Tribological Characterization of Polyether Ether Ketone (PEEK) Polymers Produced by Additive Manufacturing for Hydrodynamic Bearing Application

Abstract

:1. Introduction

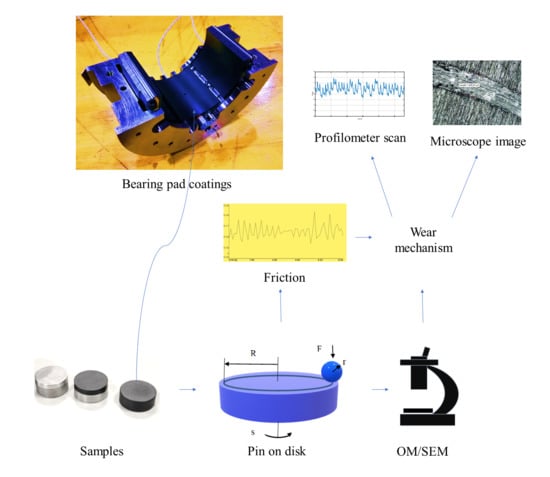

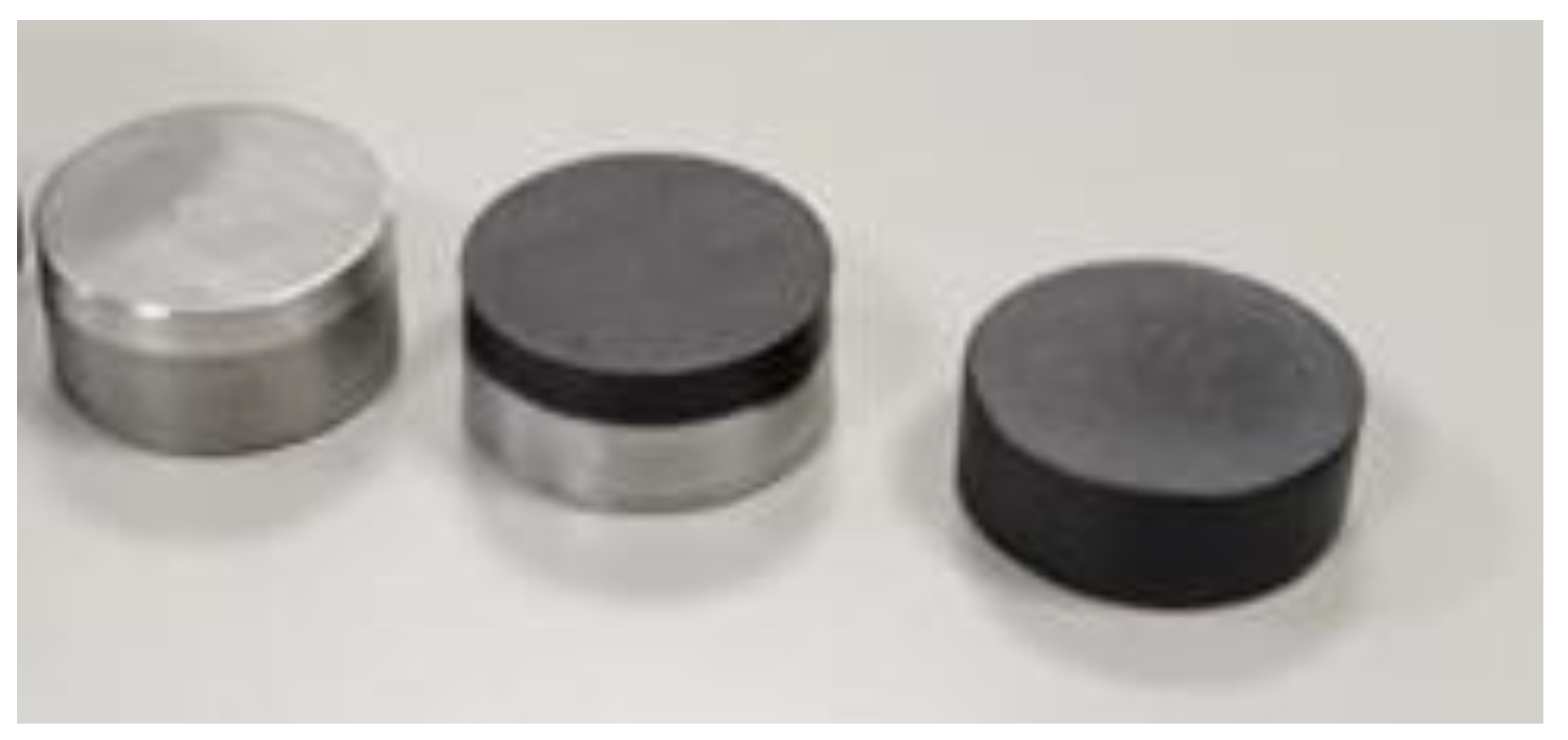

2. Materials and Methods

2.1. Materials Preparation and Characterization

