Abstract

The replacement of conventional lubricants with esters is an alternative to provide a low environmental impact and at the same time excellent lubricity features, the high solubility of additives, good viscosity index, low volatility, and high thermal stability. Friction modifiers and antiwear/extreme pressure additives are extensively used to save energy and increase operational life in machine components. In this study, the lubricity of a Group IV base oil containing ester and various benchmark friction modifiers and/or antiwear/extreme pressure additives is measured to evaluate the influence of the ester on the tribological performance of the mixture components. The tribological performance is discussed based on the tabulation of the traction coefficient using a Mini-Traction-Machine and on the measurement of the specific wear rate from the wear scar of the experimental studies using an optical profilometer. In general, results show synergies between the ester and the additive formulations, reducing the wear rate to 75% and decreasing the traction coefficient a 20 to 50%, depending on the evaluated additive.

1. Introduction

Along with the advancement of the modern automotive industry, and the exponential transformation of the internal combustion engine vehicles (ICEVs) fleet into hybrid and electric vehicles, fluids have to offer higher levels of performance and lower the life cycle cost (LCC) [1]. Current automotive lubricants are characterised to be low-viscous [2] and they are usually composed of a base oil containing a large amount of additives. One of the main objectives of using lubricants in automotive is to improve fuel efficiency by reducing frictional losses and increase the operational life by minimising wear, in increasingly harsh operating conditions, improving the life cycle assessment (LCA) of some mechanical parts [3,4]. Some studies show that for a model of a fully electric car from 2017, the frictional losses generated in the engine and transmission represent an intake of 2% of the total energy delivered from the batteries, including the recovered energy [3]. Taking action to decrease friction could be reflected in savings of up to 9% of global energy use [5]. Regarding the base oil, the conventional choices are synthetic-based, mainly polyalphaolephines (PAOs), which belong to Group IV base stocks according to the American Petroleum Institute (API) classification, and mineral oil-based lubricants due to their good performance on final application [6]. One of the biggest challenges is the development of a new generation of eco-friendly base stocks that could replace the current ones which suppose threats to the environment with the increased environmental awareness as a primary driving force. Synthetic esters (SEs) are gaining prominence as environmentally acceptable lubricants due to their no toxicity, excellent biodegradation and the possibility to achieve tailor-made properties at the same or higher level of performance as conventional lubricants [7].

The driving force in this study is the increasing demand of SEs, which belong to Group V base stocks, to form semi-synthetic lubricants that can meet and fulfil the upcoming requests from the higher performance electric vehicles operation specifications, such as the higher torque in low-temperature operative ranges compared with conventional vehicles [8]. Specifically, on bearing systems where the temperature range is comprised between 30 and 160 °C on some types of motor rotors [9]. It is well known that substantial improvements and optimisation of the engine oils and transmission fluids can be achieved when these compounds are incorporated into PAO formulations. Some biodegradable engine lubricants composed of 1:1 mixtures of esters with PAOs and conventional additives have been tested demonstrating better tribological performance and environmental compatibility [10]. Compared with low molecular weight PAOs, esters offer less volatility and higher solubility due to higher polarity. Additionally, PAOs tend to shrink rubber seals. On the other side, esters are less hydrolytically stable and may show lower oxidative stability. In comparison with mineral oil-based lubricants, SEs offer higher polarity and seal compatibility [11]. In addition, they offer better lubricity and antiwear properties, high thermal stability and conductivity, higher specific heat, environmental compatibility, and high-temperature operation range, among others. In general, SEs have analogous performance as mineral oils [12]. These properties offer promising applications in the automotive sector. For instance, by increasing the electric vehicles (EV) autonomy, and reducing the weight and waste by unifying the vehicle fluids in innovative drivetrain configurations [13]. On the contrary, the cost of esters limits its use, but considering that SEs may require less maintenance, the total energy and machine downtime savings, the cost difference can be misleading. An optimum point between environmental compatibility, performance and cost often has to be searched [14].

