1. Introduction

In the overall balance of power losses within most industrial plants, as well as in various machines and devices, a significant proportion of losses is attributed to friction. Insufficient lubrication or a complete interruption of lubrication in different motion assemblies in machines and devices is directly responsible for up to 80% of all mechanical assembly failures [

1]. Modern lubrication technologies have a crucial role in reducing friction and wear, enhancing energy efficiency, and optimizing consumption in industrial processes and various machines. Under current conditions, the use of lubricants represents the most effective form of lubrication technology, functioning by forming a lubricating film between the contact surfaces of devices and assemblies, thereby preventing direct contact and significantly mitigating the adverse effects of friction [

2].

The research is based on ideas for reducing mechanical losses, specifically friction and material wear. The underlying hypothesis is that lubricants can contribute to uniform wear of the worm gearbox gear material and a significant reduction in the material’s coefficient of friction. The basis for planning the analyses is the result of already conducted tribological tests of the materials, as well as tests on the service life of the experimental worm gearbox under specific operating conditions that simulate real-life exploitation conditions [

3,

4].

Nanoparticles incorporated into nanofluids encompass a variety of materials, including metals such as copper (Cu) and gold (Au); oxide ceramics like aluminum oxide (Al

2O

3), copper oxide (CuO), titanium dioxide (TiO

2), and zinc oxide (ZnO); and carbide ceramics such as silicon carbide (SiC) and titanium carbide (TiC); as well as non-metallic substances like diamond, fullerene, and carbon nanotubes (CNTs). A thorough understanding of how nanoparticles influence the thermophysical properties of lubricants is crucial for their effective incorporation as additives. Several review articles examining the experimental determination of nanofluid viscosity highlight factors such as particle volume or mass fraction, temperature, shape, and size as key variables influencing viscosity [

5,

6,

7,

8]. Çelik et al. [

9] investigated the effect of nano-hexagonal boron nitride (hBN) particles on the friction and wear properties of AISI 4140 steel when hBN particles were used as an additive in engine oil. The experimental results indicated that hBN particles, as oil additives, had a significant impact on the friction behavior and wear process. Specifically, the use of hBN particles as an additive led to a 14.4% increase in the friction coefficient and a 65% reduction in the wear rate. Arsul et al. [

10] investigated the wear and friction properties using a four-ball tribometer, where they examined lubricants based on CuO nanoparticles (50 nm) suspended in liquid paraffin at concentrations of 0.2, 0.25, 2, and 3 wt.%. The lowest friction coefficient was achieved at a concentration of 3% modified CuO, with a value of 0.123, while the highest friction coefficient was recorded for 0.2% modified CuO, with a value of 0.158 for liquid paraffin suspensions with modified CuO. Both types of nanoparticle suspensions, at different concentrations, exhibited clearly distinguishable differences in friction coefficients. The results indicated that higher concentrations of CuO led to an improvement in tribological properties. Lijesh et al. [

11] established that the tribological properties of mineral base oils are significantly improved with the addition of multi-walled carbon nanotubes (MWCNT), particularly under high contact pressure conditions. However, the agglomeration of MWCNTs adversely affects performance, highlighting the essential need for the application of an appropriate surfactant to maintain the MWCNTs in a deagglomerated state. Vyavhare investigated the interaction between MWCNTs and ionic liquids with the aim of determining the optimal concentration of MWCNTs as an anti-wear additive in lithium-based grease. This research was conducted by analyzing the friction and wear results obtained through the application of the four-ball standard ASTM D2266 test. The results demonstrated that MWCNTs, at a concentration of 1 wt.%, led to a 25% reduction in wear and a 39% reduction in friction [

12].

The tribological properties of glycerol nanofluids have been extensively studied due to their potential applications in lubrication. Shi et al. [

13] conducted a comparative analysis between pure glycerol and a water-based glycerol solution with the addition of rapeseed oil salt, with the rapeseed oil solution serving as the reference lubricant. Their results indicated that the friction coefficient of pure glycerol is significantly lower compared to rapeseed oil, despite glycerol’s higher viscosity. This discrepancy in the friction coefficient cannot be entirely explained by viscosity alone, suggesting the presence of specific tribological characteristics inherent to glycerol.

The study further revealed that wear was lower in the case of pure glycerol compared to rapeseed oil, indicating that glycerol has a superior ability to reduce material wear during lubrication. Additionally, it was observed that the viscosity of pure glycerol decreases with increasing water content, which may affect lubrication performance under varying conditions. In comparison to pure glycerol, the glycerol solution exhibited a lower friction coefficient, and the wear was even further reduced, suggesting the potential advantage of using glycerol solutions in applications where friction reduction is crucial for extending the lifespan of components [

5].

Carbon nanotubes have applications in the industry, primarily within lubrication systems, including lubricating oils for worm gears. There are several key reasons for the application of CNTs in lubricants for worm gear systems, such as the following [

14,

15,

16]: (a) increased viscosity—adding CNTs can improve the viscosity of the oil, thereby reducing friction between the moving parts of the gearbox, and it can also contribute to better protection of the gears and extend their service life, as well as the lifespan of the gearbox itself [

17]; (b) improved wear resistance—CNTs can create strong yet flexible structures, which help reduce wear, which is particularly important for worm gears, which are exposed to high loads [

18]; (c) thermal stability—the use of lubricating oils with added CNTs can improve thermal stability, which is crucial for the operation of worm gears under high operating temperatures, which prevents overheating and, consequently, the degradation of the lubricating oil, allowing for optimal lubrication and extending oil change intervals, thereby reducing maintenance costs [

19]; (d) reduction in friction—the use of CNTs reduces the coefficient of friction, resulting in lower energy consumption and more efficient operation of the gearbox due to the reduction in mechanical losses associated with friction in the worm gearbox [

20].

The frequent application of CNTs—based additives in lubricants is substantiated by numerous studies highlighting their efficacy in reducing friction coefficients and surface wear, enhancing load-bearing capacity, and improving the thermal conductivity of base oils. Typically, CNT concentrations ranging from 0.1 to 0.5% by weight are employed; however, certain investigations have explored higher concentrations, such as 1% and 2%, to assess their impact on tribological performance. Moreover, research has delved into the effects of lower concentrations, below 0.1%, revealing that even minimal additions of CNTs can lead to increased oil viscosity and a reduction in friction coefficients. These findings suggest that optimizing CNT concentration is crucial for maximizing lubricant performance while avoiding potential issues like nanoparticle agglomeration [

3,

4].

The intrinsic physicochemical characteristics of nanoparticles, such as their size, geometry, and concentration within the base lubricant, constitute key parameters that significantly affect the dispersion stability of nanoparticulate systems. Due to their high specific surface area and surface energy, nanoparticles exhibit a pronounced tendency toward close intermolecular interactions, leading to the formation of agglomerates and a consequent reduction in dispersion stability [

21].

This phenomenon can be theoretically analyzed through the application of Stokes’ law, which describes the sedimentation velocity of spherical particles in a viscous fluid as a function of their size and density relative to the density of the fluid. In its formalized form, Stokes’ law demonstrates that the sedimentation velocity is directly proportional to the square of the particle radius, implying that a reduction in nanoparticle size leads to a decrease in sedimentation rate, thereby enhancing dispersion stability [

22]:

where

v denotes the sedimentation velocity,

r the radius of the CNT,

g the gravitational acceleration,

ρ1 the density of the nanoparticles,

ρ2 the density of the base fluid, and

η the viscosity of the base fluid. These parameters collectively determine the factors influencing sedimentation velocity. According to this law, the sedimentation velocity is directly proportional to the square of the CNT radius, which implies that a reduction in particle size results in slower sedimentation and improved dispersion characteristics.

Choi and colleagues experimentally demonstrated that smaller CNTs (7 nm) exhibit better dispersion stability compared to their larger counterparts (50 nm). However, the reduction in nanoparticle size also leads to an increase in surface energy, which may promote stronger aggregation tendencies. Therefore, it is essential to implement concurrent strategies that enable the use of small-diameter nanoparticles while simultaneously preventing their agglomeration [

22].

In addition to particle dimensions, the morphology of nanoparticles represents another significant factor influencing dispersion stability, with the aspect ratio (the ratio of length to diameter) being of critical importance. Nanoparticles with a high aspect ratio exhibit a greater tendency toward agglomeration, which results in reduced dispersion stability. Conversely, spherical nanoparticles, due to their low aspect ratio, demonstrate superior dispersion properties compared to rod- or tube-shaped particles.

This effect was experimentally confirmed in a study conducted by Xing and colleagues [

23], who demonstrated that fullerene C60 nanoparticles exhibit superior dispersion stability compared to carbon nanotubes (CNTs), a finding attributed directly to the lower aspect ratio of fullerenes [

24].

