Abstract

The increasing demand for lightweight and high-performance brake rotors has led to the exploration of aluminum–metal matrix composites (Al-MMCs) as alternatives to conventional cast iron rotors. This study evaluated the tribological performance of squeeze-cast Al-MMC brake rotors using an AK Master dynamometer test and compared it with that of conventional gray cast iron (GCI) rotors. The Al-MMC rotors demonstrated stable coefficients of friction (CoFs) with reduced wear rates, compared to the GCI rotors. Surface analysis identified the predominant wear mechanisms, including abrasive and oxidative wear. The Al-MMC rotors exhibited sensitivity to pressure and speed, with a CoF range of 0.35–0.47 that decreased at higher pressures and speeds, whereas the GCI rotors maintained a stable CoF range of 0.38–0.44. At elevated temperatures, the GCI rotors displayed superior thermal stability and fade resistance compared to the Al-MMCs, which experienced a 40–60% loss in CoF. Wear analysis indicated material transfer from brake pads to Al-MMC rotors, resulting in protective tribofilm formation, whereas GCI rotors exhibited conventional abrasive wear. These findings highlight the potential of squeeze-cast Al-MMCs for automotive braking applications, offering advantages in weight reduction and wear resistance, but also suggest the need for further material optimization to enhance high-temperature performance and friction stability.

1. Introduction

The ongoing advancement of the automotive industry necessitates the development of lightweight high-performance materials for critical components, such as brake rotors. Traditionally, brake rotors are manufactured from gray cast iron (GCI) owing to its satisfactory wear resistance, excellent damping properties, friction behavior, volumetric heat capacity, and cost-effectiveness [1]. However, the high density of the GCI significantly contributes to the overall vehicle weight, resulting in increased fuel consumption and emissions. Furthermore, the susceptibility of GCI rotors to corrosion presents an additional challenge that requires immediate attention, particularly for electric vehicle applications [2,3]. To address these issues, researchers and manufacturers have investigated advanced lightweight materials, with a particular focus on aluminum–metal matrix composites (Al-MMCs) as potential alternatives for brake rotors [4,5,6].

Al-MMCs present a distinctive combination of high strength, low density, and enhanced thermal conductivity, making them promising candidates for automotive braking applications. The integration of ceramic reinforcements, such as silicon carbide (SiC), alumina, and graphite, enhances their mechanical and tribological properties, thereby improving the wear resistance and frictional performance under braking conditions. Among the various processing techniques available for the fabrication of Al-MMCs, squeeze casting has emerged as the preferred method because of its ability to produce components with reduced porosity, improved interfacial bonding, and enhanced mechanical properties [7]. Despite these advantages, the tribological performance of squeeze-cast Al-MMC brake rotors under realistic braking conditions has not been investigated sufficiently.

The braking system of a vehicle operates under complex and demanding conditions involving high contact pressures, fluctuating temperatures, and repeated sliding interactions. These factors significantly influence the frictional behavior, wear mechanisms, and thermal stability of brake rotors. The tribological performance of a brake rotor is primarily characterized by its coefficient of friction (CoF), wear resistance, and heat dissipation capability. A stable CoF is critical for consistent braking performance, whereas superior wear resistance ensures an extended component lifespan. In addition, its ability to dissipate heat minimizes the risk of brake fading and thermal damage [8].

Numerous studies have examined the tribological properties of Al-MMCs for braking applications. Awe et al. [9] compared the wear behavior of Al-SiC MMCs with that of coated and uncoated conventional GCI rotors and found significantly lower wear rates in Al-MMCs. This reduction in wear is attributed to the ability of the reinforcing phase to resist abrasion. Similarly, Wu et al. [10] and Ye et al. [11] demonstrated that graphite-reinforced Al-MMCs possess self-lubricating properties, which enhance frictional stability and reduce material degradation. Xiao et al. [12] reviewed the evolution of materials for train brake discs and highlighted the importance of Al-MMCs as an alternative with lower density and higher heat capacity compared to traditional iron and steel. Previous investigations by Lattanzi et al. [13] examined the effects of nickel (Ni) and zirconium (Zr) addition on the high-temperature mechanical and tribological properties of aluminum–silicon (Al–Si) matrix composites reinforced with 20 wt.% SiC particles. Their results revealed that the incorporation of Ni consistently enhanced the mechanical responses of the composites at elevated temperatures. In contrast, Zr addition did not yield comparable improvements. The increased hardness due to Ni and Zr addition was linked to secondary phase precipitation and solid solution strengthening mechanisms. However, the wear rate of the composites, ranging from 2 to 8 × 10−5 mm3/N*m, did not exhibit a direct correlation with hardness, indicating the presence of complex wear mechanisms in the system.

However, these investigations were primarily conducted using laboratory-scale pin-on-disc or ball-on-disc configurations, which do not fully replicate real-world braking conditions. To address this limitation, full-scale dynamometer testing is required to evaluate Al-MMC rotors under simulated braking scenarios. Dynamometer testing is a widely recognized method for evaluating brake rotor performance under controlled yet realistic conditions. Among the various test protocols, the AK Master test is an industry-standard procedure that provides critical insights into key tribological parameters such as CoF variation, wear rates, and thermal response, offering a comprehensive evaluation of rotor performance.

The present study aims to evaluate and compare the frictional performance of squeeze-cast Al-MMC brake rotors with varying chemical compositions of the matrix alloy using a standardized AK Master dynamometer testing protocol. The AK Master protocol (SAE J2522 [14]) is a performance test designed to simulate various braking scenarios on dynamometer stands, thereby subjecting brake systems to real driving conditions and stresses experienced during stops. This test comprises different bedding and fading phases and integrates the values of the initial speed, initial temperature, and pressure of brake applications. This is critical for characterizing brake materials and ensuring their safety and performance in automotive applications. The aim of this study is to conduct a comprehensive assessment and comparison of the tribological behavior of Al-MMC brake rotors against their conventional GCI rotor counterparts, with the goal of identifying potential advantages in performance, weight reduction, and durability. Additionally, this study seeks to evaluate the wear behavior and degradation pathways through microstructural and surface characterization techniques, along with monitoring the thermal performance during braking cycles. The outcomes of this research offer valuable empirical insights into the real-world tribological behavior of squeeze-cast Al-MMCs, contributing to the development and optimization of next-generation lightweight braking systems. Furthermore, the results are expected to guide the refinement of alloy composition, casting process parameters, and surface engineering strategies to enhance the operational performance and service life of Al-MMC brake rotors in automotive applications.

2. Materials and Methods

2.1. Brake Rotor Materials and Fabrication

The Automotive Components Floby AB (Floby, Sweden) provided the investigated brake rotors. The composites were produced by squeeze casting with a target SiC content of 20 wt.%, which were composed of a mixture of three particle size fractions designated as F360 (30 wt.%), F400 (40 wt.%), and F500 (30 wt.%). Different SiC particle size fractions were intentionally added to the aluminum composite for synergistic improvements in mechanical, tribological, and processing performance that cannot be achieved with a single particle size alone, and the particles consisted of cubic β-SiC and hexagonal/rhombic α-SiC structures with an overall average particle size of 20 μm. SiC particles were purchased from Fiven ASA (Oslo, Norway). The details of the casting procedure are described in a previous study [5]. Table 1 lists the chemical compositions of the composites, which were measured using optical emission spectrometry. The Si content in Table 1 provides the total silicon (Si) amount, the sum of the Si in the base alloy, and the Si in the SiCp for each MMC material.

Table 1.

Chemical composition [wt.%] of the investigated materials.

The GCI material, commonly employed in brake-disc applications, was examined for comparative analysis with composite materials. The elemental composition of the GCI material, expressed in weight percentages, is as follows: carbon (C), 3.7%; silicon (Si), 2.0%; manganese (Mn), 0.7%; phosphorus (P), 0.05%; sulfur (S), 0.14%; chromium (Cr), 0.10%; and copper (Cu), 0.17%.

