1. Introduction

The calculation of the load transmitted by the most-loaded rolling element has attracted the interest of researchers since the beginning of the use of rolling bearings in machines. This is one very important characteristic of the rolling bearing, especially for the calculation of the static load capacity and the rating life, but also the overall load distribution on the rolling elements inside the bearing. However, due to the complexity of the bearing construction, the way of functioning, and many other influential factors, this problem has not yet been explicitly resolved. So far, Stribeck’s method has been the most commonly used for the calculation of this load [

1].

The calculation based on the Stribeck numbers is the most commonly used method for the calculation of the load that transfers the most-loaded rolling element. Stribeck’s expressions are still in use today to calculate the static load capacity of a rolling bearing [

2,

3]. However, Stribeck’s method has one essential drawback: it does not take into account the influence of the size of the internal clearance on the load distribution within the bearing.

In this regard, this paper presents and tests a new mathematical model for the calculation of the load that is transferred by the most-loaded rolling element of the rolling bearing with internal radial clearance. The model is elaborated in detail in the paper [

4,

5] and purposed for the radially loaded rolling bearing, with balls or rollers. Based on the papers of Mitrovic et al. [

6,

7], the model is based on the so-called load factors, showing which part of the external load is transferred by the most-loaded rolling element of the bearing. By simple multiplication of the load factor with the value of the external radial load, the load that is transferred by the most-loaded rolling element of the bearing is obtained:

where is:

Fmax—the load that is transferred by the most-loaded rolling element of the bearing,

kmax—the load factor of the most-loaded rolling element,

Q—the total external radial load.

The values of the load factor for the boundary position of support (

kmaxq) were derived from the literature [

4,

5]. These values are shown in Tables 1 and 2 in reference [

5]. These values correspond to the boundary values of the bearing deflection and the boundary external radial loads, which are defined in the papers [

8,

9].

If the right side of the Equation (1) is multiplied and divided by the total number of the rolling elements (

z) of the bearing and the product

kmax·z is marked with the

S, it can be obtained:

The factor

S shows how many times the greater load is transferred by the most-loaded rolling element relative to the case when the load would be even, i.e., when every ball would transfer the load of the size

Q/

z. In the literature, this factor is often called the factor of the

non-uniformity load distribution [

10].

Stribeck determined that with an increase in the total number of balls in the bearing with zero clearance, the factor of the non-uniformity load distribution asymptotically strives to constant

S = 4.37 [

1]. This number is called the Stribeck number (

S) and in the literature is taken as a relevant value for the calculation of the load of the most-loaded ball at the bearings with zero clearance, i.e., at the calculation of the static load rating of the bearing [

11]. Palmgren later proposed that in the bearings with the rollers, the Stribeck number amounts to

S = 4.08 [

12]. For the bearings with radial clearance greater than zero, the impact of the clearance on the load distribution is approximated by increasing the value of the Stribeck number on the value

S = 5, independently of the size of the clearance. This applies to every type of ball and roller bearing with internal radial clearance. However, this kind of approach has justification for only orientational calculations because it takes into consideration only whether or not the clearance is present in the bearing, and the influence of the clearance size is not taken into account. Even the influence of the type of bearing on the load distribution is not taken into account. Still, the calculation based on the Stribeck numbers is the most commonly used method for the calculation of the load that transfers the most-loaded rolling element. Stribeck’s expressions are still in use today to calculate the static load capacity of a rolling bearing [

2,

3].

The model that is proposed in this paper takes into account the impact of the internal radial clearance and the type of bearing on the internal load distribution. The impact of the clearance is taken through the number of active rolling elements in the bearing. By its simplicity, the proposed model can be compared to the Stribeck method. The proposed model, like the Stribeck one, is based on simple mathematical operations, does not require the usage of the computer and it can be very useable for fast calculations and work in the field.

The aim of this study is to propose the guidelines to correctly choose the load factors for the new mathematical model that is developed in [

5]. For this purpose, a load calculation of the most-loaded rolling element was carried out for the two different types of radial rolling bearings: the ball bearing 6206 and the bearing with the cylindrical rollers, NU 2205 EC. For both bearing types, the analysis was conducted for different values of the internal radial clearance. The obtained results were compared with results obtained based on Stribeck coefficients. Additionally, both methods were compared with the results obtained by solving the system of static equilibrium equations [

4,

9].

The precision of the results obtained by solving the system of static equations solely depends on the precision of the numerical procedure for solving them. In this regard, these results were considered accurate, and compared to them the calculation error according to the proposed method and the Stribeck method were analyzed. Furthermore, the coefficients of Stribeck refer to only the boundary position of support on an odd number of rolling elements (

BSO position) [

13], and the analysis was performed only in relation to this position of the rolling elements set, which is shown in

Figure 1. This is justified because from the aspect of load distribution this is the most unfavorable position of the rolling bearing support. Then, the most-loaded rolling element transfers the largest part of the external load [

14]. For these reasons, so far, almost all published studies have limited their analysis to only this position of support [

15,

16,

17,

18,

19,

20].

The analysis conducted showed that by correct selection of the load factor, the new model provides much more precise results compared to the Stribeck method. Based on this, in the conclusion, guidelines for the efficient selection of load factors are proposed.

2. The Static Equilibrium Equations for the BSO Position of Support

The problem of calculating the internal load distribution is a statically indeterminate problem. Therefore, the system of static equilibrium equations needs to be extended with additional equations, which are based on the relationship between contact stresses and deformations. A detailed description of the calculation is presented in the references [

4,

8,

9].

In

Figure 1, the scheme of the internal load distribution for the

BSO position of support for the rolling bearing with internal radial clearance is presented. The force equilibrium condition for this position can be set as:

where:

Q—the external radial load,

F0—the load of the most-loaded rolling element,

Fi—the load of

i-th rolling element,

γ—the angular spacing between rolling bearing elements,

q—the number of active rolling elements.

