Study on the Influence of Bionic Structure on the Sealing Performance of Centrifugal Pump Sealing Ring

Abstract

1. Introduction

2. Numerical Calculation and Sealing Performance Prediction

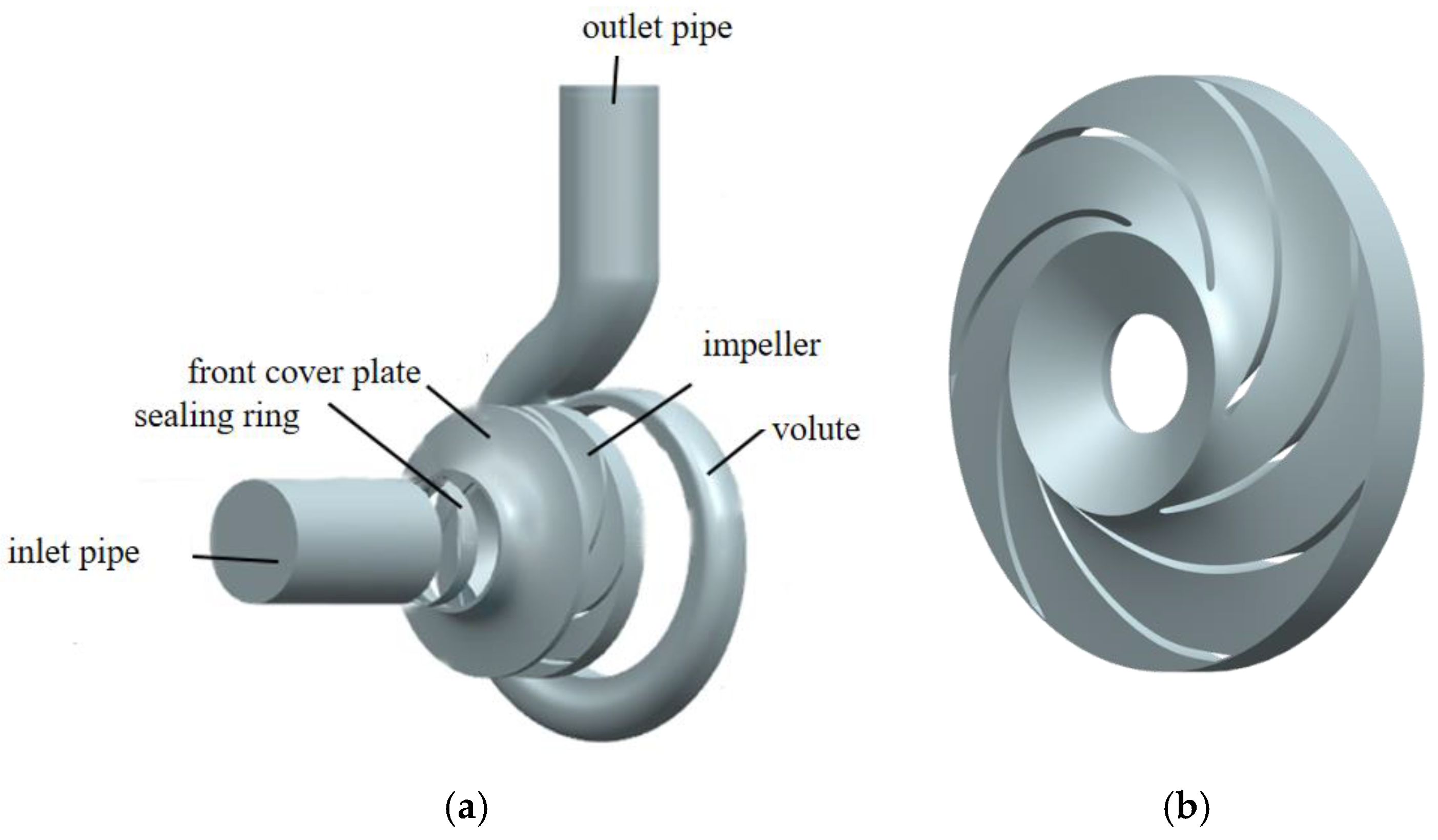

2.1. Structural Model

2.2. Numerical Calculation Model and Boundary Conditions

2.3. Grid Division and Numerical Simulation Accuracy Verification