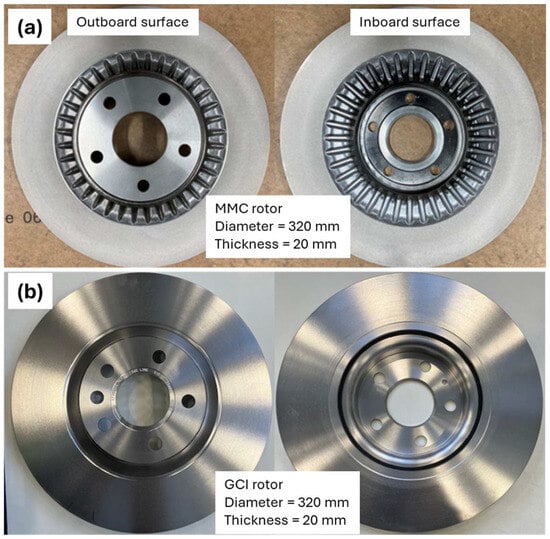

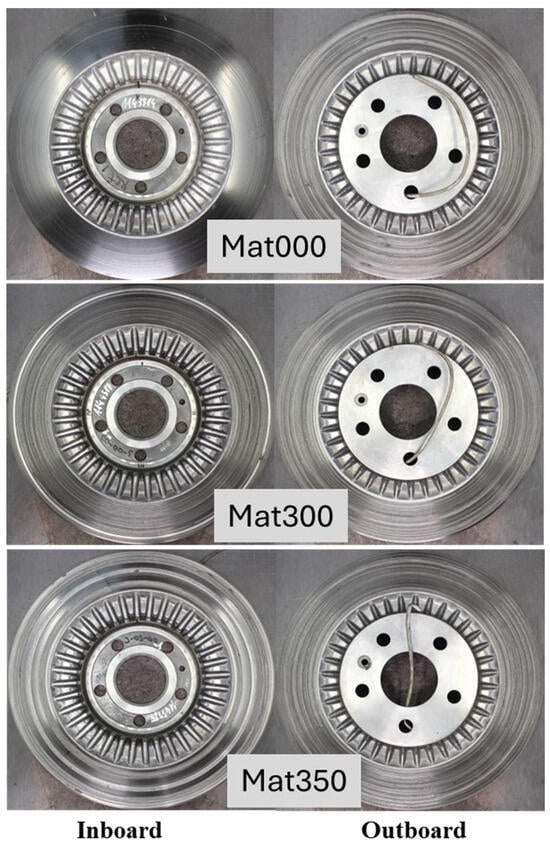

To facilitate the activation of the friction surfaces of MMC brake rotors for expedited bedding-in during the dynamometer test, the MMC rotors underwent post-machining chemical etching, as detailed in [15]. In contrast, the GCI rotor was employed without additional treatment following machining. Figure 1 presents a representative photograph of the MMC and GCI rotors before the dynamometer test, following the AK Master protocol.

Figure 1.

Representative photographs of (a) the MMC and (b) the GCI brake rotors before the test, showing the outboard and inboard friction surfaces of the rotors.

The microstructures of the various materials were investigated using optical (Olympus DSX1000) and scanning electron microscopy (TESCAN Mira 4) after standard metallographic preparation, and the different phases were identified using energy-dispersive X-ray spectroscopy (EDS, EDAX Octane Elect). The microhardness of the MMC and GCI materials was determined using a FALCON 600 Vickers hardness tester on the unetched metallographic samples, according to the ISO 6507-1:2023 standard [16]. A constant load of 1000 gf was applied for a dwelling time of 10 s, and ten readings were taken in the longitudinal direction of each sample.

2.2. Experimental Setup: AK Master Dynamometer Testing

All the rotors evaluated in this study possessed uniform dimensions, specifically, a diameter of 320 mm and a thickness of 20 mm. Variations in the design of Al-MMCs and GCI rotors are attributable to the distinct material properties, resulting in a disc weight of approximately 3.57 kg for Al-MMCs and approximately 7.53 kg for GCI. Prior to the dyno AK master test, the initial surface roughness (Ra) of the rotors was measured as follows: 1.24–1.87 µm for Mat000, 2.76–2.91 µm for Mat300, 2.42–2.69 µm for Mat350, and 1.35–1.62 µm for the GCI rotors. The braking test was executed utilizing a full-scaled dynamometer with an inertia of 46.85 kg*m2 at Federal-Mogul Bremsbelag GmbH, Glinde, Germany. This inertial configuration was fixed and replicated the characteristics of a targeted mid-sized passenger vehicle with a curb weight of approximately 2300 kg [9]. During each braking snub, the friction and temperature data were recorded at a frequency of 100 Hz. The surface temperature of the disc was measured using a rubbing thermocouple that maintained physical contact with the frictional surface of the disc throughout the test. A pair of non-asbestos organic (NAO) brake pads with a zero-copper formulation (FER9701) was employed as friction couples for the MMC and GCI brake rotors. The brake pads were produced and supplied by Federal-Mogul Bremsbelag GmbH (Glinde, Germany). However, specific details regarding the brake pads cannot be disclosed owing to commercial confidentiality.

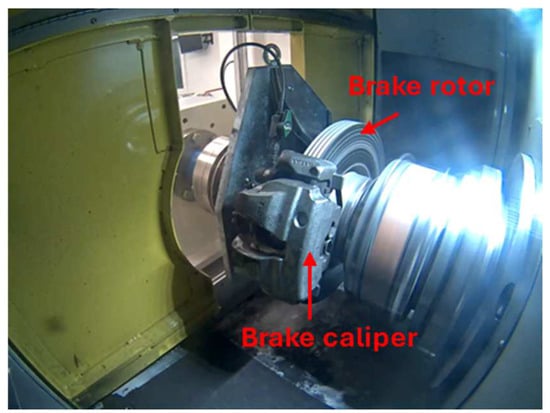

Figure 2 shows an image of the brake measurement section of the dynamometer. The braking effectiveness of various friction pairs was evaluated according to the AK master test protocol. The specific test conditions were defined according to the SAE-J2522 standard [14] and are listed in Table 2. This article focuses on the AK Master segments 4, 9–12, 14, and 15, as listed in Table 2. To elucidate the friction properties and wear mechanisms of rotor–pad braking pairs under varying conditions, repeated tests were conducted at different braking speeds and pressures. The test temperature ranges for the Al-MMC and GCI brake rotors were 50–400 °C and 100–500 °C, respectively, to simulate comparable thermal conditions for each material. However, the Al-MMC rotors were subjected to a maximum temperature of approximately 400 °C, in contrast to the GCI rotor, which was tested up to 500 °C, owing to the lower melting temperature of the Al-MMC material. The frictional performance of the rotors was assessed by monitoring the variation in the CoF across braking cycles using a computer log connected to the dynamometer. Wear analysis was performed using a mass measurement method, wherein the weights of the rotors and pads were recorded before and after the completion of the AK Master test cycles, allowing for the calculation of weight variation (Δw, g) by the rotors and pads. The weight variations were converted into volume values (Δv, cm3) according to Equation {1) using the following density (ρ, g/cm3) data: 2.75 g/cm3 for Mat000, 2.82 g/cm3 for Mat300 and Mat350, 7.2 g/cm3 for GCI, and 2.6 g/cm3 for the brake pad material [5].

Figure 2.

A section of the test rig shows the mounted brake rotor and caliper.

Table 2.

Test conditions for the AK Master protocol according to SAE-J2522 Recommended Practice [14].

The post-test surface morphology analysis of the rotors was conducted using scanning electron microscopy (SEM), EDS, and optical microscopy.

