Enhanced Friction and Wear Properties of TiN/MoS2 Composite Coating on the Surface of Plasma Nitrided Ti6Al4V Alloy

Abstract

1. Introduction

2. Materials and Methods

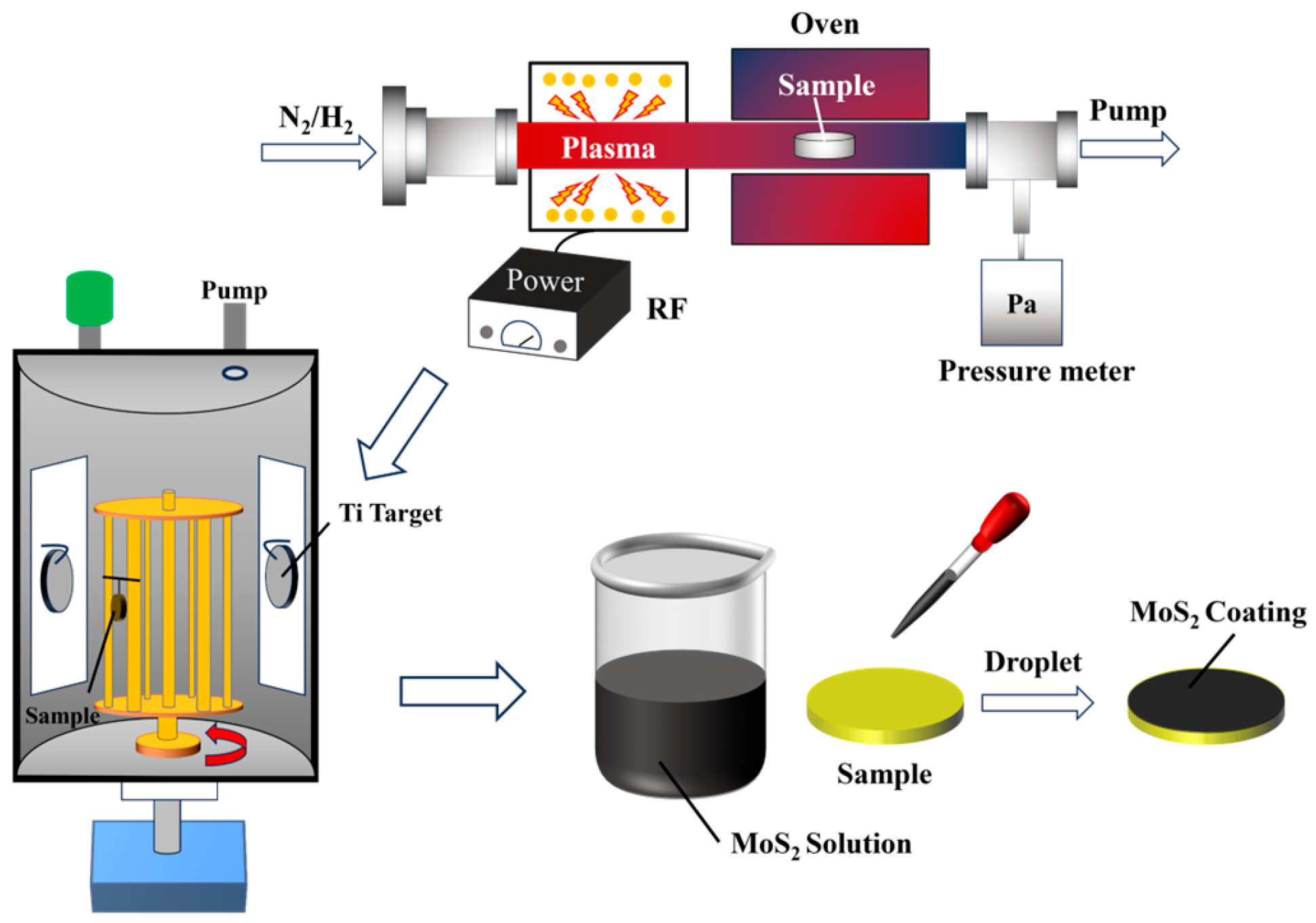

2.1. Pre-Treatments of TC4 Substrate and Coating Preparation

2.2. Structure Characterization

2.3. Mechanical and Tribological Properties

3. Results and Discussion

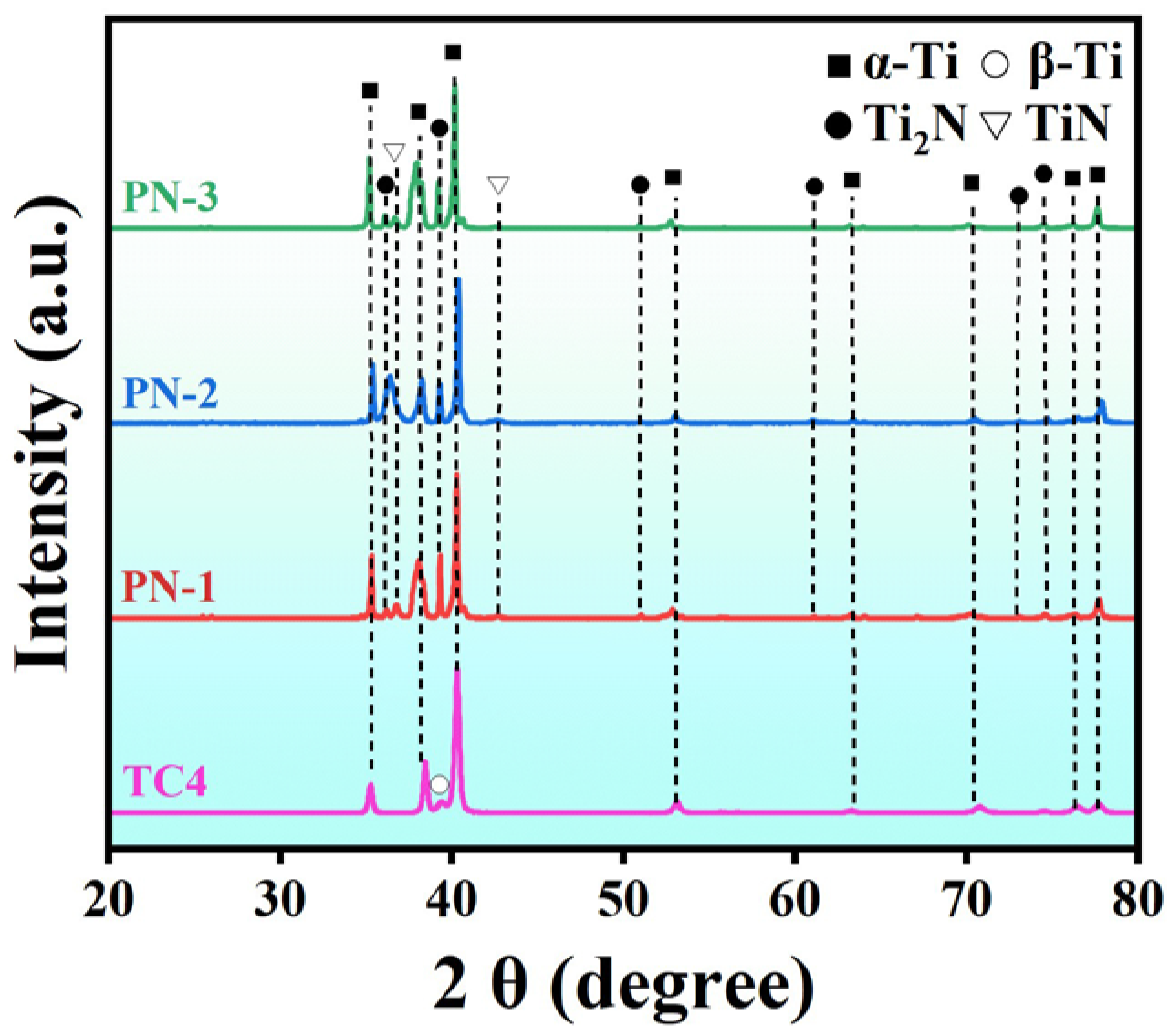