This paper is focused on the behaviour of an ester in presence of friction modifier additives, which can drastically reduce friction and keep it stable [15], and on antiwear additives due to the use of slim lubricants, in order to assure assembly integrity under the applied conditions [16]. Since lubricant additives are designed to optimise work with conventional base oils and improve tribological performance, a great number of experimental studies are available to investigate the compatibility between additives and base oils. However, to the best of our knowledge, studies aimed at understanding the effect of the esters in friction modifiers and antiwear additives have not been widely reported and the research completed cannot be generalised owing to the broad range of additives. For instance, it was found that the lubrication performance of various fatty acids and amines formulated in a polyol ester oil, is highly influenced by structural differences, such as chain length or unsaturations [17] but the influence of the ester performance on the mixture has not been evaluated. Furthermore, the tribological compatibility of a trimethylolpropane (TMP) ester as an additive in a PAO formulation containing glycerol mono-oleate (GMO), molybdenum dithiocarbamate (MoDTC) or zinc dialkyldithiophosphate (ZDDP) was also studied but the main scope was on the influence on DLC coated steel where the ester is more effective by itself [18]. In addition, it was found that under reciprocating conditions, controlled amounts of the ester can improve the lubricant performance, but they can also decrease the activity of the MoDTC additive [19]. The friction performance of molybdenum dithiophosphate (MoDTP) was also studied in an ester-containing lubricant by means of a reciprocating contact. Additionally, high concentrations of ester reduce the additive activity [20].

The aim of this paper is to evaluate the effect of a Group V ester on the tribological performance of some conventional benchmark antiwear and/or friction modifier additives, in front of steel, when it is incorporated into a Group IV base stock PAO 6 in comparison with a pure PAO 6 formulation in sliding/rolling conditions. This study is performed by means of a Mini-Traction-Machine, reproducing the possible mechanical contact mechanisms found in an EV with the test conditions, and profilometry analysis. Some studies, using this technique on steel surfaces, have been previously reported. For instance, in this study [21] where the most effective conditions of fourteen friction modifiers of various families were identified. In addition, this technique was used in a study where a synergistic tribochemical impact of some aminic friction modifiers in combination with ZDDP in PAO 4 on tribological performance was determined through severe sliding/rolling conditions [22].

2. Materials and Methods

2.1. Test Base Fluids and Additives

The base stocks used throughout the study consist of a Group IV polyalphaolefine 6 (PAO 6), and a blend (BO) Group V ester (from Industrial Química Lasem, Castellgalí, Spain) with PAO 6 at the same weight proportion. The kinematic viscosity properties of the base stocks are summarised in Table 1. The base oil was specifically designed to solubilise a 1% (%w/w) of all the additives under study. In order to just study the ester effect and not interfere with the evaluation, the final kinematic viscosity of both, PAO 6 and BO formulations, are not adjusted. The final formulations had the same kinematic viscosity as the raw base stocks.

Table 1.

Oil used.

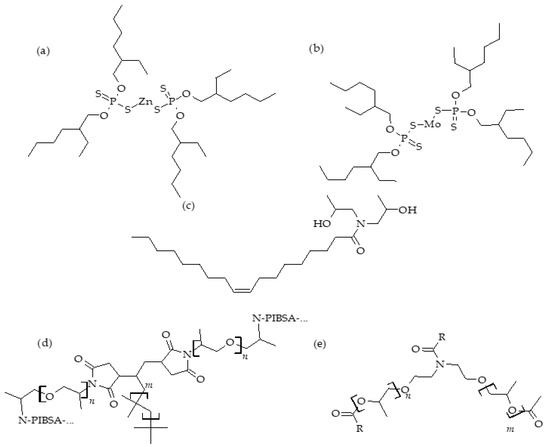

Five commercially available AW and/or FM benchmarking additives were evaluated, see detailed description in Table 2. The molecular structure of each additive used is depicted in Figure 1. All these additives are intended for the automotive sector among other applications.

Table 2.

Additives tested.

Figure 1.

Additives’ molecular structures. (a) ZDDP; (b) MoDTP; (c) OFM; (d) PFM1; (e) PFM2.

2.2. Test Materials

AISI 52100 was used as reference material for steel (MTM specimens are provided by PCS Instruments Ltd, London, UK; SRV specimens are provided by Optimol Instruments Prüftechnik GmbH, Munich, Germany). This steel grade is used in several mechanical components of engines and transmissions. AISI 52100 steel balls and discs were used to simulate steel–steel contacts. The chemical composition and main properties are summarised in Table 3 and Table 4 correspondingly. The surface roughness and hardness of SRV specimens are provided by the supplier. Conversely, the surface roughness value of MTM specimens is experimentally measured with the optical 3D measurement instrument AliconaInfiniteFocusSL (Bruker Corp., Billerica, MA, USA). Additionally, materials hardness is experimentally measured, in triplicate, with a microhardness tester FM-700 (Future-Tech Corp., Kawasaki, Japan).

Table 3.

AISI 52100 steel chemical composition. Reprinted/adapted with permission from Ref. [23]. 1996, ASM International ®.

