Abrasion Evaluation of Moon and Mars Simulants on Rotating Shaft/Sealing Materials: Simulants and Structural Materials Review and Selection

Abstract

1. Introduction

2. Materials

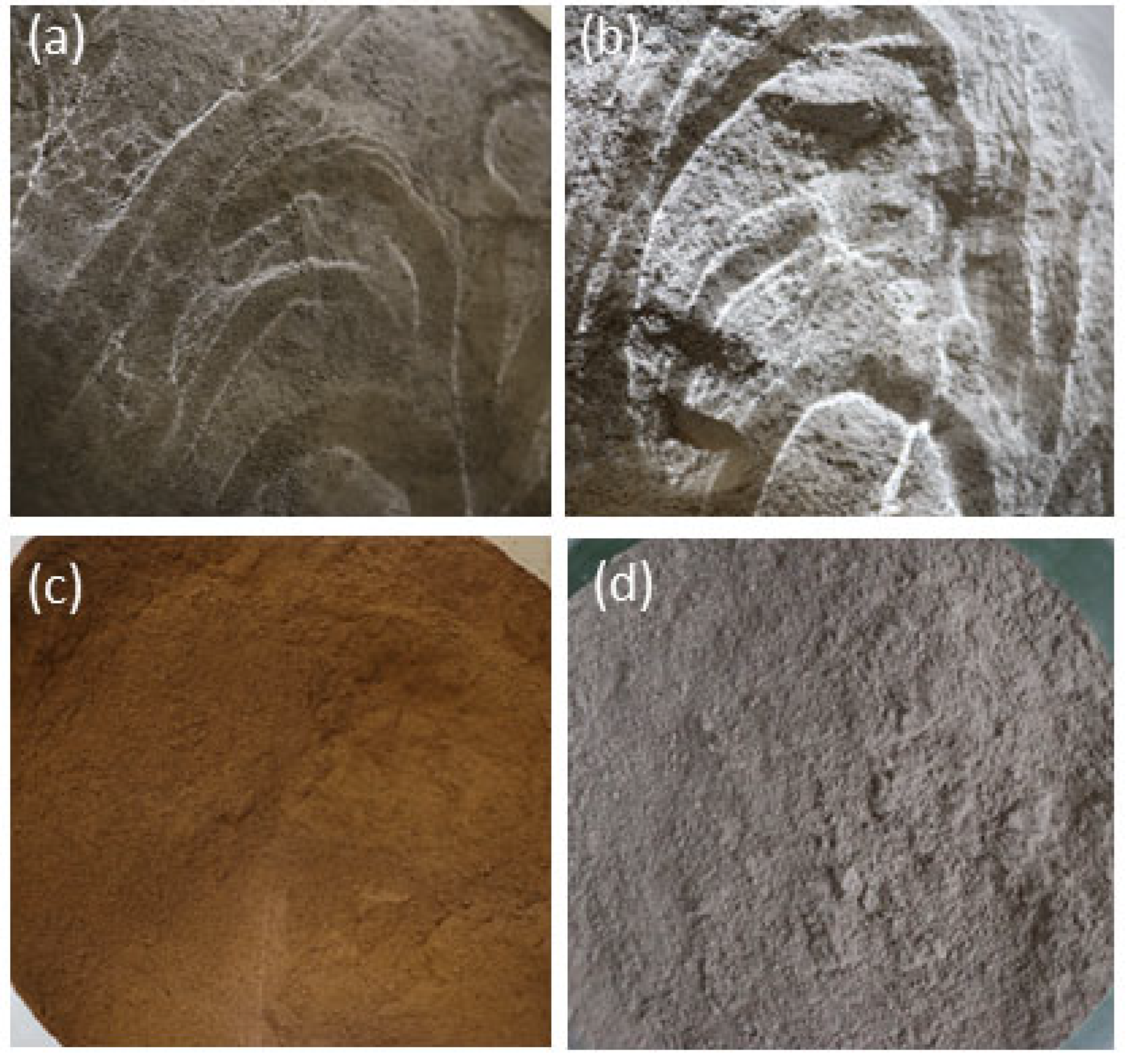

2.1. Review on the Preparation of Martian and Lunar Abrasive Simulants

- -

- Mean particle size: 50 µm

- -

- Median particle size: 45 µm

- -

- Particle size range: <0.04–300 µm

- -

- Uncompressed bulk density: 1.56 g/cm3

2.2. Frequently Applied Materials for Space Application Subjected to Possible Abrasive Conditions

2.2.1. Requirement for Target Materials

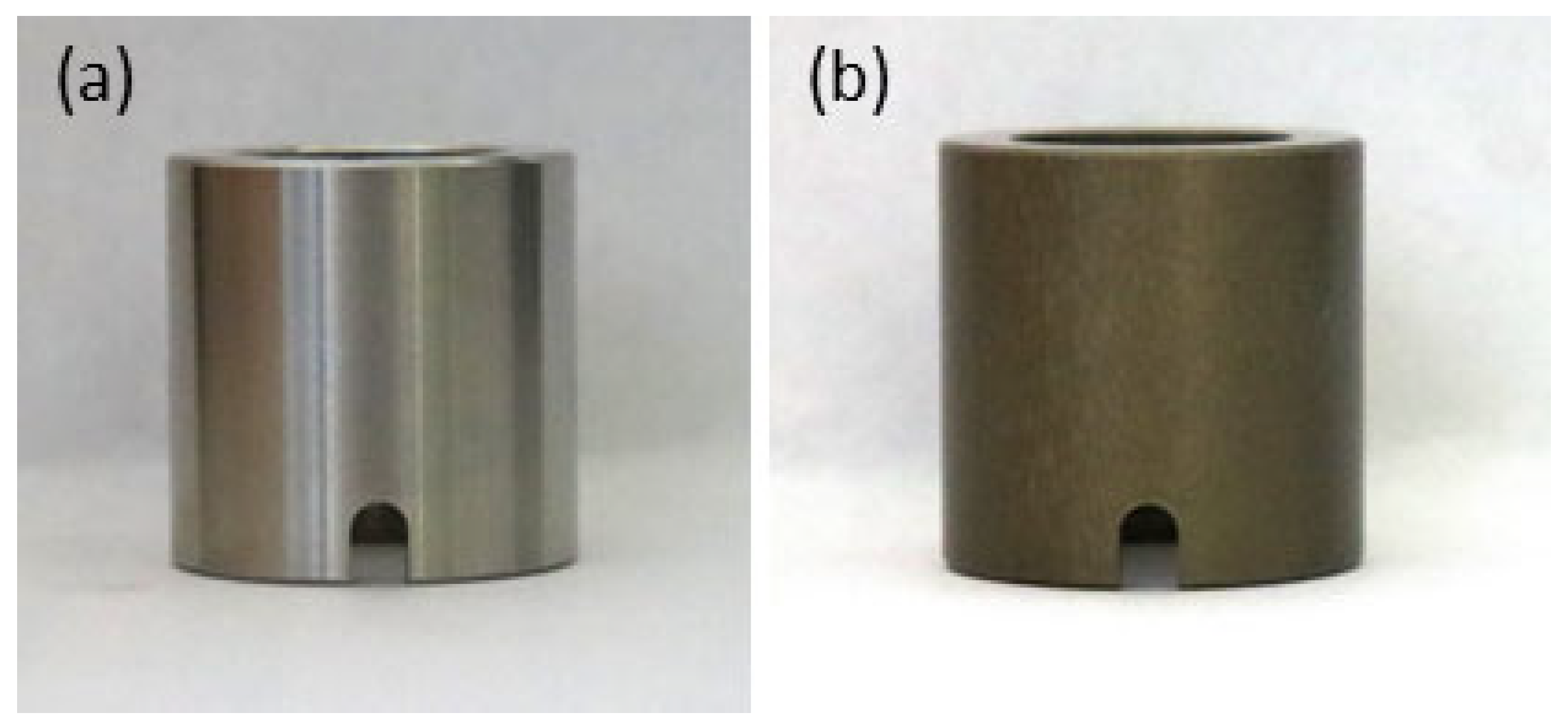

2.2.2. Materials for Drive System Units: Gears, Shafts, Cams, Guideways, Bushings

Steels [15]

Aluminum Alloys [14,15]

Titanium Alloys [14,15]

Copper-Based Alloys [14,15]

High-Density Alloys [15]

Polymer Composites [13,15]

Ceramics [14,15]

2.2.3. Summary of Possible Tribomaterials for Space Applications

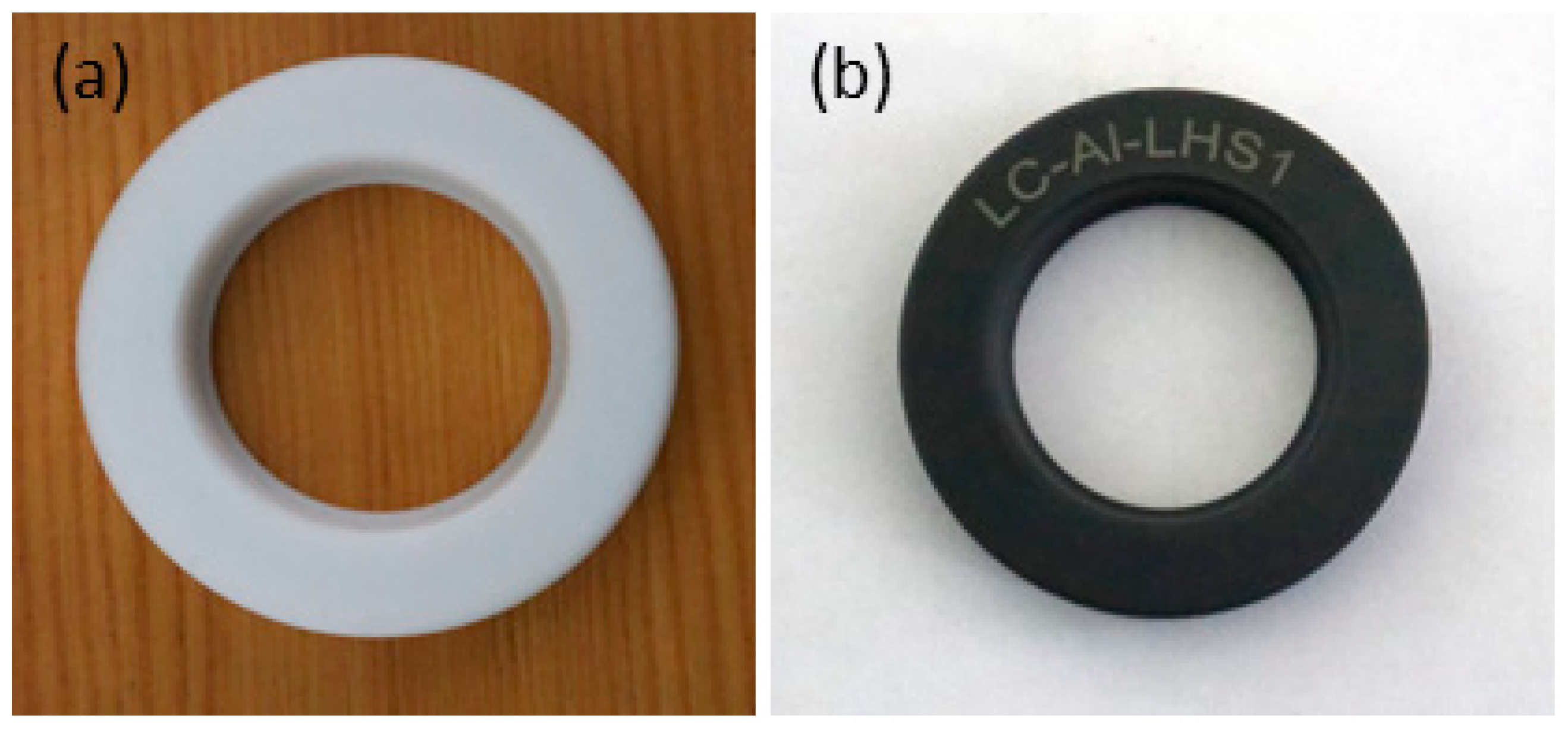

2.2.4. Identified Rotary Shaft and Seal Materials

2.2.5. Literature Analyses of Rotary/Reciprocating Shaft–Seal Mechanisms Possibly Subjected to Abrasive Conditions

3. Review on Application of Martian and Lunar Simulants

4. Discussion and Conclusions

- ○

- Level of mineralogical fidelity: particle shape and form relevant to abrasion test allowing for good representativity of the test with real lunar/Martian regolith;

- ○

- Particle size distribution;

- ○

- Density and gravity;

- ○

- Information basis of the preparation of simulants.

- -

- Structural and martensitic and manganese steel grades;

- -

- Stainless steel grades;

- -

- High-strength aluminum, anodized;

- -

- Other aluminum alloys;

- -

- Polymer/composites;

- -

- Ceramics;

- -

- Ti alloys.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gouache, T.P.; Patel, N.; Brunskill, C.; Scott, G.P.; Saaj, C.M.; Matthews, M.; Cui, L. Soil simulant sourcing for the ExoMars rover testbed. Planet. Space Sci. 2011, 59, 779–787. [Google Scholar] [CrossRef]

- Alexander, M. Mars Transportation Environment Definition Document. NASA Technical Memorandum, no. 210935. 2001. Available online: http://www.sti.nasa.gov (accessed on 7 June 2023).

