Investigation of the Effects of Cooling and Lubricating Strategies on Tribological Characteristics in Machining of Hybrid Composites

Abstract

:1. Introduction

2. Materials and Methods

2.1. Production and Characterization of Hybrid Composites

2.2. Machine Tool and Cutting Tool Properties

2.3. Machinability Experiments

2.4. Cooling and Lubricating Strategies

2.5. Devices for Measurement of Machining Variables and Graphical Abstract

3. Results

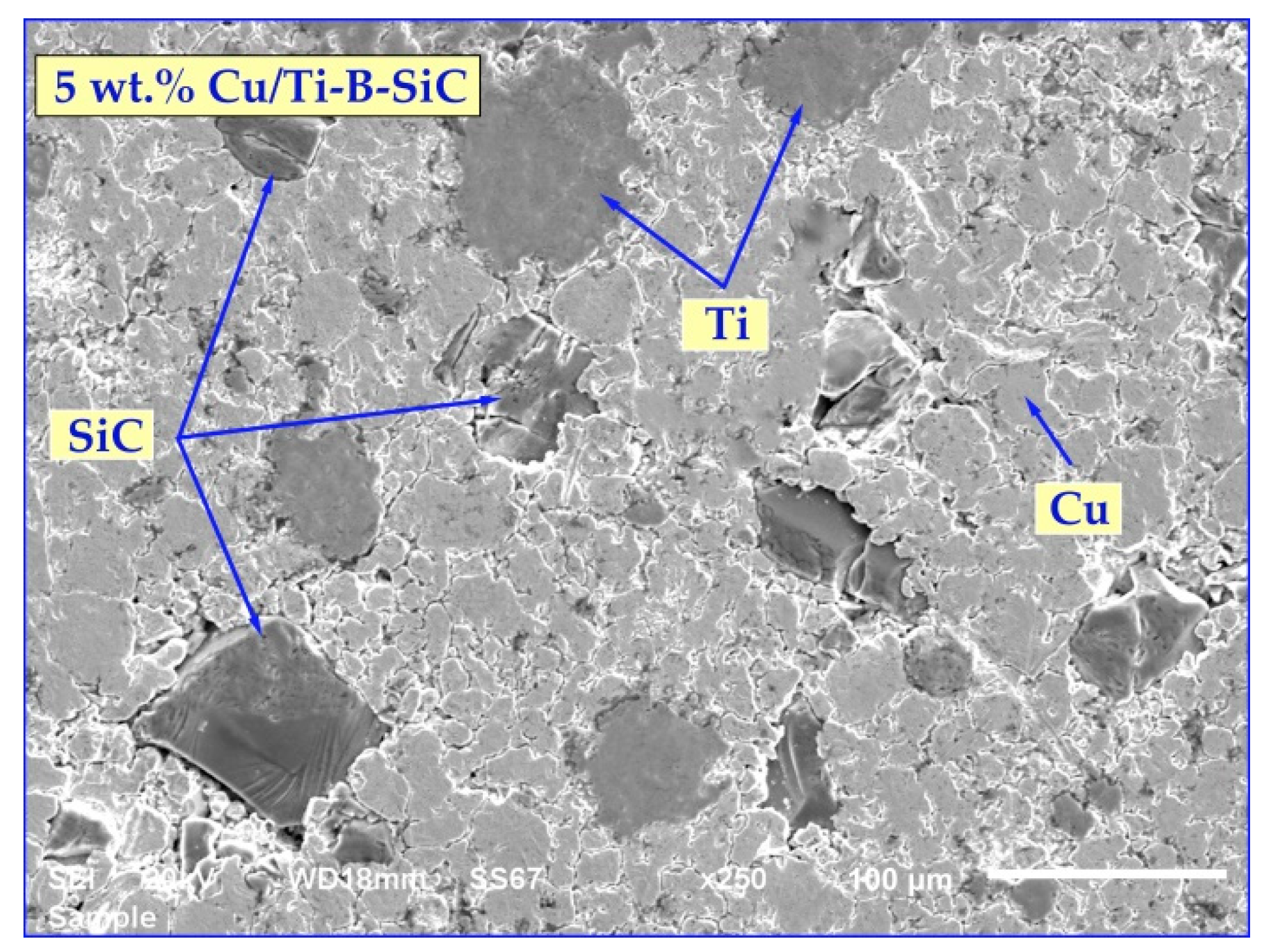

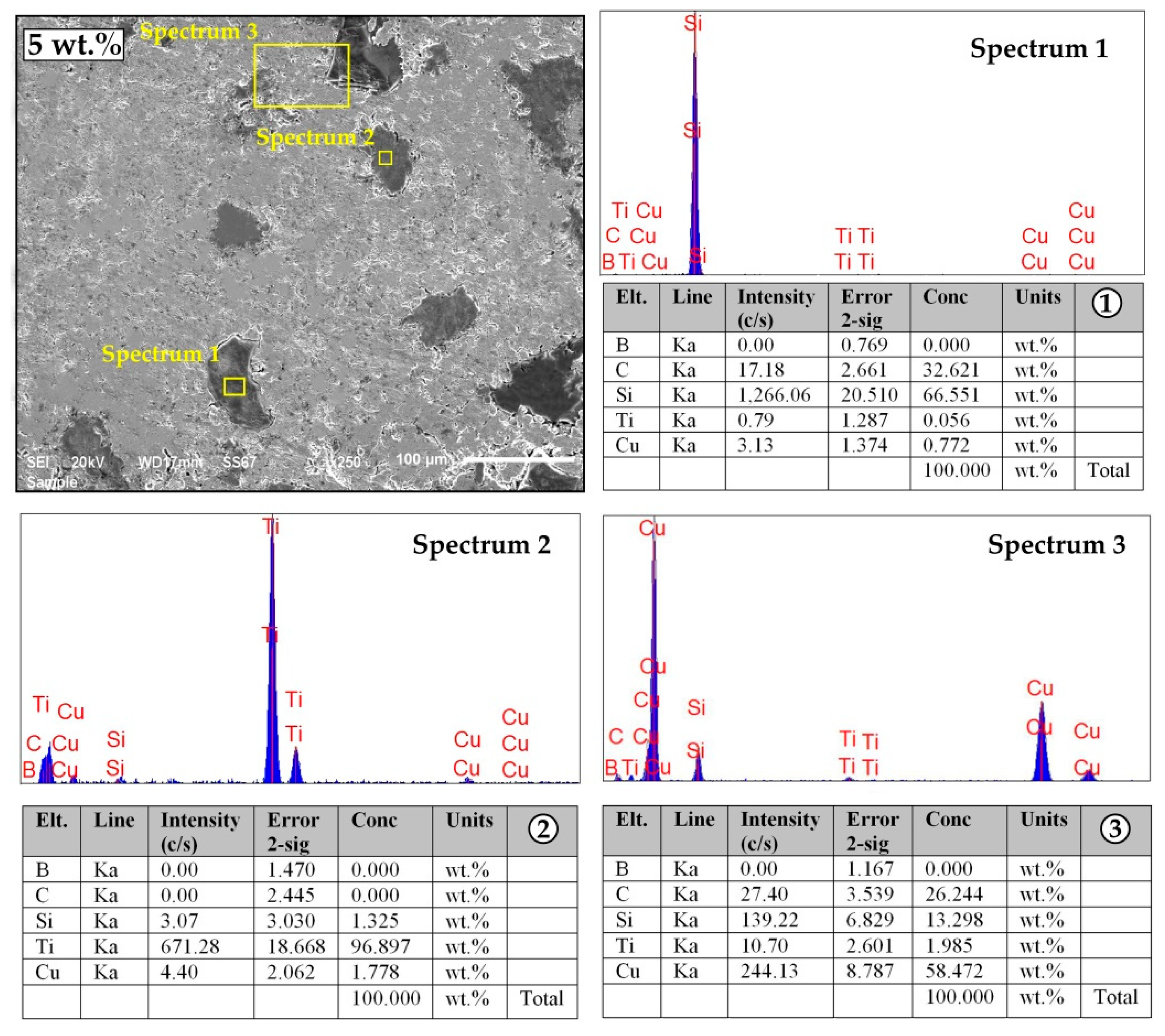

3.1. Microstructural Analysis of Sintered Cu-Based Hybbrid Composites

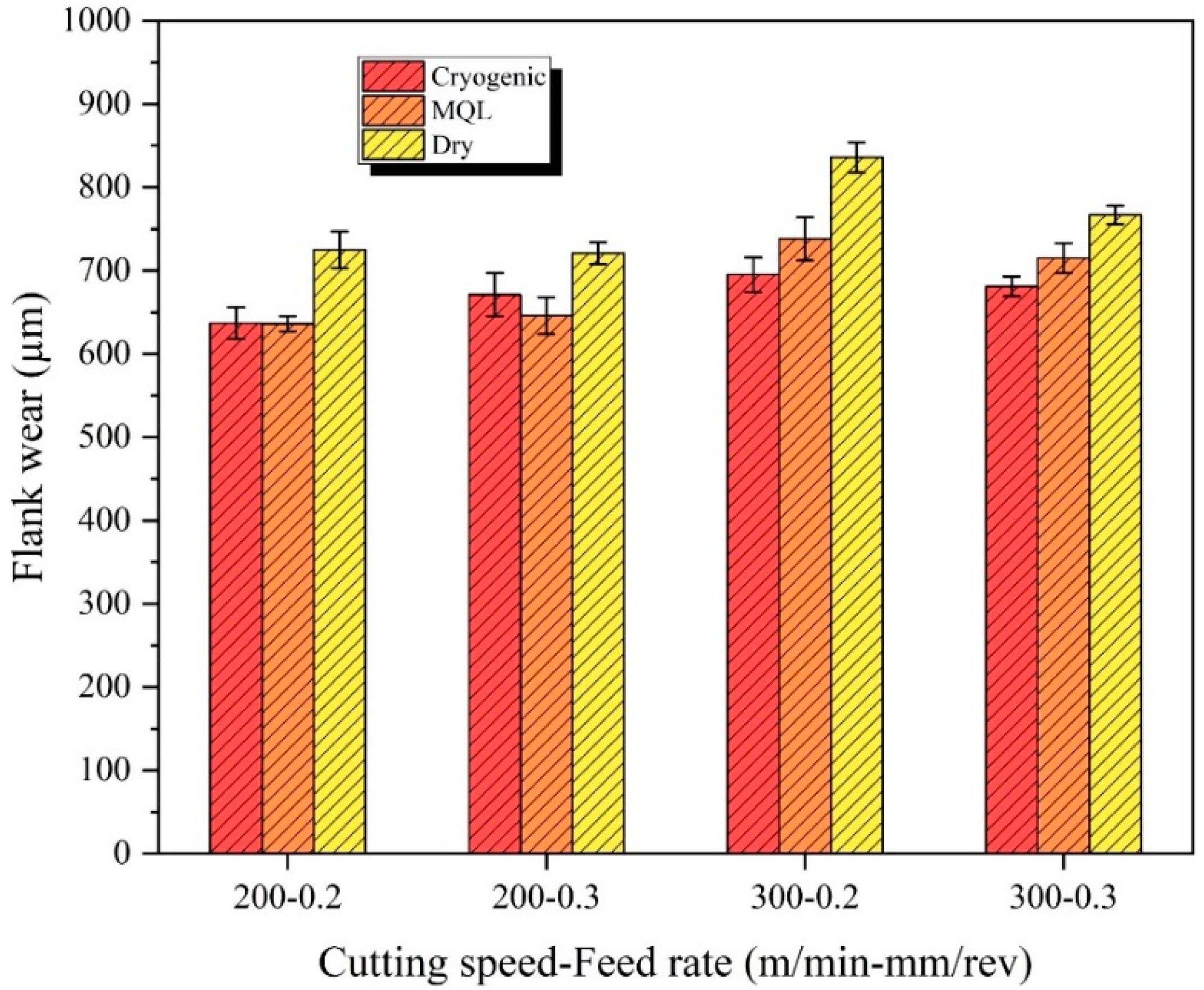

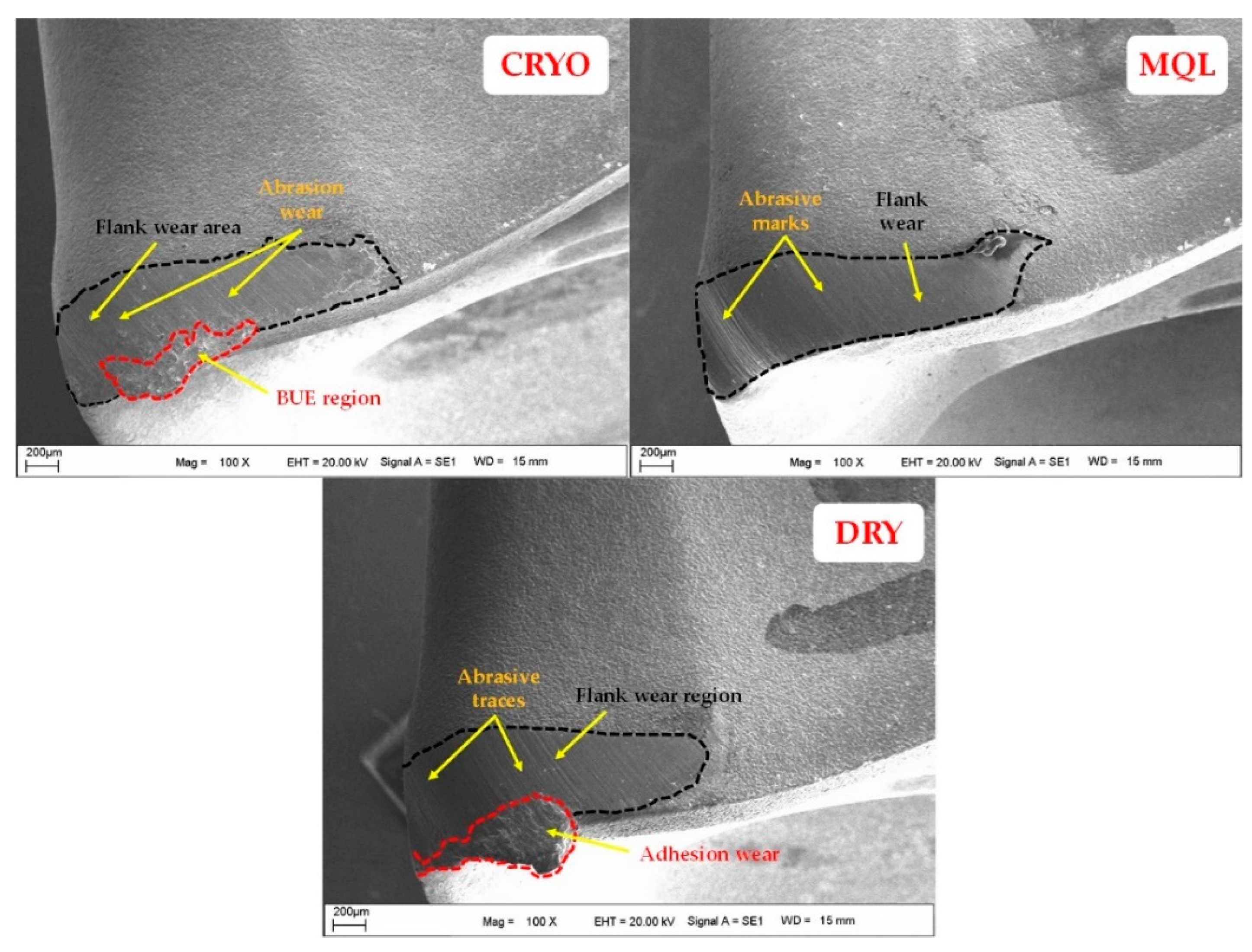

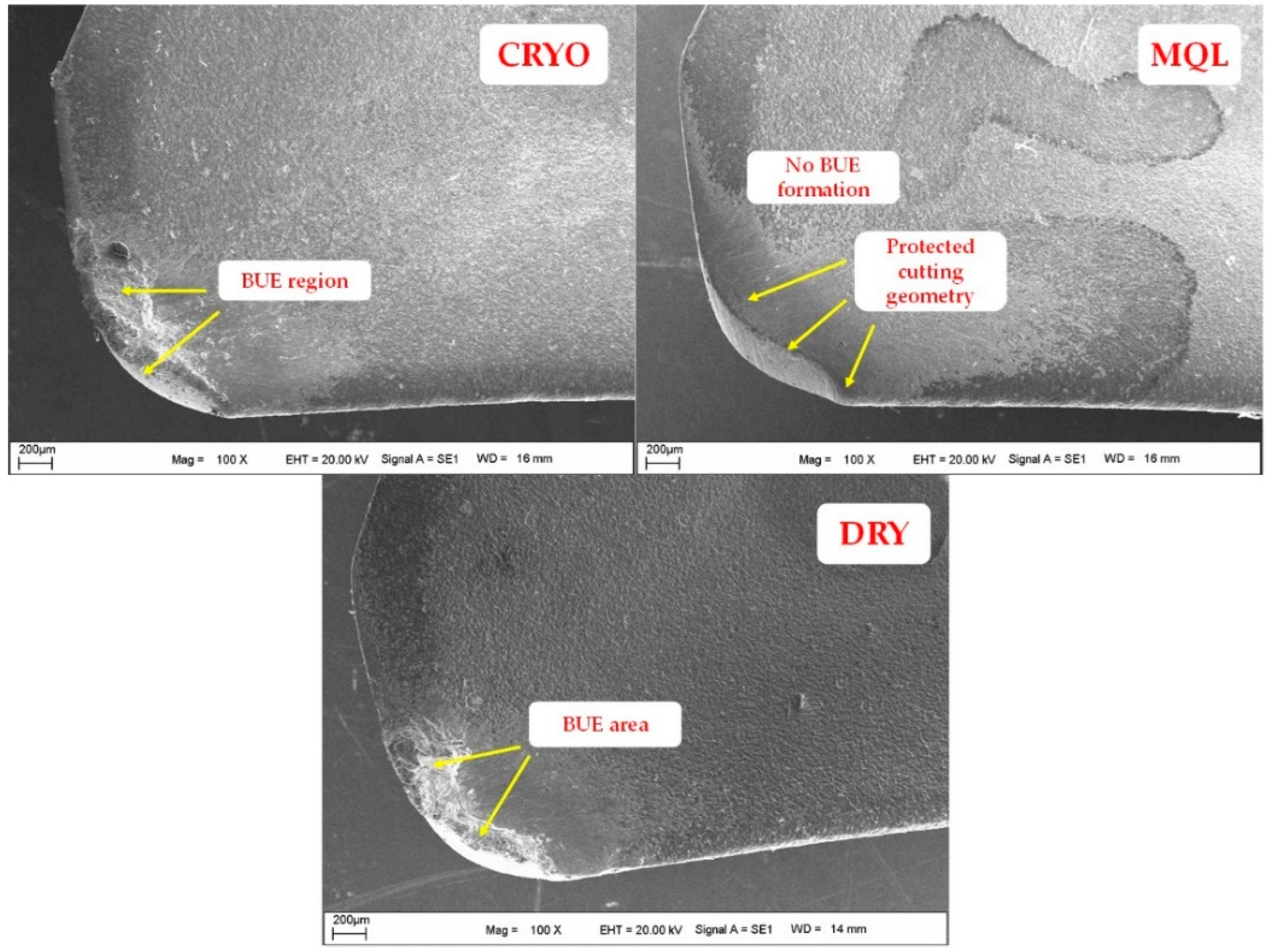

3.2. Tool Wear Mechanism and Flank Wear

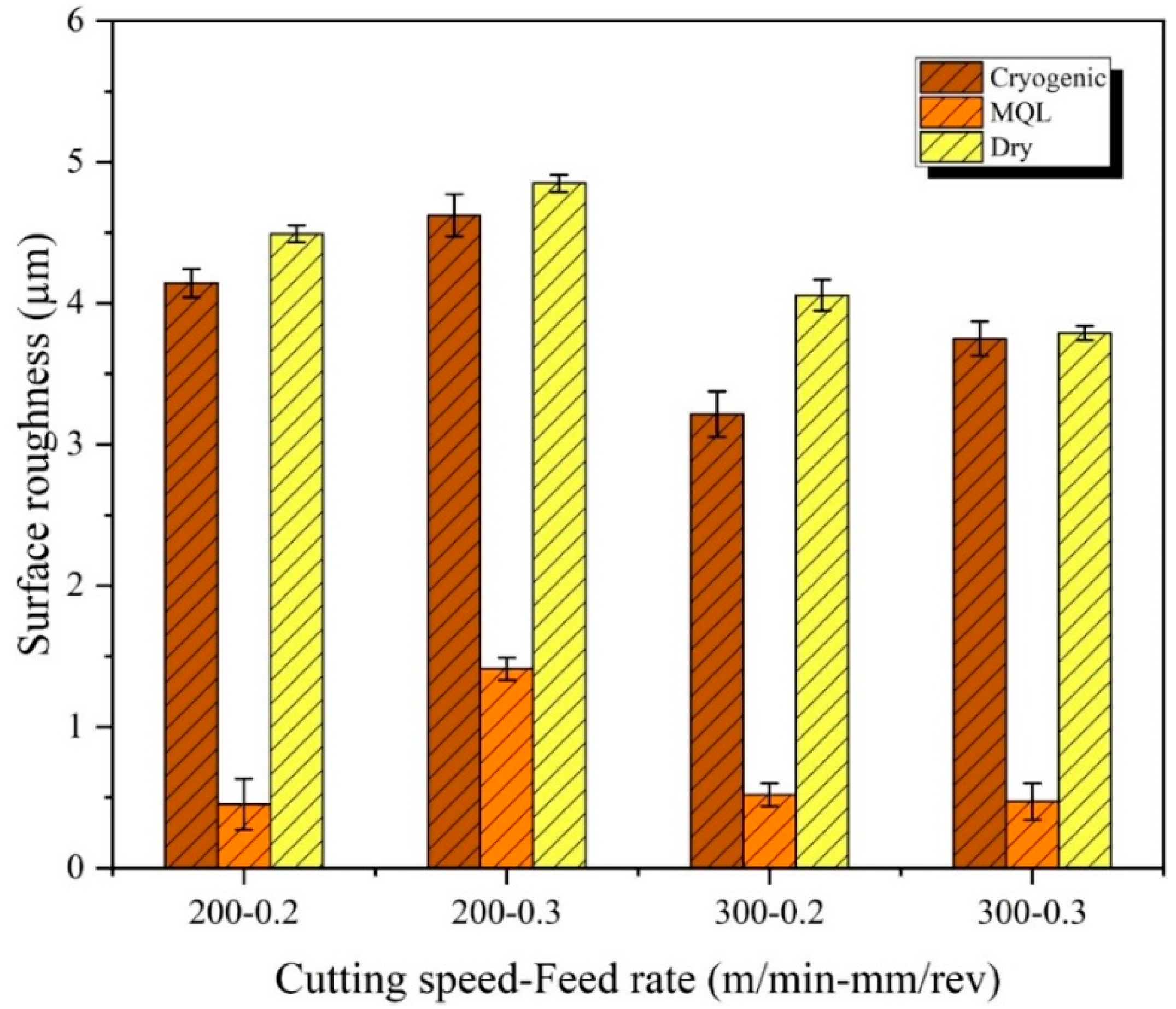

3.3. Surface Roughness and Surface Topography

