1. Introduction

Polymer composite materials (PCMs), due to their improved performance properties, are widely used as parts in friction units of various equipment. Polytetrafluoroethylene (PTFE) is characterized by thermal stability, chemical resistance, and self-lubricating properties [

1]. Due to these properties, PTFE can be used as mechanical components in friction units in the automotive industry. However, low wear resistance and high creep of PTFE in many cases excludes its use in friction units [

2]. The disadvantages of PTFE can be reduced by introducing fillers, which effectively increase wear resistance. Typically, fillers for PTFE are dispersed particles (graphite, bronze), carbon and glass fibers, and combinations [

3,

4,

5]. In recent decades, much research has focused on developing PCMs utilizing a mixture of fillers of different sizes, shapes, and chemical compositions. It is known that carbon fibers (CFs), glass fibers, and aramid fibers are used as fillers to manufacture polymer materials for tribological purposes, together with nanosized and lubricating materials (graphite, MoS

2, PTFE) [

5,

6,

7,

8,

9].

Li et al. prepared composites of the compositions PTFE/SiO

2 and PTFE/SiO

2/PAO 6, which were obtained at various pressing pressures (from 10 to 50 MPa) [

10]. The addition of PAO 6 to PTFE/SiO

2 compositions leads to a significant decrease in the coefficient of friction and an increase in wear resistance compared to PTFE/SiO

2 and the initial PTFE. The improvement in the tribological properties of PCM was explained by the synergistic effect when using PAO 6 (liquid lubricant) and PTFE polymer matrix (solid lubricant). Zhang et al. evaluated the impact of nanosized particles on the tribological characteristics of polyether ether ketone (PEEK) filled with a combination of CF/PTFE/graphite fillers [

11,

12]. For this, the authors used a commercial composition of the PEEK/CF/PTFE/graphite composite, to which nano-SiO

2 was additionally added. The addition of nano-SiO

2 to the PEEK/CF/PTFE/graphite composite is effective at high contact friction pressures. Song et al. investigated composites based on PTFE filled with CFs with MoS

2 and short glass fibers [

13]. The introduction of MoS

2 into PTFE/CF made it possible to improve the tribological properties compared to composites of the composition PTFE/CF/glass fiber. It was shown that the introduction of MoS

2 and glass fiber into the PTFE/CF composition led to a significant improvement in wear resistance. The effect of improving the tribological properties of PTFE/CF/glass fiber/MoS

2 became noticeable at high sliding speeds and pressures.

Previously, the authors of this paper studied the effect of combined fillers consisting of CFs and layered silicates (kaolin and vermiculite) on the tribological and mechanical properties of PTFE [

14]. It was shown that the introduction of mechanically activated layered silicates and CFs made it possible to increase the mechanical properties of PCM and significantly improve wear resistance compared to composites containing only fibers. Thus, it is of great interest to introduce CFs with other aluminosilicate particles into PTFE.

Zeolites are crystalline aluminosilicate minerals with microporous structures [

15]. They have a high specific surface area, resistance to heating, availability, and low cost, and are widely used to modify polymers [

16,

17,

18,

19]. Zeolite can have the same exceptional wear-reducing properties with CFs as the above fillers: kaolin and vermiculite. This study will focus on studying the effect of CFs and zeolite on the mechanical and tribological properties of PTFE.

2. Materials and Methods

PTFE (particle size of 46–135 µm and density of 2.16 g/cm

3) powders trademark PN90 were purchased by GaloPolymer, Russia. Chemically modified discrete CF brand «Belum» was obtained from Svetlogorsk Khimvolokno, Belarus. The width and length of the CF were 8–10 µm and 50–500 µm, respectively. The CF were modified by a plasma–chemical treatment in an environment with fluororganic compounds, based on a previous method [

20].

Zeolite (Zt) with a chemical composition of M2/nOAl2O3⋅xSiO2⋅yH2O was used as a mineral filler, sourced from deposits from the Sakha (Yakutia) Republic in Russia. The average specific surface of the Zt used in this study was ~15 m2/g.

PCM were prepared according to a typical process: dry-mixing the polymer and filler in a paddle mixer, molding under a pressure of 50 MPa at room temperature for 2 min, then sintering the specimen in a programmable muffle furnace (SNOL 180/400) at 375 °C. The mechanical activation of the zeolite was preliminarily carried out in a planetary mill (Activator-2) according to the previous work: the activation time was 2 min at 80 G [

14]. PTFE-based composites were prepared, and the detailed compositions were listed in

Table 1. The mass content of CF in the composites is 1 and 10 wt.%, respectively.

The mechanical properties, such as the tensile strength, elongation at break, and yield strength, were determined according to the Russian standard GOST 11262-2017 (plastics, tensile test method) using a universal testing machine (Autograph AGS-J, Shimadzu, Kyoto, Japan) at 25 °C, and a strain rate of 100 mm/min. The compressive stress at a deformation of 10% was measured following standard GOST 4651-2014 (plastics, compression test method, ISO 604: 2002, MOD) using the same instrument at a strain rate of 1 mm/min. The densities of the PTFE and PCM samples were determined according to the Russian standard GOST 15139-69 (plastics, methods for the determination of density). This method, also known as hydrostatic weighing (analog ASTM D 792), for determining the bulk density of molded products (e.g., rods, bars, and tubes), and it provides a density measurement accuracy of 0.1%. Distilled water was used as the media.