Equation (3) is a statically indeterminate equation. Unknown values are loads that transfer through the rolling elements of the bearing (Fi). By taking into account the symmetry of the problem, the number of unknown values is equal to (q + 1)/2. So, besides the equilibrium Equation (3), it is necessary to set up (q − 1)/2 additional equations, based on the relationship between the contact stresses and the deformations of the coupled parts of the bearing.

According to [

4,

8], the total deflection of the bearing is equal to the sum of the boundary deflection until the entry of the

i-th rolling element into contact with the bearing rings and the projection of the total contact deformation of the

i-th rolling element on the direction of the action of external load, i.e.,:

where is

a2i+1—the necessary bearing deflection for the entry of the i-th rolling element in contact with rings,

δi—the contact deformations on the place of the

i-th rolling element.

The necessary bearing deflection (

a2i+1) is directly dependent on the bearing type and the internal radial clearance size. For necessary bearing deflection, study [

8] adopted the term “boundary-bearing deflection” and presented a procedure for its simple determination. According to this procedure, the boundary-bearing deflection is calculated as:

where:

e—internal radial clearance,

q = 2

i + 1—number of rolling elements on which the inner bearing ring is supported, and

tq—coefficient of boundary-bearing deflection that can be obtained from the tables shown in the literature [

4,

8].

Taking into account Equation (4), the system of equations for the calculation of the internal load distribution for the

BSO position can be written as:

According to the Hertz theory [

11], the size of the contact deformations (

δi) can be calculated based on the equation:

where is

K—the effective coefficient of the bearing stiffness, and

n—exponent that is dependent on the type of the bearing (

n = 3/2 for a ball bearing and

n = 10/9 for a bearing with the rollers).

Based on

Figure 1b, it is clear that the total deflection of the bearing is equal to the contact deformation at the place of the most-loaded rolling element, i.e.,

wo = δ0. Based on that and Equation (7), the total deflection of the bearing can be written as:

That is, taking into account Equations (6)–(8), the system of equations for the calculation of the internal load distribution for the

BSO position of the rolling bearing can be written as:

The system of Equation (9) consists of (

q + 1)/2 non-linear equations. By solving this system, it is possible to obtain the loads that transfer the individual rolling elements. Since the system is non-linear, it can be only solved numerically. The total number of active rolling elements of the bearing (

q) can be easily determined based on the procedure shown in [

9].

3. Case Study of the Load Calculation That Transfers the Most-Loaded Rolling Element of the Rolling Bearing

3.1. Case Study of the Ball Bearing

The radial ball bearing 6206 was taken as an example for the calculation. The effective coefficient of the bearing stiffness is

K = 3.41·10

5 N/mm

3/2. The total number of rolling elements is

z = 9, and the maximum possible number of active rolling elements is

zs = 5 [

8]. The values of the coefficient of boundary-bearing deflection (

tq) and the coefficient of boundary external radial load (

sq) were determined from the tables, which are presented in references [

8,

9] and shown in

Table 1. The values of the load factor for the most-loaded rolling element

kmaxq are also shown in

Table 1. These values were determined based on

Table 1 from the literature [

5].

The load that transfers the most-loaded rolling element of bearing is possibly obtained by the multiplication of factors

kmaxq with the external radial load (

Q), according to Equation (1). The results of the calculation for the 6206 ball bearing are shown in

Table A1,

Table A2,

Table A3,

Table A4,

Table A5,

Table A6,

Table A7 and

Table A8, which are shown in

Appendix A. The results are shown for different values of the internal radial clearance, which were varied in the full range of standard recommended values of the internal radial clearance for the 6206 bearings (from 0 to 50 µm) [

21].

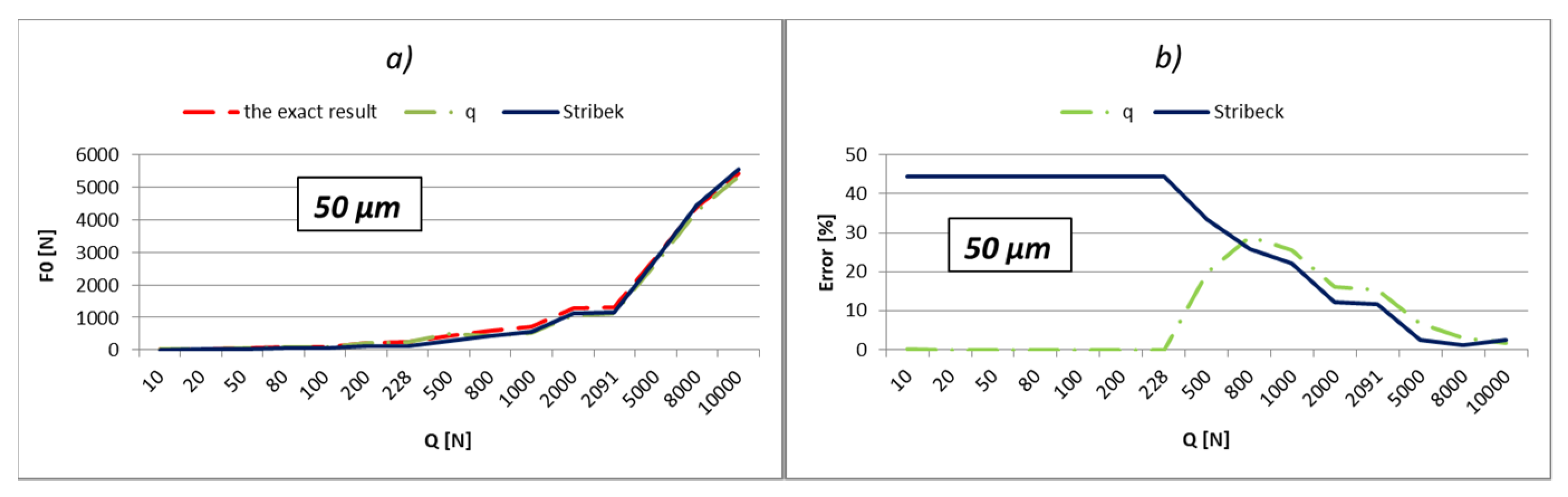

The load values for the most-loaded rolling element were calculated and shown in relation to three different methods:

Using Stribeck’s number, according to Equation (2);

By applying the load factor of the most-loaded rolling element, according to Equation (1).

