Effect of Two Graphene Coatings on the Friction and Wear of Sliding Electrical Contact Interface

Abstract

1. Introduction

2. Tests Details

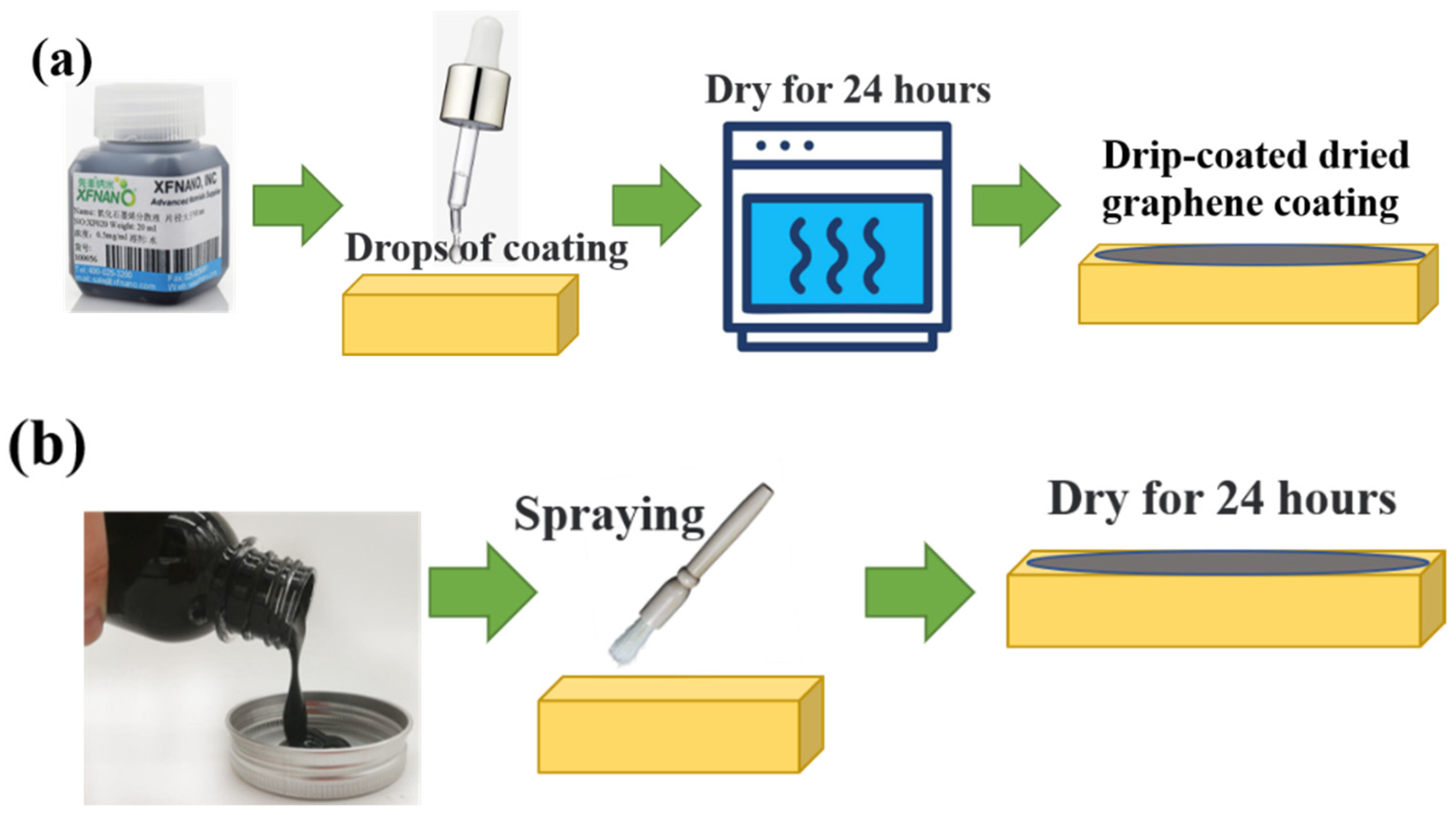

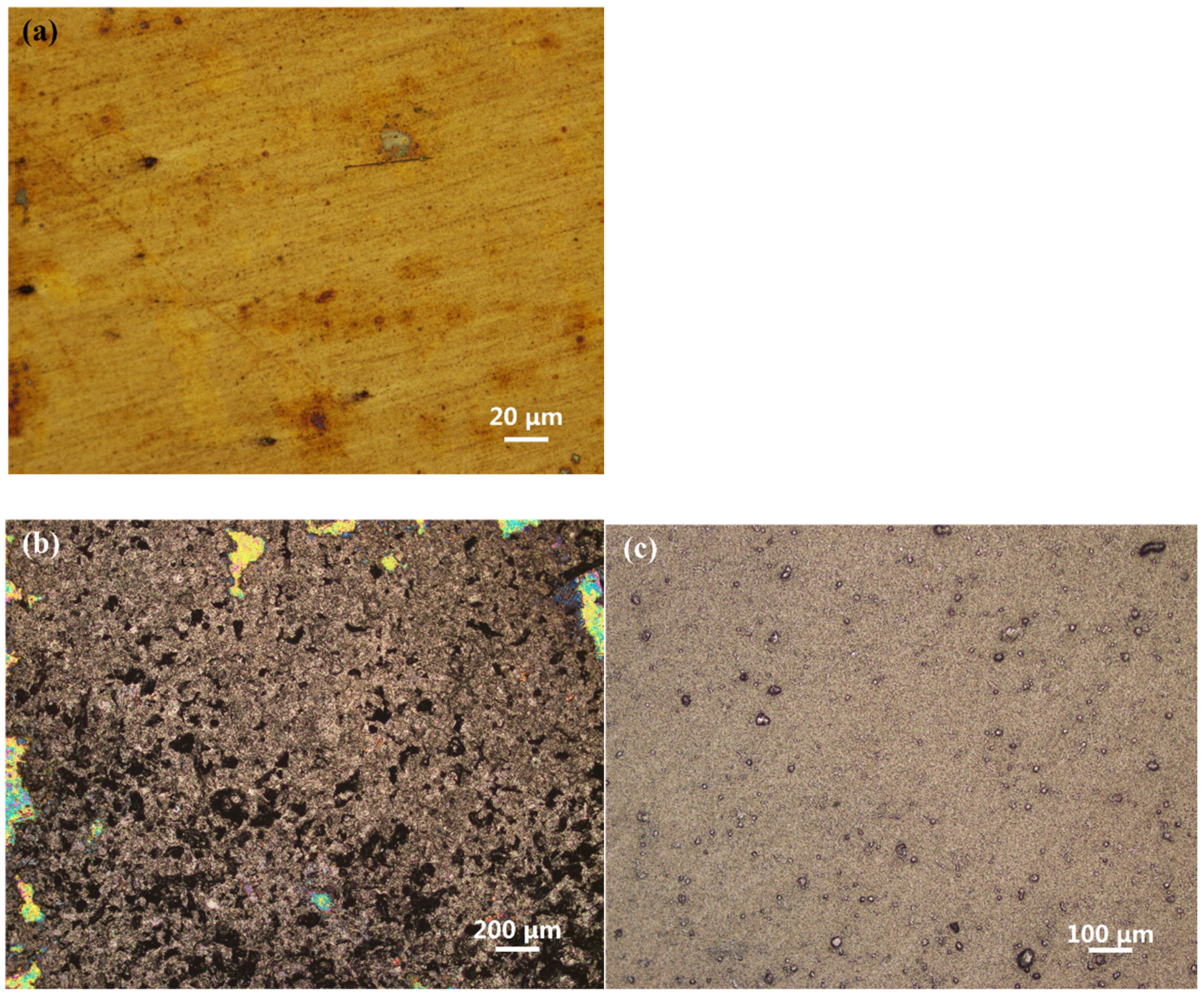

