Abstract

In recent years, hard turning has been found to be a well-known substitute for traditional grinding for acquiring the finish quality of hardened steel without sacrificing productivity. There are many issues that should be carefully understood and dealt with to attain efficacious performance in hard turning. This article discusses modern manufacturing challenges with a focus on analyzing the current state of the art of the hard turning process in terms of ensuring more environmentally friendly manufacturing through the use of greener cooling methods such as dry, wet/flood cooling, the minimum quantity of lubricant (MQL), high-pressure jet cooling, solid lubricant, nanofluids, ionic liquids (ILs), cryogenic cooling, and hybrid cooling. Nanofluids combined with the MQL system were found to be the superior cooling technique in comparison to dry, wet/flood, and MQL. Cryo-machining also provided superior performance by limiting the cutting temperature during hard turning. The performance of hybrid cooling (MQL + cryogenic) seems to have been superior to MQL and cryogenic coolant alone because it combined the benefits of lubrication and cooling from MQL and cryogenic systems, respectively. The addition of ILs to base fluids or nanofluids improves the thermal properties of the mixed fluid, resulting in better surface quality, lower tool wear, and longer tool life. Furthermore, the purpose of this study is to summarize the various LCA software used for analyzing the sustainability of the hard turning process. Overall, this paper can serve as a resource for researchers and manufacturers working in the field of sustainable machining.

1. Introduction

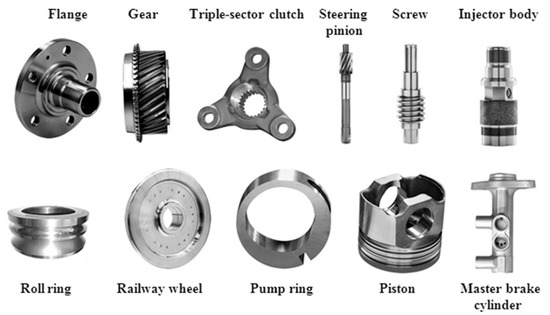

Manufacturers all over the world are constantly looking for ways to reduce manufacturing costs in order to remain sustainable and competitive in the market. Metal machining is a value-added operation in which improper raw material size and shape are transformed into accurate dimensions and high-quality products through the use of cutting tools, machine tools, and the environment. Traditional manufacturing processes, such as casting, forming, forging, and so on, are incapable of producing the desired shape, size, accuracy, and finished product, necessitating the use of machining to meet the needs of both manufacturers and users. A large number of conventional machining methods are available, namely turning, milling, planning, grinding, boring, etc. Hardened steel workpiece machining is gaining high attention due to its several applications in the automobile, press-tool, die-mold, gear, bearing, and aeronautical industries, as displayed in Figure 1 [1]. Earlier, only the grinding process was used to machine hardened steel. For two decades, the application of the turning process for machining-harden steel has grown in popularity due to several challenges (low metal removal rate, low production rate, less flexibility, low setup and cycle time, and high cost-effectiveness) in the grinding process and the development of a new generation turning tool. Hard turning was a popular term for the process of turning hardened steel (45–68 HRC). Hard turning is a machining activity in which the cylindrical surface of hardened steel (45–68 HRC) is machined using single-point cutting tools [2,3,4,5].

Figure 1.

Hardened steel machined industrial components [1].

The hard turning process was invented by the automotive industry to machine difficult-to-cut material on the shop floor for the production of various parts, including transmission shafts, roller bearings, crankshafts, crank pins, and various automotive parts. It also finds an application in the die and mold-making industries, as its job is to give shape to raw material (hardened steel) to convert it into a die or mold. Hard turning is widely used in the aerospace industry, as it is used to manufacture an aerospace engine part that needs maximum accuracy and superior quality finished products [2,5]. The application of hard turning in various sectors was mostly made possible due to the development of cutting tool materials and novel surface coating techniques. All of these applications of hard turning suggest it turning has successfully replaced the traditional grinding process. Hard turning is often termed “finish hard turning” due to its wide application in finishing operations while machining a component.

Nowadays, the hard turning process for heat-treated steels has favorably replaced cylindrical grinding due to its enormous benefits [2,5].

- ➢

- Lower energy consumption

- ➢

- Higher material removal rate

- ➢

- Lower investment in machine tool

- ➢

- Lower machining cost per piece

- ➢

- Multiple machining in one setup

- ➢

- Higher flexibility to accommodate complicated contour part

- ➢

- Suitable for interrupting machining

- ➢

- Minimum tool inventory

- ➢

- Environment friendly

- ➢

- Low residual stress

- ➢

- Improvement in surface quality

- ➢

- Higher dimensional and shape accuracy

- ➢

- Advantageous for Process reliability

The hard turning has benefits in surface quality improvement compared to grinding processes due to implementation of a new generation of cutting tools and advanced cooling systems in hard turning. In general, surface roughness greater than 1.6 micron was established as a rejecting limit in grinding hard to cut metals [6,7]. According to Puerto [8], the range of surface roughness obtained in the grinding process varied from 0.1 micron to 2 microns. There are several research papers reported the surface roughness value within the mentioned range 0.1 microns to 2 microns or less than 1.6 microns. Ozel et al. [9] found surface roughness (0.259 and 0.38 microns) in hard turning with a depth of cut of 0.254 mm and a feed rate of 0.05–0.08 mm/rev. In hard turning AISI D2 steel using corn oil-MQL cooling, Arsene et al. [10] discovered roughness values in the range of 0.151–0.452 microns.

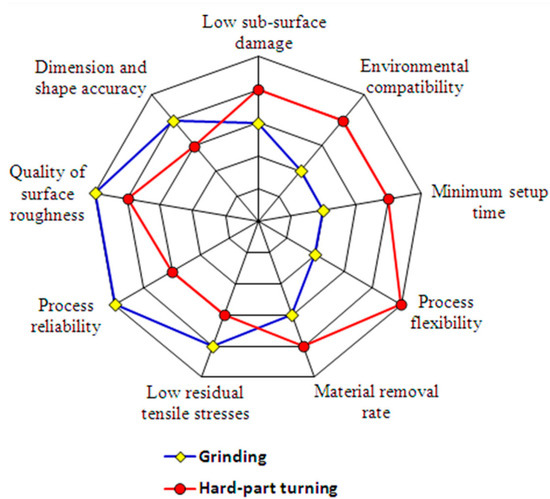

Choudhury and Chinchanikar [1] also showed the qualitative benefits of hard turning over grinding using a radar plot displayed in Figure 2. Apart from benefits, some limitations were also reported by researchers, which have been listed below [2]:

Figure 2.

Qualitative comparison of hard turning with grinding process [1].

- ➢

- The cost associated with tooling is considerably greater than grinding.

- ➢

- Chatter is produced due to high cutting pressure in the turning of long and thin products.

- ➢

- A highly rigid machine tool is needed for a higher degree of accuracy.

- ➢

- Quality of produced surface and dimensional accuracy deteriorated with the tool wear growth even under the limiting criterion of tool life.

- ➢

- Residual stress and white layer formation on the finished surface retard the performance of machining.

Cutting tools are crucial for achieving sustainable hard turning. The capabilities of CBN, PCBN, and ceramic tools for turning hardened steel are widely acknowledged. However, because these tools are more expensive, researchers are looking for a possible replacement in order to reduce the turning costs. In the last 20 years, a lot of research has been done to develop new tool materials and ceramic coatings on tool substrates to achieve superior surface finishes along with enormous productivity at a low cost in hard turning. To achieve the aforementioned goal, the tool material needs to have a number of desirable qualities, including sufficient hot hardness, increased mechanical strength, high fracture toughness, increased thermal shock resistance, increased abrasion resistance, increased resistance to adhesion/diffusion, and chemical inertness to prevent chemical interactions between the tool and the work material during machining. It is typically not feasible to obtain all these superior qualities in a single cutting tool material. The advancement of tool coating technology undoubtedly facilitates the highest percentage of these superior qualities, allowing it to provide the highest levels of productivity, performance, and economy in terms of machining. Multi-layered coatings of different ceramic materials, such as titanium carbide (TiC), titanium carbide nitride (TiCN), alumina (Al2O3), titanium nitrate (TiN), and titanium aluminum nitride (TiAlN), were used as coating materials for different cutting inserts. These coatings can facilitate increased temperature strength and greater wear resistance [3]. For the development of various coated cutting inserts, two tool coating techniques, PVD (physical vapour deposition) and CVD (chemical vapour deposition), are now widely used [3,4].

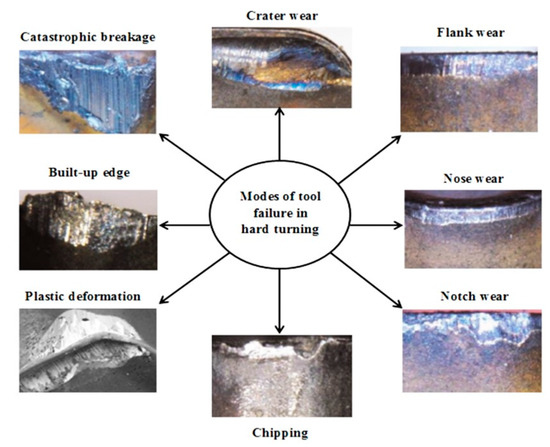

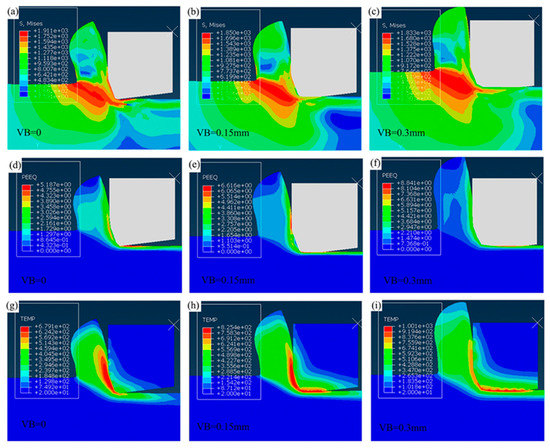

Hard turning in dry cutting surroundings is very advantageous due to the high amount of heat generated, which causes thermal softening of the work material and makes shear deformation easier. However, tool failure accelerates due to rubbing of the flank surface caused by heat and friction, reducing tool life and surface quality. According to the researchers, various types of tool wear occurred during the machining of hardened steels in dry environments [3,4,5], and these have been classified as crater wear, flank wear, nose wear, notch wear built-up-edge (BUE), plastic deformation, chipping, and catastrophic breakage [5], as shown in Figure 3. Crater wear is caused by increased cutting speed, cutting feed, and depth of cut, which degrade surface quality and reduce chip control, whereas tool flank and nose wear are caused by increased cutting speed and feed, which degrade surface quality and dimensional accuracy of the test piece. Notch wear occurred as a result of increased cutting speed and feed, which accelerated cutting forces and burr formation. Lower wear-resistant tool material was also a factor in the formation of tool crater wear, flank wear, nose wear, and notch wear. Chipping wear encourages abrasion, diffusion, and plastic deformation. Improper rigidity of work-tool holding devices, as well as tougher tools, contribute to the chipping phenomenon. A higher sum of heat generation in the cutting region as cutting speed, feed, and depth of cut increase also accelerates cutting tool tip plastic deformation, cutting edge breakage, and surface degradation. Due to adhesion, built-up-edge (BUE) developed on the cutting edge, affecting surface quality and increasing tool wear, cutting force variations, and vibration. Catastrophic failure results in an abrupt increase in cutting forces as well as a degradation in surface quality. Furthermore, at higher speeds, the cutting temperature exceeds, resulting in increased cutting force, poor surface finish, unfavorable residual stresses, and microstructure [5]. As a result of these issues, dry, hard turning may be impractical for achieving the desired machinability. In order to improve machinability in hard turning, proper lubrication and cooling medium are required. The primary functions of cutting fluid are to cool the workpiece and insert it, to remove chips from the cutting zone, and to provide lubrication at rubbing contact surfaces to reduce friction.

