Quantifying Dynamic Oil Immersion in a Spiral Bevel Gear via Image Processing for Improved Churning Loss Prediction

Abstract

1. Introduction

2. Churning Drag Torque Formulas

3. Numerical Simulation and Experimental Verification

3.1. Basic Equations

3.2. Geometry and CFD Model

3.3. Splash Lubrication Test Description

4. Analysis and Verification

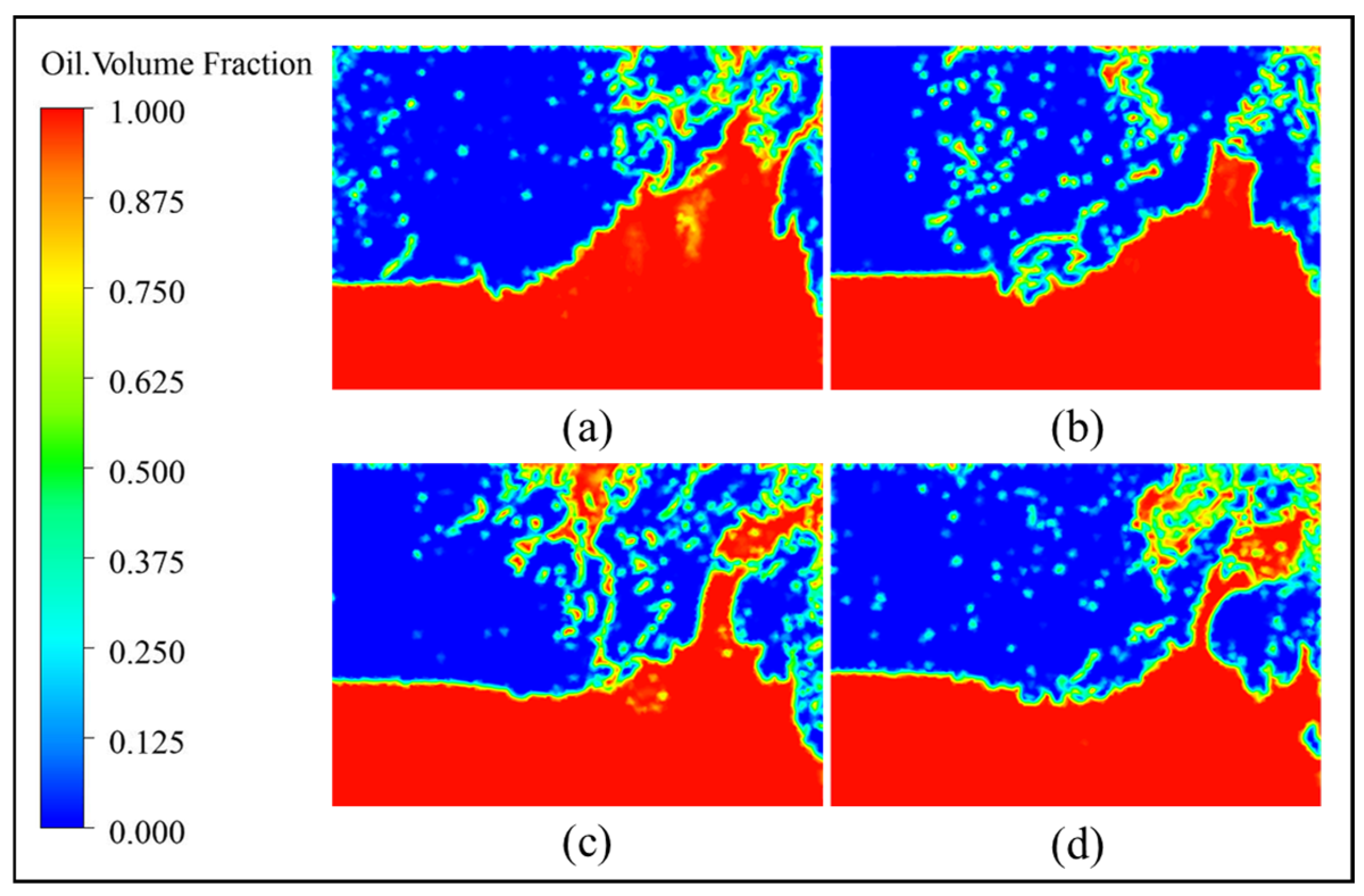

4.1. Flow Field Distribution

4.2. Practical Immersion Depth

4.3. No-Load Resisting Torque

5. Conclusions

- A significant difference in practical oil immersion depth was observed between the front and rear-end faces of the spiral bevel gear. This disparity was more pronounced at lower initial oil levels, whereas at higher oil levels, the immersion depths of both end faces tended to converge.

- The application of image processing technology facilitated the quantitative analysis of oil distribution around the spiral bevel gear. Statistical evaluation of the oil volume fraction at the front and rear-end faces showed good agreement between the measured average immersion depth and the theoretically calculated values, thereby validating the effectiveness of this approach in assessing churning behavior.

- Experimental data collected under various initial oil levels validated the accuracy of the developed gas–liquid two-phase flow model and the computational fluid dynamics (CFD) simulations. The results demonstrate that the proposed theoretical model effectively predicts the churning losses of spiral bevel gears.

- Experimental measurements demonstrated that as the oil level increases, the churning contributions from both end faces become more balanced. A quantitative correlation between practical immersion depth and churning power loss was established, offering valuable insights for optimizing the lubrication design of spiral bevel gears.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| Teeth width, mm | |

| Dimensionless churning resistance torque coefficient on the face | |