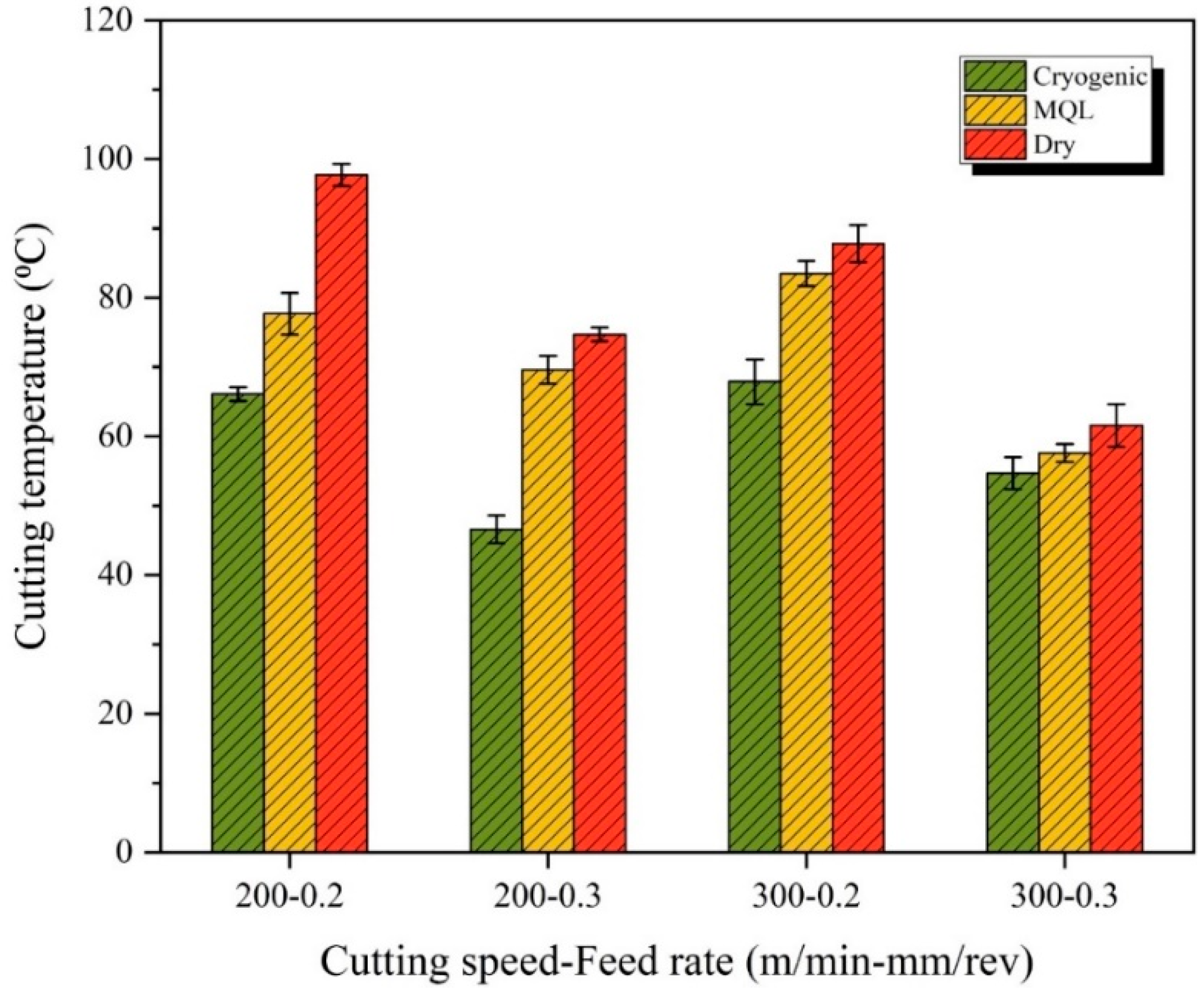

3.4. Cutting Temperatures

3.5. Cutting Energy

3.6. Chips Characteristics

4. Conclusions

- The MQL based lubricating strategy was found as the most effective approach in protecting the cutting tool from build-up-edge formation. One of the important effects of this result is the hybridized pressured air and greasing effect that enables it to protect the cutting tool from abrasive impacts, creating a thin film. On the other hand, flank wear development can be reduced with both oil mist and nitrogen assisted cooling. Sub-zero nitrogen can effectively infiltrate to the small spaces of the cutting zone by creating a cushion that results in better tribological environment for the cutting tool. Cryogenic cooling and MQL milling can increase the tool life about 20% and 13%, respectively, when compared with dry conditions during machining of the hybrid composites.

- Surface roughness and surface topography were obtained via using the MQL method as the most desired condition. However, the cryogenic environment and dry cutting affected the surface texture negatively. The dry medium suffers from the absence of the lubri-cooling effect, which puts it in a disadvantageous position. On the other hand, work hardening of the workpiece exposed to cryogenic cooling produces poor surfaces. When compared with the MQL medium, dry and cryogenic environments were obtained with reduced surface roughness values that reached 891% and 814%.

- Cryogenic cooling was found as the most efficient way in reducing the cutting temperatures, followed by MQL and dry strategies, respectively. It is an expected result due to the very low temperatures of cryogenics, which cool the cutting environment completely. Despite its success in this area, surface quality dependent results are not satisfying for cryogenic cooling, which makes the MQL method sufficient.

- In calculation of the total energy consumption during milling of the hybrid composites, MQL and LN2 based cooling provide close results. According to the different cutting parameters applied during operations, both methods may provide better results. It can be said that at higher cutting speed, MQL is effective, while at low cutting speed, cryogenic cooling demands lower energy. A general conclusion can be drawn here that, by their effective lubri-cooling influence, cutting fluids of MQL and cryogenic method improve the tribological performances of the cutting tool and reduce frictional forces and cutting forces eventually.