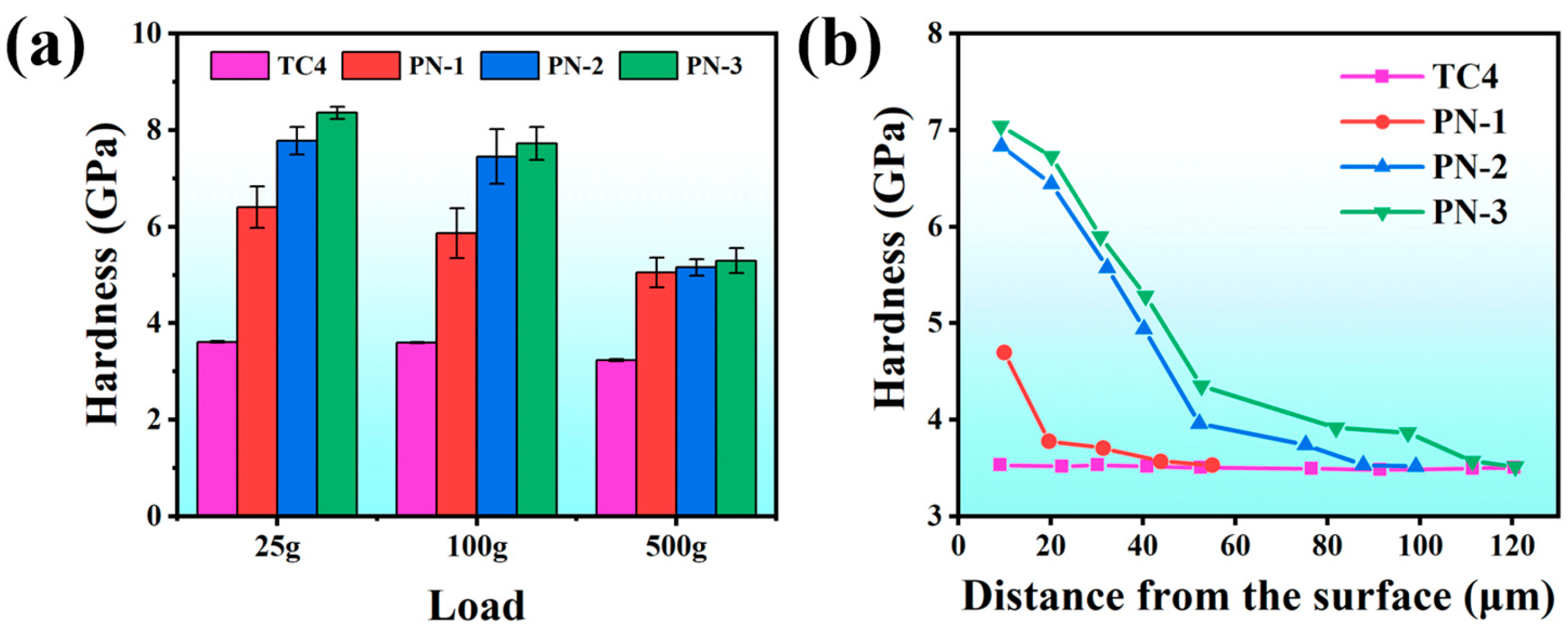

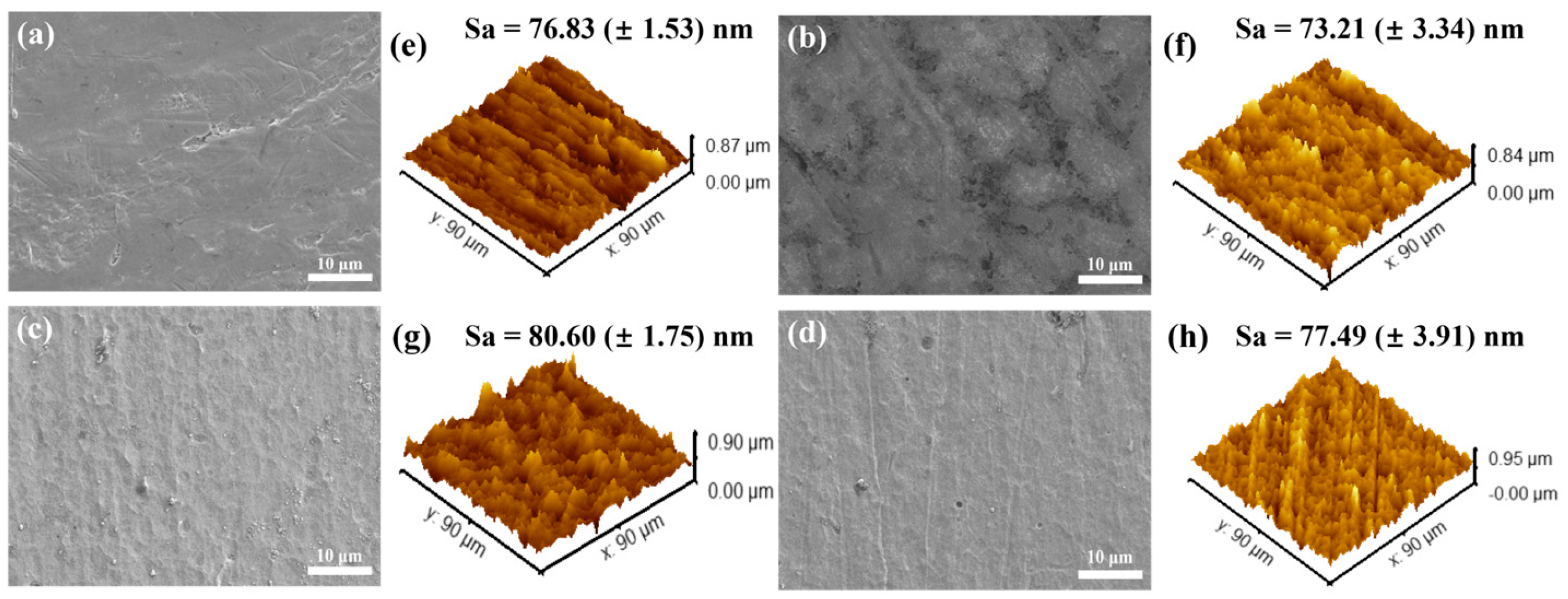

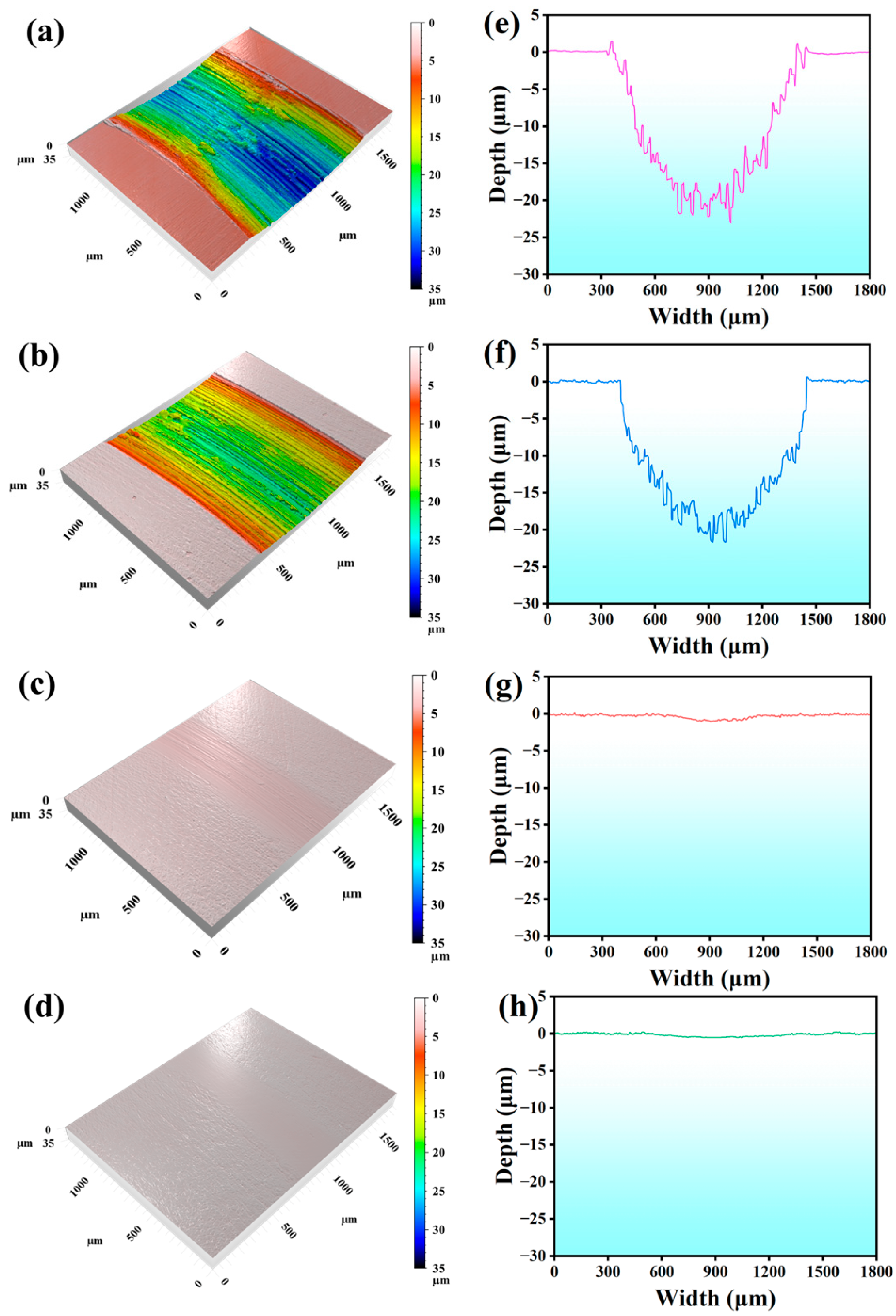

3.1. Plasma Nitriding

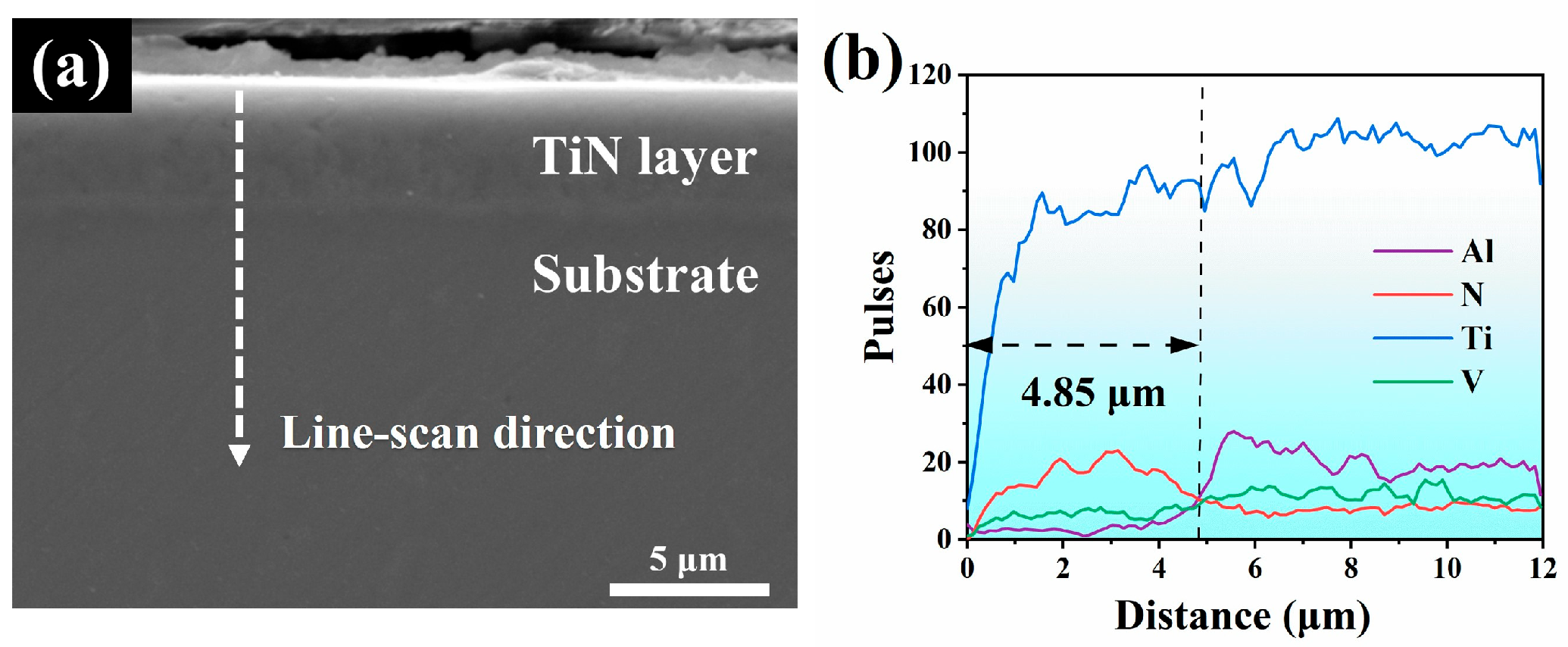

3.2. Multi-Arc Ion Plating Deposition of TiN

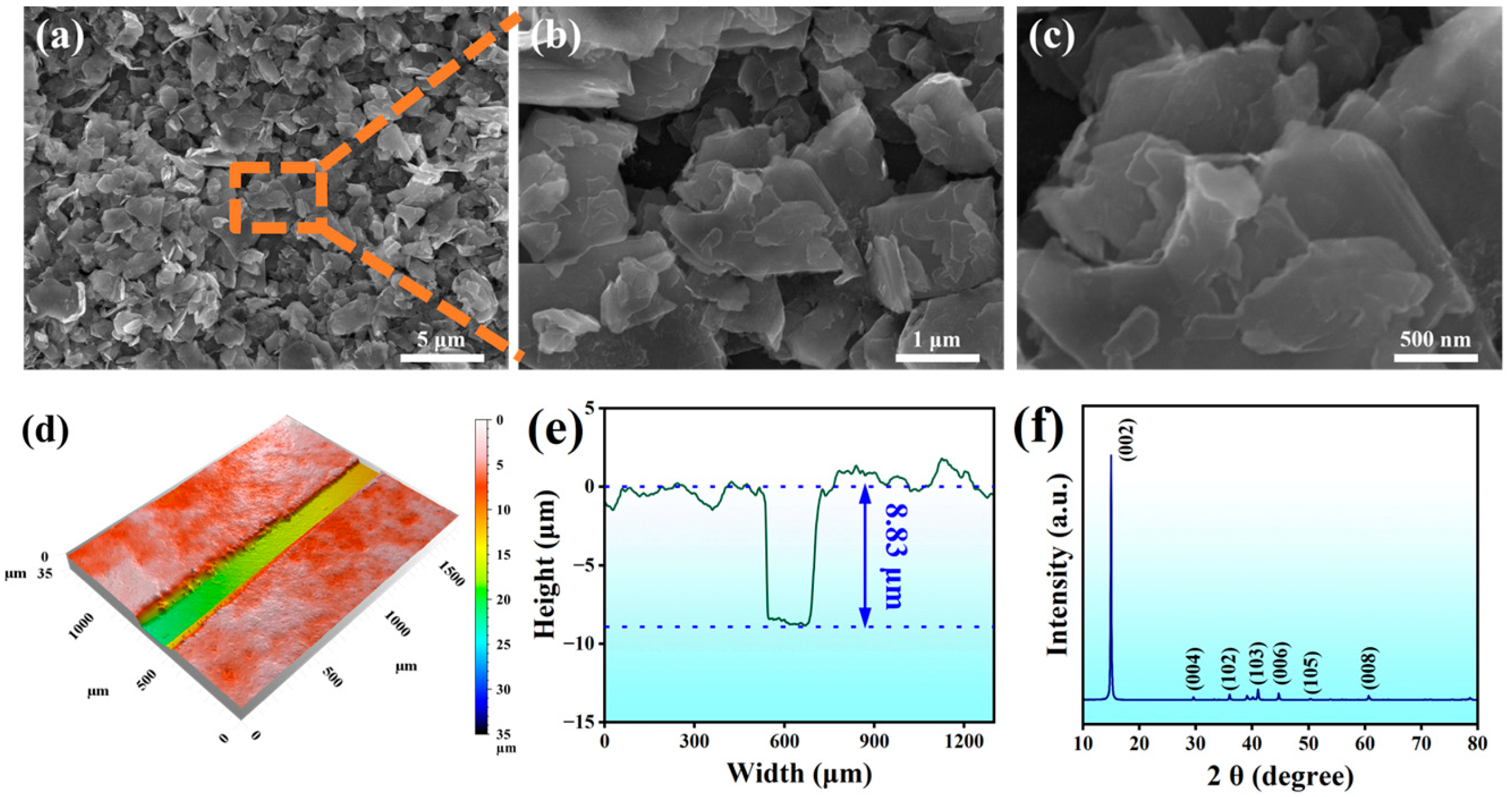

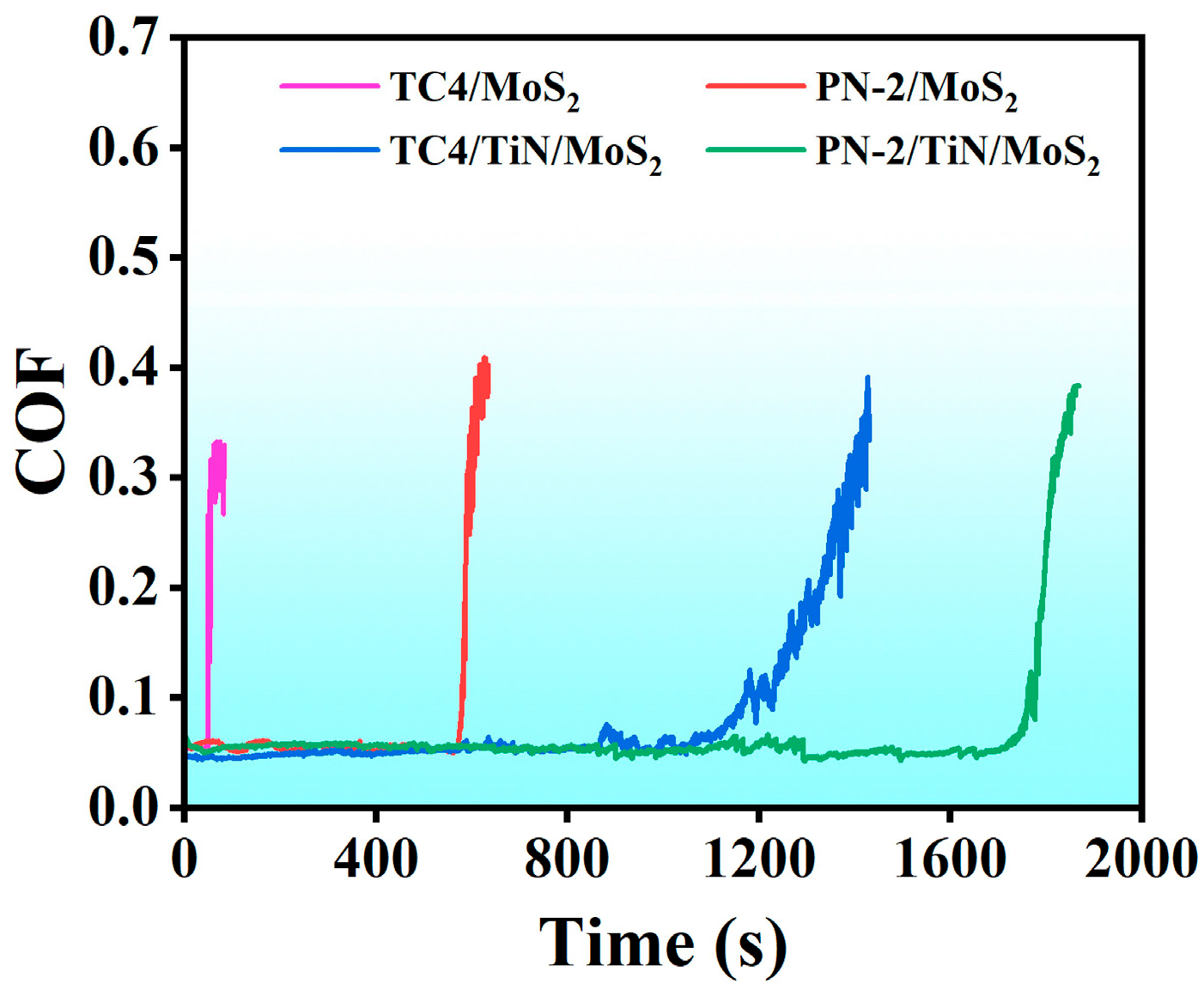

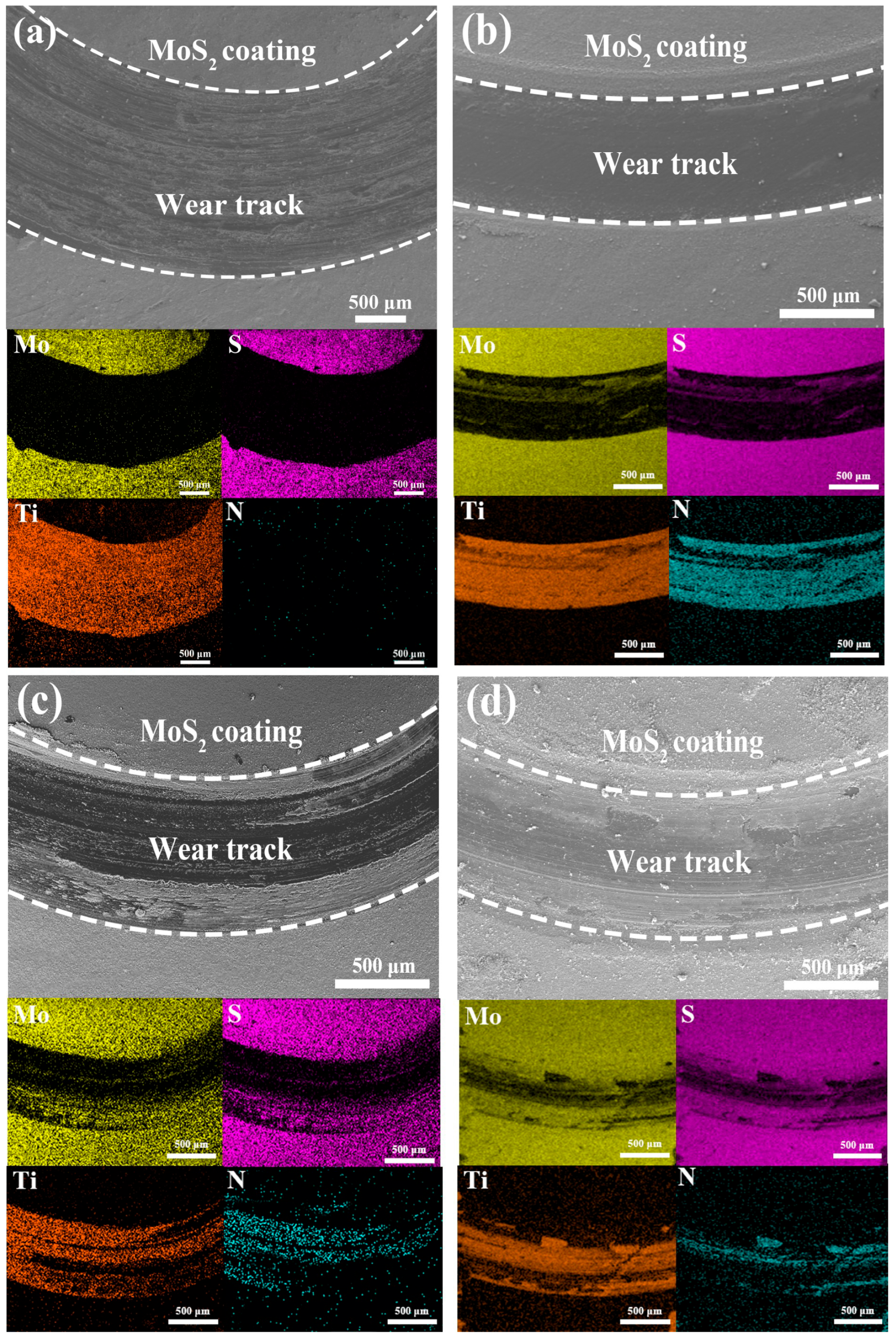

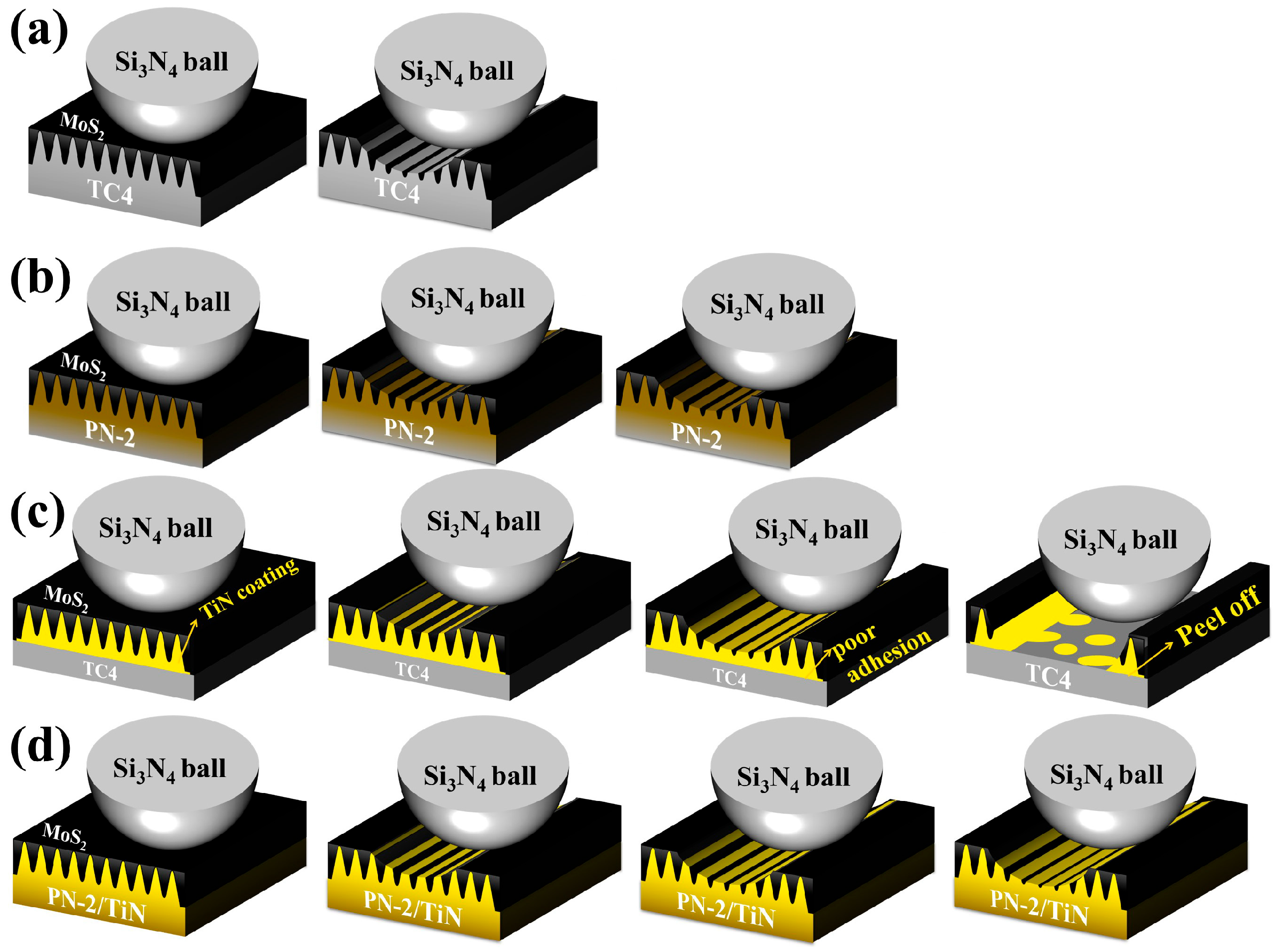

3.3. MoS2 Coating Tribological Properties