Tribological properties were evaluated in pin-on-disc tests on a UMT-3 (CETR, Mountain View, CA, USA). The counterbody was a #45 carbon-steel disk with a hardness of 45–50 HRC, and a roughness

Ra = 0.06–0.08 µm. The investigated polymer pin samples had a diameter of 10 ± 0.1 mm with 20 ± 1 mm thickness (length), while the wear track centerline on the steel discs was at 20 mm diameter. Nominal pressure is 2 MPa (the normal force was 160 N), an average sliding speed of 0.2 m/s, and a test duration of 3 h. The mean deviation values were calculated from at least three measurements. Coefficient of friction was determined according to the Russian standard GOST 11629-2017 (plastics, method for testing the friction coefficient). The wear rate

k (mm

3/N·m) was calculated after wear testing by using Equation (1):

where

FN, N—normal force;

d, m—sliding distance;

Δm, g—mass lost during sliding;

ρ, g/mm

3—density of specimens.

The crystal structure of the PTFE and its PCM was determine using X-ray powder diffractometry (XRD; ARL X’Tra, Thermo Fisher Scientific, Ecublens, Switzerland) with a CuK

α (

λ = 0.154 nm) radiation source. The degree of crystallinity was estimated from the ratio of the areas of reflections corresponding to amorphous and crystalline regions using Equation (2):

where

α,

%—degree of crystallinity;

IC—area under the crystalline peaks;

IC + IA—area under all peaks. Win XRD software (v. 2.0-6, Thermo Fisher, Ecublens, Switzerland) was used for data analysis.

The worn surface and supramolecular structures of the PTFE and PCM samples were observed by scanning electron microscopy (SEM; JSM-7800F, JEOL, Tokyo, Japan). The specimens for supramolecular structure studies were obtained by cold chipping in liquid nitrogen.

Fourier transform infrared spectroscopy (FT-IR; Varian 7000, Varian, Palo Alto, CA, USA) was used to record IR spectra with an attenuated total reflection (ATR) attachment over the range of 550–4000 cm−1. IR spectra were obtained before and after friction tests.