Figure 3.

Modes of tool failure in dry hard turning (redrawn) [5].

Flood/wet cooling is completely unsuitable for hard machining work because it is unsustainable and adds an extra financial burden to the machinist for the disposal and upkeep of the used fluids. In fact, statistics showed that in the United States, about 155 million gallons of used coolants were released into the open environment [11]. Cutting fluids’ airborne particles negatively affect a number of chronic human health conditions, including asthma, allergic reactions, skin rashes, and dermatological issues [11]. Furthermore, cleaning cutting fluids adds time and expense and has a negative impact on the environment. As a result, excessive use of flood lubrication should be avoided or reduced. Low-viscosity, water-based cutting fluids may therefore be an appropriate technique for simplicity in cleaning. Consequently, there is a constant search for alternative solutions that reduce environmental problems.

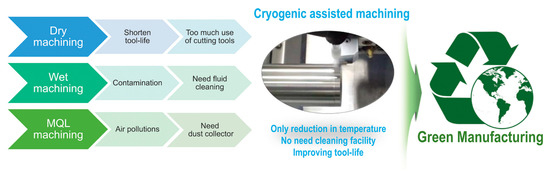

Environmentally conscious machining, also known as “green cutting technology”, is a newer concept of the twenty-first century that arose as a result of stringent environmental regulations. It includes dry machining, mist cooling, near-dry machining, or machining with minimum cutting fluid use, vegetable-oil-based cutting fluids/lubrication, compressed air cooling, nanofluid, cryogenic cooling, and hybrid cooling. Implementation of MQL (minimum quantity lubrication) demonstrated an improvement in tool life and surface finish by minimizing heat generation in the cutting zone, thereby reducing environmental issues and costs [5,12,13,14]. In MQL, a small amount of coolant was sprayed over the turning zone, saving money on coolant and eliminating the need to dispose of used coolant. Another preferable solution for cooling in hard machining is a high-pressure cooling technique, which produces segmented chips, lower cutting forces, longer insert life, and satisfactory machined surface quality [5,12,14,15]. Spray cooling (SC) is another green cooling technology used in hard steel machining [16,17,18]. In this cooling strategy, compressed air is mixed with water in a mixing nozzle before being sprayed over the cutting region [19,20,21]. This high-pressure spray cooling not only lowers the temperature and cutting forces, but it also lowers the need for cutting fluids. It is regarded as a developing technology in cutting fluid applications for reducing friction at the chip-tool interface, controlling temperature, improving heat transfer, and improving machining performance. In recent years, the use of nanoparticles with basic coolant/lubricant has been highly praised because it helps to improve the heat transfer coefficient of basic coolants, resulting in significant reductions in cutting temperature, wear, tool life, machining forces, surface roughness, power consumption, and specific cutting forces [14,22,23]. Cryogenic cooling is another emerging technique for hard turning applications, where tool life improves due to better coolant penetration into a narrow gap at the chip-tool interface [5,12,14]. Moreover, solid lubricants and vegetable oils were also widely used as coolants in hard cutting [5,12,24,25,26]. Ionic liquids added to MQL or nanofluid MQL provide superior hard machining performance [27]. Overall, it can be observed that a number of green coolants have been successfully used in hard machining to date. Therefore, choosing the best sustainable cooling strategy is crucial for achieving better results in hard turning.

Nowadays, industries are keenly interested in using sustainable machining for manufacturing their products. Sustainability can be evaluated considering three aspects such as social, environmental, and economical. It can be evaluated qualitatively using the Pugh matrix method, and quantitatively analyzed using life cycle assessment (LCA).

The proposed work provided a detailed review of hard turning under dry conditions, nanofluid-MQL, cryogenic, and hybrid cooling. Moreover, the specifics of various ionic liquids used as cutting coolant additives in machining were summarized and discussed. Furthermore, the various sustainability assessment methods for machining applications are summarized. A list of LCA software used in machining was reported, which had not previously been presented in any review work. This paper will help you choose the best coolant strategy for machining hard materials. With the help of this research, learners can adopt the most appropriate life cycle assessment software (LCA) to quantitatively analyze the sustainability of the machining research.

2. Hard Turning under Dry Condition

Hard machining under dry conditions has been very popular for the past two decades due to the development of various new cutting tool materials that have successfully replaced cylindrical grinding. The following sections provide an overview of the performance of various hard machining cutting tools.

2.1. Performance of CBN/PCBN Cutting Tool

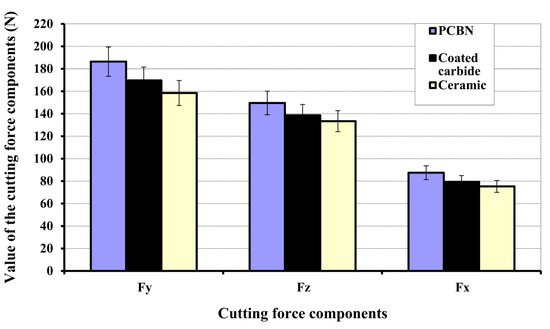

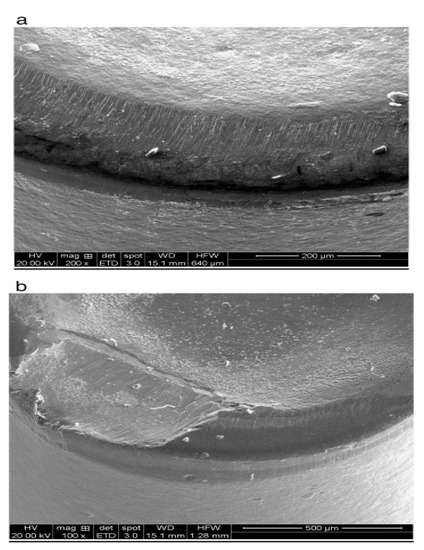

CBN/PCBN cutting tools have been extensively used in hard machining due to their higher hardness, higher micro-hardness, and higher capability to resist abrasion. According to Qian and Hossan [28], CBN and PCBN tools were highly applicable in the machining of heat-treated steel because of their high resistance capability against abrasive wear, high hardness, and resistance against chemical diffusion at elevated temperatures. Kishawy and Elbestawi [29] used a PCBN cutting tool to observe various types of surface defects, such as material side flow, micro-cracks, and cavities, on the finished surface of D2 steel. The various modes of wear, namely crater wear, flank wear, notch wear, and chipping of the cutting edge, were perceived in hard machining. Shalaby et al. [30] investigated the performance of hardened AISI D2 steel using PCBN, coated PCBN, and ceramic cutting tools. The turning force components were measured, and the comparative results for each tool material are shown in Figure 4. The radial component force (Fy) was the greatest, followed by the cutting (Fz) and axial (Fx) forces. The ceramic tool produced the lowest values of the three cutting force elements, followed by the PCBN, while the coated PCBN tool material produced the biggest force components. Moreover, abrasive marks were noted on the flank wear for both uncoated and coated PCBN tools because the tool’s flank edge rubbed against highly hard components (such as chromium and carbide) present in the work material. The faster cutting speeds enabled a consistent plastic flow of the work material on the tool face, resulting in continuous and tangled chips as allowed for in Figure 5. The ceramic tool produced the smoothest chip underside, shown in Figure 5, suggesting the least amount of chip adherence to the tool face. PCBN was next, and the coated PCBN had the most chip adhesion to the tool face.

Figure 4.

The consequence of turning tool materials on cutting force components when cutting speed = 175 m/min, feed = 0.15 mm and radius of tool = 1.2 mm [30].

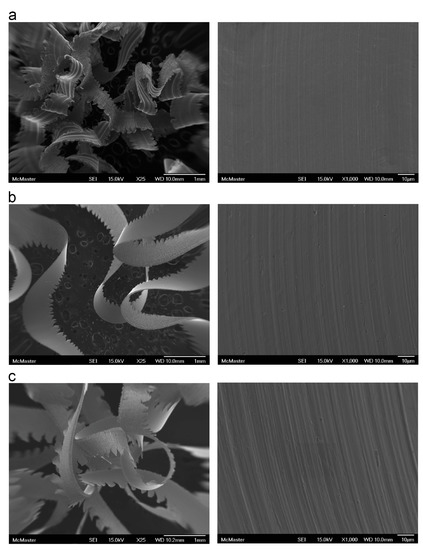

Figure 5.

SEM photos of chips obtained in hard turning using (a) mixed alumina ceramic (b) PCBN (c) TiN coated PCBN [30].

Dosbaeva et al. [31] noticed that in high precision machining when high dimensional accuracy was demanded, the PCBN cutting tool can be the superior choice over the carbide tool because of its lower rate of wear progress in the initial stages of cutting tool wear under turning of AISI D2 steel. Kishawy [32] discovered that cutting temperature increased as a result of both leading speed and feed, but cutting speed had a greater impact on temperature increment than feed. In addition, the temperature rose as the tool wear rate increased during the turning of a hardened AISI D2 work-piece with a PCBN insert. Arsecularatne et al. [33] found that the tool life was significantly improved in the machining of AISI D2 steel with a PCBN cutting tool at the lowest cutting speed. Abrasion and grooving were the main forms of wear found in hard AISI D2 steel machining. Ozturk et al. [34] conducted an experiment on AISI 4140 steel with three different micro-textured tools. It was concluded that texturing inserts were not suitable for machining AISI 4140 steel in a dry condition.

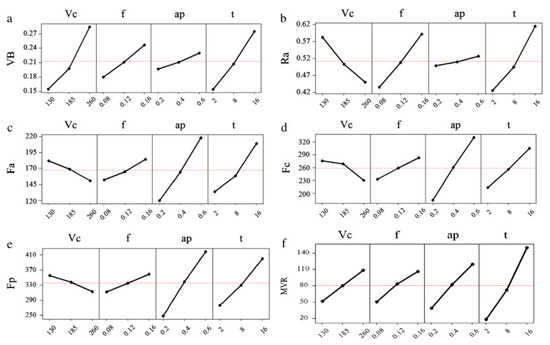

Tang et al. [35] stated that the cutting tool temperature was improving with cutting time in turning AISI D2 work specimens with CBN inserts. Kundrák et al. [36] discovered an increase in CBN tool wear in hard turning when the cutting speed exceeds 150 m/min. When the cutting speed was varied between 120 and 150 m/min, the tool wear was almost identical. Kumar and Chauhan [37] utilized the CBN cutting insert in turning AISI H13 grade steel. The hardness of the test piece, speed, and feed all had a significant impact on machining responses such as surface quality, tool-tip temperature, and cutting force. Oh [38] investigated the relationship between cutting forces, tool abrasiveness, and the quality of the turned surface obtained when turning SKD11 steel with a CBN insert. It was proposed that a low cutting speed with a high transfer ratio was most effective for removing a large amount of metal. Bouacha et al. [39] studied the influence of cutting parameters (cutting speed Vc, feed rate f, depth of cut ap, and cutting time t) on flank wear (VB), surface roughness (Ra), feed force (Fa), tangential-cutting force (Fc), thrust force (Fp), and material removal rate (MRR) as displayed in Figure 6. The flank wear was greatly amended by Vc and t, while the roughness was principally prejudiced by t, f, and Vc. Depth of cut was the most crucial term towards affecting all cutting forces. Similarly, MRR was greatly improved by t, followed by Vc, f, and ap.

