The Partial Derivative Method for Dynamic Stiffness and Damping Coefficients of Supercritical CO2 Foil Bearings

Abstract

1. Introduction

2. Mathematics for Dynamic Coefficients of Supercritical CO2 Foil Bearings

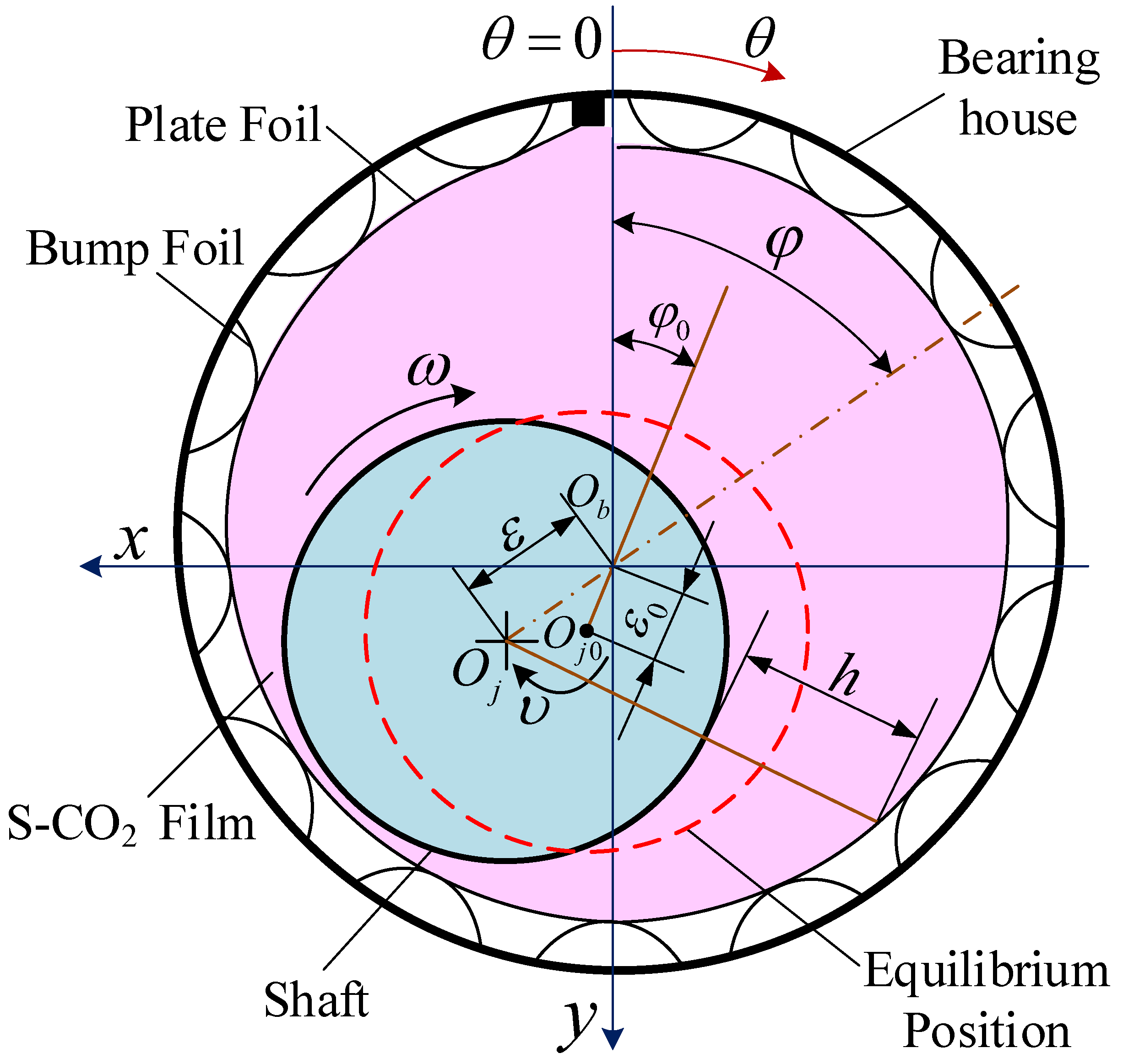