3. Results and Discussion

3.1. Microstructure Analysis of the Rotors

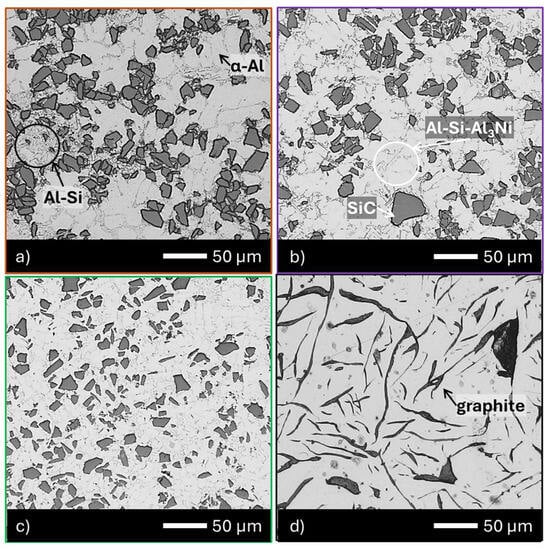

The microstructures of the composites and GCI brake rotors were examined using optical microscopy, and the findings are presented in Figure 3. Mat000 (Figure 3a) was used as the reference composite material, comprising an Al-Si9-Mg0.3 alloy reinforced with 20 wt.% SiC particles. The SiC particles were observed as dark polygonal features, consistently present across all three composite materials analyzed. The incorporation of 3.5 wt.% Ni into the matrix alloy results in the formation of Al3Ni particles, which emerge at the boundaries of the primary aluminum (Al) dendrites within the Mat300 and Mat350 microstructures (Figure 3b,c). The constituent phases within the composite materials were identified using EDS and were compared with those reported in the literature. The primary microstructural feature that distinguishes Mat300 and Mat350 from Mat000 is the presence of an Al3Ni phase, as detailed in our previous study [5], in addition to the microstructural characteristics of Mat000. The incorporation of Cu into Mat350 (Figure 3c) resulted in Cu enrichment of the Ni-based phase and primary α-Al dendrites without the formation of Cu-based phases. Figure 3d depicts the typical microstructure of GCI, which was used as a comparative material to represent the traditional automotive brake discs. This microstructure consisted of graphite flakes and manganese sulfide (MnS) particles embedded within the pearlitic matrix (Figure 3d).

Figure 3.

Microstructure of the materials investigated: (a) Mat000; (b) Mat300; (c) Mat350; (d) GCI.

3.2. Microhardness Evaluation of Brake Materials

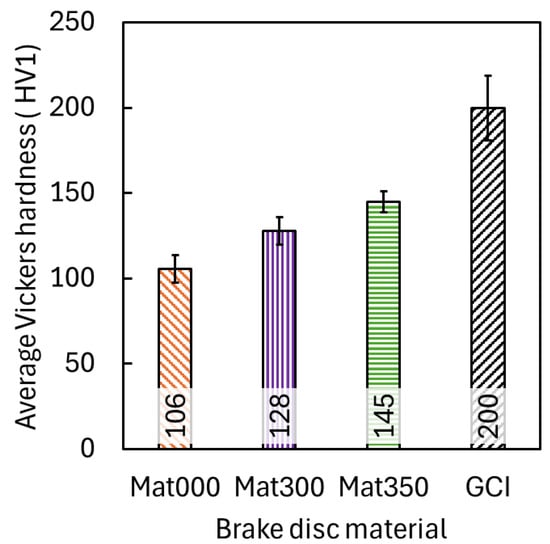

Figure 4 shows the microhardness distribution across the thickness of the friction surfaces for each brake-rotor material. Fifteen Vickers hardness measurements were taken across each rotor’s thickness, and the average hardness values for these materials are shown in Figure 4. The average hardness values for Mat000, Mat300, Mat350, and GCI were 106 HV1, 128 HV1, 145 HV1, and 200 HV1, respectively. The microhardness of the GCI brake rotor surpassed that of the Al-MMC brake rotor.

Figure 4.

The microhardness (HV1) of the investigated brake rotor materials.

However, the hardness of Mat000 (106 HV1) was slightly lower than that of Mat300 and Mat350 by 17% and 27%, respectively. The increased hardness observed in Mat300 and Mat350 compared to Mat000 can be attributed to the precipitation of secondary phases, especially Al3Ni particles, within their microstructures, as discussed in Section 3.1. Additionally, this enhancement in hardness was partially due to the solid solution strengthening of the Al matrices resulting from the incorporation of Cu and Zr. These results corroborate the previous hardness values determined using the Berkovich nanoindentation technique [5]. The hierarchy of hardness among the primary microstructural components of the composite material was as follows: SiC (34.4 ± 3.7 GPa) > Al3N (3.85 ± 1.4 GPa) > eutectic Si (2.73 ± 0.4 GPa) > α-Al (1.15 ± 0.1 GPa). Consequently, this hierarchy influences the overall hardness of the composite materials in the following order: Mat000 < Mat300 < Mat350. The results of this study indicate that the microhardness analysis of the Al-MMCs corresponds closely with previously reported nanohardness tests conducted on these materials [5].

3.3. Tribological Performance Evaluation

This section examines the impact of variations in testing temperature, pressure, and speed on braking effectiveness, with particular emphasis on analyzing and discussing the AK Master segments 4, 9–12, 14, and 15, as outlined in Table 2, for the various brake rotor materials under study. It further compares the braking performance of Al-MMC rotors with that of traditional GCI brake rotors. Owing to the differences in thermal resistance between the Al-MMCs and GCI rotors, the testing temperature for the Al-MMC discs was maintained within the range of 50–425 °C, whereas the GCI rotor was tested within the temperature range of 100–550 °C. Additionally, an analysis of the surface characteristics of the Al-MMC rotors following the dynamometer testing is presented.

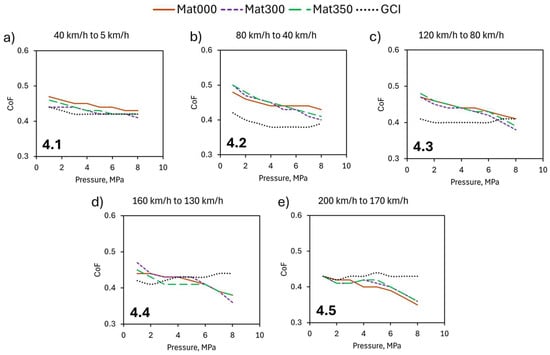

3.3.1. Pressure–Speed Sensitivity

This study investigated the frictional properties of various materials in response to changes in speed and pressure during AK master test cycles. Figure 5 provides a detailed and accurate representation of the variations in the CoF for different brake rotor materials. There are distinct tribological responses among the Al-MMCs (Mat000, Mat300, and Mat350) compared to conventional GCI rotors. Figure 5 shows that the Al-MMCs exhibited similar friction behaviors, characterized by a generally negative slope in the coefficient of the friction–pressure relationship. The Al-MMC rotors had high initial CoFs and high sensitivity to both pressure and speed conditions, with more pronounced decreases at elevated pressures, particularly at high speeds. Conversely, the GCI rotors exhibited a more stable friction coefficient across various pressure ranges and speed conditions, with minimal variation in the CoF, typically ranging from 0.38 to 0.44. The pressure sensitivity of the friction coefficient differed significantly between the Al-MMC and GCI materials. As depicted in Figure 5a–e, the Al-MMCs consistently show a decreasing trend in the friction coefficient with increasing pressure. This negative slope is most pronounced in the high-speed braking scenario (200–170 km/h) illustrated in Figure 5e, where the friction coefficient decreases from approximately 0.42 at low pressure to 0.35 at 8 MPa. This behavior is consistent with the findings in the literature, which suggest that “as the contact pressure increases, the coefficient of friction decreases” owing to the compression of the microconvex peaks on uneven surfaces that expand the real contact area [17]. In contrast, the GCI rotor exhibited a relatively stable friction coefficient, particularly within the high-speed range (Figure 5e), where the friction coefficient remained nearly constant at approximately 0.43 across the entire pressure range. This stability presents a significant advantage in maintaining consistent braking performance under various pressure conditions. Previous studies have indicated that the stability of the friction coefficient is crucial for predictable braking behavior and reduced brake fade [18,19].

Figure 5.

Variation in the average coefficient of friction (CoF) for Al-MMC (Mat000, Mat300, and Mat350) and GCI brake rotors as the pressure increased across five specified speeds: (a) from 40 km/h to 5 km/h, (b) from 80 km/h to 40 km/h, (c) from 120 km/h to 80 km/h, (d) from 160 km/h to 130 km/h, and (e) from 200 km/h to 170 km/h, in accordance with the AK master test protocol. The numbers indicate AK master test segments listed in Table 2.