2.2. Bond Strength Tests

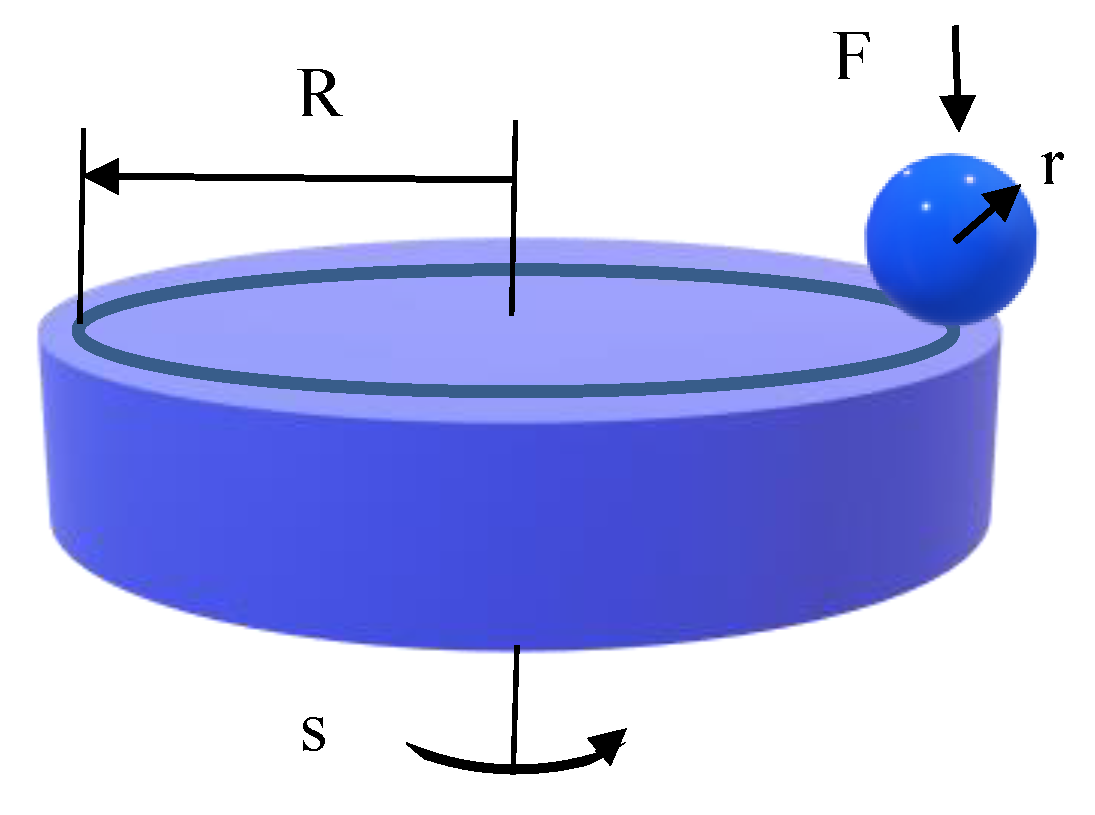

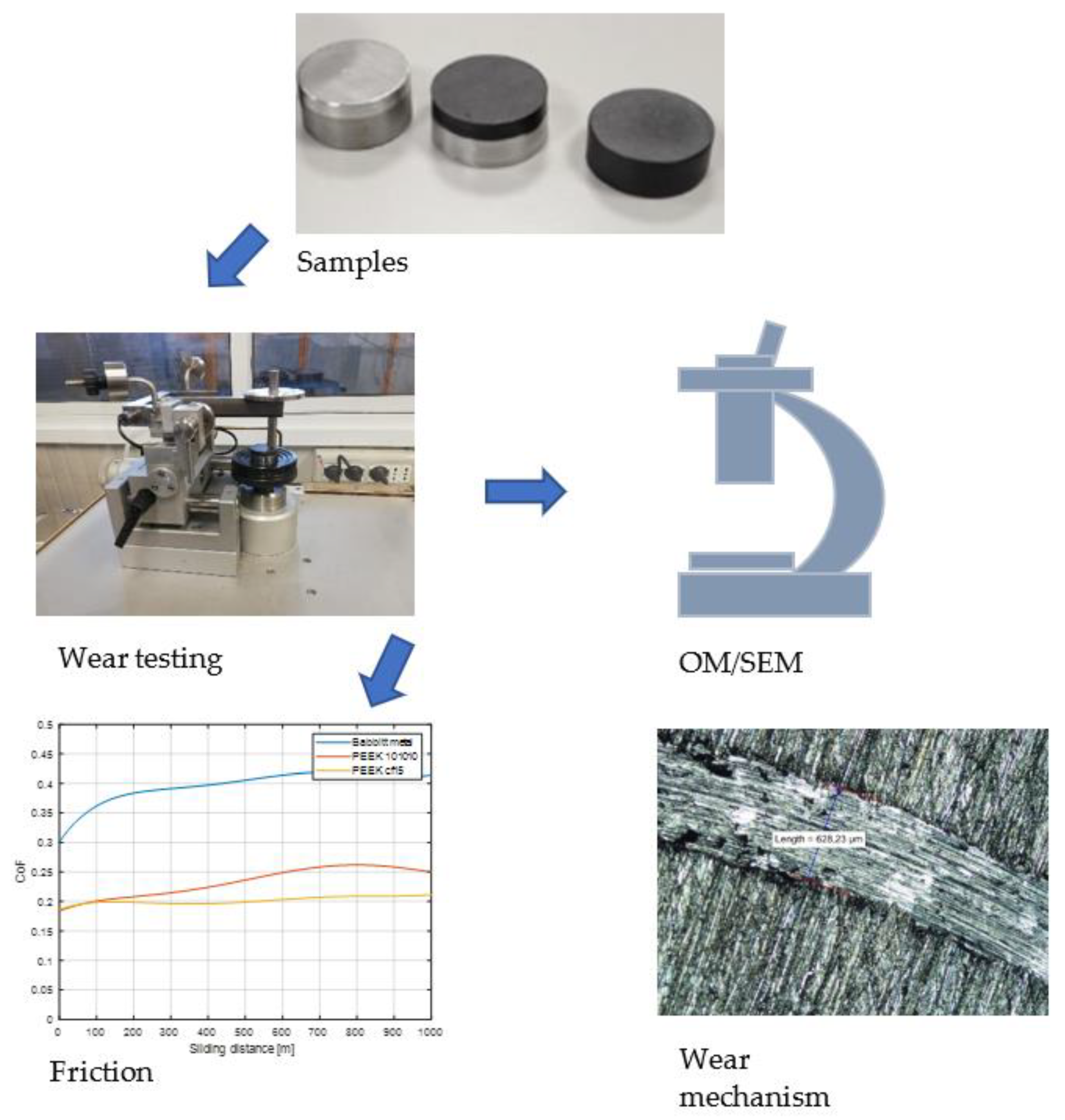

2.3. Tribological Tests

3. Results and Discussion

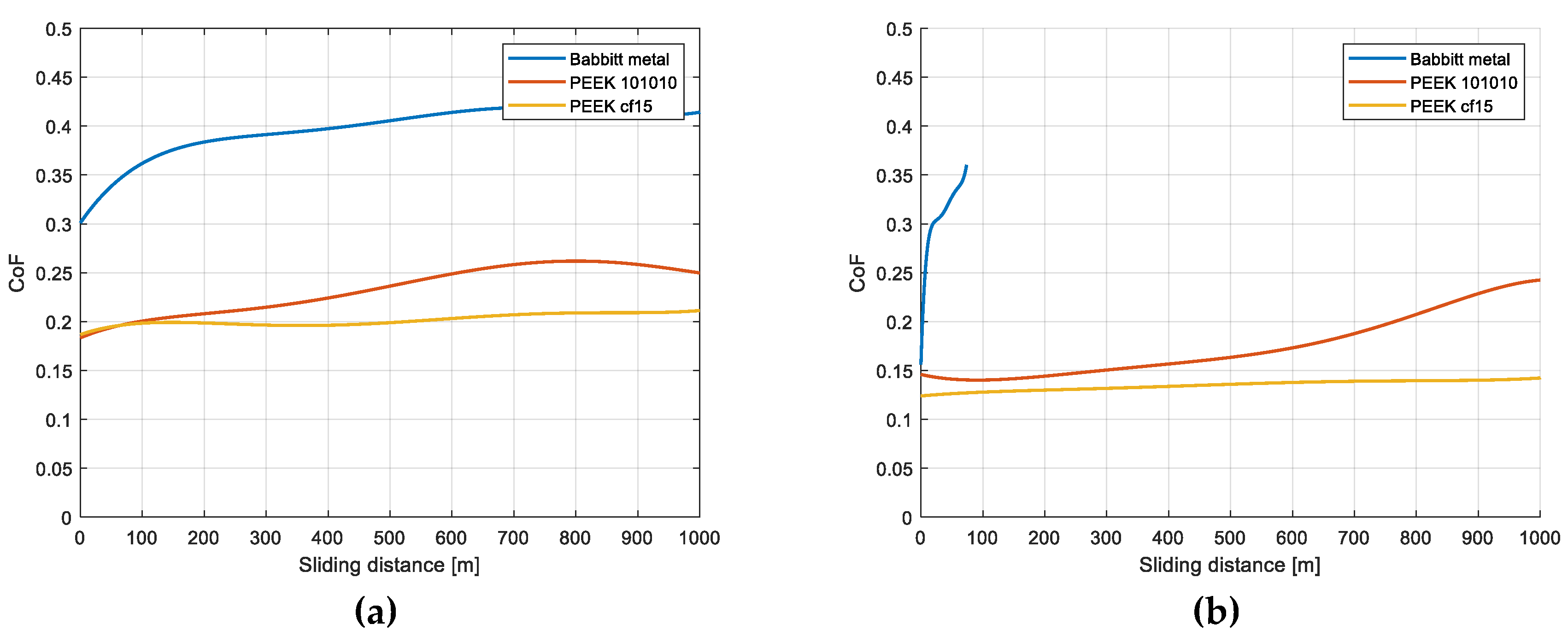

3.1. Friction Coefficient Evaluation

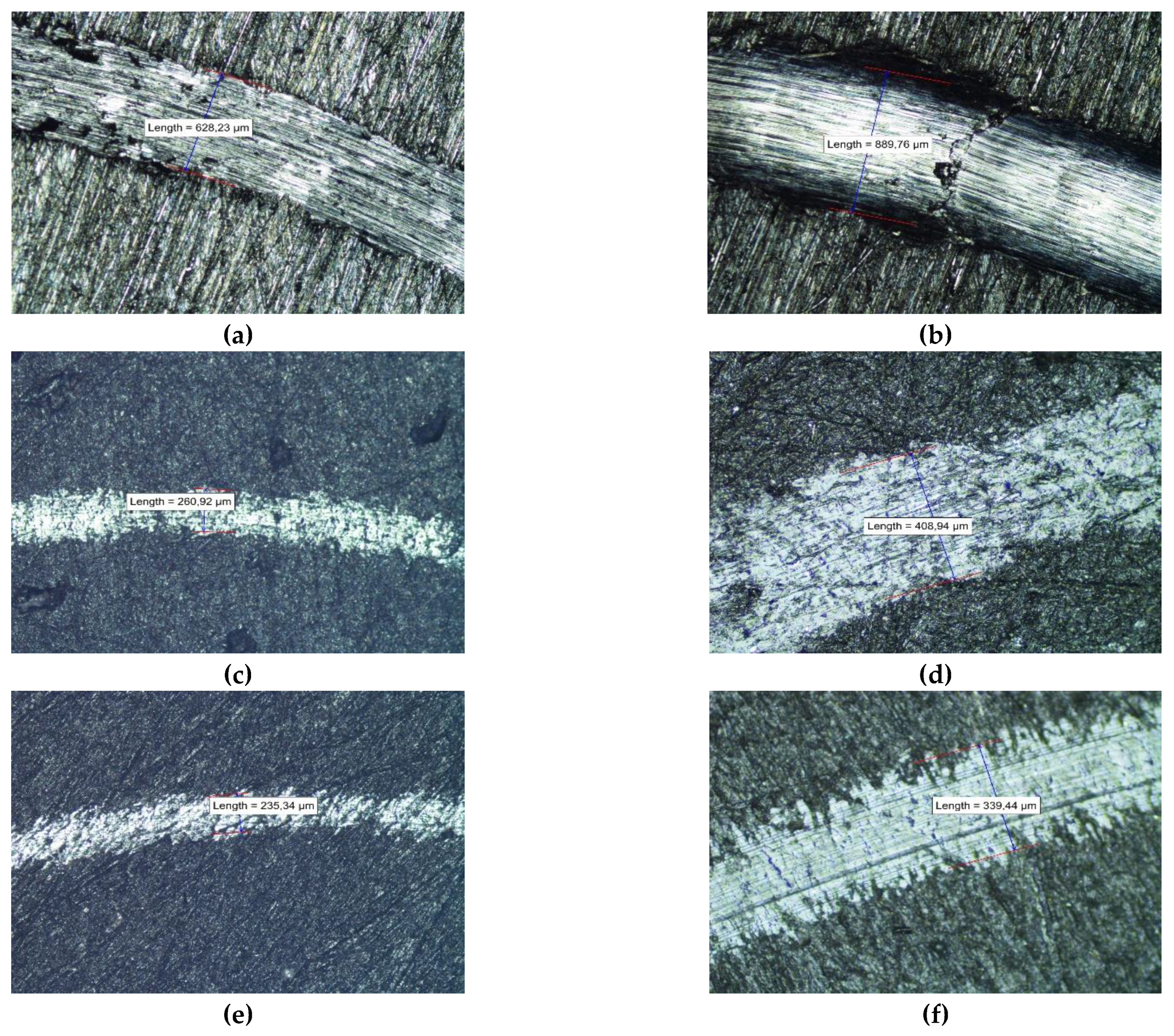