- Similarly with other findings, MQL creates the best chip morphology compared to other results. One of the deductions herein is the ability of tiny droplets to provide better shearing for the chips and improve breakability by protecting the cutting tool and workpiece material. This is an expected result due to the observations on the tool wear index and surface morphologies. In total, MQL approach was found as the most inflective way in improving the machinability performance of Cu based hybrid composites.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Usca, Ü.A.; Uzun, M.; Kuntoğlu, M.; Şap, S.; Giasin, K.; Pimenov, D.Y. Tribological aspects, optimization and analysis of Cu-B-CrC composites fabricated by powder metallurgy. Materials 2021, 14, 4217. [Google Scholar] [CrossRef] [PubMed]

- Şap, E. Investigation of mechanical properties of Cu/Mo-SiCp composites produced with P/M, and their wear behaviour with the Taguchi method. Ceram. Int. 2021, 47, 25910–25920. [Google Scholar] [CrossRef]

- Chu, K.; Jia, C. Enhanced strength in bulk graphene–copper composites. Phys. Status Solidi (A) 2014, 211, 184–190. [Google Scholar] [CrossRef]

- Ali, S.; Ahmad, F.; Yusoff, P.S.M.M.; Muhamad, N.; Oñate, E.; Raza, M.R.; Malik, K. A review of graphene reinforced Cu matrix composites for thermal management of smart electronics. Compos. Part A Appl. Sci. Manuf. 2021, 144, 106357. [Google Scholar] [CrossRef]

- Şap, S.; Uzun, M.; Usca, Ü.A.; Pimenov, D.Y.; Giasin, K.; Wojciechowski, S. Investigation on microstructure, mechanical, and tribological performance of Cu base hybrid composite materials. J. Mater. Res. Technol. 2021, 15, 6990–7003. [Google Scholar] [CrossRef]

- Fan, G.; Xu, R.; Tan, Z.; Zhang, D.; Li, Z. Development of flake powder metallurgy in fabricating metal matrix composites: A review. Acta Metall. Sin. (Engl. Lett.) 2014, 27, 806–815. [Google Scholar] [CrossRef] [Green Version]

- Aslan, A.; Salur, E.; Güneş, A.; Şahin, Ö.S.; Karadağ, H.B.; Akdemir, A. The effect of ultrasonic cleaning upon mechanical properties of metal matrix composites. Trans. Indian Inst. Met. 2021, 74, 107–118. [Google Scholar] [CrossRef]

- Zhang, X.; Xu, Y.; Wang, M.; Liu, E.; Zhao, N.; Shi, C.; Lin, D.; Zhu, F.; He, C. A powder-metallurgy-based strategy toward three-dimensional graphene-like network for reinforcing copper matrix composites. Nat. Commun. 2020, 11, 1–13. [Google Scholar] [CrossRef]

- Sap, E. Microstructure and Mechanical Effects of Co–Ti Powder Particles on Cu Matrix Composites. Russ. J. Non-Ferr. Met. 2021, 62, 107–118. [Google Scholar]

- Akbarpour, M.; Alipour, S.; Farvizi, M.; Kim, H. Mechanical, tribological and electrical properties of Cu-CNT composites fabricated by flake powder metallurgy method. Arch. Civ. Mech. Eng. 2019, 19, 694–706. [Google Scholar] [CrossRef]

- Sap, E.; Uzun, M. A Study of the Microstructure and Properties of Copper Composites Reinforced with Co-Ti. Met. Sci. Heat Treat. 2022, 63, 558–563. [Google Scholar] [CrossRef]

- Tosun, N.; Huseyinoglu, M. Effect of MQL on surface roughness in milling of AA7075-T6. Mater. Manuf. Processes 2010, 25, 793–798. [Google Scholar] [CrossRef]

- Khanna, N.; Agrawal, C.; Pimenov, D.Y.; Singla, A.K.; Machado, A.R.; da Silva, L.R.R.; Gupta, M.K.; Sarikaya, M.; Krolczyk, G.M. Review on design and development of cryogenic machining setups for heat resistant alloys and composites. J. Manuf. Processes 2021, 68, 398–422. [Google Scholar] [CrossRef]

- Zhou, M.; Ren, L.; Fan, L.; Zhang, Y.; Lu, T.; Quan, G.; Gupta, M. Progress in research on hybrid metal matrix composites. J. Alloy. Compd. 2020, 838, 155274. [Google Scholar] [CrossRef]

- Niu, Q.; Jing, L.; Yu, Z.; Li, C.; Qiu, X.; Ko, T. Experimental study on cryogenic milling performance of SiCp/Al composites with liquid nitrogen. Mach. Sci. Technol. 2021, 26, 1–17. [Google Scholar] [CrossRef]

- Gupta, M.K.; Mia, M.; Pruncu, C.I.; Khan, A.M.; Rahman, M.A.; Jamil, M.; Sharma, V.S. Modeling and performance evaluation of Al2O3, MoS2 and graphite nanoparticle-assisted MQL in turning titanium alloy: An intelligent approach. J. Braz. Soc. Mech. Sci. Eng. 2020, 42, 1–21. [Google Scholar] [CrossRef] [Green Version]

- Arul, K.; Mohanavel, V.; Kumar, S.R.; Maridurai, T.; Kumar, K.M.; Ravichandran, M. Investigation of machining attributes on machining of alloys under nano fluid MQL environment: A review. Mater. Today Proc. 2021, in press. [Google Scholar] [CrossRef]

- Danish, M.; Gupta, M.K.; Rubaiee, S.; Ahmed, A.; Korkmaz, M.E. Influence of hybrid Cryo-MQL lubri-cooling strategy on the machining and tribological characteristics of Inconel 718. Tribol. Int. 2021, 163, 107178. [Google Scholar] [CrossRef]

- Jamil, M.; Zhao, W.; He, N.; Gupta, M.K.; Sarikaya, M.; Khan, A.M.; Siengchin, S.; Pimenov, D.Y. Sustainable milling of Ti–6Al–4V: A trade-off between energy efficiency, carbon emissions and machining characteristics under MQL and cryogenic environment. J. Clean. Prod. 2021, 281, 125374. [Google Scholar] [CrossRef]

- Yıldırım, Ç.V.; Sarıkaya, M.; Kıvak, T.; Şirin, Ş. The effect of addition of hBN nanoparticles to nanofluid-MQL on tool wear patterns, tool life, roughness and temperature in turning of Ni-based Inconel 625. Tribol. Int. 2019, 134, 443–456. [Google Scholar] [CrossRef]

- Salur, E.; Kuntoğlu, M.; Aslan, A.; Pimenov, D.Y. The Effects of MQL and Dry Environments on Tool Wear, Cutting Temperature, and Power Consumption during End Milling of AISI 1040 Steel. Metals 2021, 11, 1674. [Google Scholar] [CrossRef]

- Yıldırım, Ç.V.; Kıvak, T.; Sarıkaya, M.; Şirin, Ş. Evaluation of tool wear, surface roughness/topography and chip morphology when machining of Ni-based alloy 625 under MQL, cryogenic cooling and CryoMQL. J. Mater. Res. Technol. 2020, 9, 2079–2092. [Google Scholar] [CrossRef]

- Amenta, F.; Bolelli, G.; De Lorenzis, S.; Bertarini, A.; Lusvarghi, L. Tribological Behavior of Reinforced PTFE Composites and Un-Reinforced Polyketone-Based Materials against Coated Steel. Lubricants 2021, 10, 5. [Google Scholar] [CrossRef]

