Effects of Nitrogen Modification of Porous PVD–MoS2 Coatings on the Tribological Behavior under Rolling–Sliding Conditions in Vacuum

Abstract

1. Introduction

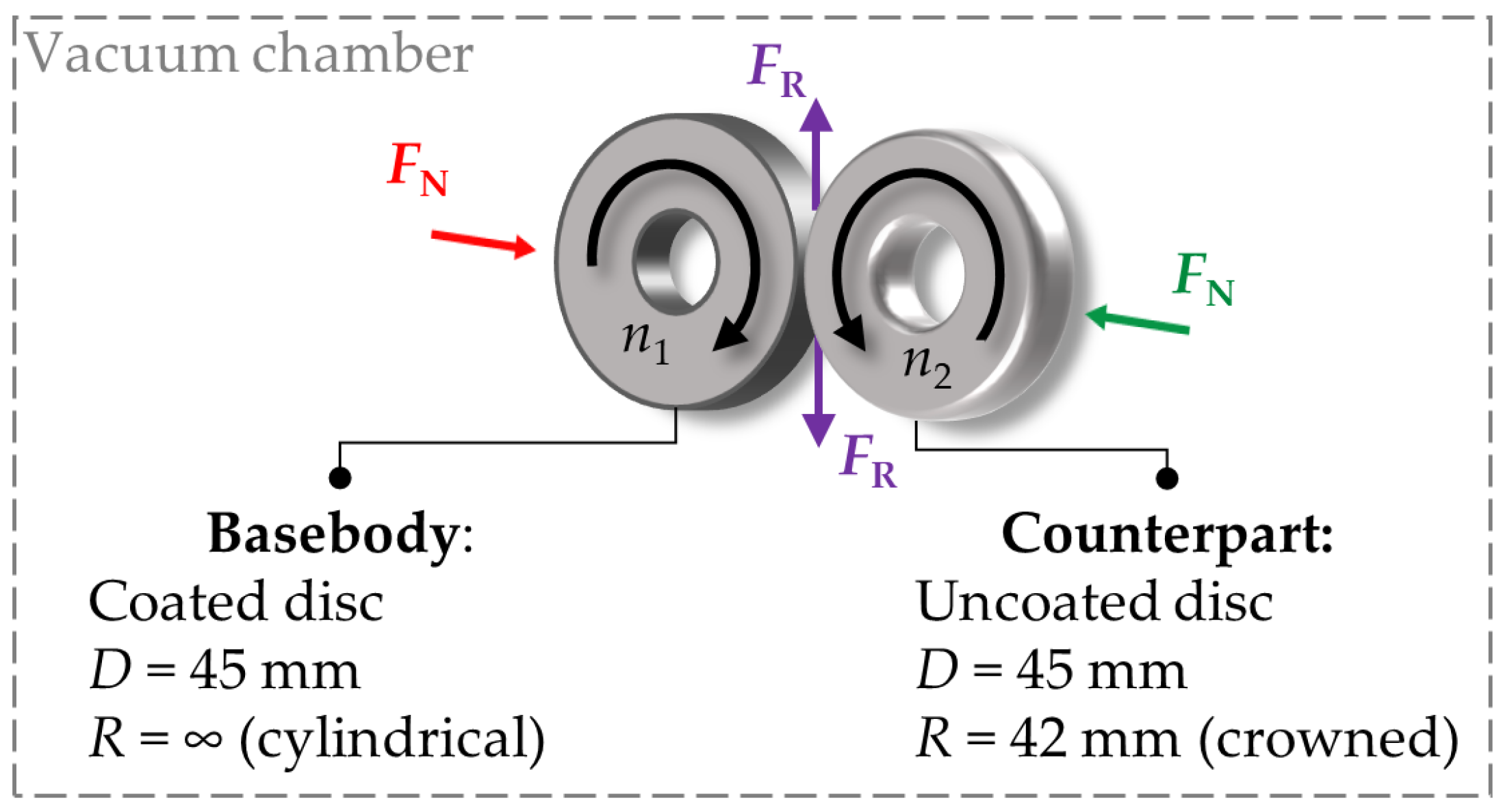

2. Materials and Methods

2.1. Specimens, Coatings, and Deposition Process

2.2. Coating Characterization

2.3. Tribological Testing

3. Results and Discussion

3.1. As-Deposited Coating Characterization

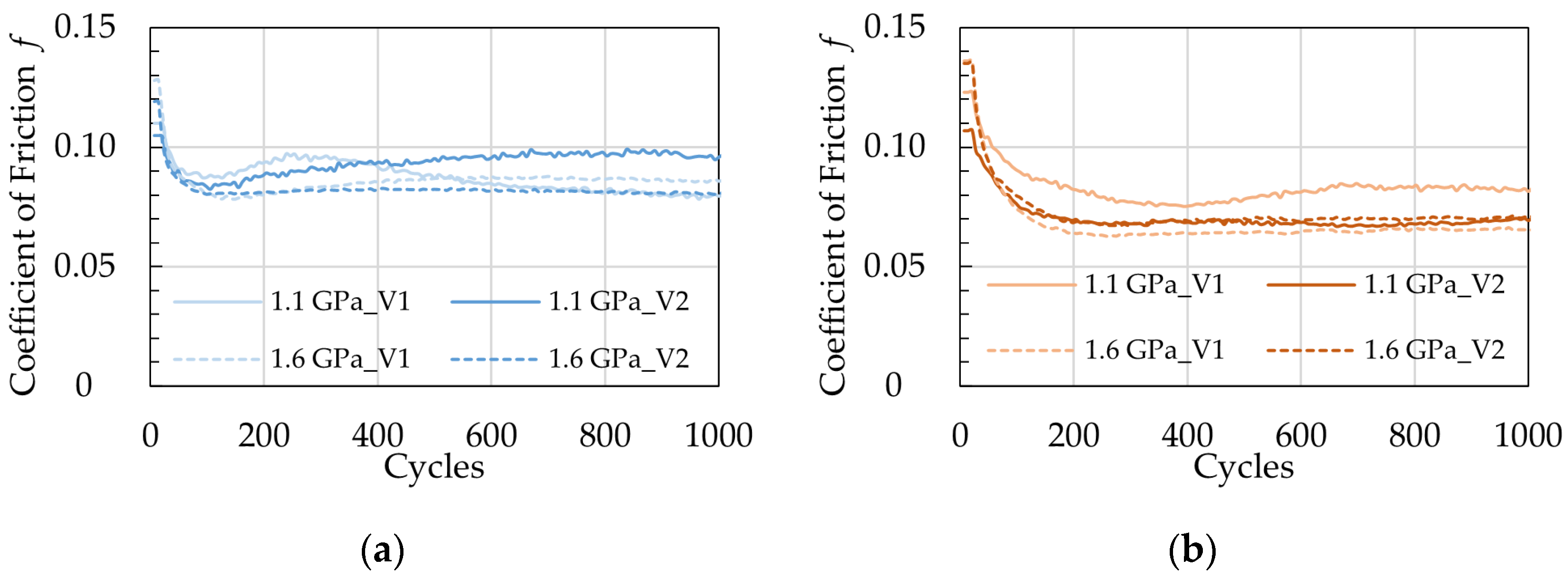

3.2. Frictional Behavior

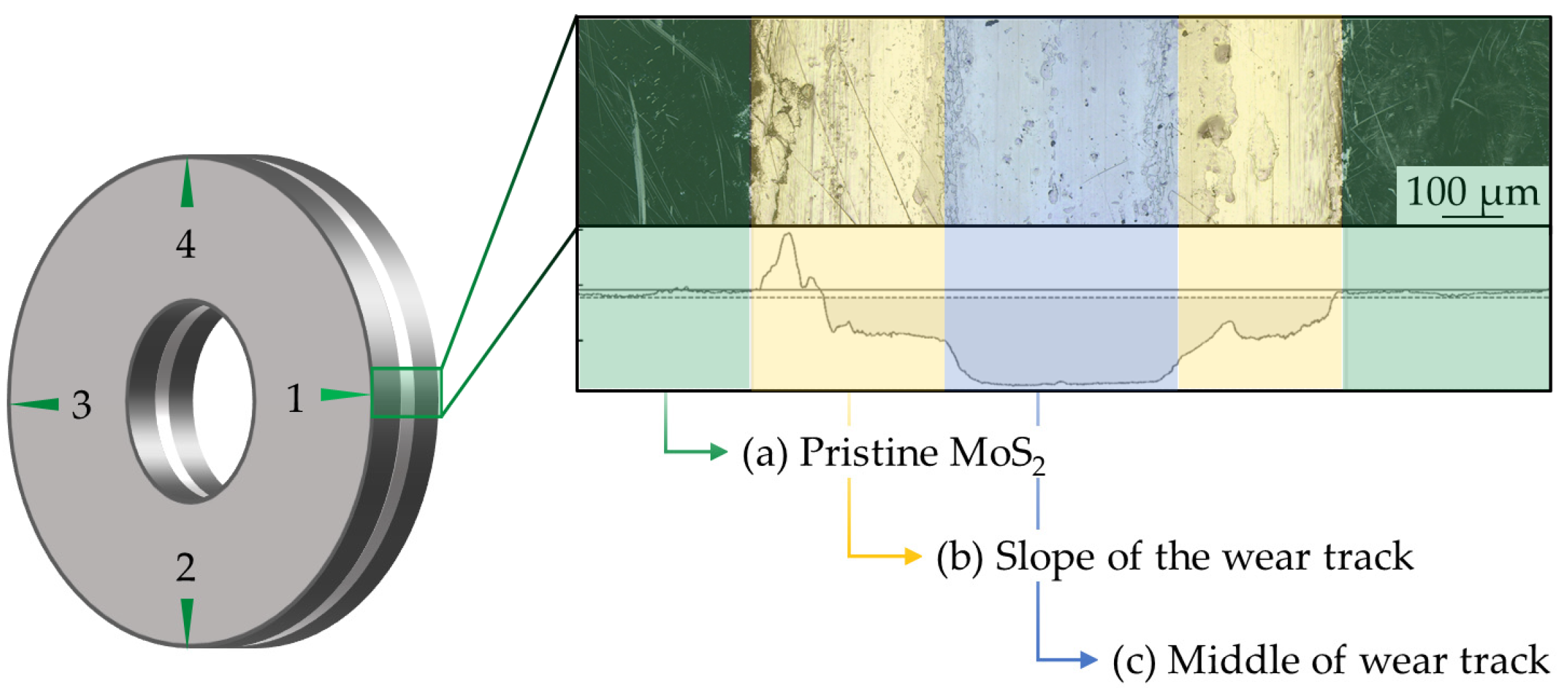