2.1. Supercritical CO2 Lubricated Foil Bearing

2.1.1. The Compressible Turbulence Reynolds Equation and Its Boundary Conditions

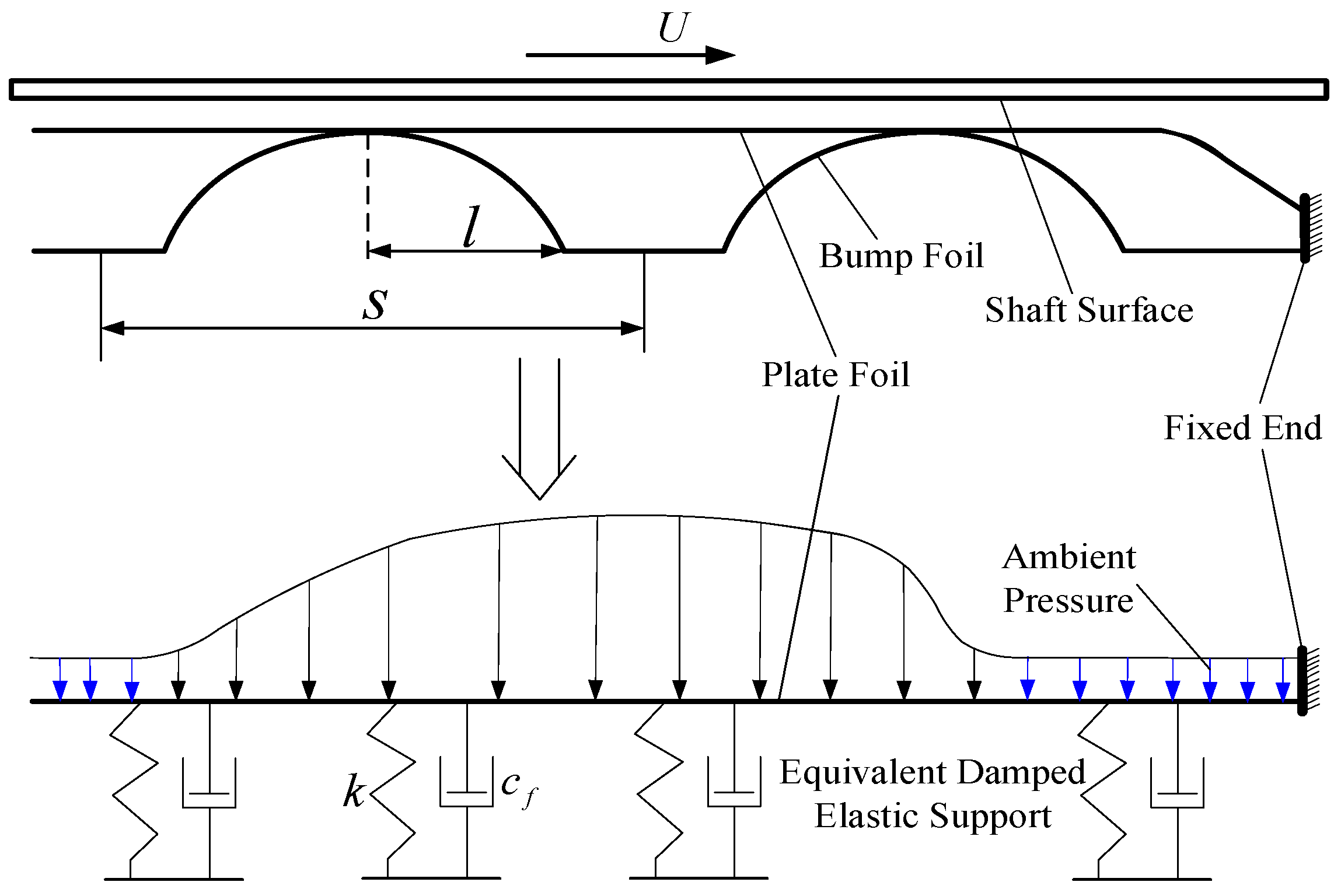

2.1.2. The Damped Elastic Support Comprehensive Dynamic Model for Foil System