3. The Influence of Bionic Surface Structure on Sealing Performance

3.1. Effect of Bionic Surface Structure on Hydraulic Performance of Centrifugal Pump

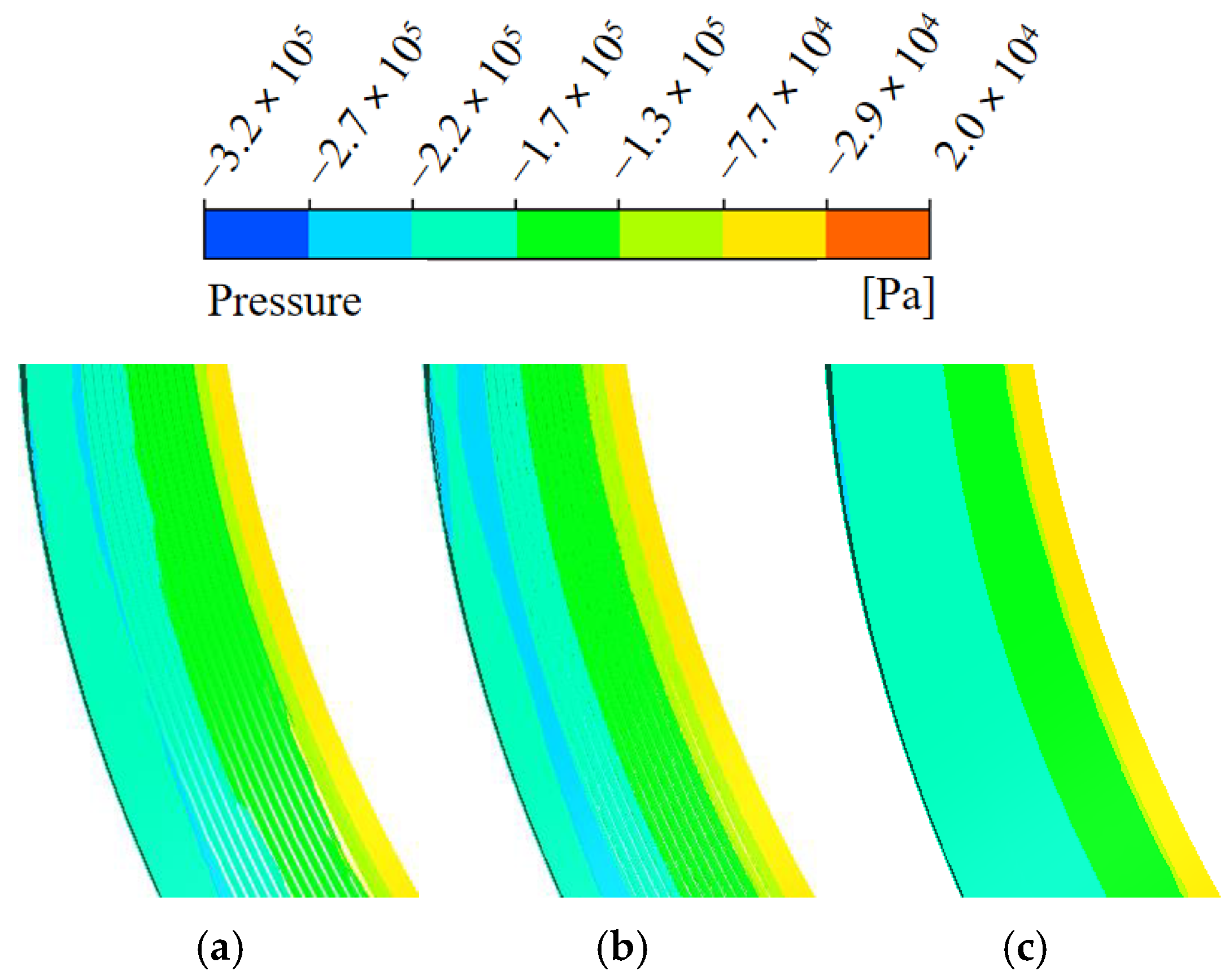

3.2. Internal Flow Field Analysis of Centrifugal Pump with Bionic Surface Structure Sealing Ring

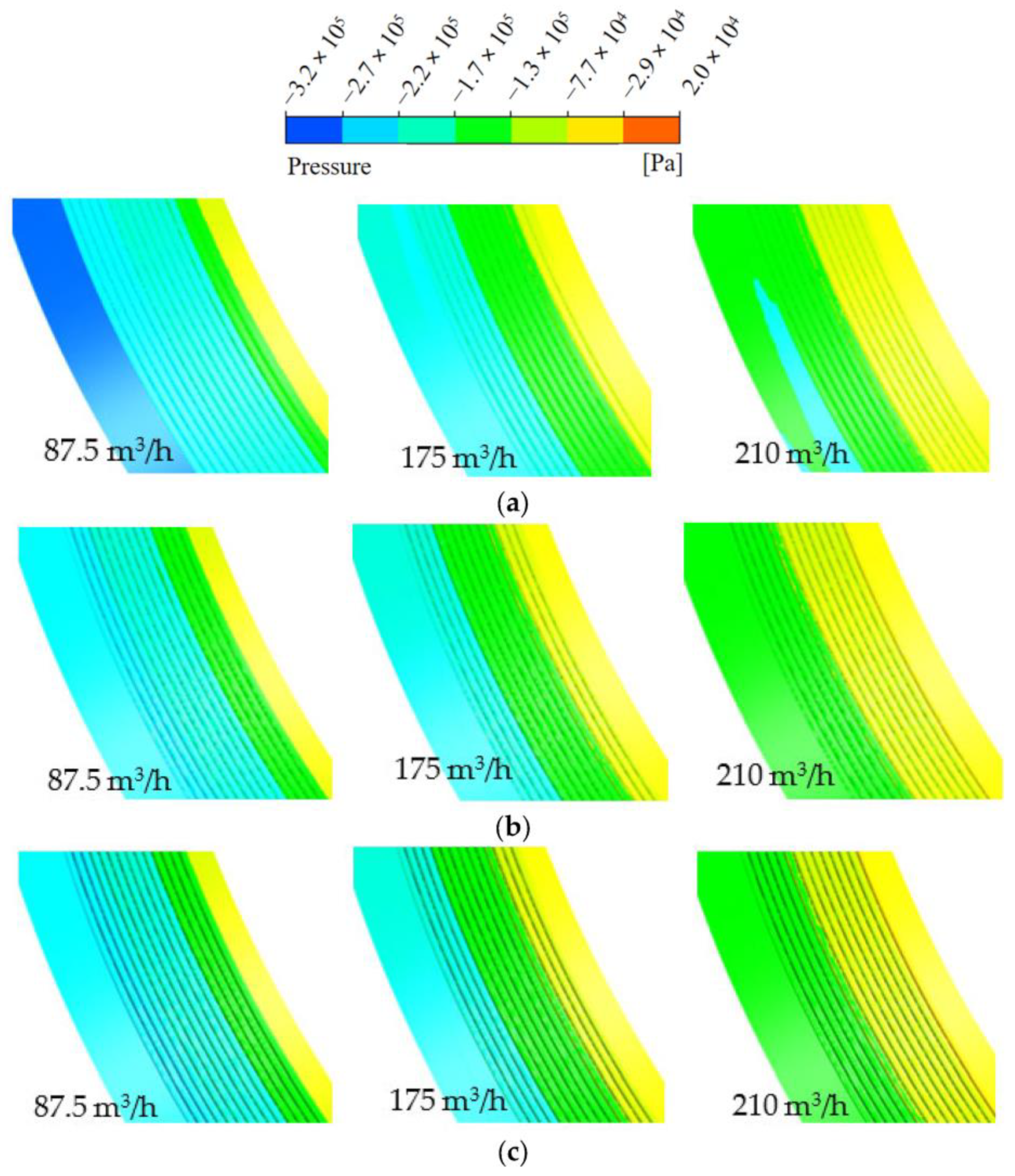

3.3. Analysis of Sealing Performance of Circular Groove Surface Structure

4. Future Research

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Aliuly, A.; Amanzholov, T.; Seitov, A.; Momysh, N.; Jaichibekov, N.; Kaltayev, A. Hydraulic design and CFD-Based parametric study for optimizing centrifugal pump impeller performance. Appl. Sci. 2024, 14, 10161. [Google Scholar] [CrossRef]

