Influence of Glyceryl Monostearate Adsorption on the Lubrication Behavior of a Slider Bearing

Abstract

1. Introduction

2. Experiment

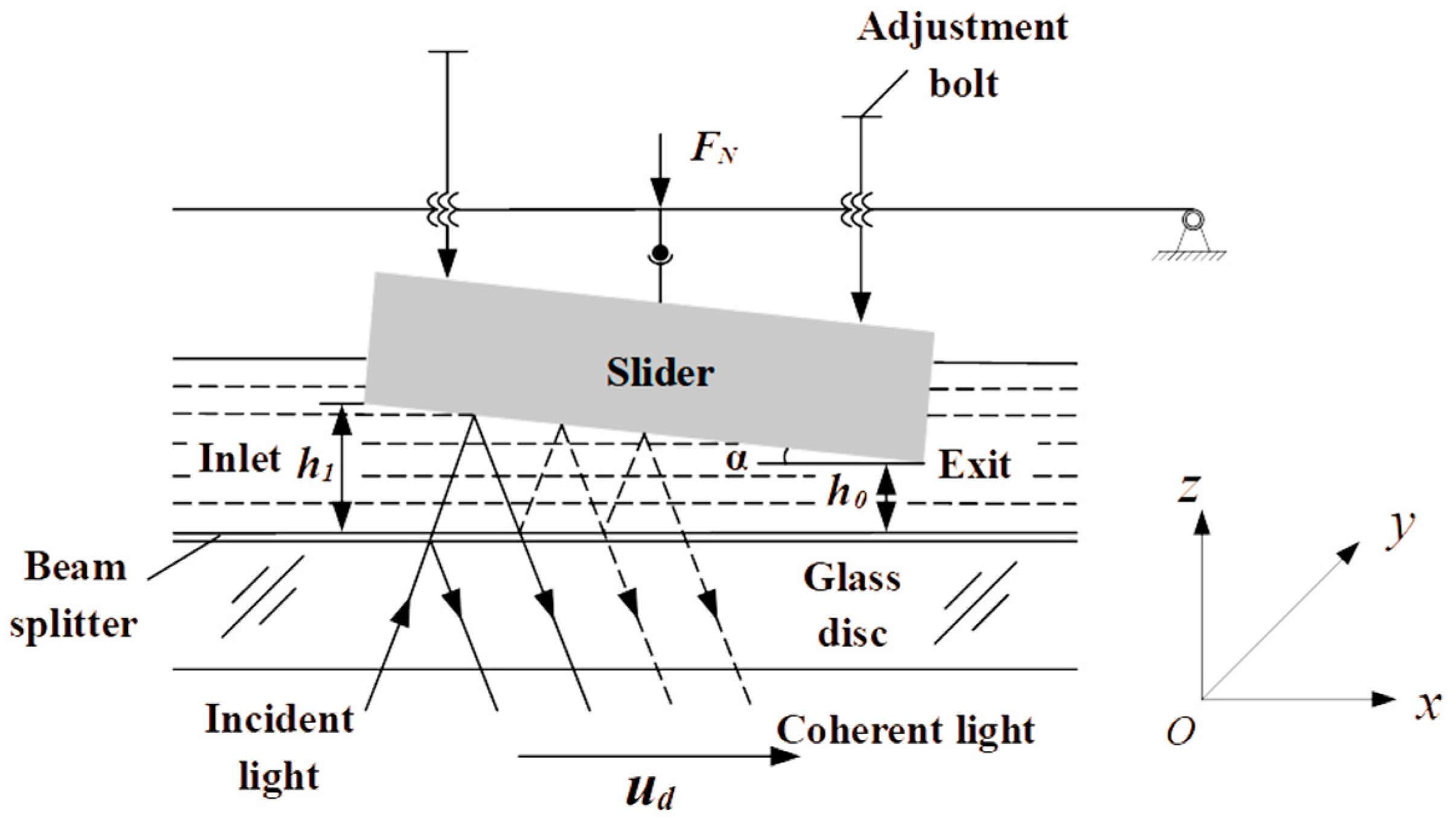

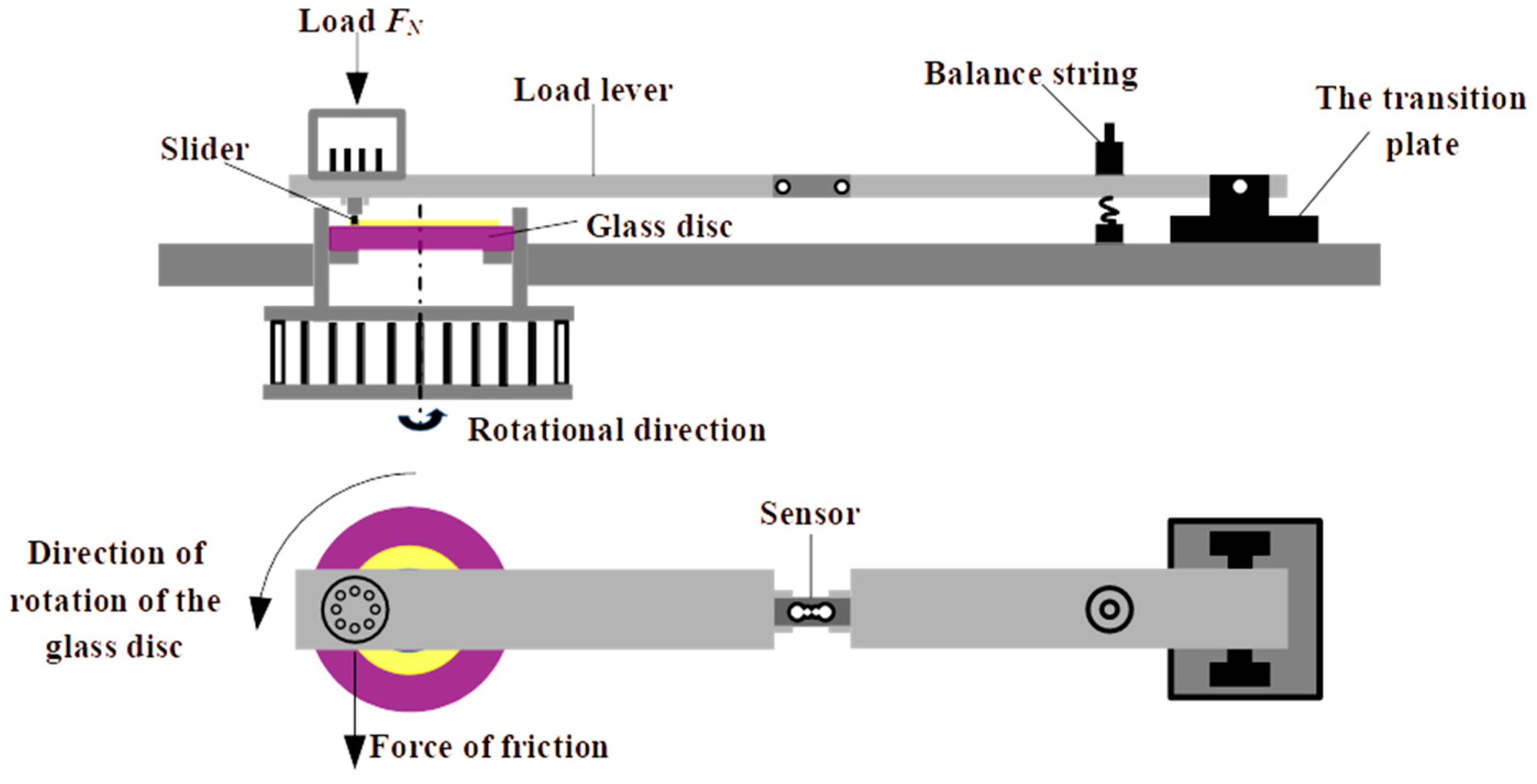

