2. Overview of the Proposed Method

In this work, an isothermal, non-Newtonian EHL formulation considering Method 2-B was developed. Although this approach does not yield the exact solution of

(

z) and

(

z), the calculation is simple and fast. As shown in

Figure 2, the local Xc-direction is considered as the direction of the pressure gradient

, and the Yc-direction is considered to be perpendicular to Xc. The flow velocities in the Xc- and Yc-directions are denoted as

and

, respectively. As the pressure gradient toward Yc is zero, the flow

is assumed to be a Couette flow, which can be represented using a linear function of

z. As the pressure gradient toward Xc is generally non-zero, the flow

is assumed to be a Poiseuille flow, which can be represented using a 4th-order polynomial of

z. As

and

cannot be precisely represented by polynomials of

z, they are expanded using polynomials of

z. In such cases, the 6th-order or even higher order polynomials can be considered; however, in this work, a lower 4th-order polynomial was employed. A viscosity corresponding to the Newtonian flow was obtained and termed as the equivalent viscosity. To replace the viscosity of the Newtonian flow with the equivalent viscosity, which is a typical process when evaluating EHL problems, the method proposed by Venner and Lubrecht [

13] can be used without any change for the isothermal, non-Newtonian EHL calculation. Given a rheological model, any non-Newtonian isothermal point contact EHL problem can be solved using the proposed method.

The calculation procedure consists of two steps. First, the Newtonian EHL calculation is executed for the base oil that yields the Newtonian pressure distribution. Second, using the pressure distribution as the initial value, the non-Newtonian EHL calculation is executed for the non-Newtonian flow. The local coordinate system, Oc, Xc, and Yc, at a particular point, depends on the pressure gradient and it is determined simultaneously in the process to obtain the pressure distribution. The equivalent viscosity is calculated based on the local coordinate system in each iteration loop to obtain the pressure distribution. Here, the method was applied to an experimental grease characterized by Bauer’s model.

3. Calculation of Velocity Distribution as a Function of z

Figure 1 presents the XYZ coordinate system. The force balance of a fluid can be expressed as follows [

10]:

where

is the pressure of the fluid, and

and

are the shear stresses in the X- and Y-directions, respectively. The parameters

and

are defined as follows:

In Bauer’s model,

is assumed to be represented as a function of

, as follows [

1,

14,

15]:

Here,

,

,

, and

are Bauer’s rheological parameters, and

and

represent the

dependent viscosity and ambient viscosity of the base oil, respectively. In this work, according to Dong and Qian [

4], the parameters

,

,

, and

were assumed to be

-independent known values determined from the

-

curve measured at the ambient pressure. In Eyring’s model, according to Conry et al. [

3] and Johnson and Tevaarwerk [

16], the relationship between

and

can be expressed as follows:

Here,

is Eyring’s rheological parameter. Therefore, the relationship between

and

can be rewritten as follows:

The effective viscosity

can be defined as follows:

The effective viscosity

is a function of

, which in turn is a function of

z. The shear stresses

and

are assumed to be represented as

Substituting Equations (7) and (8) into Equations (1) and (2), respectively, yields

The pressure gradient vector

is defined as follows:

Similar to the method employed by Yang et al. [

11], this method involves the flow being divided into Couette and Poiseuille flows. As shown in

Figure 2, the Xc-direction is considered to be along

, and its direction vector is

. The Yc-direction is perpendicular to

, and its direction vector is

. The local coordinate system, Oc, Xc, and Yc, at a given point depends on the pressure gradient and is determined simultaneously in the process to obtain the pressure distribution. In the Xc and Yc coordinate system, Equations (9) and (10) can be rewritten as follows:

Furthermore, the velocities

(

z) and

(

z) satisfy the following boundary conditions:

Here,

and

denote the velocities of the upper and lower surfaces in the Xc- direction, respectively;

and

denote the velocities of the upper and lower surfaces in the Yc-direction, respectively. Although the velocities

(

z) and

(

z) cannot be represented by polynomials exactly [

3], here they are approximated and expanded using polynomials of

z so that the velocities satisfy Equation (15), as follows. In this case, the variables

and

are unknown.