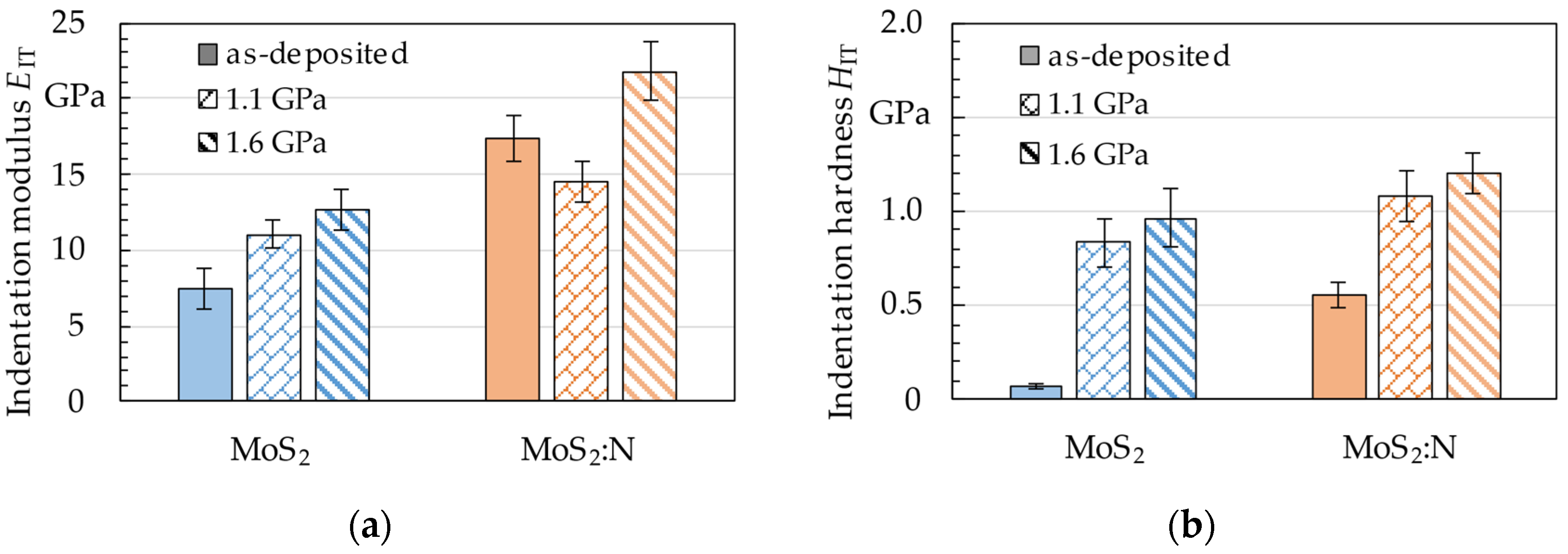

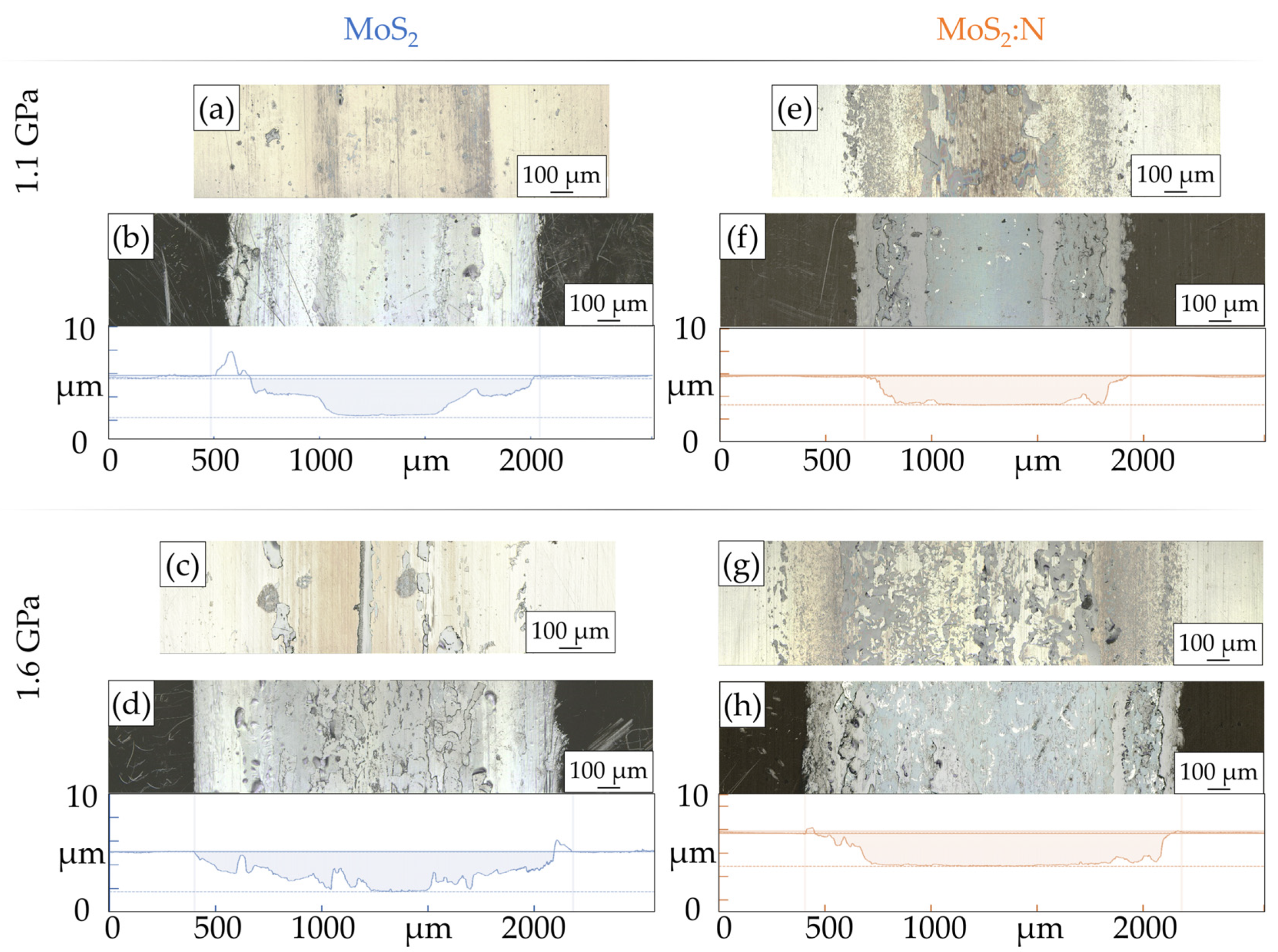

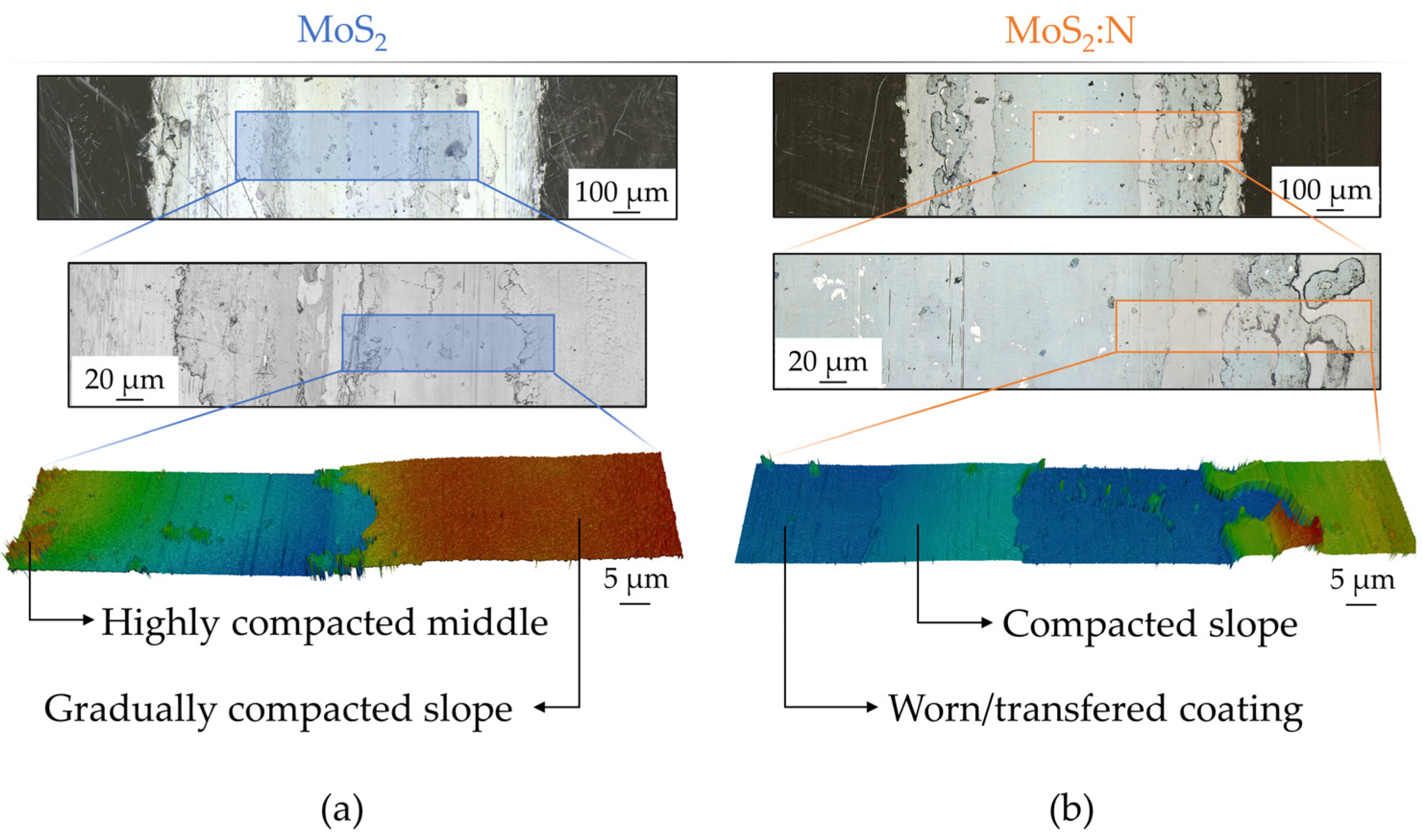

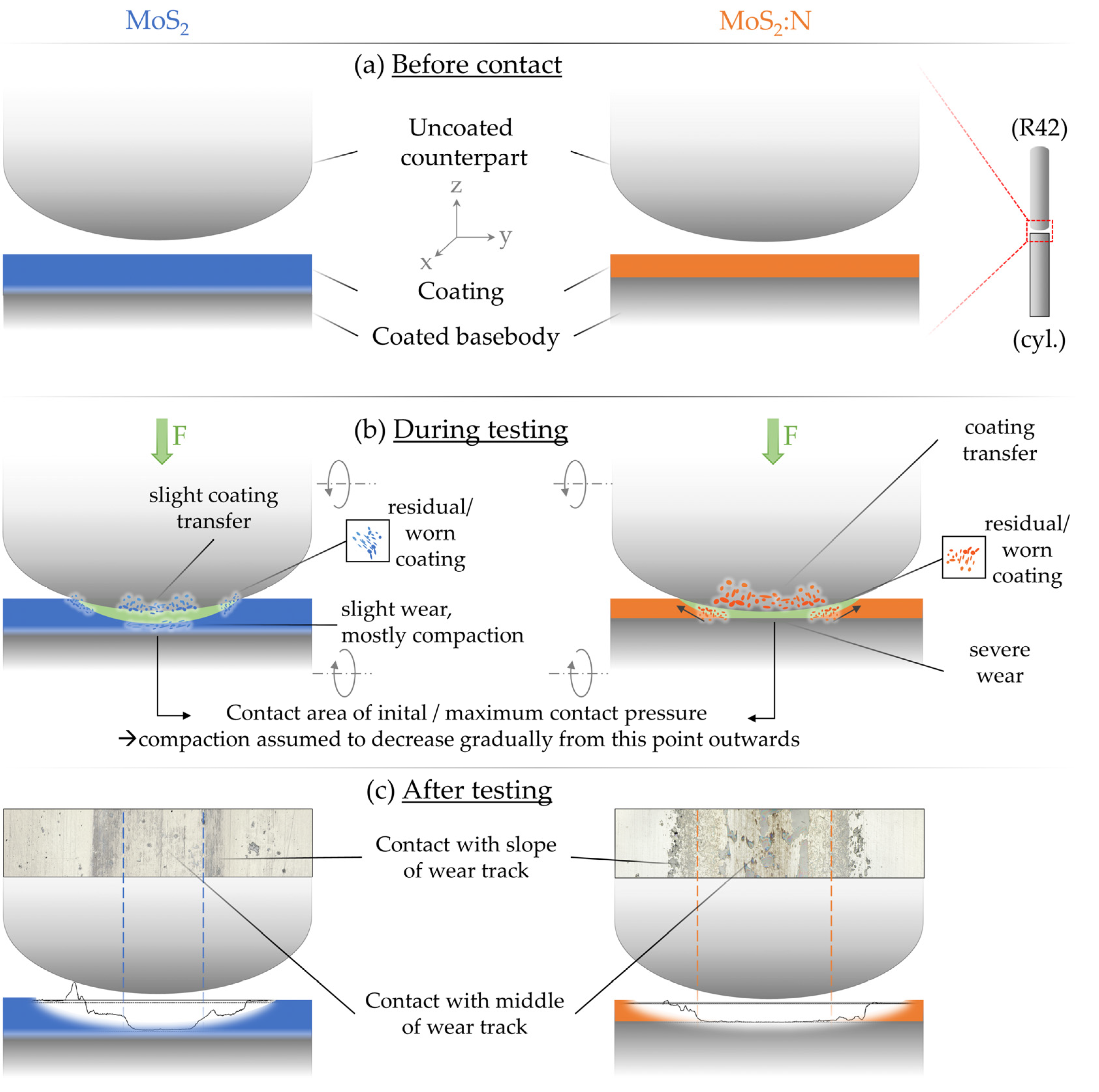

3.3. Coating Compaction

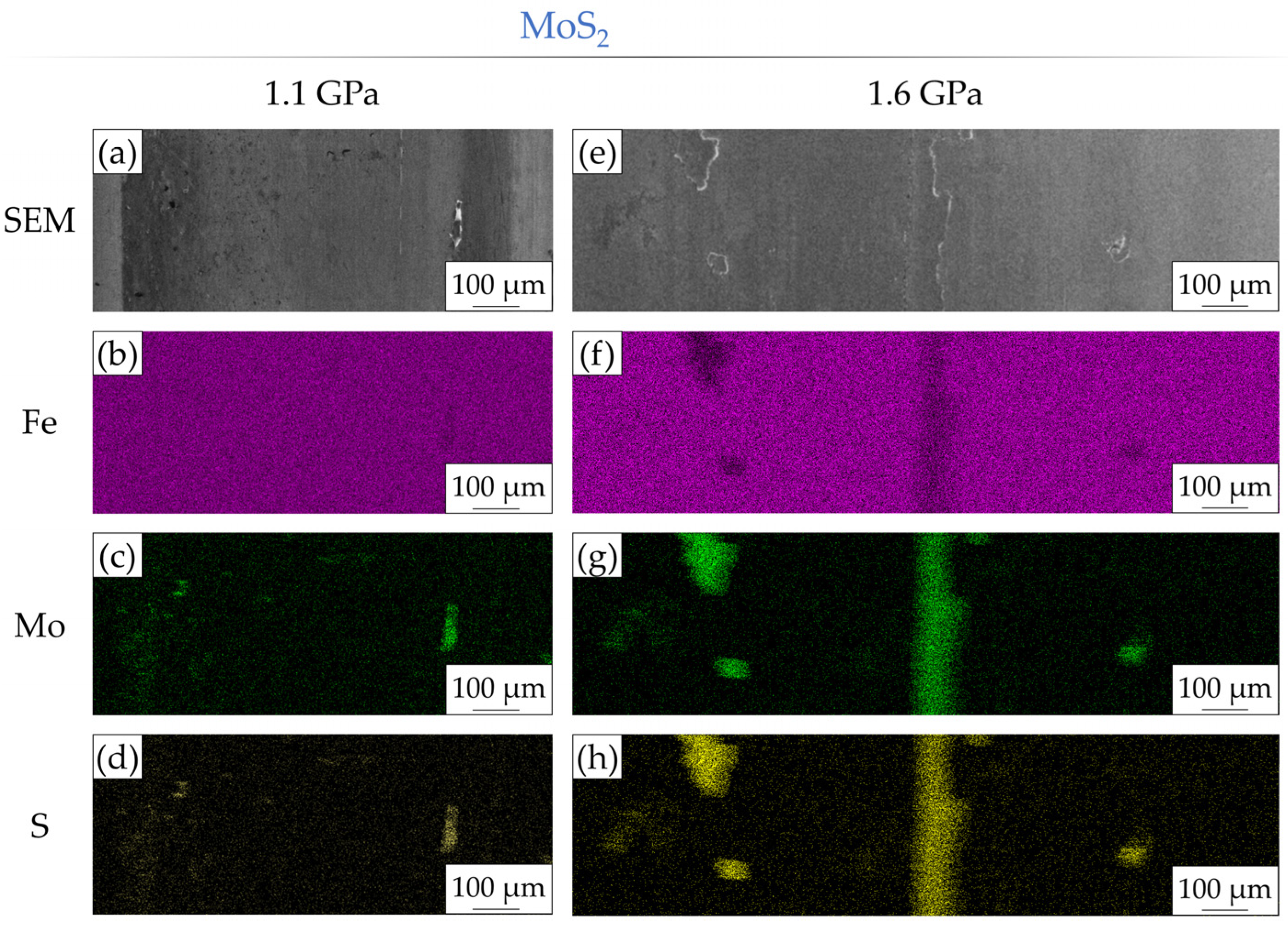

3.4. Wear Behavior

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Vazirisereshk, M.R.; Martini, A.; Strubbe, D.A.; Baykara, M.Z. Solid Lubrication with MoS2: A Review. Lubricants 2019, 7, 57. [Google Scholar] [CrossRef]