| Froude number | |

| Acceleration of gravity, m/s | |

| Oil-immersed depth, mm | |

| Churning power losses, W | |

| Outside radius, mm | |

| Outer radius of the bevel gear, mm | |

| Drag torque, Nm | |

| Circumferential torque, Nm | |

| Axial torque on the toe/heel faces, Nm | |

| Torque between the teeth, Nm | |

| Oil viscosity, Pa s | |

| Oil density, kg/m3 | |

| Dimensionless oil level | |

| Dynamic oil level | |

| Static oil level |

References

- Liu, H.; Liu, H.; Zhu, C.; Parker, R.G. Effects of lubrication on gear performance: A review. Mech. Mach. Theory 2020, 145, 103701. [Google Scholar] [CrossRef]

- Dai, Y.; Yang, C.; Zhang, R.; Zhu, X. A unified analytical model to calculate no-load power losses for the coexistence of windage-churning phenomenon for spiral bevel gears. Eur. Phys. J. Plus 2024, 139, 255. [Google Scholar] [CrossRef]

- Concli, F.; Gorla, C.; Rosa, F.; Conrado, E. Effect of the static pressure on the power dissipation of gearboxes. Lubr. Sci. 2019, 31, 347–355. [Google Scholar] [CrossRef]

- Pau, T.-D.; Korka, Z.-I.; Nedelcu, D.; Hrimiuc, C. Assessing the Meshing for Windage Power Loss Simulations of an Orthogonal Face Gear. Machines 2025, 13, 341. [Google Scholar] [CrossRef]

- Arisawa, H.; Nishimura, M.; Imai, H.; Goi, T. Computational fluid dynamics simulations and experiments for reduction of oil churning loss and windage loss in aeroengine transmission gears. J. Eng. Gas Turbines Power 2014, 136, 092604. [Google Scholar] [CrossRef]

- Mastrone, M.; Concli, F. Power losses of spiral bevel gears: An analysis based on computational fluid dynamics. Front. Mech. Eng. 2021, 7, 655266. [Google Scholar] [CrossRef]

- Legrady, B.; Taesch, M.; Tschirschnitz, G.; Mieth, C.F. Prediction of churning losses in an industrial gear box with spiral bevel gears using the smoothed particle hydrodynamic method. Forsch. Im Ingenieurwesen 2021, 86, 379–388. [Google Scholar] [CrossRef]