Here,

is the fluid film thickness, and

and

denote the velocity differences; specifically,

= and

= . A higher order term of

, for example,

, can also be considered; however, in this work, the lower-order approximation was chosen. As the pressure gradient toward the Yc direction is zero,

was assumed to be a Couette flow and approximated considering a linear equation of

z. Furthermore, as the pressure gradient toward the Xc-direction is generally non-zero,

was assumed to be a Poiseuille flow and approximated using a 4th-order polynomial of

z. If

, then

is also a Couette flow, and Equation (16) can be replaced with the following equation:

The following equations are derived from Equations (16) and (17):

The following equations are derived from Equation (19):

If rheological constitutive equations are given, the effective viscosity

(

z) can be calculated using Equations (4)–(6), (16) and (17). The integration of Equation (12) from

to

yields Equation (25), and the integration of Equation (12) from

to

yields Equation (26). These equations are used to determine the values of

and

.

Equations (21) and (22) show that both

and

do not contain

. Therefore, Equation (25) does not contain

and contains only the unknown variable

. The equation can be solved using the one-variable Newton–Raphson method. Although Equation (26) contains both

and

,

has been determined using Equation (25). Consequently, Equation (26) can be considered as an equation involving only the unknown variable

. Thus, it can also be solved using the one-variable Newton–Raphson method. To determine

, a non-dimensional variable

defined using Equation (27) and a function

defined using Equation (28) are introduced. The value of

can be calculated considering

.

When

is near the solution,

can be calculated using the following equation:

In other words, the new candidate

of

is calculated using the iterative process of Newton–Raphson’s method, as follows:

As

and

are originally functions of

,

includes

; however, in this work, the dependency was ignored, and

was approximated as in Equation (30). To determine

, a non-dimensional variable

defined using Equation (31) and a function

defined using Equation (32) are introduced. The value of

can be calculated considering

.

When

is near the solution,

can be calculated using the following equation:

In other words, the new candidate

of

is calculated using the iterative process of Newton–Raphson’s method, as follows:

As and are originally functions of , includes ; however, in this work, the dependency was ignored, and was approximated as in Equation (34). Subsequently, in the iteration process of Newton–Raphson’s method, only depends on the rheological characteristics. Therefore, if the rheological equation corresponding to Equation (5) is incorporated, any isothermal, non-Newtonian EHL calculation can be performed. As per the Newton–Raphson method, the initial value for both and can be zero. As both variables and are solved using the one-variable Newton–Raphson method, the calculation can be performed within a reasonable time.

4. Calculation of Equivalent Viscosity, Flow, and Surface Force

The flow

along the

direction can be defined using Equation (16), as follows. The density

is assumed to be independent of

z.

Here,

is the average velocity in the Xc-direction and can be expressed as follows:

The equivalent viscosity

is defined as follows:

Consequently,

can be represented as

The flow

along the

direction can be derived from Equation (17), as follows:

Here,

is the average velocity in the Yc direction and can be expressed as follows:

Hence, in the XYZ coordinate system, the flow vector

can be expressed as

Here,

is the average velocity vector of the upper and lower surfaces, defined as follows:

and

denote the average velocities in the upper and lower surfaces in the XY-direction, respectively. When the mass conservation law is applied to Equation (41), the following modified Reynolds equation is obtained.

The difference in the representation of Equations (41) and (43) and that of Newtonian flow only pertains to the viscosities

and

, respectively. In fact, the equivalent viscosity

defined by Equation (37) was determined so that Equations (41) and (43) maintain the same form as that of Newtonian flow. Therefore, the EHL calculation procedure for Newtonian flows, such as the method proposed by Venner and Lubrecht [

13], can be applied to the current calculation by simply replacing

with

. The shear stress

along the Xc-direction can be expressed as

Therefore, the surface forces

and

acting on the lower and upper surfaces along the Xc-direction, respectively, can be defined as

The shear stress

along the Yc-direction is expressed as

Therefore, the surface forces

and

acting on the lower and upper surfaces along the Yc-direction, respectively, can be defined as

In the XYZ coordinate system, the surface force vectors

and

that act on the lower and upper surfaces, respectively, can be expressed as

5. Application to a Grease

As mentioned previously, Kochi et al. [

1] conducted experiments on grease under soft EHL conditions and measured the film thickness and traction forces. In the present study, the proposed method was applied to one of the greases considered in the study by Kochi et al. [

1] so as to validate the theoretical approach. Grease A in the literature [

1] was chosen to test the proposed method. The modified Reynolds equation, as expressed in Equation (43), was solved using a multi-level method, as reported by Venner and Lubrecht [

13]. The commercial program Tribology Engineering Dynamics Contact Problem Analyzer (TED/CPA) V852 was employed.