Current research in the field of rheological matrix compatibility for the selection of base oils with carbon nanotubes (CNTs) indicates significant progress in understanding their application in the field of tribology. The use of carbon nanotubes as additives in base oils has demonstrated potential for enhancing viscosity-rheological properties and reducing friction and wear [

25,

26]. According to research, the addition of CNTs to base oils enhances their mechanical properties and thermal stability, thereby contributing to improved resistance to oxidation and elevated temperatures. The rheological properties of such oils depend on the concentration, size, and dispersion of CNTs within the base oil, where higher concentrations typically lead to an increase in viscosity, but may also result in improved tribological performance [

27,

28].

The main factors influencing the dispersion of CNTs are van der Waals interactions, (π–π) stacking interactions between aromatic rings in organic compounds and nanotubes, and hydrophobic interactions. Although dispersion methods are similar for all types of nanotubes, certain differences have been observed between single-walled (SWCNT), double-walled (DWCNT), and multi-walled (MWCNT) carbon nanotubes. In the context of SWCNT dispersion, a range of functionality pathways is considered, including double covalent functionality of the nanotubes, as well as thermodynamic and kinetic approaches for stabilizing the resulting dispersion and preventing re-aggregation of CNTs [

29,

30].

Previous research on time-dependent zeta potential measurements for evaluating the dispersion stability of CNTs has primarily focused on analyzing the interactions between CNTs and the dispersion medium, as well as developing methodologies for monitoring their stability within lubricating environments. Zeta potential, as a key indicator of electrokinetic properties, plays a crucial role in understanding the dispersion behavior of CNTs in various solvents and materials. Studies have demonstrated that high absolute values of zeta potential ensure dispersion stability by inhibiting the coagulation and aggregation of nanotubes. In several studies, time-dependent measurements of zeta potential have been employed to monitor changes in the stability of CNT dispersion as a function of time, pH variations, and electrolyte concentration. The results indicate that CNT stabilization in solutions with high zeta potential values (above ±30 mV) ensures that the dispersion remains homogeneous over an extended period. In contrast, at lower zeta potential values, faster aggregation occurs, leading to a loss of dispersion stability [

31,

32].

The use of glycerol as a base in lubricants with the addition of carbon nanotubes (CNTs) represents an advanced, innovative, and environmentally sustainable approach to the lubrication of worm gear drives. This combination of base and additive offers significant advantages in terms of friction reduction, enhanced wear resistance, and decreased environmental impact. Glycerol is a naturally occurring polyhydric alcohol known for its biodegradability and non-toxicity, while CNTs can be synthesized using environmentally benign methods to minimize their ecological footprint. Such lubricants can significantly reduce pollution and health risks in the event of leakage or evaporation, which is particularly important in industrial and agricultural applications. Unlike conventional mineral oils, glycerol can be degraded by natural environmental processes, making it an ecologically preferable choice for lubricant formulation [

33,

34].

By adding water, the viscosity of glycerol can be effectively adjusted, and a reduction in pour point can also be achieved, allowing for use over a wide range of operating temperatures. Studies have shown that glycerol is capable of achieving super-lubrication at relative humidity levels of 40–50%, with a coefficient of friction below 0.01, due to the formation of hydration layers between contact surfaces [

35].

The study examined the impact of nanomaterials in the worm gearbox lubricant, and the testing conditions were made to closely resemble the real operating conditions of the gearbox.

The main contribution of this research lies in the experimentally validated potential for tribological optimization of worm gear systems through the application of lubricants containing CNTs. Through systematic laboratory investigations, monitoring key performance parameters such as efficiency, vibration, and noise, it has been established that an optimal concentration of CNTs in the lubricant leads to significant enhancement of the operational characteristics of worm gears. The findings indicate improved reliability and extended service life of the gear unit, along with a reduction in adverse effects on the working environment—factors of particular importance under conditions of heavy industrial operation. Furthermore, the study identifies a threshold for the optimal concentration of CNTs, beyond which performance deterioration occurs, thereby emphasizing the necessity for a precise engineering approach in the formulation of advanced lubricant systems.

The key novelty of this research lies in the comprehensive experimental validation of the tribological enhancement of worm gear performance through the application of lubricants containing CNT additives. Although the use of nanomaterials in lubricants has been previously explored within the scope of general tribological systems, this study is among the first to systematically analyze and quantitatively confirm the effects of CNT-enriched lubricants specifically on worm gears operating under industrial load conditions. The findings demonstrate that optimal concentrations of CNT additives lead to significant improvements in efficiency and reductions in noise and vibration levels. Moreover, the research identifies a critical threshold beyond which further increases in additive concentration result in performance degradation. This dual finding—performance improvement within the optimal range and deterioration beyond it—provides a novel and precise framework for the formulation of high-performance lubricants tailored for worm gear applications, representing a substantial contribution to the field of power transmission and tribological optimization.

2. Testing Conditions and Equipment

2.1. Materials

A worm gear power transmission unit was tested on the experimental bench, in which the worm was made of steel DIN 20MnCr5, while the worm wheel was manufactured from tin bronze CuSn14. Tin bronze exhibits good wear resistance and provides effective lubrication even under boundary lubrication conditions. For high transmission ratios of the worm gear drive (i ≥ 20), the efficiency of the transmission unit typically ranges between 70 and 85%, due to the sliding contact and the larger lead angle. In combination with the DIN 20MnCr5 worm, which features a case-hardened surface with a hardness of approximately 60 HRC, a tribological pair is formed (hard steel/soft bronze). As a result of the combined rolling and sliding motion of the worm over the worm wheel, intensified wear of the bronze gear occurs, a phenomenon often referred to as the “sacrificial wear of bronze”. Depending on the lubricant used, as well as the quality and concentration of the additives it contains, wear can be reduced by up to 50%. Bronze also has good vibration-damping properties, contributing to quieter operation. Compared to other materials such as gray cast iron and steel, bronze reduces impact forces and acoustic resonances. When paired with DIN 20MnCr5 steel, it results in a lower noise level, which is particularly advantageous for precision devices and power transmissions used in enclosed environments [

4]. The materials used for the fabrication of the worm gear transmission components, primarily steel and bronze castings, were procured from the company RAR DOO, Belgrade, Serbia. The manufacturing of the worm gear transmission was carried out by the company V.A.G. PRO-RED GROUP DOO, Belgrade, Serbia. A portion of the sealing elements was supplied by the company Termoplast, Belgrade, Serbia.

For the lubrication of the worm gear power transmission system, a glycerol-based lubricant was used, into which CNTs were added in mass fractions of 0.1%, 0.2%, 0.5%, 1%, and 2%. The additives were introduced into the lubricant by direct injection, without the application of any additional mechanical or thermal mixing methods. The lubricant samples were stored in dedicated plastic containers with lids and kept at room temperature, without exposure to fluctuations in laboratory microconditions. The CNT additives for the lubricant were obtained from the Faculty of Mechanical Engineering, University of Belgrade, in collaboration with several academic institutions in Vienna, Austria. The synthesis of the CNT-based lubricant additives was conducted within these scientific and educational institutions. No special treatment of the CNTs such as surface functionality or ultrasonic dispersion was applied prior to their addition to the base lubricant. The intention was to assess the benefits of CNT additive incorporation without the influence of additional dispersion-enhancing methods, acknowledging that such methods would likely improve the lubricant’s performance characteristics. Given that CNTs act as nanoscale bearings between contact surfaces, the aim was to determine the extent of their influence on parameters such as transmission efficiency, noise, and vibration of the worm gear. Improved dispersion of the additives and reduction in CNT agglomeration during the experiment were achieved through frequent and vigorous stirring and shaking of the lubricant prior to its application, as well as through running-in cycles of the worm gear before actual measurements. This ensured more uniform distribution of the lubricant and especially the CNT additives between the worm and worm wheel contact surfaces.