3. Results and Discussion

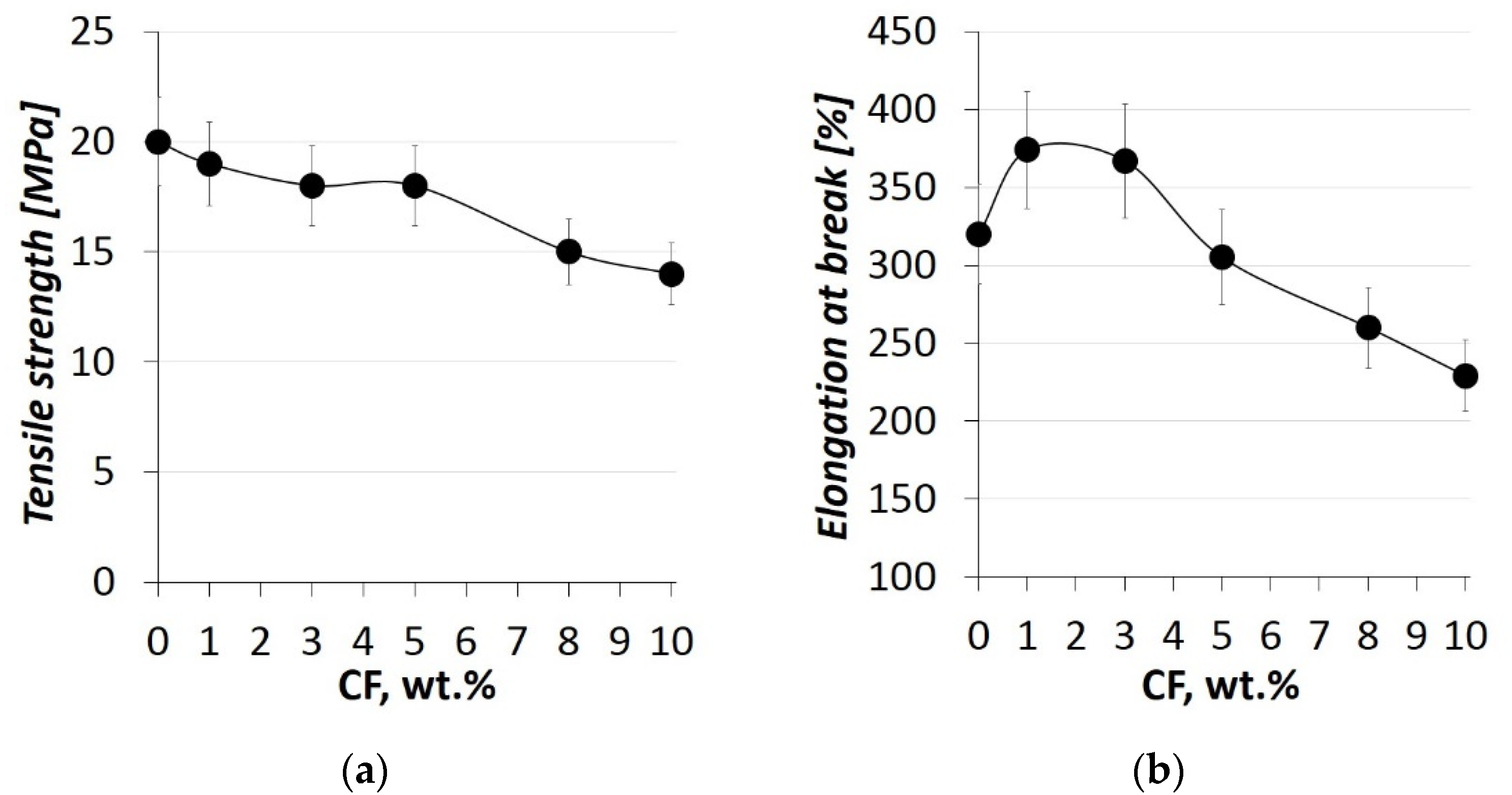

The plot of tensile strength and elongation at break of PTFE and PTFE/CF/Zt in terms of the content of CFs is presented in

Figure 1.

As can be seen from

Figure 1, the introduction of combined fillers in PTFE in an amount of 1–5 wt.% of CFs leads to the preservation of the tensile strength and elongation at break of PCM at the level of the initial polymer. The mechanical properties of polymer composites are related to the structure of the material; in the case of polymers filled with fibers, the significant role is played by the interfacial interaction at the fiber–matrix interface [

21]. It is known that modified CFs of the Belum brand are characterized by strong interfacial adhesion to PTFE [

22]. However, a CF content of 8–10 wt.% in PCM leads to a decrease in tensile strength up to 25% and elongation at break up to 30%, possibly associated with the formation of defective areas with a high content of fillers.

The compressive strength (10%) and the yield strength of PTFE and PTFE/CF/Zt depending on the content of CFs is shown in

Figure 2.

Figure 2 shows that the compressive value strength of PCM monotonically increases with an increase in the CF content. It can be seen that the compressive strength of PCM increased by 7–53% compared to the initial PTFE at a filler with increasing content of 1 to 10 wt.%. The yield point of the composites increased by 45% relative to the initial PTFE at a CF content of 8–10 wt.%. In composites, a significant increase in compressive strength and yield strength indicates the reinforcing effect of fillers. Thus, the developed materials have improved compression characteristics and yield strength, which is necessary for materials for tribological purposes.

Structural studies of PTFE and PCM were carried out using an X-ray diffractometer to determine the structural parameters of the developed materials. The X-ray diffraction patterns of PTFE and PCM are shown in the

Figure 3.

As can be seen from

Figure 3, in the initial PTFE and polymer composites, an intense diffraction peak was revealed in the region

2θ = 18° (100), which corresponds to the crystalline phase of PTFE [

23]. No other peaks were found in all X-ray diffraction patterns of PCM. It was found that the intensity of the peak at

2θ = 18° PCM increased with an increase in the content of fillers. An increase in the intensity of the PCM peak is consistent with an increase in the degree of crystallinity, as shown in

Table 2.

The degree of crystallinity is determined, from the diffraction pattern, by calculating the relative values of the integrated intensity of the crystal reflections according to Equation (2). As can be seen from

Table 2, the degree of crystallinity of PTFE increases with the introduction of fillers. PTFE/CF/Zt has a degree of crystallinity according to X-ray diffraction analysis that is higher than the initial PTFE by 1–8%. Such a change in the degree of crystallinity of PCM indicates that the fillers become crystallization centers.

The density of PCMs with a content of 1–5 wt.% CF remains at the level of the initial PTFE. With an increase in the fiber content by 8–10 wt.% CF in the polymer matrix, the density of the composites decreases in comparison with the initial polymer, reaching a minimum at 10 wt% CF. The decrease in PTFE density upon the introduction of CFs is possibly associated with a “loosening” of the supramolecular structure PCM [

14]. In addition, the contribution is made by the lower density of the initial carbon fibers (~1.45 g/cm

3), which is significantly lower in comparison with the density of the PTFE polymer matrix (~2.16 g/cm

3).