2.1. Experimental Apparatus

2.2. Test Samples Lubricants

2.3. Characterization of Lubricants

2.3.1. Basic Characteristics of Test Oils

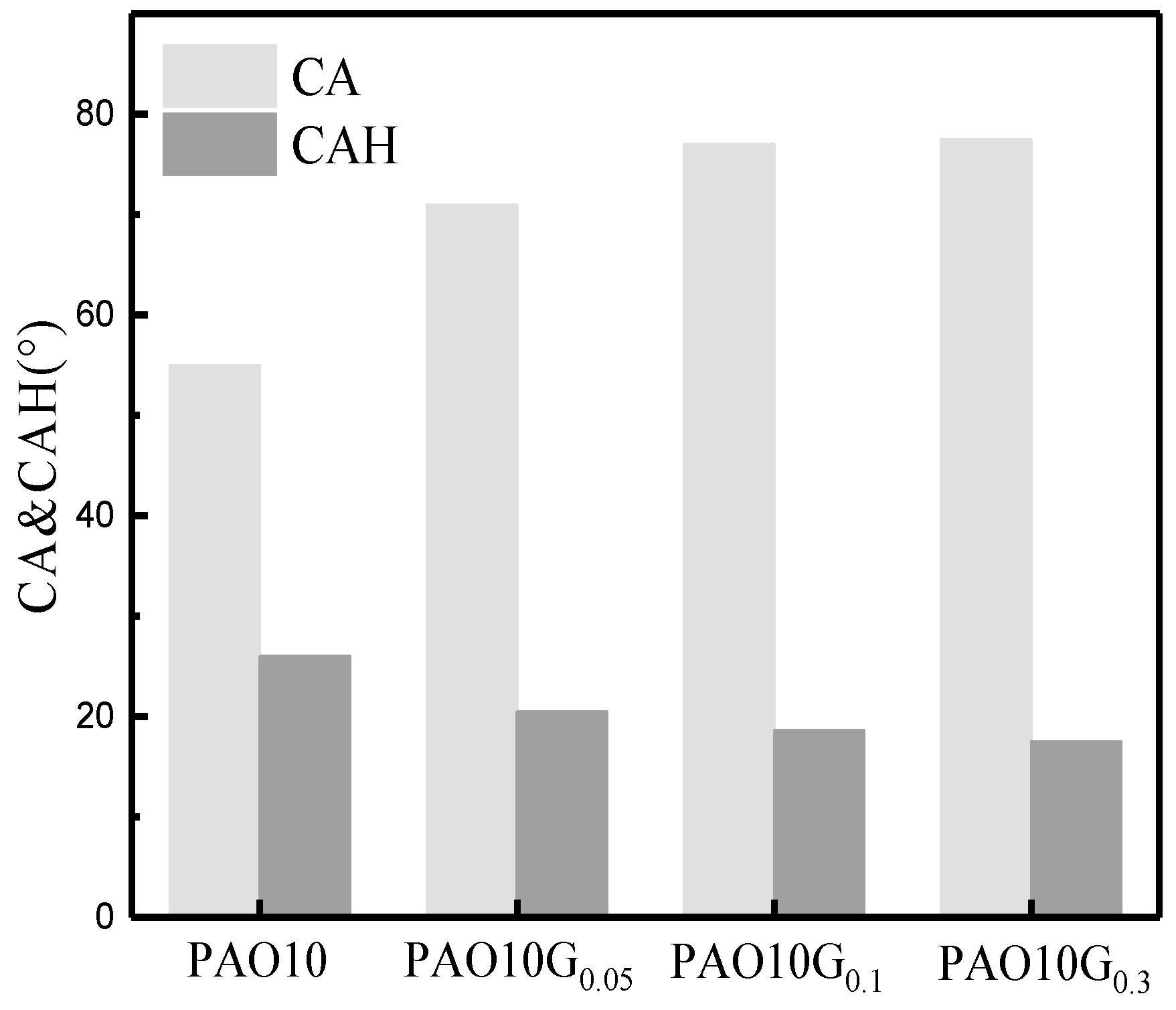

2.3.2. Characterization of GMS Adsorption