2.2. Methods and Characterizations

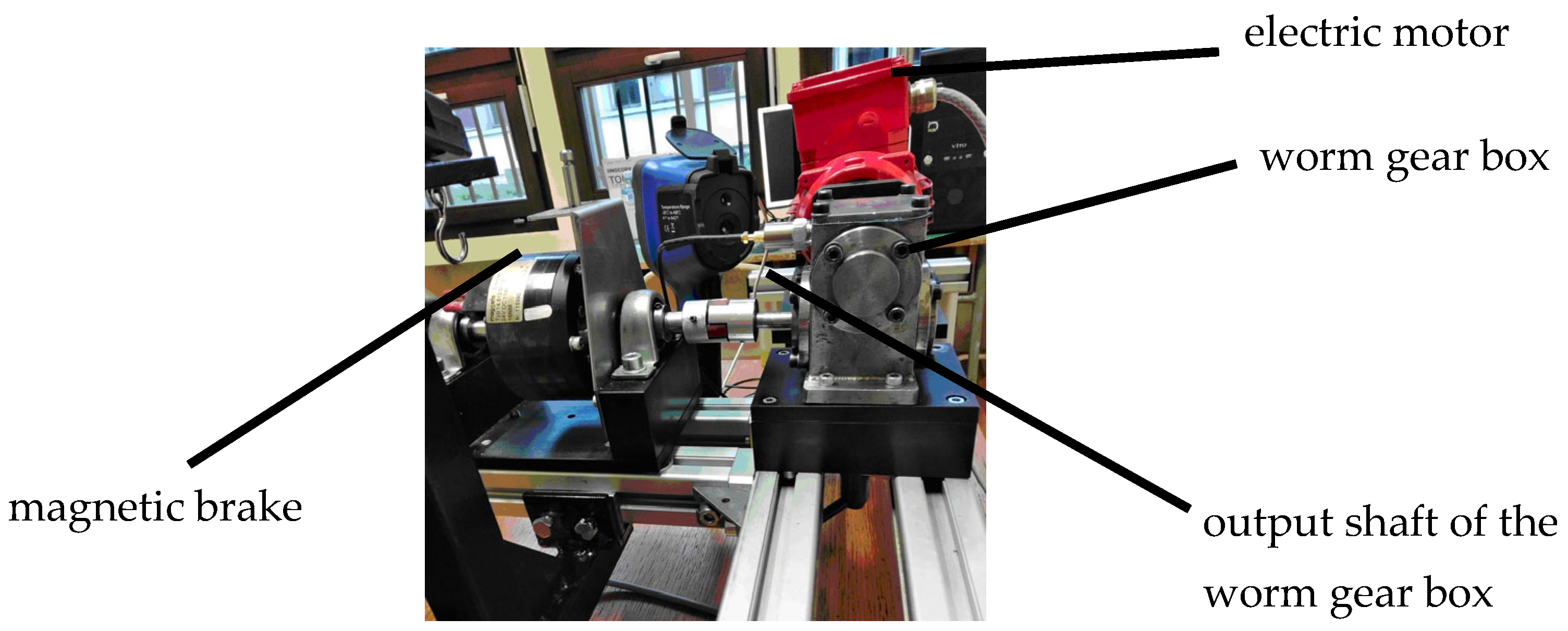

Experimental testing of the efficiency, noise and vibrations of the worm gearbox was carried out at the Center for Testing Mechanical Power Transmissions at the Faculty of Engineering, University of Kragujevac. A single-stage worm gearbox with an axial distance of 31 mm was used for the experiments. The gearbox was mounted on a device intended to test the efficiency of gear power transmissions.

Two cylindrical worm pairs with identical geometric characteristics were used for the experiment. The worm is a driving element positioned above the worm gear with a symmetric arrangement relative to the bearings. The worm is made of carbonized steel 20CrMo5, which has been heat-treated and ground. The worm gear is made of tin bronze CuSn14. Tin bronzes have a wide application in the production of worm gears due to their good resistance to corrosion and high hardness and strength, as well as their relatively high wear resistance. The housing of the worm gear power transmission is made of a welded structure of carbon steel (

Figure 1).

The worm gearbox is driven by an electric motor with a nominal power of 200 W, supported by two bearings on the device base, allowing it to rotate around its longitudinal axis. When the electric motor generates torque, it is subjected to a reaction torque of the same intensity but in the opposite direction. The input torque of the electric motor is determined using a dynamo-meter, which is positioned at the front of the housing with a lever of 50 mm in length. When the lever assumes a horizontal position, the balancing force value is read from the dynamo-meter by fixing the position using a screw for the given value. The dynamo-meter scale can measure forces up to 25 N.

The torque change on the worm gearbox’s output shaft is achieved using a magnetic brake. The brake is mounted on a two-part base, which allows it to be connected to various reducers. The brake base is fixed to the main frame of the device using clamping levers, allowing the brake to move along the frame’s guides and be easily connected to the gearbox’s output shaft. The relationship pattern of braking force, braking torque, and input power is read on the dynamo-meter, which is connected to a lever with a length of 100 mm. The adjustment of the electric motor’s rotation speed is carried out using the device’s control unit. A sensor for detecting the number of rotations is located on the output shaft of the electric motor, and its values are adjusted using a potentiometer on the control unit. The braking force values are also adjusted via the control unit by varying the current intensity within the range of 0.1–0.2 A, with a stepwise load change of 0.025 A.

The power on the input shaft of the gearbox,

P1, is determined according to the following formula:

where

T1 is input torque [Nm],

ω1 = π ×

n1 × 60

−1 is angular velocity [s

−1], and

n1 is input rotational speed [min

−1].

The input torque of the motor is determined as the product of the force measured on the dynamo-meter and the length of the lever when it is placed in a balanced (horizontal) position:

where

F1 is balancing force [N] and

ld is lever length on the dynamo-meter [mm].

The power on the output shaft of the worm gearbox,

P2, is lower than the input power due to the losses that occur during operation, and it is calculated according to the following formula:

where

T2 is output torque [Nm],

ω2 = π ×

n2 × 60

−1 is angular velocity [s

−1], and

n2 =

n1 ×

i−1 is rotational speed of the output shaft [min

−1].

The output torque is determined as the product of the braking force measured on the dynamo-meter and the length of the lever:

where

F2 is braking force [N] and

lk is lever length on the brake [mm].

The efficiency is determined as the ratio of useful power at the output shaft of the transmission to the input power; that is

A lubricant based on glycerol was used, to which MWCNTs were added to the appropriate wt.%. Pure glycerol without additives (0% additives) was used during the first measurement. Then, additives were added to the glycerol in weight fractions of 0.1, 0.2, 0.5, 1, and 2%. The worm gear transmission’s efficiency was tested at an input rotational speed of 2000 min−1. The load on the input shaft of the power transmission was adjusted accordingly. The load was expressed in terms of the electric current strength on the electromagnetic brake at the following values: 0.1, 0.125, 0.15, 0.175, and 0.2 A. Each load on the magnetic brake was mathematically expressed in terms of the torque on the output shaft of the worm gear power transmission.

For each load, vibration and force measurements were conducted on the output shaft of the power transmission in order to calculate the efficiency of the worm gear transmission using a mathematical formula within a time interval of 90 min. Before starting the measurements in the following 90 min cycle, a pause was performed to allow the tested transmission and laboratory equipment to cool down to approximately the same values as at the beginning of the first measurement. Vibration (acceleration) and force readings were taken every five minutes. After measurements were completed for each of the specified loads, expressed as the electric current strength, the rotational speed of the transmission’s input shaft was adjusted according to the specified values.