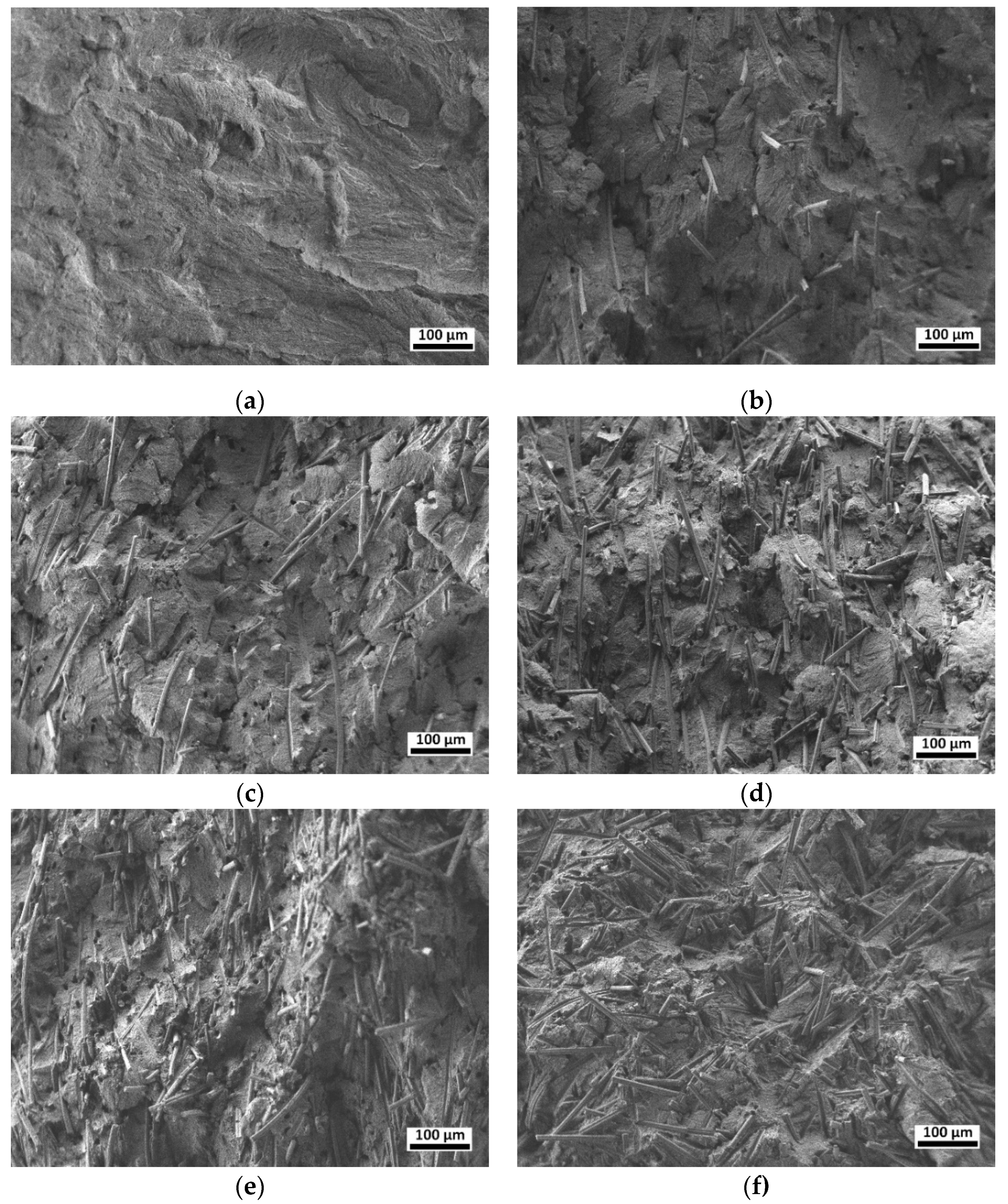

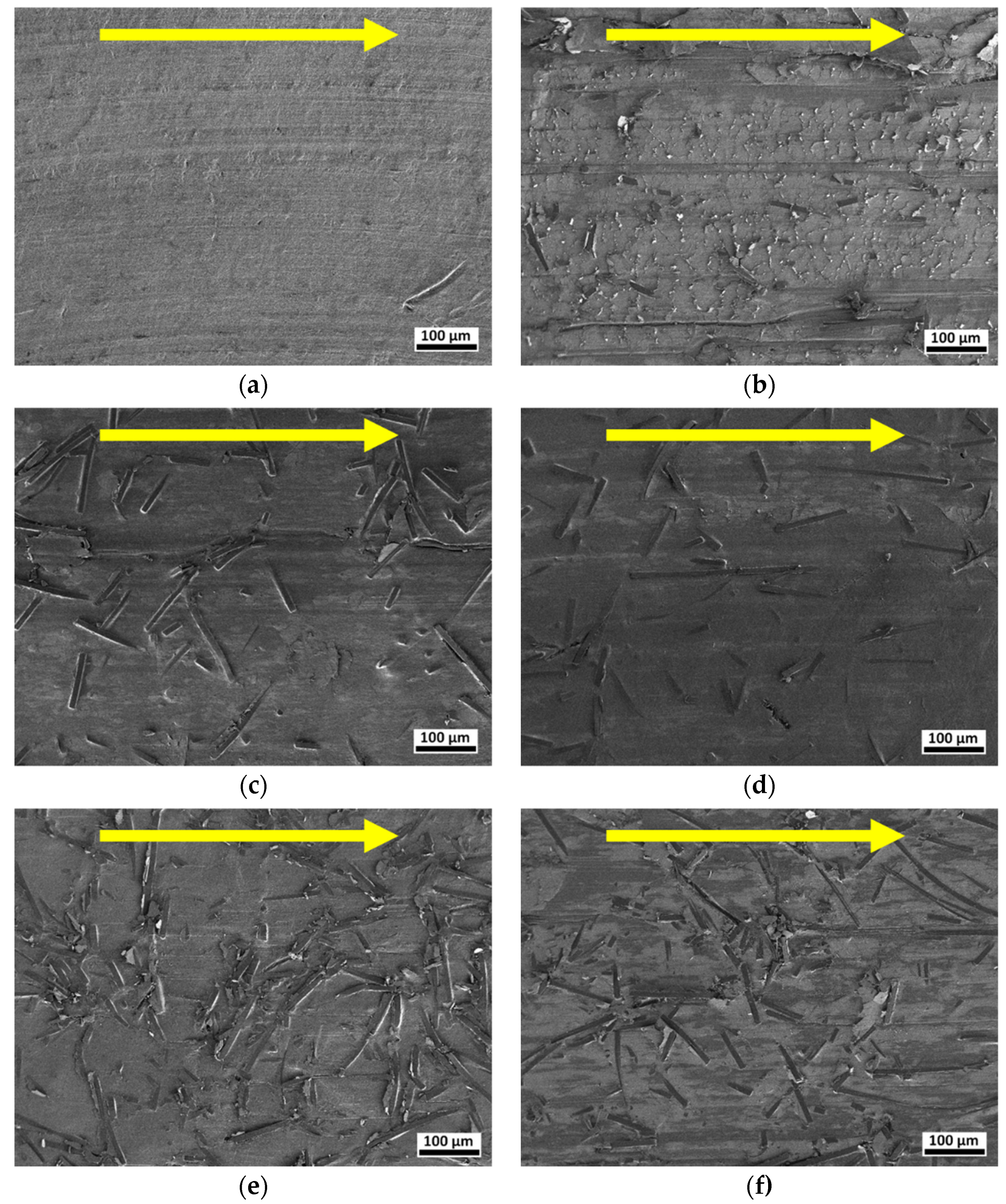

The results of a study of the supramolecular structure of the initial PTFE and PCM by scanning electron microscopy (SEM) can be seen in

Figure 4.

As seen from

Figure 4a, the supramolecular structure of the initial PTFE is characterized by the formation of a lamellae structure. In all composites, CFs were randomly oriented and relatively uniformly distributed in the supramolecular structure of the initial polymer (

Figure 4b–f). The SEM images of PCM show that the amount of fibers visually increases with an increase in the CFs content from 1 to 10 wt.%. Due to this, the yield strength and compressive strength values increase by 7–53% and 8–45% compared to the initial PTFE. The zeolite content is not visible in the supramolecular structure, associated with its low content (1 wt.%) and high dispersion mechanically activated filler.

The tribological properties of PTFE are attributed to the relatively easy sliding between the lamellae or fibrils, resulting in a low coefficient of friction but also a high of wear rate [

24]. Fillers are known to introduced into PTFE reduce the subsurface crack propagated and part of the normal load is transferred to the solid filler [

25]. In addition, wear of the PTFE-based polymer composite formation a transfer film on the surface of the steel counterbody and on the friction surface polymer composites, which contributes significantly to wear reduction. Thus, the tribofilm formed on the surface of the composite and on the counterbody protects them from wear. The surface of the composites was investigated in this work since there is practically no wear of the counterbody, since the disc is made of sufficiently strong grade 45 steel. The tribological test results for PTFE and PTFE/CF/Zt as a function of fiber content are shown in

