Microstructure Examination and Sliding Wear Behavior of Al-15%Mg2Si-xGd In Situ Composites before and after Hot Extrusion

Abstract

:1. Introduction

2. Experimental Procedures

2.1. Materials Fabrication

2.2. Hot Extrusion

2.3. Microstructural Examination

2.4. Hardness and Dry Sliding Wear Test

3. Results and Discussion

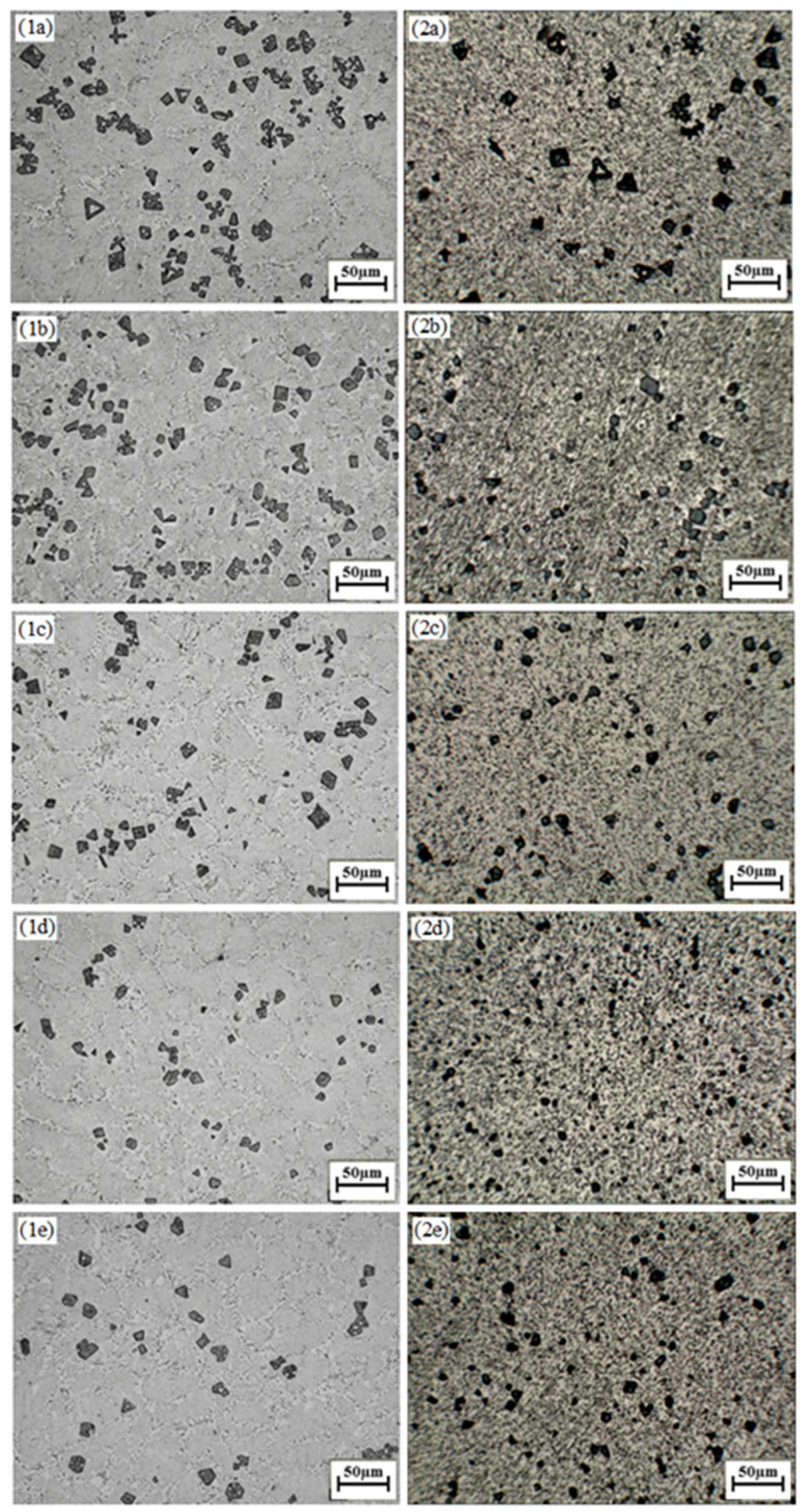

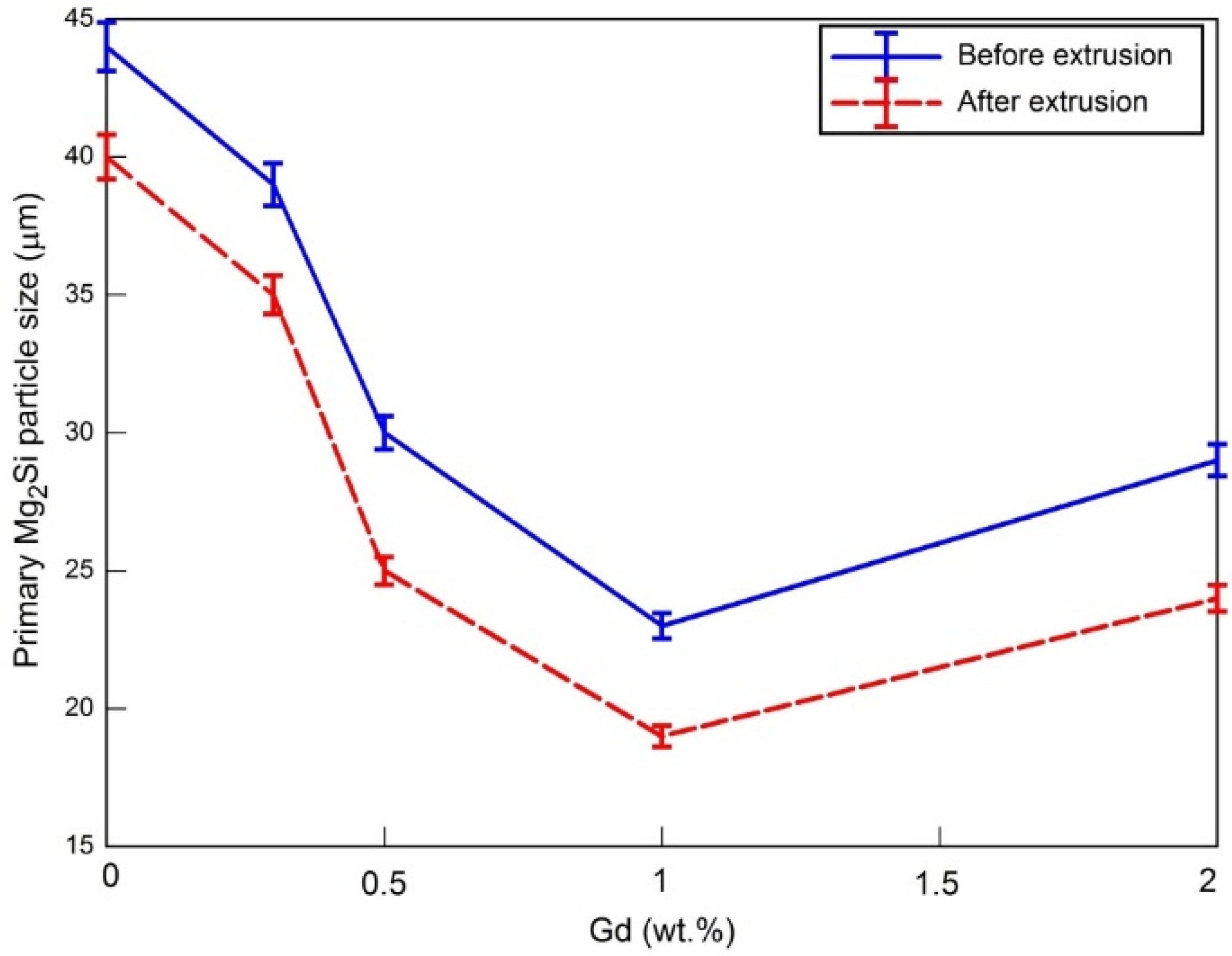

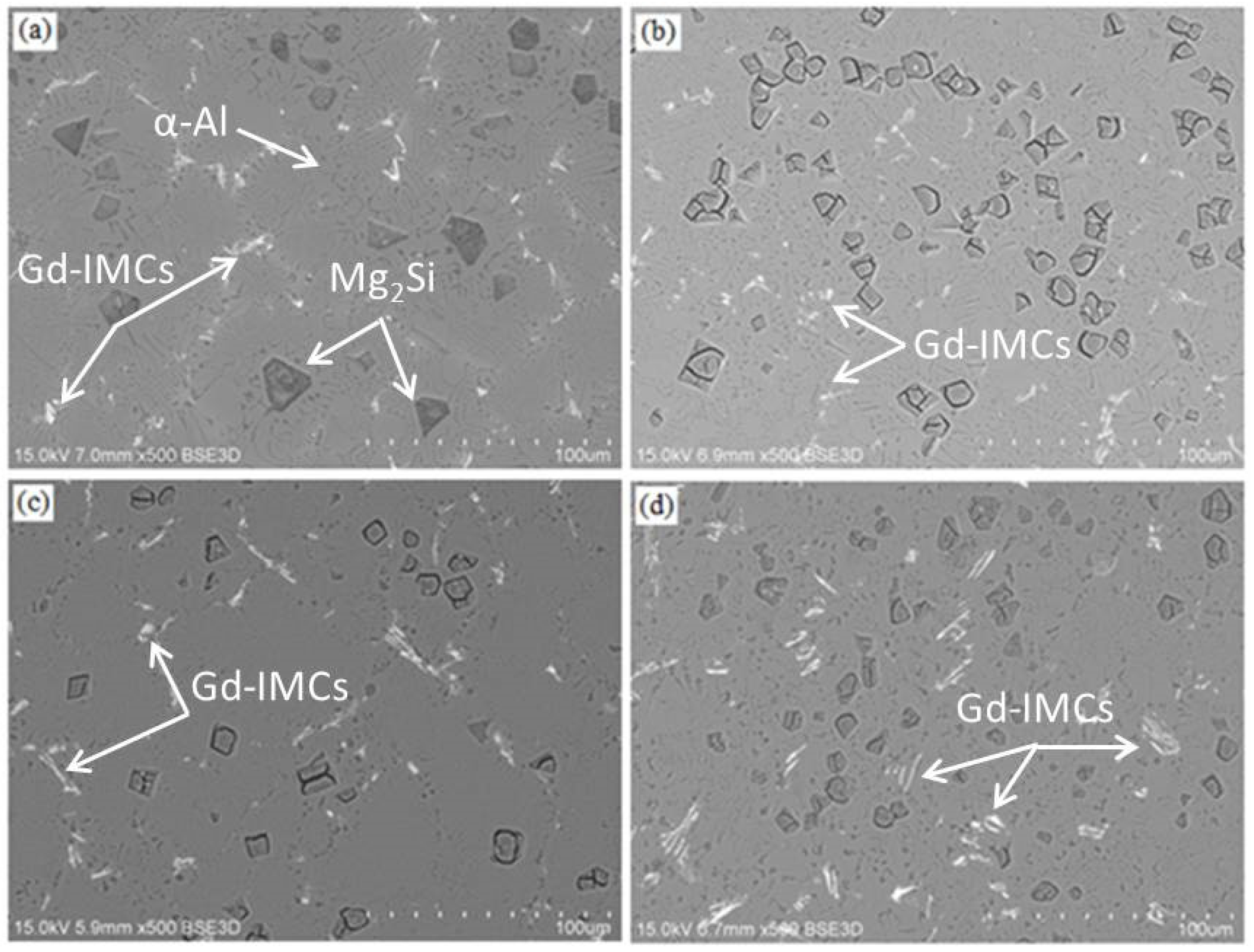

