between wear rate and lubricant film parameter. Tribol. Trans. 2013, 56, 290–300. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).