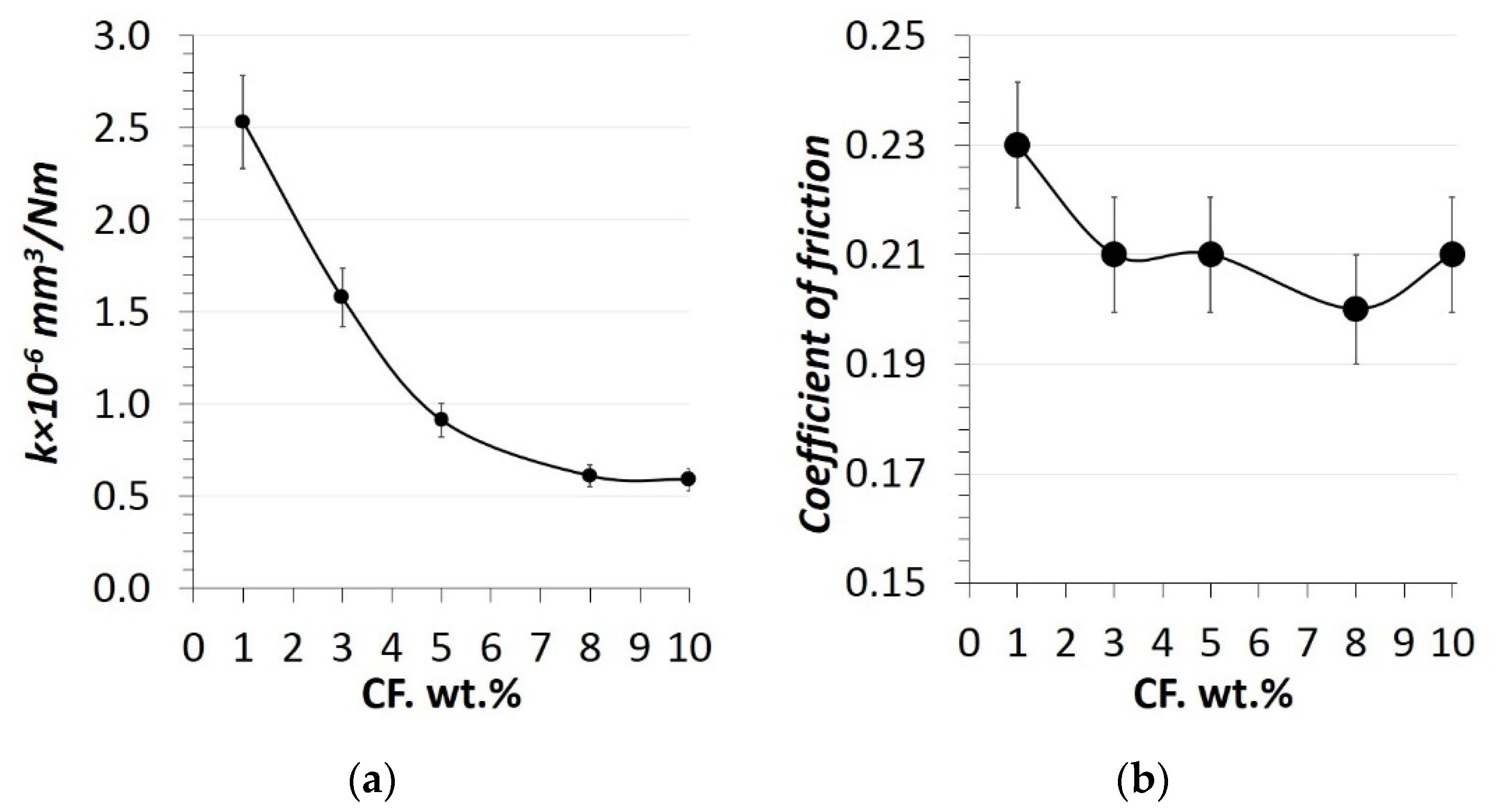

Figure 5.

As can be seen from

Figure 5a, the addition of combined fillers to PTFE increased the wear resistance by order of magnitude compared to the original polymer. In this work, the wear rate for the initial PTFE was ~4.79 × 10

−4 mm

3/N·m, and the friction coefficient was ~0.22. The results of comparing the PTFE/CF/Zt composites with the initial PTFE showed a decrease in the wear rate by a factor of ~190–810. Moreover, the wear rate of PTFE/CF/Zt depends on the CF content, so with an increase in the fiber content, the wear resistance increased from 2.53 × 10

−6 to 0.59 × 10

−6 mm

3/N·m. Composites containing 8–10 wt.% of CF have the highest wear resistance than composites containing 1–5 wt.% of CF.

The friction coefficient of PTFE/CF/Zt, regardless of the CF content, practically does not change over the entire concentration range of values, as shown in

Figure 5b. It can be seen that the friction coefficient of PTFE/CF/Zt is comparable with the results of the initial PTFE and is in a relatively narrow range of values, i.e., 0.19–0.23. An earlier work [

14] showed that the introduction of CFs with kaolin and vermiculite into PTFE increased the friction coefficient by 20–36% relative to the initial PTFE. In [

26], PTFE filled with ultra-fine kaolin particulates was investigated. The friction of PTFE filled with 5 wt.% kaolin increased the coefficient of friction of the composite relative to the initial polymer. In the work [

27], the effect of vermiculite on the mechanical and tribological properties of PTFE was investigated. Shown that the introduction of vermiculite increases the coefficient of friction PCM to compare the initial PTFE. At the same time, PTFE filled with zeolite (5 wt.%), where the friction coefficient of the composite was at the level of the initial polymer, was studied in [

19]. Based on this, it is evident that the PTFE/CF friction coefficient with the additional introduction of natural aluminosilicate depends on the structure of the used filler. Thus, the developed PTFE/CF/Zt materials are characterized by high wear resistance and a low coefficient of friction.