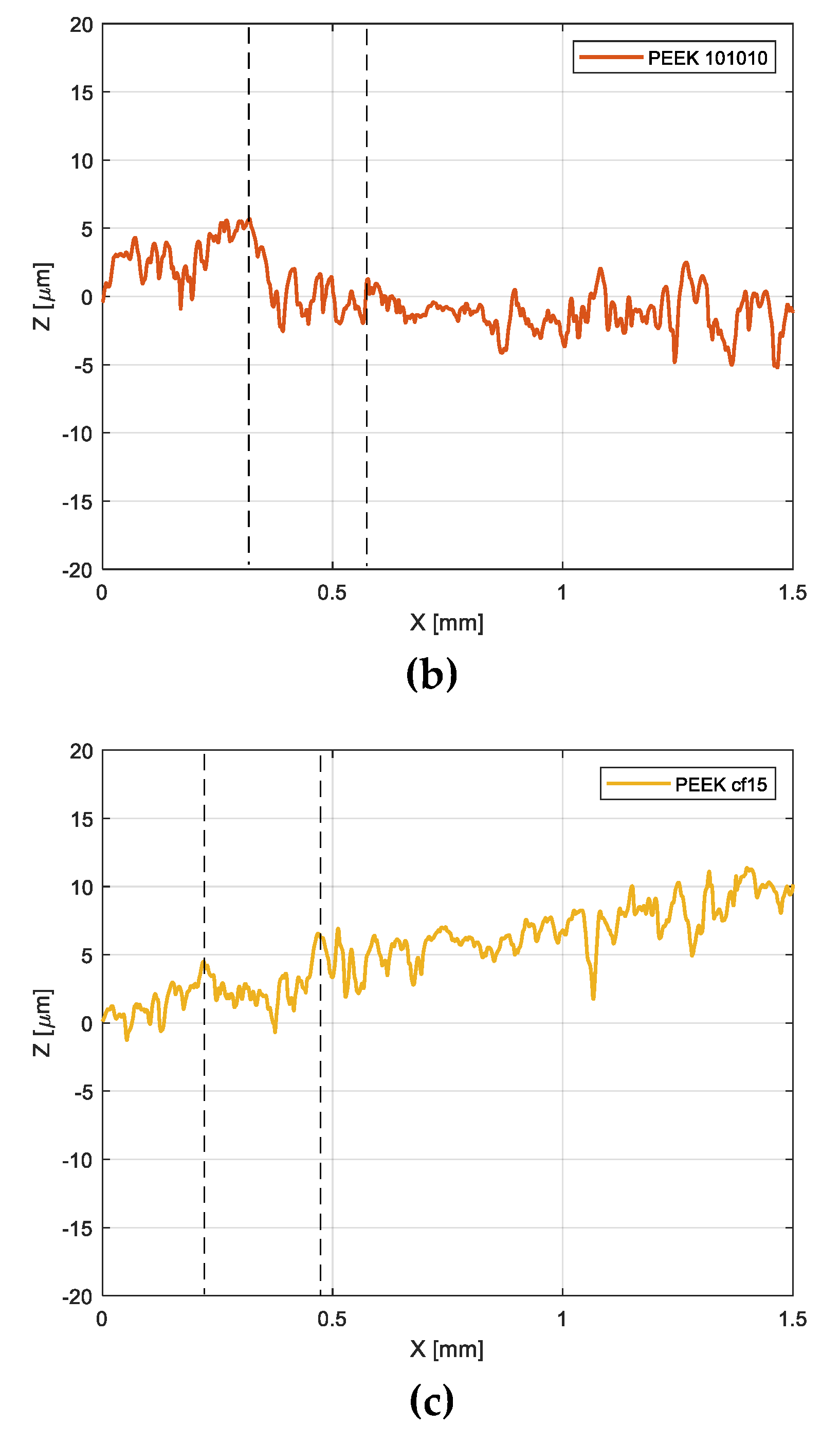

3.2. Optical Microscopy and Wear Calculation

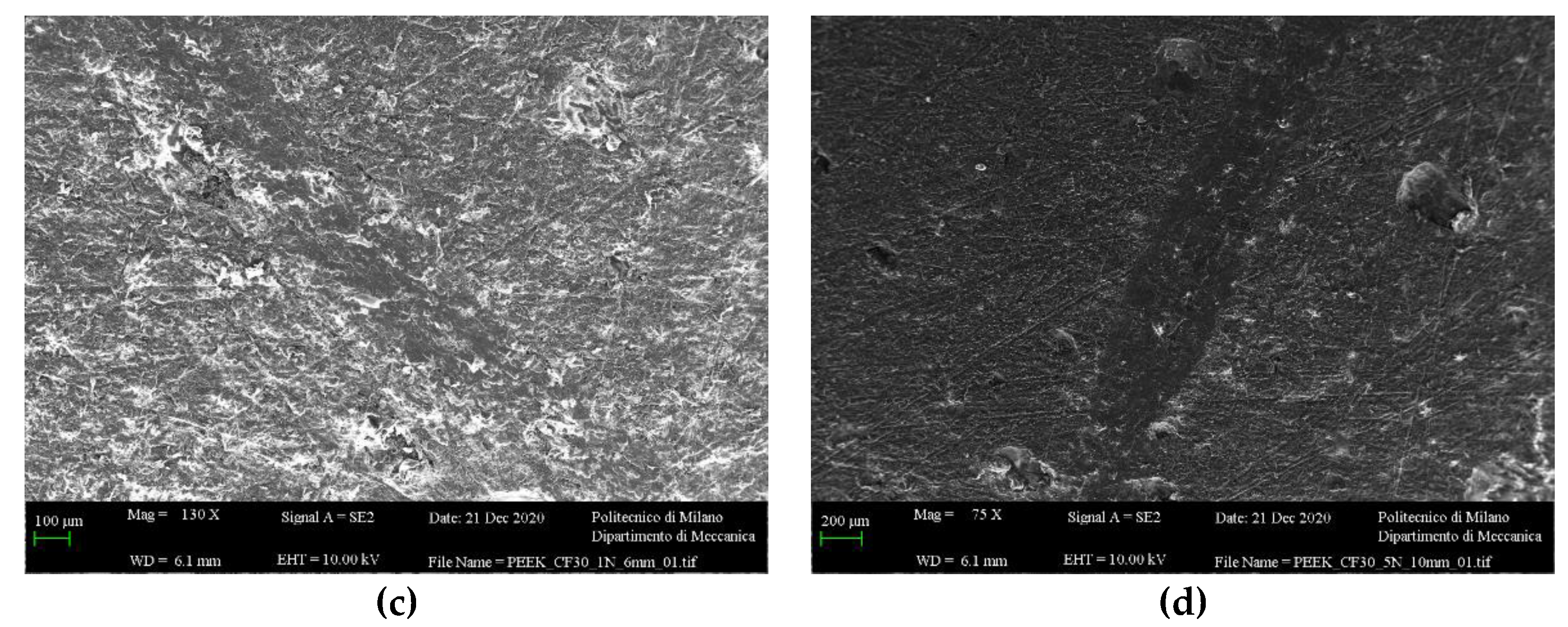

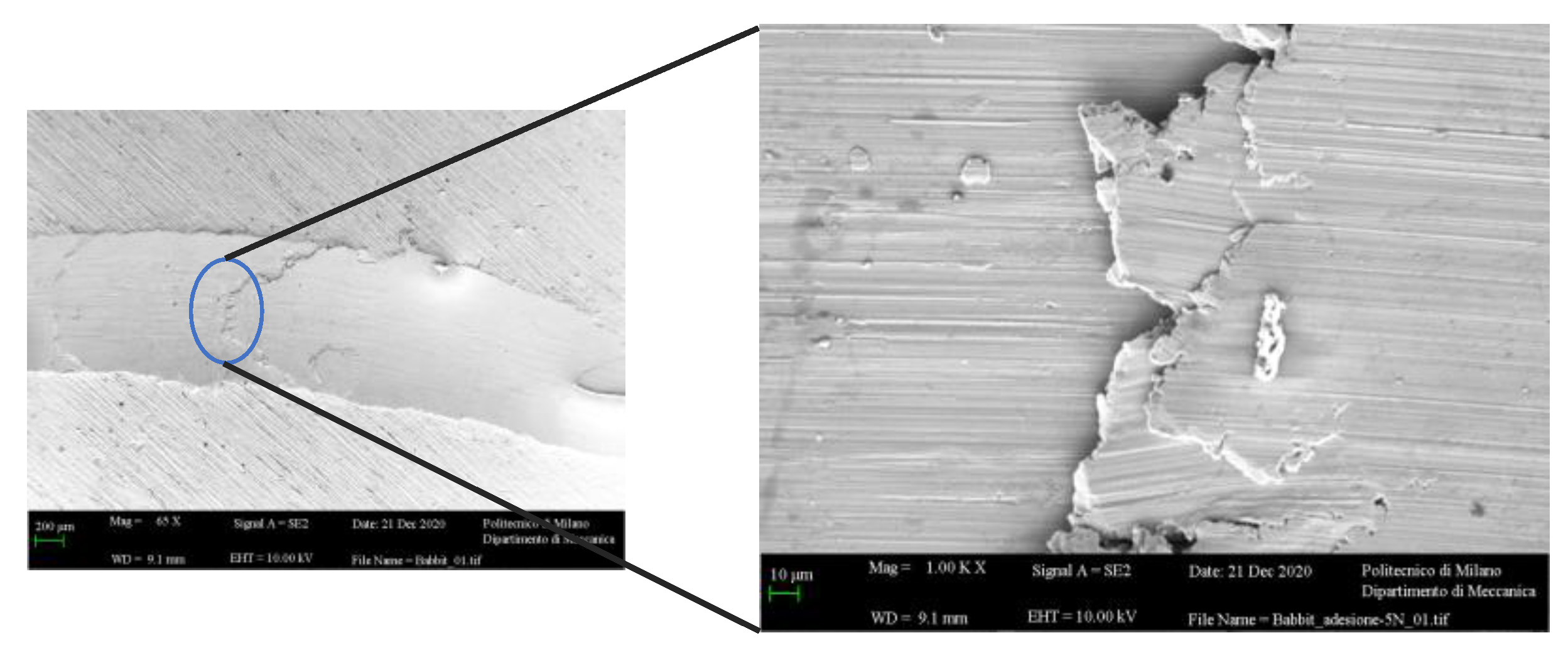

3.3. SEM Analysis of Worn Surfaces

4. Conclusions

- For the dry tests with 1 N load, the average values of CoF are 0.41 ± 0.02, 0.25 ± 0.01, and 0.20 ± 0.01 for Babbitt metal, PEEK 101010, and PEEK cf15, respectively.

- For dry tests with 5 N load, the average CoF values are 0.31 ± 0.02, 0.17 ± 0.01, and 0.14 ± 0.01 for Babbitt metal, PEEK 101010, and PEEK cf15, respectively.

- Wear for both PEEK-based coatings is low and about 50% lower than Babbitt metal for the 1 N dry tests. For the 5 N tests, the wear for the polymer-based coatings is one-tenth of that with the Babbitt.

- Adhesion tests consider different geometric shapes and different combinations of backing/coating materials. Only one test was done in female configuration while the male configuration was analyzed in detail because it is subject to detachment. Considering brass and aluminum as support material, PEEK cf15 has an adhesion strength of 29 and 27 MPa, 50% higher than PEEK 101010. With 39CrNi as the backing part, PEEK cf15 has an adhesion strength of 29 MPa, 16% higher than PEEK 101010.