The frictional behavior exhibited a significant dependence on speed. At lower speed ranges, specifically 40–5 km/h and 80–40 km/h, as illustrated in Figure 5a,b, all materials display moderate sensitivity to pressure, with the friction coefficients generally ranging from 0.38 to 0.47. However, as the speed increases to the 120–80 km/h range (Figure 5c), the difference in behavior between the GCI and Al-MMC rotors becomes more pronounced. In the highest speed range (200–170 km/h), as shown in Figure 5e, the most notable contrast emerges. While the GCI maintains a relatively stable friction coefficient of approximately 0.43, irrespective of the pressure, the Al-MMCs exhibit a significant decrease in the friction coefficient as the pressure increases. This behavior is consistent with research findings that suggest that an increased sliding velocity leads to a reduced friction coefficient and wear rate in MMC [20]. This reduction is attributed to the formation of a compact transfer layer on the worn surface of the MMCs, which is primarily composed of constituents from the counter body material (brake pads). The formation of a transfer layer on the surface of Al-MMCs is well documented in the literature [21,22,23,24].

The observed reduction in the friction coefficient of the Al-MMC rotors with increasing pressure can be explained by several tribological mechanisms. At elevated pressures, the increased contact area and temperature facilitated the formation of a protective transfer layer on the Al-MMC surface. The formation of this protective tribolayer is more pronounced under higher loads, leading to a reduced coefficient of friction compared to lower loads [25]. This transfer layer incorporates constituents from the brake pad material and functions as a lubricant between the sliding surfaces. Second, higher contact pressures can result in increased frictional heat, which can alter the mechanical properties of the contact surfaces. As documented in the literature, “at higher pressure, the heat caused by friction is much higher than the heat transferred to the environment” [17]. This increase in temperature can diminish the shear strength of the surface material, leading to a reduction in friction. The more significant reduction in the CoF for the Al-MMC rotors at higher speeds, particularly evident in Figure 5d,e, may also suggest the thermal softening effect of the matrix material. Al-MMCs are more susceptible to the thermal degradation of friction properties than GCI, which explains the stability of the GCI rotor at higher speeds and pressures [26]. Furthermore, the interaction between the hard ceramic SiC reinforcements in the Al-MMC brake rotors and the brake pad material changes with pressure. Jang et al. [27] reported that the interaction between the metal fillers of friction materials and an Al-MMC disc differs from that of GCI. This interaction becomes particularly significant under high-pressure conditions, where hard particles from the MMC may play a dominant role in controlling friction.

The relative stability of the GCI friction coefficient across pressures and speeds can be attributed to the graphite flakes providing consistent lubrication. This aligns with Österle et al. [28], who found that graphite lamellae in GCI provided stable friction films under various loading conditions. The tribolayer formed on the GCI differed from that formed on the Al-MMC, offering more consistent friction characteristics. The stability of the GCI rotor can also be attributed to its higher volumetric heat capacity, which enables better heat absorption and minimizes thermal gradients [5].

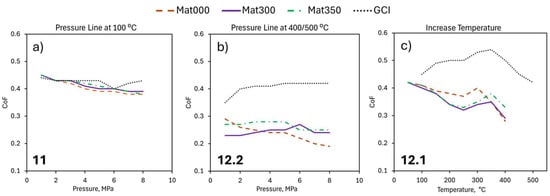

3.3.2. Temperature–Pressure Sensitivity

The effects of pressure and temperature on the frictional properties of the composites and GCI brake rotors are illustrated in Figure 6. At a constant temperature of 100 °C (Figure 6a), the materials demonstrated average CoF values ranging from 0.38 to 0.45. The frictional behavior exhibited a relatively low sensitivity to pressure variations between 1 and 8 MPa. The GCI maintains a slightly higher and more stable average CoF compared to the Al-MMCs, which present a slight decrease in the CoF with increasing pressure. A constant CoF is advantageous for the predictability of brake performance under normal operating temperatures because stable friction characteristics ensure a consistent braking response. The minimal pressure sensitivity at moderate temperatures is consistent with the tribological expectations because the contact interfaces have not yet undergone significant thermally induced modifications that would alter the friction mechanisms [27].

Figure 6.

Variation in average CoF of Al-MMCs (Mat000, Mat300, and Mat350) and GCI brake rotors with pressure at (a) 100 °C, (b) 400/500 °C, and (c) with increasing temperature according to the AK master test protocol. The numbers indicate AK master test segments.

When evaluated at elevated temperatures (Figure 6b), the materials exhibited more pronounced differences. The GCI, tested at 500 °C, exhibited a higher coefficient of friction of approximately 0.40–0.42, in contrast to the Al-MMC materials, which displayed average CoF values ranging from 0.20 to 0.30, tested at 400 °C.

Mat000 exhibited a noticeable decreasing trend with increasing pressure, whereas Mat300 and Mat350 exhibited relatively stable friction characteristics. The friction stability observed in Mat300 and Mat350 compared to Mat000 could be attributed to the presence of thermally stable secondary phases, such as Al3Ni, as observed in Figure 3. The variable average CoF at high temperatures has significant implications for brake performance under severe service conditions, such as repeated hard braking or mountain descent [29]. The substantial changes in the CoF with the applied pressure suggest that the interaction between the friction materials and the Al-MMC substrate fundamentally differs from their interaction with GCI [27]. Figure 6c shows the temperature-dependent friction behavior of the most distinctive differences between the materials. All MMCs started with similar CoF values (~0.40) at low temperatures, but their behavior diverged significantly as the temperature increased. The GCI rotor shows exceptional thermal stability, achieving the highest CoF values (0.45–0.53) within the 200–400 °C range. It shows a notable increase in average CoF as the temperature rises, reaching a peak of approximately 0.53 around 350–400 °C before gradually decreasing. The increase in friction is particularly advantageous for brake performance because it provides enhanced stopping power during thermal loading conditions, counteracting potential fading effects [29,30]. In contrast, all Al-MMC materials exhibited a general decrease in the coefficient of friction as the temperature increased, indicating potential thermal fading issues during intense braking conditions. All materials experience a reduction in CoF above 300–400 °C, with Al-MMCs exhibiting more significant decreases. The decreasing CoF observed for Al-MMCs at higher temperatures can be attributed to the softening of the matrix and degradation of the tribolayer above 300 °C [20,26,29]. At 500 °C, the difference in friction performance between GCI (CoF ~0.42) and Al-MMC materials (CoF ~0.28–0.33) becomes evident, highlighting the superior high-temperature friction stability of GCI [26].

The generally modest impact of pressure at standard operating temperatures indicates that all the materials can sustain predictable braking performance at different application pressures. However, the GCI rotor exhibited superior consistency at elevated temperatures. Although Al-MMC rotors offer advantages in terms of weight reduction, their lower coefficient of friction at high temperatures suggests potential limitations in high-performance braking applications where thermal loads are substantial.

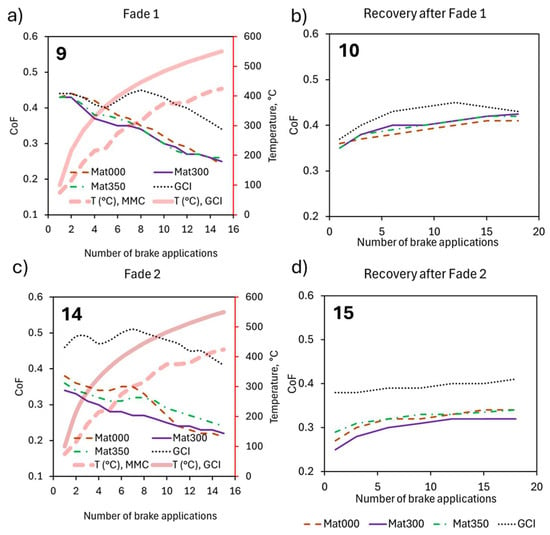

3.3.3. Friction Fade and Recovery Cycles

The data in Figure 7 offer a tribological analysis comparing the average coefficient of friction behavior of the Al-MMCs and the GCI brake rotor during the fade (at 40% deceleration) and recovery test cycles. During the initial fade cycle (Figure 7a), all Al-MMCs exhibited a marked decrease in the coefficient of friction as the temperature increased from approximately 100 °C to 425 °C. The initial CoF values for the Al-MMCs, ranging from approximately 0.42 to 0.45, progressively declined to around 0.24 to 0.25 after 15 brake applications. This reduction of approximately 40–45% indicates a significant sensitivity to thermal effects, a characteristic common to many Al-MMCs [20,26,31]. In contrast, the GCI brake rotor (Figure 7a) exhibited superior thermal stability, beginning with a coefficient of friction of approximately 0.44, which decreased to approximately 0.37 by the conclusion of the fade cycle, indicating a modest reduction of 16%. This inherent thermal stability of GCI aligns with its prevalent application in conventional braking systems and can be attributed to its microstructural characteristics and graphite flake morphology [26,28]. The second fade cycle (Figure 7b) reveals notable differences in the material behavior. The Al-MMC rotors had slightly lower CoF values than those in Fade 1, suggesting potential residual thermal effects or microstructural alterations from the preceding test cycles. Mat350 exhibited a marginally enhanced fade resistance relative to its performance in the initial fade test, possibly indicating beneficial microstructural stabilization following the initial thermal cycle. GCI demonstrates superior performance during Fade 2, with higher initial CoF values (approximately 0.47–0.50) and maintaining relatively stable friction characteristics throughout the test. The enhanced CoF stability observed during repeated thermal cycling, which may be attributed to GCI having a higher volumetric heat capacity than Al-MMC [5], represents a significant advantage for braking applications that require consistent performance under severe conditions.