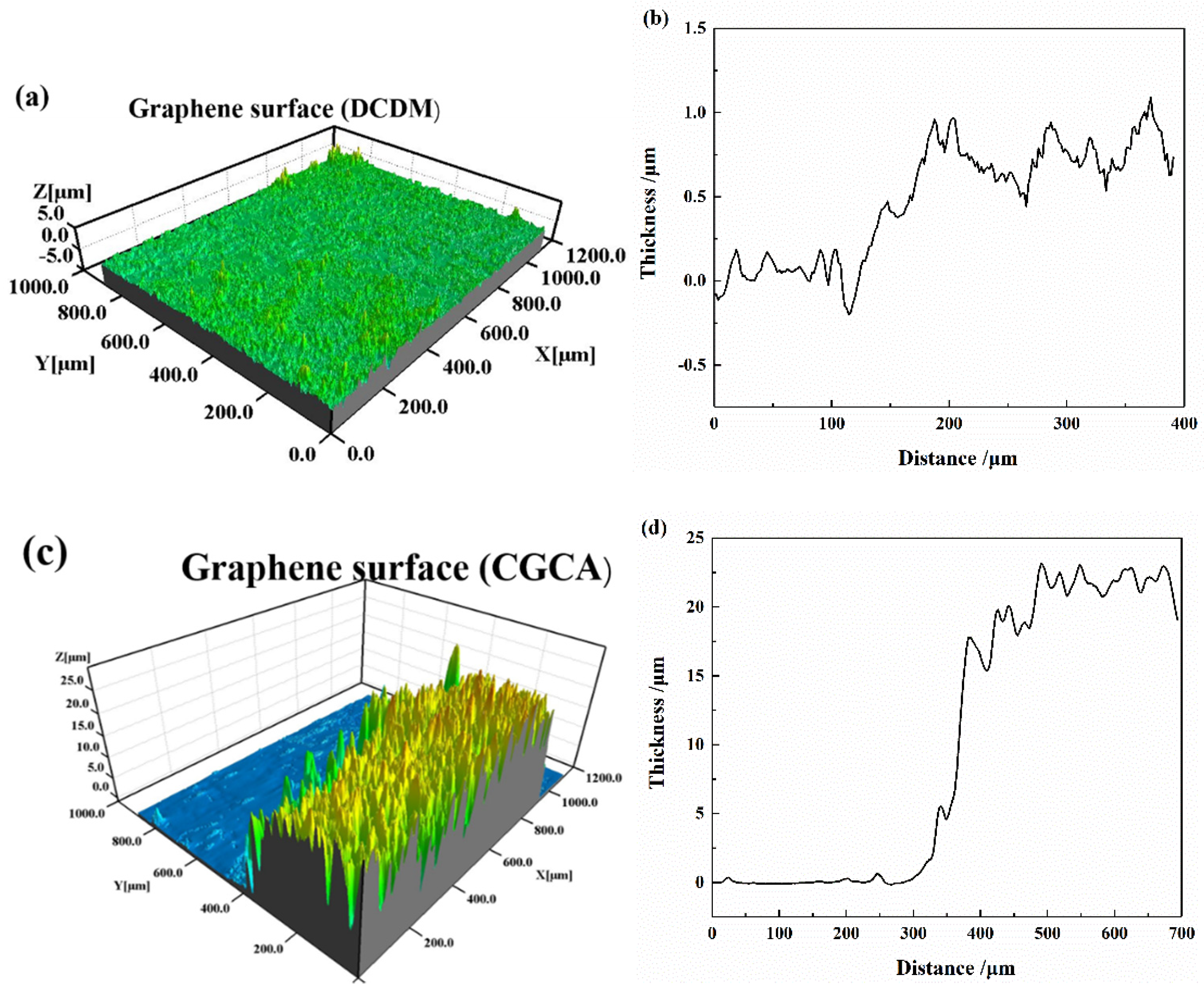

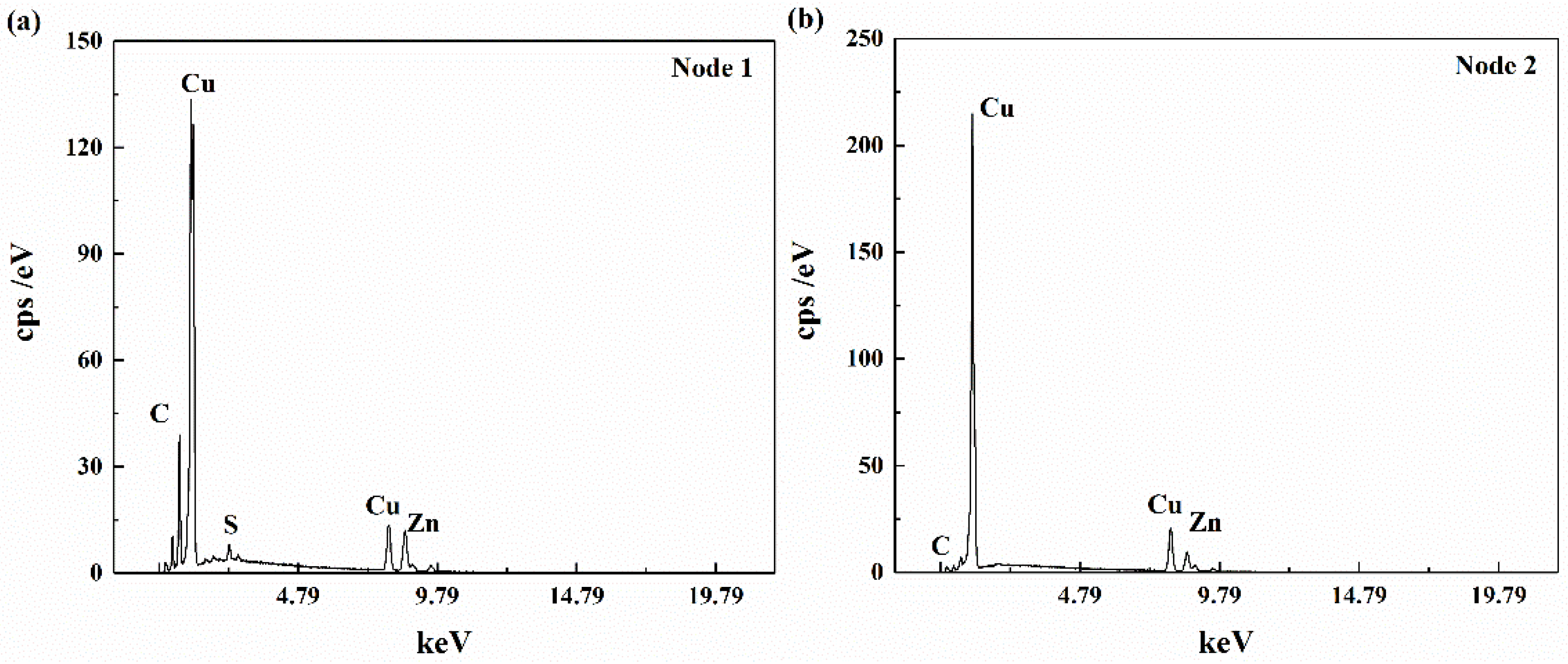

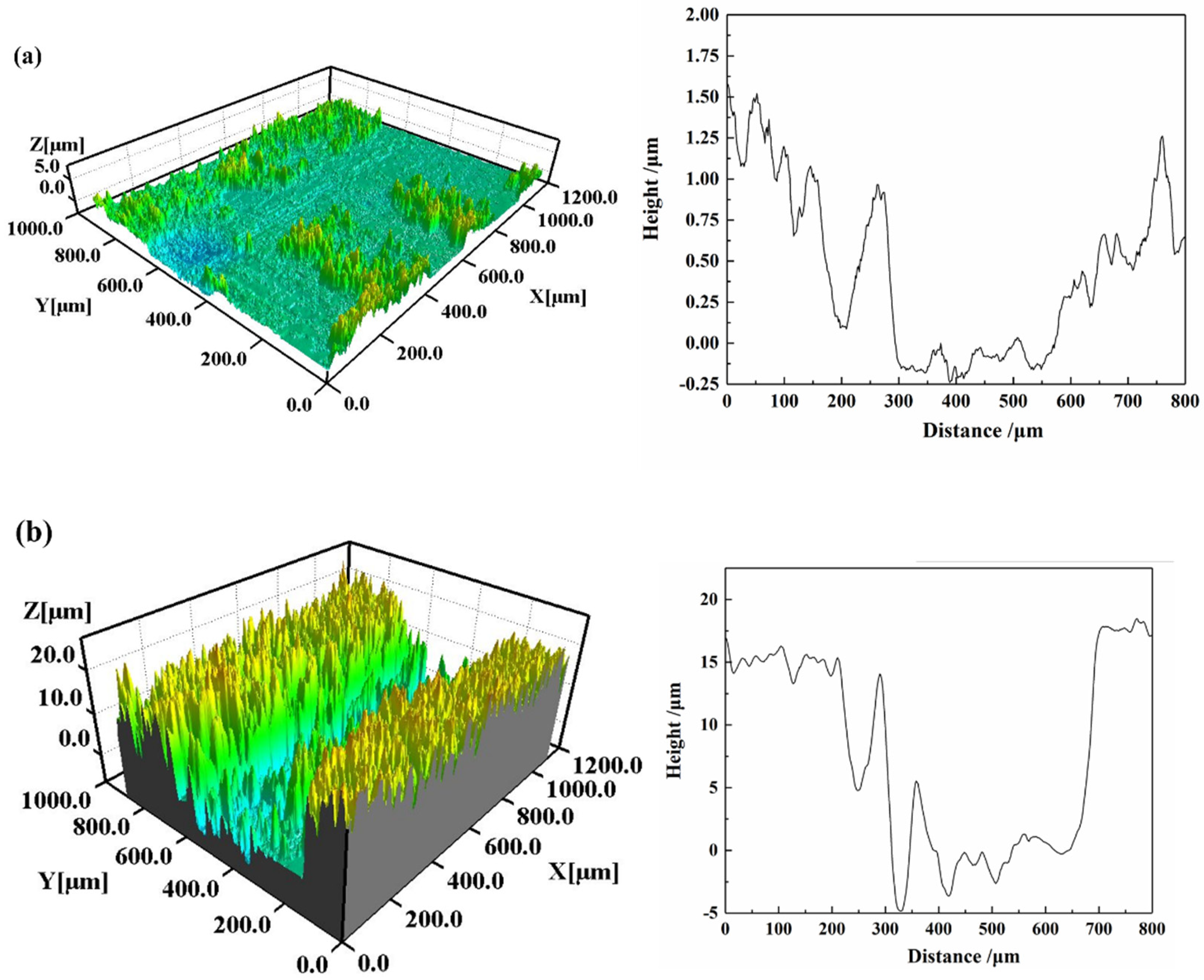

2.1. Preparation of Test Materials

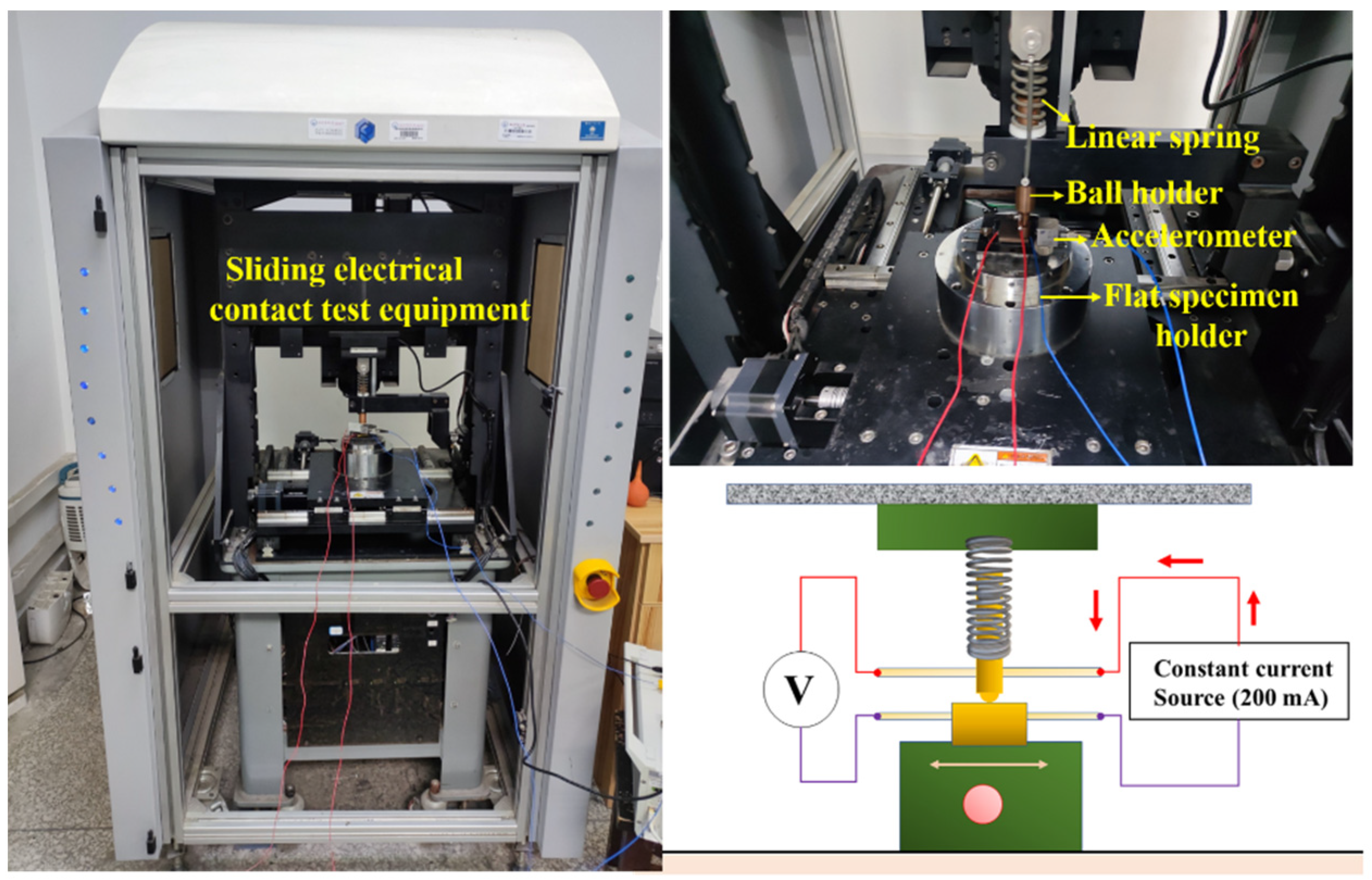