- Liu, H.; Arfaoui, G.; Stanic, M.; Montigny, L.; Jurkschat, T.; Lohner, T.; Stahl, K. Numerical modelling of oil distribution and churning gear power losses of gearboxes by smoothed particle hydrodynamics. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2019, 233, 74–86. [Google Scholar] [CrossRef]

- Atencio, B.; Yao, H.; Chernoray, V. Experiments and Lattice-Boltzmann simulation of flow in a vertically aligned gearbox. J. Tribol. 2023, 145, 114103. [Google Scholar] [CrossRef]

- Gong, R.; Gong, Q.; Che, H.; Zhang, Z. Numerical investigation on churning loss torque and oil distribution of reducer based on lattice boltzmann method. Tribol. Trans. 2021, 64, 968–979. [Google Scholar] [CrossRef]

- Seetharaman, S.; Kahraman, A. Load-independent spin power losses of a spur gear pair: Model formulation. J. Tribol. 2009, 131, 022201. [Google Scholar] [CrossRef]

- Seetharaman, S.; Kahraman, A.; Moorhead, M.D.; Petry-Johnson, T.T. Oil churning power losses of a gear pair: Experiments and model validation. J. Tribol. 2009, 131, 022202. [Google Scholar] [CrossRef]

- Shore, J.F.; Kolekar, A.S.; Ren, N.; Kadiric, A. An investigation into the influence of viscosity on gear churning losses by considering the effective immersion depth. Tribol. Trans. 2023, 66, 906–919. [Google Scholar] [CrossRef]

- Arisawa, H.; Tanaka, M.; Hashimoto, H.; Goi, T.; Banno, T.; Akahori, H. Fluid dynamic loss model with wide applicability for aeroengine transmission gears. J. Eng. Gas Turbines Power 2024, 146, 051001. [Google Scholar] [CrossRef]

- Laruelle, S.; Fossier, C.; Changenet, C.; Ville, F.; Koechlin, S. Experimental investigations and analysis on churning losses of splash lubricated spiral bevel gears. Mech. Ind. 2017, 18, 412. [Google Scholar] [CrossRef]

- Quiban, R.; Changenet, C.; Marchesse, Y.; Ville, F.; Belmonte, J. Churning losses of spiral bevel gears at high rotational speed. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2020, 234, 172–182. [Google Scholar] [CrossRef]

- Dai, Y.; Ma, F.; Zhu, X.; Ouyang, B. Development of an analytical model to estimate the churning power losses of a spiral bevel gear. Tribol. Int. 2020, 151, 106536. [Google Scholar] [CrossRef]

- Zhu, X.; Dai, Y. Development of an analytical model to predict the churning power losses of an orthogonal face gear. Eng. Sci. Technol. Int. J. 2023, 41, 101383. [Google Scholar] [CrossRef]

- Jia, F.; Wang, B.; Fu, Y. A novel prediction model for churning power loss of spur gear. Lubr. Sci. 2024, 36, 645–655. [Google Scholar] [CrossRef]

- Qian, X.; Yin, S.; Sun, T.; Yang, K.; Chen, S.; Chu, Y.; Zhang, Y.; Yu, X.; Liu, C. Churning loss modeling for shroud gears driven by physics-data hybrids. Mech. Syst. Signal Process. 2025, 229, 112532. [Google Scholar] [CrossRef]

- Teamah, A.M.; Hamed, M.S. Numerical investigation of thermal losses within an internal gear train submerged in a multiphase flow and enclosed in a rotating casing. Int. J. Thermofluids 2022, 15, 100188. [Google Scholar] [CrossRef]

- Hu, X.; Wang, A.; Li, P.; Wang, J. Influence of dynamic attitudes on oil supply for bearings and churning power losses in a splash lubricated spiral bevel gearbox. Tribol. Int. 2021, 159, 106951. [Google Scholar] [CrossRef]

- Quiban, R.; Changenet, C.; Marchesse, Y.; Ville, F. Experimental investigations about the power loss transition between churning and windage for spur gears. J. Tribol. 2021, 143, 024501. [Google Scholar] [CrossRef]