Figure 7.

Variation in average CoF of Al-MMC (Mat000, Mat300, and Mat350) and GCI brake rotors after Fade 1 (a); Fade 2 (b). Recoveries after Fade 1 (c) and Fade 2 (d) tests according to the AK master test protocol. The numbers indicate AK master test segments.

The recovery characteristics observed following Fade 1 (Figure 7c) illustrate the capacity of the materials to restore their frictional properties after thermal exposure. All materials demonstrated progressive recovery of the CoF with an increasing number of brake applications, indicating the restoration of tribological properties as the system cooled. The GCI rotor achieved the highest recovery value, peaking at approximately 0.45, thereby exhibiting superior thermal reversibility [32].

Among the Al-MMCs, Mat350 exhibited the most effective recovery performance, followed by Mat000 and Mat300. This hierarchy may indicate compositional or microstructural differences that affect the thermal recovery characteristics. The disparity between the highest performing Al-MMC (Mat350) and GCI remains evident, with the GCI rotor maintaining approximately 8–10% higher CoF values throughout the recovery phase. The recovery observed following Fade 2 (Figure 7d) demonstrates a more pronounced disparity in performance between the materials. GCI consistently exhibited substantially higher CoF values in the 0.38–0.41 range throughout the recovery phase in comparison to the Al-MMCs. The composites exhibited lower initial CoF values during the second recovery phase than during the first recovery phase (Figure 7c), indicating potential cumulative degradation or tribological surface modifications resulting from repeated thermal cycling [33]. The recovery trajectory for all materials followed a similar pattern of gradual improvement; however, GCI consistently outperformed the Al-MMCs owing to its higher resistance to elevated temperatures [26,34], maintaining approximately 15–20% higher CoF values throughout this recovery phase. This performance differential is particularly significant for braking applications, where consistent recovery characteristics are crucial for predictable vehicle handling [30,32]. The experimental results demonstrated the superior thermal stability and fade resistance of the GCI compared with those of the tested Al-MMCs. This thermal advantage of GCI can be attributed to several factors, including its higher thermal conductivity, which facilitates enhanced heat dissipation, and its graphitic microstructure, which provides inherent lubrication properties at elevated temperatures [34,35]. The more pronounced fading behavior observed in the composites is consistent with previous studies on Al-based brake materials, which identified challenges with thermal management despite their weight advantages. Jang et al. [27] identified comparable thermal sensitivity in metal matrix composites employed in braking applications, highlighting that material formulation plays a crucial role in determining high-temperature friction stability. The recovery patterns observed in these experiments provide valuable insights into the tribological mechanisms that influence brake performance. The recovery behavior of the GCI may indicate more reversible surface interactions during the braking process. When brake materials are exposed to elevated temperatures, various phenomena can occur, including oxidation, transfer film formation, and microstructural transformations [32]. The data indicate that the GCI rotor undergoes reversible transformations, enhancing its ability to effectively recover its friction properties. In contrast, the Al-MMCs exhibited lower recovery values, suggesting less reversible surface transformations. These transformations could involve permanent oxidation of the Al matrix and degradation of the interface between the matrix and reinforcement materials. Kchaou et al. [32] emphasized that recovery characteristics are crucial for braking safety because they influence the predictability of a brake system’s performance following exposure to high temperatures.

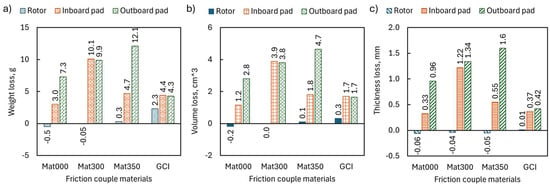

3.3.4. Wear and Surface Degradation

Figure 8 shows the wear evaluations for various friction pairs, specifically brake rotors and pads, as determined after the AK master test procedure. The main observation was the different wear behaviors exhibited by the rotors and brake pads across the tested materials. Although the AK Master test protocol was not specifically designed for comprehensive brake wear evaluation, it may provide insights into the wear behavior of the friction pair.

Figure 8.

Wear evaluations of the friction couples after the AK Master test: (a) weight loss, (b) volume loss, and (c) thickness loss.

The weight loss in Figure 8a and the volume loss in Figure 8b indicate negative loss values for the Al-MMC rotors, specifically Mat000 (−0.2 cm3) and Mat300 (−0.05 g), whereas Mat350 exhibits minimal positive volume wear (0.1 cm3), and the GCI rotor (0.3 cm3) shows conventional positive wear patterns. The negative wear suggests material transfer from the brake pads to the rotor surface, a phenomenon well-documented in the tribology of Al-MMCs [21,22,25]. This material transfer results in the formation of a protective tribofilm, fundamentally altering the wear mechanism from abrasive material removal to the development of a protective layer. The material gain in Figure 8a,b corresponds to the thickness gain on the composite rotor side, presented in Figure 8c. The weight loss in the GCI disc corresponds to limited thickness loss. In all cases, the most significant wear damage occurred at the expense of the brake pads and not the rotor.

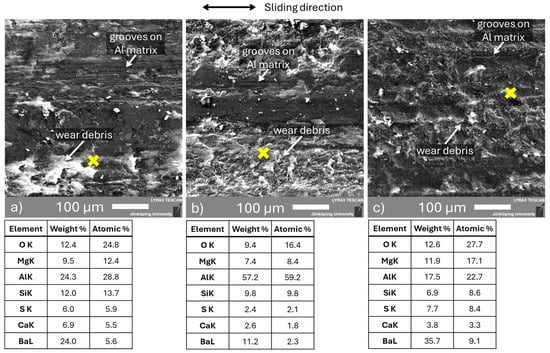

The formation of transfer layers on Al-MMC surfaces occurs through a complex tribochemical process, in which brake pad constituents become mechanically and chemically bonded to the Al matrix surface [21,22,25]. Figure 9 presents the SEM images of the worn surface on the discs after the AK master test.

Figure 9.

Surface of composite materials after AK master dyno test cycles and related EDS elemental analysis of the selected spots (yellow cross) on the wear debris deposited on the rotor surfaces: (a) Mat000, (b) Mat300, and (c) Mat350.

The wear debris adhered to the surface of all the composites investigated. Mat000 (Figure 9a) and Mat300 (Figure 9b) exhibited a comparable appearance of a compact and thick tribolayer along the sliding direction. The tribolayer was not continuous on the entire surface, with portions of the composite surface exposed and portions of the tribolayer distributed unevenly, suggesting that the layer was removed and formed again during the wear process. Mat350 (Figure 9c) presents dusty debris that is less compact than that of the other composites. The appearance of the tribolayer on a microscale can depend on the presence of hard phases in the matrix, such as the Ni-based phases in Mat350, which present an overall higher hardness compared to the other composites. The protective role of this transfer layer reduces the wear rate and friction coefficient because it is related to the negative wear (material gain) of the Al-MMC rotors in Figure 8 and the lower CoFs in Figure 7d.