2.2. Test Setup

3. Test Results and Discussion

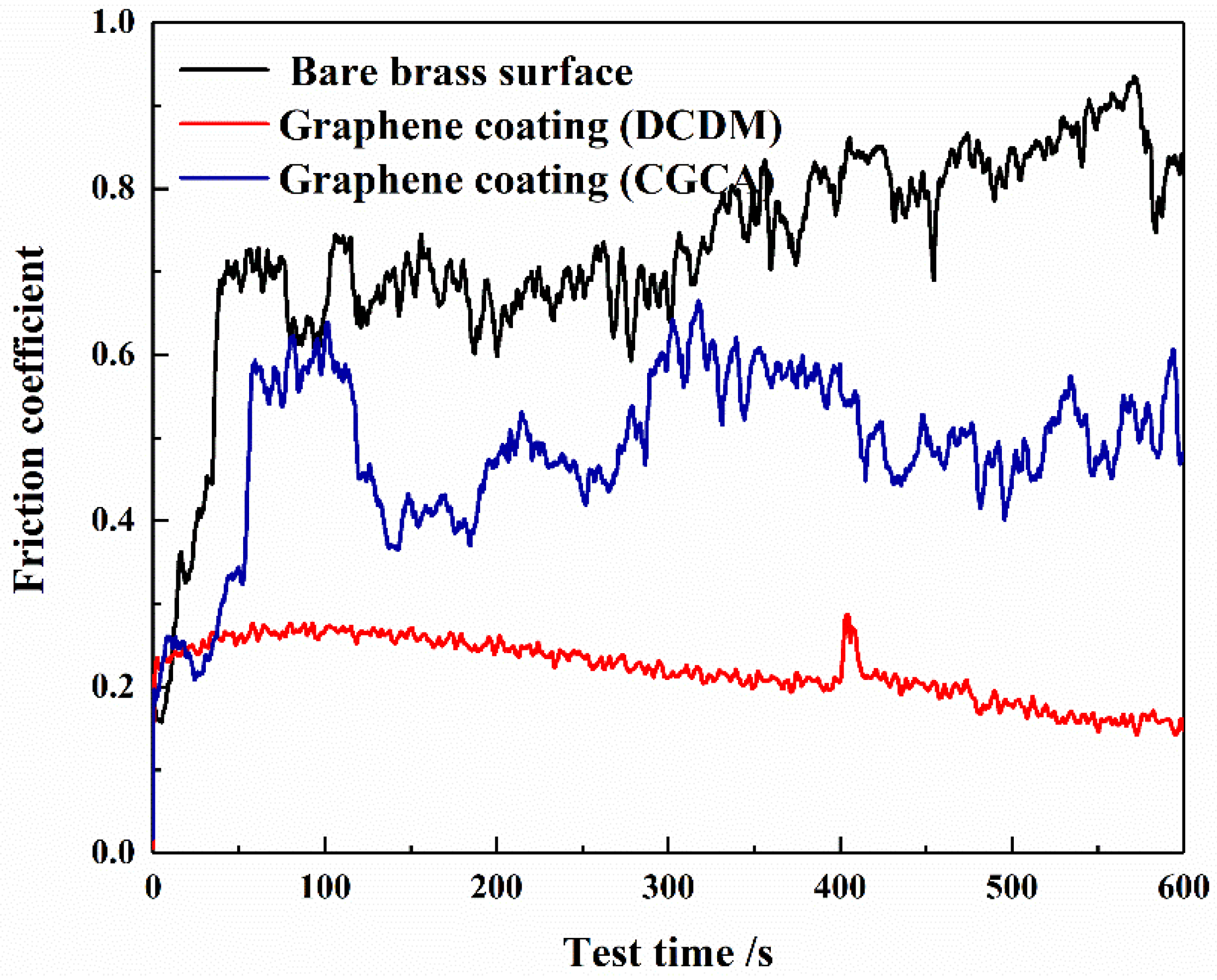

3.1. Analysis of Friction Coefficient

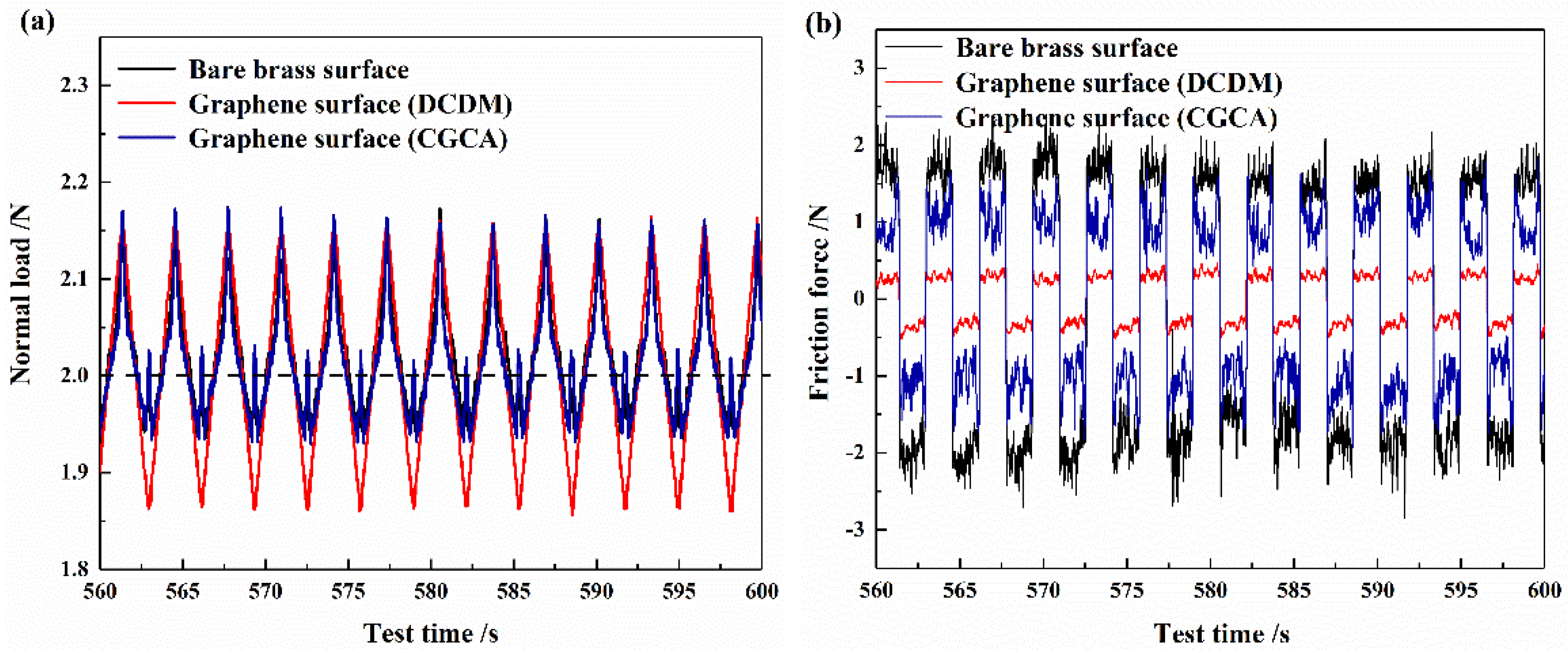

3.2. Contact Force Analysis