Table 4.

AISI 52100 steel specimens properties.

2.3. Test Method and Conditions

2.3.1. Tribological Behaviour

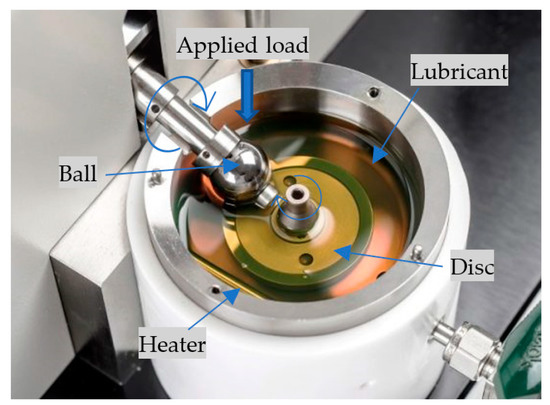

The characterisation of the tribological performance of the additives was performed by monitoring the traction coefficient through a set sliding/rolling contact generated between a steel disc and a steel ball using a Mini-Traction-Machine (MTM2; PCS Instruments, London, UK), represented in Figure 2. This apparatus is controlled with software which allows setting the load, the fluid temperature and the ball and disc rotational speeds.

Figure 2.

MTM2 assembly representation.

Test conditions are shown in Table 5. The temperature was set at 80 °C, a value comprised on the bearing’s operative temperature and a reference value on lubricity and bearing studies [24,25,26]. Fresh ball and disc specimens were used for each test. Before each test, they are immersed in heptane in an ultrasonic bath for six minutes. The test was run for 240 min. Each additive was tested in triplicate in order to ensure good repeatability.

Table 5.

MTM test parameters [27].

All tribotests were carried out at an applied load to ensure the same theoretical contact diameter of 250 μm. The initial contact pressure for the 19 mm diameter balls employed, based on Hertzian law calculous, is 0.95 GPa.

Traction coefficient is obtained from the relation of measured friction force and applied load.

2.3.2. Evaluation of ZDDP Activation Conditions

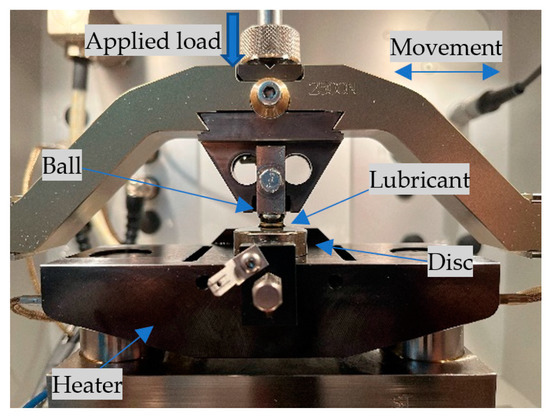

The activation study of the extreme pressure and antiwear additive was performed following the DIN Standard 51834-2. It was performed by subjecting it under reciprocating sliding conditions with a punctual contact between a steel disc and a steel ball using an SRV® 5 tribometer (Optimol Instruments Prütechnik GmbH, Munich, Germany), represented in Figure 3.

Figure 3.

SRV assembly representation.

Test conditions are in Table 6. Fresh 10 mm diameter ball and disc specimens were used for each test. Before each test, they are immersed in heptane in an ultrasonic bath for six minutes. The test was run for 120 min. Each load was tested in triplicate in order to ensure good repeatability.

Table 6.

SRV test parameters.

2.3.3. Wear Behaviour

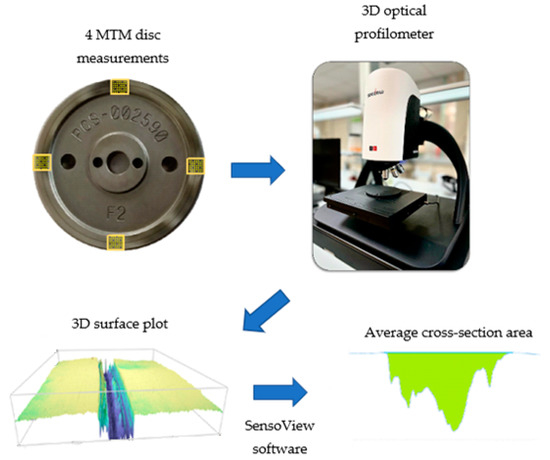

The characterisation of wear behaviour of the final formulations was performed. After the tests, specimens are cleaned by immersing them in an ultrasonic bath with heptane and analysed with a S neox 090 3D optical profilometer instrument (Sensofar Metrology, Terrassa, Spain). The scar profiles from disc specimens were obtained from 2 × 2 mm topographic images of the worn surfaces with a 100× magnification. Topographic images were processed, via SensoView v1.9 software (Sensofar Metrology, Terrassa, Spain), to obtain a mean profile of the surface where the cross-section area of the modified surface can be measured. Four topographic images are recorded for each disc, as represented in Figure 4.