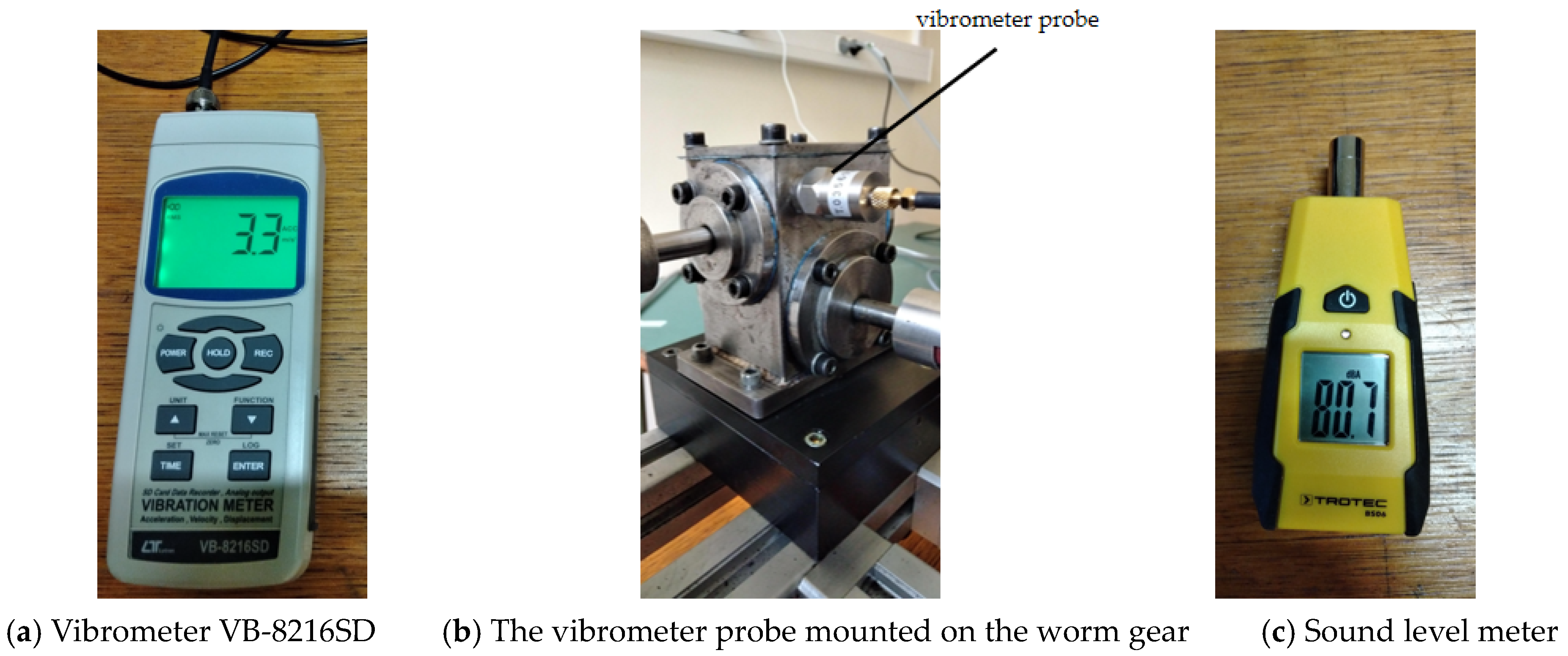

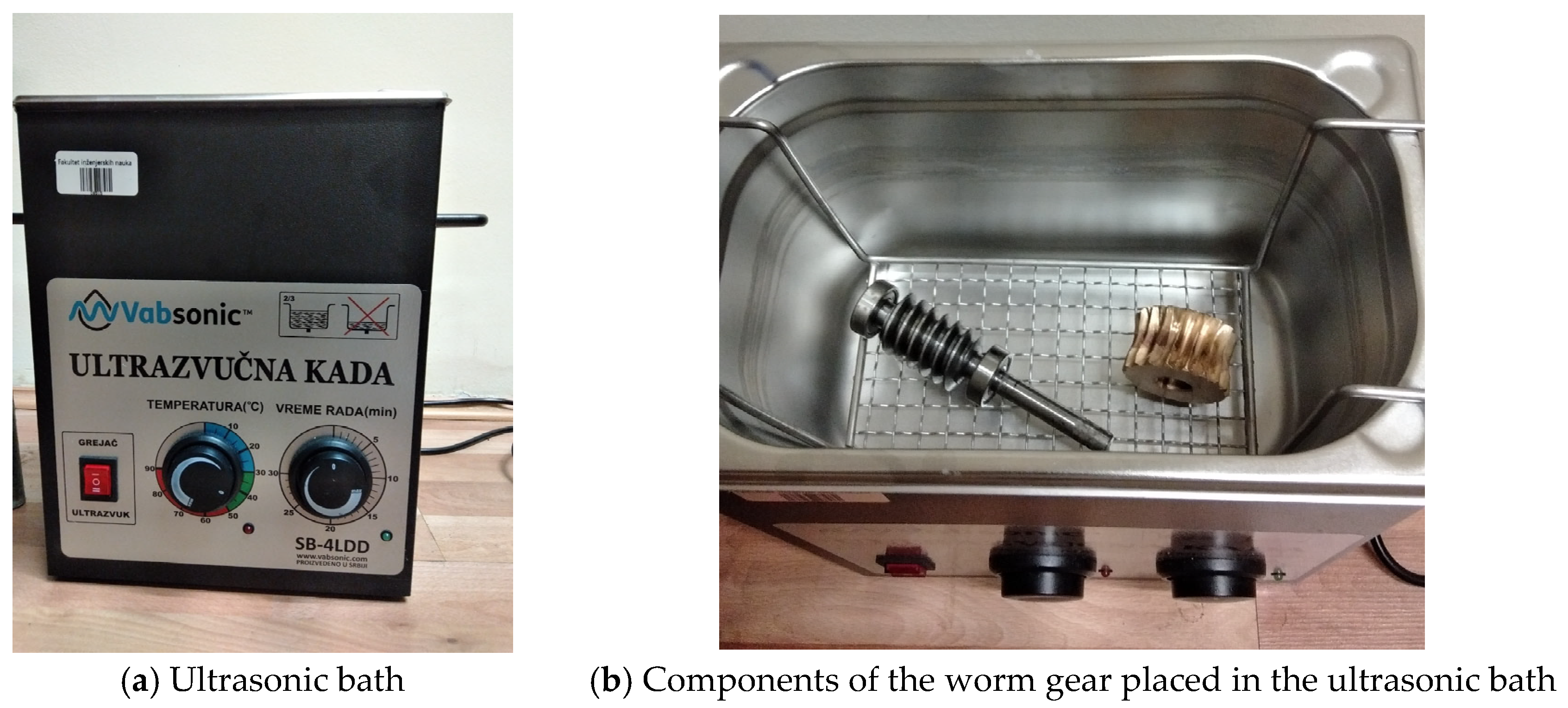

The change in the lubricant with different weight percentages of MWCNTs involved disassembling the power transmission, draining the used lubricant, and mechanically and ultrasonically cleaning the parts of the worm gear transmission to remove any residual traces of the previously used lubricant. At the beginning of the first test and during each subsequent test with a new lubricant, a break-in period of 60 min was conducted to ensure proper distribution of the new lubricant to all moving parts of the worm gear transmission. Vibration measurements were conducted on the worm gear transmission using the industrial vibration meter or vibrometer VB-8216SD (

Figure 2). In

Figure 2b, the position where the vibrometer probe was placed during the experiment for vibration measurement is shown, and this position was used throughout all measurement cycles. Vibration measurements were made by placing a magnetized sensor on the housing of the worm gear transmission without changing its position throughout the experiment. An industrial vibrometer VB-8216SD (Lutron Electronic Enterprise Co., Ltd., Taipei, Taiwan)was used to measure the vibrations of the worm power gearbox, with an acceleration measurement range of 0.5–199.9 mm/s

2, an accuracy of ±5%, and a resolution of 0.1 mm/s

2.

The noise of the worm gear drive was measured under the same conditions as those used for measuring efficiency and vibrations. The TROTEC BS06 (Trotec GmbH, Marchtrenk, Austria) noise meter was placed on a horizontal surface, on which the test equipment with the worm gear drive was also positioned, at an identical distance of 35 cm from the vertical axis of the tested worm gear drive.

In the experiment, MWCNTs with standard characteristics were used: an outer diameter of 10–30 nanometers, purity exceeding 99.5%, and synthesized MWCNTs. These specifications are consistent with those employed by other researchers, as documented in the relevant scientific literature [

36,

37,

38].

The lubricant with CNT additives was prepared by incorporating CNTs in the specified mass fractions, after which the mixture was stored in plastic bottles with caps at room temperature. Prior to each testing cycle, i.e., before replacing and refilling the lubricant with a different CNT concentration, mechanical mixing of the lubricant was performed. The bottle containing the lubricant was placed in a holder connected to equipment driven by an electric motor, which rotated it at a speed of up to 2500 min

−1 for a duration of 15 min. Subsequently, after the lubricant was added to the power transmission system, a running-in procedure was conducted at an input speed value of 1000 min

−1 for 45 min to ensure uniform distribution of the CNT additives between the contact surfaces. For each testing cycle, 45 mL of lubricant was added to the worm gear transmission system, which was sufficient to properly immerse the contact surfaces of the worm and worm wheel. After each testing cycle, the worm gear transmission system underwent thorough cleaning and washing. In addition, the worm and worm wheel were treated in an ultrasonic bath (Vabsonic, Niš, Serbia) (

Figure 3) to remove as much residual lubricant as possible from the previous test and to prepare the components and equipment for the next testing cycle.

These MWCNTs were selected for their exceptional mechanical and thermal properties, as well as their ability to enhance the tribological characteristics of lubricants. Their high specific surface area and purity contribute to better dispersion in base oils, which is crucial for achieving uniform and stable nanofluids.