2.2. The Structural Perturbation Theory of Foil Bearings

2.2.1. The Relation between the Perturbation of Foil Displacement and Perturbed Pressure

2.2.2. The Partial Differential Equations for Complex Perturbed Pressure

3. Numerical Results and Discussion

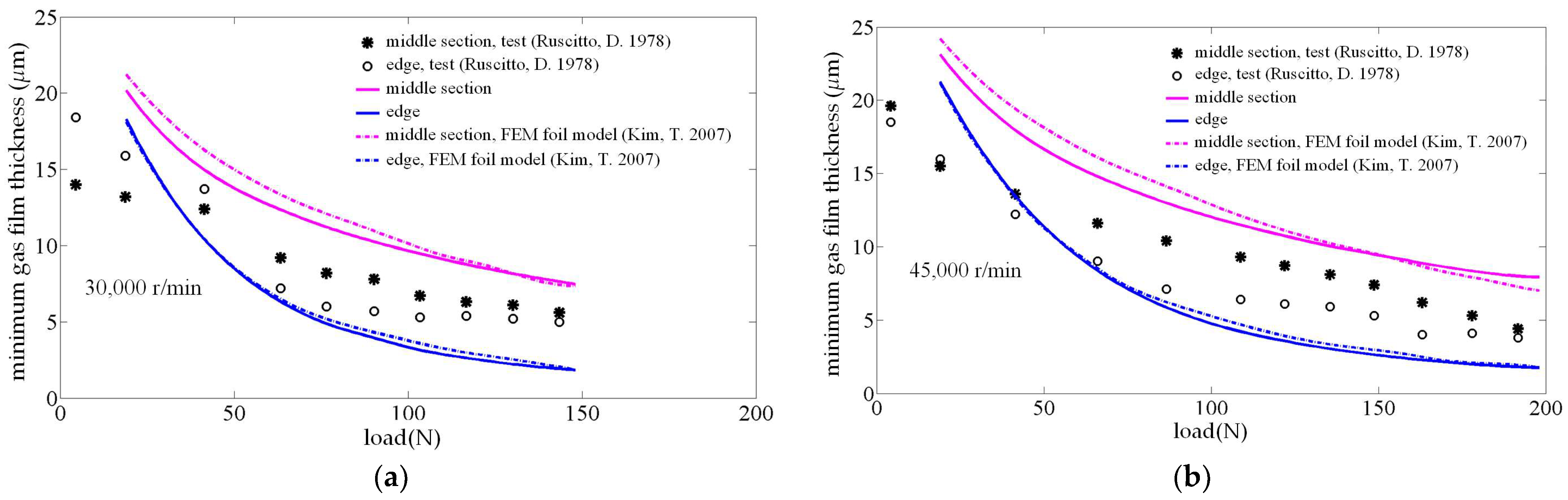

3.1. Program Verification

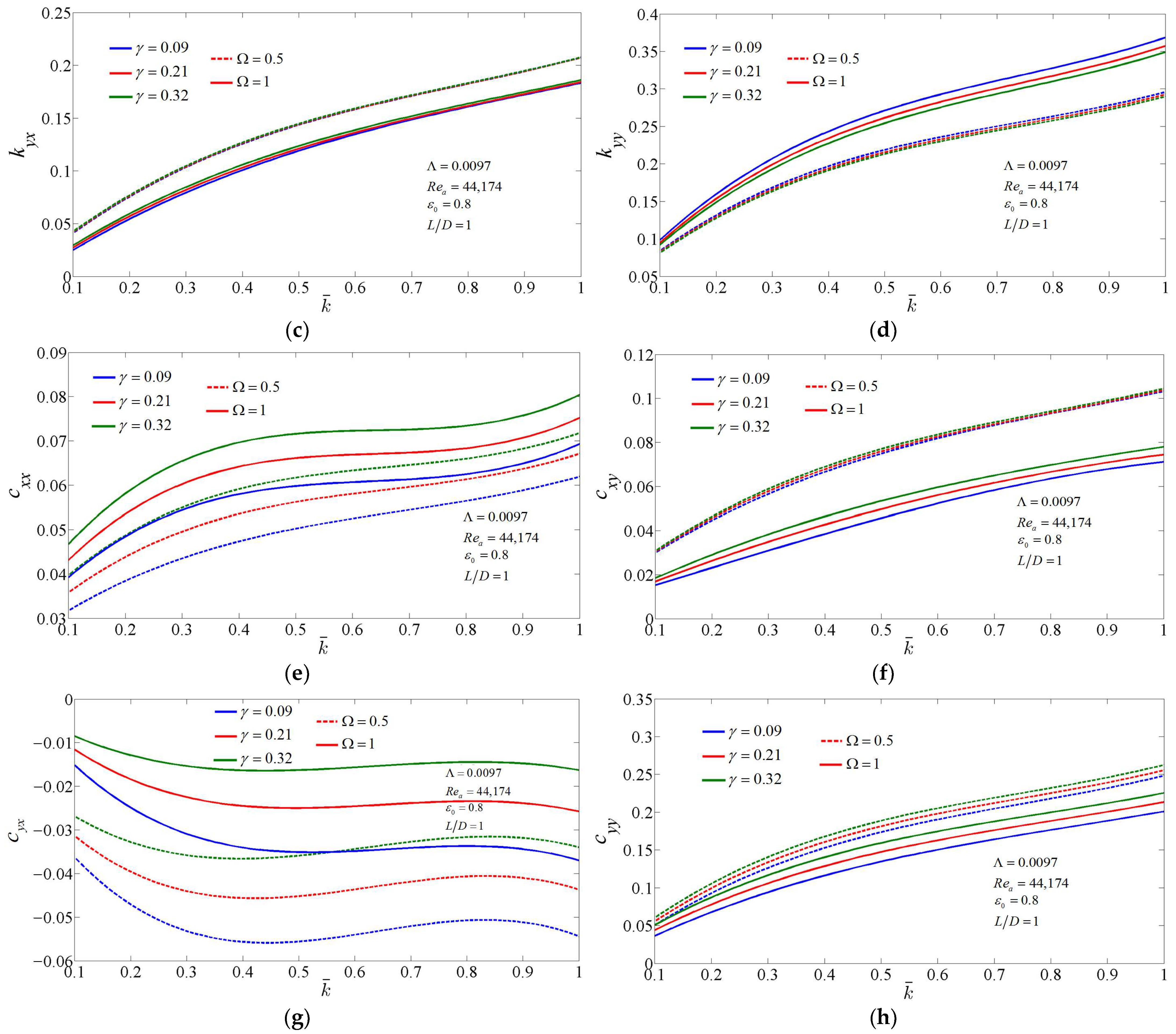

3.2. The Influence of Structural Loss Factor on the Dynamic Coefficients of Supercritical CO2 Foil Bearing