- Wang, C.; Shi, W.D.; Wang, X.K.; Jiang, X.P.; Yang, Y.; Li, W.; Zhou, L. Optimal design of multistage centrifugal pump based on the combined energy loss model and computational fluid dynamics. Appl. Energy 2017, 187, 10–26. [Google Scholar] [CrossRef]

- Zhang, Y.; Jiang, W.; Feng, W.; Jia, Q.F.; Wang, Y.C.; Chen, D.Y. Investigation of hydraulic losses in different clocking positions of pump-turbine in pump mode. J. Energy Storage 2024, 81, 110459. [Google Scholar] [CrossRef]

- Gao, Y.; Li, W.; Qi, H.D.; Ji, L.L.; Chen, Y.F. Optimized design of a multistage centrifugal pump based on volumetric loss reduction by auxiliary blades. Water 2023, 15, 2350. [Google Scholar] [CrossRef]

- Yan, J.R.; Zuo, Z.T.; Guo, W.B.; Hou, H.C.; Zhou, X.; Chen, H.S. Influences of wear-ring clearance leakage on performance of a small-scale pump-turbine. Proc. Inst. Mech. Eng. Part A J. Power Energy 2020, 234, 454–469. [Google Scholar] [CrossRef]

- Zhou, W.J.; Ma, J.; Ma, Z.L.; Yu, W.B.; Su, H.H.; Gao, B. Fluid–structure interaction on the rotor-dynamic characteristics of a low-specific-speed centrifugal pump considering multi-scale fluid excitation effects. Phys. Fluids 2024, 36, 117257. [Google Scholar] [CrossRef]

- Zhou, W.J.; Qiu, N.; Wang, L.Q.; Gao, B.; Liu, D. Dynamic analysis of a planar multi-stage centrifugal pump rotor system based on a novel coupled model. J. Sound Vib. 2018, 434, 237–260. [Google Scholar] [CrossRef]

- Van Der Walt, J.P.; Kruger, J.-H.; Du Toit, C.G. Implementation of a reduced order model for rotating seal annular leakage flow inside a centrifugal pump. Geoenergy Sci. Eng. 2024, 233, 212470. [Google Scholar] [CrossRef]

- Jia, X.Q.; Yu, Y.F.; Li, B.; Wang, F.C.; Zhu, Z.C. Effects of incident angle of sealing ring clearance on internal flow and cavitation of centrifugal pump. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2023, 238, 2867–2882. [Google Scholar] [CrossRef]

- Qiu, Q.F.; Gu, Y.Q.; Ma, L.B.; Hu, C.X.; Ding, H.X.; Wu, D.H.; Mou, J.G.; Wu, Z.X. Study of non-constant local cavitation suppression in micro-wedge structure. Phys. Fluids 2024, 36, 015150. [Google Scholar] [CrossRef]

- Hu, Y.; Zhang, J.; Chen, L.M. Design and seal performance analysis of bionic sealing ring for dynamic seal. Mechanics 2020, 26, 338–345. [Google Scholar] [CrossRef]

- Chen, H.L.; Chen, Y.J.; Han, T.; Fu, Y.X.; Cheng, Q.; Wei, Z.P.; Zhao, B.J. Effect of surface roughness on the performance of a shallow spiral groove liquid mechanical seal. Processes 2022, 10, 651. [Google Scholar] [CrossRef]

- Chen, H.Q.; Yan, R.Q.; Hong, X.Z.; Bao, X.; Ding, X.X. Micro-groove optimisation of high-speed inner ring micro-grooved pumping seal for new energy electric vehicles. Processes 2024, 12, 1281. [Google Scholar] [CrossRef]

- Sandoval, J.A.; Jadhav, S.; Quan, H.C.; Deheyn, D.D.; Tolley, M.T. Reversible adhesion to rough surfaces both in and out of water, inspired by the clingfish suction disc. Bioinspiration Biomim. 2019, 14, 066016. [Google Scholar] [CrossRef]