Figure 6.

Influence of cutting parameters on (a) Flank wear, VB (b) surface roughness, Ra (c) axial force, Fa (d) cutting force, Fc (e) radial force, Fp (f) material removal rate, MRR [39].

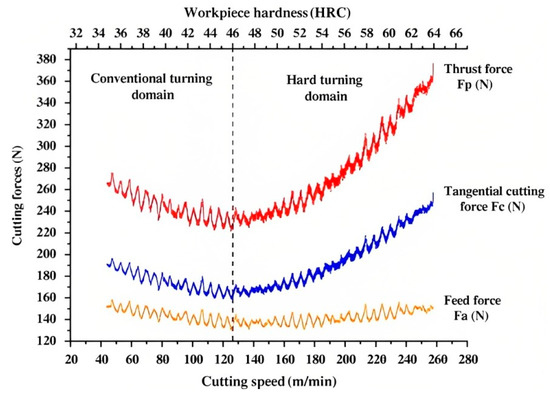

Grzesik and Żak [40] applied hard turning and ball burnishing as two sequential finishing operations while machining 41 Cr4 steel with a CBN cutting tool. Surface roughness was greatly influenced by feed during the turning process. In comparison to hard turning, the burnishing operation performed better and produced a higher quality surface. Bartarya and Choudhury [41,42] examined the significance of input machining variables on forces as well as on the roughness of the machined surface during the finish turning of an EN 31 work-specimen (60 ± 2 HRC) with an uncoated CBN insert. It was discovered that radial depth, followed by axial feed and speed, significantly influenced the roughness of the turned surface. Khamel et al. [43] examined the impact of machining input variables on tool life, cutting forces, and surface roughness in finish turning on prior heat-treated AISI 52100 work specimens with a CBN tool. Surface roughness was chiefly controlled by tool feed, followed by speed and radial depth of cutting. Rashid et al. [44] implemented a surface defect machining method to improve the quality of the surface. By applying this method, the cutting temperature and cutting forces were reduced, while a significant improvement in surface quality was noticed compared to traditional turning on prior AISI 4340 work-specimens utilizing the CBN cutting tool. Bouacha et al. [45] explained the nature of cutting forces obtained in conventional and hard turning processes with variations in cutting speed as displayed in Figure 7. The conventional turning domain was considered when job hardness was below 46 HRC. For this case, when the cutting speed was leading up to 120 m/min, all the components of forces were decreasing. Similarly, for hard turning, the cutting force components were leading with simultaneous increments in job hardness and cutting speed. In addition, when turning AISI 52100 work-specimens with the CBN tool, the surface quality decreased with increasing feed rate while increasing with increasing cutting speed.

Figure 7.

Influence of workpiece hardness and cutting speed on components of turning force at fixed feed = 0.08 mm/rev and fixed depth of cut = 0.3 mm cutting conditions [45].

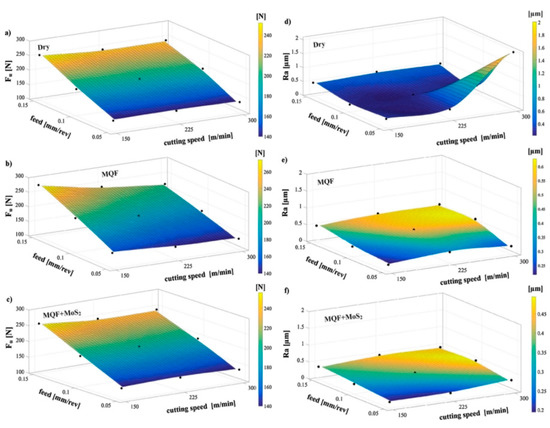

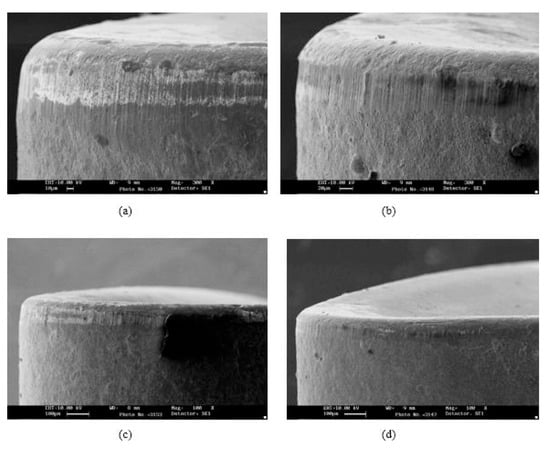

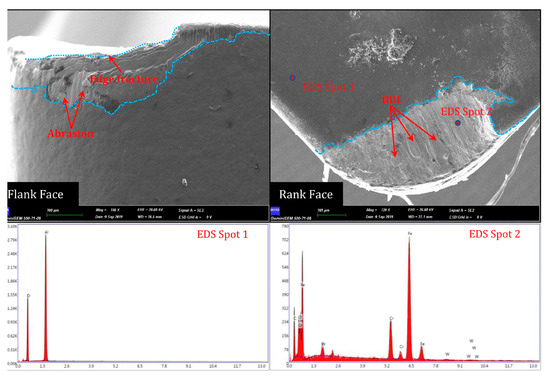

Sahin [46] emphasized a comparison of tool life between ceramics and cubic boron nitride inserts using the Taguchi method. CBN cutting tools outperformed ceramic tools for undercutting AISI 52100 steel. Cutting speed had the greatest influence on wear at the insert surface, followed by insert hardness and rate of feed. Dureja et al. [47] characterized the wear mechanisms of inserts in turning an AISI H11 hard work-specimen with a coated (TiN) CBN cutting insert. Machining with lower speed and feed causes abrasion wear, whereas machining with high speed causes adhesive wear due to tribo-chemical action between tool and workpiece. The built-up edges were formed at a medium cutting speed. Ghani et al. [48] deliberated on the tool wear and heat partition on turning of an AISI H13 work-specimen with a CBN cutting insert and established that the wear on the tooltip was highly dependent on the intensity of the temperature evolved in cutting and the amount of heat conceded by the insert during high-speed turning. Higher temperatures reduce the bonding strength of the cutting tool, resulting in tooltip chipping or shearing-off failure. Due to the high speed, the contact area was reduced, which shifted the maximum temperature and stress zone to the cutting edge. However, greater crater wear and concentrated plastic deformation took place on the tool edge. More et al. [49] carried out the cost analysis during the turning process, which revealed the lower cost of machining with the CBN tool compared to PCBN and showed that it can be used as a substitute tool for PCBN in the turning of hardened AISI 4340 work-specimens. Morehead and Huang [50] observed segmental as well as continuous chips with saw tooth profiles in the machining of AISI 52100 steel with the CBN tool. The spacing between two adjacent saw teeth and the height of the segmental chip were reduced with tool wear growth, whereas for the continuous chip, it was increased with tool wear. Niaki et al. [51] investigated hardened AISI 4340 steel using CBN inserts with various cutting edges to find out the responses such as tool wear, cutting force, and surface roughness. It was observed that the stability of the CBN cutting was the initial factor in the determination of the tool’s life. CBN tools of grades A and B provided a 60% improvement in tool life and inferior tool wear in comparison to CBN tools grade C. Suarez et al. [52] performed a machining operation on hardened AISI D6 material with a PCBN tool under various cooling environments to determine the effects of tool wear, quality of the surface, tool life, and cutting force. According to reports, MQF + MoS2 provides longer tool life than MQF alone. Figure 8 depicts the wear pattern of the PCBN tool in dry machining. Different-sized abrasion marks and micro-chipping on the tooltip were seen in Figure 8. At the beginning of the machining process, the tool edge radius encountered a micro-chipping structure. Further spreading in the direction of wear that was preferred caused a localized increase in machining force, resulting in large abrasive markings on the tooltip.

Figure 8.

PCBN worn cutting edges obtained in dry machining [52].

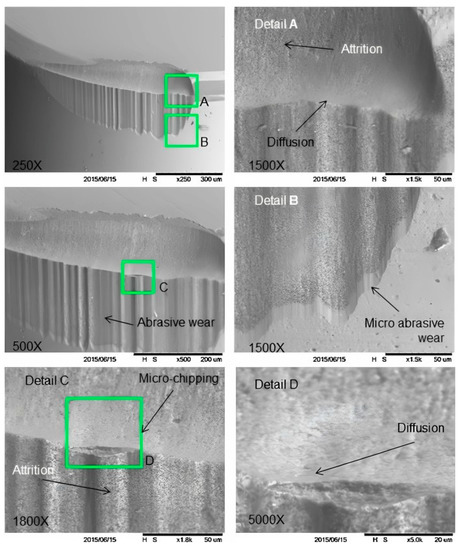

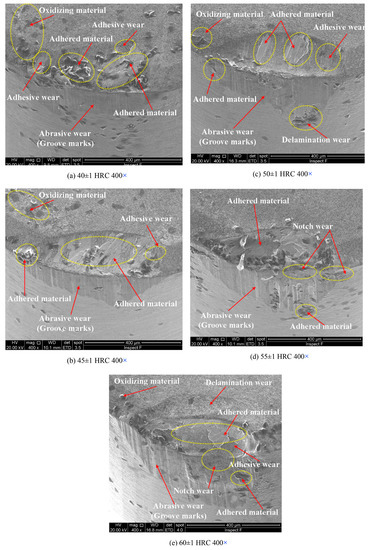

Rafighi et al. [53] executed experiments on the turning of AISI D2 hardened steel by implementing CBN and ceramic tools and discussed their comparative performances. CBN provided a superior surface quality over ceramic, but the cutting forces were higher on the side of the CBN tool. Nose radius and tool speed was traced to be noteworthy toward surface roughness for both tools. Kumar et al. [54] executed the turning trials on hardened AISI H13 by taking samples of different hardnesses using the CBN tool under different machining conditions. The obtained results revealed that the cutting forces and surface roughness were mostly exaggerated by the work material’s hardness. Higher work material hardness produced higher forces but displayed a superior surface finish. Bonafa et al. [55] examined the recital of MQL while turning hard AISI D6 tool steel with PCBN tools in comparison to dry conditions. It was found that, compared with elevated values of feed rate, tool wear was smaller because of the lower feed rate. When cutting speed increased, tool wear also increased when compared with dry machining. In addition, the interaction between cutting speed and feed was very important because it gave a better surface finish without compromising the products. Kumar et al. [56] performed experiments on AISI 4340 hard steel using a CBN tool (TiN-coated), noticing that increased work hardness and feed rate resulted in a larger cutting force and a higher interface temperature. This was because frictional heat production and flank surface wear increased. It was also discovered that the machining performance of CBN tools was superior in all machining situations. Tang et al. [57] examined the tooling wear performance of the PCBN tool during machining of hardened AISI D2 steel with different hardnesses under the dry conditions, and the images of wear were displayed in Figure 9. For workpiece hardness between 40 and 55 HRC, abrasive wear was seen as the main mode of tool wear on the flank surface. Similar to this, delamination and abrasive wear were discovered for jobs with a hardness of 60 HRC because of an abrupt increase in friction at tool-work piece contacts, whereas the major wear in the rake face of PCBN tools is the crater wear.