To obtain an effective analysis, the calculation was performed by using the load factors, especially for all three values of factors

kmaxq shown in

Table 1. The errors of calculation in percentages are shown below the results. The errors were obtained by comparing obtained results with the exact value. The external load values were varied in the range from 10 to 10,000 N, which is very close to the static load rating of the bearing, which is 11,200 N. In addition, the calculation was performed also with respect to the boundary values of external load (

Qq). These values in the tables are bold. The boundary values of the external load were calculated in relation to the following Equation [

9]:

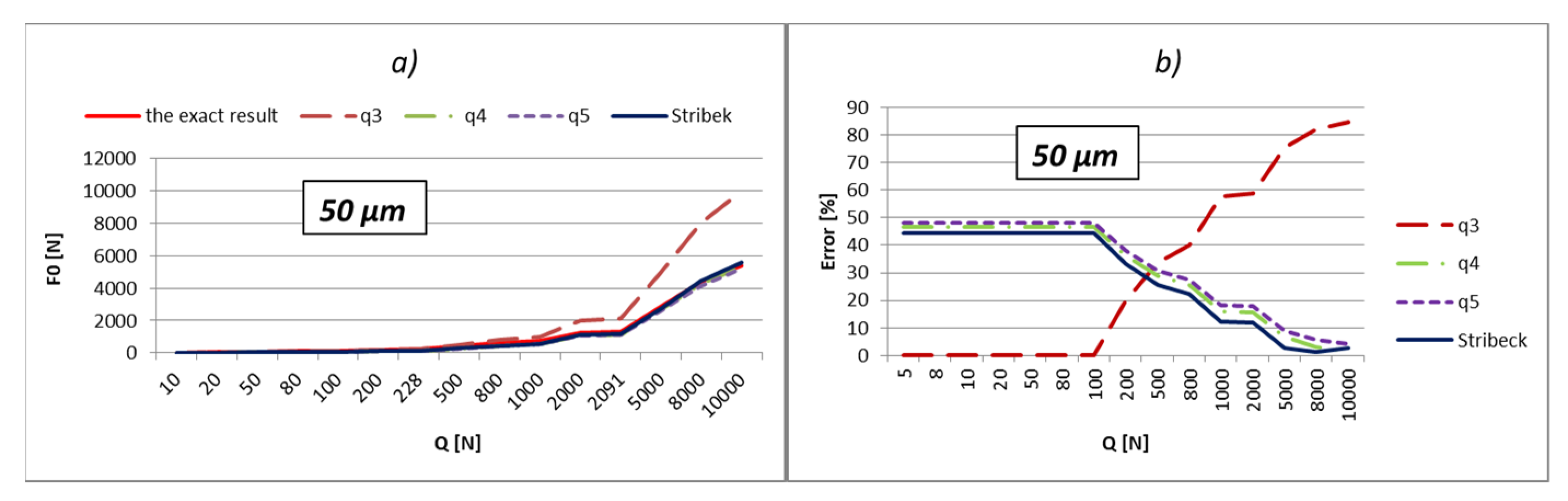

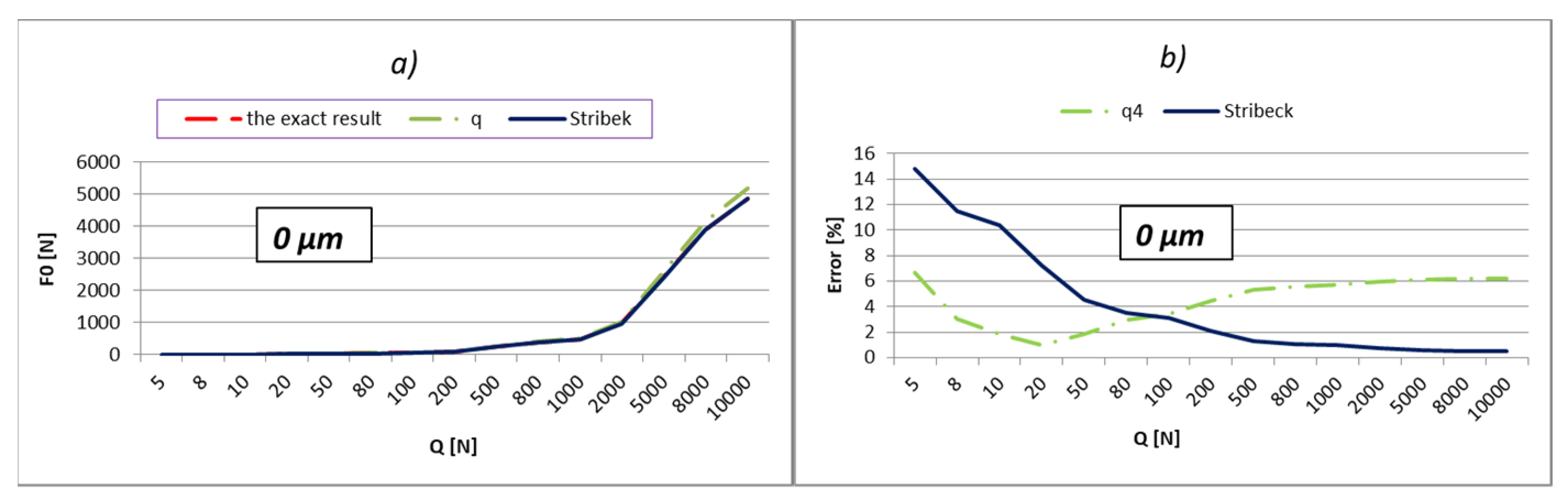

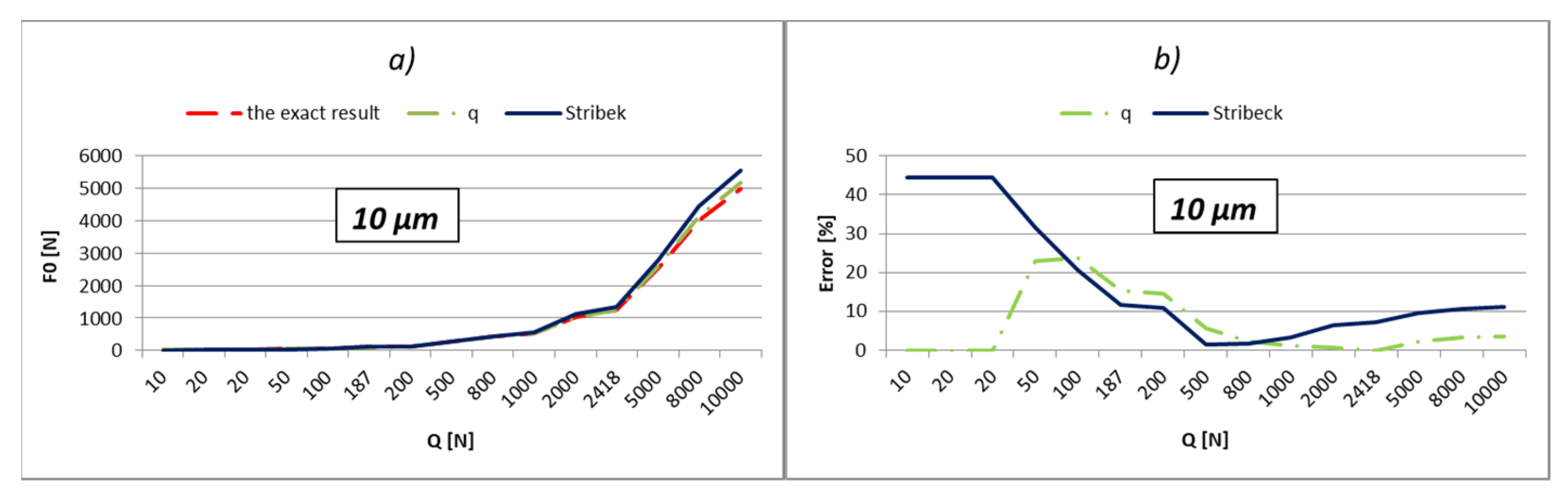

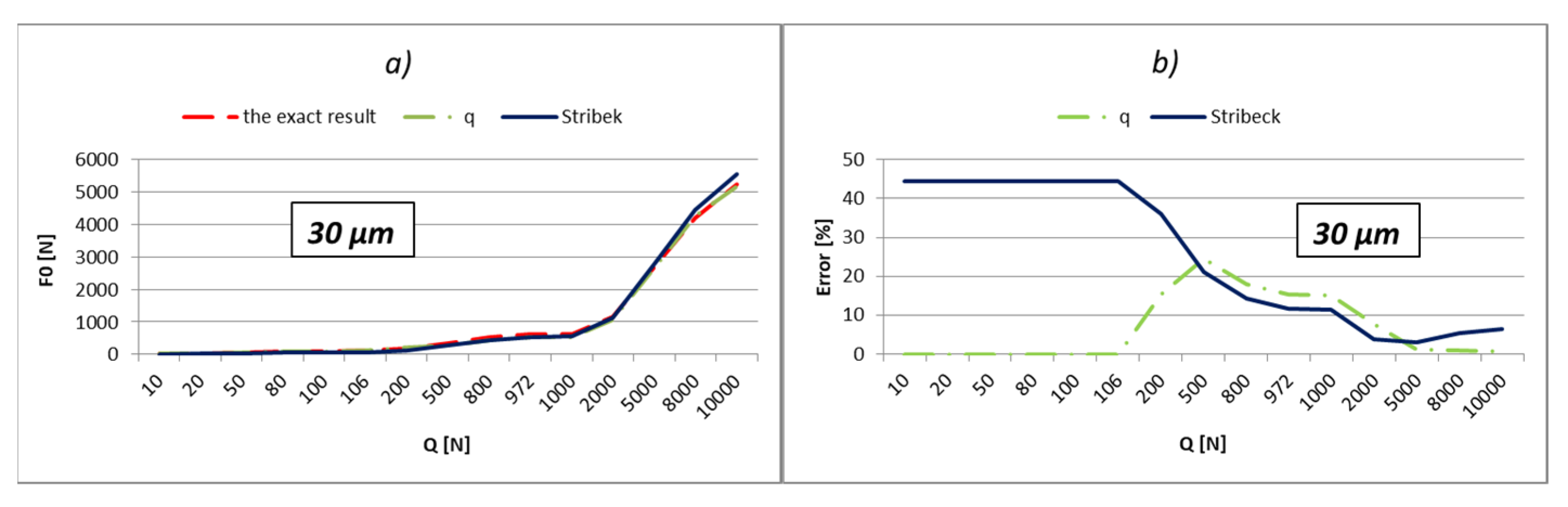

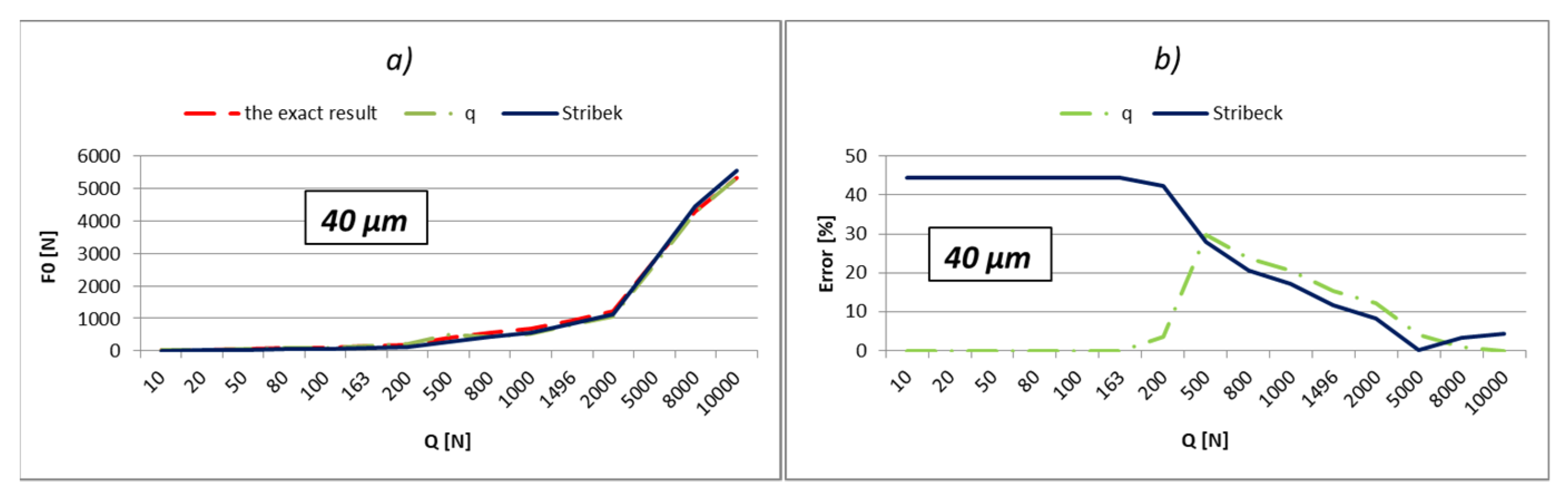

The results shown in

Table A1,

Table A2,

Table A3,

Table A4,

Table A5,

Table A6,

Table A7 and

Table A8 are graphically presented in

Figure 2,

Figure 3,

Figure 4,

Figure 5,

Figure 6,

Figure 7,

Figure 8 and

Figure 9. The calculation results of the load of the most-loaded rolling element are shown on the left side (

a), and the errors in a percentage are shown on the right side (

b) of

Figure 2,

Figure 3,

Figure 4,

Figure 5,

Figure 6,

Figure 7,

Figure 8 and

Figure 9.

3.2. Case Study of Bearing with Rollers

As an example for the calculation, a radial roller bearing with cylindrical rollers (NU 2205 EC) was taken. The effective coefficient of the stiffness of this bearing is

K = 3.14·10

5 N/mm

10/9. The total number of rolling elements is

z = 13, and the maximal possible number of active rolling elements is

zs = 7 [

8]. The values of the coefficient of boundary-bearing deflection (

tq) and the coefficient of boundary external radial load (

sq) for this bearing are shown in

Table 2, and they are determined from the tables that are presented in the literature [

8,

9]. The values of the load factor of the most-loaded rolling element

kmaxq are also shown in

Table 2. These values are determined according to

Table 2 from the literature [

5].