An important characteristic observed in Figure 8 is the significant asymmetry in pad wear between the outboard and inboard pads across various Al-MMCs. For Mat300, both the outboard and inboard pads exhibited similarly high-volume wear rates of 3.8 cm3. In contrast, Mat000 and Mat350 exhibited significant differences in wear between the outboard and inboard pads. This asymmetric wear behavior can be attributed to variations in the contact pressure distribution, thermal gradients, influence of protruding hard SiC particles, rotor surface roughness after aggressive thermal loads, and local tribological conditions within the brake caliper assembly. The high pad wear rates observed in certain Al-MMCs, particularly Mat350 with an outboard pad volume wear of 4.7 cm3, suggest that while the rotor surface is protected by the formation of a transfer layer, the brake pad material undergoes accelerated consumption. This phenomenon aligns with findings indicating that Al-MMC discs can present superior wear resistance when the structure and composition of the lining material of the brake pad are optimally configured [21,25].

The fundamental difference in the wear behavior between the Al-MMC and GCI rotors highlights distinct tribological mechanisms. The GCI rotors exhibit conventional abrasive wear, evidenced by a positive volume wear loss of 0.3 cm3, while maintaining relatively consistent pad wear at both the outboard and inboard (1.7 cm3) positions (Figure 8). This balanced wear distribution in the GCI rotor–pad system suggests a more traditional two-body abrasive wear mechanism, in which both surfaces contribute to material removal. Typically, GCI brake discs operate via a well-established tribological mechanism involving the formation of tribofilms primarily composed of iron oxides [36]. The graphite flakes in the GCI rotor serve as solid lubricants, forming tribofilms that reduce both friction and wear under dry sliding conditions [14,17]. The presence of graphite created a more stable tribological interface, resulting in the observed balanced wear distribution between the rotor and pads, as shown in Figure 8. The negative wear values observed in the Al-MMC rotors are related to the formation of stable transfer layers that offer protective coverage, as observed on their surfaces in Figure 10. These transfer layers are formed through compaction galling, where brake pad debris accumulates on the surface and becomes mechanically interlocked with the surface [37]. The dimpled surface morphology typical of processed Al-MMC materials enhances the bonding of the transfer layer through mechanical interlocking mechanisms.

Figure 10.

Surface appearance of Al-MMC brake rotors after the AK master dyno test.

Figure 10 depicts the surface appearance of all Al-MMC rotors following the AK master test protocol. Unfortunately, the test laboratory did not document photographs of the surface condition of the GCI rotor following the AK master test before the tested GCI sample was discarded. Consequently, post-test surface characterization of the GCI rotor could not be conducted for comparison with the Al-MMC rotors. The figure illustrates several distinctive characteristics of the friction surfaces of the Al-MMCs. For rotor Mat000, the friction surface was relatively smooth, exhibiting minimal visible wear. The surface appears uniform, indicating a less aggressive material interaction. No significant grooves or deep scratches were evident, suggesting low material transfer or abrasive wear during testing. The surface characteristics of the friction interfaces of Mat300 exhibited more pronounced wear marks than those of Mat000. The observable scratches and slight discoloration suggest increased friction and heat generation. The presence of light scoring indicates abrasive wear, which is related to the hardness variations of the composite material or its interaction with the brake pads. In contrast, the friction surfaces of Mat350 demonstrated the most significant wear, characterized by deeper scratches, more pronounced scoring, and areas of discoloration. The surface appears rougher than that of the other two composites. The increased scoring and roughness imply higher abrasive wear and potentially more substantial material transfer between the rotor and brake pad. This could suggest higher friction but also greater wear on the Mat350 rotor surface, as shown in Figure 8.

From a tribological perspective, the smoother appearance of the Mat00 friction ring suggests better wear resistance, reduced contact area, and a lower friction coefficient, leading to less material loss [38]. These features may also indicate a lower grip with the brake pads, potentially reducing the braking efficiency under high-stress conditions. The moderate wear and scoring of Mat300 suggest a balanced tribological performance. The material provides a higher friction coefficient than Mat000, improving the grip with the brake pads, but at the cost of increased wear. The rougher surface and deeper scoring in Mat350 indicate a higher friction coefficient, which could enhance the braking performance by improving the pad–rotor interaction [39,40]. The increased wear suggests poorer durability, as the rotor may degrade faster over time, potentially leading to more frequent replacement. These observations align closely with the wear patterns depicted in Figure 8 and the friction behavior reported in Figure 7d. Overall, all the Al-MMCs exhibited a relatively uniform friction surface appearance, indicating consistent pad-to-rotor contact during the AK master test protocol.

3.4. Practical Implications for Braking Performance

Al-MMC and GCI brake rotors exhibit distinct performance characteristics and trade-offs within braking systems. This study presents a structured comparison of their practical braking performance implications, as derived from the findings of this investigation.

- Thermal capacity and heat dissipationThe superior thermal conductivity of Al compared to GCI offers substantial benefits in brake thermal management [5]. Al-MMC brake rotors exhibit a 25% higher rate of heat dissipation relative to GCI rotors, leading to a more uniform thermal distribution and a reduction in the formation of hot spots, which are commonly observed in GCI rotors. The thermal performance contributes to a more consistent braking behavior, diminishes thermal stress-induced distortion, reduces thermal fade during repeated braking, and facilitates quick recovery between braking events. The latter is advantageous in performance-driven scenarios. Nonetheless, the incorporation of ceramic reinforcements into Al-MMCs can pose challenges to thermal conductivity, necessitating careful optimization of the reinforcement content and distribution to ensure adequate heat dissipation while maintaining the mechanical properties. Conversely, the higher volumetric thermal capacity of GCI rotors enables superior heat absorption during intense braking, as observed in this investigation. This characteristic ensures a more consistent performance during repeated heavy braking events, rendering GCI rotors ideal for heavier vehicles and high-load applications.

- Friction stability and performance consistencyThe formation of stable transfer layers on Al-MMC rotors contributes to more consistent friction coefficients throughout the braking cycle. The Al-MMC brake discs can sustain stable friction coefficients while demonstrating superior wear resistance compared to conventional rotors. The generally modest impact of pressure at standard operating temperatures lower than 500 °C suggests that all Al-MMCs can maintain predictable braking performance across different application pressures. The evolution of the tribological interface during braking influences the stability of the friction coefficient through the dynamic formation and reformation of the contact plateaus. However, the capacity of Al-MMC surfaces to accommodate transfer materials and sustain stable tribological interfaces contributes to reduced brake fade and more predictable braking performance under varying conditions. The consistently stable CoF of the GCI rotor under aggressive and repeated braking events renders it suitable for extreme temperature braking up to 700 °C.

- Weight considerationsThe GCI has a significantly high density of approximately 7.2 g/cm3, which contributes to increased unsprung weight and adversely affects vehicle dynamics, acceleration, and fuel efficiency. In contrast, Al-MMCs exhibit a density of approximately 2.8 g/cm3, resulting in a reduction of rotational inertia and unsprung weight by 50–60%. This reduction leads to enhanced handling, acceleration, and fuel economy, with an estimated improvement of 1–2% in overall vehicle efficiency. The reduced weight of the Al-MMC rotors makes them optimal candidates for electric vehicle applications, where weight reduction and corrosion resistance are prioritized.

- Wear resistance and dust generationThe findings of this study suggest that the GCI rotor exhibited a higher wear rate, evidenced by a 2.3 g weight loss in the AK master dynamometer test, when used in conjunction with an NAO friction material. This observation indicates that the GCI disc produces dust and thus necessitates further modification of the friction surfaces to comply with the Euro 7 regulation. The balanced wear characteristics of the GCI are likely associated with more stable friction coefficients during braking, more predictable thermal behavior, potentially superior noise, vibration, and harshness (NVH) performance, and more uniform pressure distribution and thermal management across the brake assembly. These factors typically result in a more consistent brake torque and pedal feel during operation. In contrast, the Al-MMC rotors exhibited negative or nearly zero wear characteristics compared to the GCI rotor. The Al-SiC MMC rotors had superior wear resistance, leading to a reduction in particulate emissions by 86.9–121.7% compared to the GCI rotors. Although the negative weight loss in Al-MMC materials may contribute to an extended rotor lifespan, the associated asymmetrical pad wear could potentially undermine the overall system reliability and performance consistency. Specific pad formulations are required to prevent excessive wear; with appropriate engineering, comparable lifespans can be achieved. Al-MMC rotors are particularly advantageous for applications that prioritize weight reduction, environmental impact, and low wear. The GCI is preferable for high-stress high-temperature conditions that require uncompromised thermal stability. Advances in coating technologies and rotor designs can reduce performance disparities, thereby enhancing the viability of Al-MMC for mainstream automotive adoption.