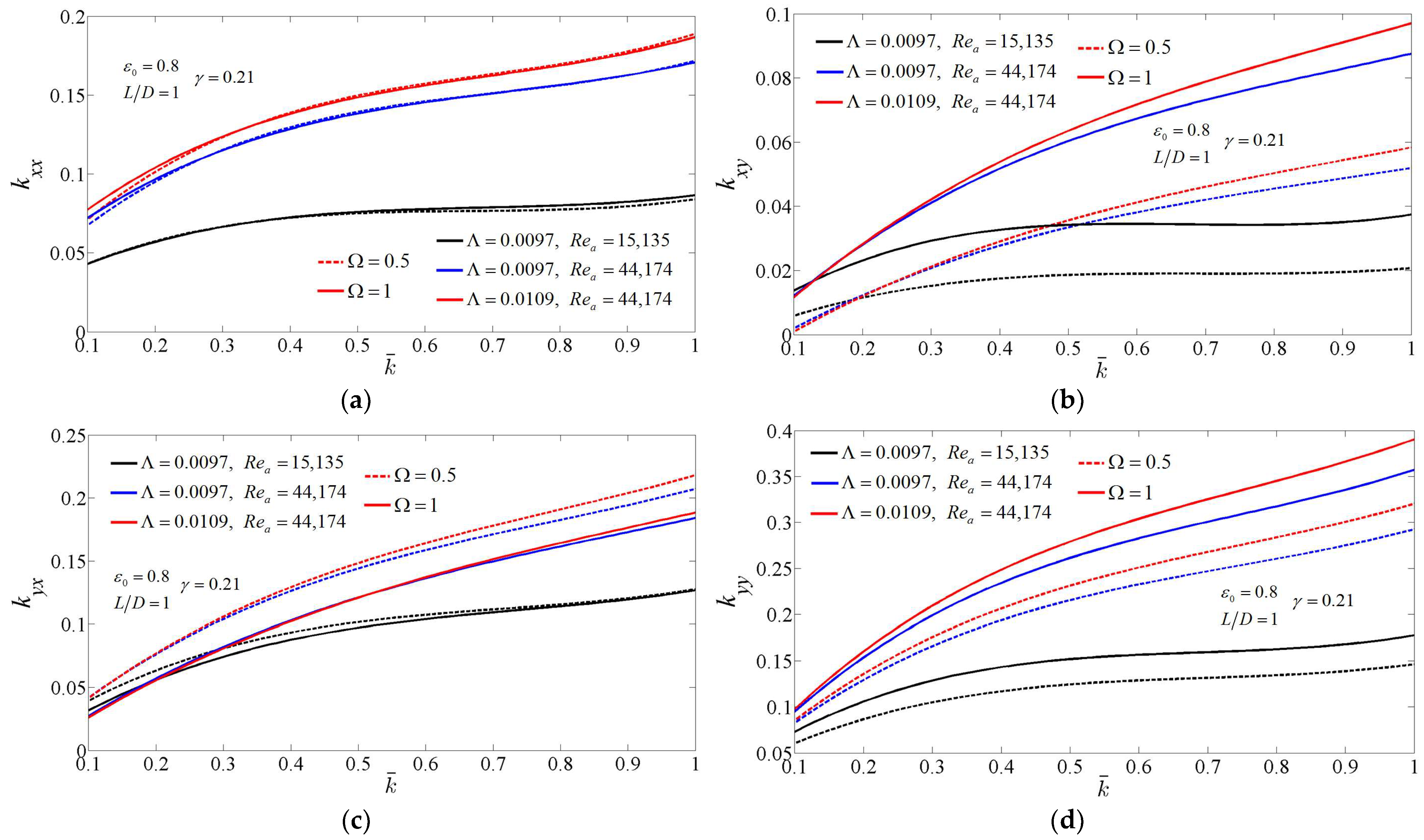

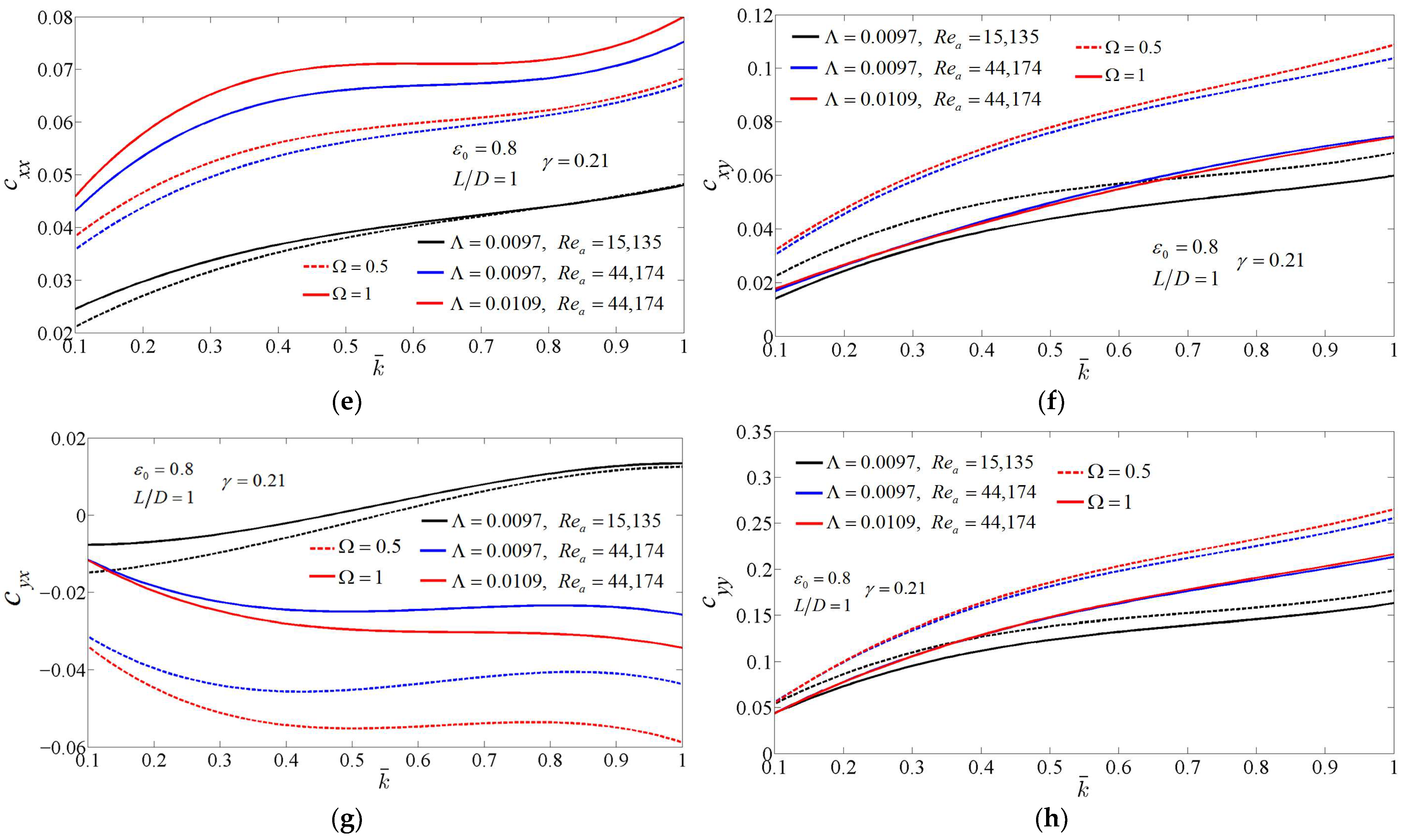

3.3. The Influence of Bearing Number and Average Reynolds Number on the Dynamic Coefficients of Supercritical CO2 Foil Bearing