2.4. Characterization of Lubricants

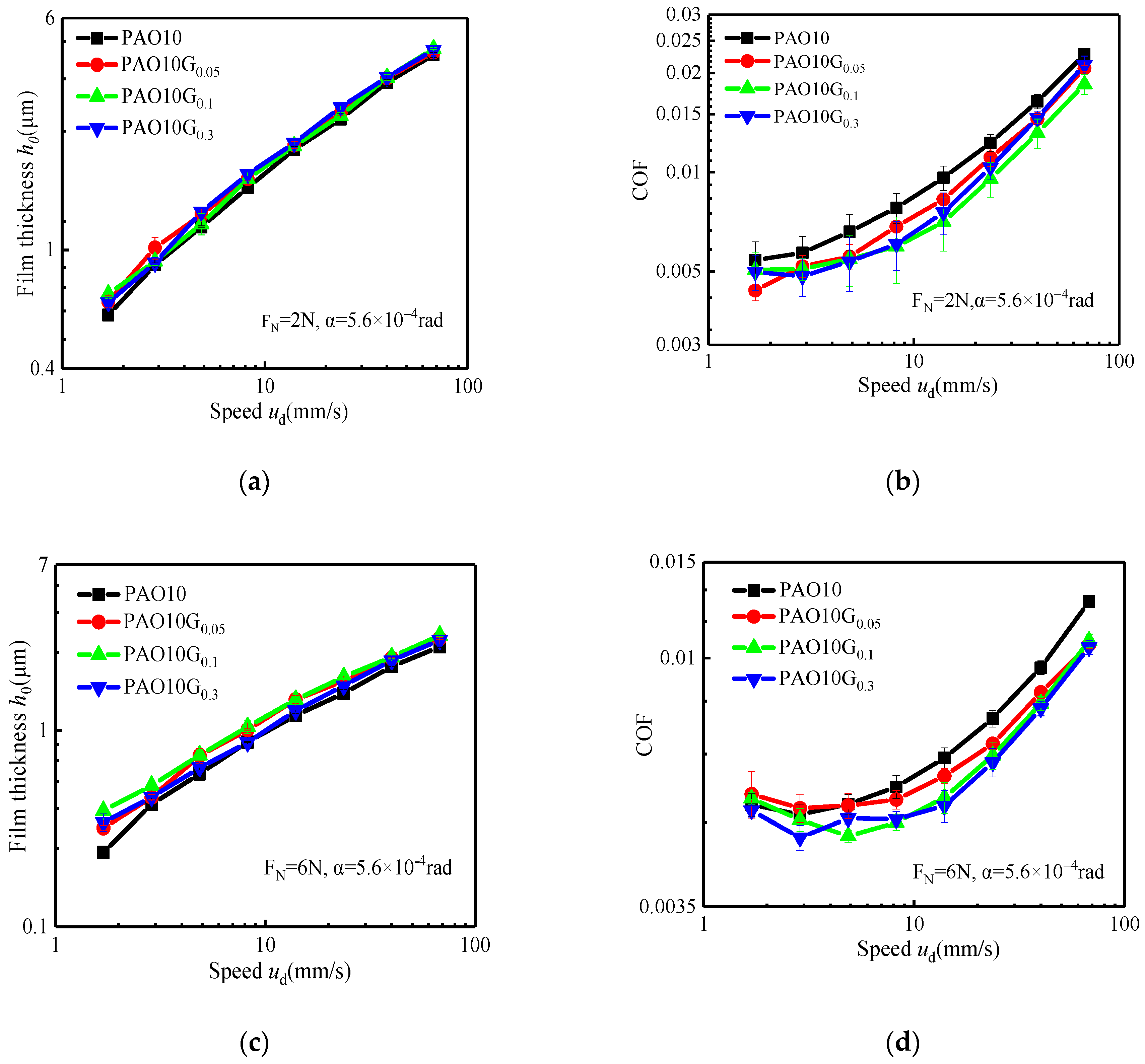

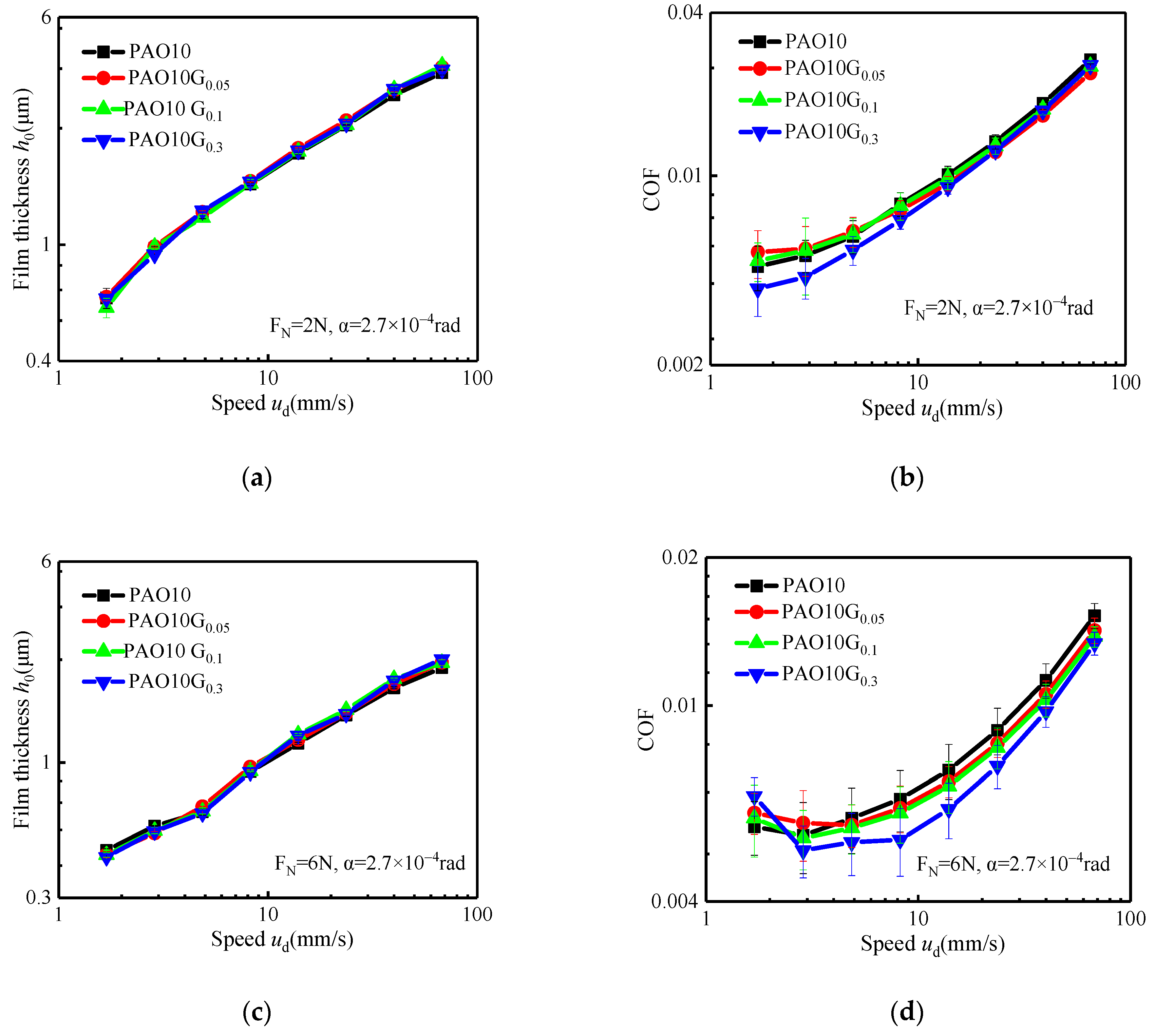

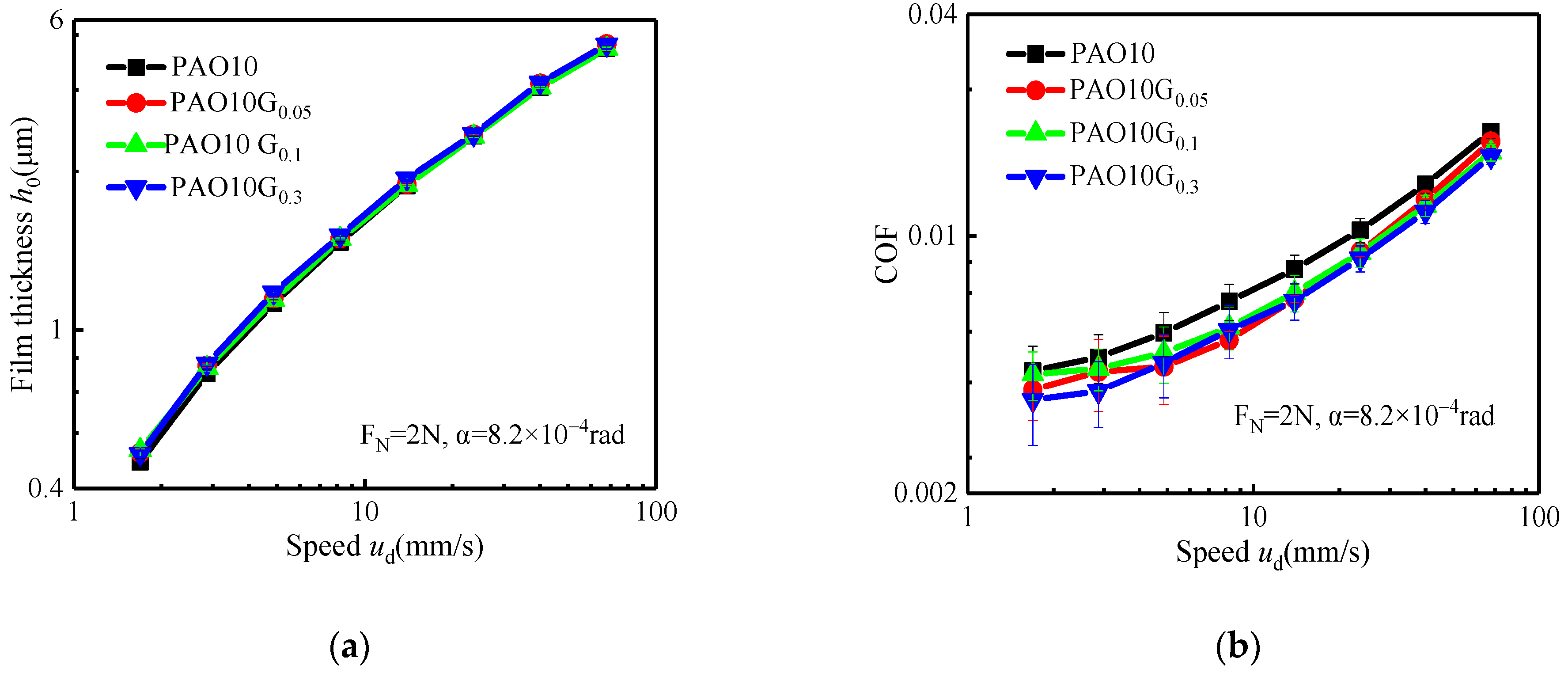

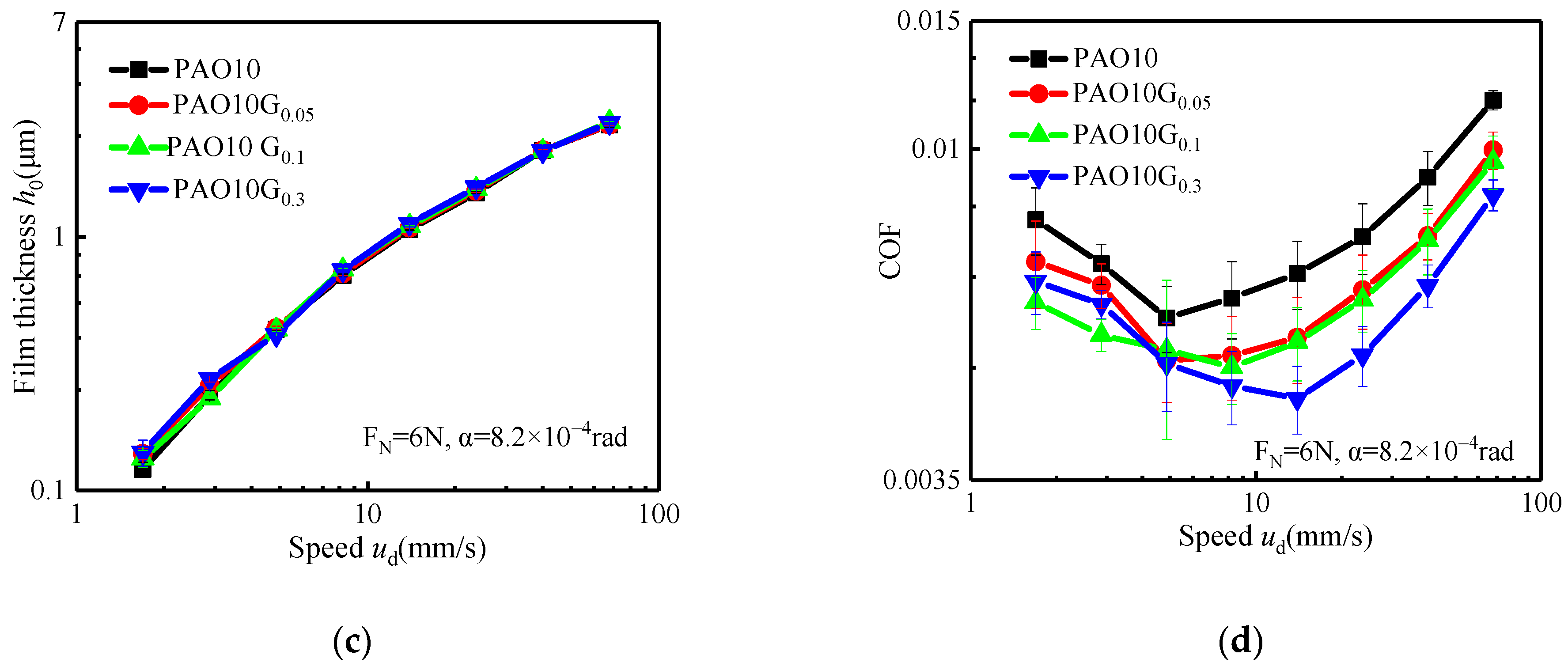

3. Results

4. Discussion