4. Conclusions

- (a)

- The combined treatment coatings were deposited on TC4 alloy using plasma nitriding and multi-arc ion plating to improve wear resistance.

- (b)

- Plasma nitriding treatment enhances the adhesion performance between the TC4 substrate and TiN coating.

- (c)

- The primary factor influencing the friction lifetime of MoS2 is surface hardness; specifically, an increase in surface hardness correlates with an extended friction lifetime. This phenomenon is attributed to the material robust load-bearing capability.

- (d)

- The PN-2/TiN/MoS2 coating offers a promising approach to enhance the tribological properties of TC4 alloys, ultimately contributing to the development of improved tribological systems.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sarraf, M.; Rezvani Ghomi, E.; Alipour, S.; Ramakrishna, S.; Liana Sukiman, N. A State-of-the-Art Review of the Fabrication and Characteristics of Titanium and Its Alloys for Biomedical Applications. Biodes Manuf. 2022, 5, 371–395. [Google Scholar] [CrossRef] [PubMed]

- Sun, K.; Dong, Y.; Yao, L.; Mahapatra, M.; Xu, Y. Surface Lubrication with Thermal- and PH-Sensitive PNIPAM-Co-PAA-(IF-MoS2/GO) Composite Microgels under YG8/TC4 Contact. Appl. Surf. Sci. 2024, 669, 160461. [Google Scholar] [CrossRef]

- Yetim, A.F.; Yildiz, F.; Vangolu, Y.; Alsaran, A.; Celik, A. Several Plasma Diffusion Processes for Improving Wear Properties of Ti6Al4V Alloy. Wear 2009, 267, 2179–2185. [Google Scholar] [CrossRef]

- Wang, J.; Lu, H.; Wen, Z.; Lian, Y.; Li, Z.; Yue, Z. Prediction of Fatigue Life of TC4 Titanium Alloy Based on Normalized Equivalent Initial Flaw Size Model. Theor. Appl. Fract. Mec. 2022, 122, 103563. [Google Scholar] [CrossRef]

