Experimental Investigation of Unsteady Pressure Pulsation in New Type Dishwasher Pump with Special Double-Tongue Volute

Abstract

:1. Introduction

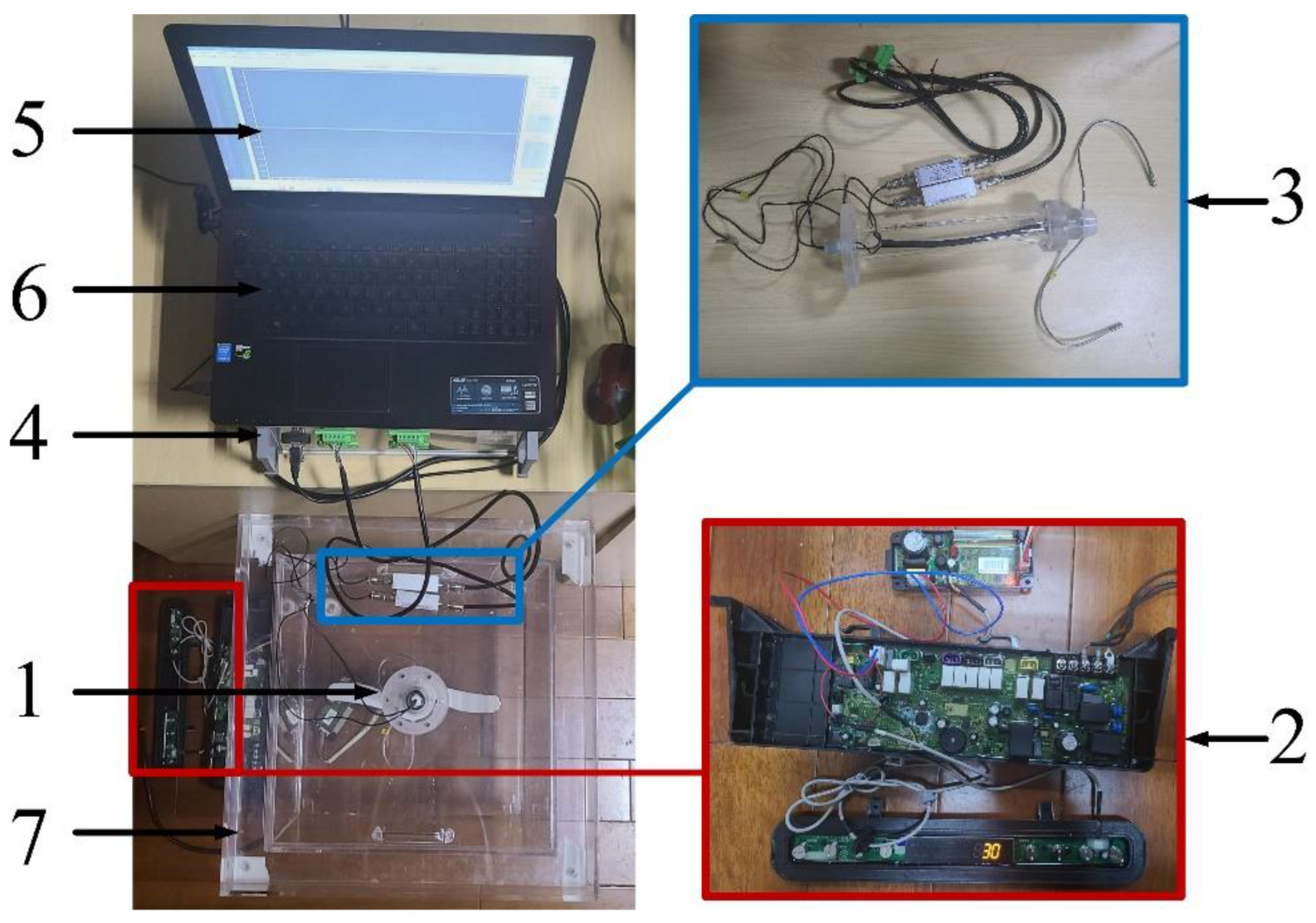

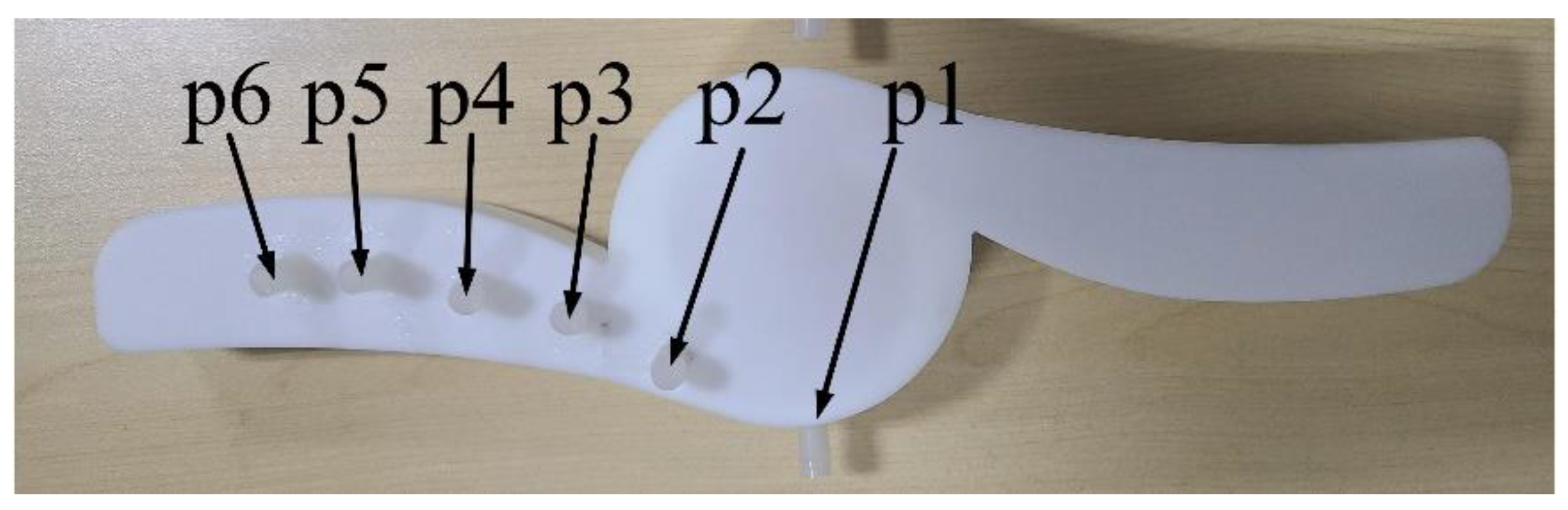

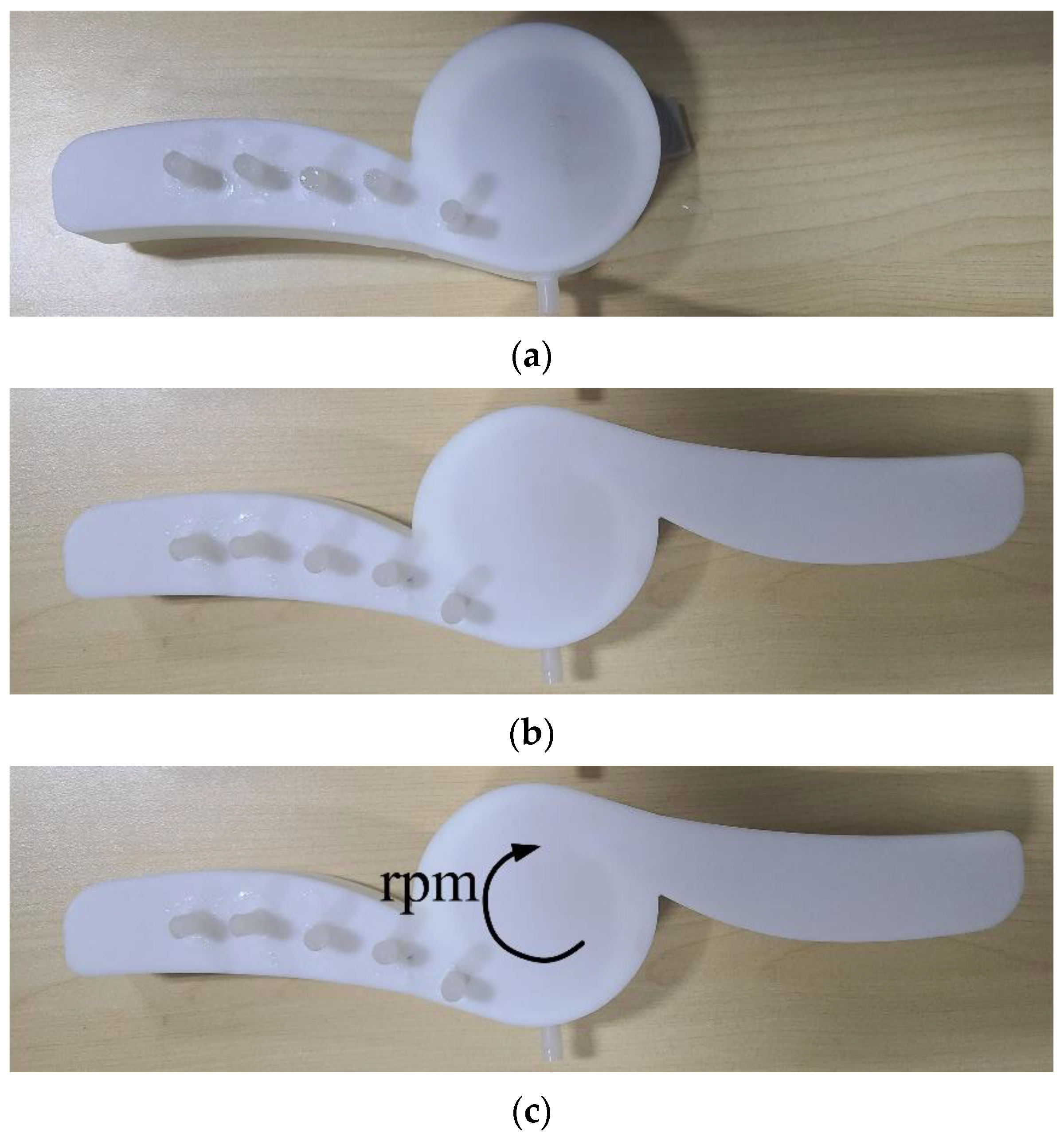