Figure 9.

Tool wear images obtained in dry hard turning at different hardness levels [57].

Nayak et al. [58] conducted an experiment on AISI D6 material using the CBN tool and reported that feed rate was the important parameter for surface roughness. Karthik et al. [59] investigated on hardened EN31 steel with the CBN tool and the result revealed that for different values of cutting speed and depth of cut, the surface roughness of EN31 steel augments with the raise in the feed so feed was the most leading and influencing factor for increasing of surface roughness. Gundarneeya et al. [60] applied Taguchi’s L9 orthogonal array and ANOVA to undertake hard turning operations with a CBN tool on EN24 material. The rotational speed has mainly impacted the workpiece surface and, subsequently, the insert nose radius, while the depth of cut and feed rate have had less of an impact. However, the depth of cut influences the dimensional accuracy of components the most, followed by spindle speed and nose radius. Nikam et al. [61] evaluated tool life, tool-edge wear, cutting forces, and surface roughness in CBN insert-assisted hard machining on AISI 4140 steel. In comparison to the feeding and cutting forces, the radial force exhibits the maximum magnitude during forceful turning. The maximum tool life of 58.02 min was recorded during machining at 0.1 mm/rev feed and 200 m/min cutting speed. Balwan et al. [62] investigated the hard machining operation on EN353 steel with CBN inserts. According to ANOVA, cutting forces were significantly influenced by feed rate and depth of cut. The brief details about the used cutting tool and machining parameters for the hard turning process are shown in Table 1.

Table 1.

Details of used cutting tool and cutting parameters in hard turning.

2.2. Performance of Ceramic and Cermet Tools

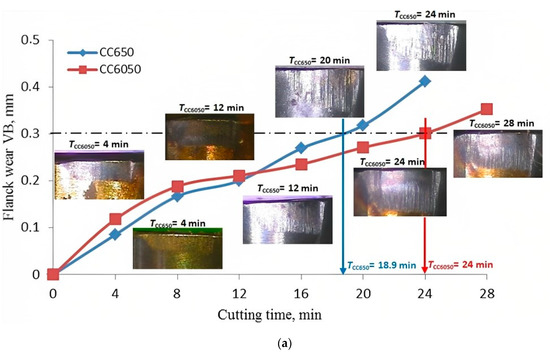

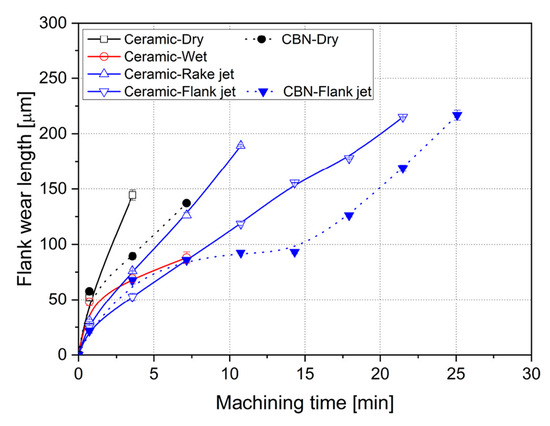

In the manufacturing sector, ceramic cutting tools are used for the machining of various hard materials. High melting points, great hardness, and outstanding wear resistance are all characteristics of ceramics. According to Basak et al. [63], to get 0.8 µm of turned work surface roughness of AISI D2 alloy steel with the ceramic tool, the speed of machining should be 220 m/min, while to get a supreme rate of production, the tool-feed should be taken from 0.11 to 0.15 mm/rev. Lima et al. [64] found improved surface quality in the tuning of AISI D2 steel (58 HRC) with coated carbide, PCBN, and ceramic cutting inserts compared to cylindrical grinding. Flank wear seemed to be improved with cutting speed along with the depth of cut. Salem et al. [65] observed a saw tooth profile of chips in the orthogonal cutting of an AISI D2 work-specimen with a ceramic insert, and it occurred due to crack propagation in the quenched structure of the material. Due to the increase in cutting speed, the chips became soft and ductile; however, segmentation of the chips took place and looked similar to a saw-tooth pattern on the chips. Yuan et al. [66] examined the wear characteristics of an alumina mixed uncoated ceramic insert at diverse cutting speeds during the turning of hardened AISI D2 work-specimens and noticed tribofilm generation at the friction surface, which directly affects the tool life. Davim and Figueira [67,68] inspected the machining indicators of AISI D2 hardened alloy steel using ceramic tools. Tool wear was extremely sensitive to changes in cutting speed and time. Wear at insert surface was rapidly increased with growing speed and turning time. Kamely and Noordin [69] studied microstructure, residual stress, and the development of a white layer during the cutting of AISI D2 work specimens with a coated PVD ceramic cutting insert. The microstructure was changed due to metallurgical alteration and chemical phenomena that happened due to elevated cutting temperatures. Bensouilah et al. [70] conducted hard-turning experiments on AISI D3 hardened steel (63 HRC) using coated and uncoated ceramic tools. The tool life and surface roughness were measured with growth in machining time, and the results are shown graphically in Figure 10a,b, respectively. With a wear limit of 0.3 mm, the tool service life with the uncoated ceramic tool was 18.9 min while it was 24 min for the coated tool. The amount of flank wear significantly impacted the surface roughness. The estimated roughness of coated and untreated tools at the end of their useful lives was 1.37 and 1.46 microns, respectively.

Figure 10.

Comparison of coated and uncoated ceramic tool performance using graphs of (a) Flank wear vs. Cutting time (b) Surface roughness vs. Cutting time [70].

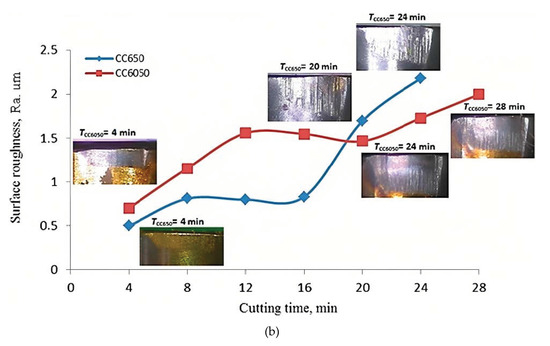

Ferreira et al. [71] analyzed the comparative performance capability of the multi-radii and conventional ceramic tools on turning of H13 steel. The roughness of the machined surface was noticed to be improved with the use of multi-radii insert compared to the conventional tools. Karpuschewski et al. [72] provided the sequence-wise stages for preparation and performance of the cutting edge that were a significant element in controlling the cutting edge in the turning of heat-treated high-alloyed steel utilizing TiN coating and an uncoated ceramic tool. Bhemuni et al. [73] found the largest affecting term of flank wear was the depth of cut trailed by cutting speed and feed rate. It was also suggested to use a small magnitude of the depth of cut to avoid chatter during turning on an AISI D3 work specimen with a ceramic (Al2O3 and TiC) cutting insert. Pal et al. [74] emphasized the investigation of cutting forces, chip-tool-interface temperature, and roughness of the machined surface in turning on prior heat-treated AISI 4340 work-specimens with the mixed ceramic tool and noticed the increasing trend of the roughness of the machined surface with growth in feed, whereas temperature was increasing with increasing speed and job hardness. Suresh and Basavarajappa [75] investigated tool wear and surface roughness in turning hard steel AISI H13 using a PVD-applied TiCN-coated ceramic tool. Tool wear is greatly stimulated by cutting variables, while the feed is the dominant agent for surface roughness. Figure 11 shows the worn tool obtained in different cutting conditions. The flank wear faces have distinct mechanical ploughing grooves and ridges, which are indications of typical abrasive wear. However, it was discovered that at high machining conditions, abrasion was the primary mode of wear, while adhesion was observed at low machining conditions.

Figure 11.

Obtained images of worn tool tips under various machining situations [75].