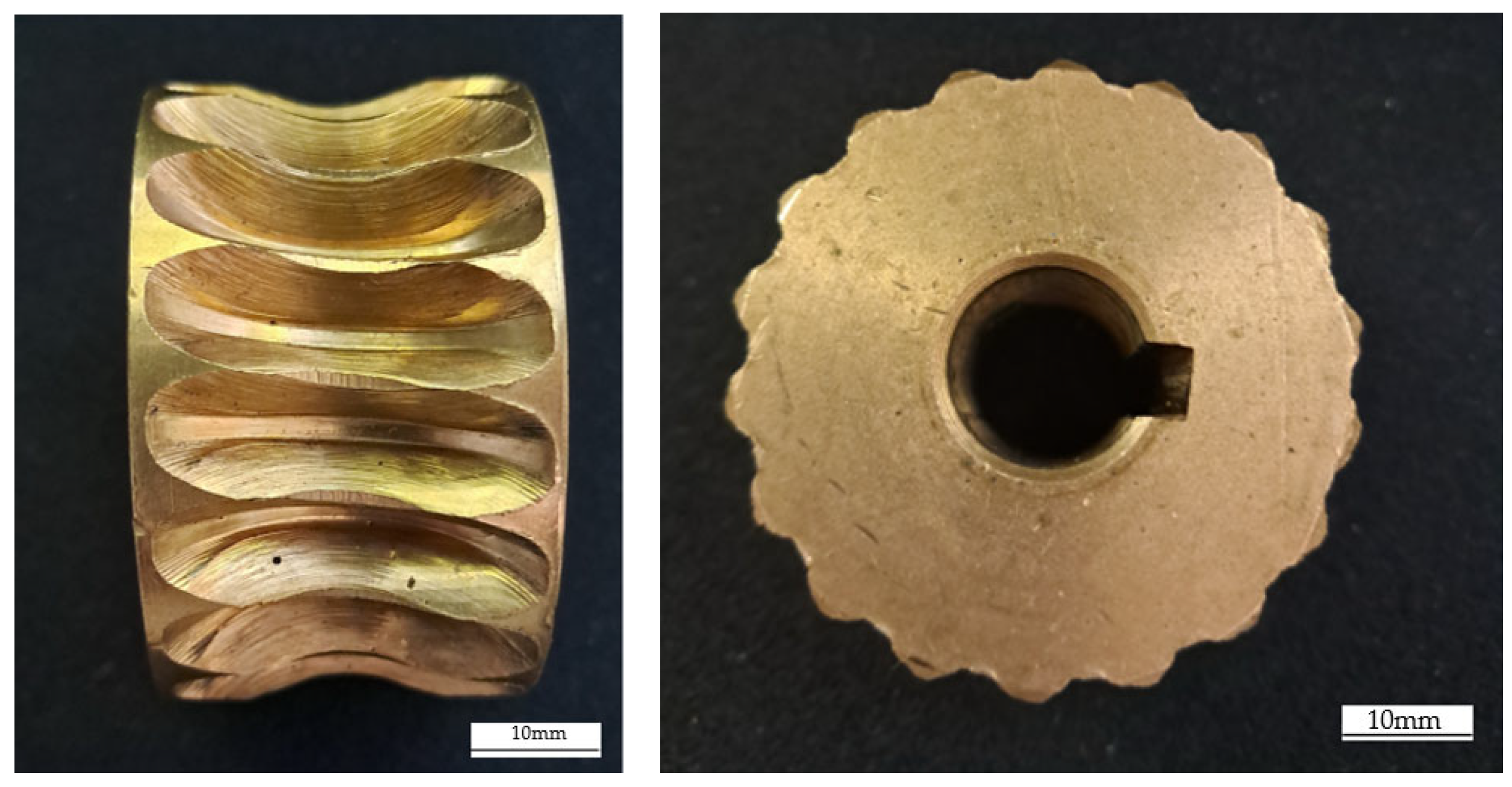

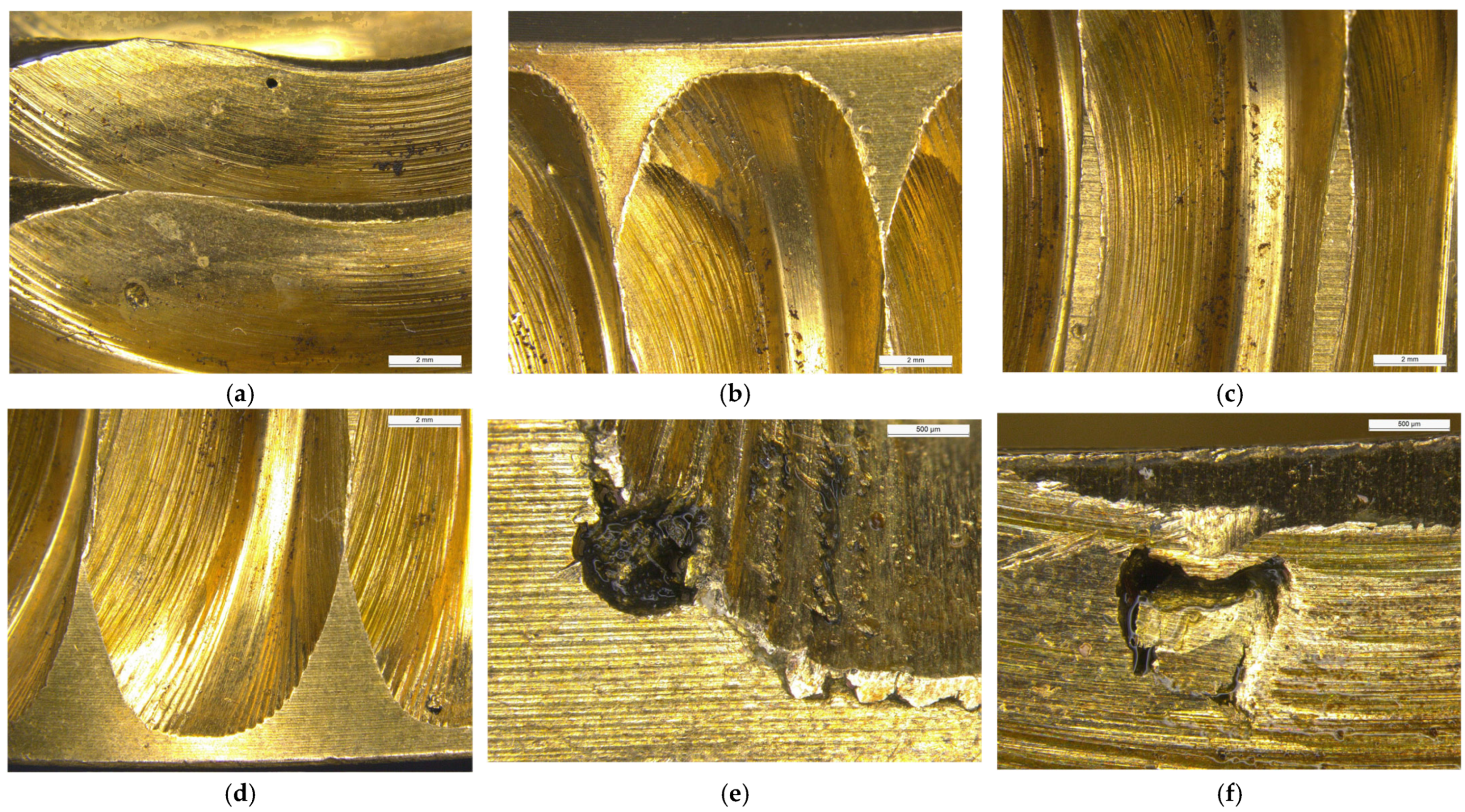

The surfaces of the tin-bronze worm gear were examined using scanning electron microscopy (SEM) following the completion of lubrication cycles. The microstructural analysis revealed characteristic wear phenomena, including abrasive wear, plastic deformation, and localized surface polishing. Compared to samples lubricated with pure glycerol, those treated with CNT-enhanced glycerol exhibited considerably reduced wear severity. The CNT additives demonstrated a nanoscale bearing effect, effectively reducing direct asperity contact under load. On certain surface areas, remnants of lubricant were visible as thin films within micro-cracks and indentations. Scanning electron microscopy also confirmed the presence of residual lubricant components, indicating that glycerol with CNT additives forms a stable boundary film. The observed surfaces displayed fewer defects and cracks, corroborating the additive’s role in mitigating wear under boundary lubrication conditions. Although some wear was still present in the contact zone, the overall surface degradation was significantly less than in samples without CNTs. These findings suggest that incorporating CNT additives into glycerol-based lubricants can enhance the tribological performance of worm gear transmissions and extend the operational lifetime of tin-bronze component [

39,

40]. The worn surfaces of the worm gear are shown in the images in

Figure 4 and

Figure 5.