- Basmaci, G.; Yoruk, A.S.; Koklu, U.; Morkavuk, S. Impact of cryogenic condition and drill diameter on drilling performance of CFRP. Appl. Sci. 2017, 7, 667. [Google Scholar] [CrossRef] [Green Version]

- Liu, M.; Li, C.; Zhang, Y.; An, Q.; Yang, M.; Gao, T.; Mao, C.; Liu, B.; Cao, H.; Xu, X. Cryogenic minimum quantity lubrication machining: From mechanism to application. Front. Mech. Eng. 2021, 16, 649–697. [Google Scholar] [CrossRef]

- Kim, J.; Bai, W.; Roy, A.; Jones, L.C.; Ayvar-Soberanis, S.; Silberschmidt, V.V. Hybrid machining of metal-matrix composite. Procedia CIRP 2019, 82, 184–189. [Google Scholar] [CrossRef]

- James, S.J.; Annamalai, A.R. Machinability study of developed composite AA6061-ZrO2 and analysis of influence of MQL. Metals 2018, 8, 472. [Google Scholar] [CrossRef] [Green Version]

- Khanna, N.; Suri, N.M.; Shah, P.; Hegab, H.; Mia, M. Cryogenic turning of in-house cast magnesium based MMCs: A comprehensive investigation. J. Mater. Res. Technol. 2020, 9, 7628–7643. [Google Scholar] [CrossRef]

- Giasin, K.; Barouni, A.; Dhakal, H.N.; Featherson, C.; Redouane, Z.; Morkavuk, S.; Koklu, U. Microstructural investigation and hole quality evaluation in S2/FM94 glass-fibre composites under dry and cryogenic conditions. J. Reinf. Plast. Compos. 2021, 40, 273–293. [Google Scholar] [CrossRef]

- Lavorel, F.; El Mansori, M.; Chegdani, F.; Tazibt, A. Wear under brittle removal regime of an under-expanded cryogenic nitrogen jet machining of bio-composites. Wear 2021, 477, 203795. [Google Scholar] [CrossRef]

- Koklu, U.; Morkavuk, S.; Featherston, C.; Haddad, M.; Sanders, D.; Aamir, M.; Pimenov, D.Y.; Giasin, K. The effect of cryogenic machining of S2 glass fibre composite on the hole form and dimensional tolerances. Int. J. Adv. Manuf. Technol. 2021, 115, 125–140. [Google Scholar] [CrossRef]

- Chen, J.; Yu, W.; Zuo, Z.; Li, Y.; Chen, D.; An, Q.; Wang, H.; Chen, M. Tribological properties and tool wear in milling of in-situ TiB2/7075 Al composite under various cryogenic MQL conditions. Tribol. Int. 2021, 160, 107021. [Google Scholar] [CrossRef]

- Kohli, A.; Bains, H.; Jain, S. Tool Wears in Milling of Al/SiCp Composites by Dry and MQL Milling. In Recent Trends in Industrial and Production Engineering; Springer: Singapore, 2022; pp. 279–287. [Google Scholar]

- Saberi, M.; Niknam, S.A.; Hashemi, R. On the impacts of cutting parameters on surface roughness, tool wear mode and size in slot milling of A356 metal matrix composites reinforced with silicon carbide elements. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2021, 235, 1655–1667. [Google Scholar] [CrossRef]

- Morkavuk, S.; Köklü, U.; Bağcı, M.; Gemi, L. Cryogenic machining of carbon fiber reinforced plastic (CFRP) composites and the effects of cryogenic treatment on tensile properties: A comparative study. Compos. Part B Eng. 2018, 147, 1–11. [Google Scholar] [CrossRef]

- Danish, M.; Gupta, M.K.; Rubaiee, S.; Ahmed, A.; Mahfouz, A.; Jamil, M. Machinability investigations on CFRP composites: A comparison between sustainable cooling conditions. Int. J. Adv. Manuf. Technol. 2021, 114, 3201–3216. [Google Scholar] [CrossRef]

- Cococcetta, N.M.; Pearl, D.; Jahan, M.P.; Ma, J. Investigating surface finish, burr formation, and tool wear during machining of 3D printed carbon fiber reinforced polymer composite. J. Manuf. Processes 2020, 56, 1304–1316. [Google Scholar] [CrossRef]

- Usca, Ü.A.; Şap, S.; Uzun, M.; Kuntoğlu, M.; Salur, E.; Karabiber, A.; Pimenov, D.Y.; Giasin, K.; Wojciechowski, S. Estimation, optimization and analysis based investigation of the energy consumption in machinability of ceramic-based metal matrix composite materials. J. Mater. Res. Technol. 2022, 17, 2987–2998. [Google Scholar] [CrossRef]

- Şap, S.; Turgut, A.; Uzun, M. Investigation of microstructure and mechanical properties of Cu/Ti–B–SiCp hybrid composites. Ceram. Int. 2021, 47, 29919–29929. [Google Scholar] [CrossRef]

- German, R.M. Powder Metallurgy Science; Metal Powder Industries Federation: Princeton, NJ, USA, 1984. [Google Scholar]

- Uzun, M.; Usca, U.A. Effect of Cr particulate reinforcements in different ratios on wear performance and mechanical properties of Cu matrix composites. J. Braz. Soc. Mech. Sci. Eng. 2018, 40, 1–9. [Google Scholar] [CrossRef]

- Casati, R.; Vedani, M. Metal matrix composites reinforced by nano-particles—A review. Metals 2014, 4, 65–83. [Google Scholar] [CrossRef]

- Efe, G.C.; Altinsoy, I.; Ipek, M.; Zeytin, S.; Bindal, C. Some properties of Cu-SiC composites produced by powder metallurgy method. Kov. Mater 2011, 49, 131. [Google Scholar]

- Sap, E. Microstructural and Mechanical Properties of Cu-Based Co-Mo-Reinforced Composites Produced by the Powder Metallurgy Method. J. Mater. Eng. Perform. 2020, 29, 8461–8472. [Google Scholar] [CrossRef]

- Usca, Ü.A.; Uzun, M.; Kuntoğlu, M.; Sap, E.; Gupta, M.K. Investigations on tool wear, surface roughness, cutting temperature, and chip formation in machining of Cu-B-CrC composites. Int. J. Adv. Manuf. Technol. 2021, 116, 3011–3025. [Google Scholar] [CrossRef]

- Salur, E.; Aslan, A.; Kuntoğlu, M.; Güneş, A.; Şahin, Ö. Optimization of cutting forces during turning of composite materials. Acad. Platf. J. Eng. Sci. 2020, 8, 423–431. [Google Scholar] [CrossRef]

- Sarıkaya, M.; Gupta, M.K.; Tomaz, I.; Pimenov, D.Y.; Kuntoğlu, M.; Khanna, N.; Yıldırım, Ç.V.; Krolczyk, G.M. A state-of-the-art review on tool wear and surface integrity characteristics in machining of superalloys. CIRP J. Manuf. Sci. Technol. 2021, 35, 624–658. [Google Scholar] [CrossRef]

- Şap, E.; Usca, Ü.A.; Gupta, M.K.; Kuntoğlu, M.; Sarıkaya, M.; Pimenov, D.Y.; Mia, M. Parametric Optimization for Improving the Machining Process of Cu/Mo-SiCp Composites Produced by Powder Metallurgy. Materials 2021, 14, 1921. [Google Scholar] [CrossRef]

- Salur, E.; Aslan, A.; Kuntoglu, M.; Gunes, A.; Sahin, O.S. Experimental study and analysis of machinability characteristics of metal matrix composites during drilling. Compos. Part B Eng. 2019, 166, 401–413. [Google Scholar] [CrossRef]

- Coromant, S. Modern Metal Cutting: A Practical Handbook; Sandvik Coromant: Sandviken, Sweden, 1994. [Google Scholar]

- ISO 8688-1; Tool Life Testing in Milling. Part 1: Face Milling. International ISO Standard: Geneva, Switzerland, 1989.