- Newson, T.; Ahmed, A.; Joshi, D.; Zhang, X.; Osinski, G.R. Assessment of the Geomechanical Properties of Lunar Simulant Soils. in Earth and Space 2021: Space Exploration, Utilization, Engineering, and Construction in Extreme Environments. In Proceedings of the 17th Biennial International Conference on Engineering, Science, Construction, and Operations in Challenging Environments, Online, 19–23 April 2021; pp. 146–156. [Google Scholar] [CrossRef]

- Böttger, U.; De Vera, J.P.; Fritz, J.; Weber, I.; Hübers, H.W.; Schulze-Makuch, D. Optimizing the detection of carotene in cyanobacteria in a martian regolith analogue with a Raman spectrometer for the ExoMars mission. Planet. Space Sci. 2012, 60, 356–362. [Google Scholar] [CrossRef]

- Allen, C.C.; Morris, R.V.; Karen, M.J.; Golden, D.C.; Lindstrom, M.M.; Lockwood, J.P. Martian Regolith Simulant JSC Mars-1. In Lunar and Planetary Science Conference XXIX, 1998, no. Table 2. p. 1690. Available online: https://ui.adsabs.harvard.edu/abs/1998LPI....29.1690A/abstract (accessed on 7 June 2023).

- Cannon, K.M.; Britt, D.T.; Smith, T.M.; Fritsche, R.F.; Batcheldor, D. Mars global simulant MGS-1: A Rocknest-based open standard for basaltic martian regolith simulants. Icarus 2019, 317, 470–478. [Google Scholar] [CrossRef]

- Just, G.H.; Joy, K.H.; Roy, M.J.; Smith, K.L. Geotechnical characterisation of two new low-fidelity lunar regolith analogues (UoM-B and UoM-W) for use in large-scale engineering experiments. Acta Astronaut. 2020, 173, 414–424. [Google Scholar] [CrossRef]

- Linke, S.; Windisch, L.; Kueter, N.; Wanvik, J.E.; Voss, A.; Stoll, E.; Schilde, C.; Kwade, A. TUBS-M and TUBS-T based modular Regolith Simulant System for the support of lunar ISRU activities. Planet. Space Sci. 2020, 180, 104747. [Google Scholar] [CrossRef]

- Simulants, Feedstocks, and Additives. Available online: https://www.offplanetresearch.com/simulants-feedstocks-and-additives (accessed on 9 May 2022).

- Lunar Mare (LMS-1) High-Fidelity Moon Dirt Simulant. Available online: https://exolithsimulants.com/collections/regolith-simulants/products/lms-1-lunar-mare-simulant (accessed on 10 May 2022).

- Gruener, J.E.; Deitrick, S.R.; Tu, V.M.; Clark, J.V.; Ming, D.W. Cambon, Greenland ‘White Mountain’ Anorthosite: A New Lunar Polar Regolith Simulant Component. 2020. Available online: https://hudsonresourcesinc.com/nasa-greenspar-lunar-simulant-abstract-greenland-white-mountain-anorthosite-a-new-lunar-polar-regolith-simulant-component/ (accessed on 7 June 2023).

- Battler, M.M.; Spray, J.G. The Shawmere anorthosite and OB-1 as lunar highland regolith simulants. Planet. Space Sci. 2009, 57, 2128–2131. [Google Scholar] [CrossRef]

- Chen, J.; Ding, N.; Li, Z.; Wang, W. Organic polymer materials in the space environment. Prog. Aerosp. Sci. 2016, 83, 37–56. [Google Scholar] [CrossRef]

- Naser, M.Z.; Chehab, A.I. Materials and design concepts for space-resilient structures. Prog. Aerosp. Sci. 2018, 98, 74–90. [Google Scholar] [CrossRef]

- Roberts, E.W.; Eiden, M. A Space Tribology Handbook; Warrington: European Space Tribology Laboratory: Cheshire, UK, 2013. [Google Scholar]

- Lim, S.; Anand, M. Space Architecture Technology for Settlement and Exploration on Other Planetary Bodies—In-Situ Resource Utilisation (ISRU) Based Structures on the Moon. May 2014. Available online: https://els2014.arc.nasa.gov (accessed on 7 June 2023).

- Mars Atmosphere: Facts about the Composition and Climate. Available online: https://www.space.com/16903-mars-atmosphere-climate-weather.html (accessed on 18 March 2022).

- Lindsey, N.J. Lunar Station Protection: Lunar Regolith Shielding. In Proceedings of the International Lunar Conference, Hawaii Island, HI, USA, 16–22 November 2003. [Google Scholar]

- Toutanji, H.A.; Evans, S.; Grugel, R.N. Performance of lunar sulfur concrete in lunar environments. Constr. Build. Mater. 2012, 29, 444–448. [Google Scholar] [CrossRef]

- Nealy, J.; Wilson, J.; Townsend, L. Solar-Flare Shielding with Regolith at a Lunar-Base Site; NASA Technical Paper; NASA: Washington, DC, USA, 1989. [Google Scholar]

- Kanamori, H.; Matsumoto, S.; Ishikawa, N. Long-term properties of mortar exposed to a vacuum. ACI Spec. Publ. 1991, 125, 57–69. [Google Scholar] [CrossRef]

- Duffie, J.A.; Beckman, W.A. Solar Engineering of Thermal Processes, 4th ed.; Solar Energy Laboratory University of Wisconsin: Madison, WI, USA, 2013. [Google Scholar]

- Uythoven, E.; Mäusli, P.-A.; Toussaint, C.; Udriot, M.; Kneib, J.-P. Design of a Novel Separation Mechanism for High-Power Model Rockets. ESMATS-2021. Available online: https://www.esmats.eu/esmatspapers/pastpapers/pdfs/2021/uythoven.pdf (accessed on 10 October 2022).

- Kanji, S.; Buratynsky, M. Challenges Associated with Testing Mechanisms for a Martian Environement. In Proceedings of the 18th European Space Mechanisms and Tribology Symposium 2019, Munich, Germany, 18–20 September 2019. [Google Scholar]

- Penagos, J.J.; Pereira, J.I.; Machado, P.C.; Albertin, E.; Sinatora, A. Synergetic effect of niobium and molybdenum on abrasion resistance of high chromium cast irons. Wear 2017, 376–377, 983–992. [Google Scholar] [CrossRef]

- Qiu, J.; Fu, Z.; Liu, B.; Liu, Y.; Yan, J.; Pan, D.; Zhang, W.; Baker, I. Effects of niobium particles on the wear behavior of powder metallurgical γ-TiAl alloy in different environments. Wear 2019, 434–435, 202964. [Google Scholar] [CrossRef]

- Dalai, R.; Das, S.; Das, K. Effect of thermo-mechanical processing on the low impact abrasion and low stress sliding wear resistance of austenitic high manganese steels. Wear 2019, 420–421, 176–183. [Google Scholar] [CrossRef]

- Mpagazehe, J.N.; Street, K.W.; Delgado, I.R.; Higgs, C.F. An experimental study of lunar dust erosive wear potential using the JSC-1AF lunar dust simulant. Wear 2014, 316, 79–91. [Google Scholar] [CrossRef]

- Bühler, C.A. Experimental investigation of lunar dust impact wear. Wear 2015, 342–343, 244–251. [Google Scholar] [CrossRef]

- Sengupta, A.; Kulleck, J.; Van Norman, J.; Mehta, M. Thermal coating erosion in a simulated Martian landing environment. Wear 2011, 270, 335–343. [Google Scholar] [CrossRef]