Figure 4.

Wear measurement sequence.

The mean cross-section area is multiplied by the corresponding track perimeter to obtain the scar volume. Finally, by dividing the worn volume by the total sliding distance and the applied load, the specific wear rate is obtained.

3. Results

The friction behaviour of the different additives is summarised in Figure 5, where a representative traction curve for each formulation is represented, due to no significant differences between replicates.

Figure 5.

Traction curves comparison for (a) ZDDP; (b) MoDTP; (c) OFM; (d) PFM1; (e) PFM2 during sliding/rolling test under steel–steel contact.

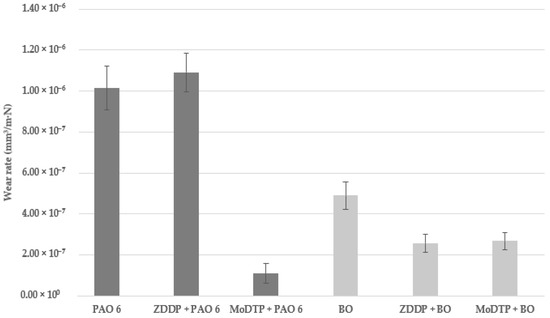

After the sliding/rolling test, the surface profilometries of the cleaned discs and balls, used with the final formulations, were completed. The overall average wear rates are represented in Figure 6.

Figure 6.

Steel discs specific wear rates. No measurable wear scars are obtained with OFM, PFM1 and PFM2 additives.

The traction curve of PAO 6 shows a constant increase in the traction coefficient until 0.135 with a sharp oscillation around 120 min. When the ester is added, the traction curve lows the slope, stabilising the traction coefficient around 0.093, since the minute 60 (Figure 5). The evaluation of the disc surface used in PAO 6 test, shows a wear rate value of 1.01 × 10−6 mm3·m−1·N−1. When ester is added, the wear rate decreases to 4.89 × 10−7 mm3·m−1·N−1 (Figure 6).

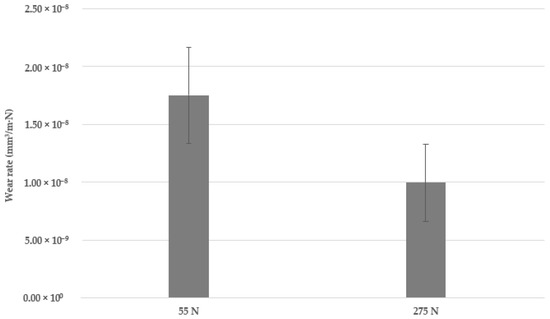

When ZDDP additive is added to PAO 6, a noticeable increase in the traction coefficient is observed during the first 60 min to finally stabilise around 0.141, the highest value of this study. When an ester is added to the formulation, the traction coefficient is reduced, and it is stabilised around 0.083 (Figure 5a). The behaviour of the traction curve is similar to the observed in the BO traction curve, but the result is even lower. The evaluation of the disc surface after the test under ZDDP in PAO 6 gives a wear rate value of 1.09 × 10−6 mm3·m−1·N−1, showing no significant change, compared with the PAO 6 wear rate. Conversely, when the ester is added, the obtained wear rate value is 2.55 × 10−7 mm3·m−1·N−1 (Figure 6) improving the results obtained in all the previous formulations, PAO 6; BO; and ZDDP + PAO 6. In order to check the activity of the ZDDP additive, the wear behaviour of the same ZDDP in BO formulation was tested using the DIN 51834-2 as standard at 55 and 275 N by triplicate, observing the antiwear performance of this additive improves when conditions are harsher, see Figure 7.

Figure 7.

Antiwear performance of ZDDP additive in BO.

In the case of the MoDTP additive in PAO 6, the traction curve shows a sharp increase during the first 20 min and then it decreases slowly until a final value of 0.087. A clear traction reduction and a change in the behaviour of the traction curve compared with PAO 6 is observed. When ester is added, the traction coefficient increases to 0.110 (Figure 5b), a higher value compared with the previous formulation and the BO. The behaviour of the traction curve is like the observed in the ZDDP in PAO 6 mixture. The wear rate values of the MoDTP in PAO 6 and MoDTP in BO are 1.09 × 10−7 and 2.68 × 10−7 mm3·m−1·N−1 correspondingly (Figure 6). A great protection against wear is observed and it is similar in both cases, improving the performance of both base stocks.