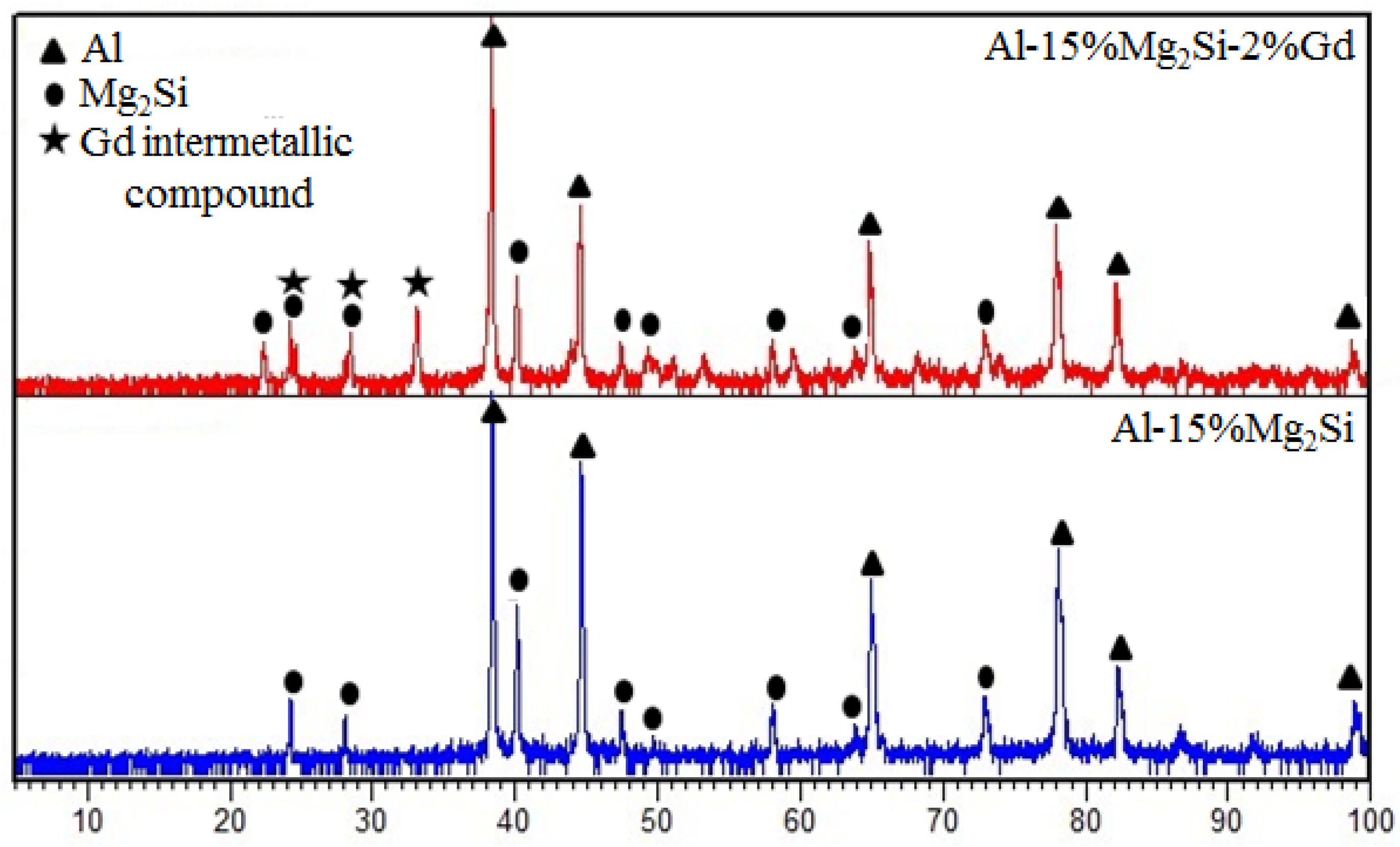

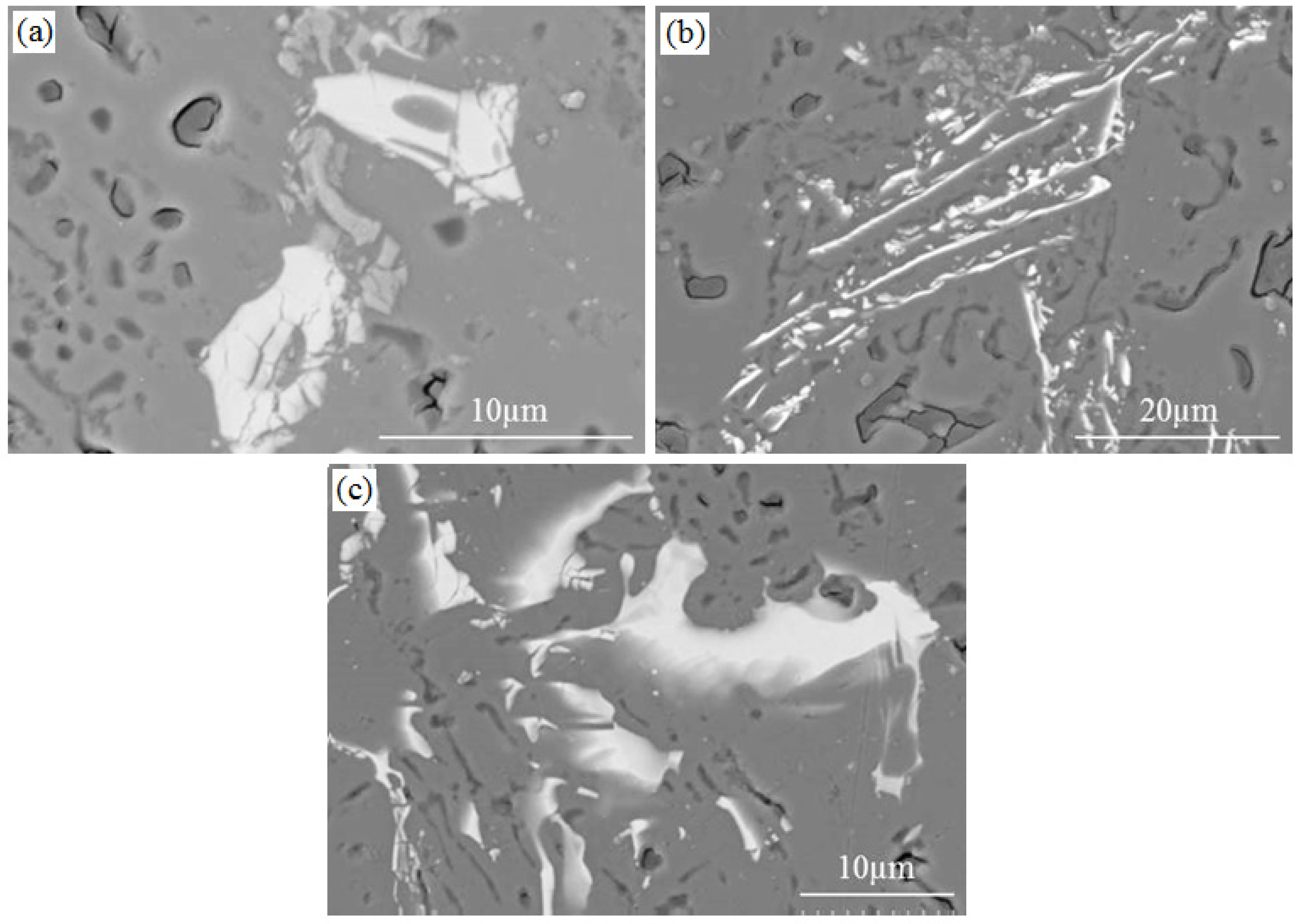

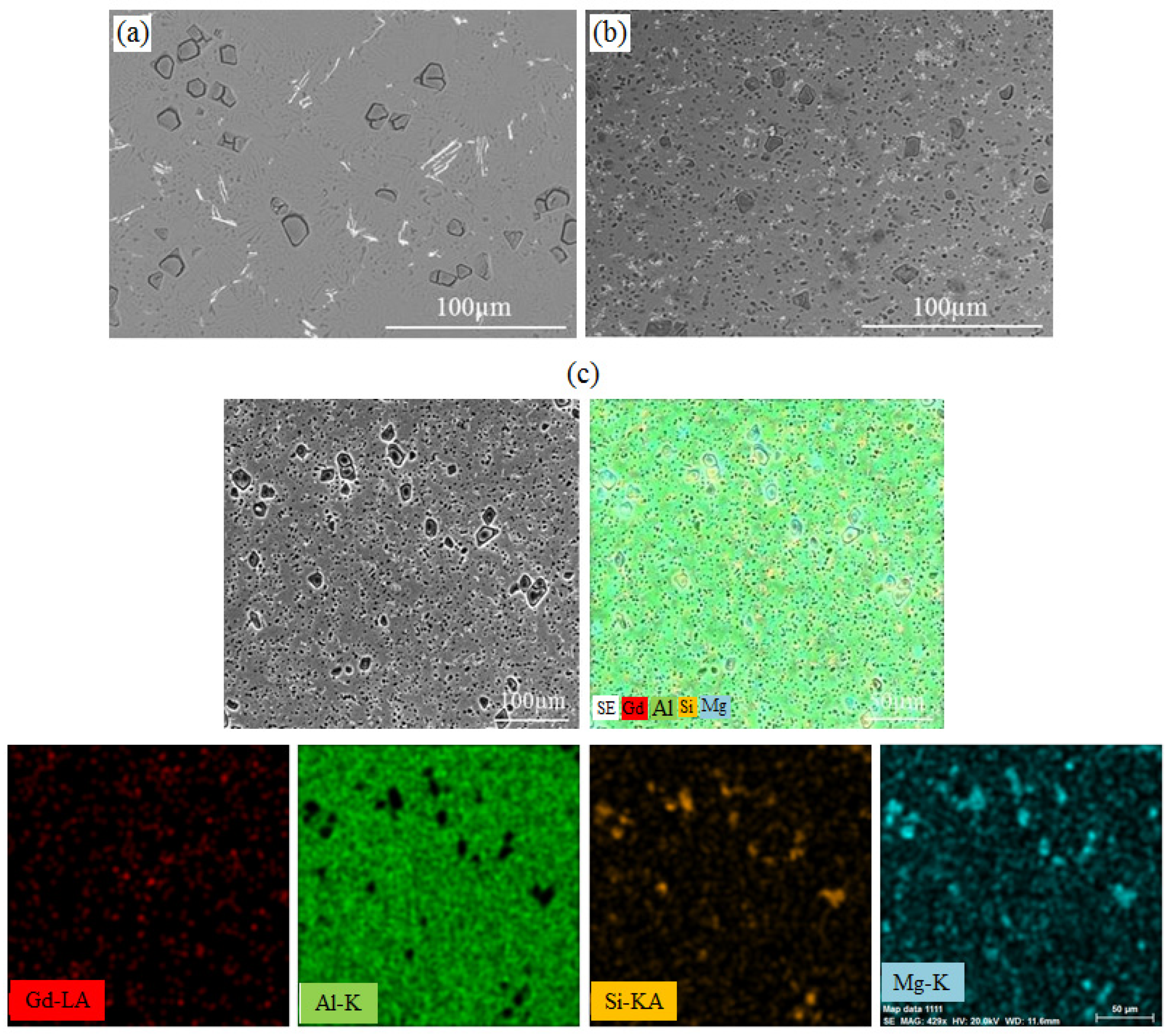

3.1. Microstructural Characterization

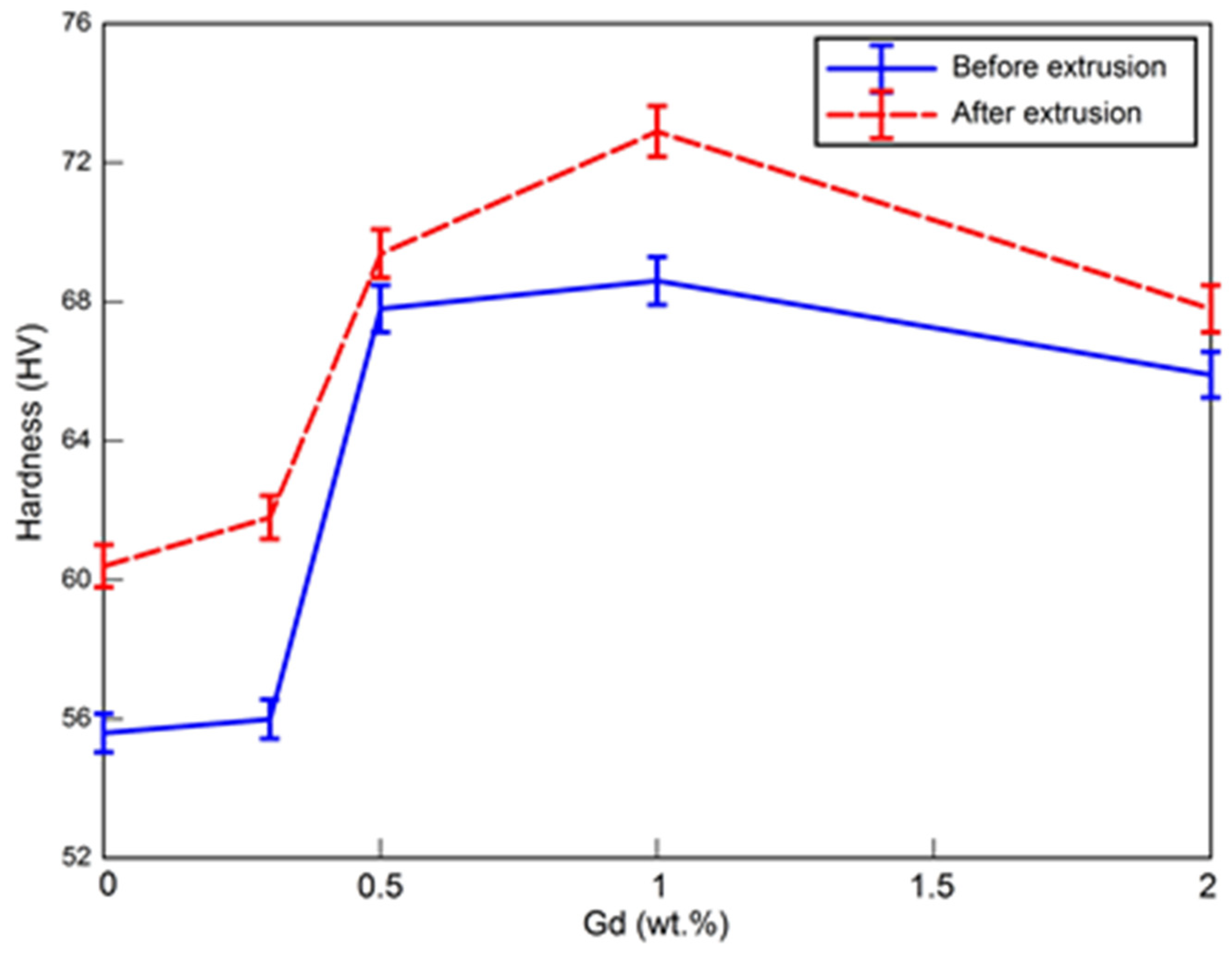