- The adhesive wear phenomenon is only evident in the dry test with 5 N load for the Babbitt metal coating, as can be seen from the microscopic optical/electron images and profilometer scan images.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Keyser, P. A new look at Heron’s “Steam Engine”. Arch. Hist. Exact Sci. 1992, 44, 107–124. [Google Scholar] [CrossRef]

- Scaife, W. From Galaxies to Turbines: Science, Technology and the Parsons Family; CER Press: Brussels, Belgium, 1999. [Google Scholar]

- Pennacchi, P. Introduction of advanced technologies for steam turbine bearings. In Advances in Steam Turbines for Modern Power Plants, 1st ed.; Woodhead Publishing: Duxford, UK, 2017; pp. 321–380. [Google Scholar]

- Koring, R. Improved White Metal Alloys—An International Comparison, 5th ed.; ECKA Granules Germany GmbH: Velden, Germany, 2008. [Google Scholar]

- Fuerst, T.K.A. Behaviour of big bearings: Polymer coated bearings in comparison to Babbitt bearings. Alstom HYDRO 2005, 17–20. [Google Scholar]

- Glavatskih, S. Evaluating Thermal Performance of a PTFE-Faced Tilting Pad Thrust Bearing. J. Tribol. 2003, 125, 319–324. [Google Scholar] [CrossRef]

- Ricci, R.; Chatterton, S.; Pennacchi, P.; Vania, A. Multiphysics modeling of a tilting pad thrust bearing: Comparison between white metal and polymeric layered pads. In Proceedings of the ASME 2011 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Washington, DC, USA, 28–31 August 2011; pp. 995–1002. [Google Scholar]

- Ettles, C.M.; Knox, R.T.; Ferguson, J.H.; Horner, D. Test Results for PTFE-Faced Thrust Pads, With Direct Comparison Against Babbitt-FacedPads and Correlation with Analysis. J. Tribol. 2013, 125, 814–823. [Google Scholar] [CrossRef]

- Glavatskih, S.B.; Fillon, M. TEHD Analysis of Thrust Bearings With PTFE-Faced Pads. J. Tribol. 2005, 128, 49–58. [Google Scholar] [CrossRef]

- Zhou, J.; Blair, B.; Argires, J.; Pitsch, D. Experimental Performance Study of a High Speed Oil Lubricated Polymer Thrust Bearing. Lubricants 2015, 3, 3–13. [Google Scholar] [CrossRef] [Green Version]

- Davim, J.P.; Cardoso, R. Tribological behaviour of the composite PEEK-CF30 at dry sliding against steel using statistical techniques. Mater. Des. 2006, 27, 338–342. [Google Scholar] [CrossRef]

- Soifer, A.M.; Kodnir, D.S.; Baiborodov, Y.I. An elastic sliding bearing on the basis of elastically deforming material MR in combination with fluoroplas. Izv. Vyss. Uchebn. Zaved. Mashinostr. 1966, 15, 514–517. [Google Scholar]

- Wodtke, M. Hydrodynamic Thrust Bearings with Polymer Lining. Tribologia 2016, 268, 225–237. [Google Scholar] [CrossRef]

- Hentschke, C. Interlocking metal-polymer bond by 3D-printed grid structure for hydrodynamic thrust bearings with PEEK-lined pads. In Proceedings of the 18th EDF—PPRIME Work, Palaiseau, France, 10–11 October 2019. [Google Scholar]

- Berchtold, O.; Pajaczkowski, P.A. Hydrodynamic Bearing Pad Construction. Patent EP 3 276 191 A1, 2018. [Google Scholar]

- Riboni, G. Cuscitto PEEK. Patent 102020000023422, 2020. [Google Scholar]

- Croccolo, D.; De Agostinis, M.; Vincenzi, N. Design of hybrid steel-composite interference fitted and adhesively bonded connections. Int. J. Adhes. Adhes. 2012, 37, 19–25. [Google Scholar] [CrossRef]

- Tseng, J.W.; Liu, C.Y.; Yen, Y.K.; Belkner, J.; Bremicker, T.; Liu, B.H.; Sun, T.-J.; Wang, A.B. Screw extrusion-based additive manufacturing of PEEK. Mater. Des. 2018, 140, 209–221. [Google Scholar] [CrossRef]

- Feuerbach, T.; Thommes, M. Design and Characterization of a Screw Extrusion Hot-End for Fused Deposition Modeling. Molecules 2021, 26, 590. [Google Scholar] [CrossRef] [PubMed]

- Kurtz, S.M.; Nevelos, J. PEEK bearing materials for total joint replacement. In PEEK Biomaterials Handbook; William Andrew: Norwich, NY, USA, 2019; pp. 403–418. [Google Scholar]

- Brockett, C.L.; Carbone, S.; Fisher, J.; Jennings, L.M. PEEK and CFR-PEEK as alternative bearing materials to UHMWPE in a fixed bearing total knee replacement: An experimental wear study. Wear 2017, 374, 86–91. [Google Scholar] [CrossRef] [PubMed]