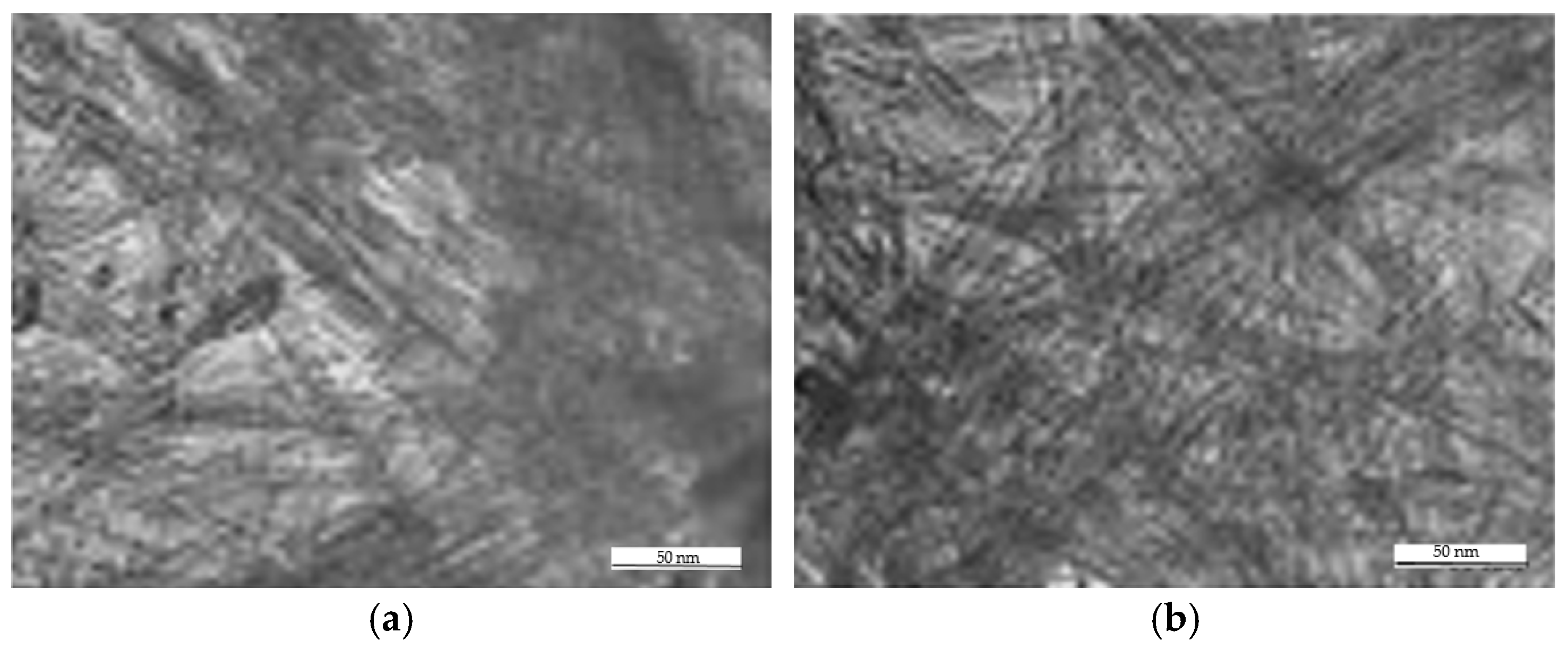

Figure 6 presents microscope images of CNT additives dispersed in the lubricant. It is important to emphasize that the experiment utilized MWCNT additives with a diameter of 50 nm and a length of 10–15 μm. The first image shows the lubricant with a CNT concentration of 0.2%, while the second image depicts the lubricant with a CNT concentration of 1%. The difference in CNT additive density within the lubricant is clearly observable.

The examination of the samples was performed using a LEICA M205 A stereomicroscope (Leica Microsystems GmbH, Wetzlar, Germany), equipped with a DFC 295 camera and LAS 4.3.1 software for data acquisition and processing, and was documented through photographic imaging. Below are the detailed technical specifications for the Leica M205 A microscope with the DFC 295 camera (Leica Microsystems GmbH, located in Wetzlar, Germany) and LAS 4.3.1 software, with specification as shown in

Table 1.

3. Results and Discussion

The calculation of the efficiency of the transmission was performed according to the defined testing plan with six lubricants of different weight fractions of MWCNTs (0, 0.1, 0.2, 0.5, 1, and 2) and five levels of load (torques T2 on the output shaft of the worm gear transmission). Mathematical formulas for calculating the efficiency of the worm gearbox are presented in Formulas (1) to (5), where the input variables in the formulas are obtained by measuring the balancing force F1 and breaking force F2, for selected rotation speeds and loads.

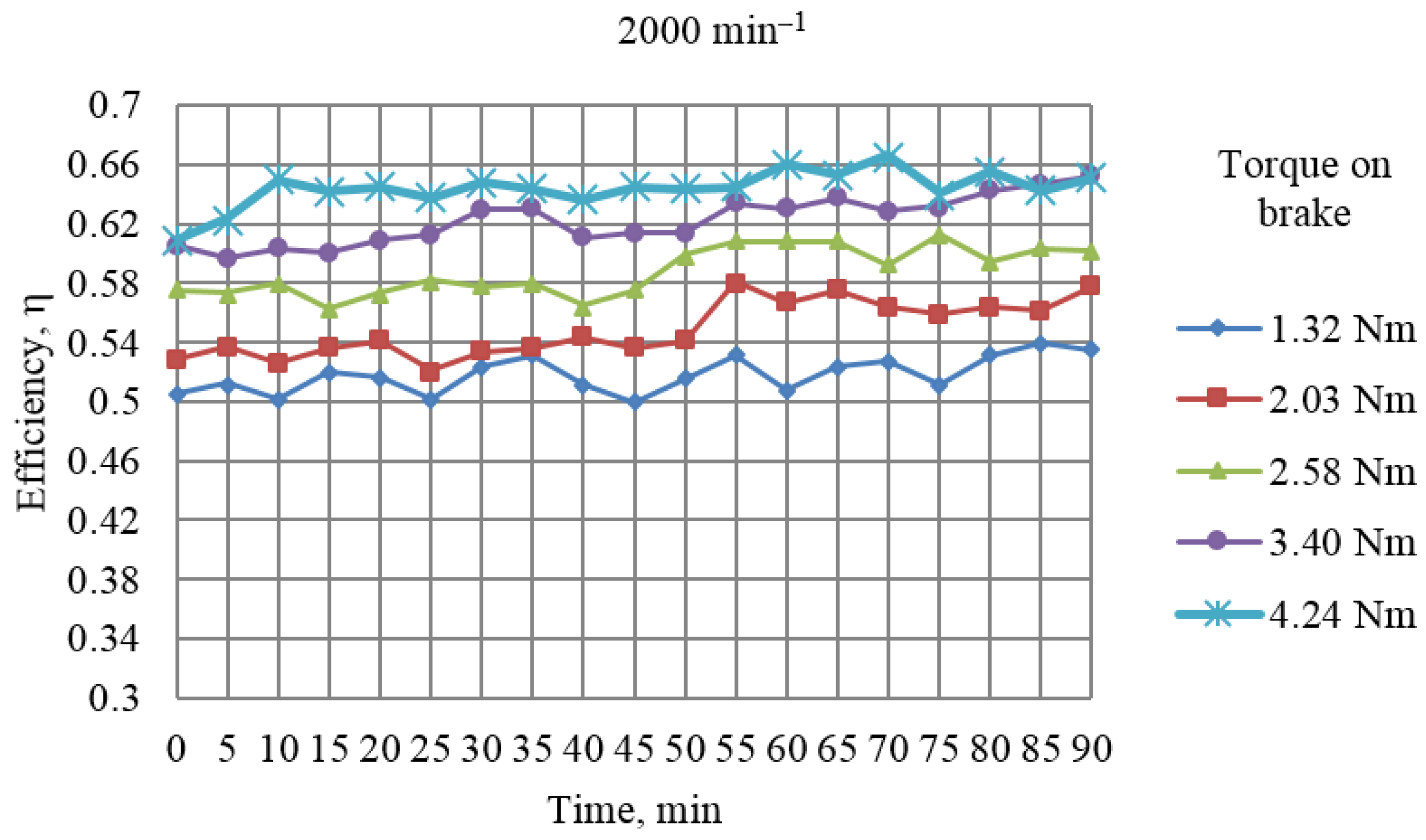

The test was carried out by changing the torque on the brake for one lubricant, for the same values of the input speed. The value of the current intensity changed from 1.32 Nm to 4.24 Nm every 90 min, which is a total of 7.5 h for one type of lubricant and one value of the input speed (

Figure 7). The diagram shows the change in efficiency during the time for the lubricant that demonstrated the best performance during testing (1% of additive MWCNT).

The diagram in

Figure 7 clearly illustrates that, as the load—specifically, the output torque—on the worm gearbox increases, there is a corresponding rise in its efficiency. This behavior is characteristic of worm gear systems, where higher loads often lead to improved efficiency due to enhanced meshing conditions and reduced relative sliding between gear teeth.

This diagram focuses on depicting the variation in efficiency over a 90 min experimental cycle, with measurements taken at five-minute intervals. While the figure specifically presents data for a lubricant containing 1% MWCNT additive, this concentration was chosen as a representative example because it demonstrated the most favorable performance in terms of both efficiency and vibration reduction during the experiments. The observed trends in this diagram are consistent across other experimental conditions, including different angular velocities, loads, and varying MWCNT additive concentrations in the lubricants.