- Tramacere, F.; Appel, E.; Mazzolai, B.; Gorb, S.N. Hairy suckers: The surface microstructure and its possible functional significance in the Octopus vulgaris sucker. Beilstein J. Nanotechnol. 2014, 5, 561–565. [Google Scholar] [CrossRef] [PubMed]

- Tramacere, F.; Pugno, N.M.; Kuba, M.J.; Mazzolai, B. Unveiling the morphology of the acetabulum in octopus suckers and its role in attachment. Interface Focus 2015, 5, 20140050. [Google Scholar] [CrossRef] [PubMed]

- Kimbara, R.; Nakamura, M.; Oguchi, K.; Kohtsuka, H.; Miura, T. Pattern of sucker development in cuttlefishes. Front. Zool. 2020, 17, 24. [Google Scholar] [CrossRef]

- Tramacere, F.; Beccai, L.; Kuba, M.; Gozzi, A.; Bifone, A.; Mazzolai, B. The morphology and adhesion mechanism of octopus vulgaris suckers. PLoS ONE 2013, 8, e65074. [Google Scholar] [CrossRef] [PubMed]

- Ditsche, P.; Summers, A. Learning from northern clingfish (Gobiesox maeandricus): Bioinspired suction cups attach to rough surfaces. Philos. Trans. R. Soc. B Biol. Sci. 2019, 374, 20190204. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.H.; Wang, S.K.; Zheng, L.; Ren, L.Q. Adhesion behavior in fish: From structures to applications. Biomimetics 2023, 8, 534. [Google Scholar] [CrossRef]

- Li, J.; Zhang, Y.; Liu, S.; Liu, J.L. Insights into adhesion of abalone: A mechanical approach. J. Mech. Behav. Biomed. Mater. 2018, 77, 331–336. [Google Scholar] [CrossRef]

- Xi, P.; Cong, Q.; Xu, J.; Sun, L. Surface movement mechanism of abalone and underwater adsorbability of its abdominal foot. Bioinspired Biomim. Nanobiomaterials 2019, 8, 254–262. [Google Scholar] [CrossRef]

- Lin, A.Y.M.; Brunner, R.; Chen, P.Y.; Talke, F.E.; Meyers, M.A. Underwater adhesion of abalone: The role of van der Waals and capillary forces. Acta Mater. 2009, 57, 4178–4185. [Google Scholar] [CrossRef]

- Xi, P.; Ye, S.B.; Cong, Q. Abalone adhesion: The role of various adhesion forces and their proportion to total adhesion force. PLoS ONE 2023, 18, e0286567. [Google Scholar] [CrossRef]

- Wang, J.; Yu, P.F.; Li, R.; Liu, Y.J.; Wang, T.G.; Liu, C. Effect of structural parameters of rectangular grooves on lubrication performance of water-lubricated bearings. Ship Eng. 2024, 46, 90–98. [Google Scholar] [CrossRef]

- He, T.; Zhang, Q.Q.; Yan, Y.; Dong, J.T.; Zhou, P. Numerical simulation of a new designed mechanical seals with spiral groove structures. Lubricants 2023, 11, 70. [Google Scholar] [CrossRef]

- Tian, L.M.; Tian, X.M.; Wang, Y.C.; Hu, G.L.; Ren, L.Q. Anti-wear properties of the molluscan shell Scapharca subcrenata: Influence of surface morphology, structure and organic material on the elementary wear process. Mater. Sci. Eng. C 2014, 42, 7–14. [Google Scholar] [CrossRef] [PubMed]

- Hirvonen, J.P.; Lappalainen, R.; Koskinen, J.; Likonen, J.; Pekkarinen, M. Wear and friction of unio crassus shell in dry sliding contact with steel. Mrs Online Proc. Libr. 1993, 330, 133–137. [Google Scholar] [CrossRef]

- Gu, Y.Q.; Ma, L.B.; Yan, M.H.; He, C.D.; Zhang, J.J.; Mou, J.G.; Wu, D.H.; Ren, Y. Strategies for improving friction behavior based on carbon nanotube additive materials. Tribol. Int. 2022, 176, 107875. [Google Scholar] [CrossRef]