- Pei, Z.; Song, R.; Ba, Q.; Feng, Y. Dimensionality wear analysis: Three-body impact abrasive wear behavior of a martensitic steel in comparison with Mn13Cr2. Wear 2018, 414–415, 341–351. [Google Scholar] [CrossRef]

- Huang, L.; Deng, X.; Li, C.; Jia, Y.; Wang, Q.; Wang, Z. Effect of TiC particles on three-body abrasive wear behaviour of low alloy abrasion-resistant steel. Wear 2019, 434–435, 202971. [Google Scholar] [CrossRef]

- Li, Y.; Gao, Y. Three-body abrasive wear behavior of CC/high-Cr WCI composite and its interfacial characteristics. Wear 2010, 268, 511–518. [Google Scholar] [CrossRef]

- Harsha, A.P. An investigation on low stress abrasive wear characteristics of high performance engineering thermoplastic polymers. Wear 2011, 271, 942–951. [Google Scholar] [CrossRef]

- Huang, L.; Deng, X.; Jia, Y.; Li, C.; Wang, Z. Effects of using (Ti,Mo)C particles to reduce the three-body abrasive wear of a low alloy steel. Wear 2018, 410–411, 119–126. [Google Scholar] [CrossRef]

- Hu, C.; Wan, X.; Wu, K.; Xu, D.; Li, G.; Xu, G.; Misra, R. On the impacts of grain refinement and strain-induced deformation on three-body abrasive wear responses of 18Cr–8Ni austenitic stainless steel. Wear 2020, 446–447, 203181. [Google Scholar] [CrossRef]

- Varga, M. High temperature abrasive wear of metallic materials. Wear 2017, 376–377, 443–451. [Google Scholar] [CrossRef]

- Penagos, J.J.; Ono, F.; Albertin, E.; Sinatora, A. Structure refinement effect on two and three-body abrasion resistance of high chromium cast irons. Wear 2015, 340–341, 19–24. [Google Scholar] [CrossRef]

- Antonov, M.; Hussainova, I.; Veinthal, R.; Pirso, J. Effect of temperature and load on three-body abrasion of cermets and steel. Tribol. Int. 2012, 46, 261–268. [Google Scholar] [CrossRef]

- Shah, M.; Bakshi, S.D. Three-body abrasive wear of carbide-free bainite, martensite and bainite-martensite structure of similar hardness. Wear 2018, 402–403, 207–215. [Google Scholar] [CrossRef]

- Varga, M.; Rojacz, H.; Winkelmann, H.; Mayer, H.; Badisch, E. Wear reducing effects and temperature dependence of tribolayer formation in harsh environment. Tribol. Int. 2013, 65, 190–199. [Google Scholar] [CrossRef]

- Bakshi, S.D.; Sinha, D.; Chowdhury, S.G.; Mahashabde, V.V. Surface and sub-surface damage of 0.20 wt% C-martensite during three-body abrasion. Wear 2018, 394–395, 217–227. [Google Scholar] [CrossRef]

- Mukhopadhyay, P.; Kannaki, P.S.; Srinivas, M.; Roy, M. Microstructural developments during abrasion of M50 bearing steel. Wear 2014, 315, 31–37. [Google Scholar] [CrossRef]

- Nahvi, S.M.; Shipway, P.H.; McCartney, D.G. Particle motion and modes of wear in the dry sand–rubber wheel abrasion test. Wear 2009, 267, 2083–2091. [Google Scholar] [CrossRef]

- Jokari-Sheshdeh, M.; Ali, Y.; Gallo, S.C.; Lin, W.; Gates, J.D. Comparing the abrasion performance of NiHard-4 and high-Cr-Mo white cast irons: The effects of chemical composition and microstructure. Wear 2022, 492–493, 204208. [Google Scholar] [CrossRef]

- Ramadas, H.; Sarkar, S.; Nath, A.K. Three-body dry abrasive wear properties of 15–5 precipitation hardening stainless steel produced by laser powder bed fusion process. Wear 2021, 470–471, 203623. [Google Scholar] [CrossRef]

- Damião, C.A.; Alcarria, G.C.; Teles, V.C.; de Mello, J.D.B.; da Silva, W.M. Influence of metallurgical texture on the abrasive wear of hot-rolled wear resistant carbon steels. Wear 2019, 426–427, 101–111. [Google Scholar] [CrossRef]

- Zafar, S.; Sharma, A.K. Abrasive and erosive wear behaviour of nanometric WC–12Co microwave clads. Wear 2016, 346–347, 29–45. [Google Scholar] [CrossRef]

- Jian, Y.; Huang, Z.; Xing, J.; Li, J. Effects of chromium additions on the three-body abrasive wear behavior of Fe-3.0 wt% B alloy. Wear 2017, 378–379, 165–173. [Google Scholar] [CrossRef]

- Hernandez, S.; Hardell, J.; Winkelmann, H.; Ripoll, M.R.; Prakash, B. Influence of temperature on abrasive wear of boron steel and hot forming tool steels. Wear 2015, 338–339, 27–35. [Google Scholar] [CrossRef]

- Petrica, M.; Katsich, C.; Badisch, E.; Kremsner, F. Study of abrasive wear phenomena in dry and slurry 3-body conditions. Tribol. Int. 2013, 64, 196–203. [Google Scholar] [CrossRef]

- Delgado, I.R.; Handschuh, M.J. Preliminary Assessment of Seals for Dust Mitigation of Mechanical Components for Lunar Surface Systems. In Proceedings of the 40th Aerospace Mechanisms Symposium, Cocoa Beach, FL, USA, 12–14 May 2010. [Google Scholar]

- Budinski, K.G. Adhesive transfer to abrasive particles in abrasion testing. Wear 2011, 271, 1258–1263. [Google Scholar] [CrossRef]

- Fildes, J.M.; Meyers, S.J.; Mulligan, C.P.; Kilaparti, R. Evaluation of the wear and abrasion resistance of hard coatings by ball-on-three-disk test methods—A case study. Wear 2013, 302, 1040–1049. [Google Scholar] [CrossRef]

- Thakare, M.R.; Wharton, J.A.; Wood, R.J.K.; Menger, C. Effect of abrasive particle size and the influence of microstructure on the wear mechanisms in wear-resistant materials. Wear 2012, 276–277, 16–28. [Google Scholar] [CrossRef]

- Nieto, A.; Yang, H.; Jiang, L.; Schoenung, J.M. Reinforcement size effects on the abrasive wear of boron carbide reinforced aluminum composites. Wear 2017, 390–391, 228–235. [Google Scholar] [CrossRef]

- Woldman, M.; van der Heide, E.; Schipper, D.J.; Tinga, T.; Masen, M.A. Investigating the influence of sand particle properties on abrasive wear behaviour. Wear 2012, 294–295, 419–426. [Google Scholar] [CrossRef]

- Qin, K.; Zhou, Q.; Zhang, K.; Feng, Y.; Zhang, T.; Zheng, G.; Xia, B.; Liu, B. Non-uniform abrasive particle size effects on friction characteristics of FKM O-ring seals under three-body abrasion. Tribol. Int. 2019, 136, 216–223. [Google Scholar] [CrossRef]

- Grandy, D.; Panek, N.; Routhier, G.; Ridolfi, P. Development and Qualification of The Exomars Bogie Electro-Mechanical Assembly (Bema) Rotary Actuators. In Proceedings of the ESMATS—18th European Space Mechanisms and Tribology Symposium, Munich, Germany, 18–20 September 2019. [Google Scholar]

- Dougherty, S. Micro-Imager Dust Cover, Micro-Imager Contact Sensor, and Mössbauer Spectrometer Contact Sensor Mechanisms for the Mars Exploration Rovers. In European Space Agency, (Special Publication) ESA SP, 2003. Available online: https://ui.adsabs.harvard.edu/abs/2003ESASP.524...73D/abstract (accessed on 8 June 2023).