- Yao, C.; Qi, Z.; Chen, W.; Zhang, C. Effect of CF/PEEK plasticity behavior on the mechanical performance of interference-fit joint. Polym. Compos. 2021, 42, 2574–2588. [Google Scholar] [CrossRef]

- Zhu, J.; Xie, F.; Dwyer-Joyce, R.S. PEEK composites as self-lubricating bush materials for articulating revolute pin joints. Polymers 2020, 12, 665. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sumer, M.; Unal, H.; Mimaroglu, A. Evaluation of tribological behaviour of PEEK and glass fibre reinforced PEEK composite under dry sliding and water lubricated conditions. Wear 2008, 265, 1061–1065. [Google Scholar] [CrossRef]

- Theiler, G. PTFE- and PEEK-Matrix Composites for Tribological Applications at Cryogenic Temperatures and in Hydrogen. Doctoral Dissertation, Technischen Universität Berlin, Berlin, Germany, 2005. [Google Scholar]

- Aly, A.A. Heat treatment of polymers: A review. Int. J. Mater. Chem. Phys. 2015, 1, 132–140. [Google Scholar]

- Dickens, P.M. PEEK as a Bearing Material. In Advances in Manufacturing Technology; McGoldrick, P.F., Ed.; Springer: Boston, MA, USA, 1986. [Google Scholar]

- Deng, X.; Zeng, Z.; Peng, B.; Yan, S.; Ke, W. Mechanical properties optimization of poly-ether-ether-ketone via fused deposition modeling. Materials 2018, 11, 216. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Jiménez, A.-E.; Bermúdez, M.-D. 2-Friction and wear. In Tribology for Engineers; Woodhead Publishing: Sawston, UK, 2011; pp. 33–63. [Google Scholar]

| Babbitt Metal | PEEK Polymers | ||

|---|---|---|---|

| Young’s modulus | (N/mm2) | 57,000 | 7800 |

| Poisson’s ratio | (-) | 0.35 | 0.42 |

| Thermal conductivity | (W/m K) | 45 | 0.66 |

| Characteristic Tested | Coating Material Tested | Sample Geometry |

|---|---|---|

| Tribological |

| Cylindrical |

| Bond strength |

| ISO 4386-2 |

| Sample # | Interlocking Shape | Backing | Coating | Area | Max. Force | Bond Strength Rch. |

|---|---|---|---|---|---|---|

| (-) | (-) | (-) | (-) | (mm2) | (N) | (MPa) |

| 1 | MALE | 39CrNi | PEEK CF15 | 81 | 2333 | 29 |

| 2 | MALE | Brass | PEEK CF15 | 81 | 2534 | 29 |

| 3 | MALE | Aluminum | PEEK CF15 | 81 | 2373 | 27 |

| 4 | MALE | AISI 304 | PEEK CF15 | 81 | 2446 | 30 |

| 5 | MALE | 39CrNi | PEEK 101010 | 81 | 2058 | 25 |

| 6 | MALE | Brass | PEEK 101010 | 81 | 885 | 11 |

| 7 | MALE | Aluminum | PEEK 101010 | 81 | 954 | 12 |

| 8 | FEMALE | 39CrNi | PEEK CF15 | 79 | 4276 | 54 |

| BOD Parameters | ||

|---|---|---|

| Parameters | Units | Value |

| Radius track | (mm) | 4–10 |

| Linear speed | (m/s) | 0.3 |

| Normal load | (N) | 1–5 |

| Stop condition (sliding length) | (m) | 1000 |

| Temperature | (°C) | 25 |

| Humidity | (%) | 50 |

| Acquisition rate | (Hz) | 10 |

| Ball materials | (-) | 100Cr6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Massocchi, D.; Riboni, G.; Lecis, N.; Chatterton, S.; Pennacchi, P. Tribological Characterization of Polyether Ether Ketone (PEEK) Polymers Produced by Additive Manufacturing for Hydrodynamic Bearing Application. Lubricants 2021, 9, 112. https://doi.org/10.3390/lubricants9110112

Massocchi D, Riboni G, Lecis N, Chatterton S, Pennacchi P. Tribological Characterization of Polyether Ether Ketone (PEEK) Polymers Produced by Additive Manufacturing for Hydrodynamic Bearing Application. Lubricants. 2021; 9(11):112. https://doi.org/10.3390/lubricants9110112

Chicago/Turabian StyleMassocchi, Davide, Giacomo Riboni, Nora Lecis, Steven Chatterton, and Paolo Pennacchi. 2021. "Tribological Characterization of Polyether Ether Ketone (PEEK) Polymers Produced by Additive Manufacturing for Hydrodynamic Bearing Application" Lubricants 9, no. 11: 112. https://doi.org/10.3390/lubricants9110112

APA StyleMassocchi, D., Riboni, G., Lecis, N., Chatterton, S., & Pennacchi, P. (2021). Tribological Characterization of Polyether Ether Ketone (PEEK) Polymers Produced by Additive Manufacturing for Hydrodynamic Bearing Application. Lubricants, 9(11), 112. https://doi.org/10.3390/lubricants9110112