3.2. Mechanical Properties

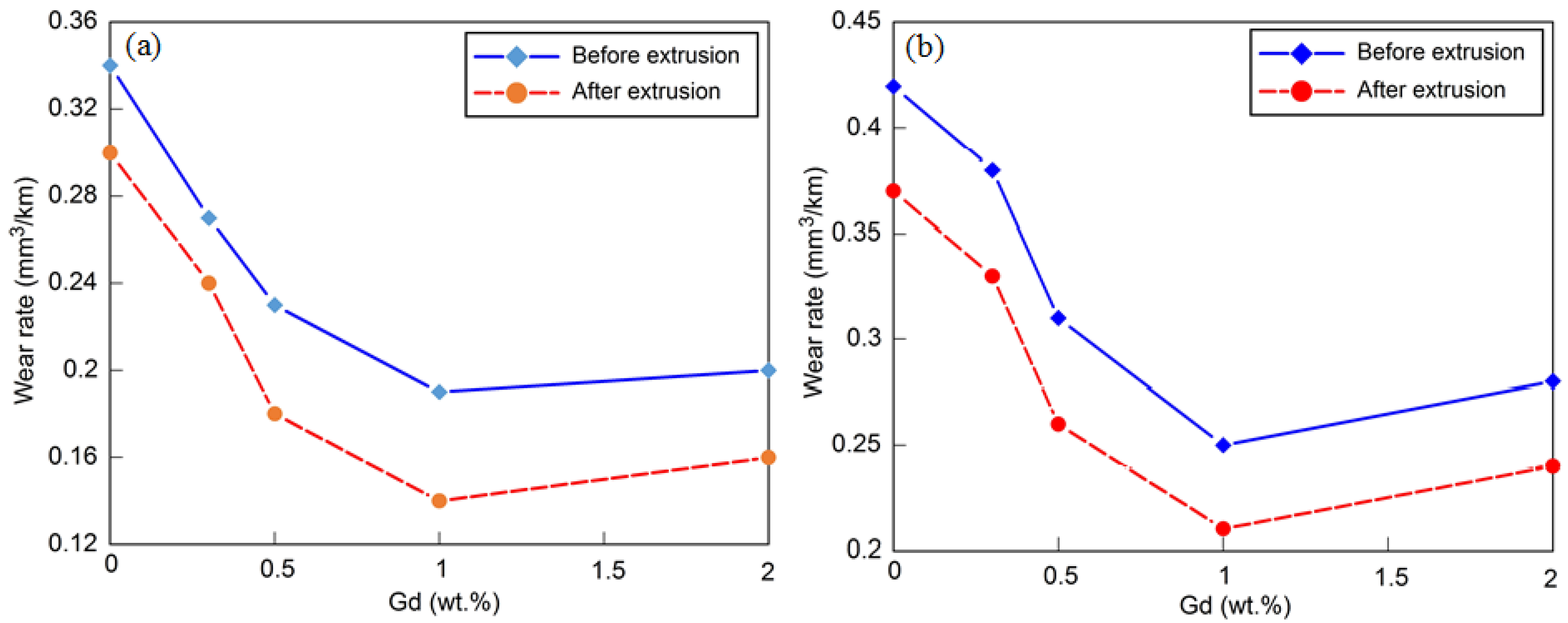

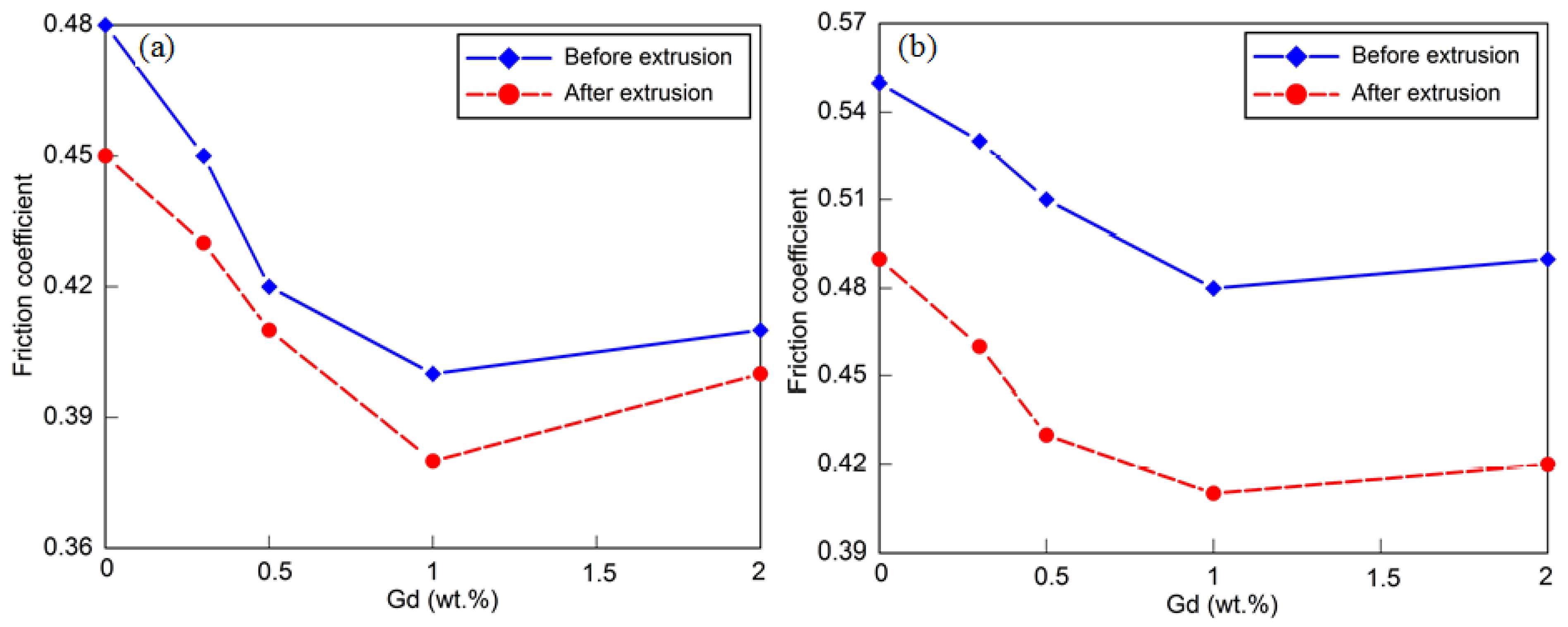

3.3. Wear Properties

4. Conclusions

- (1)

- For both as-cast and extruded composites, 1.0 wt.% Gd was found to be the best content to induce refinement/modification of primary Mg2Si particles in Al-15%Mg2Si composite. However, exceeding this amount has an adverse influence on the modification of primary Mg2Si particles.

- (2)

- Addition of Gd element up to 1.0 wt.% to Al-15%Mg2Si composite as well as conducting hot extrusion results in improvement of the hardness value by 31% as compared to the as-cast unmodified composite.

- (3)