Figure 3 illustrates the calculation conditions. The upper body was a steel ball, and the lower body was a disk composed of glass or polycarbonate (PC). The rheological properties of the grease were assumed to be represented by Bauer’s model, according to existing literature [

1]. Detailed properties of the steel, glass, PC, and grease are described in the previous study [

1]. The pressure dependency of the density was defined using Dowson–Higginson’s formula, as follows:

The pressure dependency of the base oil viscosity was assumed to be defined using Barus’ formula:

In particular, Equation (6) diverges when

approaches zero. It was assumed that if

is lower than a certain value

cmin=100.0 s

−1, then

varies linearly with the gradient

at

cmin. Bauer’s parameter

was assumed to be the base oil ambient viscosity

. The values of Bauer’s parameters

,

, and

were determined from the apparent viscosity curve of grease A, as shown in Figure 9 of Kochi et al. [

1]. When

, the curve was assumed to pass through the following three points: 100 mm/s, 6.46475 Pa·s; 10,000 mm/s, 0.16712 Pa·s; and 1,000,000 mm/s, 0.06573 Pa·s.

The values of

,

, and

were determined to ensure that Bauer’s curve passes through the abovementioned three points, as follows:

Figure 4 presents the central film thickness of grease A and base oil as a function of the rolling velocity in the case of pure rolling and

. The solid lines show the calculation results and the dotted lines show the experimental results. The experimental data were read using the caliper from Figure 4 of Kochi et al. [

1].

Figure 4a,b shows the cases of a PC disk and glass disk, respectively. The calculation range was set as follows: −1.0 ≤ X ≤ 0.4 and −0.6 ≤ Y ≤ 0.6.

However, in the case of grease A, a glass disk, and a velocity of less than or equal to 300 mm/s, the range was set as follows: −0.35 ≤ X ≤ 0.14 and −0.2 ≤ Y ≤ 0.2.

In these cases, the oil film was thin and the wide range calculation became hard to perform. In the case of the PC disk, the calculation results exhibited good agreement with the experimental results. In the case of the glass disk, the results of the base oil showed some difference but the other data showed reasonable agreement.