3.3. Analysis of Contact Voltage

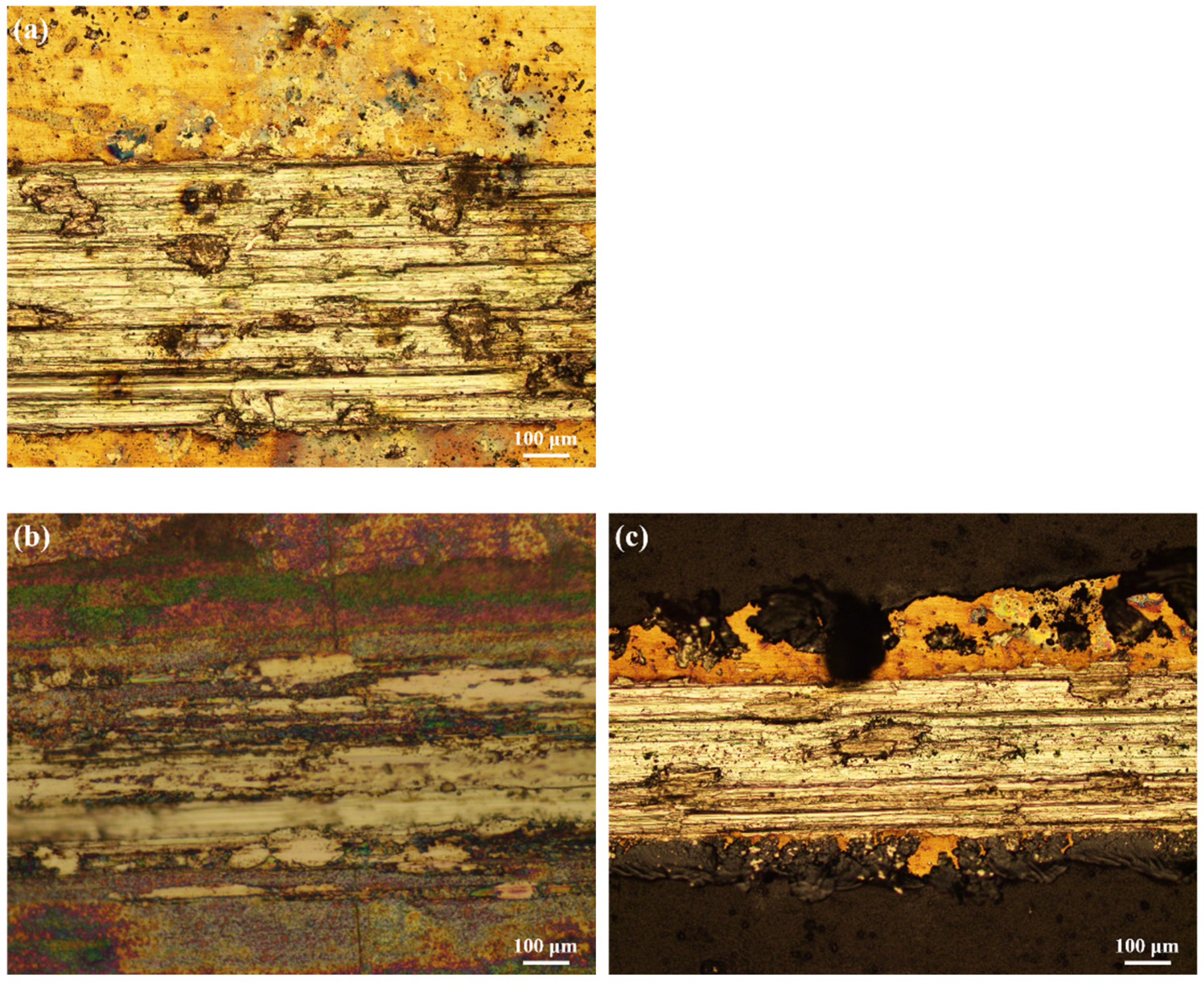

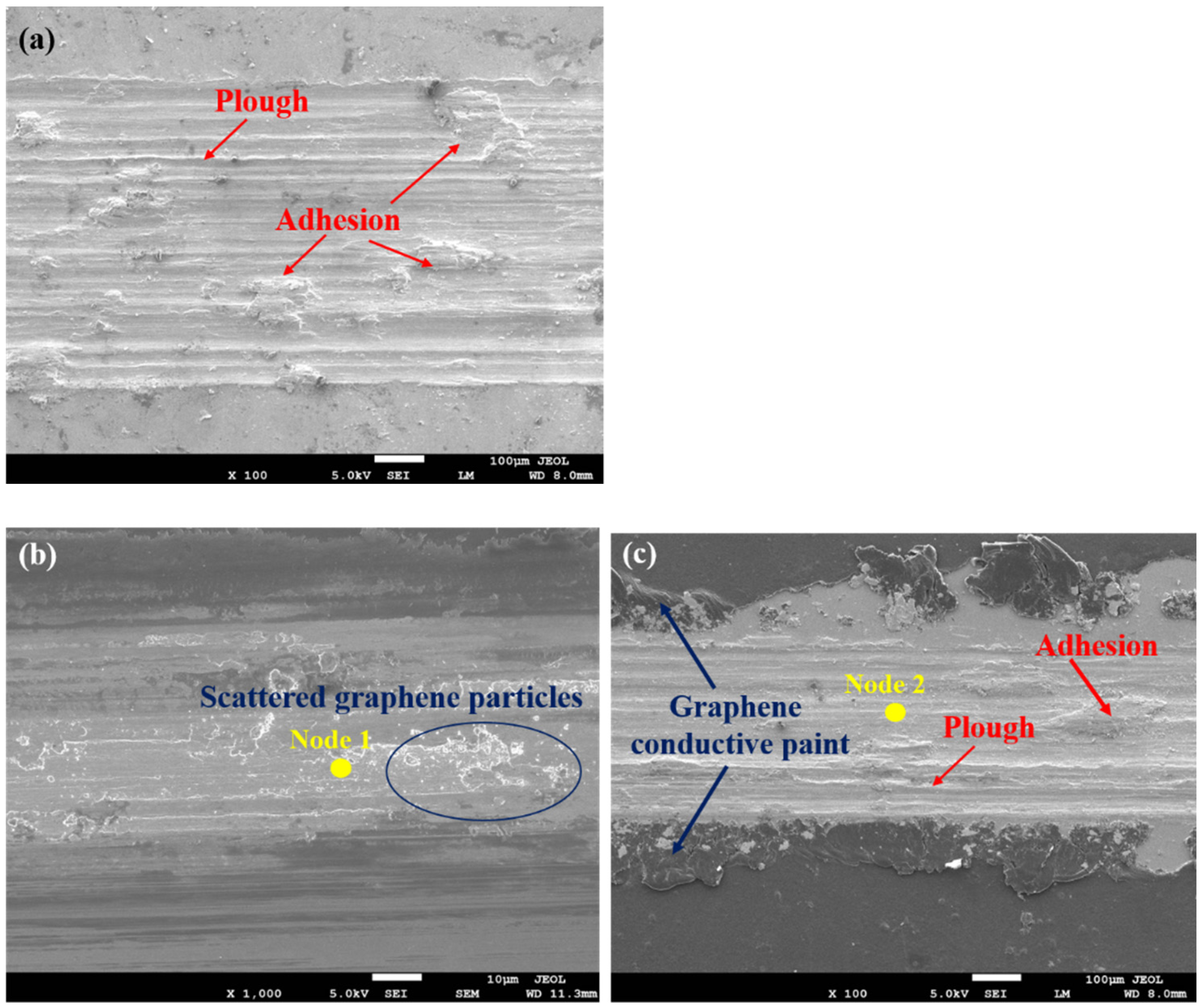

3.4. Wear Morphology Analysis

4. Numerical Analysis and Discussion

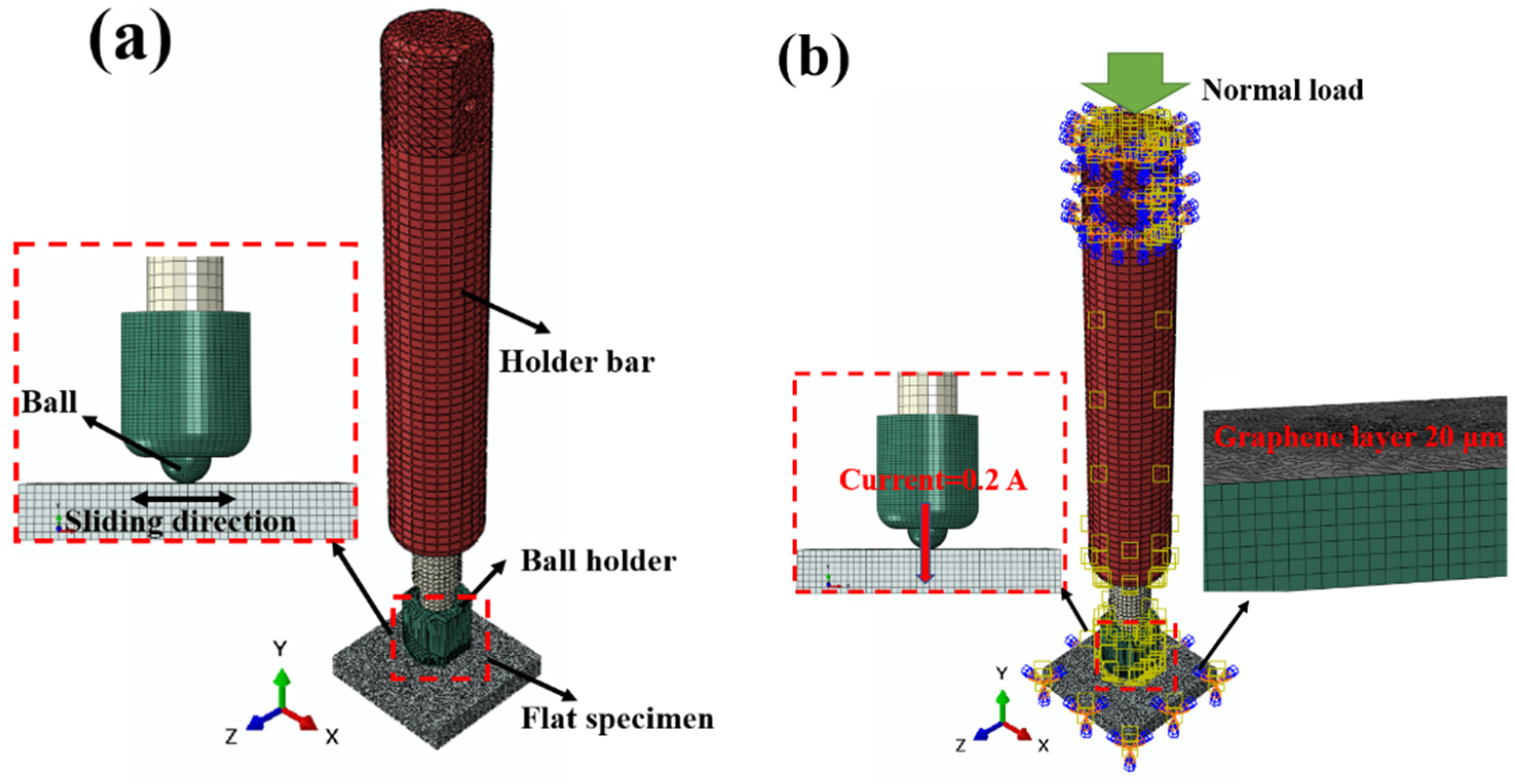