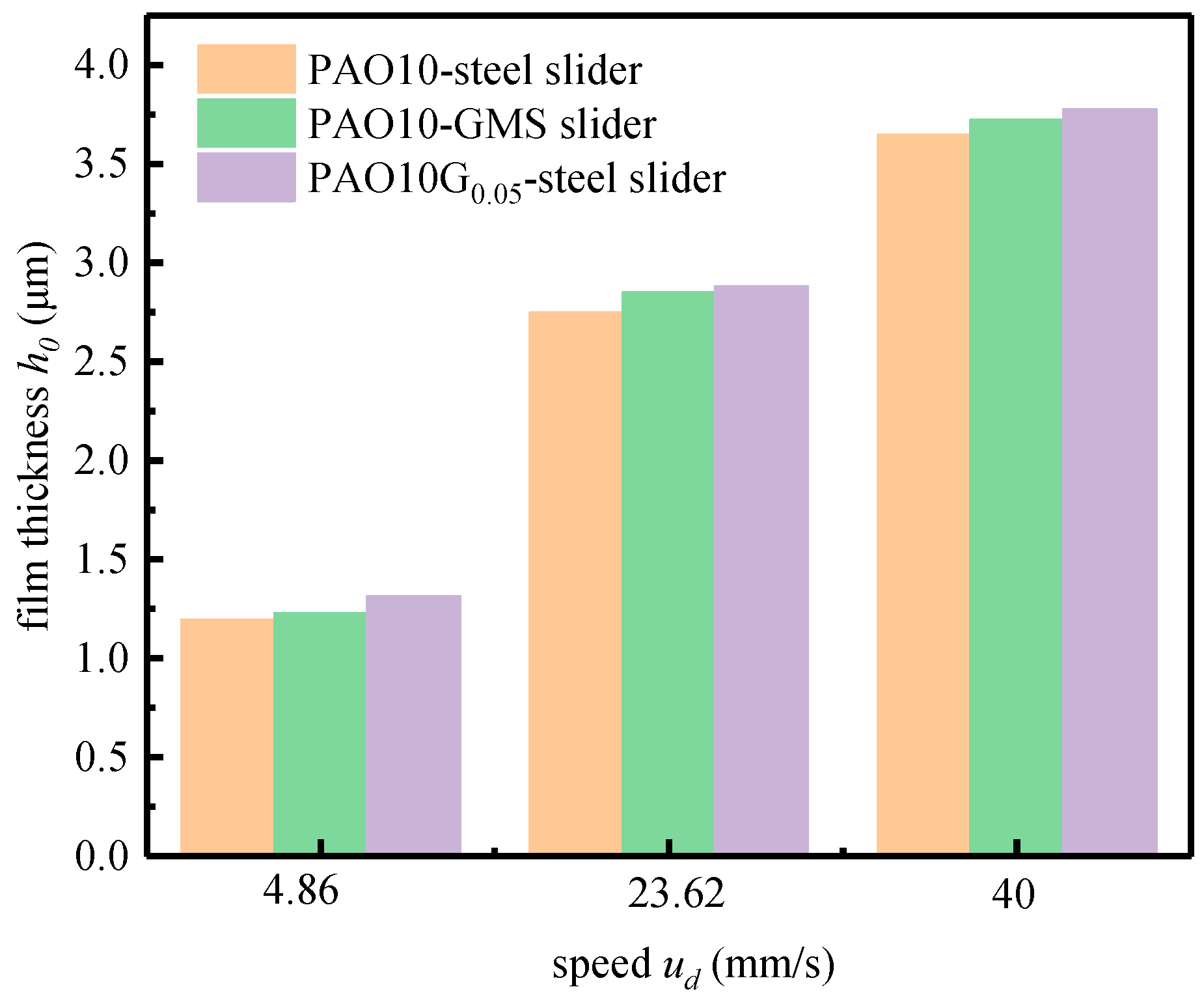

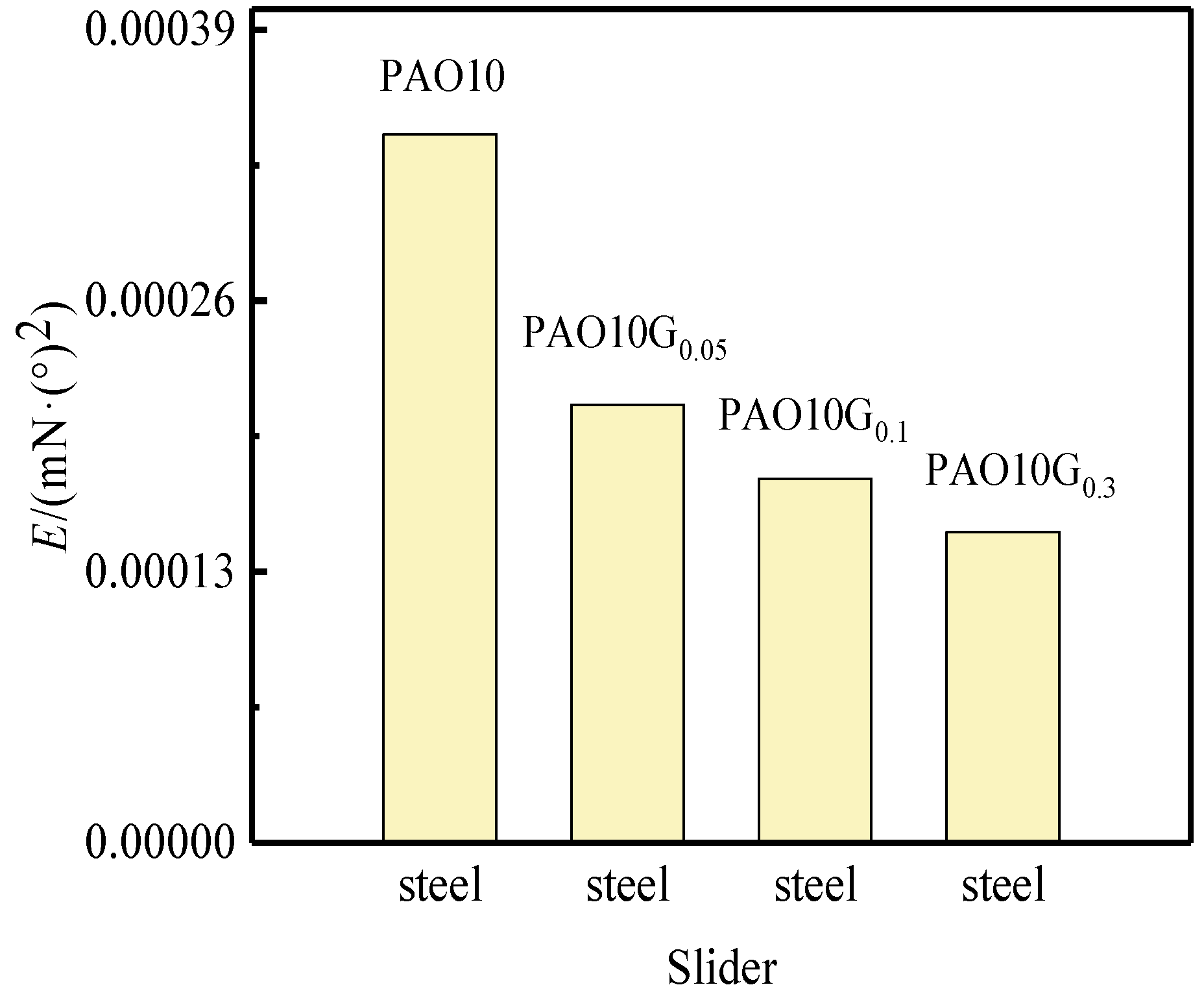

4.1. Analysis of COF

4.1.1. Trends of COF Variation with Velocity

4.1.2. COF of Various Lubricants with the Same Inclination of the Slider