When OFM additive is added to PAO 6, a clear decrease in the traction coefficient is observed until a final value of 0.048. During the test, the traction coefficient decreases following a slight slope and shows a broad oscillation, an undesired result. When an ester is added, the traction coefficient increases to 0.083 (Figure 5c). Even with this increase, the OFM in the BO mixture gives better results compared with both reference base stocks and also, the traction curve is more stable than the one obtained with the OFM additive in PAO 6. The traction curve is similar to the result with ZDDP in PAO 6 but with a lower increase in the traction at the beginning of the curve. Negligible wear rates are obtained.

The traction coefficient behaviour and the final traction value of the PFM1 additive mixtures with PAO 6 and BO are similar in both cases. The final traction coefficient values are 0.075 for the additive in PAO 6 and 0.079 in BO (Figure 5d). Only a slight difference is observed around the 45 min of the PFM1 in the PAO 6 test, where a sudden destabilisation of the curve takes place. Negligible wear rates are obtained.

The last study case is the PFM2 additive. It presents a solubility problem under PAO 6 which is solved when the ester is added. Regarding the traction curve in PAO 6, the lowest traction coefficient of this study is obtained with a value of 0.039. The traction curve has a similar behaviour to the MoDTP in PAO 6, but with a more pronounced slope. When an ester is added the traction coefficient increases. A sudden decrease in the traction curve takes place during the first 30 min to finally get stabilised to 0.063 (Figure 5e). It is the lowest value among the different additives in BO mixtures. Negligible wear rates are obtained.

4. Discussion

When an ester is added to the pure base stock, a decrease of 31% in the traction coefficient is observed. In addition, the wear behaviour is drastically improved, reducing the wear rate ratio a 52%. The ester interacts with the surface and creates a tribofilm which is able to reduce the traction coefficient and also protects the surface against wear.

Regarding the traction coefficient and wear rate of the ZDDP additive, when it is blended with PAO 6, the highest values of this study are obtained. ZDDP (Figure 1a) is described as one of the most effective and broadly used antiwear additives under steel–steel contact. It also offers other advantages such as antioxidants, corrosion inhibitors and extreme pressure properties [28]. It interacts with the surface through a chemical process through the formation of a sacrificial bilayer [29]. This bilayer has a solid-like morphology which is able to inhibit the entrainment of liquid lubricant between the rubbing surfaces [30]. This effect keeps the boundary friction value of the tests up to 4% above the reference PAO 6 friction value. Conversely, when the ester is blended with the previous formulation, the obtained traction coefficient is lower, decreasing the formulation traction coefficient by 41%. This result clearly shows that the ester has a detergency effect on the additive tribofilm. Regarding the wear behaviour, the addition of ZDDP additive in PAO 6 has a worsening effect, increasing the wear rate value to around an 8% (Figure 6). Even though, when the ester is added, the wear rate is reduced a 77% and 48% compared to ZDDP + PAO 6 and pure BO samples, correspondingly (Figure 6). The antiwear behaviour of the additive ZDDP in PAO 6 has not been seen under MTM test conditions which are not harsher enough (Figure 6), whereas under SRV harsher conditions, ZDDP shows a decrease in the wear rate values (Figure 7). The ester has synergistic effects with this additive and improves considerably the capacity of protection against wear of the formulation under both MTM and SRV test conditions.

MoDTP has been investigated as well (Figure 1b). It is classified as a highly effective friction modifier from the family of organomolybdenum compounds. MoDTP is also able to reduce wear and act as an antioxidant additive by itself and also presents synergism with ZDDP [31]. Friction and wear reduction on steel surfaces are achieved through an oxidation and reduction process, resulting in an amorphous phosphate glass tribofilm, containing MoS2 composites among others [32] which usually requires harsh conditions of pressure and temperature to be generated [33].

Even observing a decrease of 36% of the traction coefficient with respect to the PAO 6 reference, probably the additive is not working under its optimum conditions. When an ester is added, a worsening effect takes place, and the traction coefficient increases by 26%. The friction performance is even worse than the BO reference. The friction modifier properties of this additive are inhibited in presence of an ester. The antiwear behaviour of formulations with and without ester is maintained. Yet the addition of an ester has a worsening effect and an increase of 45% in the wear rate value is observed. The ester and the additive have competitive surface interaction mechanisms and these results could also be explained due to ester–additive interaction.