- Long-term durability and maintenance considerationsThe wear data indicate that Al-MMC brake rotors have the potential to endure the entire lifespan of a vehicle [41] owing to their exceptional wear resistance and the formation of a protective transfer layer. Nevertheless, this benefit is accompanied by increased brake pad consumption, particularly for specific formulations such as Mat350. This trade-off necessitates careful evaluation of the overall system cost and maintenance requirements. The selection of the rotor variant depends on the intended application. For general use, Mat000 is preferable owing to its lower wear rate, although it may compromise braking power. In contrast, for performance-oriented applications where stopping power is paramount, Mat350 is superior; its higher wear rate suggests that it is more suitable for scenarios in which rotors can be replaced more frequently. Mat300 provides a balance between braking performance and durability, rendering it a versatile option for a wide range of conditions. Pairing these rotors with brake pads that complement their friction characteristics could further enhance the overall braking efficiency and longevity.

4. Conclusions

This study presents a comprehensive comparative evaluation of squeeze-cast aluminum–metal matrix composite (Al-MMC) brake rotors and conventional gray cast iron (GCI) rotors using the AK Master dynamometer protocol. The investigation emphasizes tribological performance, wear mechanisms, and practical implications for automotive brake applications. The principal conclusions of this study are as follows:

The Al-MMC rotors exhibited stable coefficients of friction (CoFs) under moderate temperature and pressure conditions, with initial CoF values comparable to those of GCI rotors. Nevertheless, the Al-MMC rotors displayed pressure and speed-sensitive friction coefficients (0.35–0.47), which decreased at higher pressures and speeds. In contrast, the GCI rotors maintained a more consistent friction response (0.38–0.44) across all tested conditions. At elevated temperatures, GCI rotors demonstrate superior performance compared to Al-MMCs, exhibiting enhanced thermal stability and resistance to fade. GCI maintained a higher and more stable CoF during repeated high-temperature braking cycles, whereas Al-MMC rotors experienced significant fading, with a reduction in CoF of up to 40–45% and demonstrated less effective recovery following thermal exposure. The thermal fade resistance of GCI was notably superior, retaining 84% of the initial CoF at 500 °C, in contrast to the 40–60% loss of Al-MMC at 400 °C.

The incorporation of ceramic reinforcements, specifically silicon carbide (SiC), along with alloying elements such as nickel (Ni), copper (Cu), and zirconium (Zr), into Al-MMCs has been shown to enhance both hardness and wear resistance. Nevertheless, the thermal softening of the Al matrix at elevated temperatures limits its friction stability. The predominant wear mechanisms observed in Al-MMCs are abrasive and oxidative, with the protective tribolayer playing a pivotal role in mitigating wear.

Al-MMC rotors present a significant reduction in density, approximately 50–60% lower than GCI, resulting in enhanced vehicle dynamics, improved fuel efficiency, and a reduction in particulate emissions by 87–122% compared to GCI. This characteristic renders Al-MMCs particularly advantageous for vehicle applications that prioritize weight reduction and environmental compliance, particularly in urban and electric vehicle contexts.

These findings highlight the potential of squeeze-cast Al-MMCs for automotive braking applications, offering benefits in terms of weight reduction and wear resistance. However, they also indicate the necessity for further material optimization to improve the high-temperature performance and friction stability.

Author Contributions

Conceptualization, S.A.A. and L.L.; methodology, S.A.A.; validation, S.A.A. and L.L.; formal analysis, S.A.A.; investigation, S.A.A. and L.L.; resources, S.A.A. and L.L.; data curation, S.A.A. and L.L.; writing—original draft preparation, S.A.A.; writing—review and editing, L.L.; visualization, L.L.; project administration, L.L.; funding acquisition, L.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Stiftelsen för kunskaps- och kompetensutveckling (KK-Stiftelsen), Sweden, through the project “Properties and formability of Al-SiCp MMCs” (ProForAl) [Prospekt, diarienr. 20200217].

Data Availability Statement

The authors will supply research data upon reasonable request.

Acknowledgments

The authors gratefully acknowledge R. Westergård from Gränges Finspång AB for supplying master alloys, as well as P. Jansson from Comptech i Skillingaryd AB and C. Rudenstam from Husqvarna AB who participated in the ProForAl Project. We gratefully acknowledge A. Jarfors, E. Ghassemali, and J-E. Ståhl for their advice.

Conflicts of Interest

Author Samuel A. Awe was employed by Automotive Components Floby AB. The remaining authors declare no conflicts of interest.

References

- Awe, S.A. Evaluating the Impact of Natural Ageing and Stress-Relief Heat Treatment on Grey Cast Iron Rotor’s Resonant Frequency, Damping Characteristics, and Hardness: A Comparative Study. Int. J. Met. 2025. [Google Scholar] [CrossRef]

- Gweon, J.; Shin, S.; Jang, H.; Lee, W.; Kim, D.; Lee, K. The Factors Governing Corrosion Stiction of Brake Friction Materials to a Gray Cast Iron Disc; SAE Technical Papers; SAE: Warrendale, PA, USA, 2018. [Google Scholar] [CrossRef]

- Ghouri, I.; Barker, R.; Brooks, P.; Kosarieh, S.; Barton, D. The Effects of Corrosion on Particle Emissions from a Grey Cast Iron Brake Disc. In Proceedings of the Brake Colloquium & Exhibition-40th Annual, Grand Rapids, MI, USA, 25–28 September 2022. [Google Scholar] [CrossRef]

- Uyyuru, R.K.; Surappa, M.K.; Brusethaug, S. Tribological Behavior of Al–Si–SiCp Composites/Automobile Brake Pad System under Dry Sliding Conditions. Tribol. Int. 2007, 40, 365–373. [Google Scholar] [CrossRef]

- Lattanzi, L.; Awe, S.A. Thermophysical Properties of Al-Based Metal Matrix Composites Suitable for Automotive Brake Discs. J. Alloys Metall. Syst. 2024, 5, 100059. [Google Scholar] [CrossRef]

- Laden, K.; Guérin, J.D.; Watremez, M.; Bricout, J.P. Frictional Characteristics of Al-SiC Composite Brake Discs. Tribol. Lett. 2000, 8, 237–247. [Google Scholar] [CrossRef]

- Sajjadi, S.A.; Ezatpour, H.R.; Beygi, H. Microstructure and Mechanical Properties of Al–Al2O3 Micro and Nano Composites Fabricated by Stir Casting. Mater. Sci. Eng. A 2011, 528, 8765–8771. [Google Scholar] [CrossRef]

- Alam, M.A.; Ya, H.B.; Azeem, M.; Mustapha, M.; Yusuf, M.; Masood, F.; Marode, R.V.; Sapuan, S.M.; Ansari, A.H. Advancements in Aluminum Matrix Composites Reinforced with Carbides and Graphene: A Comprehensive Review. Nanotechnol. Rev. 2023, 12, 20230111. [Google Scholar] [CrossRef]

- Awe, S.; Eilers, E.; Gulden, F. Sustainable Aluminium Brake Discs and Pads for Electrified Vehicles. In Proceedings of the Eurobrake 2023, Barcelona, Spain, 12–15 September 2023; FISITA: Barcelona, Spain, 2023. [Google Scholar]

- Wu, H.; Zhang, H.; Gao, A.; Gong, L.; Ji, Y.; Zeng, S.; Li, S.; Wang, X. Friction and Wear Performance of Aluminum-Based Self-Lubricating Materials Derived from the 3D Printed Graphite Skeletons with Different Morphologies and Orientations. Tribol. Int. 2024, 195, 109614. [Google Scholar] [CrossRef]

- Ye, W.; Shi, Y.; Zhou, Q.; Xie, M.; Wang, H.; Bou-Saïd, B.; Liu, W. Recent Advances in Self-Lubricating Metal Matrix Nanocomposites Reinforced by Carbonous Materials: A Review. Nano Mater. Sci. 2024, 6, 701–713. [Google Scholar] [CrossRef]

- Xiao, Y.; Zhou, L.; Zhao, H.; Wang, T.; Du, J.; Shen, M. The Evolution of Brake Disc Materials for Trains: A Review. Coatings 2025, 15, 628. [Google Scholar] [CrossRef]

- Lattanzi, L.; Etienne, A.; Li, Z.; Chandrashekar, G.T.; Gonapati, S.R.; Awe, S.A.; Jarfors, A.E.W. The Effect of Ni and Zr Additions on Hardness, Elastic Modulus and Wear Performance of Al-SiCp Composite. Tribol. Int. 2022, 169, 107478. [Google Scholar] [CrossRef]

- SAE International Recommended Practice SAE J2522—Inertia Dynamometer Disc and Drum Brake Effectiveness Test Procedure; Warrendale, PA, USA. 2023. Available online: https://www.sae.org/standards/content/j2522_202312/ (accessed on 7 May 2025).