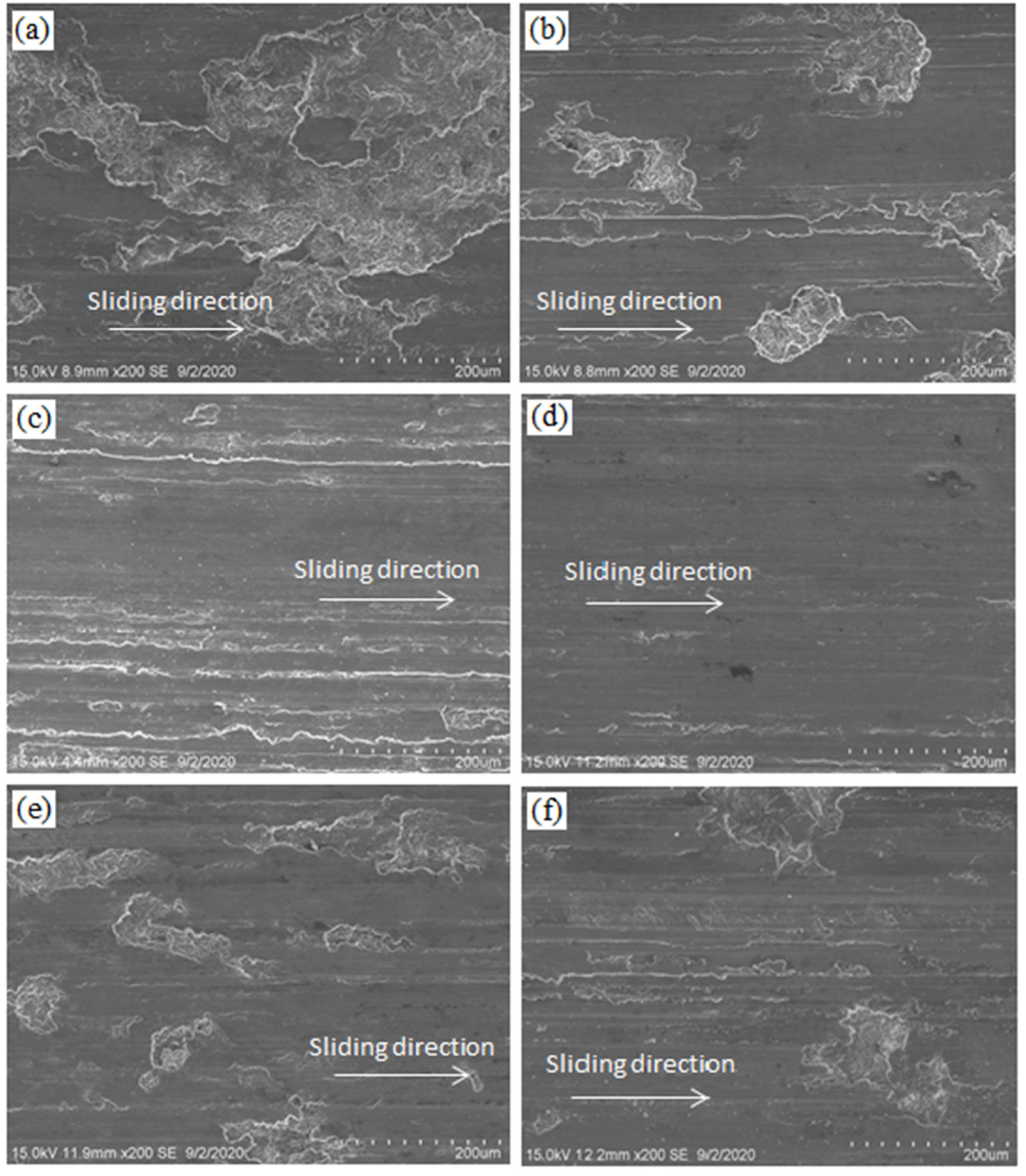

- The wear properties including wear rate and coefficient of friction of as-cast Al-15%Mg2Si composite modified with 1.0 wt.% Gd was found to be considerably higher than the unmodified composite due to refinement/modification of primary Mg2Si particles and formation of Gd IMCs. Further improvement of the wear properties was achieved after conducting hot extrusion due to fragmentation of primary Mg2Si particles and Gd IMCs.

- (4)

- When the as-cast Al-15%Mg2Si composite was modified with 1.0 wt.% Gd, the wear mechanism changed to abrasion and adhesion compared to abrasion and delamination in the as-cast unmodified composite. The wear mechanism changed to mild abrasion after performing the hot extrusion on Al-15%Mg2Si-1.0% Gd composite.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Palta, A.; Sun, Y.; Ahlatci, H. Effect of copper addition on wear and corrosion behaviours of Mg2Si particle reinforced composites. Mater. Des. 2012, 36, 451–458. [Google Scholar] [CrossRef]

- Li, C.; Liu, X.; Wu, Y. Refinement and modification performance of Al–P master alloy on primary Mg2Si in Al–Mg–Si alloys. J. Alloys Compd. 2008, 465, 145–150. [Google Scholar] [CrossRef]

- Emamy, M.; Khorshidi, R.; Honarbakhsh-Raouf, A. The influence of pure Na on the microstructure and tensile properties of Al-Mg2Si metal matrix composite. Mater. Sci. Eng. A 2011, 528, 4337–4342. [Google Scholar] [CrossRef]

- Ghandvar, H.; Idris, M.H.; Abu Bakar, T.A.; Nafari, A.; Ahmad, N. Microstructural characterization, solidification characteristics and tensile properties of Al-15%Mg2Si-x(Gd-Sb) in-situ composite. J. Mater. Res. Technol. 2020, 9, 3272–3291. [Google Scholar] [CrossRef]

- Ghandvar, H.; Idris, M.H.; Ahmad, N. Effect of hot extrusion on microstructural evolution and tensile properties of Al-15%Mg2Si-xGd in-situ composites. J. Alloys Compd. 2018, 751, 370–390. [Google Scholar] [CrossRef]

- Jafari Nodooshan, H.R.; Liu, W.; Wu, G.; Bahrami, A.; Pech-Canul, M.I.; Emamy, M. Mechanical and Tribological Characterization of Al-Mg2Si Composites After Yttrium Addition and Heat Treatment. J. Mater. Eng. Perform. 2014, 23, 1146–1156. [Google Scholar] [CrossRef]

- Lashgari, H.R.; Zangeneh, S.; Shahmir, H.; Saghafi, M.; Emamy, M. Heat treatment effect on the microstructure, tensile properties and dry sliding wear behavior of A356–10%B4C cast composites. Mater. Des. 2010, 31, 4414–4422. [Google Scholar] [CrossRef]

- Lu, L.; Lai, M.; Hoe, M. Formaton of nanocrystalline Mg2Si and Mg2Si dispersion strengthened Mg-Al alloy by mechanical alloying. Nanostruct. Mater. 1998, 10, 551–563. [Google Scholar] [CrossRef]

- Montoya-Dávila, M.; Pech-Canul, M. Effect of bi-and trimodal size distribution on the superficial hardness of Al/SiCp composites prepared by pressureless infiltration. Powder Technol. 2007, 176, 66–71. [Google Scholar] [CrossRef]

- Farahany, S.; Ghandvar, H.; Bozorg, M.; Nordin, A.; Ourdjini, A.; Hamzah, E. Role of Sr on microstructure, mechanical properties, wear and corrosion behaviour of an Al–Mg2Si–Cu in-situ composite. Mater. Chem. Phys. 2020, 239, 121954. [Google Scholar] [CrossRef]

- Soltani, N.; Jafari Nodooshan, H.R.; Bahrami, A.; Pech-Canul, M.I.; Wencai, L.; Wu, G. Effect of hot extrusion on wear properties of Al–15 wt. % Mg2Si in situ metal matrix composites. Mater. Des. 2014, 53, 774–781. [Google Scholar] [CrossRef]