- Jandura, L. Mars Science Laboratory Sample Acquisition, Sample Processing and Handling: Subsystem Design and Test Challenges. In Proceedings of the 40th Aerospace Mechanisms Symposium, Cocoa Beach, FL, USA, 12–14 May 2010. [Google Scholar]

- Ng, T.C.; Yung, K.L. Mars Rock Corer and Planetary Micro Sampling Tools. In Proceedings of the 33rd Lunar and Planetary Science Conference, Houston, TX, USA, 11–15 March 2010. [Google Scholar]

- Arkwright, B.; Buchele, P.; Di Leonardo, P. Development of a modular two-axis gimbal mechanism for spacecraft antenna and thruster pointing. In Proceedings of the 8th European Space Mechanisms and Tribology Symposium, Toulouse, France, 29 September–1 October 1999. [Google Scholar]

- Description Of Harmonic Gear Assembly Operation Harmonic Drive LLC Web Site. Available online: http://harmonic-drive.com/ (accessed on 11 October 2022).

- McClendon, M. NIRSpec MSS Magnet Actuator Life Test Unit Wear Particle Evaluation. 16 May 2011. Available online: https://esmats.eu/amspapers/pastpapers/pdfs/2012/krantz.pdf (accessed on 11 October 2022).

- Galary, J. Rolling Wear and Fatigue in Lubricated Contacts. Ph.D. Thesis, University of Massachusetts at Dartmouth, Dartmouth, MA, USA, 2018. [Google Scholar]

- Lamotte, E.; Bozet, J.-L.; Kabuya, A. Modelling of Friction and Wear for Cryogenic Valve Seals of Rocket Engines. Techspace Aero, 2000. Available online: https://www.esmats.eu/esmatspapers/pastpapers/pdfs/1999/lamotte.pdf (accessed on 11 October 2022).

- Provedo, B.; Jaio, G.; Viñals, J. Sealing cap for metis instrument in solar orbiter fdm subsystem. In ESMATS 2017; SENER: Getxo, Spain, 2017; pp. 20–22. [Google Scholar]

- Sidz, M.; Powęska, Ł.; Wilson, N.; Pulker, S. Umbilical Release Mechanisms (URM) for exomars2020 mission. In Proceedings of the European Space Mechanisms and Tribology Symposium, Munich, Germany, 18–20 September 2019; pp. 18–20. [Google Scholar]

- Fouché, F.; Leproux, F.; Leverd, M.; Sicre, J. Development and Qualification of a High-Temperature Shape Memory Alloys Based Actuator for Hold Down and Release Mechanisms (HDRM). 19th ESMATS, 2021. Available online: https://www.esmats.eu/esmatspapers/pastpapers/pdfs/2021/fouche2.pdf (accessed on 11 October 2022).

- Powęska, Ł.; Sidz, M.; Ybarra, G. Qualification of Resource Transfer Mechanisms as Part of International Berthing and Docking Mechanism—Hard Capture System Development. 19th ESMATS, 2021. Available online: https://www.esmats.eu/esmatspapers/pastpapers/pdfs/2021/poweska.pdf (accessed on 11 October 2022).

- Obara, S.; Sasaki, A.; Haraguchi, M.; Imagawa, K.; Nishimura, M.; Kawashima, N. Evaluation tests of industrial vacuum bearings for space use. Tribotest 2003, 10, 117–134. [Google Scholar] [CrossRef][Green Version]

- Schmalbach, M.; Eigenmann, M.; Schmidt, T. Development of a Two Hinge Shutter and Calibration Mechanism. 2011. Available online: www.enmap.com (accessed on 8 June 2023).

- Verhoeven, D.; Renté, D. Locking mechanism for ixv re-entry demonstrator flap control system. In Proceedings of the 14th European Space Mechanisms and Tribology Symposium—ASMATS, Constance, Germany, 28–30 September 2011. [Google Scholar]

- Viñals, J.; Borque, C.; Jaio, G.; Provedo, B. Doors mechanism for feedthrough operation in solar orbiter FDM subsystem. In Proceedings of the 16th European Space Mechanisms and Tribology Symposium 2015, Bilbao, Spain, 1–30 September 2015. [Google Scholar]

- Garland, M.; Allouis, E.; Rucinski, M.; Coates, A.; Marc, R. Design and Implementation of the Lightweight Advanced Robotic Arm Demonstrator (LARAD). 2017. Available online: https://www.esmats.eu/esmatspapers/pastpapers/pdfs/2017/garland.pdf (accessed on 14 October 2022).

- Strube, B.; Glier, M.; Manthey, K.; Trauthan, F.; Schmitz, N.; Jaumann, R.; Michaelis, H. Exomars Pancam High Resolution Camera (HRC): Evolution from BB to FM. 2019. Available online: https://esmats.eu/esmatspapers/pastpapers/pdfs/2019/strube2.pdf (accessed on 7 November 2022).

- Jones, W.R.; Jansen, M.J.; Gschwender, L.J.; Snyder, C.E.; Sharma, S.K.; Predmore, R.E.; Dube, M.J. The tribological properties of several silahydrocarbons for use in space mechanisms. J. Synth. Lubr. 2004, 20, 303–315. [Google Scholar] [CrossRef][Green Version]

- Cadiergues, L.; Bourdit, C.; Trouchet, D.; Larcher, V.; Sugranes, P.; Leletty, R. A mirror control mechanism for space telescope. In Proceedings of the 10th European Space Mechanisms and Tribology Symposium, San Sebastián, Spain, 24–26 September 2003. [Google Scholar]

- Henein, S.; Spanoudakis, P.; Schwab, P.; Giriens, L.; Lisowski, L.; Onillon, E.; Myklebust, L.I. Mechanical slit mask mechanism for the james webb space telescope spectrometer. In Optical, Infrared, and Millimeter Space Telescopes; SPIE: Bellingham, WA, USA, 2003. [Google Scholar]

- Caprini, G.C.; Mondello, G.; Brotini, M.; Corsini, R.; Gasparini, L.; Battazza, F.; Formaro, R. Main port mechanism for prisma. In Proceedings of the 15th European Space Mechanisms and Tribology Symposium (ESMATS), Noordwijk, The Netherlands, 25–27 September 2013. [Google Scholar]

- Mohtar, T.; Bursi, A.; Galbiati, A.; Spinelli, M. Actuated Cover Door with Emergency Opening Function for Space Telescopes. 19th ESMATS, 2021. Available online: https://www.esmats.eu/esmatspapers/pastpapers/pdfs/2021/mohtar.pdf (accessed on 15 October 2022).