4.1.3. COF of the Same Lubricant with Different Inclinations of the Slider

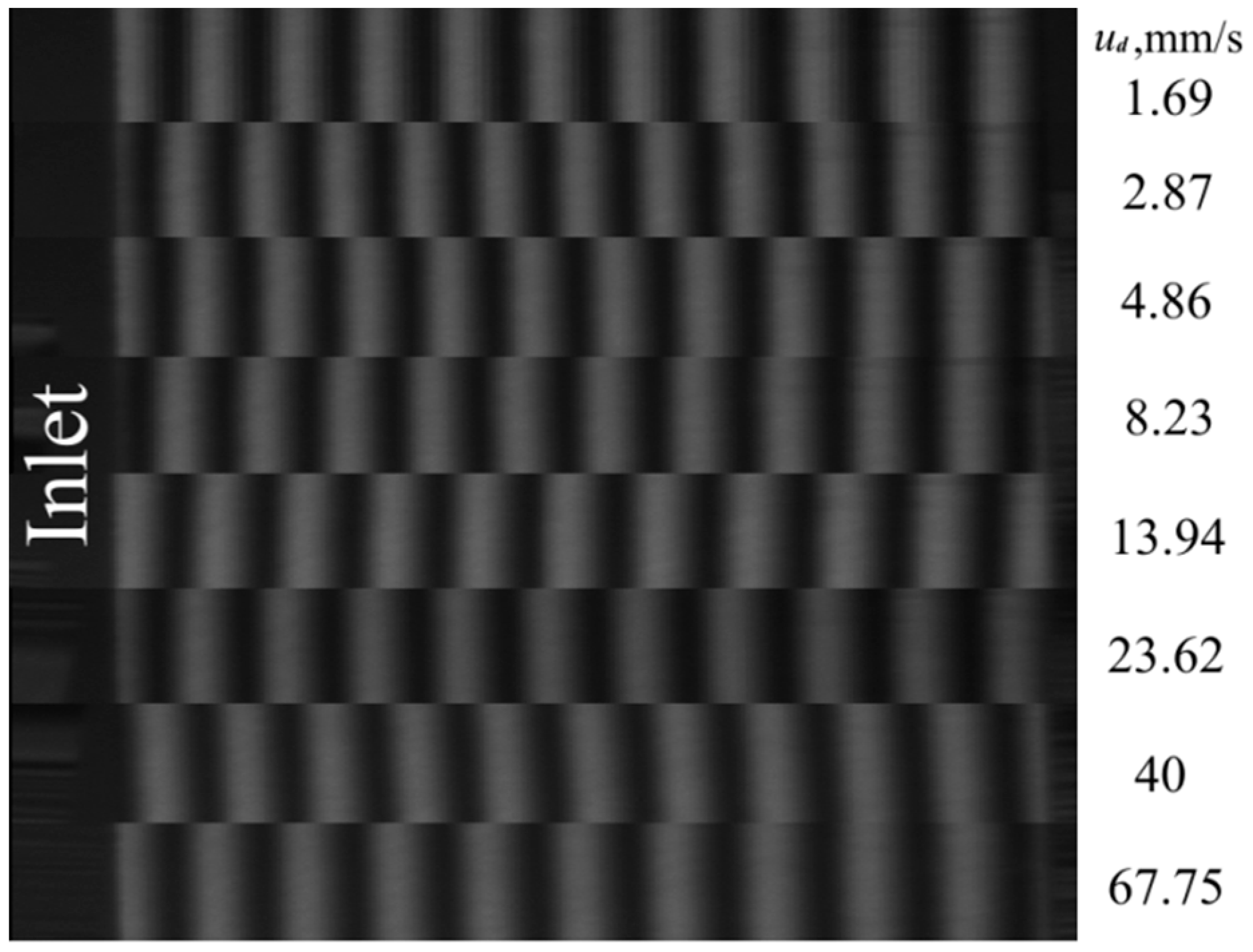

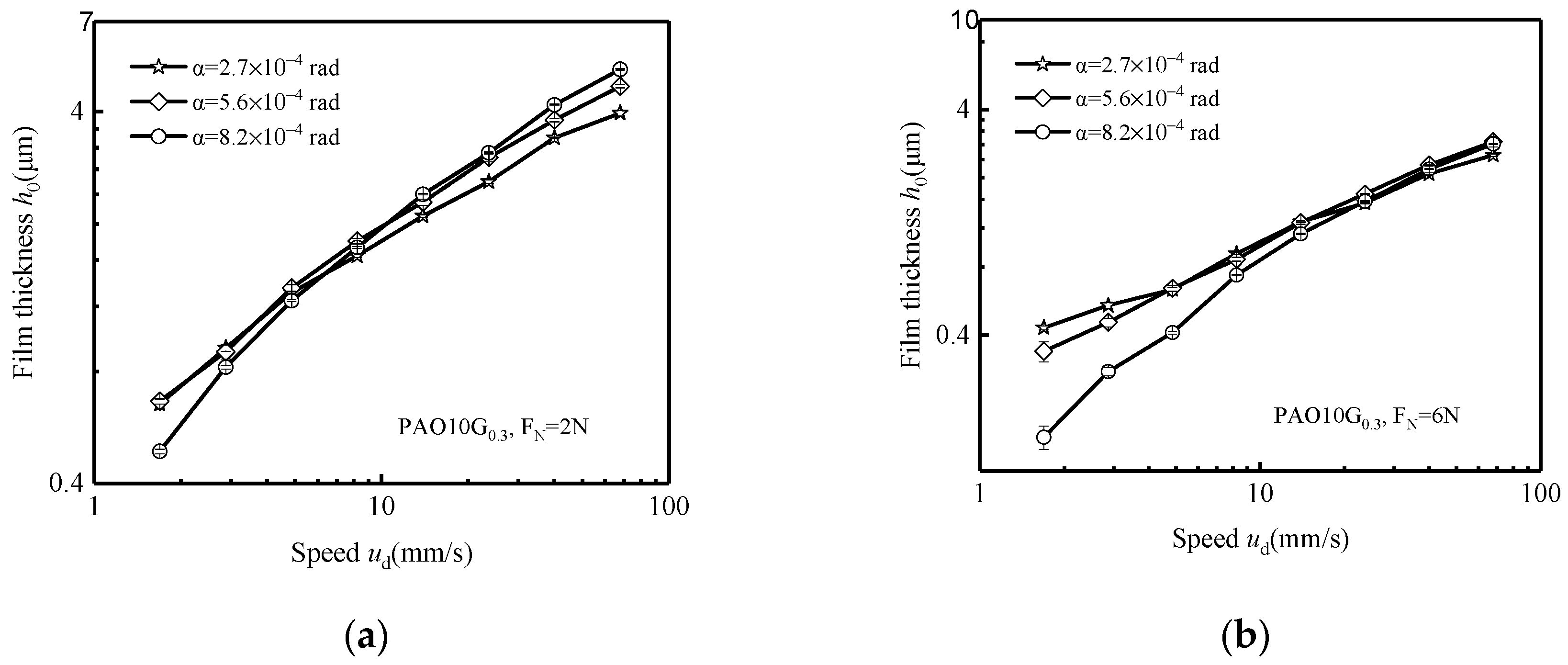

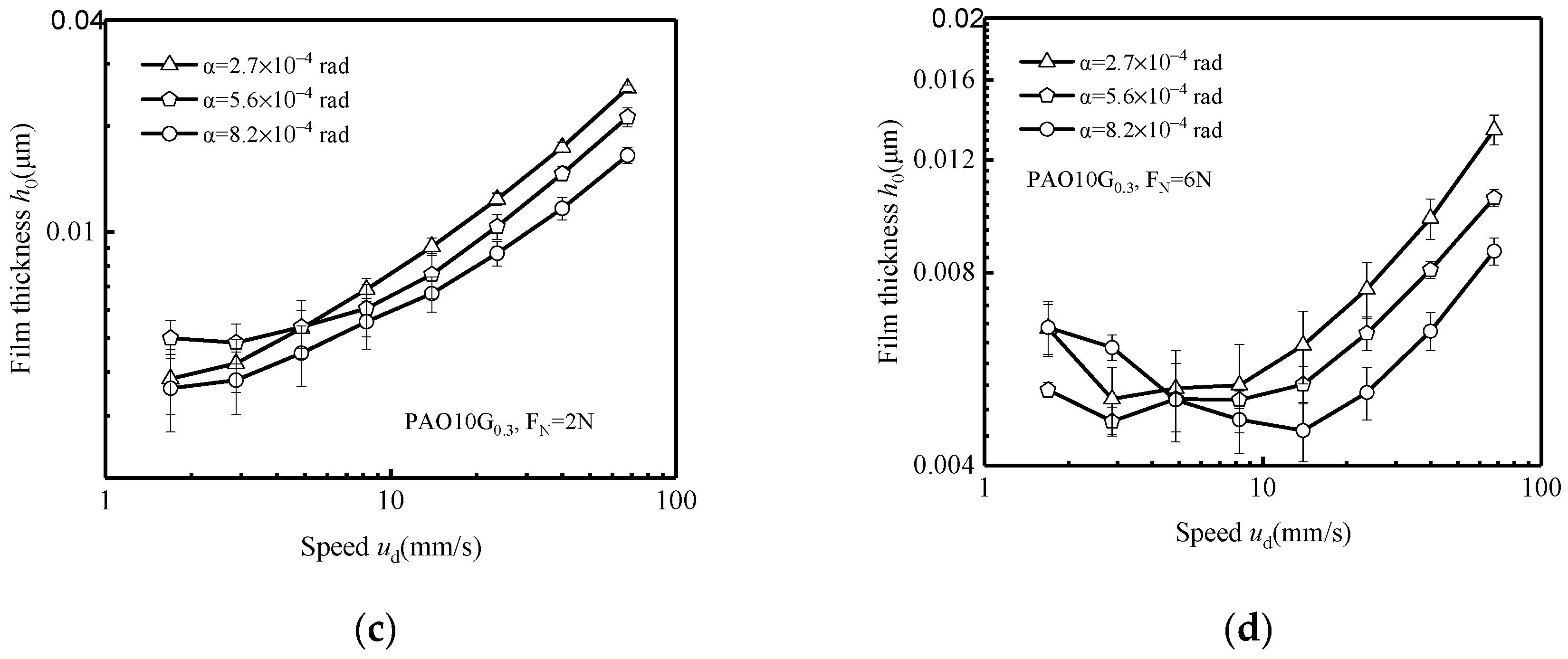

4.2. Analysis of Film Thickness

5. Conclusions

- GMS as an OFM can be effectively adsorbed on the contact surface of the friction pair, improving the lubrication performance of base oil, reducing COF, as well increasing the film thickness.