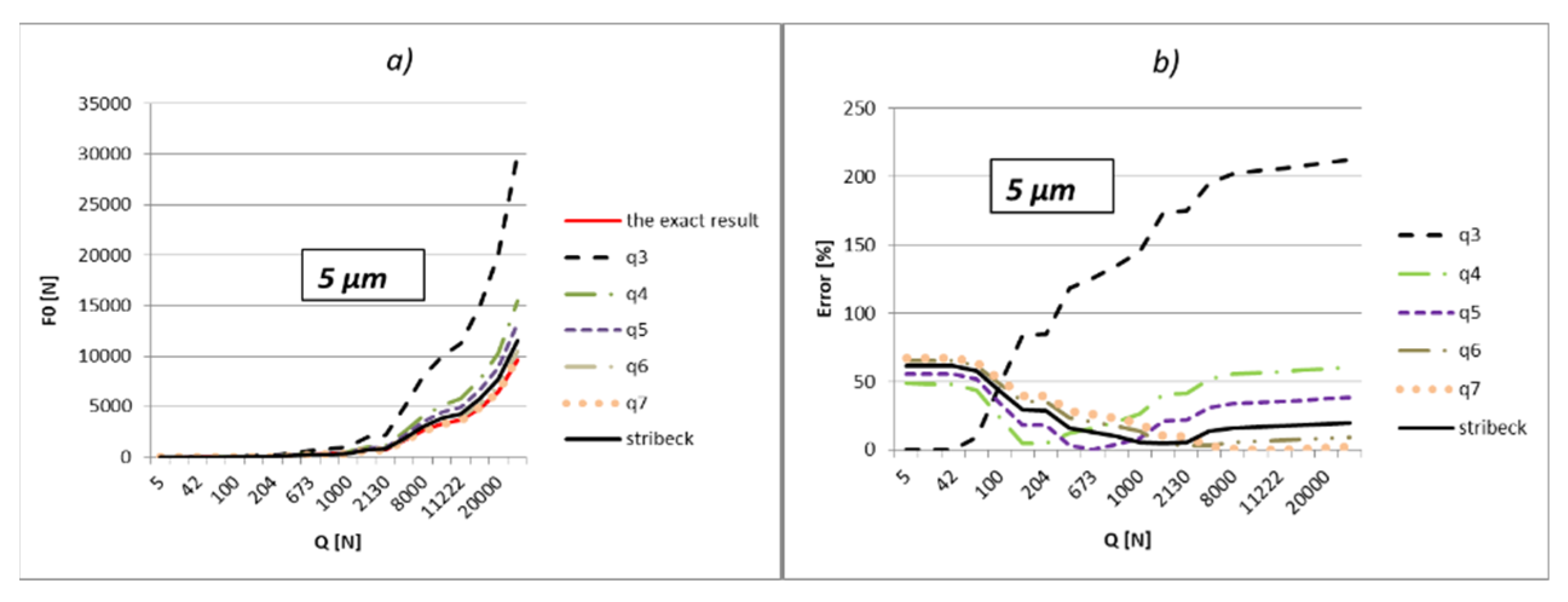

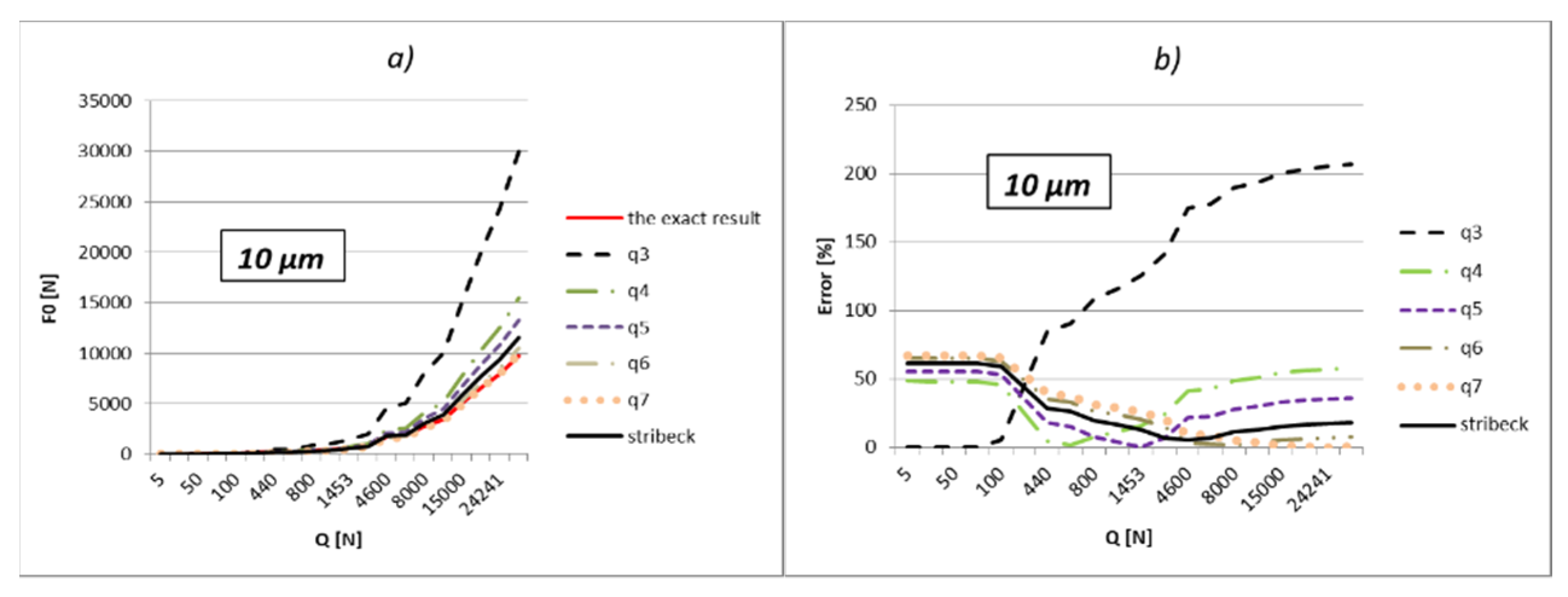

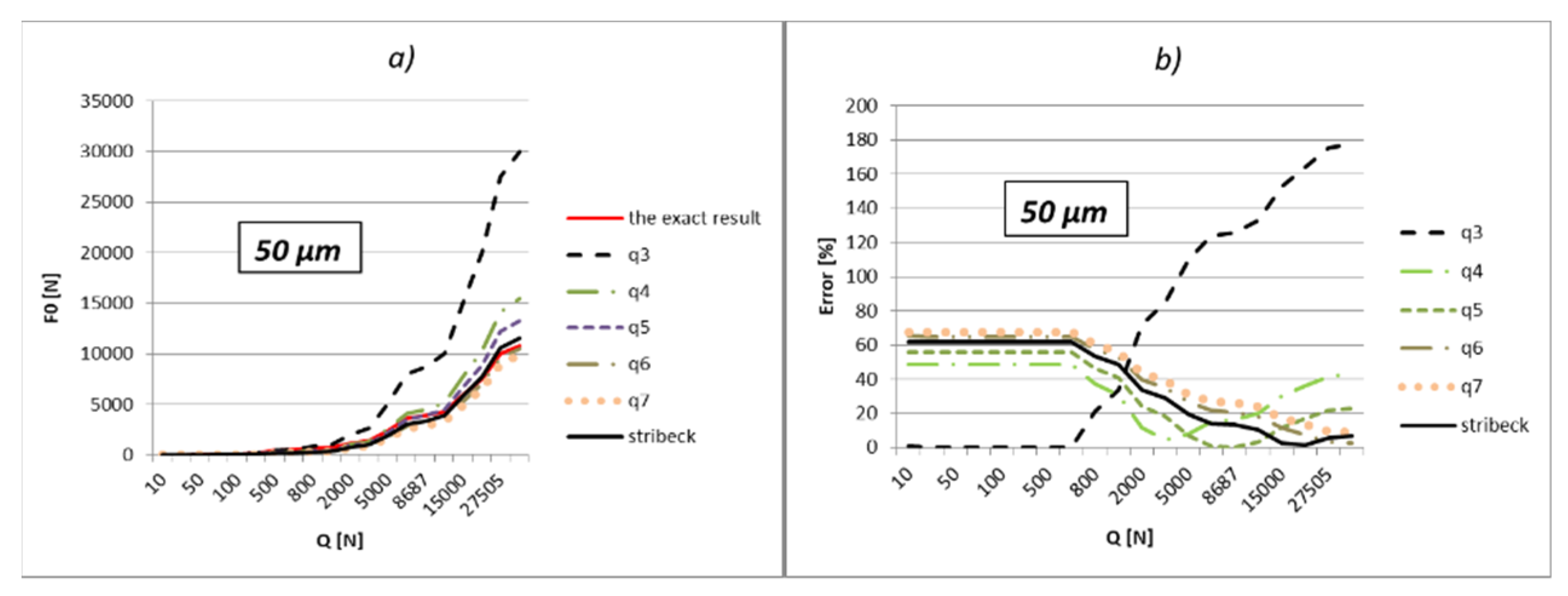

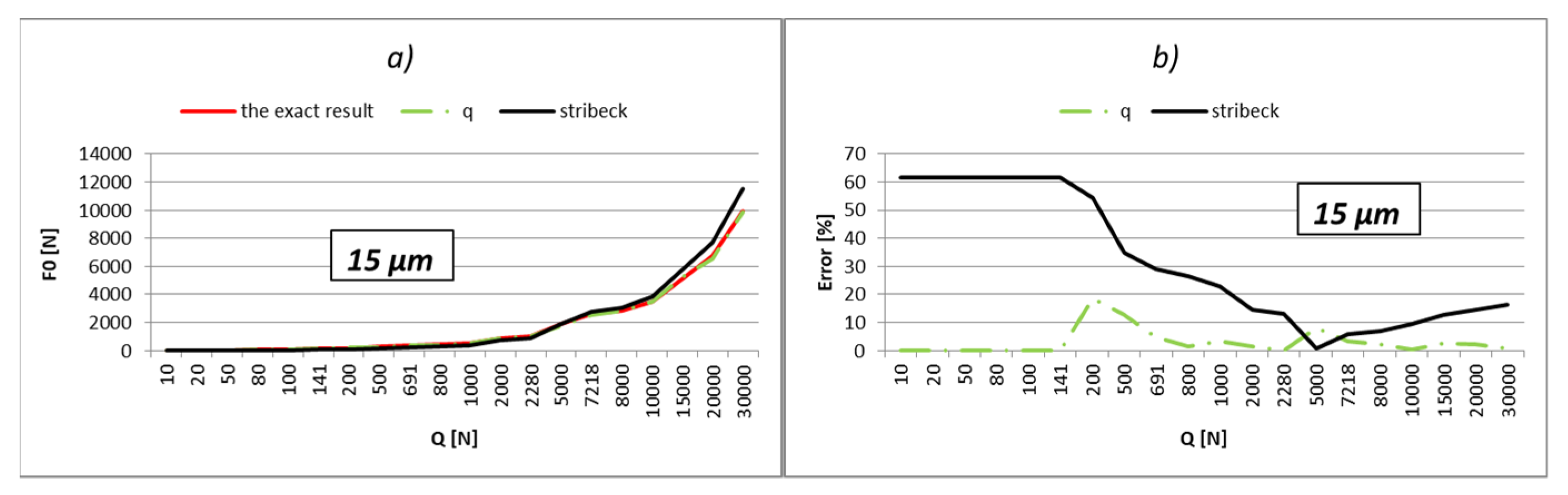

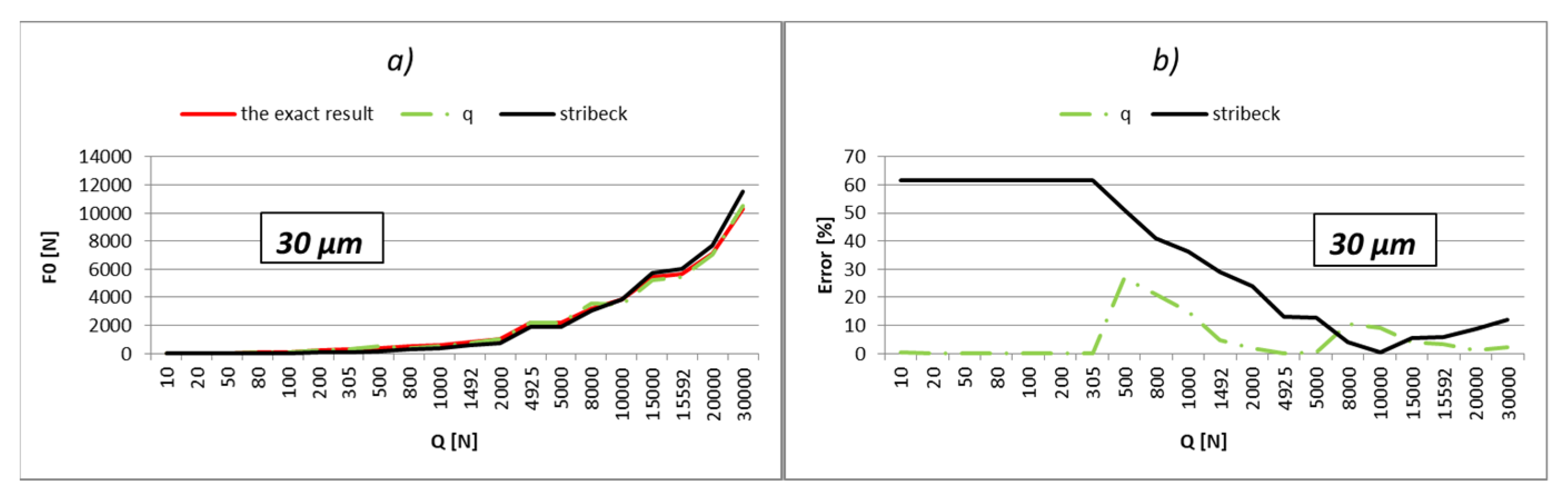

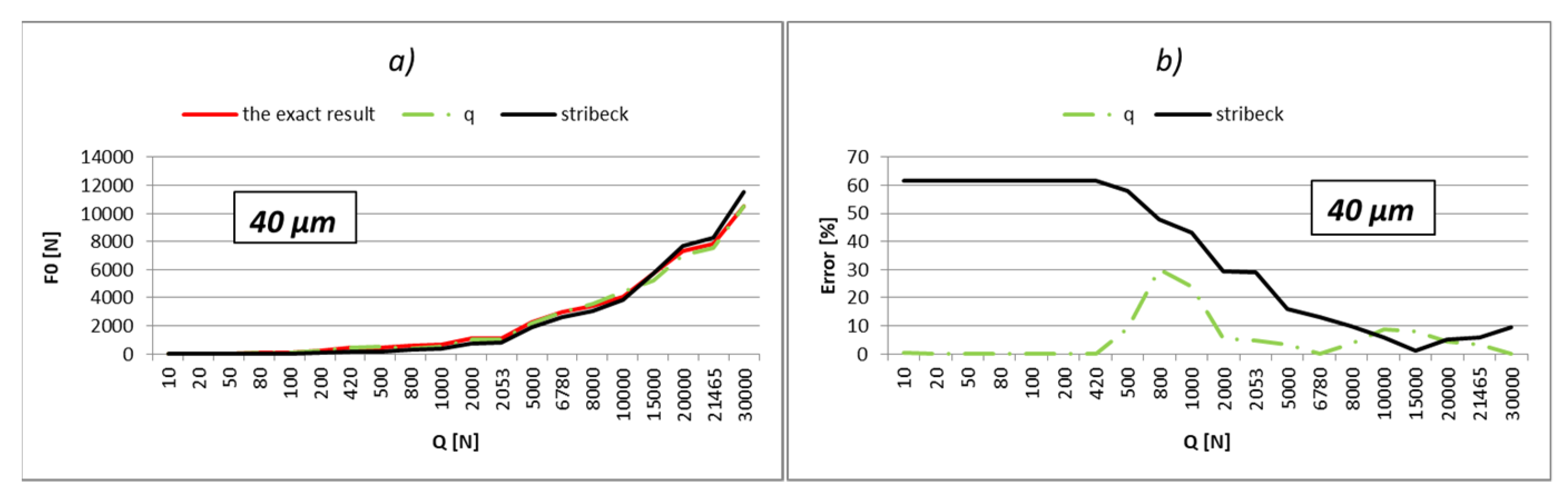

The results of the calculation are shown in

Table A9,

Table A10,

Table A11,

Table A12,

Table A13,

Table A14,

Table A15 and

Table A16 (

Appendix B). The analysis is performed for different values of the internal radial clearance, which were varied between 0 and 50 µm. For this example too, the values of the load were calculated and shown regarding the three above-mentioned methods. The values of the external load were varied in the range from 10 to 30,000 N, which is close to the static load rating of this bearing, which is 34,100 N. Additionally, the results acquired in relation to the values of the boundary external load (

Qq) are bold in the tables. Results from

Table A9,

Table A10,

Table A11,

Table A12,

Table A13,

Table A14,

Table A15 and

Table A16 are graphically shown in

Figure 10,

Figure 11,

Figure 12,

Figure 13,

Figure 14,

Figure 15,

Figure 16 and

Figure 17.

3.3. Discussion of the Results