- Nava, N.; Collado, M.; Cabás, R. New deployment mechanisms based on sma technology for space applications. In Proceedings of the 15th European Space Mechanisms and Tribology Symposium (ESMATS), Noordwijk, The Netherlands, 25–27 September 2013. [Google Scholar]

- Thiel, M.; Stöcker, J.; Rohe, C.; Kömle, N.I.; Kargl, G.; Hillenmaier, O.; Lell, P. The Rosetta lander anchoring system. In Proceedings of the 10th European Space Mechanisms and Tribology Symposium, San Sebastián, Spain, 25 September 2003. [Google Scholar]

- Billing, R. Caging Mechanisms for the Mars Exploration Rover Instrument Deployment Device. 2003. Available online: http://www.asi-space.com (accessed on 8 June 2023).

- Billing, P.A.R.; Fleischner, C.-A.R. Mars Science Laboratory Robotic Arm. In Proceedings of the 14th European Space Mechanisms and Tribology Symposium—ASMATS, Constance, Germany, 28–30 September 2011. [Google Scholar]

- Urgoiti, E.; Ramirez, A.; Coste, P. GAIA M2M positioning mechanism. In Proceedings of the 11th Euro. Space Mechanisms & Tribology Symp (ESMATS), Lucerne, Switzerland, 21–23 September 2005. [Google Scholar]

- Campo, P.; Barrio, A.; Puente, N.; Kyle, R. Development of a high temperature antenna pointing mechanisms for bepicolombo planetary orbiter. In Proceedings of the 15th European Space Mechanisms and Tribology Symposium (ESMATS), Noordwijk, The Netherlands, 25–27 September 2013. [Google Scholar]

- Gewehr, M.; Schneider, A.; Dalcolmo, J.; Klinkner, S.; Gmbh, S. Design and Testing of a Novel Miniaturised Sealed Tether-Recoil Mechanism for the Nanokhod Microrover. ESMATS, 2021. Available online: https://esmats.eu/esmatspapers/pastpapers/pdfs/2021/gewehr.pdf (accessed on 15 October 2022).

- Schmid, B.; Flüeli, P.; Houghton, P.; Blum, D. Development of the lid opening mechanism (LOM). In Proceedings of the 13th European Space Mechanisms & Tribology Symposium, Vienna, Austria, 23–25 September 2009. [Google Scholar]

- Melzer, C.; Cubillo, A.A.; Nadler, M.; Pfitzner, F.; Hahn, R. Mechanical Testing on the Core Sample Transportation Mechanism of the ExoMars 2018 Mission. Available online: https://esmats.eu/esmatspapers/pastpapers/pdfs/2015/melzer.pdf (accessed on 7 November 2022).

- Paul, R.; Tattusch, T.; Redlich, D.; Ott, S.; Dobrea, D.; Richter, L.; Thiel, M.; Cubillo, A.; Weisz, H.; Musso, F.; et al. ‘Backlash-free’ gas-tight high precision sample handling mechanisms – lessons learned from qualification testing & Design and lessons learned of the core sample handling mechanism (cshs) on the Exomars 2020 rover. In Proceedings of the 43rd Aerospace Mechanisms Symposium, NASA Ames Research Center, Hatfield, UK, 20–22 September 2017. [Google Scholar]

- Suetta, E.; Cherubini, G.; Mondello, G.; Piccini, G. Four Cover Mechanisms for the Rosetta Mission. Available online: https://ui.adsabs.harvard.edu/abs/1999ESASP.438..127S/abstract (accessed on 8 June 2023).

- Kiener, L.; Perruchoud, G.; Schwab, P.; Verhaeghe, A.; Spanoudakis, P.; Gumy, M. Development challenges of a focus mechanism for EXOMARS mission submitted to the harsh Martian environment. In Advances in Optical and Mechanical Technologies for Telescopes and Instrumentation; SPIE: Bellingham, WA, USA, 2018; p. 39. [Google Scholar] [CrossRef]

- Tattusch, T.; Wieser, J.; Müller, A.; Mecucci, C.B.; Senese, S.; Böhm, V.; Jalba, L.; Schwarz, C. DEAR-Providing a Dusty Environment for Planetary Exploration Robotics Testing. 19th ESMATS, 2021. Available online: https://esmats.eu/esmatspapers/pastpapers/pdfs/2021/tattusch.pdf (accessed on 15 October 2022).

- Budzyn, D.; Zare-Behtash, H.; Cowley, A.; Cammarano, A. Topology optimization of compliant mechanisms as a design method to improve hardware performance in lunar dust environment. In Proceedings of the 19th European Space Mechanisms and Tribology Symposium, Online, 20–24 September 2021. [Google Scholar]

- Baumgartner, E.T.; Bonitz, R.G.; Melko, J.P.; Shiraishi, L.R.; Leger, P.C. The Mars Exploration Rover Instrument Positioning System. 2005 IEEE Aerospace Conference, 2005. Available online: https://www.academia.edu/4453248/The_Mars_Exploration_Rover_instrument_positioning_system (accessed on 7 June 2023).

- Harrington, B.D.; Voorhees, C. The Challenges of Designing the Rocker-Bogie Suspension for the Mars Exploration Rover. In Proceedings of the 37th Aerospace Mechanisms Symposium, Galveston, TX, USA, 29–21 May 2004. [Google Scholar]

- Colorado School of Mines, Planetary Simulant Database. Available online: https://simulantdb.com/ (accessed on 11 July 2023).

- Chuang, K.C.; Gornet, T.J.; Schneidau, K.; Koerner, H. Laser Sintering of Thermoset Polyimide Composites 2019. Available online: https://ntrs.nasa.gov/search.jsp?R=20190031841 (accessed on 15 October 2022).