- Zhao, Y.; Lu, M.; Fan, Z.; Huang, S.; Huang, H. Laser Deposition of Wear-Resistant Titanium Oxynitride/Titanium Composite Coatings on Ti-6Al-4V Alloy. Appl. Surf. Sci. 2020, 531, 147212. [Google Scholar] [CrossRef]

- Kuang, F.; Pan, Y.; Sun, J.; Liu, Y.; Lei, C.; Lu, X. Crafting High-Strength and Ductile Powder Metallurgy Ti6Al4V Alloy with a Multi-Scale Microstructure. Mater. Sci. Eng. A 2024, 892, 146054. [Google Scholar] [CrossRef]

- Guo, Y.; Lu, X.; Han, W.; Min, J.; Dai, G.; Sun, Z.; Chang, H.; Xia, Y. Effect of WC Addition on Microstructure and Properties of Laser Melting Deposited Ti6Al4V. Mater. Charact. 2024, 217, 114344. [Google Scholar] [CrossRef]

- Huang, L.; Yuan, J.; Li, C. Influence of Titanium Concentration on Mechanical Properties and Wear Resistance to Ti6Al4V of Ti-C:H on Cemented Carbide. Vacuum 2017, 138, 1–7. [Google Scholar] [CrossRef]

- Wang, L.; Cai, X.; Shi, B.; Zhang, J.; Zhan, X. Direct Energy Deposition of TiC/Ti6Al4V Graded Materials and Heat Resistance Improvement during the Ablation Process. J. Mater. Res. Technol. 2024, 33, 8482–8490. [Google Scholar] [CrossRef]

- Shi, B.; Huang, S.; Zhu, P.; Xu, C.; Guo, P.; Fu, Y. In-Situ TiN Reinforced Composite Coatings Prepared by Plasma Spray Welding on Ti6Al4V. Mater. Lett. 2020, 276, 128093. [Google Scholar] [CrossRef]

- Luo, Y.J.; Chen, J.B.; Wang, X.F.; Zhao, Y.X.; Zhang, A.B.; Xie, C.; Chen, Y.; Du, J.K. A Micromechanical Model to Study the Closure Stress Effect on Fatigue Life of Ti6Al4V Subjected to Laser Shock Peening. Eng. Fract. Mech. 2018, 200, 327–338. [Google Scholar] [CrossRef]

- Li, H.; Sun, Y.; Zhang, J. Effect of ZrO2 Particle on the Performance of Micro-Arc Oxidation Coatings on Ti6Al4V. Appl. Surf. Sci. 2015, 342, 183–190. [Google Scholar] [CrossRef]

- Ceschini, L.; Lanzoni, E.; Martini, C.; Prandstraller, D.; Sambogna, G. Comparison of Dry Sliding Friction and Wear of Ti6Al4V Alloy Treated by Plasma Electrolytic Oxidation and PVD Coating. Wear 2008, 264, 86–95. [Google Scholar] [CrossRef]

- Strąkowska, P.; Beutner, R.; Gnyba, M.; Zielinski, A.; Scharnweber, D. Electrochemically Assisted Deposition of Hydroxyapatite on Ti6Al4V Substrates Covered by CVD Diamond Films—Coating Characterization and First Cell Biological Results. Mater. Sci. Eng. C 2016, 59, 624–635. [Google Scholar] [CrossRef]

- Lima, G.D.; Nascimento, B.L.; de Souza Alves Júnior, I.; Trindade, M.P.; Griza, S. Fatigue Behavior and Life Predictions of Thermally Oxidized Ti6Al4V Alloy According to Oxidation Parameters. Eng. Fail. Anal. 2021, 130, 105737. [Google Scholar] [CrossRef]

- Vorobyova, M.; Biffoli, F.; Giurlani, W.; Martinuzzi, S.M.; Linser, M.; Caneschi, A.; Innocenti, M. PVD for Decorative Applications: A Review. Materials 2023, 16, 4919. [Google Scholar] [CrossRef]

- Kamat, A.M.; Copley, S.M.; Todd, J.A. A Two-Step Laser-Sustained Plasma Nitriding Process for Deep-Case Hardening of Commercially Pure Titanium. Surf. Coat. Technol. 2017, 313, 82–95. [Google Scholar] [CrossRef]

- Sun, F.; Liu, X.L.; Luo, S.Q.; Xiang, D.D.; Ba, D.C.; Lin, Z.; Song, G.Q. Duplex Treatment of Arc Plasma Nitriding and PVD TiN Coating Applied to Dental Implant Screws. Surf. Coat. Technol. 2022, 439, 128449. [Google Scholar] [CrossRef]

- Yang, J.; Le, K.; Chen, H.; Zhao, X.; Xie, X.; Luo, Y.; Xu, S.; Liu, W. The Significantly Enhanced Mechanical and Tribological Performances of the Dual Plasma Nitrided and PVD Coated Ti6Al4V Alloy. Int. J. Precis. Eng. Man. 2023, 24, 607–619. [Google Scholar] [CrossRef]

- Hu, Y.; Wang, J.; Li, W.; Tang, X.; Tan, T.; Li, Z.; Feng, H.; Zhang, G. The Effects of Ti Content on Tribological and Corrosion Performances of MoS2–Ti Composite Films. Vacuum 2024, 221, 112889. [Google Scholar] [CrossRef]

- Wang, X.; Ma, C.; Yang, G.; Zhang, S.; Zhang, Y.; Jiang, Z.; Yu, L.; Zhang, P. Preparation of Molybdenum Disulfide/Bentonite Nanohybrid and Its Tribological Properties as Lubricant for Water-Based Drilling Fluids. Tribol. Int. 2025, 202, 110309. [Google Scholar] [CrossRef]

- Liu, X.; Le, K.; Yang, W.; Liu, Y.; Luo, Y.; Zheng, X.; Chen, H.; Xu, S.; Liu, W. Tailoring the Crystallinity and Phase Composition of MoS2 Nanosheets for Better Lubrication Performance. Appl. Surf. Sci. 2024, 673, 160856. [Google Scholar] [CrossRef]

- Liang, J.; Le, K.; Liu, Y.; Jang, Y.J.; Jiang, F.; Yang, Z.; Li, H.; Xu, S.; Liu, W. Adaptive Tribological Performance of Porous Ticn-MoS2 Composite Coatings in Response to Fluctuating Humidity Conditions. Surf. Coat. Technol. 2024, 482, 130666. [Google Scholar] [CrossRef]