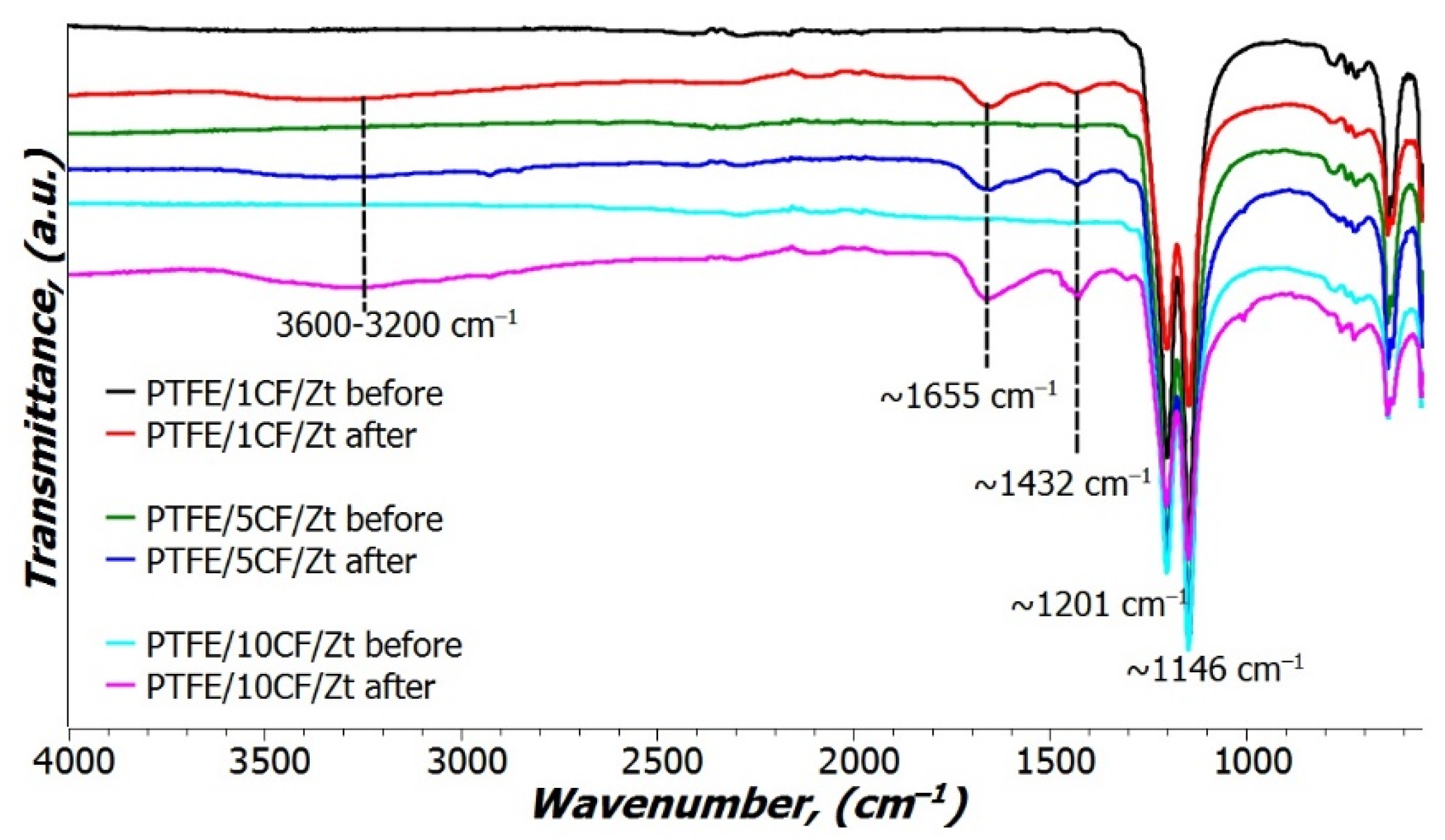

The surface of the PCM before and after friction was investigated by infrared (IR) spectroscopy. The IR spectra of PCM before and after friction can be seen in

Figure 6.

As seen in

Figure 6, the results of analysis of the obtained IR spectra showed the presence of a region of characteristic absorption of PTFE; new peaks were also revealed on the friction surfaces of PCM. Intense peaks at ~1201 and ~1146 cm

−1 are characteristic of PTFE (-CF

2 asymmetric and symmetric stretching bands) [

28]. On the worn surface of the composites, new absorption peaks were revealed in the range of ~1432 cm

−1, ~1655 cm

−1, and 3200–3600 cm

−1. From literature data, it is known that the peaks ~1432 cm

−1 and ~1655 cm

−1 are attributed to metal chelates of salts of perfluorinated carboxylic acids M

2(R

f-COO

−) [

29]. These peaks are found on the friction surface of the counterbody and on the worn surface of the composites [

28]. The broad peak at 3600–3200 cm

−1 is attributed to the associated hydroxyl groups –OH. The new absorption peaks recorded in the IR spectra of PCM after friction are associated with the rupture of the polymer chain at C–C bonds. Further, these broken bonds form radicals that can react with oxygen and ambient moisture to form end groups of carboxylic acids [

30]. Thus, the friction of the PTFE/CF/Zt composite against a steel counterbody leads to tribochemical reactions.

Figure 7 shown the results of studying the worn surface of PCM depending on the composition of fillers by the SEM method.

As shown in

Figure 7a, the worn surface of the initial PTFE is characterized by tiny grooves and is relatively smooth along the friction direction. Such a friction surface of unfilled PTFE is typical and was observed in the work [

31]. The formation of such morphology of the PTFE worn surface is due to the structure of the polymer [

25]. In the case of the introduction of combined fillers (CF/Zt) into PTFE, fibers visible on the friction surface protect the polymer surface layer from fracture during friction.

Figure 7 shows that grooves are visible in PCM at 1 wt.% CF, which is characterized by the increased wear, while in other composites, such a morphology on the friction surface is not observed. Thus, in all composites, CFs on the friction surface were uniformly distributed and randomly oriented; the number of CFs visible on the worn surfaces increased with increasing CF content in the PCM, which is consistent with the results of the wear rate.