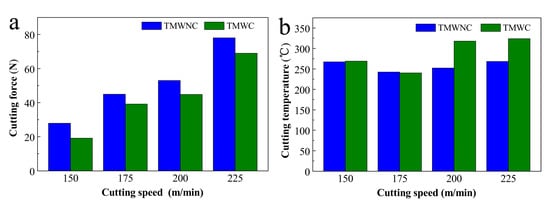

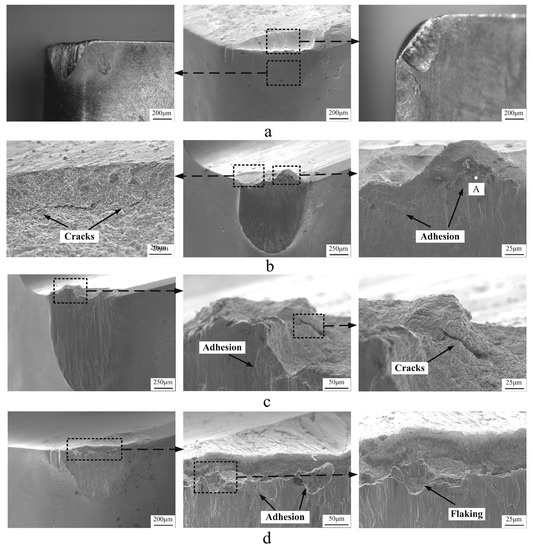

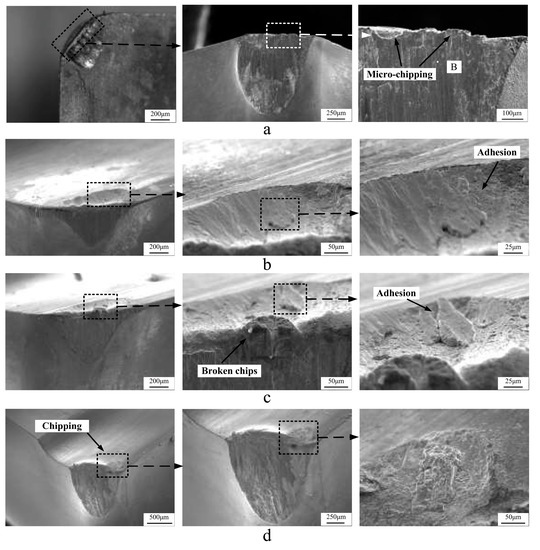

Elbah et al. [76] observed that the surface quality of AISI 4140 steel of hardness 60 HRC was greatly improved with inserts of wiper ceramics when compared to conventional ceramics, and the roughness value was noticed to be lower than 0.9 microns even though the tool attained the wear at the flank face limit of 0.3 mm. Mandal et al. [77] experimentally noticed that the machining at a higher speed produced a good surface finish, which is very essential for hardened steel, when subjected to the machining of an AISI 4340 work-specimen at high speed with a cutting insert (Yttria stabilized zirconia toughened alumina). Aslantas et al. [78] observed the most dominating wear type was crater as a result of chipping or insert-tip cracking in a concise span of time. Machining AISI 52100 steel with an uncoated ceramic insert generates a superior temperature compared to a coated ceramic insert, owing to the lower conductivity of the uncoated insert. The coated tool was more sensitive to the formation of BUE during machining. Meddour et al. [79] found that the nose radius and cutting feed were the utmost factors influencing the work surface roughness whereas cutting forces were highly dominant by the depth of cut. Effects of cutting feed on surface finish could be reduced by elevating the cutting speed in AISI 4140 steel turning using a mixed ceramic cutting tool. Lalwani et al. [80] discovered good quality surfaces when they machined MDN250 steel with coated ceramic cutting inserts at higher speeds, deeper cuts, and lower feed rates. Xu et al. [81] developed Ti (C, N) based (TMWNC and TMWC) cermet tools and investigated their performance in machining 32–36 HRC hard 42CrMo workpieces. The TMWC tool produced a lower cutting force in comparison to the TMWNC tool, as presented in Figure 12a. The cutting force for both tools improved with cutting speed. TMWNC’s tool produced a relatively lower cutting temperature in comparison to TMWC due to its lower thermal conductivity, as shown in Figure 12b. The tool wear images for TMWNC and TMWC tools at various cutting speeds are shown in Figure 13 and Figure 14, respectively. The wear rate of the TMWC tool was higher than that of the TMWNC tool because the TMWC tool’s adhesive wear degree was greater than that of the TMWNC tool. According to According to Khan et al. [82], job hardness was the most important determining factor for tool life. Hard turning of an AISI D2 workpiece with a wiper-ceramic insert causes notching, wear scars, and oxidation wear. Rashid et al. [83] and Agarwal et al. [84] claimed that although machining with a smaller feed rate improved surface quality, the corresponding tool wear volume was high due to the longer length of tool movement during machining. According to Godoy and Diniz [85], the dominant mechanism for ceramic tools was abrasion, whereas for the CBN insert, abrasion was dominant at the slowest speed and diffusion was dominant at the fastest speed when turning an AISI 4340 work specimen. Oliveira et al. [86] found three times the tool life of a PCBN tool compared to a ceramic tool when machining AISI 4340 steels. The major wear phenomena associated with the end of ceramic tool life were abrasion followed by diffusion, whereas an adhesive phenomenon was more sensitive for PCBN tools. The ceramic tool produced a better-quality surface than the PCBN tool. Kumar and Patel [87] mentioned that the temperature was elevated with the progress of time and tool wear, but the rate of elevation of temperature in turning on an AISI 52100 work specimen was higher when utilizing an uncoated ceramic tool compared to a coated ceramic cutting tool due to the greater thermal stability of the coated tool for a longer duration. Helical-shaped chips were reported with uncoated tool whereas longer snarled type of chips was noticed for coated tools. Panda et al. [88] confirmed the superiority of ceramic tools in the turning of hard AISI 52100 work specimens as the width of wear at the flank face and work surface roughness were achieved within the recommended values of 0.3 mm and 1.6 µm, respectively.

Figure 12.

Comparison of TMWNC and TMWC tools (a) Cutting force (b) Cutting temperature [81].

Figure 13.

TMWNC tool wear images at diverse cutting speeds (a) 150 m/min, (b) 175 m/min, (c) 200 m/min and (d) 225 m/min [81].

Figure 14.

TMWC tool wear images at diverse cutting speeds (a) 150 m/min, (b) 175 m/min, (c) 200 m/min and (d) 225 m/min [81].

Kam et al. [89] performed a hard turning process on AISI 4140 steels using ceramic tools and noticed that machinability was improved due to the increases in toughness achieved by decreasing the hardness of the workpiece. In addition, the feed rate was directly correlated with the increase in vibration amplitude values. Shalaby et al. [90] investigated hardened AISI 4340 steels with two different types of alumina ceramic inserts: ZrO2 and Al2O3 coated and Al2O3 and TiC coated. Results revealed that alumina ceramic tools with ZrO2 added are more resistant than ceramic tools (mixed) with TiC coating. From the SEM and XPS analyses, it was established that the triboflims created at the machining zone at the time of machining affected the tool wear resistance and impacted the coefficient of friction at the tooltip interface. Arsene et al. [10] studied and examined the turning of hardened AISI D2 steel with a ceramic wiper cutting tool and found that, in terms of surface quality, cutting with a ceramic insert gives a good performance as compared to grinding. In addition, lower tool wear was observed in MQL than in dry situations, and adhesion and major chipping were also noticed. Rath et al. [91] conducted machining operations on hardened AISI D3 steel using a mixed ceramic tool (Al2O3 + TiCN) under dry conditions. The results showed that by selecting appropriate cutting parameters, both surface finish and machining force could be improved simultaneously.

Das et al. [92] examined the performance of hardened AISI 4340 steels with uncoated carbide and coated cermet inserts. Coated carbides showed reduced cutting force, flank wear, and surface temperature as compared to uncoated carbides, but greater feed force and radial force. Tiwari et al. [93] studied the machining responses such as surface roughness, cutting force, and chip coefficient in hard part turning of AISI 4340 steel utilizing the cermet cutting tool and observed that surface roughness increased with the radial depth of cut and axial feed. MRR improves almost linearly as the radial depth of cut increases, but slowly as feed and speed increase. The details of the workpiece, cutting parameters, and responses studied in hard turning with a ceramic tool are listed in Table 2.

Table 2.

Details of workpiece, cutting parameters and responses studied in hard turning using ceramic tool.

2.3. Performance of Coated and Uncoated Carbide Tools

Nowadays, because of the availability of various advanced coated carbide tools, the use of more expensive ceramic and CBN inserts for hard machining is being reduced, which contributes to a reduction in machining cost and, as a result, product cost. In hard machining, numerous studies have been conducted to investigate the cutting ability to distinguish coated (TiN/TiCN/Al2O3/TiN), (TiN), (TiAlN/AlCrN), (TiAlN), (AlTiN), (TiCN/Al2O3/TiN), (TiCN/Al2O3/TiN) carbide insert and uncoated tool. The following are some of the most significant findings:

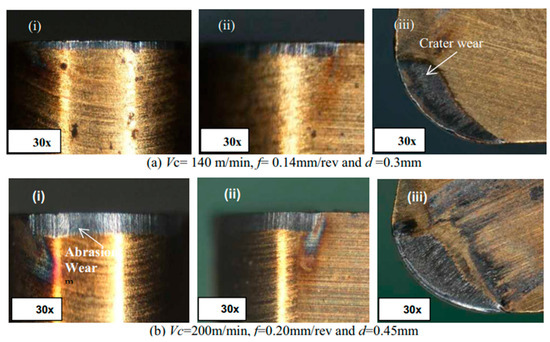

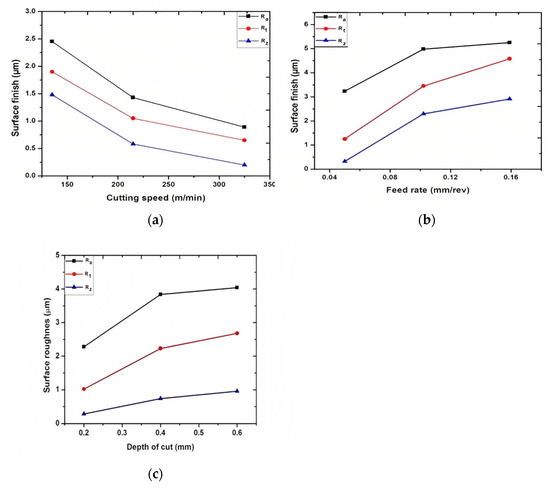

Sahoo and Sahoo [3] accomplished a comparative evaluation of the dry-machining performance of (TiN/TiCN/Al2O3/TiN) coated carbide with an uncoated tool. The observed growth of wear width at the flank face for the coated tool was uniform with no immature failure, whereas abrasion was noticed to be the principal wear mechanism. Sahoo and Sahoo [4] emphasized surface finish, wear of the tool flank, chip formation, and machining forces while turning the AISI 4340 rods by using uncoated and coated carbide cutting inserts. The tool life of coated tools was found to be very high in comparison to uncoated tools. Compared to the uncoated tools, better surface finish and lower machining costs were achieved during turning with a coated tool. Srithar et al. [94,95] found diminished quality of the surface with rising depth-of-cut and cutting feed, while it was improved with rising cutting speed. The forces developed seemed to improve with speed, whereas a subsequent decrement was noticed with the rise in cutting feed. Cutting feed was traced to be the greatest influencing agent for forces and surface quality in machining on an AISI D2 work-specimen with a coated carbide cutting tool. The graph depicts various surface roughness characteristics in relation to cutting speed, depth of cut, and feed rate, as shown in Figure 15. The curve for surface roughness parameters with regard to cutting speed is shown in Figure 15a. The graphs indicate that when the cutting speed increases, the surface roughness parameter decreases. The graph for surface roughness with relation to feed rate is shown in Figure 15b. The graph clearly demonstrates that when the feed rate increases, the surface roughness parameter values increase. Furthermore, when the other factors are taken into account, the experimental findings indicate that the impact of feed rate on the surface roughness parameter is greater. Figure 15c illustrates a graph of surface roughness factors as a function of cut depth. The surface roughness parameter value increases as the depth of cut rises from 0.2 to 0.6 mm, according to the graph. Silva et al. [96] presented the larger magnitudes of cutting as well as thrust forces in the turning of AISI D2 steel with an uncoated carbide cutting tool due to its greater tensile strength and hardness. The sharp increment in cutting force was noticed with the cutting feed. Sahoo [97] applied a titanium nitride-coated tool in turning of heat-treated AISI D2 steel and noticed the acceptable quality of the work surface within the accepted limit of 1.6 microns. Higher speed is attributed to the improved quality of the finish due to the absence of BUE at higher speed. Jiang et al. [98] introduced the simulation approach to validate the obtained simulated results with the results obtained during the turning of an AISI D2 work specimen with a coated (TiAlN) carbide cutting tool. Maximum shear stress between the coated layer and substrate of the tool was improved with cutting speed, while the effect of feeding was very minute. The thrust force was enhanced by the feed rate. Due to the increased deformation degree of the saw tooth chip, the thrust forces at a cutting speed of 90 m/min are greater than those at a cutting speed of 60 m/min.

Figure 15.

Graph shows surface roughness with respect to (a) cutting speed (b) Feed rate (c) depth of cut [95].