- Marian, M.; Berman, D.; Rota, A.; Jackson, R.L.; Rosenkranz, A. Layered 2D Nanomaterials to Tailor Friction and Wear in Machine Elements—A Review. Adv Mater. Inter 2022, 9, 2101622. [Google Scholar] [CrossRef]

- Gradt, T.; Schneider, T. Tribological Performance of MoS2 Coatings in Various Environments. Lubricants 2016, 4, 32. [Google Scholar] [CrossRef]

- Koch, F.; Nocentini, R.; Heinemann, B.; Lindig, S.; Junghanns, P.; Bolt, H. MoS2 coatings for the narrow support elements of the W-7X nonplanar coils. Fusion Eng. Des. 2007, 82, 1614–1620. [Google Scholar] [CrossRef]

- Serles, P.; Gaber, K.; Pajovic, S.; Colas, G.; Filleter, T. High Temperature Microtribological Studies of MoS2 Lubrication for Low Earth Orbit. Lubricants 2020, 8, 49. [Google Scholar] [CrossRef]

- Prozhega, M.V.; Kharkov, M.M.; Reschikov, E.O.; Rykunov, G.I.; Kaziev, A.V.; Kukushkina, M.S.; Kolodko, D.V.; Stepanova, T.V. Estimation of MoS2 Coating Performance on Bronze and Steel in Vacuum at High Temperatures. Coatings 2022, 12, 125. [Google Scholar] [CrossRef]

- Roberts, E.W. Space tribology: Its role in spacecraft mechanisms. J. Phys. D Appl. Phys. 2012, 45, 503001. [Google Scholar] [CrossRef]

- Donnet, C.; Martin, J.M.; Le Mogne, T.; Belin, M. Super-low friction of MoS2 coatings in various environments. Tribol. Int. 1996, 29, 123–128. [Google Scholar] [CrossRef]

- Mukhtar, S.H.; Wani, M.F.; Sehgal, R.; Sharma, M.D. Nano-mechanical and nano-tribological characterisation of self-lubricating MoS2 nano-structured coating for space applications. Tribol. Int. 2023, 178, 108017. [Google Scholar] [CrossRef]