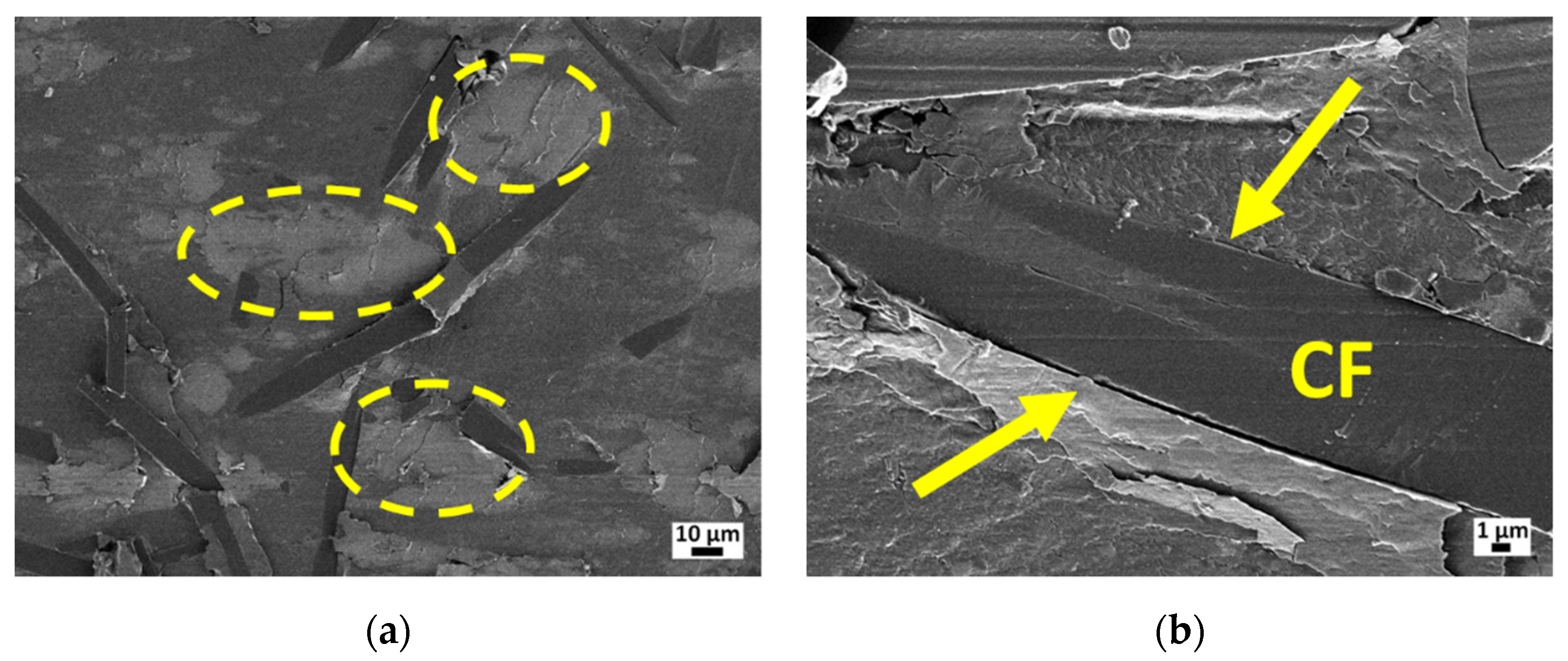

One of the theories explaining the decrease in wear with the introduction of micro-sized fillers in PTFE is associated with the interruption of the propagation of subsurface cracks by filler particles [

32]. However, the additional introduction of layered silicates into PTFE/CF leads to a significant increase in wear resistance compared to PTFE filled only with fibers, which is explained by the formation of secondary reinforced structures in the form of tribofilms between fibers on the worn surface [

14]. Such tribofilms were found on the PTFE/CF/Zt worn surface at high magnification of SEM images (

Figure 8).

It is known that under friction, PTFE/CF occurs over a steel counterbody, the CF becomes a protruding on the worn surface that protects the polymer material from wear, and in addition, the fibers wear and can be pulled out of the polymer matrix [

33]. Tribofilms are formed on the worn surface of the PCM between the fibers, as shown in

Figure 8a. The formation of such tribofilms protects the fibers from destruction, thereby significantly reducing material wear (

Figure 8b). It should be noted that tribofilms on the PCM friction surface are formed when mechanically activated aluminosilicates are introduced, which can also be evidenced by the occurrence of tribochemical reactions during friction by IR spectroscopy [

14,

33]. In addition, many works showed that the appearance of carboxyl groups on the friction surface of PCM and the metal counterbody coincided with a low wear rate due to the formation of a strong transfer film on the metal counterbody [

24,

34,

35].

The wear rate and the coefficient of friction of PTFE/CF/Zt composites compared with PTFE/CF/Kl and PTFE/CF/Vl (referred to as Kl—kaolin, Vl—vermiculite) from [

14] are shown in

Figure 9. For comparison of tribological characteristics, polymer composites based on PTFE filled with 8–10 wt.% CF were selected.

As shown in

Figure 9, PTFE/CF/Zt composite is characterized by high wear resistance and a low coefficient of friction in comparison with polymer composites of the compositions PTFE/CF/Kl and PTFE/CF/Vl. The wear rate of PCM with zeolite at a CF content of 8 wt.% is higher by 8–14%, at a CF content of 10 wt.% by 27–49% compared to composites with PTFE/CF/Kl and PTFE/CF/Vl. The coefficient of friction of PCM with zeolite is lower by 30–50% and 52–61% compared to composites containing Kl and Vl at a content of 8–10 wt.%, respectively. Perhaps one of the explanations for the higher wear resistance of PTFE/CF/Zt relative to PTFE/CF/Kl and PTFE/CF/Vl is the low coefficient of friction of composites with zeolite. Obviously, such a difference in tribological characteristics between the composites is associated with the type of used aluminosilicate.