The part of the load that transfers the most-loaded rolling element of the rolling bearing is possible to obtain simply by the multiplication of load factor kmaxq with the value of the external radial load. On the level of the load of the most-loaded rolling element, the largest influence is the number of active rolling elements. On the other hand, what the number of active rolling elements in the bearing will be is primarily dependent on the size of internal radial clearance and applied external load. The larger external load will cause a greater number of active rolling elements, and at low values of the external load, the number of active rolling elements will be smaller and will be in an interval q = 1÷3. It implies that for the lower values of the external load, the calculation with the factor of load kmax3 will give more accurate results. This is also shown by the results presented in the previous subchapter. The factor kmax3 corresponds to supporting the three active rolling elements of the bearing.

On the other side, for larger values of external loads, more accurate results are obtained with kmaxq factors, which correspond to the larger number of active rolling elements.

The internal radial clearance negatively affects the number of active rolling elements. The larger values of internal radial clearance, then as a consequence have a smaller number of active rolling elements in the bearing. In this regard, larger values of internal clearance will increase the zones in which the calculation with coefficient kmax3 provides the best results. By reducing the value of the internal clearance, the size of this zone will be proportionally narrower. For example, for a relatively small clearance of e = 5 µm and bearing 6206, the length of the zone in which factor kmax3 provides the best results reaches up to about 10 N, and up to 40 N for bearing NU 2205. On the other side, for clearance e = 50 µm, this zone increases up to 200 N for bearing 6206, or 900 N for bearing NU 2205 EC.

So, the larger the value of the external load and the smaller the size of the internal clearance, the calculation with load factor kmaxq provides more accurate results compared to the calculation recommended by Stribeck. This is especially expressed in the bearings with rollers. For loads that allow supporting with the maximum possible number of rolling elements, the calculation using the load factor provides much more accurate results compared to Stribeck’s method.

The calculation provides accurate results for the boundary values of external load (Qq), which correspond to the boundary-bearing deflection (aq). In those situations, the support system of the inner ring switches from q − 1 on q active rolling elements. Extremely high accuracy of the results is obtained also in the areas that are relatively close to the boundary values of the external load. Furthermore, a higher total number of active rolling elements in the bearing increases the accuracy and width of high-accuracy zones.

The calculation results for the boundary loads are highlighted in bold. Until the first bold load, the inner bearing ring will support according to

support systems 1–2 [

4,

13]. At higher loads, the third rolling element engages the ring of the bearing and becomes active. The next bold column corresponds to the load when the inner ring begins to support four rolling elements, etc.

By analyzing the results shown in the pictures (

Figure 2,

Figure 3,

Figure 4,

Figure 5,

Figure 6,

Figure 7,

Figure 8,

Figure 9,

Figure 10,

Figure 11,

Figure 12,

Figure 13,

Figure 14,

Figure 15,

Figure 16 and

Figure 17), it can be concluded that a much greater precision of results can be acquired by the proper selection of load factors that will give the best accuracy for a given bearing and applied external load. In doing so, it is good to keep the following recommendations and conclusions:

The calculation provides the most accurate results in areas that are close to the boundary values of external load;

For relatively low loads, which are expected to cause support on the maximum of three active rolling elements, the best results are obtained by calculation using the coefficient kmax3;

For support on the maximum possible number of active rolling elements (zs), the best results are obtained using the coefficient corresponding to that number (kmaxzs).