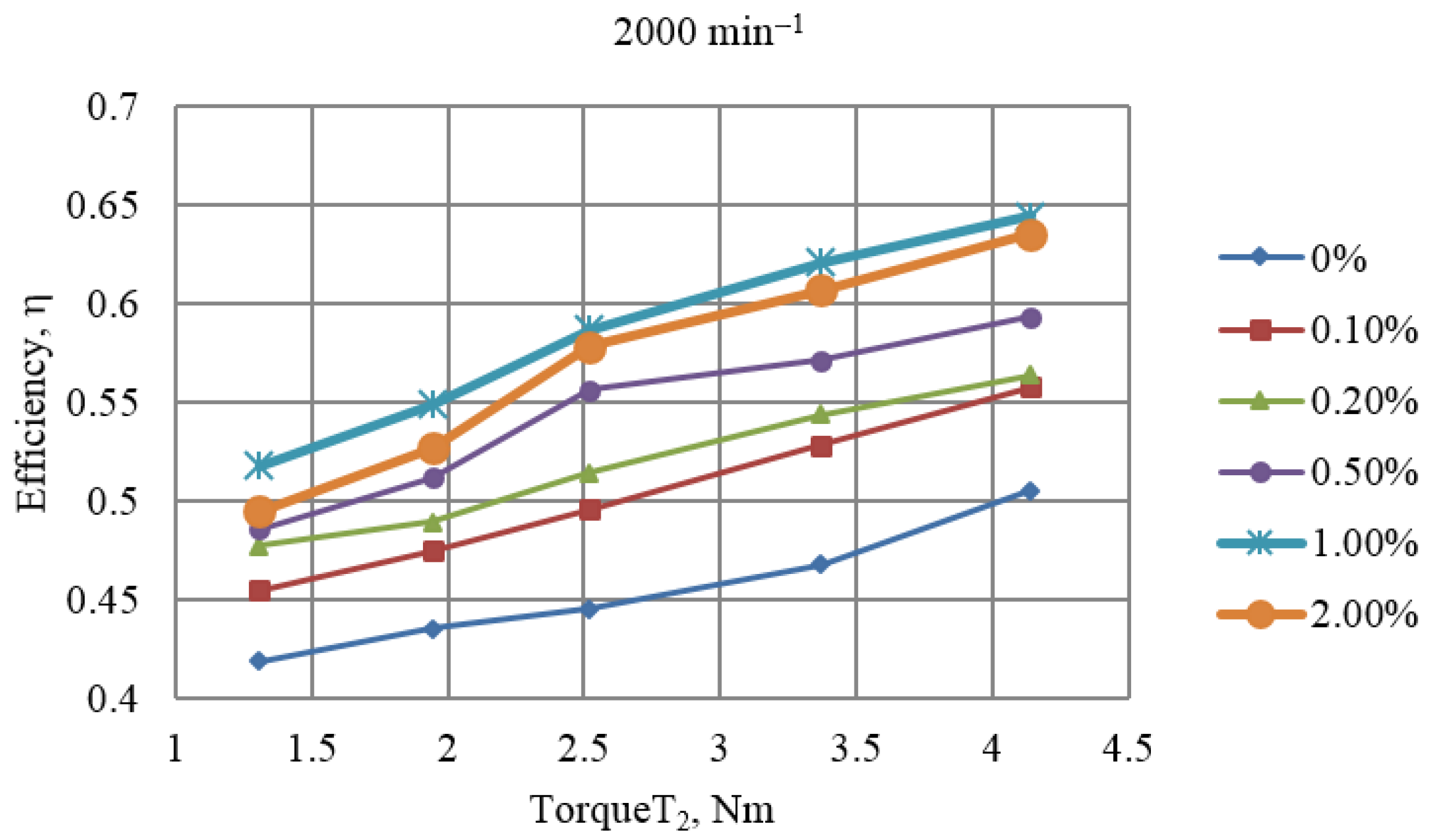

The diagram in

Figure 8 shows the change in efficiency depending on the lubricant applied in the worm gear transmission, i.e., the concentration of carbon nanotube additives in glycerol. It can be noticed that the efficiency increases with an increase in load, changing from 0.42 to 0.65. Noticeably, the efficiency when using lubricants without additives is extremely low, falling below the average threshold for worm power transmission systems. With the addition of additives, the efficiency increases sharply and then gradually increases as lubricants with a higher percentage of MWCNTs are used, where an average increase in the efficiency is observed from 0.47 with the use of lubricants without additives to 0.56 when using lubricants with 0.5% additive at the lowest angular speed. Applying a lubricant with 1 wt.% MWCNTs, a further increase in the efficiency is noticed, which at the same angular speed and load increases to 0.63. However, in the case of lubricant with 2 wt.% MWCNTs is used, a decrease in the efficiency is observed to approx. 0.60.

It can be concluded that the addition of 1% carbon nanotubes (CNTs) to the lubricant resulted in an increase in the efficiency of the worm gearbox by as much as 54.8% compared to the use of pure glycerol without additives.

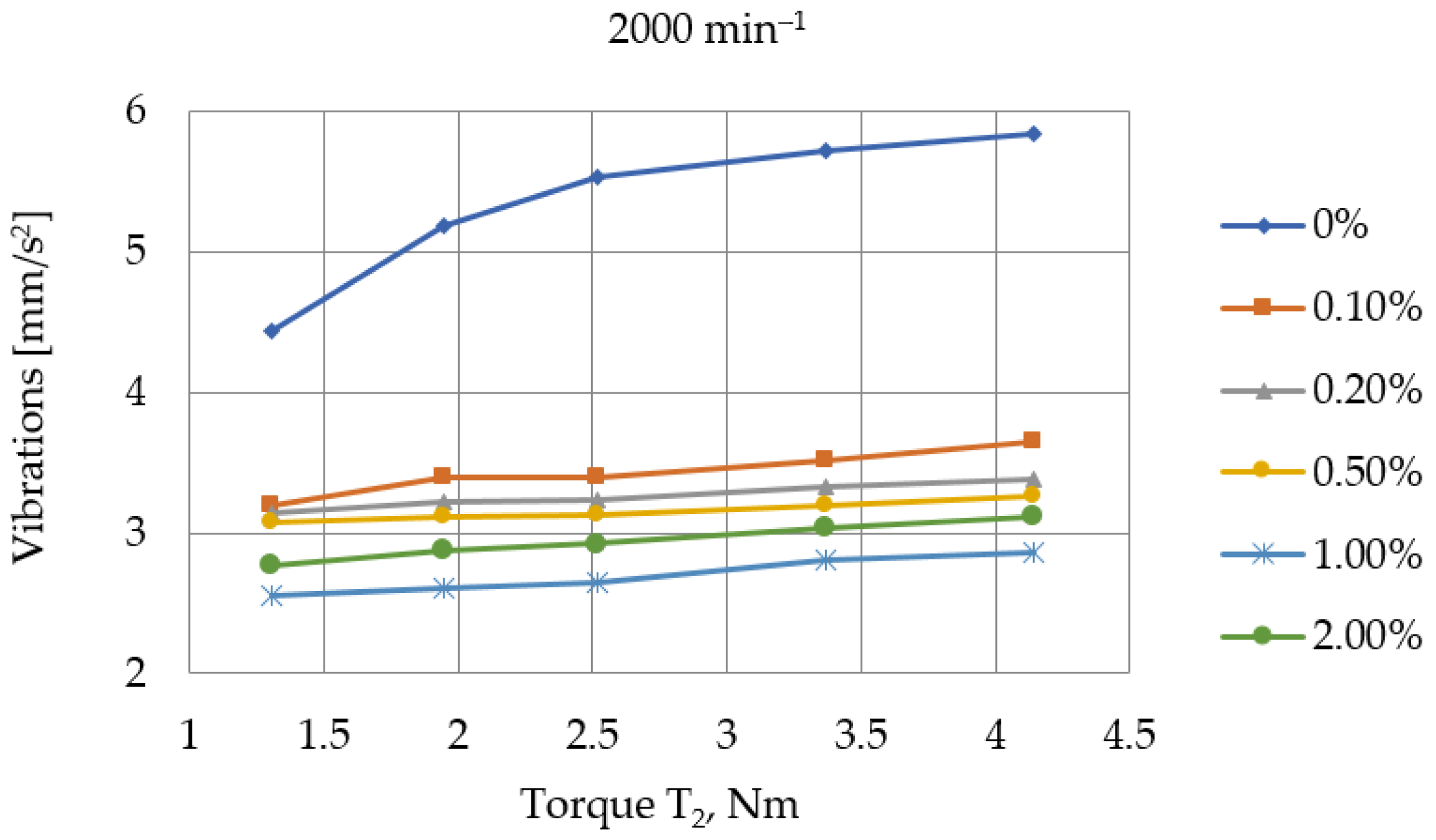

In further analysis, attention was paid to the vibrations of the worm power transmission. The diagram in

Figure 9 shows the change in vibrations with the lubricant used in the worm power transmission, i.e., with the concentration of MWCNTs in glycerol. With an increase in load, the intensity of vibrations in the power transmission decreases, changing from 5.83 to 2.56 mm/s

2. It could be noticed that vibrations in the case when the lubricant without additives is used are extremely high, up to 5.8 mm/s

2. By adding MWCNTs to the lubricant, vibrations decrease, first significantly (with lubricant containing 0.1 wt.% MWCNTs) and then uniformly (with lubricants containing a higher percentage of MWCNTs), so that with the use of 0.5 wt.% MWCNTs, vibrations decrease to 3.3 mm/s

2. Lubricant with 1 wt.% MWCNTs showed the most significant reduction in vibrations of the worm power transmission, which were as low as 2.8 mm/s

2. On the other hand, lubricant with 2 wt.% MWCNTs showed an increase in vibrations, which reached values of up to 3.1 mm/s