- Zhang, J.; Li, K.; Hu, J. Performances Investigation of Ti6Al4V Alloy Modified by Plasma Nitriding + Plasma Enhanced Chemical Vapor Deposition and Laser Remelting Process in Simulated Body Fluid. Met. Mater. Int. 2021, 27, 4757–4767. [Google Scholar] [CrossRef]

- Yumusak, G.; Leyland, A.; Matthews, A. The Effect of Pre-Deposited Titanium-Based PVD Metallic Thin Films on the Nitrogen Diffusion Efficiency and Wear Behaviour of Nitrided Ti Alloys. Surf. Coat. Technol. 2020, 394, 125545. [Google Scholar] [CrossRef]

- El-Hossary, F.M.; Negm, N.Z.; Khalil, S.M.; Raaif, M. Surface Modification of Titanium by Radio Frequency Plasma Nitriding. Thin Solid. Films 2006, 497, 196–202. [Google Scholar] [CrossRef]

- Li, M.; Xu, X.; Wu, W.; Peng, S.; Chen, W.; Zhai, Z.; Luo, Q.; Peng, H.; Zhang, A. Development and Diagnostic Study of the RF Nitrogen Atom Source. Vacuum 2025, 231, 113820. [Google Scholar] [CrossRef]

- Ata, M.H.; El-Lateef, H.M.A.; Elrouby, M. Effects of Plasma Powers on the Corrosion, Mechanical, Wear, and Tribological Surface Features of the Fe52Ni28Co17Ti3 Shape Memory Alloy. Sur. Interfaces 2021, 26, 101384. [Google Scholar] [CrossRef]

- Galdikas, A.; Petraitiene, A.; Moskalioviene, T. Internal Stress Assisted Nitrogen Diffusion in Plasma Nitrided Medical CoCr Alloys. Vacuum 2015, 119, 233–238. [Google Scholar] [CrossRef]

- Daymond, M.R. Internal Stresses in Deformed Crystalline Aggregates. Rev. Mineral Geochem. 2006, 63, 427–458. [Google Scholar] [CrossRef]

- Li, L.; Lu, Z.; Pu, J.; Hou, B. Investigating the Tribological and Corrosive Properties of MoS2/Zr Coatings with the Continuous Evolution of Structure for High-Humidity Application. Appl. Surf. Sci. 2021, 541, 148453. [Google Scholar] [CrossRef]

- Zheng, J.; Hao, J.; Liu, X.; Gong, Q.; Liu, W. TiN/TiCN Multilayer Films Modified by Argon Plasma Treatment. Appl. Surf. Sci. 2013, 280, 764–771. [Google Scholar] [CrossRef]

- Yang, Z.; Shi, X.; Wu, C.; Zhou, H.; Guo, M.; Liu, S.; Lin, J.; Fu, C. Study on Tribological and Friction Noise Performance of Ti6Al4V Self-Lubricating Composites. J. Mater. Eng. Perform. 2019, 28, 6063–6072. [Google Scholar] [CrossRef]

- Chen, Q.; Wu, G.; Li, D.; Li, A.; Shang, L.; Lu, Z.; Zhang, G.; Wu, Z.; Tian, G. Understanding the Unusual Friction Behavior of TiN Films in Vacuum. Tribol. Int. 2019, 137, 379–386. [Google Scholar] [CrossRef]

- Zhou, H.; Shi, X.; Yang, Z.; Wu, C.; Lu, G.; Xue, Y.W. Tribological Property and Frictional Noise Performance of Titanium Alloys with Sn–Ag–Cu and TiC Filled into Surface Dimples. Tribol. Int. 2020, 144, 106121. [Google Scholar] [CrossRef]

- Zhao, H.; Liu, Z.; Yu, C.; Liu, C.; Zhan, Y. Finite Element Analysis for Residual Stress of TC4/Inconel718 Functionally Gradient Materials Produced by Laser Additive Manufacturing. Opt. Laser Technol. 2022, 152, 108146. [Google Scholar] [CrossRef]

- Chen, H.; Wang, W.; Le, K.; Liu, Y.; Gao, X.; Luo, Y.; Zhao, X.; Liu, X.; Xu, S.; Liu, W. Effects of Substrate Roughness on the Tribological Properties of Duplex Plasma Nitrided and MoS2 Coated Ti6Al4V Alloy. Tribol. Int. 2024, 191, 109123. [Google Scholar] [CrossRef]

- Wang, C.; Zhang, J.; Le, K.; Niu, Y.; Gao, X.; Che, Q.; Xu, S.; Liu, Y.; Liu, W. Effect of Substrate Roughness and Contact Scale on the Tribological Performance of MoS2 Coatings. Lubricants 2023, 11, 191. [Google Scholar] [CrossRef]

- Kong, N.; Wei, B.; Li, D.; Zhuang, Y.; Sun, G.; Wang, B. A Study on the Tribological Property of MoS2/Ti-MoS2/Si Multilayer Nanocomposite Coating Deposited by Magnetron Sputtering. RSC Adv. 2020, 10, 9633–9642. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, H.; Le, K.; Wang, G.; Ren, Z.; Liu, Y.; Yang, Z.; Zheng, L.; Xu, S. Enhanced Friction and Wear Properties of TiN/MoS2 Composite Coating on the Surface of Plasma Nitrided Ti6Al4V Alloy. Lubricants 2025, 13, 37. https://doi.org/10.3390/lubricants13010037

Li H, Le K, Wang G, Ren Z, Liu Y, Yang Z, Zheng L, Xu S. Enhanced Friction and Wear Properties of TiN/MoS2 Composite Coating on the Surface of Plasma Nitrided Ti6Al4V Alloy. Lubricants. 2025; 13(1):37. https://doi.org/10.3390/lubricants13010037

Chicago/Turabian StyleLi, Hongyu, Kai Le, Ganggang Wang, Zhenghao Ren, Yuzhen Liu, Zhenglong Yang, Liwei Zheng, and Shusheng Xu. 2025. "Enhanced Friction and Wear Properties of TiN/MoS2 Composite Coating on the Surface of Plasma Nitrided Ti6Al4V Alloy" Lubricants 13, no. 1: 37. https://doi.org/10.3390/lubricants13010037

APA StyleLi, H., Le, K., Wang, G., Ren, Z., Liu, Y., Yang, Z., Zheng, L., & Xu, S. (2025). Enhanced Friction and Wear Properties of TiN/MoS2 Composite Coating on the Surface of Plasma Nitrided Ti6Al4V Alloy. Lubricants, 13(1), 37. https://doi.org/10.3390/lubricants13010037