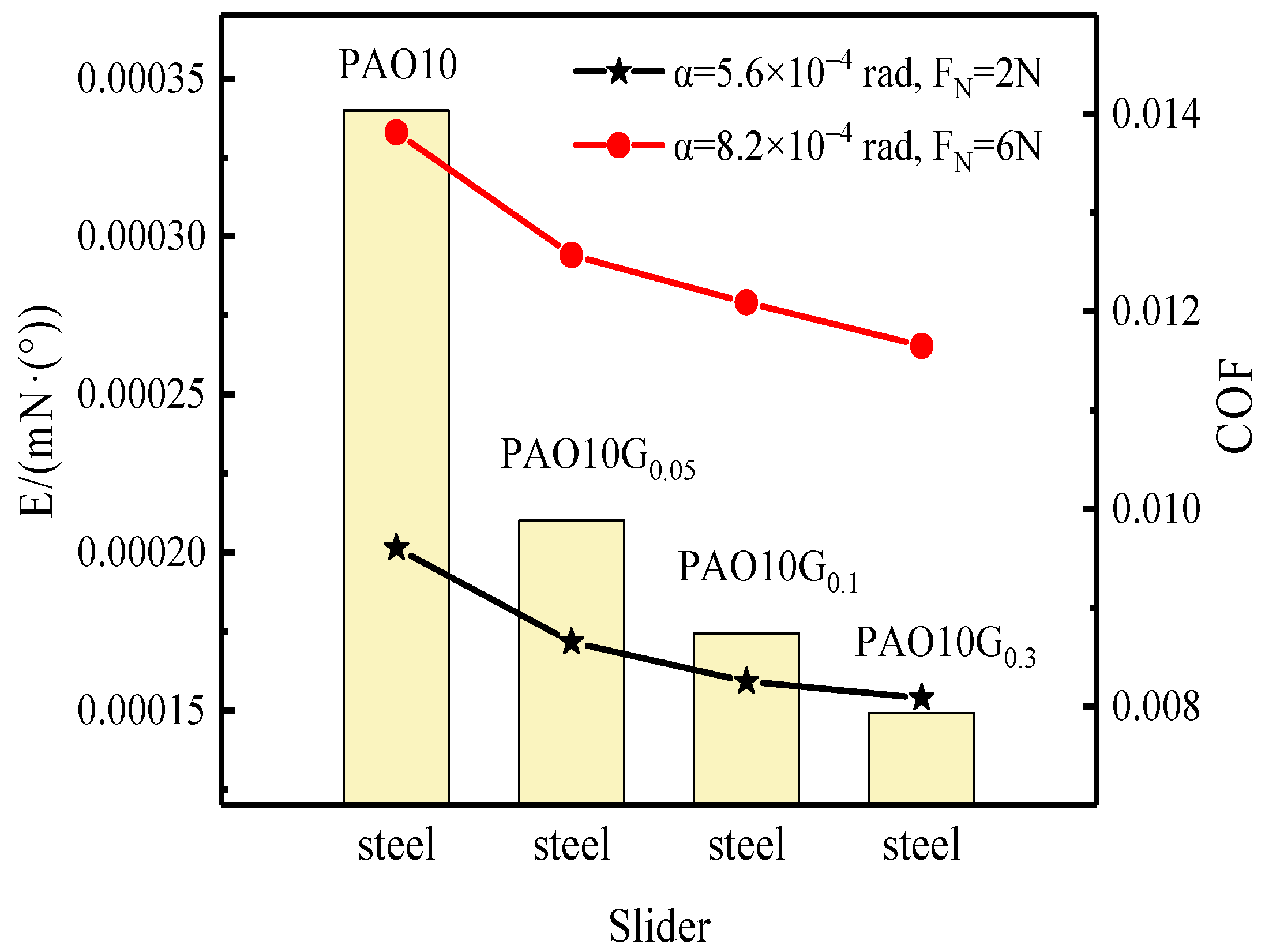

- The film thickness and COF of PAO10 and PAO10G under different slider inclinations are compared. The friction performance of PAO10G is better than that of PAO10 under various slider inclinations; under the same working conditions, the film thickness tends to increase with an increase in slider inclinations, while the COF decreases.

- The relationship between lubricant wettability and potential energy barrier is analyzed. The potential energy barrier and COF have the same variation trend. It is proved that CAH can better characterize lubricant wettability.

- The reason why the COF of PAO10G decreases while the film thickness increases under full-film lubrication is analyzed, and it is speculated that interface slippage may have occurred.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Yi, S.; Ge, X.Y.; Li, J.J. Development and prospects of liquid superlubricity. J. Tsinghua Univ. Sci. Technol. 2020, 60, 617–629. [Google Scholar]

- Tang, Z.L.; Li, S.H. A review of recent developments of friction modifiers for liquid lubricants (2007–present). Curr. Opin. Solid State Mater. Sci. 2014, 18, 119–139. [Google Scholar] [CrossRef]

- Faig, J.J.; Zhang, Y.Y.; Ng, M.K.; Luo, S.J.; Shough, A.M.; Schilowitz, A.; Dierolf, M.; Uhrich, K.E. Thermocleavable friction modifiers for controlled release in lubricants. Tribol. Int. 2018, 120, 58–69. [Google Scholar] [CrossRef]

- Wells, H.; Southcombe, J. Theory and practice of lubrication. Sci. Am. 1920, 2, 32–36. [Google Scholar] [CrossRef]

- Langmuir, I.P. The mechanism of the surface phenomena of flotation. Trans. Faraday Soc. 1920, 15, 62–74. [Google Scholar] [CrossRef]

- Hardy, W.B.; Doubleday, I. Boundary lubrication—The paraffin series. Proc. R. Soc. Lond. Ser. A 1922, 100, 550–574. [Google Scholar]

- Beltzer, M.; Jahanmir, S. Effect of additive molecular structure on friction. Lubr. Sci. 1988, 1, 3–26. [Google Scholar] [CrossRef]

- Kus, M.; Kalin, M. Influence of additives and their molecular structure on the static and dynamic wetting of oil on steel at room temperature. Appl. Surf. Sci. 2019, 490, 420–429. [Google Scholar] [CrossRef]

- Kalin, M.; Kus, M. New strategy for reducing the EHL friction in steel contacts using additive-formed oleophobic boundary films. Friction 2021, 9, 1346–1360. [Google Scholar] [CrossRef]

- Bowden, F.P. Friction and adhesion of brittle solids. In The Friction and Lubrication of Solids; Clarendon Press: Oxford, UK, 1971; Chapter VII; pp. 117–127. [Google Scholar]

- Levine, O.; Zisman, W.A. Physical properties of monolayers adsorbed at the solid-air interface. I. friction and wettability of aliphatic polar compounds and effect of halogenation. J. Phys. Chem. 1957, 61, 1068–1077. [Google Scholar] [CrossRef]

- Spikes, H. Friction modifier additives. Tribol. Lett. 2015, 60, 1. [Google Scholar] [CrossRef]

- Sánchez, R.; Franco, J.M.; Delgado, M.A.; Valencia, C.; Gallegos, C. Rheology of oleogels based on sorbitan and glyceryl monostearates and vegetable oils for lubricating applications. Grasas Aceites 2011, 62, 328–336. [Google Scholar]

- Campen, S.; Green, J.; Lamb, G.; Atkinson, D.; Spikes, H. On the increase in boundary friction with sliding speed. Tribol. Lett. 2012, 48, 237–248. [Google Scholar] [CrossRef]

- Ji, M.; Liu, S.H.; Xiao, H.P. Impacts of Glyceride Additive on Tribological Properties of Water-Based Drilling Mud for Steel–Steel Contact. Tribol. Lett. 2018, 66, 147. [Google Scholar] [CrossRef]

- Nunes, D.G.; da Sliva, A.D.M.; Cajaiba, J.; Perez-Gramatges, A.; Lachter, E.R.; Nascimento, R.S.V. Influence of glycerides-xanthan gum synergy on their performance as lubricants for water-based drilling fluids. J. Appl. Polym. Sci. 2014, 131, 41085. [Google Scholar] [CrossRef]

- Sönmez, A.; Verşan Kök, M.; Özel, R. Performance analysis of drilling fluid liquid lubricants. J. Petrol. Sci. Eng. 2013, 108, 64–73. [Google Scholar] [CrossRef]

- Ouyang, C.K.; Bai, P.P.; Wen, X.L.; Zhang, X.J.; Meng, Y.G.; Ma, L.R.; Tian, Y. Effects of conformational entropy on antiwear performances of organic friction modifiers. Tribol. Int. 2021, 156, 106848. [Google Scholar] [CrossRef]