2. From the above, it can be observed that there was a reduction in vibration levels of up to 56.1%.

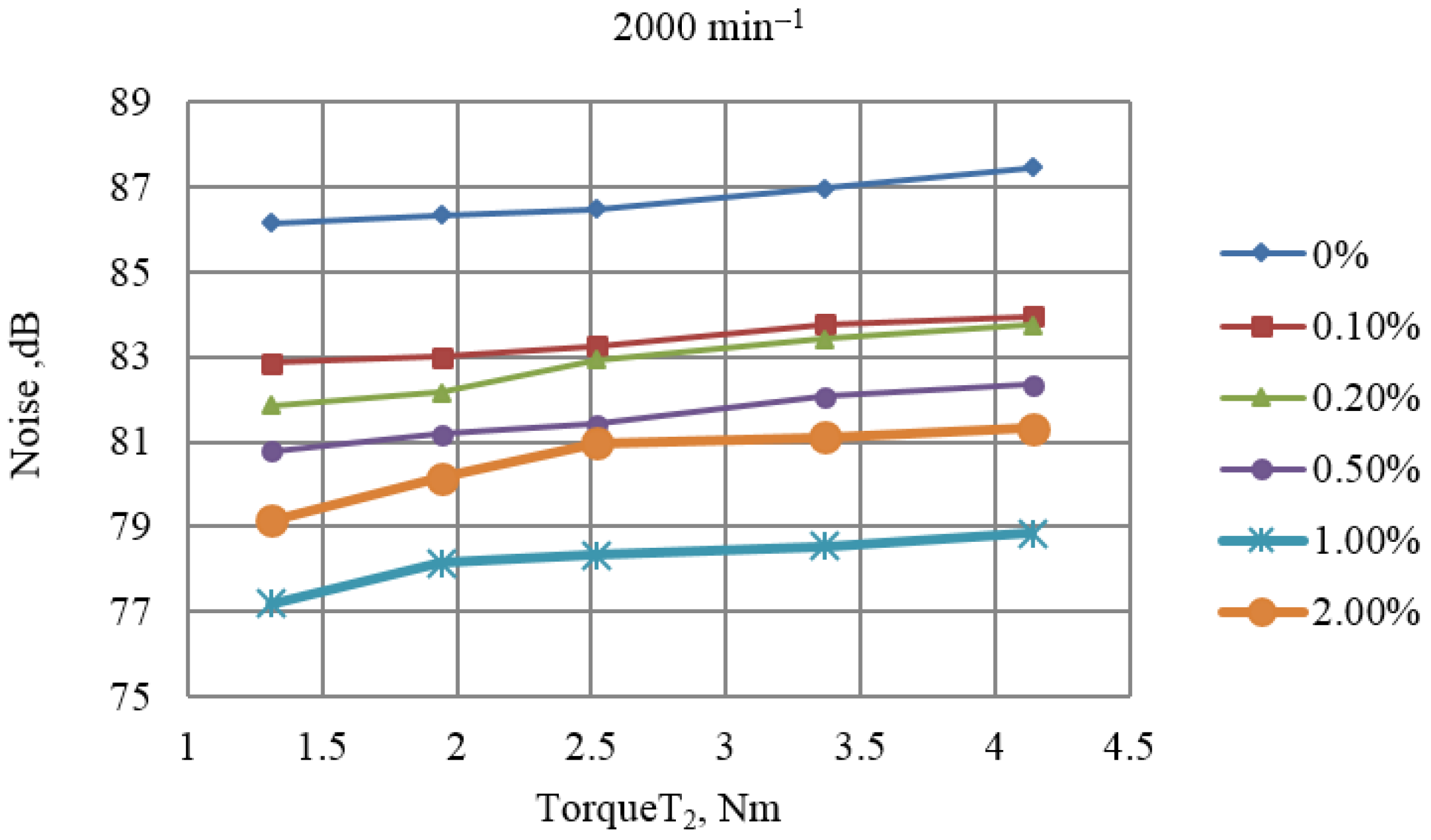

During the testing, noise emission was also measured for different concentrations of MWCNTs in the lubricant. The diagram in

Figure 10 shows the change in noise depending on the lubricant applied in the worm gear transmission, i.e., the concentration of carbon nanotube additives in glycerol. With an increase in load, the intensity of noise in the power transmission decreases, changing from 87.5 to 77.2 dB.

It could be noticed that noise in the case when the lubricant without additives is used is extremely high, up to 87.5 dB. By adding MWCNTs to the lubricant, noise decreases, first significantly (with lubricant containing 0.1 wt.% MWCNTs) and then uniformly (according to a similar pattern as in vibration measurement), so that with the use of 0.5 wt.% MWCNTs, noise decreases to 80.8 dB. Lubricant with 1 wt.% MWCNTs showed the most significant reduction in noise of the worm power transmission, which was as low as 77.2 dB. However, lubricant with 2 wt.% MWCNTs showed an increase in noise, which reached values of up to 81.3 dB. An analysis of the obtained results indicates that the use of lubricant containing 1% carbon nanotubes (CNTs), compared to the additive-free lubricant, resulted in an 11.8% reduction in the vibration level of the worm gear box.

Analysis of all the results shows that using a lubricant with 1% MWCNT additive provides optimal outcomes for each of the three measured values.

Based on scientific findings [

3,

5], increasing the concentration of multi-walled carbon nanotube (MWCNT) additives beyond an optimal level (over 1% MWCNT) can lead to nanoparticle agglomeration, resulting in reduced lubricant efficiency. Increasing the concentration of the MWCNT additive to 2% leads to increased agglomeration and sedimentation of carbon nanotubes, resulting in higher frictional resistance and a reduction in the lubricating ability of the lubricant.

Due to their three key mechanisms of action—protective film formation, rolling effect, and surface irregularity filling—carbon nanotube (CNT) additives lead to a reduction in noise and vibration and increasing of efficiency of mechanical systems, as has been confirmed in previous studies.

In the experimental study by Bhaumik et al. [

41], using industrial mineral oil with the addition of 0.5% CNT, it was found that the coefficient of friction decreased by 37%, while the efficiency of the worm gearbox increased by 8% under constant load and speed. The results of this study confirmed the established mechanisms of CNT additive action. Consequently, in our experiment of the worm gear transmission using a lubricant containing 1% CNT, an increase in efficiency of 54.8% was achieved in comparison to glycerol-based lubricant without additives.

Nabhan et al. [

42] demonstrated in their work that the addition of 1% CNT additive to lubricant resulted in a reduction in vibration acceleration by up to 28%, and a decrease in noise levels by 11%, indicating that the nanolubricant has a superior effect, with the 1% CNT concentration yielding the most effective results compared to lower concentrations. Similar findings were reported in another study by Nabhan [

43], in which the introduction of CNTs at a concentration of 0.5% into lithium grease led to a 32% reduction in vibration amplitudes in bearing assemblies.

The positive effects of CNT additives were also confirmed in the present study, where a vibration reduction of up to 56.1% and noise reduction of 11.8% were measured when using a glycerol-based lubricant containing 1% CNTs, compared to a lubricant based solely on pure glycerol.

These improvements can be attributed to the fact that CNT particles come into direct contact with rotating elements, fill surface asperities, and, through their rolling behavior, form a separation film that reduces friction between the contact surfaces of bearings, gears, and other moving components.

Due to the occurrence of CNT particle sedimentation on the internal surfaces of the worm gear drive, the lubricant was shaken in its container prior to each filling with a formulation containing a different CNT concentration. Furthermore, before each measurement cycle, a running-in phase was conducted at an input angular velocity of 500 min−1. This procedure served multiple purposes: reaching the operating temperature, allowing the mating surfaces of the worm gear elements to adapt, and ensuring the uniform distribution of CNT particles across the surfaces of moving components. Through this process, the particles could fill contact interfaces, surface asperities, pores, and irregularities, while simultaneously mitigating the inevitable phenomenon of particle sedimentation. Nevertheless, it should be emphasized that the issue of CNT particle sedimentation was not specifically addressed or systematically investigated in this study.

4. Conclusions

The main disadvantage of worm gear transmissions is their relatively low efficiency, resulting from mechanical losses due to sliding friction between the meshing flanks of the gear teeth. Therefore, it is of great importance to study the impact of the type and characteristics of the fluid used for lubrication, as it can decisively affect the performance of the power transmission.

The paper shows the positive effects of MWCNTs addition into the glycerol under conditions of varying operating regimes, i.e., their addition led to a significant increase in efficiency while simultaneously reducing vibration levels. The best effects are achieved by adding 1 wt.% MWCNTs, meaning that up to this limit, the characteristics of the power transmission continuously improve. However, above this value, specifically for a 2 wt.% MWCNTs, the measured parameters begin to deteriorate.

The results of experimental investigations indicate significant improvements in gearbox performance due to the addition of carbon nanotubes (CNTs) to the lubricant. The efficiency of the gearbox increased from an initial value of 0.42 to 0.65, representing a relative improvement of 54%. Simultaneously, the vibration levels of the worm gear were reduced from 5.83 to 2.56 mm/s2, corresponding to a 56% decrease, while the noise level dropped from 87.5 to 77.2 dB, marking a reduction of 12%. These enhancements were achieved by increasing the CNT concentration in the lubricant up to a maximum of 1%. However, exceeding this experimentally defined threshold resulted in a decline in gearbox efficiency, accompanied by an increase in both noise and vibration levels.

Considering that the efficiency, vibration and noise levels of the worm power transmission are determined and measured for precisely defined values of load, shaft rotational speed, and the percentage of additives, future research would benefit from the application of an appropriate mathematical method or simulation model that could determine the desired parameters for other operating conditions, work regimes, and different types of lubricants.

Future research could also be directed toward evaluating the stability of CNT dispersions over specific time intervals, with particular emphasis on assessing the sedimentation tendency of CNTs in lubricants, as a function of their concentration. Comparative analysis of different CNT loadings would enable the identification of an optimal lubricant formulation.