- Siddhpura, A.; Paurobally, R. A review of flank wear prediction methods for tool condition monitoring in a turning process. Int. J. Adv. Manuf. Technol. 2013, 65, 371–393. [Google Scholar] [CrossRef]

- Sivalingam, V.; Zan, Z.; Sun, J.; Selvam, B.; Gupta, M.K.; Jamil, M.; Mia, M. Wear behaviour of whisker-reinforced ceramic tools in the turning of Inconel 718 assisted by an atomized spray of solid lubricants. Tribol. Int. 2020, 148, 106235. [Google Scholar] [CrossRef]

- Khan, M.; Mithu, M.; Dhar, N.R. Effects of minimum quantity lubrication on turning AISI 9310 alloy steel using vegetable oil-based cutting fluid. J. Mater. Processing Technol. 2009, 209, 5573–5583. [Google Scholar] [CrossRef]

- Kuntoğlu, M. Measurement and Analysis of Sustainable Indicators in Machining of ARMOX 500T Armor Steel. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2022. online first. [Google Scholar] [CrossRef]

- Kuntoğlu, M.; Gupta, M.K.; Aslan, A.; Salur, E.; Garcia-Collado, A. Influence of tool hardness on tool wear, surface roughness and acoustic emissions during turning of AISI 1050. Surf. Topogr. Metrol. Prop. 2022, 10, 015016. [Google Scholar] [CrossRef]

- Laghari, R.A.; Li, J.; Xie, Z.; Wang, S.-q. Modeling and optimization of tool wear and surface roughness in turning of Al/SiCp using response surface methodology. 3D Res. 2018, 9, 1–13. [Google Scholar] [CrossRef]

- Asiltürk, I.; Çelik, L.; Canli, E.; Önal, G. Regression modeling of surface roughness in grinding. Adv. Mater. Res. 2011, 271–273, 34–39. [Google Scholar] [CrossRef]

- Demir, H.; Ulaş, H.B.; Binali, R. Investigation of the effects on surface roughness and tool wear in the toolox44 material. Technol. Appl. Sci. 2018, 13, 19–28. [Google Scholar]

- Jamil, M.; He, N.; Zhao, W.; Khan, A.M.; Laghari, R.A. Tribology and machinability performance of hybrid Al2O3-MWCNTs nanofluids-assisted MQL for milling Ti-6Al-4 V. Int. J. Adv. Manuf. Technol. 2021, 119, 2127–2144. [Google Scholar] [CrossRef]

- Usca, U.; Uzun, M.; Şap, S.; Kuntoğlu, M.; Giasin, K.; Pimenov, D.Y.; Wojciechowski, S. Tool wear, surface roughness, cutting temperature and chips morphology evaluation of Al/TiN coated carbide cutting tools in milling of Cu-B-CrC based ceramic matrix composites. J. Mater. Res. Technol. 2022, 16, 1243–1259. [Google Scholar] [CrossRef]

- Gupta, M.K.; Etri, H.E.; Korkmaz, M.E.; Ross, N.S.; Krolczyk, G.M.; Gawlik, J.; Yaşar, N.; Pimenov, D.Y. Tribological and surface morphological characteristics of titanium alloys: A review. Arch. Civ. Mech. Eng. 2022, 22, 1–23. [Google Scholar] [CrossRef]

- Shokrani, A.; Al-Samarrai, I.; Newman, S.T. Hybrid cryogenic MQL for improving tool life in machining of Ti-6Al-4V titanium alloy. J. Manuf. Processes 2019, 43, 229–243. [Google Scholar] [CrossRef]

- Damir, A.; Shi, B.; Attia, M.H. Flow characteristics of optimized hybrid cryogenic-minimum quantity lubrication cooling in machining of aerospace materials. CIRP Ann. 2019, 68, 77–80. [Google Scholar] [CrossRef]

- Gupta, M.K.; Korkmaz, M.E.; Sarıkaya, M.; Krolczyk, G.M.; Günay, M.; Wojciechowski, S. Cutting forces and temperature measurements in cryogenic assisted turning of AA2024-T351 alloy: An experimentally validated simulation approach. Measurement 2022, 188, 110594. [Google Scholar] [CrossRef]

- Ross, N.S.; Gopinath, C.; Nagarajan, S.; Gupta, M.K.; Shanmugam, R.; Kumar, M.S.; Boy, M.; Korkmaz, M.E. Impact of hybrid cooling approach on milling and surface morphological characteristics of Nimonic 80A alloy. J. Manuf. Processes 2022, 73, 428–439. [Google Scholar] [CrossRef]

- Gupta, M.K.; Boy, M.; Korkmaz, M.E.; Yaşar, N.; Günay, M.; Krolczyk, G.M. Measurement and analysis of machining induced tribological characteristics in dual jet minimum quantity lubrication assisted turning of duplex stainless steel. Measurement 2022, 187, 110353. [Google Scholar] [CrossRef]

- An, Q.; Cai, C.; Zou, F.; Liang, X.; Chen, M. Tool wear and machined surface characteristics in side milling Ti6Al4V under dry and supercritical CO2 with MQL conditions. Tribol. Int. 2020, 151, 106511. [Google Scholar] [CrossRef]

- Sarikaya, M.; Gupta, M.K.; Tomaz, I.; Danish, M.; Mia, M.; Rubaiee, S.; Jamil, M.; Pimenov, D.Y.; Khanna, N. Cooling techniques to improve the machinability and sustainability of light-weight alloys: A state-of-the-art review. J. Manuf. Processes 2021, 62, 179–201. [Google Scholar] [CrossRef]

- Gupta, M.K.; Singh, G.; Sood, P.K. Experimental investigation of machining AISI 1040 medium carbon steel under cryogenic machining: A comparison with dry machining. J. Inst. Eng. Ser. C 2015, 96, 373–379. [Google Scholar] [CrossRef]

- Kumar, K.K.; Choudhury, S. Investigation of tool wear and cutting force in cryogenic machining using design of experiments. J. Mater. Processing Technol. 2008, 203, 95–101. [Google Scholar] [CrossRef]

- Salur, E.; Aslan, A.; Kuntoğlu, M.; Acarer, M. Effect of ball milling time on the structural characteristics and mechanical properties of nano-sized Y2O3 particle reinforced aluminum matrix composites produced by powder metallurgy route. Adv. Powder Technol. 2021, 32, 3826–3844. [Google Scholar] [CrossRef]

- Salur, E.; Nazik, C.; Acarer, M.; Şavklıyıldız, İ.; Akdoğan, E.K. Ultrahigh hardness in Y2O3 dispersed ferrous multicomponent nanocomposites. Mater. Today Commun. 2021, 28, 102637. [Google Scholar] [CrossRef]