The OFM additive is classified as a friction modifier, belonging to the nitrogen-derivated organic friction modifiers subclass. To understand its action mechanism, it is necessary to deeply understand the molecular structure (Figure 1c). A polar head which includes the amide and hydroxyl functional groups can be differentiated from a lipophilic hydrocarbon chain, originally from the tallow oil fatty acids. The polar group interacts with polar metal surfaces while non-polar chains are extended to the base oil. Molecules interact with each other creating a protective layer on the metal surface. Furthermore, a multilayer system is formed via a conglomeration process [34]. These layers exhibit low shear-off strength between them, boosting friction reduction.

As can be expected from an organic friction modifier, after surface conditioning, the OFM additive keeps the traction coefficient constant, and the traction coefficient is decreased a 64% compared with PAO 6. When an ester is added, the traction coefficient shows a substantial increase of 73% but it continues reducing the traction coefficient of both base stocks. A kind of surface adsorption competition exists between both, but at this concentration are compatible.

PFM1 is classified as a friction modifier from the block copolymer family. Two main types of blocks can be identified in its structure: on one side, polar blocks, constituted by polyetheramine monomers and on the other side, non-polar blocks, which in this additive are the polyisobutyl chains from polyisobutylsuccinate. This configuration is responsible for the friction reduction mechanism [35]. Polar blocks remain anchored with the polar surface, while lipophylic blocks are extended to the oil and give lubricity to the system (Figure 1d) [36,37].

When the PFM1 additive is added to the PAO 6 base stock, the traction coefficient is decreased by 44% compared to the reference oil. The addition of the ester has a neutral effect on the additive performance. The lubricity effects provided by the structure of the polymer prevail rather than the possible surface competition effects between ester and additive.

Finally, PFM2 is classified as a friction modifier and structurally can be identified as a complex amide/ester compound, a polymer of low molecular weight. The interaction with the surface is similar to the PFM1 additive behaviour. The polar part includes the polypropyleneglycol, the amide and the ester functional groups. The non-polar blocks are formed by the hydrocarbon chains from fatty acids (Figure 1e).

The evaluation of the PFM2 additive in PAO 6 shows better friction modifier properties, decreasing the traction coefficient to 71% compared to pure PAO 6. The addition of the ester has a clear worsening effect on the traction coefficient which increases by 62%. Still, the traction coefficient decreased by around 32% compared with the BO reference. In this case, the surface competition has a greater impact than the lubricity provided by the polymer structure. Probably, the polymer is not large enough to avoid the contact between surfaces, oppositely to the PFM1 additive.

5. Conclusions

The combination of the PAO, as base stock, and the additives under study show great efficiency. The obtained traction curves of the PAO–ester formulations, show better performance than the base oil traction curve, so ester addition has a great effect on the evaluated parameters. The friction modifying properties of the additives have also improved the friction behaviour of the used base oil, showing synergism or neutral effect of the ester. One exception is observed, MoDTP additive formulation shows a larger traction coefficient, but it keeps its antiwear properties. The surface competition between ester and those additives which physically interacts with the surface has been proven. Further understanding of ester–additive interactions is required. In addition, it has been demonstrated that under the test conditions, without high temperature and high pressure, the ZDDP additive is unactive. Even though, when the base oil contains a part of ester, ZDDP additive seems to be more effective, while ester is able to decrease the traction coefficient. Synergism between both ester and additive takes place. Either way, the addition of an ester into the studied formulations has had, in general, a positive effect on the tribological behaviour of the final formulations, decreasing the PAO 6 traction coefficient a 20 to 50% depending on the additive. The partial substitution of mineral oils and synthetic base oils for SEs is possible. Further investigations are being performed to study the influence of the additives in tribology for different metal contacts, especially those where aluminium is present.

Author Contributions

Conceptualisation, G.C., A.E., M.C., A.N., L.B., M.V. and J.V.; methodology, G.C.; investigation, G.C., A.E., M.C., A.N., L.B., M.V. and J.V.; resources, A.N. and L.B.; writing—original draft preparation, G.C.; writing—review and editing, G.C. and M.V.; funding acquisition, L.B. and M.V. All authors have read and agreed to the published version of the manuscript.