- He, W.L.; Ahmat, M.; Zhou, H.F.; Li, Z.H.; Qiu, W.; Li, D.Z. Influence of diamond-like carbon coatings and micro-texturing on friction and wear of seal interfaces: Experiment and simulation study. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2024, 23, 09544089241226632. [Google Scholar] [CrossRef]

- Zhang, N.; Liu, Y.C.; Li, Z.T.; Zhan, X.H. Sealing performance and optimization design of squamous textured mechanical seal. Tribol. Int. 2024, 193, 109425. [Google Scholar] [CrossRef]

- Ning, H.W.; Qian, S.Z.; Zhou, T. Applications of level set method in computational fluid dynamics: A review. Int. J. Hydromechatronics 2023, 6, 1–33. [Google Scholar] [CrossRef]

- Gu, Y.Q.; Qiu, Q.F.; Ren, Y.; Ma, L.B.; Ding, H.X.; Hu, C.X.; Wu, D.H.; Mou, J.G. Cavitation flow of hydrofoil surface and turbulence model applicability analysis. Int. J. Mech. Sci. 2024, 277, 109515. [Google Scholar] [CrossRef]

- Gu, Y.Q.; Yin, Z.F.; Yu, S.W.; He, C.D.; Wang, W.T.; Zhang, J.J.; Wu, D.H.; Mou, J.G.; Ren, Y. Suppression of unsteady partial cavitation by a bionic jet. Int. J. Multiph. Flow 2023, 164, 104466. [Google Scholar] [CrossRef]

- Qu, K.; Xu, Y.Y.; Huang, J.X.; Wen, B.H. Numerical simulation of hydrodynamic characteristics of submerged floating tunnels under the action of focused waves. J. Chang. Univ. Sci. Technol. 2023, 20, 127–141. [Google Scholar] [CrossRef]

- Shaheed, R.; Mohammadian, A.; Kheirkhah Gildeh, H. A comparison of standard k-ε and realizable k-ε turbulence models in curved and confluent channels. Environ. Fluid Mech. 2019, 19, 543–568. [Google Scholar] [CrossRef]

| Grid Numbers | Head (m) | Efficiency (%) | Flow Rate (m3/h) | Motor Power (kW) | |

|---|---|---|---|---|---|

| Whole grid 1 | 765,434 | 22.88 | 86.15 | 175 | 11.97 |

| Whole grid 2 | 1,213,479 | 23.09 | 87.27 | 175 | 11.97 |

| Whole grid 3 | 1,440,992 | 23.20 | 87.33 | 175 | 11.97 |

| Whole grid 4 | 1,695,523 | 23.30 | 87.40 | 175 | 11.97 |

| Whole grid 5 | 2,245,709 | 23.31 | 87.41 | 175 | 11.97 |

| Whole grid 6 | 2,634,590 | 23.28 | 87.39 | 175 | 11.97 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cai, Y.; Xie, Z.; Yang, F.; Yan, M.; Mou, C.; Huang, Z.; Jin, Y.; Mou, J.; Gu, Y. Study on the Influence of Bionic Structure on the Sealing Performance of Centrifugal Pump Sealing Ring. Lubricants 2025, 13, 26. https://doi.org/10.3390/lubricants13010026

Cai Y, Xie Z, Yang F, Yan M, Mou C, Huang Z, Jin Y, Mou J, Gu Y. Study on the Influence of Bionic Structure on the Sealing Performance of Centrifugal Pump Sealing Ring. Lubricants. 2025; 13(1):26. https://doi.org/10.3390/lubricants13010026

Chicago/Turabian StyleCai, Ye, Zhengpu Xie, Feixiang Yang, Muhan Yan, Chengqi Mou, Zhangcheng Huang, Yuxin Jin, Jiegang Mou, and Yunqing Gu. 2025. "Study on the Influence of Bionic Structure on the Sealing Performance of Centrifugal Pump Sealing Ring" Lubricants 13, no. 1: 26. https://doi.org/10.3390/lubricants13010026

APA StyleCai, Y., Xie, Z., Yang, F., Yan, M., Mou, C., Huang, Z., Jin, Y., Mou, J., & Gu, Y. (2025). Study on the Influence of Bionic Structure on the Sealing Performance of Centrifugal Pump Sealing Ring. Lubricants, 13(1), 26. https://doi.org/10.3390/lubricants13010026