- Storstein, T.; Kuylenstierna, C.; Kalmi, J. EP1165983B1—A Friction Member and a Method for Its Surface Treatment. 2002. Available online: https://patents.google.com/patent/EP1165983B1/en (accessed on 6 August 2025).

- ISO 6507-1:2023; Metallic materials-Vickers hardness test. Part 1: Test method. International Organization for Standardization: Geneva, Switzerland, 2023.

- Utama, B.P.; Budiono, H.S.; Surojo, E.; Muhayat, N. Frictional Characterization Of Grey Cast Iron Train Brake Block Using A Reduced Scale Dynamometer. Mek. Maj. Ilm. Mek. 2022, 21, 31–39. [Google Scholar] [CrossRef]

- Aleksendrić, D.; Barton, D.C.; Vasić, B. Prediction of Brake Friction Materials Recovery Performance Using Artificial Neural Networks. Tribol. Int. 2010, 43, 2092–2099. [Google Scholar] [CrossRef]

- Wu, J.; Li, Z.; Wen, G.; Gao, Z.; Li, Y.; Li, Y.; Xiao, P. Sepiolite: A New Component Suitable for 380 Km/h High-Speed Rail Brake Pads. Adv. Powder Mater. 2024, 3, 100199. [Google Scholar] [CrossRef]

- Shorowordi, K.M.; Haseeb, A.S.M.A.; Celis, J.P. Velocity Effects on the Wear, Friction and Tribochemistry of Aluminum MMC Sliding against Phenolic Brake Pad. Wear 2004, 256, 1176–1181. [Google Scholar] [CrossRef]

- Kumar, S.; Kumar, R.; Goyal, K.K.; Sharma, N. Development of Aluminium Based Hybrid MMC and Investigation of Tribological Properties. Mater. Today Proc. 2022, 63, 400–405. [Google Scholar] [CrossRef]

- Rajesh, A.M.; Kaleemulla, K.M.; Saleemsab, D.; Bharath, K.N. Generation of Mechanically Mixed Layer during Wear in Hybrid Aluminum MMC under As-Cast and Age Hardened Conditions. SN Appl. Sci. 2019, 1, 860. [Google Scholar] [CrossRef]

- Venkataraman, B.; Sundararajan, G. Correlation between the Characteristics of the Mechanically Mixed Layer and Wear Behaviour of Aluminium, Al-7075 Alloy and Al-MMCs. Wear 2000, 245, 22–38. [Google Scholar] [CrossRef]

- Rosenberger, M.R.; Schvezov, C.E.; Forlerer, E. Wear of Different Aluminum Matrix Composites under Conditions That Generate a Mechanically Mixed Layer. Wear 2005, 259, 590–601. [Google Scholar] [CrossRef]

- Lyu, Y.; Wahlström, J.; Tu, M.; Olofsson, U. A Friction, Wear and Emission Tribometer Study of Non-Asbestos Organic Pins Sliding against Alsic Mmc Discs. Tribol. Ind. 2018, 40, 274–282. [Google Scholar] [CrossRef]

- Blau, P.J. Compositions, Functions, and Testing of Friction Brake Materials and Their Additives; Oak Ridge National Laboratory: Oak Ridge, TN, USA, 2001. [Google Scholar]

- Jang, H.; Ko, K.; Kim, S.J.; Basch, R.H.; Fash, J.W. The Effect of Metal Fibers on the Friction Performance of Automotive Brake Friction Materials. Wear 2004, 256, 406–414. [Google Scholar] [CrossRef]

- Österle, W.; Prietzel, C.; Kloß, H.; Dmitriev, A.I. On the Role of Copper in Brake Friction Materials. Tribol. Int. 2010, 43, 2317–2326. [Google Scholar] [CrossRef]

- Stojanović, N.; Abdullah, O.I.; Schlattmann, J.; Grujić, I.; Glišović, J. Investigation of the Penetration and Temperature of the Friction Pair under Different Working Conditions. Tribol. Ind. 2020, 42, 288–298. [Google Scholar] [CrossRef]

- Day, A. Braking of Road Vehicles; Elsevier: Amsterdam, The Netherlands, 2014; pp. 1–472. [Google Scholar] [CrossRef]

- Nakanishi, H.; Kakihara, K.; Nakayama, A.; Murayama, T. Development of Aluminum Metal Matrix Composites (Al-MMC) Brake Rotor and Pad. JSAE Rev. 2002, 23, 365–370. [Google Scholar] [CrossRef]

- Kchaou, M.; Sellami, A.; Fajoui, J.; Kus, R.; Elleuch, R.; Jacquemin, F. Tribological Performance Characterization of Brake Friction Materials: What Test? What Coefficient of Friction? Proc. Inst. Mech. Eng. Part J. J. Eng. Tribol. 2019, 233, 214–226. [Google Scholar] [CrossRef]

- Haley, J.; Cheng, K. Investigation into Precision Engineering Design and Development of the Next-Generation Brake Discs Using Al/SiC Metal Matrix Composites. Nanotechnol. Precis. Eng. 2021, 4, 43003. [Google Scholar] [CrossRef]

- Gigan, G.; Norman, V.; Ahlström, J.; Vernersson, T. Thermomechanical Fatigue of Grey Cast Iron Brake Discs for Heavy Vehicles. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2019, 233, 453–467. [Google Scholar] [CrossRef]

- Wang, G.; Chen, X.; Li, Y.; Liu, Z. Effects of Inoculation on the Pearlitic Gray Cast Iron with High Thermal Conductivity and Tensile Strength. Materials 2018, 11, 1876. [Google Scholar] [CrossRef]

- Jacobson, S.; Hogmark, S. Tribofilms-On the Crucial Importance of Tribologically Induced Surface Modifications. In Recent Developments in Wear Prevention, Friction and Lubrication; Nikas, G.K., Ed.; Research Signpost: Kerala, India, 2010; ISBN 978-81-308-0377-7. [Google Scholar]

- Cai, R.; Zhang, J.; Nie, X.; Tjong, J.; Matthews, D.T.A. Wear Mechanism Evolution on Brake Discs for Reduced Wear and Particulate Emissions. Wear 2020, 452–453, 203283. [Google Scholar] [CrossRef]

- Rhee, S.K.; Jacko, M.G.; Tsang, P.H.S. The Role of Friction Film in Friction, Wear, and Noise of Automotive Brakes; SAE Technical Papers; SAE International: Warrendale, PA, USA, 1990. [Google Scholar] [CrossRef]

- Gurumoorthy, S.; Bhimchand, N.; Bourgeau, A.; Bhumireddy, Y. Effect of Surface Roughness on Tribological and NVH Behaviour of Brake System; SAE Technical Papers; SAE International: Warrendale, PA, USA, 2024. [Google Scholar] [CrossRef]

- Neis, P.D.; Ferreira, N.F.; Sukumaran, J.; De Baets, P.; Ando, M.; Matozo, L.; Masotti, D. Characterization of Surface Morphology and Its Correlation with Friction Performance of Brake Pads. Int. J. Sustain. Constr. Des. 2015, 6, 6. [Google Scholar] [CrossRef]

- SiCAlight-AC Floby. Available online: https://www.sicalight.com/ (accessed on 1 March 2024).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).