- Binali, R.; Yaldiz, S.; Neşeli, S. S960QL Yapı Çeliğinin İşlenebilirliğinin Sonlu Elemanlar Yöntemi ile İncelenmesi. Avrupa Bilim Ve Teknol. Derg. 2021, 31, 85–91. [Google Scholar]

- Rüstem, B.; Süleyman, Y.; Süleyman, N. Optimization of Machinability Parameters of S960QL Structural Steel by Finite Elements and Taguchi Method. In Proceedings of the International Conference on Engineering Technologies (ICENTE’21) (Tam Metin Bildiri/Sözlü Sunum) (Yayın No: 7301857), Konya, Turkey, 18–20 November 2021. [Google Scholar]

- Sertkaya, A.A.; Ozdemir, M.; Canli, E. Effects of pin fin height, spacing and orientation to natural convection heat transfer for inline pin fin and plate heat sinks by experimental investigation. Int. J. Heat Mass Transf. 2021, 177, 121527. [Google Scholar] [CrossRef]

- Kuntoğlu, M.; Salur, E.; Gupta, M.K.; Sarıkaya, M.; Pimenov, D.Y. A state-of-the-art review on sensors and signal processing systems in mechanical machining processes. Int. J. Adv. Manuf. Technol. 2021, 116, 2711–2735. [Google Scholar] [CrossRef]

- Danish, M.; Gupta, M.K.; Rubaiee, S.; Ahmed, A.; Sarıkaya, M.; Krolczyk, G.M. Environmental, technological and economical aspects of cryogenic assisted hard machining operation of inconel 718: A step towards green manufacturing. J. Clean. Prod. 2022, 337, 130483. [Google Scholar] [CrossRef]

- Gupta, M.K.; Khan, A.M.; Song, Q.; Liu, Z.; Khalid, Q.S.; Jamil, M.; Kuntoğlu, M.; Usca, Ü.A.; Sarıkaya, M.; Pimenov, D.Y. A review on conventional and advanced minimum quantity lubrication approaches on performance measures of grinding process. Int. J. Adv. Manuf. Technol. 2021, 117, 729–750. [Google Scholar] [CrossRef]

- Pusavec, F.; Lu, T.; Courbon, C.; Rech, J.; Aljancic, U.; Kopac, J.; Jawahir, I. Analysis of the influence of nitrogen phase and surface heat transfer coefficient on cryogenic machining performance. J. Mater. Processing Technol. 2016, 233, 19–28. [Google Scholar] [CrossRef]

- Korkmaz, M.E.; Gupta, M.K.; Boy, M.; Yaşar, N.; Krolczyk, G.M.; Günay, M. Influence of duplex jets MQL and nano-MQL cooling system on machining performance of Nimonic 80A. J. Manuf. Processes 2021, 69, 112–124. [Google Scholar] [CrossRef]

- Bilga, P.S.; Singh, S.; Kumar, R. Optimization of energy consumption response parameters for turning operation using Taguchi method. J. Clean. Prod. 2016, 137, 1406–1417. [Google Scholar] [CrossRef]

- Benjamin, D.M.; Sabarish, V.N.; Hariharan, M.; Raj, D.S. On the benefits of sub-zero air supplemented minimum quantity lubrication systems: An experimental and mechanistic investigation on end milling of Ti-6-Al-4-V alloy. Tribol. Int. 2018, 119, 464–473. [Google Scholar] [CrossRef]

- Sani, A.S.A.; Abd Rahim, E.; Sharif, S.; Sasahara, H. Machining performance of vegetable oil with phosphonium-and ammonium-based ionic liquids via MQL technique. J. Clean. Prod. 2019, 209, 947–964. [Google Scholar] [CrossRef]

- Shah, P.; Khanna, N. Comprehensive machining analysis to establish cryogenic LN2 and LCO2 as sustainable cooling and lubrication techniques. Tribol. Int. 2020, 148, 106314. [Google Scholar] [CrossRef]

- Kouam, J.; Songmene, V.; Balazinski, M.; Hendrick, P. Effects of minimum quantity lubricating (MQL) conditions on machining of 7075-T6 aluminum alloy. Int. J. Adv. Manuf. Technol. 2015, 79, 1325–1334. [Google Scholar] [CrossRef]

- Aslan, A. Optimization and analysis of process parameters for flank wear, cutting forces and vibration in turning of AISI 5140: A comprehensive study. Measurement 2020, 163, 107959. [Google Scholar] [CrossRef]

- Kuntoğlu, M.; Sağlam, H. Investigation of signal behaviors for sensor fusion with tool condition monitoring system in turning. Measurement 2021, 173, 108582. [Google Scholar] [CrossRef]

| Material Systems | Machining Process | Cutting Environments | Cutting Fluids | Observed Results | References |

|---|---|---|---|---|---|

| TiB2/Al7075 | Milling | Dry, Cryo, MQL and CMQL | Water-based oil, and CO2 | Abrasive and adhesive wear ↓, 200% improved tool life as compared to dry | [32] |

| SiCp/Al | Milling | Dry and MQL | - | Flank wear ↓ | [33] |

| SiCp/A356 | Milling | Dry, flood and MQL | Bio-lubricant | Tool wear ↓, no discernible differences in Ra | [34] |

| CFRP | Milling | Dry and Cryo | LN2 | Surface roughness ↓, delamination factor ↓, cutting forces ↑ | [35] |

| CFRP | Milling | Dry, MQL and Cryo | Synthetic-based oil, LN2 and CO2 | Machining time ↓, Surface roughness ↓, Tool life ↑ | [36] |

| CFRP | Milling | Dry and MQL | Oil-based fluid | Tool wear ↓, Surface quality ↑ Reduced burr formation compared with dry | [37] |

| Cutting Parameters | 1st Level | 2nd Level | 3rd Level |

|---|---|---|---|

| Cutting speed (m/min) | 200 | 300 | – |

| Feed rate (mm/rev) | 0.2 | 0.3 | – |

| Environment | Dry | MQL | Cryo |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Şap, S.; Usca, Ü.A.; Uzun, M.; Kuntoğlu, M.; Salur, E.; Pimenov, D.Y. Investigation of the Effects of Cooling and Lubricating Strategies on Tribological Characteristics in Machining of Hybrid Composites. Lubricants 2022, 10, 63. https://doi.org/10.3390/lubricants10040063

Şap S, Usca ÜA, Uzun M, Kuntoğlu M, Salur E, Pimenov DY. Investigation of the Effects of Cooling and Lubricating Strategies on Tribological Characteristics in Machining of Hybrid Composites. Lubricants. 2022; 10(4):63. https://doi.org/10.3390/lubricants10040063

Chicago/Turabian StyleŞap, Serhat, Üsame Ali Usca, Mahir Uzun, Mustafa Kuntoğlu, Emin Salur, and Danil Yurievich Pimenov. 2022. "Investigation of the Effects of Cooling and Lubricating Strategies on Tribological Characteristics in Machining of Hybrid Composites" Lubricants 10, no. 4: 63. https://doi.org/10.3390/lubricants10040063

APA StyleŞap, S., Usca, Ü. A., Uzun, M., Kuntoğlu, M., Salur, E., & Pimenov, D. Y. (2022). Investigation of the Effects of Cooling and Lubricating Strategies on Tribological Characteristics in Machining of Hybrid Composites. Lubricants, 10(4), 63. https://doi.org/10.3390/lubricants10040063