- Babuska, T.F.; Curry, J.F.; Dugger, M.T.; Lu, P.; Xin, Y.; Klueter, S.; Kozen, A.C.; Grejtak, T.; Krick, B.A. Role of Environment on the Shear-Induced Structural Evolution of MoS2 and Impact on Oxidation and Tribological Properties for Space Applications. ACS Appl. Mater. Interfaces 2022, 14, 13914–13924. [Google Scholar] [CrossRef]

- Hilton, M.R.; Fleischauer, P.D. TEM lattice imaging of the nanostructure of early-growth sputter-deposited MoS2 solid lubricant films. J. Mater. Res. 1990, 5, 406–421. [Google Scholar] [CrossRef]

- Pan, S.; Jin, K.; Wang, T.; Zhang, Z.; Zheng, L.; Umehara, N. Metal matrix nanocomposites in tribology: Manufacturing, performance, and mechanisms. Friction 2022, 10, 1596–1634. [Google Scholar] [CrossRef]

- Furlan, K.P.; de Mello, J.D.B.; Klein, A.N. Self-lubricating composites containing MoS2: A review. Tribol. Int. 2018, 120, 280–298. [Google Scholar] [CrossRef]

- Donnet, C.; Le Mogne, T.; Martin, J.M. Superlow friction of oxygen-free MoS2 coatings in ultrahigh vacuum. Surf. Coat. Technol. 1993, 62, 406–411. [Google Scholar] [CrossRef]

- Le Mogne, T.; Donnet, C.; Martin, J.M.; Tonck, A.; Millard-Pinard, N.; Fayeulle, S.; Moncoffre, N. Nature of super-lubricating MoS2 physical vapor deposition coatings. J. Vac. Sci. Technol. A Vac. Surf. Film. 1994, 12, 1998–2004. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, P.; Ji, L.; Liu, X.; Wan, H.; Chen, L.; Li, H.; Jin, Z. Tribological properties of MoS2 coating for ultra-long wear-life and low coefficient of friction combined with additive g-C3N4 in air. Friction 2021, 9, 789–801. [Google Scholar] [CrossRef]

- Domínguez-Meister, S.; Rojas, T.C.; Brizuela, M.; Sánchez-López, J.C. Solid lubricant behavior of MoS2 and WSe2-based nanocomposite coatings. Sci. Technol. Adv. Mater. 2017, 18, 122–133. [Google Scholar] [CrossRef]

- Zhang, X.; Lauwerens, W.; He, J.; Celis, J.-P. Structure and growth of basal and random oriented MoSx coatings deposited by magnetron sputtering. J. Vac. Sci. Technol. A Vac. Surf. Film. 2003, 21, 416–421. [Google Scholar] [CrossRef]

- Vierneusel, B.; Schneider, T.; Tremmel, S.; Wartzack, S.; Gradt, T. Humidity resistant MoS2 coatings deposited by unbalanced magnetron sputtering. Surf. Coat. Technol. 2013, 235, 97–107. [Google Scholar] [CrossRef]

- Muratore, C.; Voevodin, A.A. Control of molybdenum disulfide basal plane orientation during coating growth in pulsed magnetron sputtering discharges. Thin Solid Film. 2009, 517, 5605–5610. [Google Scholar] [CrossRef]

- Krauß, S.; Seynstahl, A.; Tremmel, S.; Meyer, B.; Bitzek, E.; Göken, M.; Yokosawa, T.; Zubiri, B.A.; Spiecker, E.; Merle, B. Structural reorientation and compaction of porous MoS2 coatings during wear testing. Wear 2022, 500–501, 204339. [Google Scholar] [CrossRef]

- Seynstahl, A.; Krauß, S.; Bitzek, E.; Meyer, B.; Merle, B.; Tremmel, S. Microstructure, Mechanical Properties and Tribological Behavior of Magnetron-Sputtered MoS2 Solid Lubricant Coatings Deposited under Industrial Conditions. Coatings 2021, 11, 455. [Google Scholar] [CrossRef]

- Bondarev, A.; Ponomarev, I.; Muydinov, R.; Polcar, T. Friend or Foe? Revising the Role of Oxygen in the Tribological Performance of Solid Lubricant MoS2. ACS Appl. Mater. Interfaces 2022, 14, 55051–55061. [Google Scholar] [CrossRef]

- Wang, J.; Lauwerens, W.; Wieers, E.; Stals, L.M.; He, J.; Celis, J.P. Structure and tribological properties of MoSx coatings prepared by bipolar DC magnetron sputtering. Surf. Coat. Technol. 2001, 139, 143–152. [Google Scholar] [CrossRef]

- Babuska, T.F.; Curry, J.F.; Thorpe, R.; Chowdhury, M.I.; Strandwitz, N.C.; Krick, B.A. High-Sensitivity Low-Energy Ion Spectroscopy with Sub-Nanometer Depth Resolution Reveals Oxidation Resistance of MoS2 Increases with Film Density and Shear-Induced Nanostructural Modifications of the Surface. ACS Appl. Nano Mater. 2023, 6, 1153–1160. [Google Scholar] [CrossRef] [PubMed]

- Serles, P.; Sun, H.; Colas, G.; Tam, J.; Nicholson, E.; Wang, G.; Howe, J.; Saulot, A.; Singh, C.V.; Filleter, T. Structure-Dependent Wear and Shear Mechanics of Nanostructured MoS2 Coatings. Adv Mater. Inter 2020, 7, 1901870. [Google Scholar] [CrossRef]

- Ding, X.; Zeng, X.T.; He, X.Y.; Chen, Z. Tribological properties of Cr- and Ti-doped MoS2 composite coatings under different humidity atmosphere. Surf. Coat. Technol. 2010, 205, 224–231. [Google Scholar] [CrossRef]

- Lu, X.; Yan, M.; Yan, Z.; Chen, W.; Sui, X.; Hao, J.; Liu, W. Exploring the atmospheric tribological properties of MoS2-(Cr, Nb, Ti, Al, V) composite coatings by high throughput preparation method. Tribol. Int. 2021, 156, 106844. [Google Scholar] [CrossRef]

- Wang, X.; Xing, Y.; Ma, S.; Zhang, X.; Xu, K.; Teer, D.G. Microstructure and mechanical properties of MoS2/titanium composite coatings with different titanium content. Surf. Coat. Technol. 2007, 201, 5290–5293. [Google Scholar] [CrossRef]