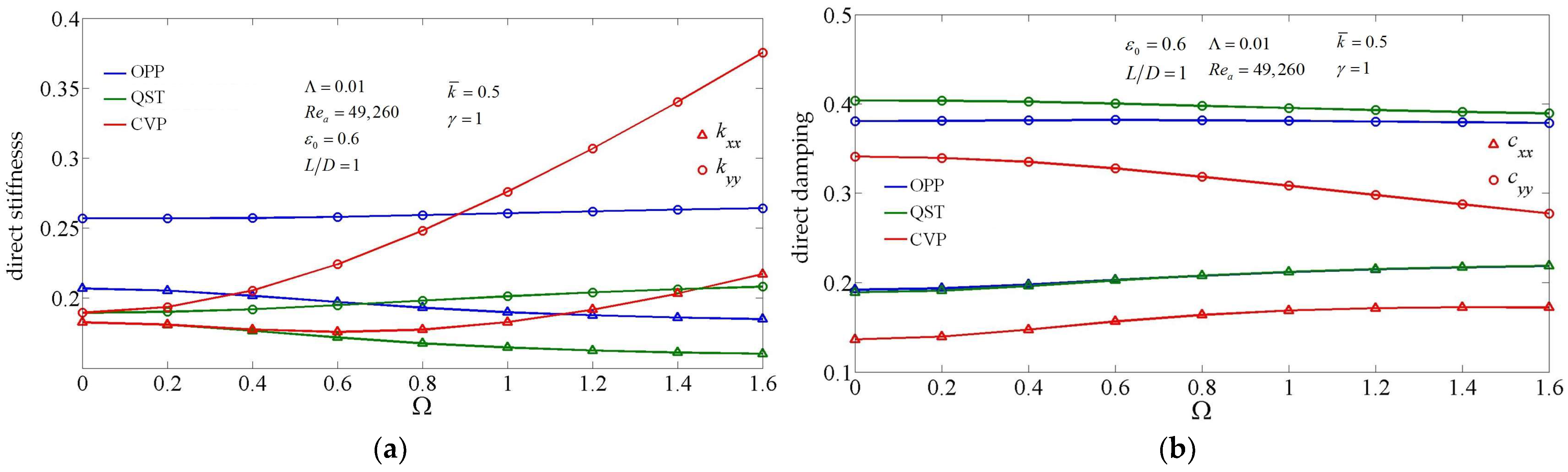

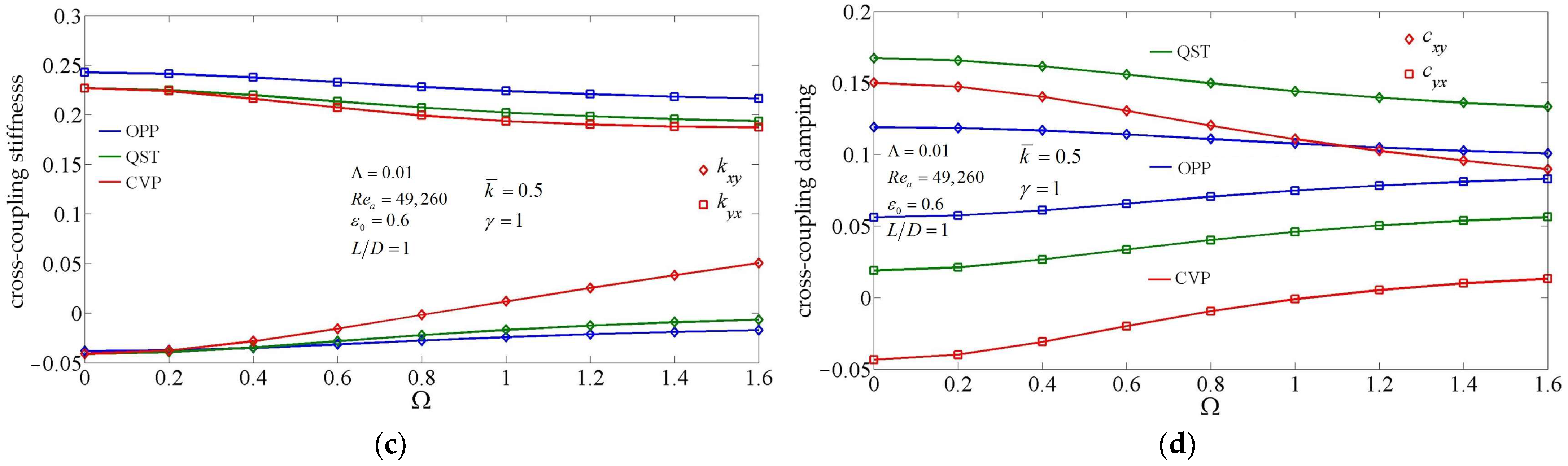

3.4. The Influence of Compressibility of Supercritical CO2 on the Dynamic Coefficients

4. Conclusions

- The results of minimum film thickness of an air foil bearing were calculated by the program of the method of this research (through a simple change) and compared with the test and calculation data in the literature. It is verified that the two-dimensional uniform spring model for support stiffness is reasonable for foil bearings.

- The partial derivative method is able to take into account the influence of structural loss factor as well as perturbation frequency on the dynamic coefficients of foil bearings. The structural loss factor has influence on the stiffness coefficients as well as the damping coefficients. Thus, for compressible lubricated bearings, the static stiffness and damping coefficients (obtained under perturbation frequency infinitely close to zero) are not the dynamic coefficients required for rotor dynamics analysis. The structural loss factor has little influence on the trend of dynamic coefficients changing with the dimensionless support stiffness, but mainly affects their value.

- Due to the turbulence effect, the bearing number is not able to directly determine the characteristics of supercritical CO2 foil bearings, which is different from air bearings. For the same average Reynolds number, the trends of stiffness and damping coefficients changing with the dimensionless support stiffness are similar, and the bearing number only affects the value of dynamic coefficients. The average Reynolds number not only affects the values of the dynamic coefficients but also has influence on their variations with the dimensionless support stiffness.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| θ | circumferential angular coordinate |

| ε | eccentricity ratio |

| attitude angle | |

| Oj | shaft center |

| Ob | bearing center |

| h | film thickness |

| ω | rotational circular frequency |

| υ | shaft perturbation circular frequency |

| Ω | dimensionless perturbation frequency |

| t | time |

| ρ | density |

| μ | viscosity |

| p | pressure |

| λ | dimensionless axial coordinate |

| Λ | bearing number |

| Gx, Gz | turbulence coefficients |

| α1, β1, α2, β2 | constants in the turbulence coefficients |

| wt | displacement of plate foil |

| k | support stiffness |

| cf | structure damping |

| γ | structural loss factor |

| R | bearing radius |

| L | bearing length |

| C0 | radius clearance |

| Pε, Pφ | complex perturbed pressure |

| Subscripts | |

| 0 | static variables |

| d | perturbations |

| a | ambient parameters |

| Headers | |

| - | dimensionless variables |

| ~ | complex amplitude of frequency perturbation |

| Abbreviations | |

| CVP | complete variables perturbations |

| QST | quasi-static treatment |

| OPP | only perturbed pressure |

References

- Kimball, K.; Clementoni, E. Supercritical carbon dioxide Brayton power cycle development overview. In Proceedings of the ASME Turbo Expo 2012: Turbine Technical Conference and Exposition, Copenhagen, Denmark, 11–15 June 2012. [Google Scholar]