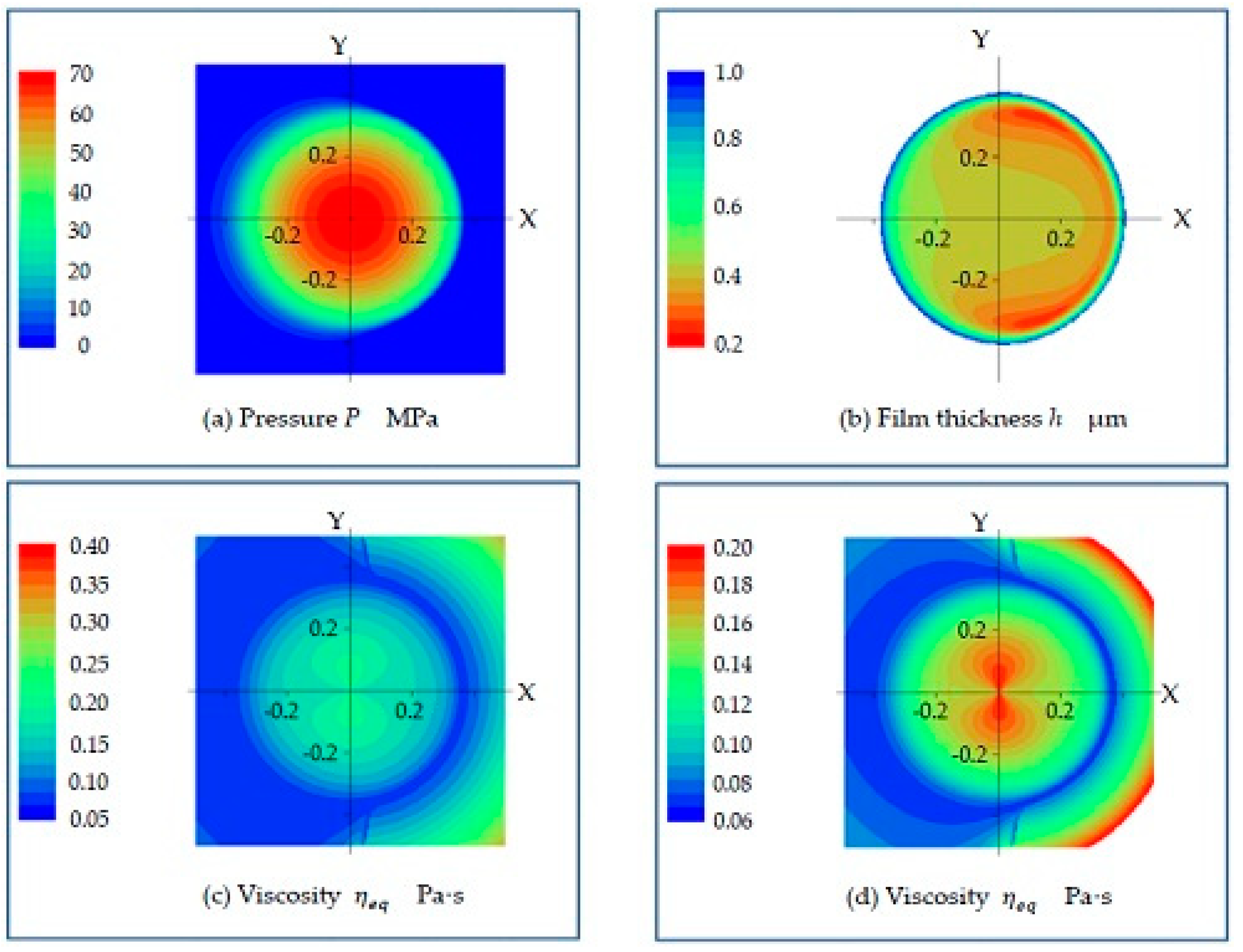

Figure 5, which illustrates a sample calculation, shows the distribution of

, and

for the case involving a PC disk, a pure rolling velocity of 1200 mm/s, and grease A. Typically, in the case of pure rolling velocity,

is small and

is large. In addition, only the appearance of the distribution of

differs from that of the base oil.

Figure 5d shows the distribution of

at section Y = 0. It can be seen that

becomes extremely large at the center, where the pressure gradient is small and the flow volume is low.

Figure 6 presents the traction coefficient as a function of the slide roll ratio when

. The solid lines show the calculation results and the dotted lines show the experimental results. The experimental data were read using the caliper from Figure 8 of Kochi et al. [

1]. The slide roll ratio is the difference between the upper and lower velocities divided by their average value. The traction coefficient was calculated according to the approaches proposed in the existing literature [

1,

17]:

Here, and denote the X-direction traction forces acting on the lower and upper surfaces, respectively; is the load. The calculation range was −0.8 ≤ X ≤ 0.5, −0.5 ≤ Y ≤ 0.5. The calculation results were in fairly good agreement with the experimental results.

Figure 7, which illustrates a sample calculation, shows the distribution of

and

for the case involving grease A and a slide roll ratio of 10%. Only the appearance of the distribution of