Zeghni and Hashmi [99] found a higher wear resistance capability of coated substrates compared to uncoated substrates, whereas TiC introduced greater wear resistance in relation to TiN coating in the course of turning AISI D2 as well as AISI D3 grade steels. Haron et al. [100] stated that the coated tool outperformed compared to the uncoated in terms of wear during the turning of the 95 MnCrW1 steel bar. Smooth growth of wear was noticed with the coated tool, while the wear zone was concentrated on the tool-tip region. For coated tools, chipping was noticed at the end of the tool’s life. The chips’ color varied with tool wear and cutting speed.

According to Selvaraj et al. [101], the tool wear was dominated by abrasion during turning on duplex stainless steel with a coated (TiC and TiCN) carbide cutting insert at lower cutting speeds, but when turning was carried out at higher speeds, mechanisms such as diffusion, thermal softening, and notching were most prominent. Chinchanikar and Choudhury [102,103] reported that the tool wear directly influenced the radial as well as feed forces in tuning an AISI 4340 work-specimen with PVD and CVD cutting tools. Rapid wear, as well as catastrophic breakage of the tool, was more dominant for the PVD tools whereas gradual progress of wear was noticed for the CVD tool.

Gowd et al. [104] discovered a rising trend in MRR with increasing depth-of-cut, while tool wear improved with increasing speed, tool feed, and tool-radial-depth in turning AISI S2 work-specimen with carbide inserts. It was also noticed that the cutting force was improving with the rising cutting speed. Sahoo and Sahoo [105,106] studied the machinability properties such as wear in the flank, chip formation, and surface finish obtained during the turning of AISI 4340-grade steel. The tool wear in hard-turning was primarily caused by abrasion and chipping. TiN-coated carbide produces a better surface finish. Major factors for tool wear were machining speed, depth of cut, and cutting feed. The economical interpretation was performed using optimal setting data, and Rs 3.17 was found for the machining cost for the considered machining variables. Chinchanikar and Choudhury [107,108,109,110] worked on the machinability properties of AISI 4340-grade steel while machining with coated and uncoated carbide tools. The change in machining force varied proportionately with cutting depth and axial feed. In another work, the performances of TiAIN and coated carbide tools (TiCN/Al2O3/TiN) while turning AISI 4340-grade steel were carried out. PVD-coated tools produced less machining force than CVD-coated tools. The single-layered tool produced a lower width of wear, but for the multi-layered tools, the wear growth was increasing rapidly because of the flaking of coatings. Higher cutting forces were noticed when machining harder work pieces, while they were influenced by the cutting feed and the depth of cut. Mechanisms associated with the failure of the tool were nose wear and chipping because of abrasion and adhesion. Suresh et al. [111,112] reported the advantages of lowered processing costs, better material properties, and improved productivity in machining AISI 4340-grade steel using multi-layered carbide inserts. It was found that the cutting feed was exceedingly influenced by the particular cutting force, whereas the cutting power and wear of the cutting tool increased directly with cutting speed and axial cutting feed. In addition, greater machining speed and a lower cutting feed are attributed to the improved surface quality. Chip breaking occurred due to the higher cutting speed. Figure 16 shows the wear SEM image of a coated carbide cutting tool after machining. Wear was occurring due to high pressure and temperature. Grooves were discovered on the rake face of the tool as a result of the abrasive mechanism and material adhesion, as shown in Figure 16a. Furthermore, tool wear in the nose region was frequently deliberated due to higher pressure and thermal softening of the tool material. In Figure 16b, chipping of the cutting tool edge was shown, which shows the major tool wear at the highest values of cutting parameters. Dave et al. [113] revealed that the positive insert produced a higher rate of material removal compared to the negative insert. The rate of material removed was affected by the depth of cut when turning on EN31 and EN8 with a coated (TiN) cutting insert. Kene et al. [114] noticed that the carbide tool with PVD coating exhibited extended tool life, enhanced quality of the work surface, more dimensional precision, and a higher temperature in the turning of hard AISI 4340-grade steel without using any coolant. The cutting forces improved with the progress of wear width, whereas tool wear was affected by contact stress and interface temperature in turning. Sethi and Kumar [115] worked on the turning of EN31 work specimens using a coated carbide tool. The results suggested that the wear at the flank face increased with all turning parameters, whereas cutting speed was noticed to be a highly dominant variable, followed by depth of cut and cutting feed. Motorcu et al. [116] found the most compelling factor on interface (tool-chip) temperature was turning speed, whereas tool temperature was largely stimulated by the depth of cut. The quality of the surface was significantly influenced by turning feed when turning on AISI 4140 with a PVD coated carbide cutting insert. Lima et al. [117] stated that the turning forces improved with the hardness of the test specimen, whereas the variation in forces followed the linear trend with rising cutting feed as well as the depth of cut. The abrasion tool mechanism was more prominent towards wear, whereas sudden breakage of the tool appeared with longer machining periods under turning on AISI 4340 by means of a coated carbide tool. Das et al. [118] investigated the machining performance of hard AISI D6 material in a dry environment utilizing two types of cemented coated tools (AlTiN and AlTiSiN) and found that the scalable pulsed power plasma (SPPP)-AlTiN coated tool outperformed the other two tools in aspects of enhanced surface quality, minimized cutting force, and longer tool life. In machining, serated and saw tooth segmented type chips were generated. Due to the inadequate heat dissipation capabilities of the AlTiN tool, bigger and broader saw tool chips were produced.

Figure 16.

Tool wear image of the coated carbide insert obtained under different cutting conditions (a) cutting speed = 200 m/min, feed = 0.1 mm/rev, cutting duration = 2 min and cutting depth = 1 mm; and (b) cutting speed = 260 m/min, feed = 0.26 mm/rev, cutting duration = 2 min and cutting depth = 1.2 mm [112].

Zang et al. [119] examined the cutting temperature during the machining of a hardened AISI H13 steel specimen with multi-layered coated tools. Kumar et al. [120] carried out a hard part turning on AISI D2 steel by CVD (TiN/TiCN/Al2O3) coated carbide and uncoated carbide insert under a dry environment and observed the responses such as tool wear, cutting temperature, surface roughness. The researcher noticed that, compared with uncoated carbide tools, coated carbide tools performed well in terms of tool life. When the temperature rises, the upper layer of Al2O3 acts as a thermal barrier, protecting the tool from abrasion and diffusion. The TiCN coating also provides stronger adherence to the tool, protecting it from flank wear. Allu et al. [121] evaluated surface roughness utilizing a wiper carbide insert during a hard turning operation on AISI 52100 steel in a dry cutting environment and reported the type of cutting tool was the most influential factor, followed by feed rate and nose radius. When compared to regular inserts, wiper inserts have a superior surface finish. Chavan et al. [122] used multi-layered PVD coated tungsten carbide inserts to machine harden AISI 52100 steel under various cooling conditions to determine the values of surface roughness, residual stress, microhardness, and white layer formation. In addition, compared to a dry environment, the hybrid NF-MQCL cutting environment resulted in less tool wear and less white layer formation due to the reduction of friction and temperature in the cutting zone area. Das et al. [123] accomplished a comparative study of the tool life, tool wear, cutting temperature, and surface integrity of HSN2-TiAlxN and TiCN-coated carbide tools on hardened AISI D6 steel. TiAlxN-coated carbide tools provide better machinability performance in terms of lessened flank and crater wear, higher tool life, enhanced surface integrity, and minimal cutting temperature. In addition, the TiAlxN-coated carbide tool provided considerable manufacturing cost reductions as compared to the TiCN-coated insert. Hamadi et al. [124] compared the machining performances of PVD, CVD, MTCVD, and uncoated carbide tools in a dry cutting environment using hardened AISI 4140 steel. The flank wear rate of the TiN coated tool was roughly twice that of the TICN/Al2O3/TiN and four times that of the TiCN/Al2O3, with the uncoated tool showing the most wear. The highest cutting force was found with an MTCVD (TiCN/Al2O3/TiN) cutting insert. In terms of surface quality, MTCVD (TiCN/Al2O3/TiN) cutting inserts were recognized as the leading material. The details of coated tool coatings and cutting parameters used in hard turning are shown in Table 3.

Table 3.

Details of coated tool coatings and cutting parameters used in hard turning.

Furthermore, in recent years, the use of customized textured cutting tools in hard turning has grown in popularity due to the potential to increase tool life without the use of coolant. Sivaiah and Bodicherla [125] used two types of surface texture tools in their experimental study, namely surface texture grooves 45° angled to the primary cutting tool edge and perforated holes tool, in addition to the nontexture conventional tool in a MQL environment. Surface textured tools (grooves 45° inclined to the principal cutting edge) considerably minimize the average surface roughness and tool flank wear. Orra and Choudhury [126] developed vertical, horizontal, and elliptical micro-textured tools and compared their hard turning performance. In comparison to a non-textured cutting tool, the micro-textured tool provided a significant decrease in the coefficient of friction, allowing for a significant reduction in cutting force. Kim et al. [127] obtained improved tribological characteristics when an EDM assisted micropatterned CBN insert was used in hard machining. The coefficients of friction, cutting force, and tool wear were considerably reduced in comparison to when a non-patterned tool was used. With reduction of cutting speed, non-patterned insert exhibited 9.7 to 11.4% gain in tool wear in contrast to patterned tool. Patel et al. [128] examined the impact of micro-textured/micro-grooved tungsten carbide (WC/Co) cutting tools on cutting forces, friction coefficients, and tool wear during dry cutting of alloy steel AISI 4340. Chip-tool contact is reduced as spacing and groove width are increased, while chip flow and adhesion into micro-grooves are increased. Song et al. [129] used self-lubricating and conventional tools to conduct dry machining trials on AISI 1045 hardened steel. When compared to the conventional tool, the self-lubricating tool embedded with graphite demonstrated excellent efficiency and stability in reducing cutting temperature and tool wear.

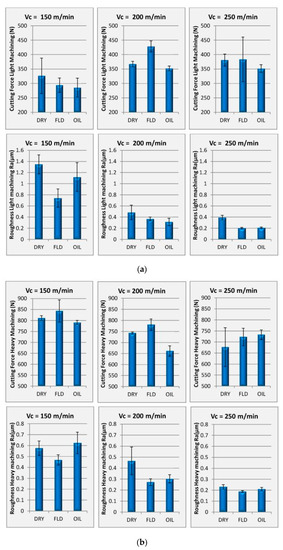

3. Hard Turning Performance under Different Cooling/Lubricating Conditions

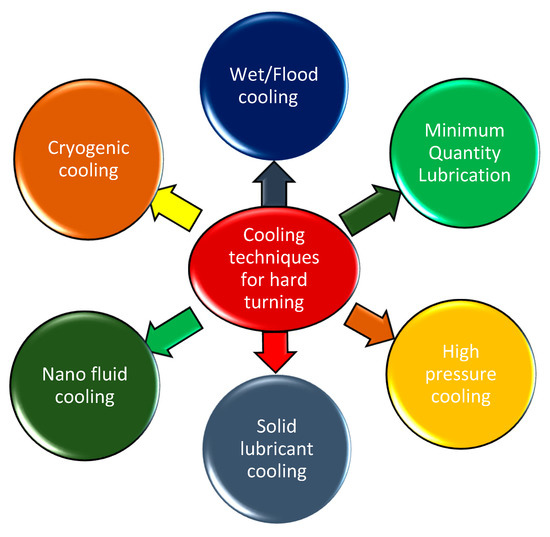

Dry hard turning has certain limitations, such as higher cutting temperatures, fast tool wear, reduced surface finish, high cutting forces, high stresses, high power consumption, etc. Therefore, lots of works using different coolant/cooling techniques have been done till date to improve the hard machining machinability. This section presents a review of hard machining under different cooling and lubrication conditions. Figure 17 depicts the various cooling techniques used in hard-turning machining.