- Hild, W.; Opitz, A.; Schaefer, J.A.; Scherge, M. The effect of wetting on the microhydrodynamics of surfaces lubricated with water and oil. Wear 2003, 254, 871–875. [Google Scholar] [CrossRef]

- Choo, J.H.; Spikes, H.A.; Ratoi, M.; Glovnea, R.; Forrest, A. Friction reduction in low-load hydrodynamic lubrication with a hydrophobic surface. Tribol. Lett. 2005, 40, 154–159. [Google Scholar] [CrossRef]

- Joseph, P.; Tabeling, P. Direct measurement of the apparent slip length. Phys. Rev. E 2005, 71, 035303. [Google Scholar] [CrossRef]

- Yaminsky, V.V. Molecular mechanisms of hydrophobic transitions. J. Adhes. Sci. Technol. 2000, 14, 187–233. [Google Scholar] [CrossRef]

- Kalin, M.; Polajnar, M. The correlation between the surface energy, the contact angle and the spreading parameter, and their relevance for the wetting behaviour of DLC with lubricating oils. Tribol. Int. 2013, 66, 225–233. [Google Scholar] [CrossRef]

- Guo, L. Research on Boundary Slippage in Thin Film Hydrodynamic Lubrication. Ph.D. Thesis, City University of Hong Kong, Hong Kong, China, 2015. [Google Scholar]

- Ponjavic, A.; Wong, J.S.S. The effect of boundary slip on elastohydrodynamic lubrication. RSC Adv. 2014, 4, 20821–20829. [Google Scholar] [CrossRef]

- Pit, R.; Hervet, H.; Léger, L. Friction and slip of a simple liquid at a solid surface. Tribol. Lett. 1999, 7, 147. [Google Scholar] [CrossRef]

- Pit, R.; Hervet, H.; Leger, L. Direct experimental evidence of slip in hexadecane: Solid interfaces. Phys. Rev. Lett. 2000, 85, 980–983. [Google Scholar] [CrossRef]

- Zhu, Y.X.; Granick, S. Limits of the hydrodynamic no-slip boundary condition. Phys. Rev. Lett. 2002, 88, 106102. [Google Scholar] [CrossRef]

- Zhu, Y.X.; Granick, S. No-slip boundary condition switches to partial slip when fluid contains surfactant. Langmuir 2002, 18, 10058–10063. [Google Scholar] [CrossRef]

- Guo, F.; Yang, S.Y.; Ma, C.; Wong, P.L. Experimental study on lubrication film thickness under different interface wettabilities. Tribol. Lett. 2014, 54, 81–88. [Google Scholar] [CrossRef]

- Spikes, H.A. The half-wetted bearing. Part 1: Extended Reynolds equation. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2003, 217, 1. [Google Scholar] [CrossRef]

- Spikes, H.A. The half-wetted bearing. Part 2: Potential application in low load contacts. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2003, 217, 15. [Google Scholar] [CrossRef]

- Polajnar, M.; Kalin, M. Effect of the slide-to-roll ratio and the contact kinematics on the elastohydrodynamic friction in diamond-like-carbon contacts with different wetting behaviours. Tribol. Lett. 2015, 60, 8. [Google Scholar] [CrossRef]

- Björling, M.; Shi, Y. DLC and glycerol: Superlubricity in rolling/sliding elastohydrodynamic lubrication. Tribol. Lett. 2019, 67, 23. [Google Scholar] [CrossRef]

- Choo, J.H.; Glovnea, R.P.; Forrest, A.K.; Spikes, H.A. A low friction bearing based on liquid slip at the wall. J. Tribol. 2007, 129, 611–620. [Google Scholar] [CrossRef]

- Guo, F.; Wong, P.L. A multi-beam intensity-based approach for lubricant film measurements in non-conformal contacts. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2002, 216, 281–291. [Google Scholar] [CrossRef]

- Li, L.; Li, L.; Li, D.; Zhang, L.B.; Lu, J.; Du, X.X.; Wu, Y.L. Effect of glycerin monostearate on emulsion stability of recombined dairy cream formed with caseins. Food Sci. 2022, 43, 60–67. [Google Scholar]

- Allen, C.M.; Drauglis, E. Boundary layer lubrication: Monolayer or multilayer. Wear 1969, 14, 363–384. [Google Scholar] [CrossRef]

- Whyman, G.; Bormashenko, E.; Stein, T. The rigorous derivation of Young, Cassie–Baxter and Wenzel equations and the analysis of the contact angle hysteresis phenomenon. Chem. Phys. Lett. 2008, 450, 355–359. [Google Scholar] [CrossRef]

- Fan, S.S. Experimental Study on the Effect of Oiliness Agent Adsorption on Lubrication in Non-Conformal Contact. Master’s Thesis, Qingdao University of Technology, Qingdao, China, 2022. [Google Scholar]

- Li, X. Development for Lubricating Film Measurement in Conformal Contacts and Experimental Studies of Lubricating. Ph.D. Thesis, Qingdao University of Technology, Qingdao, China, 2014. [Google Scholar]

- Jian, Y.S.; Jing, Z.G.; Guo, F.; Wong, P.L.; Li, X.M. Experimental study on the lubrication enhancement of slider-on-disc contact by stearic acid adsorption under limited lubricant supply. Lubricants 2022, 10, 353. [Google Scholar] [CrossRef]

- Singh, S.; Kango, S. Thermohydrodynamic performance of convergent slider bearings using different placement of square micro-textures and slip boundary. Phys. Scr. 2024, 99, 025015. [Google Scholar] [CrossRef]

| Lubricant | Dynamic Viscosity η/(mPas@22 °C) | Refractive Index n |

|---|---|---|

| PAO10 | 117.3 | 1.4635 |

| PAO10G0.05 | 117.4 | 1.4637 |

| PAO10G0.1 | 116.9 | 1.4635 |

| PAO10G0.3 | 117.1 | 1.4635 |

| Slider | Lubricant | Contact Angle, CA/(°) | Contact Angle Hysteresis, CAH/(°) |

|---|---|---|---|

| Steel | PAO10 | 55 ± 2.2 | 26 ± 1.5 |

| Steel | PAO10G0.05 | 71 ± 2 | 20.5 ± 1 |

| Steel | PAO10G0.1 | 77 ± 0.5 | 18.6 ± 0.5 |

| Steel | PAO10G0.3 | 77.5 ± 0.2 | 17.5 ± 0.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, Q.; Jing, Z.; Du, S.; Guo, F.; Mu, R. Influence of Glyceryl Monostearate Adsorption on the Lubrication Behavior of a Slider Bearing. Lubricants 2024, 12, 67. https://doi.org/10.3390/lubricants12030067

Xu Q, Jing Z, Du S, Guo F, Mu R. Influence of Glyceryl Monostearate Adsorption on the Lubrication Behavior of a Slider Bearing. Lubricants. 2024; 12(3):67. https://doi.org/10.3390/lubricants12030067

Chicago/Turabian StyleXu, Qiaoni, Zhaogang Jing, Shijie Du, Feng Guo, and Ruitao Mu. 2024. "Influence of Glyceryl Monostearate Adsorption on the Lubrication Behavior of a Slider Bearing" Lubricants 12, no. 3: 67. https://doi.org/10.3390/lubricants12030067

APA StyleXu, Q., Jing, Z., Du, S., Guo, F., & Mu, R. (2024). Influence of Glyceryl Monostearate Adsorption on the Lubrication Behavior of a Slider Bearing. Lubricants, 12(3), 67. https://doi.org/10.3390/lubricants12030067