- Betti, A.; Forte, P.; Ciulli, E. Turbulence Effects in Tilting Pad Journal Bearings: A Review. Lubricants 2022, 10, 171. [Google Scholar] [CrossRef]

- Dostal, V.; Hejzlar, P.; Driscoll, M.J. The Supercritical Carbon Dioxide Power Cycle: Comparison to Other Advanced Power Cycles. Nucl. Technol. 2006, 154, 283–301. [Google Scholar] [CrossRef]

- Ertas, B.; Bidkar, R. Apollo High Efficiency sCO2 Centrifugal Compressor Continuation Report, Section 7: Gas Bearing Design and Testing. DOE Contract EE0007109, 16 February 2017.

- Mehdi, S.M.; Kim, T.H. Computational Model Development for Hybrid Tilting Pad Journal Bearings Lubricated with Supercritical Carbon Dioxide. Appl. Sci. 2022, 12, 1320. [Google Scholar] [CrossRef]

- Thatte, A.; Loghin, A.; Shin, Y.; Ananthasayanam, B. Performance and life characteristics of hybrid gas bearing in a 10 MW supercritical CO2 turbine. In Proceedings of the ASME Turbo Expo 2016: Turbomachinery Technical Conference and Exposition, Seoul, Korea, 13–17 June 2016. [Google Scholar]

- Qin, K.; Jahn, I.H.; Gollan, R.; Jacobs, P. Development of a Computational Tool to Simulate Foil Bearings for Supercritical CO2 Cycles. J. Eng. Gas Turbines Power 2016, 138, 092503. [Google Scholar] [CrossRef]

- Hacks, A.; Schuster, S.; Dohmen, H.J.; Benra, F.-K.; Brillert, D. Turbomachine design for supercritical carbon dioxide within the sCO2-HeRo. eu project. In Proceedings of the ASME Turbo Expo 2018: Turbomachinery Technical Conference and Exposition, Oslo, Norway, 11–15 June 2018. [Google Scholar]

- Wright, S.; Radel, R.; Vernon, M.; Rochau, G.; Pickard, P. Operation and Analysis of a Supercritical CO2 Brayton Cycle; Sandia Report. No. SAND2010-0171; Sandia National Laboratories (SNL): Albuquerque, NM, USA; Livermore, CA, USA, 2010.

- Cho, J.; Shin, H.; Ra, H.S.; Lee, G.; Roh, C.; Lee, B.; Baik, Y.J. Development of the Supercritical Carbon Dioxide Power Cycle Experimental Loop in KIER. In Proceedings of the ASME Turbo Expo 2016: Turbomachinery Technical Conference and Exposition, Seoul, Korea, 13–17 June 2016. [Google Scholar]

- Li, C.; Du, J.; Li, J.; Xu, Z. Investigations on the Frictional Hysteresis Effect of Multi-Leaf Journal Foil Bearing: Modeling, Predictions and Validations. Lubricants 2022, 10, 261. [Google Scholar] [CrossRef]

- Wang, C.; Wang, X.; Hu, Y. Investigation on start-up performance of gas foil bearing considering wear topography evolution of non-Gaussian surface. Tribol. Int. 2023, 177, 108003. [Google Scholar] [CrossRef]

- Bou-Saïd, B.; Lahmar, M.; Mouassa, A.; Bouchehit, B. Dynamic Performances of Foil Bearing Supporting a Jeffcot Flexible Rotor System Using FEM. Lubricants 2020, 8, 14. [Google Scholar] [CrossRef]

- Li, H.; Geng, H.; Wang, B.; Zheng, W. Feasibility investigation of a compressor rotor supported by gas foil bearings with inhomogeneous bump foils. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2022, 236, 174–183. [Google Scholar] [CrossRef]

- Tian, J.; Yang, B.; Feng, S.; Yu, L.; Zhou, J. Investigation of rotor–gas foil bearing system and its application for an ultra-high-speed permanent magnet synchronous motor. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2022, 236, 595–606. [Google Scholar] [CrossRef]

- Xu, F.; Kim, D. Three-Dimensional Turbulent ThermoElastohydrodynamic Analyses of Hybrid Thrust Foil Bearings using Real Gas Model. In Proceedings of the ASME Turbo Expo 2016: Turbomachinery Technical Conference and Exposition, Seoul, Korea, 13–17 June 2016. [Google Scholar]

- Conboy, T. Real-gas effects in foil thrust bearings operating in the turbulent regime. J. Tribol. 2013, 135, 031703. [Google Scholar] [CrossRef]

- Munroe, T.A. COMSOL Multiphysics Predictions of Pressurized CO2 Foil Thrust Bearing Characteristics. In Proceedings of the Supercritical CO2 Power Cycle Symposium, Boulder, CO, Canada, 24–25 May 2011. [Google Scholar]

- Kim, D. Design Space of Foil Bearings for Closed-Loop Supercritical CO2 Power Cycles Based on Three-Dimensional Thermohydrodynamic Analyses. J. Eng. Gas Turbines Power 2016, 138, 032504. [Google Scholar] [CrossRef]