- Qin, Q.D.; Zhao, Y.G.; Zhou, W.; Cong, P.J. Effect of phosphorus on microstructure and growth manner of primary Mg2Si crystal in Mg2Si/Al composite. Mater. Sci. Eng. A 2007, 44, 186–191. [Google Scholar] [CrossRef]

- Straffelini, G. Experimental Observations of Subsurface Damage and Oxidative Wear in Al-Based Metal-Matrix Composites. Wear 2000, 245, 216–222. [Google Scholar] [CrossRef]

- Vencl, A.; Bobic, I.; Arostegui, S.; Bobic, B.; Marinkovic, A.; Babic, M. Structural, mechanical and tribological properties of A356 aluminum alloy reinforced with Al2O3, SiC and SiC+ Graphite particles. J. Alloys Compd. 2010, 506, 631–639. [Google Scholar] [CrossRef]

- Wang, K.Y.; Zhao, R.D.; Wu, F.F.; Wu, X.F.; Chen, M.H.; Xiang, J. Improving microstructure and mechanical properties of hypoeutectic Al-Mg2Si alloy by Gd addition. J. Alloys Compd. 2020, 813, 152178. [Google Scholar] [CrossRef]

- Wu, X.F.; Zhang, G.G.; Wu, F.F. Microstructure and dry sliding wear behavior of cast Al–Mg2Si in-situ metal matrix composite modified by Nd. Rare Met. 2013, 32, 284–289. [Google Scholar] [CrossRef] [Green Version]

- Wu, X.F.; Zhang, G.A.; Wu, F.F. Influence of Bi addition on microstructure and dry sliding wear behaviors of cast Al-Mg2Si metal matrix composite. Trans. Nonferrous Met. Soc. China 2013, 23, 1532–1542. [Google Scholar] [CrossRef]

- Zhu, M.; Jian, Z.Y.; Yao, L.J.; Liu, C.X.; Yang, G.C.; Zhou, Y.H. Effect of mischmetal modification treatment on the microstructure, tensile properties, and fracture behavior of Al–7.0 % Si–0.3 % Mg foundry aluminum alloys. J. Mater. Sci. 2011, 46, 2685. [Google Scholar] [CrossRef]

| Element | Al | Mg | Si | Fe | V | Cr | Ni | Ti | Sn | Mn |

|---|---|---|---|---|---|---|---|---|---|---|

| Weight% | 84.6 | 8.5 | 6.7 | 0.12 | 0.02 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 |

| (a) Non Uniform White Phase | (b) White Needle-like Phase | (c) Chinese Script-like Phase | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Al | Si | Gd | Mg | Al | Si | Gd | Mg | Al | Si | Gd | Mg |

| 41.65 | 43.12 | 12.95 | 3.76 | 50.06 | 52.98 | 45.36 | 0.88 | 6.45 | 3.10 | 42.20 | 46.50 |

| 39.54 | 43.74 | 13.52 | 2.54 | 60.37 | 52.50 | 54.93 | 2.00 | 5.36 | 4.81 | 35.82 | 39.71 |

| 37.07 | 40.52 | 20.01 | 4.88 | 46.03 | 47.76 | 40.93 | 1.01 | 7.01 | 6.52 | 34.02 | 38.58 |

| 38.17 | 41.02 | 20.81 | 1.98 | 57.98 | 46.70 | 49.51 | 0.53 | 3.55 | 2.09 | 39.79 | 38.21 |

| 38.10 | 43.42 | 18.48 | 5.20 | 50.41 | 51.14 | 52.47 | 0.50 | 8.22 | 6.31 | 39.11 | 37.88 |

| 38.43 | 39.20 | 20.62 | 3.25 | 58.92 | 56.14 | 48.95 | 1.97 | 4.16 | 3.40 | 40.93 | 41.64 |

| 38.47 | 40.80 | 20.73 | 4.41 | 76.50 | 62.75 | 55.22 | 1.78 | 6.39 | 3.55 | 38.20 | 41.48 |

| 44.48 | 37.09 | 15.88 | 2.87 | 54.01 | 41.29 | 48.33 | 2.03 | 3.75 | 1.66 | 42.10 | 39.99 |

| 37.57 | 41.13 | 18.33 | 5.48 | 66.24 | 54.54 | 55.39 | 2.45 | 5.01 | 4.08 | 38.32 | 40.05 |

| 41.48 | 38.11 | 17.08 | 2.06 | 72.80 | 68.62 | 65.61 | 1.65 | 3.98 | 2.79 | 40.93 | 39.47 |

| Al2Si2Gd | AlSiGd | MgGd | |||||||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ghandvar, H.; Jabbar, M.A.; Bahador, A.; Abu Bakar, T.A.; Fadil, N.A.; Kondoh, K. Microstructure Examination and Sliding Wear Behavior of Al-15%Mg2Si-xGd In Situ Composites before and after Hot Extrusion. Lubricants 2022, 10, 3. https://doi.org/10.3390/lubricants10010003

Ghandvar H, Jabbar MA, Bahador A, Abu Bakar TA, Fadil NA, Kondoh K. Microstructure Examination and Sliding Wear Behavior of Al-15%Mg2Si-xGd In Situ Composites before and after Hot Extrusion. Lubricants. 2022; 10(1):3. https://doi.org/10.3390/lubricants10010003

Chicago/Turabian StyleGhandvar, Hamidreza, Mostafa Abbas Jabbar, Abdollah Bahador, Tuty Asma Abu Bakar, Nor Akmal Fadil, and Katsuyoshi Kondoh. 2022. "Microstructure Examination and Sliding Wear Behavior of Al-15%Mg2Si-xGd In Situ Composites before and after Hot Extrusion" Lubricants 10, no. 1: 3. https://doi.org/10.3390/lubricants10010003

APA StyleGhandvar, H., Jabbar, M. A., Bahador, A., Abu Bakar, T. A., Fadil, N. A., & Kondoh, K. (2022). Microstructure Examination and Sliding Wear Behavior of Al-15%Mg2Si-xGd In Situ Composites before and after Hot Extrusion. Lubricants, 10(1), 3. https://doi.org/10.3390/lubricants10010003