| Composition | Viking Lander I—Surface Soil (wt%) |

|---|---|

| SiO2 | 43 |

| FeO | 0 |

| Fe2O3 | 18.5 |

| Al2O3 | 7.3 |

| SO3 | 6.6 |

| MgO | 6.0 |

| CaO | 5.9 |

| Others/not identified | 12.7 |

| Component | P-MRS (wt%) | S-MRS (wt%) |

|---|---|---|

| Gabbro | 3 | 32 |

| Olivine | 2 | 15 |

| Quartz | 10 | 3 |

| Hematite | 5 | 13 |

| Montmorillonite | 45 | - |

| Charmosite | 20 | - |

| Kaolinite | 5 | - |

| Siderite | 5 | |

| Hydromagnesite | 5 | - |

| Goethite | - | 7 |

| Gypsum | - | 30 |

| VL-1 | WL-2 | Pathfinder | JSC Mars-1 | ||

|---|---|---|---|---|---|

| Oxide | Wt% | Wt% | Wt% | Wt% | Wt% |

| SiO2 | 43 | 43 | 44.0 | 34.5 | 43.5 |

| Al2O3 | 7.3 | 7 | 7.5 | 18.5 | 23.3 |

| TiO2 | 0.66 | 0.56 | 1.1 | 3.0 | 3.8 |

| Fe2O3 | 18.5 | 17.8 | 16.5 | 12.4 | 15.6 |

| MnO | n.a. | n.a. | n.a. | 0.2 | 0.3 |

| CaO | 5.9 | 5.7 | 5.6 | 4.9 | 6.2 |

| MgO | 6 | 6 | 7.0 | 2.7 | 3.4 |

| K2O | <0.15 | <0.15 | 0.3 | 0.5 | 0.6 |

| Na2O | n.a. | n.a. | 2.1 | 1.9 | 2.4 |

| P2O5 | n.a. | n.a. | n.a. | 0.7 | 0.9 |

| SO3 | 6.6 | 8.1 | 4.9 | n.a. | n.a. |

| Cl | 0.7 | 0.5 | 0.5 | n.a. | n.a. |

| LOI | n.a. | n.a. | n.a. | 21.8 | n.a. |

| Total | 89 | 89 | 89.5 | 101.1 | 100.0 |

| Size (µm) | Wt% |

|---|---|

| 450–1000 | 21 |

| 250–449 | 30 |

| 150–249 | 24 |

| 53–149 | 19 |

| 5–52 | 5 |

| <5 | 1 |

| Component | TUBS-M (Wt%) | TUBS-T (Wt%) |

|---|---|---|

| Basalt | 100 | 0 |

| Anorthosite | 0 | 100 |

| Oxide | TUBS-M (Wt%) | TUBS-T (Wt%) |

|---|---|---|

| SiO2 | 48.61 | 48.71 |

| TiO2 | 2.29 | 0.12 |

| Al2O3 | 13.28 | 30.33 |

| FeO> | 10.14 | 1.05 |

| MgO | 8.73 | 0.57 |

| CaO | 8.31 | 14.57 |

| Na2O | 3.67 | 3.05 |

| K2O | 1.71 | 0.22 |

| MnO | 0.18 | 0.015 |

| Cr2O3 | 0.04 | 0.00 |

| Property | TUBS-M | TUBS-T |

|---|---|---|

| Grain density | 2.96 g/cm3 | 2.71 g/cm3 |

| Bulk density | 1.41 g/cm3 | 1.18 g/cm3 |

| Angle of repose | 41.9–45.8° | 37.91° |

| Particle size range | 0–2.0 mm | 0–2.0 mm |

| Median | 87 µm | 87 µm |

| Cohesion | 0.6 kPa | 1.46 kPa |

| Component | Wt% |

|---|---|

| Pyroxene | 32.8 |

| Glass-rich basalt | 32.0 |

| Anorthosite | 19.8 |

| Olivine | 11.1 |

| Ilmenite | 4.3 |

| Oxide | Wt% |

|---|---|

| SiO2 | 46.9 |

| TiO2 | 3.6 |

| Al2O3 | 12.4 |

| FeO | 8.6 |

| MnO | 0.6 |

| MgO | 16.8 |

| CaO | 7.0 |

| Na2O | 1.7 |

| K2O | 0.7 |

| P2O5 | 0.2 |

| Major Oxides | Average Wt% |

|---|---|

| SiO2 | 50.18 |

| Al2O3 | 30.88 |

| Fe2O3 | 0.49 |

| MgO | 0.19 |

| CaO | 14.58 |

| Na2O | 2.63 |

| K2O | 0.23 |

| TiO2 | 0.05 |

| P2O5 | 0.01 |

| MnO | <0.01 |

| Cr2O3 | <0.01 |

| V2O5 | <0.01 |

| Property | Value |

|---|---|

| Mean particle size | 82.25 µm |

| Median particle size | 35.97 µm |

| Specific gravity | 3.071 |

| Bulk density | 1.815 g/cm3 |

| Oxide | Apollo 16 Average Soil wt% | OB-1 | Shawmere Anorthosite Average wt% |

|---|---|---|---|

| SiO2 | 45 | - | 48.28 |

| Al2O3 | 26.7 | - | 32.01 |

| FeO | - | - | 1.34 |

| Fe2O3 | - | - | 0.09 |

| MgO | 6.14 | - | 0.22 |

| CaO | 15.3 | - | 15.43 |

| Na2O | 0.457 | - | 2.38 |

| K2O | 0.12 | - | 0.16 |

| TiO2 | 0.595 | - | 0.05 |

| P2O5 | - | - | 0.01 |

| MnO | - | - | 0.01 |

| Cr2O3 | - | - | - |

| V2O5 | - | - | - |

| Parameter | Earth | Moon | Mars | Kepler- | Proxima Centauri b |

|---|---|---|---|---|---|

| Total mass compared with Earth (%) | - | 1.2 | 10.7 | 190 | 80–110 |

| Approximate distance from Earth (km) | - | 3.84 × 105 | 2.25 × 108 | 1.32 × 1016 | 3.9 × 1013 |

| Day period (h) | 23.9 | 655.7 | 24.7 | - | - |

| Revolution period (days) | 365.3 | 27.3 | 686.9 | 384.8 | 11.2 |

| Average surface temperature (°C) | 13 | −30 | −57 | −8 | −39 |

| Atmospheric pressure (kPa) | 101.3 | Negligible | 0.7 | Unknown | Unknown |

| Alloy Group | Wrought Alloys Major Alloying Elements | Alloy Group | Cast Alloys Major Alloying Elements |

|---|---|---|---|

| 1XXX | 99.00% minimum aluminum | 1XX.0 | 99.00 percent minimum aluminum |

| 2XXX | Copper | 2XX.0 | Copper |

| 3XXX | Manganese | 3XX.0 | Silicon with added copper and/or magnesium |

| 4XXX | Silicon | 4XX.0 | Silicon |

| 5XXX | Magnesium | 5XX.0 | Magnesium |

| 6XXX | Magnesium and silicon | 6XX.0 | Unused series |

| 7XXX | Zinc | 7XX.0 | Zinc |

| 8XXX | Other elements | 8XX.0 | Tin |

| 9XXX | Unused series | 9XX.0 | Other elements |

| Material Families | For Tribological Applications | |||

|---|---|---|---|---|

| Not Recommended or Strongly Limited | May Be Proposed with Surface and Structural Modifications | May Be Suggested (Some Typical Application) | Possibly in Abrasive Condition | |

| Maraging steel | + | + | + | |

| Precipitation hardening steel | + | ? | + | |

| Quenched and tempered steels | + | + | + | |

| Steel alloys: Cr, Ni alloyed steel, austenitic steels, multiphase steels | ? | |||