- Stoyanov, P.; Fishman, J.Z.; Lince, J.R.; Chromik, R.R. Micro-tribological performance of MoS2 lubricants with varying Au content. Surf. Coat. Technol. 2008, 203, 761–765. [Google Scholar] [CrossRef]

- Chien, H.-H.; Ma, K.-J.; Vattikuti, S.P.; Kuo, C.-H.; Huo, C.-B.; Chao, C.-L. Tribological behaviour of MoS2/Au coatings. Thin Solid Film. 2010, 518, 7532–7534. [Google Scholar] [CrossRef]

- Yin, X.; Jin, J.; Chen, X.; Ma, T.; Zhang, C. A New Pathway for Superlubricity in a Multilayered MoS2-Ag Film under Cryogenic Environment. Nano Lett. 2021, 21, 10165–10171. [Google Scholar] [CrossRef] [PubMed]

- Zhao, X.; Lu, Z.; Wu, G.; Zhang, G.; Wang, L.; Xue, Q. Preparation and properties of DLC/MoS2 multilayer coatings for high humidity tribology. Mater. Res. Express 2016, 3, 66401. [Google Scholar] [CrossRef]

- Niakan, H.; Zhang, C.; Hu, Y.; Szpunar, J.A.; Yang, Q. Thermal stability of diamond-like carbon–MoS2 thin films in different environments. Thin Solid Film. 2014, 562, 244–249. [Google Scholar] [CrossRef]

- Baker, C.C.; Voevodin, A.A.; Zabinski, J.S. Comparison of WC/DLC/WS2 and YSZ/Au/DLC/MoS2 “Chameleon” Coatings for Tribological Applications. In World Tribology Congress III, Volume 2; World Tribology Congress III: Washington, DC, USA, 2005; pp. 379–380. ISBN 0-7918-4202-9. [Google Scholar]

- Baker, C.C.; Chromik, R.R.; Wahl, K.J.; Hu, J.J.; Voevodin, A.A. Preparation of chameleon coatings for space and ambient environments. Thin Solid Film. 2007, 515, 6737–6743. [Google Scholar] [CrossRef]

- Hudec, T.; Roch, T.; Gregor, M.; Orovčík, Ľ.; Mikula, M.; Polcar, T. Tribological behaviour of Mo-S-N solid lubricant coatings in vacuum, nitrogen gas and elevated temperatures. Surf. Coat. Technol. 2021, 405, 126722. [Google Scholar] [CrossRef]

- Fu, Y.; He, T.; Yang, W.; Xu, J.; Mu, B.; Pang, X.; Wang, P. Structure, Mechanical and Tribological Properties of MoSN/MoS2 Multilayer Films. Coatings 2019, 9, 108. [Google Scholar] [CrossRef]

- Hebbar Kannur, K.; Yaqub, T.B.; Pupier, C.; Héau, C.; Cavaleiro, A. Mechanical Properties and Vacuum Tribological Performance of Mo-S-N Sputtered Coatings. ACS Appl. Mater. Interfaces 2020, 12, 43299–43310. [Google Scholar] [CrossRef]

- Hebbar Kannur, K.; Yaqub, T.B.; Huminiuc, T.; Polcar, T.; Pupier, C.; Héau, C.; Cavaleiro, A. Synthesis and structural properties of Mo-S-N sputtered coatings. Appl. Surf. Sci. 2020, 527, 146790. [Google Scholar] [CrossRef]

- Hudec, T.; Mikula, M.; Satrapinskyy, L.; Roch, T.; Truchlý, M.; Švec, P.; Huminiuc, T.; Polcar, T. Structure, mechanical and tribological properties of Mo-S-N solid lubricant coatings. Appl. Surf. Sci. 2019, 486, 1–14. [Google Scholar] [CrossRef]

- Patzer, G.; Woydt, M.; Shah, R.; Miller, C.; Iaccarino, P. Test Modes for Establishing the Tribological Profile under Slip-Rolling. Lubricants 2020, 8, 59. [Google Scholar] [CrossRef]

- Woydt, M.; Scholz, C.; Burbank, J.; Spaltmann, D. Slip-rolling resistant steel alloys up to P0max of 3,920 MPa. Wear 2021, 474–475, 203707. [Google Scholar] [CrossRef]

- Polzer, M.; Bartz, M.; Rothammer, B.; Schulz, E.; Wartzack, S. Tribological behavior of different doped ta-C coatings for slip-rolling contacts with high hertzian contact pressure. ILT, 2023; ahead-of-print. [Google Scholar] [CrossRef]

- Burbank, J.; Woydt, M. Friction and wear reductions in slip-rolling steel contacts through pre-conditioned chemical tribofilms from bismuth compounds. Wear 2016, 360–361, 29–37. [Google Scholar] [CrossRef]

- Yilmaz, M.; Kratzer, D.; Lohner, T.; Michaelis, K.; Stahl, K. A study on highly-loaded contacts under dry lubrication for gear applications. Tribol. Int. 2018, 128, 410–420. [Google Scholar] [CrossRef]

- Hofmann, S.; Yilmaz, M.; Maier, E.; Lohner, T.; Stahl, K. Friction and contact temperature in dry rolling-sliding contacts with MoS2-bonded and a-C:H:Zr DLC coatings. Int. J. Mech. Mater. Eng. 2021, 16, 9. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. Measurement of hardness and elastic modulus by instrumented indentation: Advances in understanding and refinements to methodology. J. Mater. Res. 2004, 19, 3–20. [Google Scholar] [CrossRef]

- Bückle, H.; Frank, K. Mikrohärteprüfung und Ihre Anwendung; Berliner Union: Stuttgart, Germany, 1965. [Google Scholar]

- Archard, J.F. Contact and Rubbing of Flat Surfaces. J. Appl. Phys. 1953, 24, 981–988. [Google Scholar] [CrossRef]

- Dreva, K.; Morina, A.; Yang, L.; Neville, A. The effect of temperature on water desorption and oxide formation in MoS2 coatings and its impact on tribological properties. Surf. Coat. Technol. 2022, 433, 128077. [Google Scholar] [CrossRef]

- Rigato, V.; Maggioni, G.; Patelli, A.; Boscarino, D.; Renevier, N.; Teer, D. Properties of sputter-deposited MoS2/metal composite coatings deposited by closed field unbalanced magnetron sputter ion plating. Surf. Coat. Technol. 2000, 131, 206–210. [Google Scholar] [CrossRef]