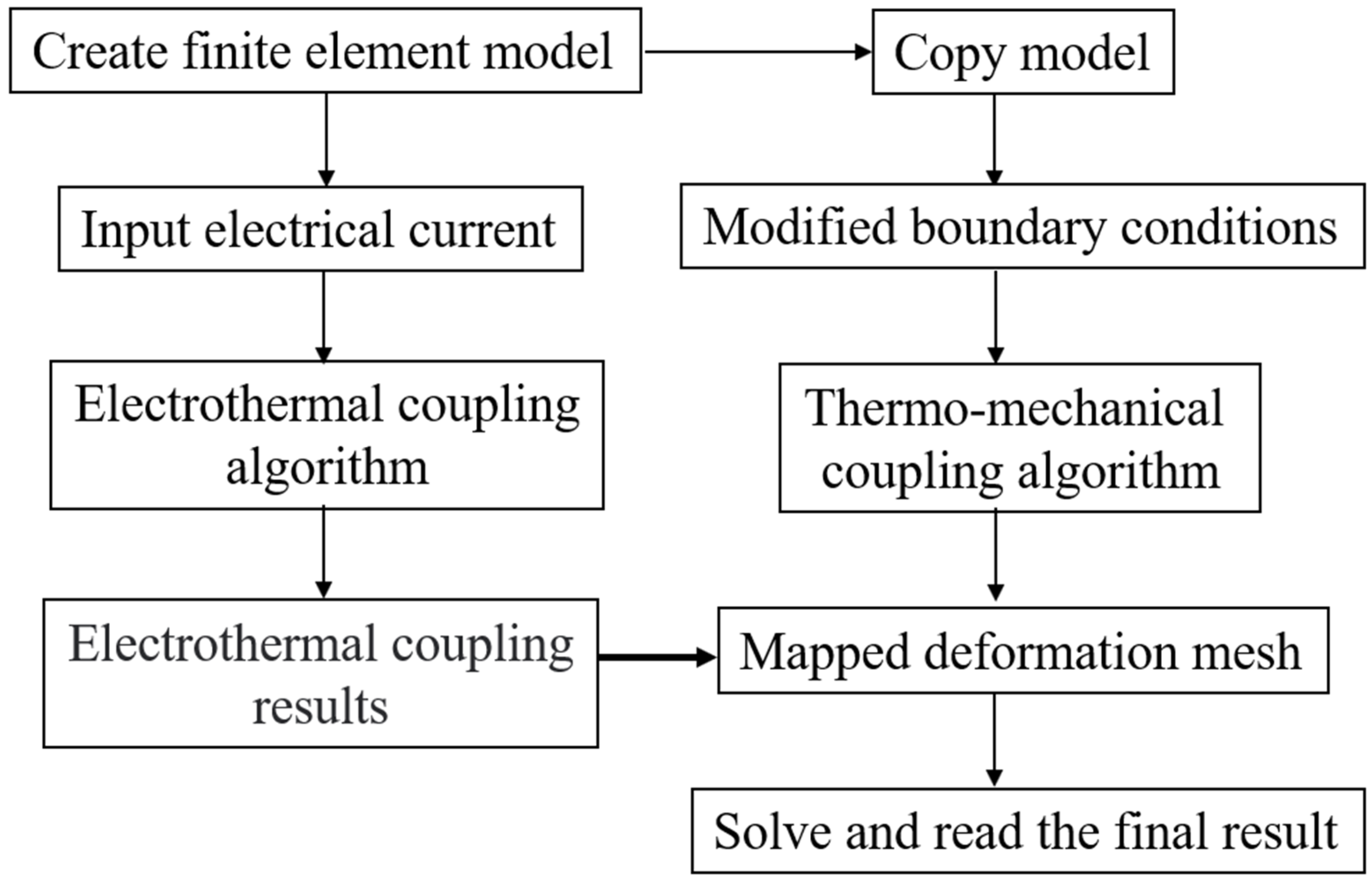

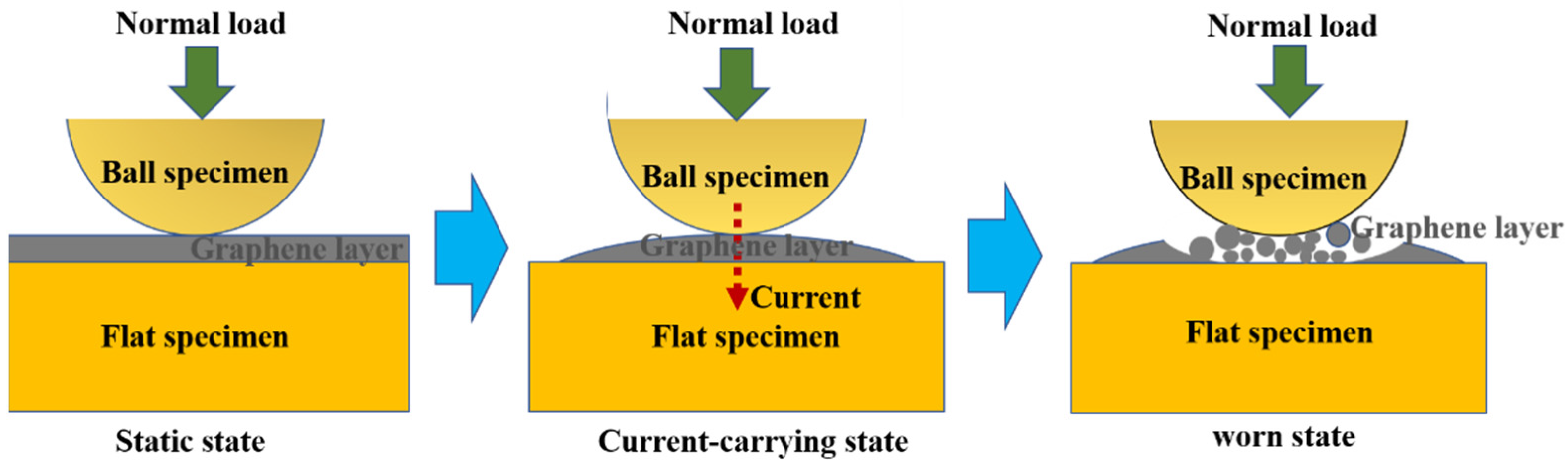

4.1. Finite Element Model and Electric–Thermal–Mechanical Sequential Coupling Analysis

4.2. Electric–Thermal–Mechanical Coupling Analysis