- Handschuh, M.; Guner, A.; Kahraman, A. An experimental investigation of windage and oil churning power losses of gears and discs. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2023, 237, 163–177. [Google Scholar] [CrossRef]

- Dai, Y.; Yang, C.; Liu, H.; Zhu, X. Analytical and Experimental Investigation of Windage–Churning Behavior in Spur, Bevel, and Face Gears. Appl. Sci. 2024, 14, 7603. [Google Scholar] [CrossRef]

- Qian, X.; Zhang, S.; Yang, K.; Yan, W.; Chen, S.; Zhang, Y.; Liu, C. Strategy of directional oil transport for splash lubrication systems. Int. J. Mech. Sci. 2024, 269, 109059. [Google Scholar] [CrossRef]

- Lu, F.; Wang, M.; Bao, H.; Huang, W.; Zhu, R. Churning power loss of the intermediate gearbox in a helicopter under splash lubrication. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2022, 236, 49–58. [Google Scholar] [CrossRef]

- Lu, F.; Cao, X.; Bao, H.; Zhu, R. Nonlinear tribo-dynamic model of helicopter mid-reducer system under light loss of lubrication. J. Mech. Sci. Technol. 2022, 36, 5327–5339. [Google Scholar] [CrossRef]

- Chen, S.; Matsumoto, S. Influence of relative position of gears and casing wall shape of gear box on churning loss under splash lubrication condition-some new ideas. Tribol. Trans. 2016, 59, 993–1004. [Google Scholar] [CrossRef]

- Hildebrand, L.; Liu, H.; Paschold, C.; Lohner, T.; Stahl, K. Classification of numerical, experimental, and analytical approaches for gearbox oil flow and no-load gear power loss. Eng. Sci. Technol. Int. J. 2024, 53, 101661. [Google Scholar] [CrossRef]

- Polly, J.; Talbot, D.; Kahraman, A.; Singh, A.; Xu, H. An experimental investigation of churning power losses of a gearbox. J. Tribol. 2018, 140, 031102. [Google Scholar] [CrossRef]

- Neurouth, A.; Changenet, C.; Ville, F.; Octrue, M.; Tinguy, E. Experimental investigations to use splash lubrication for high-speed gears. J. Tribol. 2017, 139, 061104. [Google Scholar] [CrossRef]

| Parameters | Value |

|---|---|

| Outside radius (/mm) | 79.15 |

| Outer transverse module (/mm) | 3.8 |

| Number of teeth (Z/–) | 41 |

| Teeth width (/mm) | 27 |

| Face angle (/°) | 72.4 |

| Spiral angle (/°) | 35 |

| Normal pressure angle (/°) | 20 |

| Handedness (-) | left |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dai, Y.; Huang, X.; Zhong, J.; Yang, C.; Zhu, X. Quantifying Dynamic Oil Immersion in a Spiral Bevel Gear via Image Processing for Improved Churning Loss Prediction. Lubricants 2025, 13, 223. https://doi.org/10.3390/lubricants13050223

Dai Y, Huang X, Zhong J, Yang C, Zhu X. Quantifying Dynamic Oil Immersion in a Spiral Bevel Gear via Image Processing for Improved Churning Loss Prediction. Lubricants. 2025; 13(5):223. https://doi.org/10.3390/lubricants13050223

Chicago/Turabian StyleDai, Yu, Xin Huang, Jianfeng Zhong, Caihua Yang, and Xiang Zhu. 2025. "Quantifying Dynamic Oil Immersion in a Spiral Bevel Gear via Image Processing for Improved Churning Loss Prediction" Lubricants 13, no. 5: 223. https://doi.org/10.3390/lubricants13050223

APA StyleDai, Y., Huang, X., Zhong, J., Yang, C., & Zhu, X. (2025). Quantifying Dynamic Oil Immersion in a Spiral Bevel Gear via Image Processing for Improved Churning Loss Prediction. Lubricants, 13(5), 223. https://doi.org/10.3390/lubricants13050223