- Buck, V. Lattice parameters of sputtered MoS2 films. Thin Solid Film. 1991, 198, 157–167. [Google Scholar] [CrossRef]

- Renevier, N.; Fox, V.; Teer, D.; Hampshire, J. Coating characteristics and tribological properties of sputter-deposited MoS2/metal composite coatings deposited by closed field unbalanced magnetron sputter ion plating. Surf. Coat. Technol. 2000, 127, 24–37. [Google Scholar] [CrossRef]

- Simmonds, M.; Savan, A.; Pflüger, E.; van Swygenhoven, H. Mechanical and tribological performance of MoS2 co-sputtered composites. Surf. Coat. Technol. 2000, 126, 15–24. [Google Scholar] [CrossRef]

- Pan, S.; Saso, T.; Yu, N.; Sokoluk, M.; Yao, G.; Umehara, N.; Li, X. New study on tribological performance of AA7075-TiB2 nanocomposites. Tribol. Int. 2020, 152, 106565. [Google Scholar] [CrossRef]

- Sklenak, S.; Brimmers, J.; Brecher, C. Analyse der Wirkmechanismen im fluidfreien Wälzkontakt mit beschichteten Oberflächen. Forsch. Ing. 2022, 86, 357–366. [Google Scholar] [CrossRef]

- Yang, Z.; Bhowmick, S.; Sen, F.G.; Alpas, A.T. Microscopic and atomistic mechanisms of sliding friction of MoS2: Effects of undissociated and dissociated H2O. Appl. Surf. Sci. 2021, 563, 150270. [Google Scholar] [CrossRef]

- Marian, M.; Feile, K.; Rothammer, B.; Bartz, M.; Wartzack, S.; Seynstahl, A.; Tremmel, S.; Krauß, S.; Merle, B.; Böhm, T.; et al. Ti3C2Tx solid lubricant coatings in rolling bearings with remarkable performance beyond state-of-the-art materials. Appl. Mater. Today 2021, 25, 101202. [Google Scholar] [CrossRef]

| Deposition Parameters | MoS2 | MoS2:N |

|---|---|---|

| Adhesion layer duration in s | 480 | - |

| Functional layer duration in s | 3600 | 4200 |

| Sputtering power in kW | 2.0 | |

| Bias voltage in V | –100 | |

| Argon gas flow in sccm | 120 | |

| Nitrogen gas flow in sccm | – | 15 |

| Temperature (chamber) in °C | 50 | |

| Load Case | 1 | 2 |

|---|---|---|

| FN in N | 265 | 675 |

| pmax in GPa | 1.1 | 1.6 |

| n1 in rpm | 423 | |

| n2 in rpm | 381 | |

| Δv in ms−1 | 0.1 | |

| Cycles ntotal | 1000 | |

| T in °C | RT | |

| Repetitions n | 2 | |

| SRR in % | 10.5 | |

| Coating Properties | MoS2 | MoS2:N |

|---|---|---|

| Roughness Ra in nm | 45 ± 7 | 46 ± 7 |

| Coating thickness in µm | 4.0 ± 0.2 | 2.7 ± 0.1 |

| Indentation modulus EIT in GPa | 7.44 ± 1.29 | 17.29 ± 1.40 |

| Indentation hardness HIT in GPa | 0.07 ± 0.02 | 0.56 ± 0.06 |

| O2 content in at % | 3.34 ± 0.85 | 4.87 ± 1.21 |

| S content in at % | 60.57 ± 0.67 | 55.42 ± 2.19 |

| Mo content in at % | 33.13 ± 0.45 | 30.09 ± 1.48 |

| S/Mo-ratio | 1.83 ± 0.01 | 1.84 ± 0.03 |

| Frictional Behavior | MoS2 | MoS2:N | ||

|---|---|---|---|---|

| 1.1 GPa | 1.6 GPa | 1.1 GPa | 1.6 GPa | |

| Mean COF f500–1000 | 0.090 ± 0.007 | 0.084 ± 0.003 | 0.075 ± 0.007 | 0.068 ± 0.003 |

| Wear Behavior | MoS2 | MoS2:N | ||

|---|---|---|---|---|

| 1.1 GPa | 1.6 GPa | 1.1 GPa | 1.6 GPa | |

| Mean wear track depth hwear in µm | 3.19 ±0.27 | 3.02 ±0.40 | 2.65 ±0.14 | 2.62 ±0.14 |

| Mean wear track width bwear in mm | 1.54 ±0.06 | 1.79 ±0.06 | 1.34 ±0.02 | 1.88 ±0.04 |

| Mean wear track area Awear in mm2 | 2.54 ±0.25 | 2.73 ±0.44 | 2.16 ±0.41 | 3.24 ±0.29 |

| Mean wear coefficient wwear in 10−6 × mm3N−1m−1 | 9.57 ±0.96 | 4.05 ±0.65 | 8.14 ±1.56 | 4.79 ±0.42 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Seynstahl, A.; Polzer, M.; Bartz, M.; Wartzack, S.; Tremmel, S. Effects of Nitrogen Modification of Porous PVD–MoS2 Coatings on the Tribological Behavior under Rolling–Sliding Conditions in Vacuum. Lubricants 2023, 11, 335. https://doi.org/10.3390/lubricants11080335

Seynstahl A, Polzer M, Bartz M, Wartzack S, Tremmel S. Effects of Nitrogen Modification of Porous PVD–MoS2 Coatings on the Tribological Behavior under Rolling–Sliding Conditions in Vacuum. Lubricants. 2023; 11(8):335. https://doi.org/10.3390/lubricants11080335

Chicago/Turabian StyleSeynstahl, Armin, Markus Polzer, Marcel Bartz, Sandro Wartzack, and Stephan Tremmel. 2023. "Effects of Nitrogen Modification of Porous PVD–MoS2 Coatings on the Tribological Behavior under Rolling–Sliding Conditions in Vacuum" Lubricants 11, no. 8: 335. https://doi.org/10.3390/lubricants11080335

APA StyleSeynstahl, A., Polzer, M., Bartz, M., Wartzack, S., & Tremmel, S. (2023). Effects of Nitrogen Modification of Porous PVD–MoS2 Coatings on the Tribological Behavior under Rolling–Sliding Conditions in Vacuum. Lubricants, 11(8), 335. https://doi.org/10.3390/lubricants11080335