Funding

This work received the support of the Pla de Doctorats Industrials from Secretaria d’Universitats i Recerca del Departament d’Empresa i Coneixement of the Generalitat de Catalunya.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Chen, Y.; Jha, S.; Raut, A.; Zhang, W.; Liang, H. Performance Characteristics of Lubricants in Electric and Hybrid Vehicles: A Review of Current and Future Needs. Front. Mech. Eng. 2020, 6, 571464. [Google Scholar] [CrossRef]

- Tormos, B.; Ramírez, L.; Johansson, J.; Björling, M.; Larsson, R. Fuel consumption and friction benefits of low viscosity engine oils for heavy duty applications. Tribol. Int. 2017, 110, 23–34. [Google Scholar] [CrossRef]

- Holmberg, K.; Erdemir, A. The impact of tribology on energy use and CO2 emission globally and in combustion engine and electric cars. Tribol. Int. 2019, 135, 389–396. [Google Scholar] [CrossRef]

- Czerwinski, F. Current Trends in Automotive Lightweighting Strategies and Materials. Materials 2021, 14, 6631. [Google Scholar] [CrossRef] [PubMed]

- Holmberg, K.; Andersson, P.; Erdemir, A. Global energy consumption due to friction in passenger cars. Tribol. Int. 2012, 47, 221–234. [Google Scholar] [CrossRef]

- Nagendramma, P.; Kaul, S. Development of ecofriendly/biodegradable lubricants: An overview. Renew. Sustain. Energy Rev. 2012, 16, 764–774. [Google Scholar] [CrossRef]

- Pettersson, A. High-performance base fluids for environmentally adapted lubricants. Tribol. Int. 2007, 40, 638–645. [Google Scholar] [CrossRef]

- Greaves, M. Oil Soluble Synthetic Polyalkylene Glycols A New Type of Group V Base Oil. Lube-Tech 2013, 104, 1–23. [Google Scholar]

- Zhou, A.; Du, C.; Peng, Z.; Peng, Q.; Qin, D. Rotor Temperature Safety Prediction Method of PMSM for Electric Vehicle on Real-Time Energy Equivalence. Math. Probl. Eng. 2020, 2020, 3213052. [Google Scholar] [CrossRef]

- Siegel, R.; Skidd, C. Case studies utilizing mobile on-site recycling of industrial oils for immediate reapplication. Lubr. Eng. 1995, 51, 767–770. [Google Scholar]

- Brown, P. Synthetic basestocks (Groups IV and V) in lubricant applications. Lubr. Eng. 2003, 59, 20–22. Available online: https://www.proquest.com/scholarly-journals/synthetic-basestocks-groups-iv-v-lubricant/docview/226966160/se-2?accountid=15300 (accessed on 3 December 2022).

- Shah, R.; Gashi, B.; Rosenkranz, A. Latest developments in designing advanced lubricants and greases for electric vehicles—An overview. Lubr. Sci. 2022, 34, 515–526. [Google Scholar] [CrossRef]

- Tung, S.C.; Woydt, M.; Shah, R. Global Insights on Future Trends of Hybrid/EV Driveline Lubrication and Thermal Management. Front. Mech. Eng. 2020, 6, 571786. [Google Scholar] [CrossRef]

- Pettersson, A. Tribological characterization of environmentally adapted ester based fluids. Tribol. Int. 2003, 36, 815–820. [Google Scholar] [CrossRef]

- Spikes, H. Friction Modifier Additives. Tribol. Lett. 2015, 60, 5. [Google Scholar] [CrossRef]

- Bunemann, T.F.; Kenbeck, D. Lubricants and additives Chapter 7. Organic friction modifiers. In Lubricant Additives: Chemistry and Applications, 3rd ed.; CRC Press, Taylor & Francis Group: Boca Raton, FL, USA, 2017; pp. 195–210. [Google Scholar]

- Cyriac, F.; Tee, X.Y.; Poornachary, S.K.; Chow, P.S. Influence of structural factors on the tribological performance of organic friction modifiers. Friction 2021, 9, 380–400. [Google Scholar] [CrossRef]

- Zahid, R.; Mufti, R.A.; Gulzar, M.; Hassan, M.B.H.; Alabdulkarem, A.; Varman, M.; Kalam, A.; Zulkifli, N.W.B.M.; Yunus, R. Tribological compatibility analysis of conventional lubricant additives with palm trimethylolpropane ester (TMP) and tetrahedral amorphous diamond-like carbon coating (ta-C). Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2018, 232, 999–1013. [Google Scholar] [CrossRef]

- Trindade, E.D.; Durango, A.Z.; Sinatora, A. Friction and wear performance of MoDTC-containing and ester-containing lubricants over steel surfaces under reciprocating conditions. Lubr. Sci. 2015, 27, 217–229. [Google Scholar] [CrossRef]