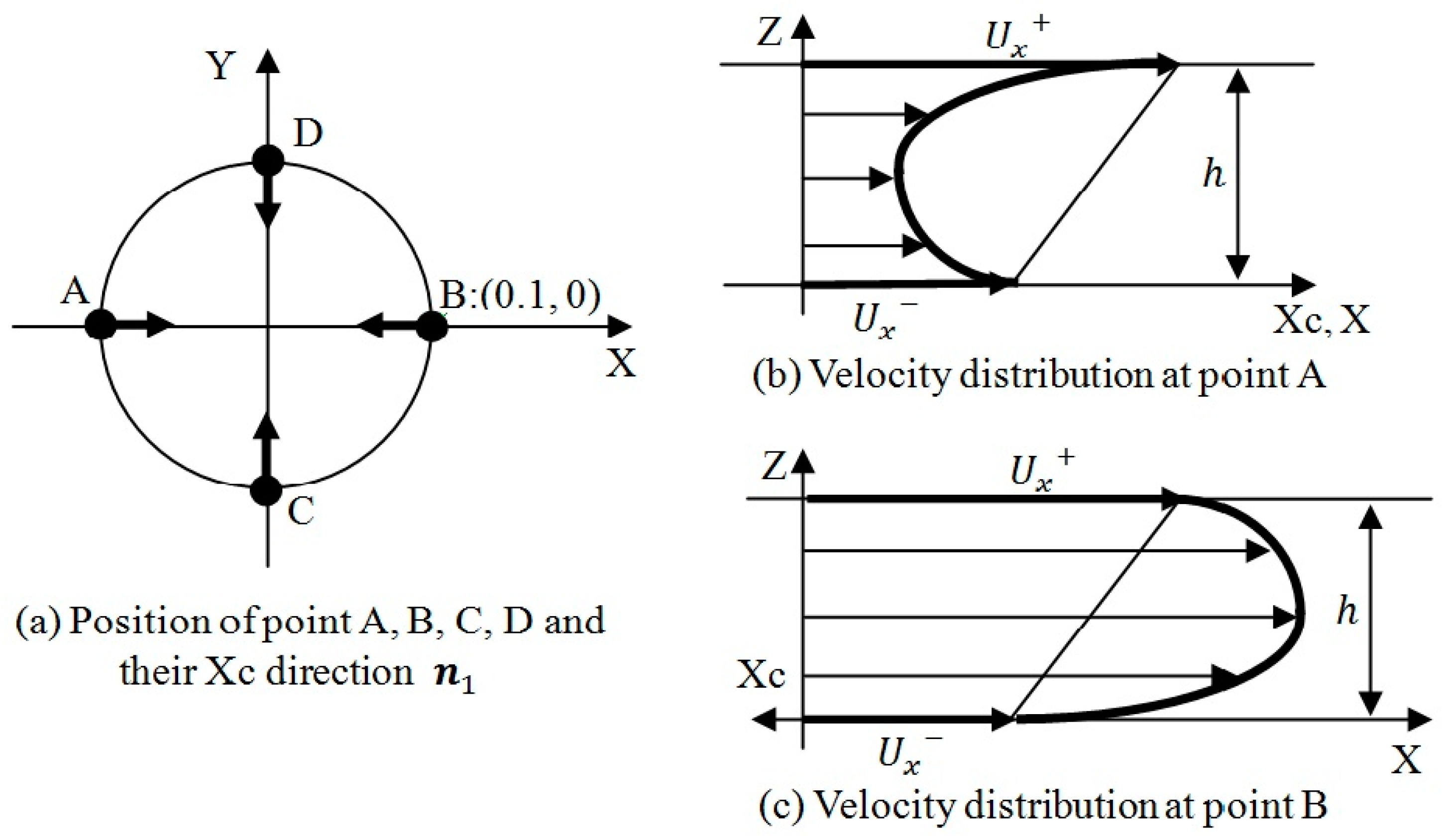

differs from that of the base oil, exhibiting a figure eight in the vicinity of the contact point.

Figure 7c,d shows the same distribution of

in different display ranges. It can be observed that

reduces in the rapid flow region. The figure eight phenomenon is characteristic of non-Newtonian flow, in which the apparent viscosity becomes large at a low velocity gradient. This phenomenon can be explained as follows. Let the XY coordinates of points A, B, C, and D be

,

,

, and

, respectively. The velocity gradient vector

at these points are approximately

,

,

, and

, respectively, as shown in

Figure 8a. When

in Equation (37) is neglected,

can be expressed as follows:

Calculating

from Equation (25) and substituting it into Equation (56) yields:

At points C and D, the direction of flow and that of

is orthogonal, so

. Consequently, the equivalent viscosity parameters

and

at points C and D are given as follows:

At point A, where

directs towards

and the velocity gradient at

is greater than that at

(as shown in

Figure 8b), the following equation is satisfied:

At point B, where

directs towards

, and the velocity gradient at

is smaller than that at

(as shown in

Figure 8c), the following equation is satisfied:

In any case, the equivalent viscosity parameters

and

at points A and B become smaller than

and

by the effect of the second term of Equation (57). In the pure rolling case, where

is 0, Equation (57) results in Equation (58). It can be understood that in such a case, no figure-eight-shaped distribution appears as is shown in

Figure 5c.