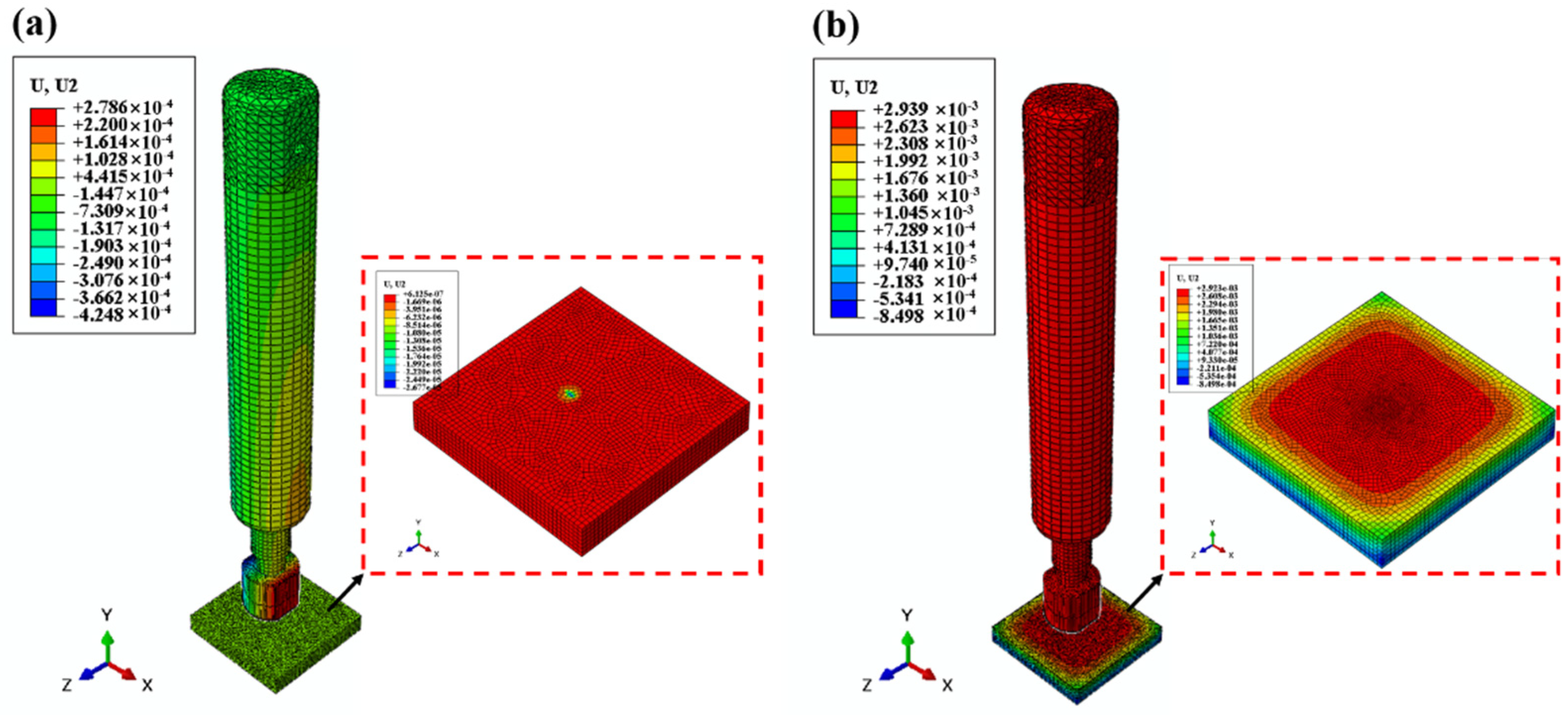

4.2.1. Contact Displacement Analysis

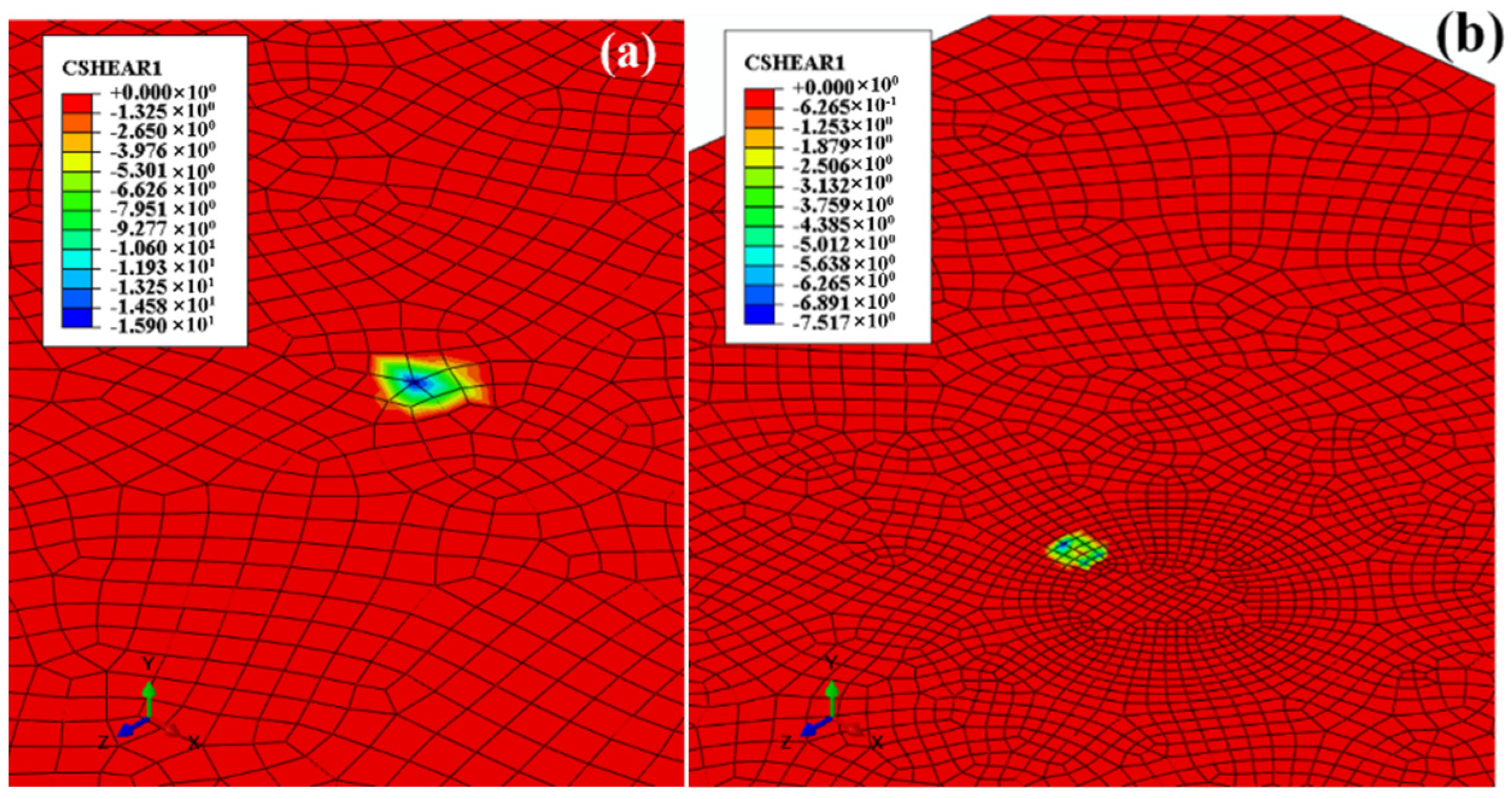

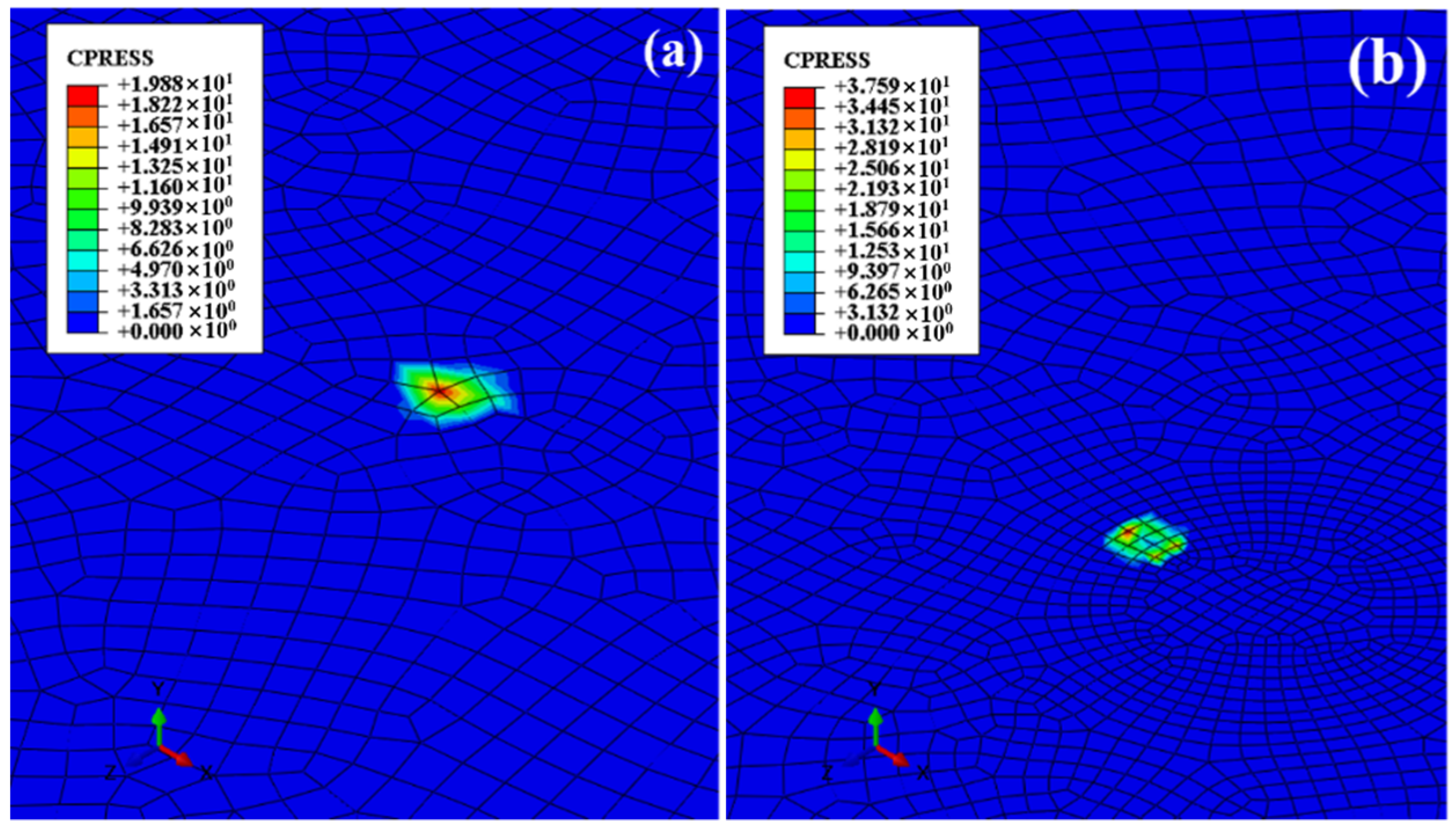

4.2.2. Contact Stress Analysis

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Han, C.; Park, S.; Lee, H. Intermittent failure in electrical interconnection of avionics system. Reliab. Eng. Syst. Saf. 2018, 185, 61–71. [Google Scholar] [CrossRef]