Figure 17.

Different Cooling techniques used in hard turning (redrawn) [14].

3.1. Wet/Flood Cooling

Wet or flood cooling is a machining technique in which a cooling jet is focused into the active zone to cool, lubricate, and remove chips. This approach is best suited for turning and grinding, where sparks and higher temperatures may occur due to the coolant’s water content, which is present in the emulsion [130].

Khatai et al. [131] utilized a PVD-coated tool to turn a hard component from EN31 steel with a hardness of 56 ± 1 HRC in a dry and flood cooled environment. Under flood cooling conditions, surface roughness values were found to be lower and MRR was found to be higher. According to the data, surface quality is primarily determined by feed, whereas MRR is primarily determined by depth of cut. Selvam and Sivaram [132] investigated the effect of dry, flooded, and near-dry cooling on the surface finish obtained in turning AISI 4340 steel. It was reported that MQL machining resulted in less tool wear, better surface quality, and lower cutting fluid consumption than dry and flood cooling methods. Details of the cutting tool, cutting parameters, and response studies used in the flood cooling environment are shown in Table 4.

Table 4.

Details of cutting tool, cutting parameters and response studies in flood cooling environment for hard turning operation.

3.2. Minimum Quantity Lubrication

Khan et al. [20] described the consequence of vegetable oil MQL on the turning performance of a low carbon alloy (AISI 9310 steel) using an uncoated carbide cutting insert. MQL applied machining exhibited a 10% decrease in mean chip-tool interface temperature, brighter and smoother chips, no built-up edge (BUE) formation, reduced wear, and improved finished surface quality when compared to dry and wet environments. Chinchankar et al. [21] explored the effects of dry, water, and coconut oil mixed cutting fluid on surface finish in turning heat-treated AISI 52100 steel using a PVD-coated carbide tool. Implementation of coconut oil at a higher cutting speed generated lower values of surface finish, whereas the roughness of the surface was primarily affected by the cutting feed. Attanasio et al. [133] found worker safety, environmental protection, and cost-effectiveness benefits in the application of MQL during the turning operation of 100 Cr6 steel with a coated carbide cutting tool. There was not much deviation in flank wear under dry and MQL surroundings, but the life of the tool was considerably improved under MQL surroundings. Elmunafi et al. [134] observed improved machining performance with MQL using castor oil as a machining fluid over dry cutting during the turning of AISI 420 stainless steel with PVD coating (TiAlN) carbide cutting inserts. However, compared to dry machining, MQL provided a longer tool life. Varadarajan et al. [135] studied the performance of MQL in hardened AISI 4340 steel using a coated (TiC, TiN, and TiCN) carbide tool in dry and wet conditions. The MQL was found to be superior in all cutting situations in terms of obtaining favorable machining forces, insert longevity, surface finishing, machining temperature, and tool chip interaction length. Chinchanikar and Choudhury [136] experimentally observed prolonged tool life when AlTiCrN coated carbide tool was used on turning of AISI 4340 steel. Cutting tool life was increased in the MQL environment as a result of lower cutting temperature generation. Tool nose wear and chipping were observed to be the leading wear patterns in both dry and MQL cutting environments. Dhar et al. [137,138] found that turning hardened AISI 1040 steel with an uncoated carbide cutting insert in a MQL environment yielded better results in terms of machining forces, tool wear, chip reduction coefficient, chip-tool interaction, machining temperatures, surface quality, and dimensional accuracy than dry cutting.

Netake and Chinchanikar [139] predicted the cutting forces and surface quality in turning heat treated AISI 52100 steel employing a PVD coated TiSiN-TiAlN carbide tool under MQL conditions. The quality of the finished surface varied linearly with cutting feed and radial depth. The force was largely impacted by cutting depth, followed by cutting feed rate. Hwang and Lee [140] noticed reduction in forces and enhancement in quality of finished work under turning of the AISI 1045 with coated carbide cutting insert under MQL compared to dry situation. Senevirathne and Punchihewa [141] varied the temperature of the aerosol in MQL assisted hard turning and found a better quality surface compared to dry and wet cooling when machining AISI P20 and AISI D2 steel with a TiCN/Al2O3/TiN CVD coated carbide cutting tool. Kumar et al. [142] found the favorable performance of MQL over wet assisted turning on AISI 4340 with a CBN cutting insert. Mahadi et al. [143] found the enhanced quality of surface under boric acid mixed palm kernel oil coolant compared to regular lubricants in turning AISI 431 steel with coated (TiAlN and AlCrN) cutting tool. Gürbüz and Gonülacar [144] evaluated the performance of hardened 4140 steel under dry, wet, and MQL cutting circumstances. In comparison to wet and dry machining, MQL cutting conditions were shown to significantly reduce tool wear. According to Ozbek and Sarukh [145], MQL enabled machining reduced tool wear (23%), tool vibration amplitude (45%), and cutting temperature (25%), when compared with a dry machining environment. Zbek et al. [146] investigated the machinability of Vanadis 10 steel in dry and MQL environments. When compared to dry machining, MQL revealed significant enhancements in output performances (cutting temperature, surface quality, tooling wear, life of tool, and cutting tool vibration amplitude). Cutting speed was the most effective term for tool wear (32.41%) as well as for vibration amplitude (46.22%). The details of the cutting fluid used in the MQL coolant delivery system were disclosed in Table 5.

Table 5.

Details about cutting fluid used in MQL delivery system in hard turning.

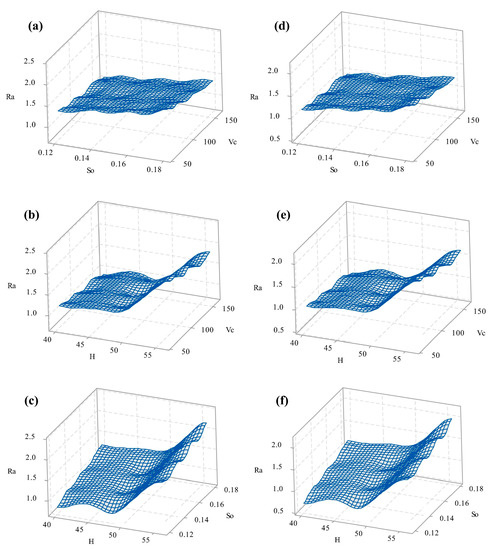

3.3. High Pressure Cooling

Machining using high-pressure cooling (HPC) is also gaining popularity in the metal-cutting sector as a technique for significantly enhancing the removal rate and productivity. Depending on the pressure and flow rate of the fluid jet, cooling with high pressures in turning operations is an effective way for enhancing productivity, decreasing cutting zone temperature, and improving chip control. Based on the literature, the pressure in HPC may vary from 4 MPa to 80 MPa [15]. Mia and Dhar [15] stated that the quality of the finished surface of EN24 steel was improved with the application of high-pressure jet cooling using coated carbide inserts. The surface roughness was increasing with feed while decreasing with cutting speed in both dry and HPC conditions, as displayed in Figure 18. Mia et al. [147] conducted an experiment using three different hardened steels with coated carbide tools under both dry and high-pressure coolant jets, where the depth of cut was kept constant. It was determined that, compared to dry cutting, high pressure coolant jet was successful in reducing surface roughness, tool wear, and cutting temperature. Statistical analysis revealed that for both cutting temperature and surface roughness, work piece hardness was the most significant. Kramar et al. [148] performed turning operations on hardened AISI 1045 steel utilizing high-pressure cooling and compared the performance in dry, conventional, and HPC cooling. HPC outperformed dry cooling and conventional cooling in terms of tool life, chip breakability, and reduced coolant use. Details about cutting tools and cutting parameters used in HPC are shown in Table 6.

Figure 18.

Surface roughness plots in 3D (a–c) dry turning, (d–f) HPC assisted turning [10].

Table 6.

Details of cutting tools and cutting parameters used in HPC in hard turning.

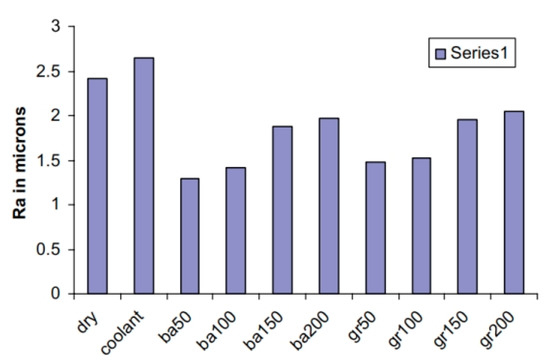

3.4. Solid Lubricant

Solid lubricants are substances that can reduce friction between two surfaces moving against one another without the use of a liquid medium. These lubricants can also lubricate effectively at temperatures higher than those for liquid and oil-based lubricants [149]. In recent years, many distinguished types of solid lubricants were implemented directly or via MQL in hard-turning applications. The commonly used solid lubricants in hard turning operations are as follows: Graphite, MoS2-Molybdenum disulphide, h-BN-Hexagonal boron nitride, WS2-Tungsten disulfide, ZnS-Zinc sulfide, CaF2-Calcium fluoride and BaF2-Barium fluoride. Rao and Krishna [19] utilized graphite and boric acid solid lubricants in hard turning and compared the results with dry and conventional flood/wet cooling. The particle size of 50 microns was found to be better in comparison to other sizes. Boric acid solid lubricant was providing the least surface roughness in contrast to graphite, dry cooling, and flood cooling, as illustrated in Figure 19.

Figure 19.

Average surface roughness (Ra) for different cooling environments [14] (ba—boric acid, gr—graphite, Nos. 50, 100, 150 and 200 have shown particle size in micron).

Suarez et al. [52] compared the hard turning performance under dry, pure oil-MQL, and Pure oil + MoS2 MQL environments. Both cooling solutions (MQL and MoS2 + MQL) resulted in an increase in tool life. 150 m/min cutting speed was advised for industrial operations in order to make the process feasible and improve tool life using PCBN tools. Figure 20 illustrates that, regardless of the usage of the lubricant cooling system, a rise in cutting speed supports a steady reduction in the machining force (Fu). Furthermore, Figure 20 showed that, as compared to dry cutting, the surface quality (Ra) was typically minimized by the use of a cutting fluid by MQF, either pure oil or with the addition of MoS2. This improvement was particularly noticeable at the lower feed rate of 0.05 mm/rev. Chinchanikar et al. [150] discovered that increasing the proportions of boric acid concentration in sunflower oil reduced cutting forces and surface roughness in hard turning. Makhesana and Patel [151] examined the effectiveness of hard turning under various conditions, including dry, conventional flood cooling, MQL, and MQL + CaF2 solid lubricant. Additionally, the impact of particle size and concentration on surface trait and flank tool wear was examined; compared to results obtained under neat oil, flood cooling, and dry conditions, CaF2 blended oil performed better. Larger-sized CaF2 particles showed greater flank tool wear and surface trait under conditions of lowest cutting speed (90 m/min). In comparison to other concentrations, 20 wt% concentrations result in lesser surface quality and tooling wear as cutting speed increases. In a different study, Makhesana and Patel [152] investigated the effects of various solid lubricant concentrations when hard-turning EN 31 steel using CVD-coated carbide tools. They compared solid lubricant performance to that of dry, wet, and MQL lubrication. Temperature, surface roughness, and flank wear were all improved by using solid lubricant at a 15% concentration. Figure 21 indicated that adhesion and abrasion mechanisms accounted for the majority of tool wear. Each cutting circumstance clearly reveals abrasive marks. Solid lubricant conditions were shown to have the least tool wear in comparison to dry, wet, and MQL.