| Aluminum alloys | + | + | ? | ? |

| Titanium alloys | + | ? | ? | |

| Phosphor bronzes | + | ? | ||

| Aluminum bronzes | + | ? | ||

| Manganese bronzes | + | ? | ||

| High-leaded tin bronzes | + | ? | ||

| Beryllium–copper alloys | + | - | ||

| Tungsten-based alloy | + | ? | ? | |

| Polymer composites | + | + | ||

| Ceramics | + | ? | ||

| Room Conditions | Vacuum or Neutral Gas and Room Temperature | Low and High Temperatures | Vacuum and High/ Low Temperatures | With Simulants | |

|---|---|---|---|---|---|

| Structural steel | 7 | 2 | 11 | 1 | 1 |

| Martensitic steel | 6 | ||||

| Manganese steel and other alloyed steel | 8 | 1 | |||

| Stainless steel | 3 | 2 | 4 | ||

| Ceramics | 11 | 1 | 1 | ||

| Rubber/elastomer | 12 | ||||

| Polymer/composite | 3 | 4 | 1 | 1 | |

| Alloyed cast irons | 3 | ||||

| Titanium alloy | 1 | ||||

| WC-based sintered or hard metal | 3 | 1 | |||

| Aluminum/coated and alloys | 1 | 3 | 1 | 1 | 2 |

| Shaft/Machine Elements | Room Conditions | Vacuum or Neutral Gas and Room Temperature | Low and High Temperatures | Vacuum and High/Low Temperatures | With Simulants |

|---|---|---|---|---|---|

| Aluminum | Al2024 Anodized aluminum | Anodized aluminum | Al2024, Al7000 series | Anodized aluminum | |

| Copper | Beryllium copper | ||||

| Steel | Stainless steel | Stainless steel | Nitronic 60 (stainless steel) 400C, S2100 | Stainless steel | |

| Titanium | Ti6Al4V | ||||

| Seal | |||||

| Polymer | PCTFE, PI/MoS2 PTFE 3x | PTFE 3x | PCTFE, PI/MoS2 | PTFE 3x | |

| Hybrid structure | Polymer/metal |

| Mechanism | Number of Case |

|---|---|

| Any rover applications | 4 |

| Open–close mechanisms | 6 |

| Positioning mechanisms/mechatronics | 4 |

| Berthing—docking | 4 |

| Robotic arm | 4 |

| Doors | 4 |

| Other rotary/reciprocating shafts | 5 |

| Shaft Materials | Number of Cases |

|---|---|

| Cooper–beryllium alloy | 4 |

| Titanium alloy | 7 |

| Al and Al alloy | 9 |

| Stainless steel | 9 |

| Other steel alloys | 4 |

| Seal materials | Number of cases |

| PTFE | 19 |

| PTFE—composite | 4 |

| Hybrid: metal/polymer combinations | 1 |

| Metallic | 3 |

| Other polymers (HPM, UHMW-PE…) | 6 |

| Simulant Type | Name | Supplier | Country | Description | Particle Size Range | Mineralogical Fidelity | Price | Availability |

|---|---|---|---|---|---|---|---|---|

| Lunar Mare | LMS-1 | Exolith Lab | USA | High mineralogical fidelity | <0.04 µm–300 µm | USD 35/kg | Available | |

| OPRL2N | Off Planet Research | USA | Mechanical simulant | Apollo 17 PSD | About USD 80/kg | Available | ||

| UoM-B and UoM-W | University of Manchester | UK | Low-fidelity, angular grain shapes | B: 0.1–0.7 mm W: <125 µm | From feedstock supplier | |||

| TUBS-M | TU Braunschweig | Germany | ISRU-oriented base simulant, customizable | 0–2 mm | ||||

| Lunar Highland | LHS-1 | Exolith Lab | USA | High mineralogical fidelity, Subangular grains, lower specific gravity | <0.04 µm–400 µm | USD 35/kg | Available | |

| GreenSpar | Hudson Resources | Greenland | High anorthite content | <250 µm or <90 µm | High An% | Unknown | Available | |

| OPRH2N | Off Planet Research | USA | Mechanical simulant | Apollo highland sample PSD average | High An% | About USD 80/kg | Available | |

| OB-1 | Deltion Innovations | Canada | High glass content, angular grains, high specific gravity | Apollo 16 sample 64,500 PSD | High An% | Unknown | Unknown | |

| TUBS-T | TU Braunschweig | Germany | ISRU-oriented base simulant, customizable | 0–2 mm | Customizable |

| Simulant Type | Name | Supplier | Country | Description | Particle Size Range | Mineralogical Fidelity | Price | Availability |

|---|---|---|---|---|---|---|---|---|

| Mars | MGS-1 | Exolith Lab | USA | High mineral, chemical, volatile, and spectral fidelities. | >0.04 µm–600 µm | USD 35/kg | Available | |

| ES-x | Varies | Europe | Geotechnical simulants in different size ranges. | 1: <10–32 μm 2: ~ >30–125 μm 3: ~>30–20,000 μm 4: ~0.1–500 μm | Some available from ESA or supplier | |||

| OUCM OUEB OUHR OUSR | Open University | UK | Astrobiology simulants. Each has a standard composition (−1) and adjusted Fe2+ concentration (−2). | 200–2000 µm | ||||

| JSC Mars-1 | NASA JSC | USA | Spectral analogue, supports general scientific and engineering studies. | <1 mm | Only pay for shipping | Available | ||

| P/S-MRS | DLR | Germany | For Raman spectral studies. | <1 mm | Unknown | Unknown | ||

| Mars Jezero | JEZ-1 | Exolith Lab | USA | MGS-1 mixed with smectite, Mg–carbonate, and additional olivine. | <0.04–500 μm | USD 35/kg | Available |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Barkó, G.; Kalácska, G.; Keresztes, R.; Zsidai, L.; Shegawu, H.; Kalácska, Á. Abrasion Evaluation of Moon and Mars Simulants on Rotating Shaft/Sealing Materials: Simulants and Structural Materials Review and Selection. Lubricants 2023, 11, 334. https://doi.org/10.3390/lubricants11080334

Barkó G, Kalácska G, Keresztes R, Zsidai L, Shegawu H, Kalácska Á. Abrasion Evaluation of Moon and Mars Simulants on Rotating Shaft/Sealing Materials: Simulants and Structural Materials Review and Selection. Lubricants. 2023; 11(8):334. https://doi.org/10.3390/lubricants11080334

Chicago/Turabian StyleBarkó, György, Gábor Kalácska, Róbert Keresztes, László Zsidai, Hailemariam Shegawu, and Ádám Kalácska. 2023. "Abrasion Evaluation of Moon and Mars Simulants on Rotating Shaft/Sealing Materials: Simulants and Structural Materials Review and Selection" Lubricants 11, no. 8: 334. https://doi.org/10.3390/lubricants11080334

APA StyleBarkó, G., Kalácska, G., Keresztes, R., Zsidai, L., Shegawu, H., & Kalácska, Á. (2023). Abrasion Evaluation of Moon and Mars Simulants on Rotating Shaft/Sealing Materials: Simulants and Structural Materials Review and Selection. Lubricants, 11(8), 334. https://doi.org/10.3390/lubricants11080334