- Kloch, K.T.; Kozak, P.; Mlyniec, A. A review and perspectives on predicting the performance and durability of electrical contacts in automotive applications. Eng. Fail. Anal. 2021, 121, 105143. [Google Scholar] [CrossRef]

- Cao, Z.F.; Xia, Y.Q.; Chen, C.; Zheng, K.; Zhang, Y. A synergetic strategy based on laser surface texturing and lubricating grease for improving the tribological and electrical properties of Ag coating under current-carrying friction. Friction 2021, 9, 978–989. [Google Scholar] [CrossRef]

- Kong, Z.; Swingler, J. Combined effects of fretting and pollutant particles on the contact resistance of the electrical con-nectors. Prog. Nat. Sci. Mater. Int. 2017, 27, 385–390. [Google Scholar] [CrossRef]

- Bouchoucha, A.; Chekroud, S.; Paulmier, D. Influence of the electrical sliding speed on friction and wear processes in an electrical contact copper–stainless steel. Appl. Surf. Sci. 2004, 223, 330–342. [Google Scholar] [CrossRef]

- Antler, M. Survey of Contact Fretting in Electrical Connectors. IEEE Trans. Compon. Hybrids Manuf. Technol. 1985, 8, 87–104. [Google Scholar] [CrossRef]

- Sun, Y.; Song, C.; Liu, Z.; Li, J.W.; Sun, Y.M.; Shangguan, B.; Zhang, Y.Z. Effect of relative humidity on the tribological/conductive properties of Cu/Cu rolling contact pairs. Wear 2019, 436, 203023. [Google Scholar] [CrossRef]

- Beake, B.D.; Harris, A.J.; Liskiewicz, T.W.; Wagner, J.; McMasterd, S.J.; Goodes, S.R.; Neville, A.; Zhang, L. Friction and electrical contact resistance in reciprocating nano-scale wear testing of metallic materials. Wear 2021, 474, 203866. [Google Scholar] [CrossRef]

- Cao, Z.; Xia, Y.; Liu, L.; Feng, X. Study on the conductive and tribological properties of copper sliding electrical contacts lubricated by ionic liquids. Tribol. Int. 2018, 130, 27–35. [Google Scholar] [CrossRef]

- Poljanec, D.; Kalin, M.; Kumar, L. Influence of contact parameters on the tribological behaviour of various graphite/graphite sliding electrical contacts. Wear 2018, 406, 75–83. [Google Scholar] [CrossRef]

- Zhao, H.; Feng, Y.; Zhou, Z.; Qian, G.; Zhang, J.C.; Huang, X.C.; Zhang, X.B. Effect of electrical current density, apparent contact pressure, and sliding velocity on the electrical sliding wear behavior of Cu-Ti3AlC2 composites. Wear 2020, 444, 203156. [Google Scholar] [CrossRef]

- Wang, Y.A.; Li, J.X.; Yan, Y.; Qiao, L.J. Effect of electrical current on tribological behavior of copper-impregnated metallized carbon against a Cu-Cr-Zr alloy. Tribol. Int. 2012, 50, 26–34. [Google Scholar] [CrossRef]

- Ghosh, S.; Calizo, I.; Teweldebrhan, D.; Pokatilov, E.P.; Nika, D.L.; Balandin, A.A.; Bao, W.; Miao, F.; Lau, C.N. Extremely high thermal conductivity of graphene: Prospects for thermal management applications in nanoelectronic circuits. Appl. Phys. Lett. 2008, 92, 151911. [Google Scholar] [CrossRef]

- Zhang, L.; Zhang, F.; Yang, X.; Long, G.K.; Wu, Y.P.; Zhang, T.F.; Leng, K.; Huang, Y.; Ma, Y.F.; Yu, A.; et al. Porous 3D graphene-based bulk materials with exceptional high surface area and excellent conductivity for super capacitors. Sci. Rep. 2013, 3, 1408. [Google Scholar] [CrossRef] [PubMed]

- Simon, P.; Gogotsi, Y. Capacitive Energy Storage in Nanostructured Carbon–Electrolyte Systems. Accounts Chem. Res. 2012, 46, 1094–1103. [Google Scholar] [CrossRef]

- Berman, D.; Erdemir, A.; Sumant, A.V. Graphene as a protective coating and superior lubricant for electrical contacts. Appl. Phys. Lett. 2014, 105, 231907. [Google Scholar] [CrossRef]

- Berman, D.; Erdemir, A.; Sumant, A.V. Reduced wear and friction enabled by graphene layers on sliding steel surfaces in dry nitrogen. Carbon 2013, 59, 167–175. [Google Scholar] [CrossRef]

- Mao, F.; Wiklund, U.; Andersson, A.M.; Jansson, U. Graphene as a lubricant on Ag for electrical contact applications. J. Mater. Sci. 2015, 50, 6518–6525. [Google Scholar] [CrossRef]

- Mao, J.; Chen, G.; Zhao, J.; He, Y.; Luo, J. An investigation on the tribological behaviors of steel/copper and steel/steel friction pairs via lubrication with a graphene additive. Friction 2020, 9, 228–238. [Google Scholar] [CrossRef]

- Sahoo, S.K.; Mallik, A. Fundamentals of fascinating graphene nanosheets: A comprehensive study. Nano 2019, 14, 1930003. [Google Scholar] [CrossRef]

- Restuccia, P.; Righi, M.C. Tribochemistry of graphene on iron and its possible role in lubrication of steel. Carbon 2016, 106, 118–124. [Google Scholar] [CrossRef]

- Saini, V.; Seth, S.; Ramakumar, S.S.V.; Bijwe, J. Carbon Nanoparticles of Varying Shapes as Additives in Mineral Oil Assessment of Comparative Performance Potential. ACS Appl. Mater. Interfaces 2021, 13, 38844–38856. [Google Scholar] [CrossRef] [PubMed]

- Georgantzinos, S.K.; Giannopoulos, G.I.; Anifantis, N.K. Numerical investigation of elastic mechanical properties of gra-phene structures. Mater. Des. 2010, 31, 4646–4654. [Google Scholar] [CrossRef]

- Chandra, Y.; Adhikari, S.; Flores, E.S.; Figiel, L. Advances in finite element modelling of graphene and associated nanostructures. Mater. Sci. Eng. R: Rep. 2020, 140, 100544. [Google Scholar] [CrossRef]

| Parameters | — | — |

|---|---|---|

| Material Name | Brass | Graphene layer |

| Elasticity modulus /MPa | 112,000 | 1,100,000 |

| Poisson’s ratio | 0.3 | 0.4 |

| Thermal conductivity W/(mm°C) | 0.16 | 5.3 |

| Thermal expansivity /°C−1 | 1.776 × 10−5 | 1 × 10−6 |

| Electrical conduction | 23,200 | 100,000 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, D.; Li, F.; Chen, X.; Li, H.; Chen, W.; Zhang, P. Effect of Two Graphene Coatings on the Friction and Wear of Sliding Electrical Contact Interface. Lubricants 2022, 10, 305. https://doi.org/10.3390/lubricants10110305

Wang D, Li F, Chen X, Li H, Chen W, Zhang P. Effect of Two Graphene Coatings on the Friction and Wear of Sliding Electrical Contact Interface. Lubricants. 2022; 10(11):305. https://doi.org/10.3390/lubricants10110305

Chicago/Turabian StyleWang, Dongwei, Faqiang Li, Xiao Chen, Huaqiao Li, Wei Chen, and Peng Zhang. 2022. "Effect of Two Graphene Coatings on the Friction and Wear of Sliding Electrical Contact Interface" Lubricants 10, no. 11: 305. https://doi.org/10.3390/lubricants10110305

APA StyleWang, D., Li, F., Chen, X., Li, H., Chen, W., & Zhang, P. (2022). Effect of Two Graphene Coatings on the Friction and Wear of Sliding Electrical Contact Interface. Lubricants, 10(11), 305. https://doi.org/10.3390/lubricants10110305