Figure 20.

Influence of cutting parameters on (a–c) machining Force (d–f) surface roughness under different cooling scenarios [52].

Figure 21.

Tool wear morphology under (a) wet (b) Dry (c) MQL (d) MQSL cutting environments [152].

Singh and Rao [153,154] developed a new experimental setup to deliver solid lubricant powder in hard turning of bearing grade steels. It was discovered that the application of hard turning assisted by molybdenum disulphide improves machinability and surface quality significantly. Additionally, the cutting force remained essentially constant while the lubricating flow rate varied from 3 to 10 g/min. Kumar et al. [155] exhibited hard part turning experiments on AISI 4340 steel using two different solid lubricant environments (h-BN and ZnS), and the results (cutting force and chip-tool interface temperature) were in contrast to wet cooling and dry cutting results. Solid lubricant-assisted machining outperformed both dry and wet machining. The solid lubricant h-BN performed better than the ZnS lubricant. In the hard turning of AISI 4340 steel, Paul and Varadarajan [156] used a novel semi-solid assisted machining conception to manage cutting temperature, cutting force, tool wear, and surface traits. Using a special semi-solid lubricant applicator developed for this purpose, a mixture of grease and 10% graphite was applied at the cutting tool formed chip interface, work-tool interface, and back side of the chip. The results demonstrated that using grease and graphite, semi-solid lubricants, at the cutting tool-chip interface, a small amount of cutting fluid applied over the insert reduced cutting force, cutting temperature, tool wear, vibration, and enhanced surface smoothness. Similarly, in hard turning of AISI 52100 steel using a mixed ceramic tool, D.U. et al. [157] studied the effects of solid lubricants (graphite and MoS2). Furthermore, the trials were also conducted in dry conditions, and the outcomes in solid lubricant were contrasted with those in dry settings. Dry cutting produced the roughest surface on the completed product, whereas MoS2 solid lubricant produced the least. Additionally, the roughness decreased with increasing speed up to 125 m/min while improving after this speed. The details of the solid lubricant and cutting parameters used in hard turning are shown in Table 7.

Table 7.

Details of solid lubricants and cutting parameters used in hard turning.

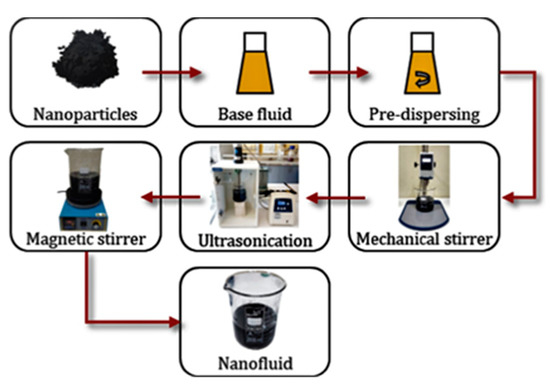

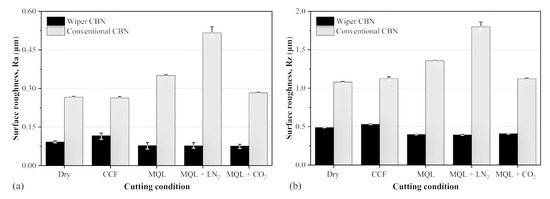

3.5. Nanofluids

Nanofluid is an emerging coolant for hard-turning applications as it reduces tool wear, cutting force, cutting temperature, friction coefficients, and power consumption. Nanofluid synthesis has a prime role in achieving effective lubrication and cooling in machining processes. The synthesis of nano fluid is a very important aspect of getting effective lubrication and cooling results in machining. The nano fluid was synthesized using a one-step or two-step methodology. Several authors have preferred the use of a two-step methodology due to its lower budget and simple implementation [158,159]. The two-step methodology to prepare a nano fluid was displayed in Figure 22. Generally, for preparing the nano fluid mixture, two different methods were used, i.e., one step and two-steps. Most of the researchers used the two-step method because its application is simple and its synthesis cost is minimal. The performance of nano fluid was highly dependent on its concentration and its dispersion stability. The higher stability of nano fluid was more advantageous in machining applications. According to Yu and Xie’s [160] report, nano fluids had improved thermo-physical characteristics such as thermal conductivity, convective heat transfer coefficient, thermal diffusivity, and viscosity compared to base cutting fluids such as water or oil.

Figure 22.

Preparation of Nano fluid by using two step methods [159].

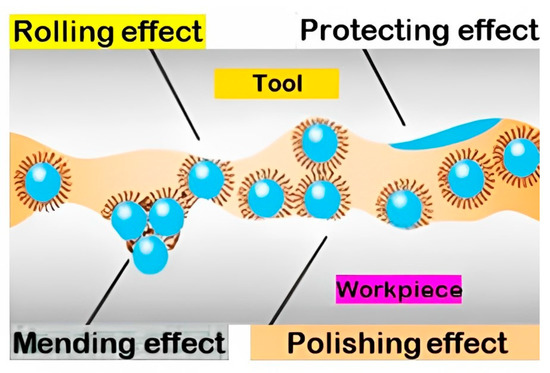

The addition of nanoparticles (≤100 nm) into the parent fluid provided an adequate augmentation in heat transfer thus considerably dropping the cutting temperature in the shearing area [161]. The augmentation in lubricious features of nanoparticles-mixed cutting fluid is attained by establishing a tribe-thin-film between two meshing surfaces [162], the ball-bearing effect [163], polishing impact [164], and the mending consequence [165]. Referring to Lee et al.’s [166] results, polishing and mending of nano fluids were the important approaches responsible for the enhancement in the machining procedure. Likewise, according to Peng et al. [167], adhesion among two mating surfaces and the anti-wear properties of nanoparticle-mixed coolant are enhanced by four distinct mechanisms: (a) Spherical nanoparticles roll smoothly between two meshing surfaces, reversing the slipping friction into rolling and sliding frictions. (b) Propensity to mix with friction surfaces and form a thin surface-protecting layer. (c) During the cutting process, impinged nanofluid collected on the mating surfaces and formed a thin tribo-film that compensated for the material loss; this is known as the “mending effect”. In addition, the lubricating surface roughness was reduced by friction due to the presence of nanoparticles between the contact surface, a phenomenon known as the polishing effect [168], (d) Evenly dispersed nanoparticles sustain the machining load (compressive), and reduced the stress concentration. These mechanisms are illustrated in Figure 23.

Figure 23.

Mechanism of Interaction with CuO nanoparticles in lubricant during machining [168].

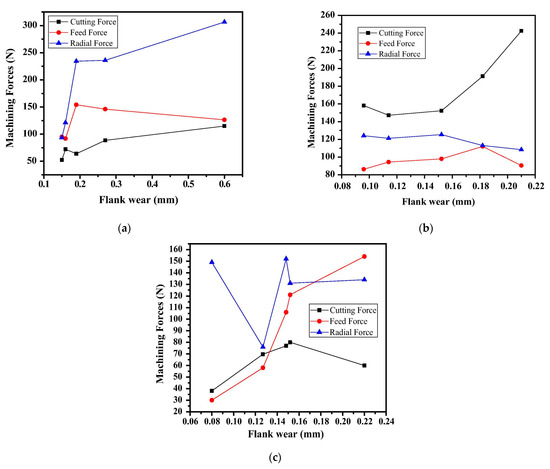

Further, many nanofluids have been utilized in hard turning to investigate the machinability of hardened steel. However, a critical analysis was made below to select the most appropriate nanofluids for machining hardened steel. Sharma et al. [25,26] presented an overview of the implementation of nano enriched coolants in machining work. Improvements in tool life and reductions in forces, temperatures, and surface roughness were reported. In another work, hybrid (Alumina + MoS2) based nanofluids have been implemented in hard turning on AISI 304 steel with carbide insert. Al-MoS2 mixture-based nanofluid showed better results relative to Al2O3-based nanofluid. Khalil et al. [169] investigated the effect of using Al2O3 nano lubricant while turning AISI 1050-grade steel with a coated carbide cutting tool and noticed lower tool wear as well as a very long tool life. Khajehzadeh et al. [170] experimentally studied water-based TiO2 nanofluid using hardened AISI 4140 steel and found that lower rates of cutting tool flank wear were obtained by increasing nanoparticle concentration from 3% to 5% or reducing the nanoparticle size from 50 to 10 nm. Furthermore, it can improve the machining performance and total manufacturing cost of a component. Das et al. [171] executed a machining operation on hardened AISI 4340 steel with MQL-Al2O3-based nano fluid and found a relevant enhancement in tool wear relative to water-soluble materials and compressed air. Further, the variations in turning forces with flank wear were studied for all three cutting environments (compressed air, water-soluble coolant, and nanofluid). Figure 24 illustrates the impact of flank wear on turning forces. The flank wear greatly affects the intensity of forces produced in turning. The lowest range of cutting forces was found in the nanofluid machining environment in comparison to others.

Figure 24.

Effects of progress in flank wear on turning forces in different cutting environments (a) compressed air (b) Water soluble coolant (c) Nanofluid [171].

In another work, Das et al. [172] utilized three different nanofluids (CuO, Al2O3, and Fe2O3) via MQL. CuO nanofluid exhibited the superior result among these nanofluids, as the least flank wear and lower surface roughness were noticed. Patole et al. [173] conducted an experiment using different parameters on the hard turning of AISI 4340 with nanofluid (multiwalled carbon nanotube) under MQL conditions. The results showed that feed rate played a vital role in the creation of lower surface roughness, followed by the depth of cut, whereas cutting speed had the least significance in producing a lower surface roughness under MQL using nanofluid. Singh et al. [174] presented the mathematical expressions to study the role of grain size on the thermal conductivity of nano solids and noticed the significant retardation of thermal conductivity with a decrease in grain size. Sharma et al. [175] found enhanced quality of the surface and improved lubricating action in machining by using higher concentrations of nano particles in nanofluid compared to traditional cutting fluid and dry conditions. In addition, minimizing trends of frictions, forces, power utilization, flank wear, and temperature were observed during machining with the nanofluid surrounding. The factors such as mode of lubrication, nano element size, nano element concentration, nozzle orientation, air pressure, and spraying distance were major terms that affected the overall machining performances. Thakur et al. [176] compared the performance of MQL and SiC-based nanofluid MQL environments in turning EN24 alloy steel and discovered that SiC-based nanofluid MQL turning outperformed MQL turning in terms of surface roughness height, cutting force, and cutting temperature.