- Wang, W.; Li, C.; Yang, J.; Shen, Y.; Xu, J. Friction performance of MoDTP and ester-containing lubricants between CKS piston ring and cast iron cylinder liner. Lubr. Sci. 2018, 30, 33–43. [Google Scholar] [CrossRef]

- Guegan, J.; Southby, M.; Spikes, H. Friction Modifier Additives, Synergies and Antagonisms. Tribol. Lett. 2019, 67, 83. [Google Scholar] [CrossRef]

- Soltanahmadi, S.; Esfahani, E.A.; Nedelcu, I.; Morina, A.; van Eijk, M.C.P.; Neville, A. Surface Reaction Films from Amine-Based Organic Friction Modifiers and Their Influence on Surface Fatigue and Friction. Tribol. Lett. 2019, 67, 80. [Google Scholar] [CrossRef]

- Davis, R.; Davis, J.R. Cast Irons; AMS International: Materials Park, OH, USA, 1996. [Google Scholar]

- Fujita, H.; Spikes, H.A. Study of Zinc Dialkyldithiophosphate Antiwear Film Formation and Removal Processes, Part II: Kinetic Model. Tribol. Trans. 2005, 48, 567–575. [Google Scholar] [CrossRef]

- Salmeron, G.C.; Leckner, J.; Schwack, F.; Westbroek, R.; Glavatskih, S. Greases for electric vehicle motors: Thickener effect and energy saving potential. Tribol. Int. 2022, 167, 107400. [Google Scholar] [CrossRef]

- Gonda, A.; Capan, R.; Bechev, D.; Sauer, B. The Influence of Lubricant Conductivity on Bearing Currents in the Case of Rolling Bearing Greases. Lubricants 2019, 7, 108. [Google Scholar] [CrossRef]

- Fujita, H.; Glovnea, R.P.; Spikes, H.A. Study of Zinc Dialkydithiophosphate Antiwear Film Formation and Removal Processes, Part I: Experimental. Tribol. Trans. 2005, 48, 558–566. [Google Scholar] [CrossRef]

- Spikes, H. The History and Mechanisms of ZDDP. Tribol. Lett. 2004, 17, 469–489. [Google Scholar] [CrossRef]

- Ratoi, M.; Niste, V.B.; Alghawel, H.; Suen, Y.F.; Nelson, K. The impact of organic friction modifiers on engine oil tribofilms. RSC Adv. 2014, 4, 4278–4285. [Google Scholar] [CrossRef]

- Miklozic, K.T.; Forbus, T.R.; Spikes, H.A. Performance of Friction Modifiers on ZDDP-Generated Surfaces. Tribol. Trans. 2007, 50, 328–335. [Google Scholar] [CrossRef]

- Bobzin, K.; Brögelmann, T.; Kalscheuer, C.; Thiex, M. Formation of tribochemical reaction layers on a metal modified amorphous carbon coating a-C:H:Zr (ZrCg). Tribol. Int. 2019, 135, 152–160. [Google Scholar] [CrossRef]

- Grossiord, C.; Martin, J.; Le Mogne, T.; Palermo, T. In situ MoS2 formation and selective transfer from MoDPT films. Surf. Coat. Technol. 1998, 108–109, 352–359. [Google Scholar] [CrossRef]

- De Barros’Bouchet, M.; Martin, J.; Le-Mogne, T.; Vacher, B. Boundary lubrication mechanisms of carbon coatings by MoDTC and ZDDP additives. Tribol. Int. 2005, 38, 257–264. [Google Scholar] [CrossRef]

- Tang, Z.; Li, S. A review of recent developments of friction modifiers for liquid lubricants (2007–present). Curr. Opin. Solid State Mater. Sci. 2014, 18, 119–139. [Google Scholar] [CrossRef]

- Ye, J.; Burris, D.L.; Xie, T. A Review of Transfer Films and Their Role in Ultra-Low-Wear Sliding of Polymers. Lubricants 2016, 4, 4. [Google Scholar] [CrossRef]

- Martini, A.; Ramasamy, U.S.; Len, M. Review of Viscosity Modifier Lubricant Additives. Tribol. Lett. 2018, 66, 58. [Google Scholar] [CrossRef]

- Müller, M.; Topolovec-Miklozic, K.; Dardin, A.; Spikes, H.A. The Design of Boundary Film-Forming PMA Viscosity Modifiers. Tribol. Trans. 2006, 49, 225–232. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).