- Xie, Z.; Jiao, J.; Yang, K.; He, T.; Chen, R.; Zhu, W. Experimental and numerical exploration on the nonlinear dynamic behaviors of a novel bearing lubricated by low viscosity lubricant. Mech. Syst. Signal Process. 2023, 182, 109349. [Google Scholar] [CrossRef]

- Han, D.; Bi, C.; Chen, C.; Yang, J. Dynamic Coefficients of Tilting Pad Bearing by Perturbing the Turbulence Model. Appl. Sci. 2022, 12, 6348. [Google Scholar] [CrossRef]

- Wu, Y.; Yang, L.; Xu, T.; Wu, W. Thermo-Elasto-Hydrodynamic Characteristics Analysis of Journal Microbearing Lubricated with Rarefied Gas. Micromachines 2020, 11, 955. [Google Scholar] [CrossRef] [PubMed]

- Chapman, P.A. Advanced Gas Foil Bearing Design for Supercritical CO2 Power Cycles. In Proceedings of the 6th International Supercritical CO2 Power Cycles Symposium, Pittsburgh, PA, USA, 27–29 March 2018. [Google Scholar]

- Bi, C.; Han, D.; Yang, J. The frequency perturbation method for predicting dynamic coefficients of supercritical carbon dioxide lubricated bearings. Tribol. Int. 2020, 146, 106256. [Google Scholar] [CrossRef]

- Bi, C.; Han, D.; Wu, Y.; Li, Y.; Yang, J. Thermohydrodynamic investigation for supercritical carbon dioxide high speed tilting pad bearings considering turbulence and real gas effect. Phys. Fluids 2021, 33, 125114. [Google Scholar] [CrossRef]

- Ku, C. An experimental and theoretical study of the dynamic structural stiffness in compliant foil journal bearings. In Proceedings of the ASME DETC93, 14th Biennial Conference on Mechanical Vibration and Noise: Vibrations of Mechanical Systems and the History of Mechanical Design, Albuquerque, NM, USA, 19–22 September 1993. [Google Scholar]

- Rubio, D.; San Andres, L. Structural stiffness, dry friction coefficient, and equivalent viscous damping in a bump-type foil gas bearing. J. Eng. Gas Turbines Power 2007, 129, 494–502. [Google Scholar] [CrossRef]

- Pronobis, T.; Liebich, R. Comparison of stability limits obtained by time integration and perturbation approach for Gas Foil Bearings. J. Sound Vib. 2019, 458, 497–509. [Google Scholar] [CrossRef]

- Ruscitto, D.; Mc Cormick, J.; Gray, S. Hydrodynamic Air Lubricated Compliant Surface Bearing for an Automotive Gas Turbine Engine I-Journal Bearing Performance; NASA CR-135368; National Aeronautics and Space Administration (NASA) Lewis Research Center: Cleveland, OH, USA, 1978.

- Kim, T. Analysis of Side End Pressurized Bump Type Gas Foil Bearings: A Model Anchored to Test Data; Texas A&M University: College Station, TX, USA, 2007. [Google Scholar]

- Iordanoff, I. Analysis of an aerodynamic compliant foil thrust bearing: Method for a rapid design. J. Tribol. 1999, 121, 816–822. [Google Scholar] [CrossRef]

| Parameters | Value | Unit |

|---|---|---|

| Bearing length L | 38.1 | mm |

| Bearing radius R = D/2 | 19.05 | mm |

| Circumferential length of top foil lx | 120 | mm |

| Radius Clearance C0 | 31.8 | μm |

| Top foil thickness tt | 101.6 | μm |

| Bump foil thickness tb | 101.6 | μm |

| Bump foil pitch S | 4.572 | mm |

| Half bump length l | 1.778 | mm |

| Bump height hb | 0.508 | mm |

| Number of bumps | 26 | / |

| Young’s modulus of elasticity Eb | 214 | GPa |

| Poisson’s ratio νb | 0.29 | / |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Han, D.; Bi, C. The Partial Derivative Method for Dynamic Stiffness and Damping Coefficients of Supercritical CO2 Foil Bearings. Lubricants 2022, 10, 307. https://doi.org/10.3390/lubricants10110307

Han D, Bi C. The Partial Derivative Method for Dynamic Stiffness and Damping Coefficients of Supercritical CO2 Foil Bearings. Lubricants. 2022; 10(11):307. https://doi.org/10.3390/lubricants10110307

Chicago/Turabian StyleHan, Dongjiang, and Chunxiao Bi. 2022. "The Partial Derivative Method for Dynamic Stiffness and Damping Coefficients of Supercritical CO2 Foil Bearings" Lubricants 10, no. 11: 307. https://doi.org/10.3390/lubricants10110307

APA StyleHan, D., & Bi, C. (2022). The Partial Derivative Method for Dynamic Stiffness and Damping Coefficients of Supercritical CO2 Foil Bearings. Lubricants, 10(11), 307. https://doi.org/10.3390/lubricants10110307