2. Open Test Rig Setup for Dishwasher Pump

3. Experimental Tests

4. Result and Discussion

4.1. Pressure Pulsation Analysis with Different Volutes

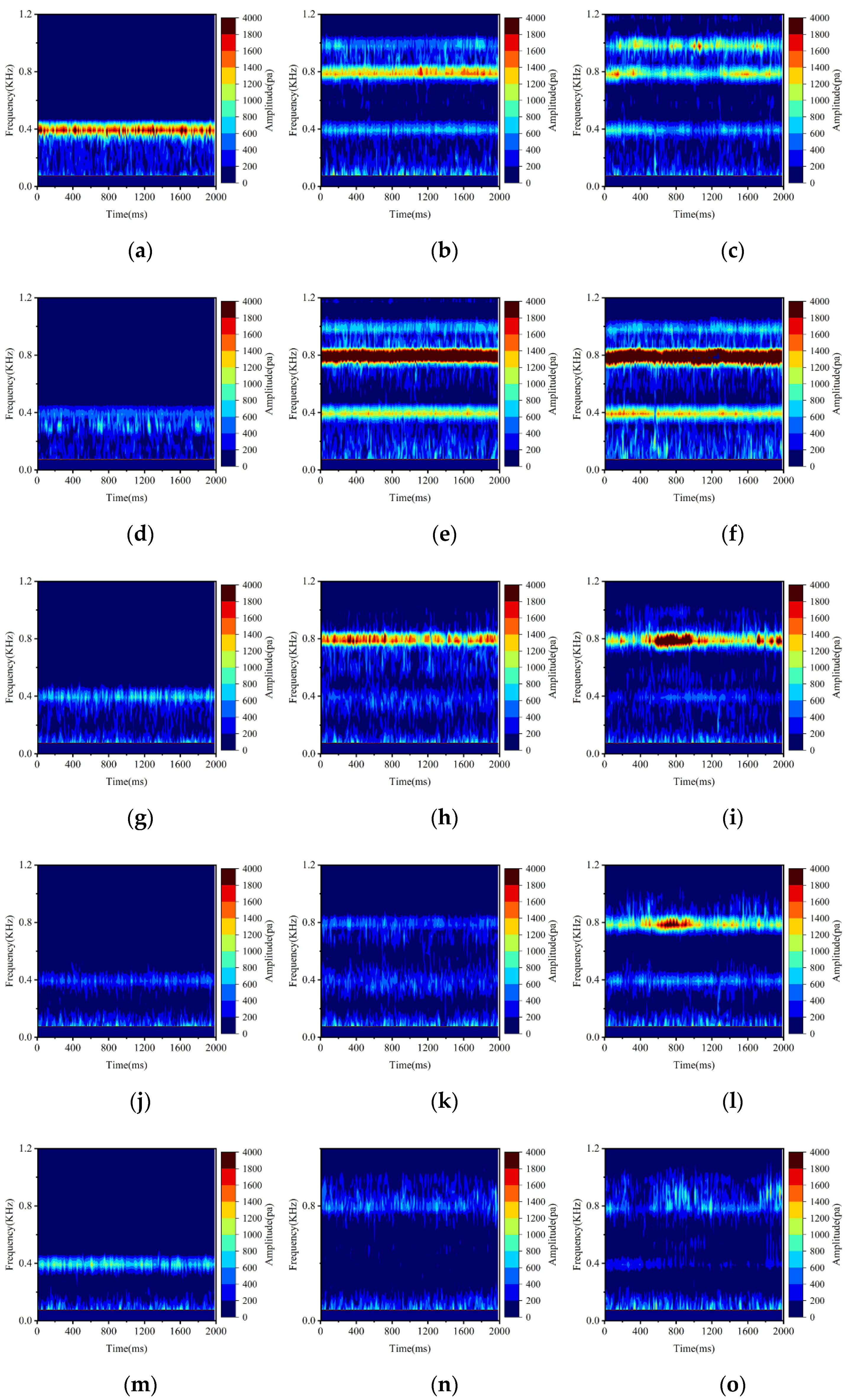

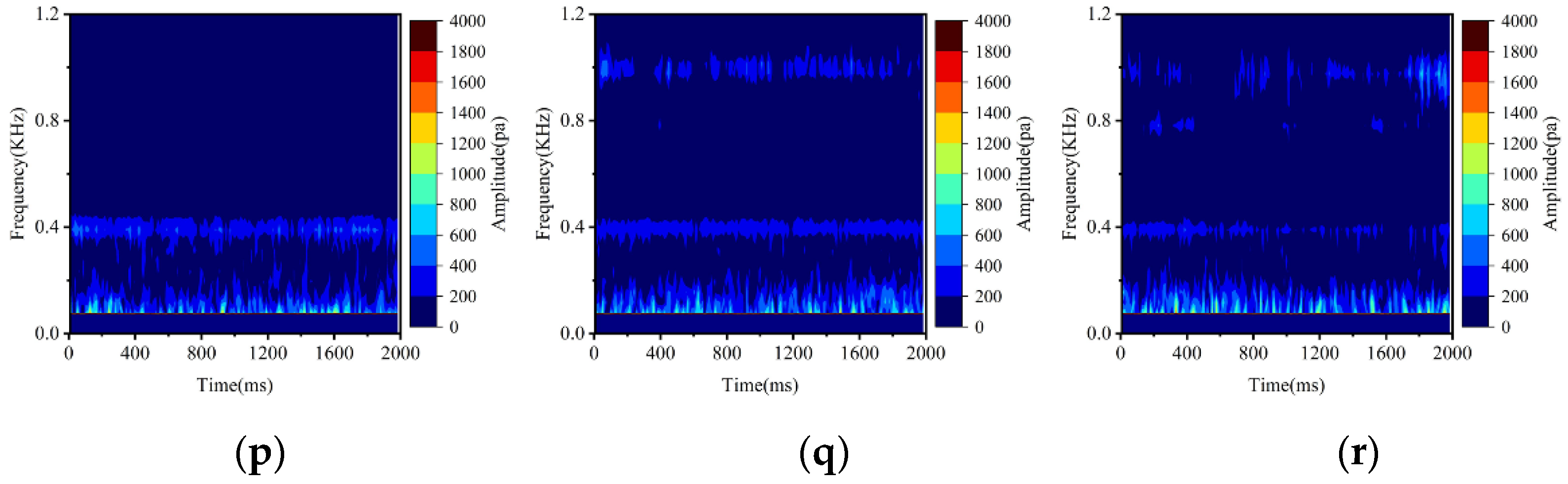

4.1.1. Time–Frequency Domain Analysis of Pressure Pulsation

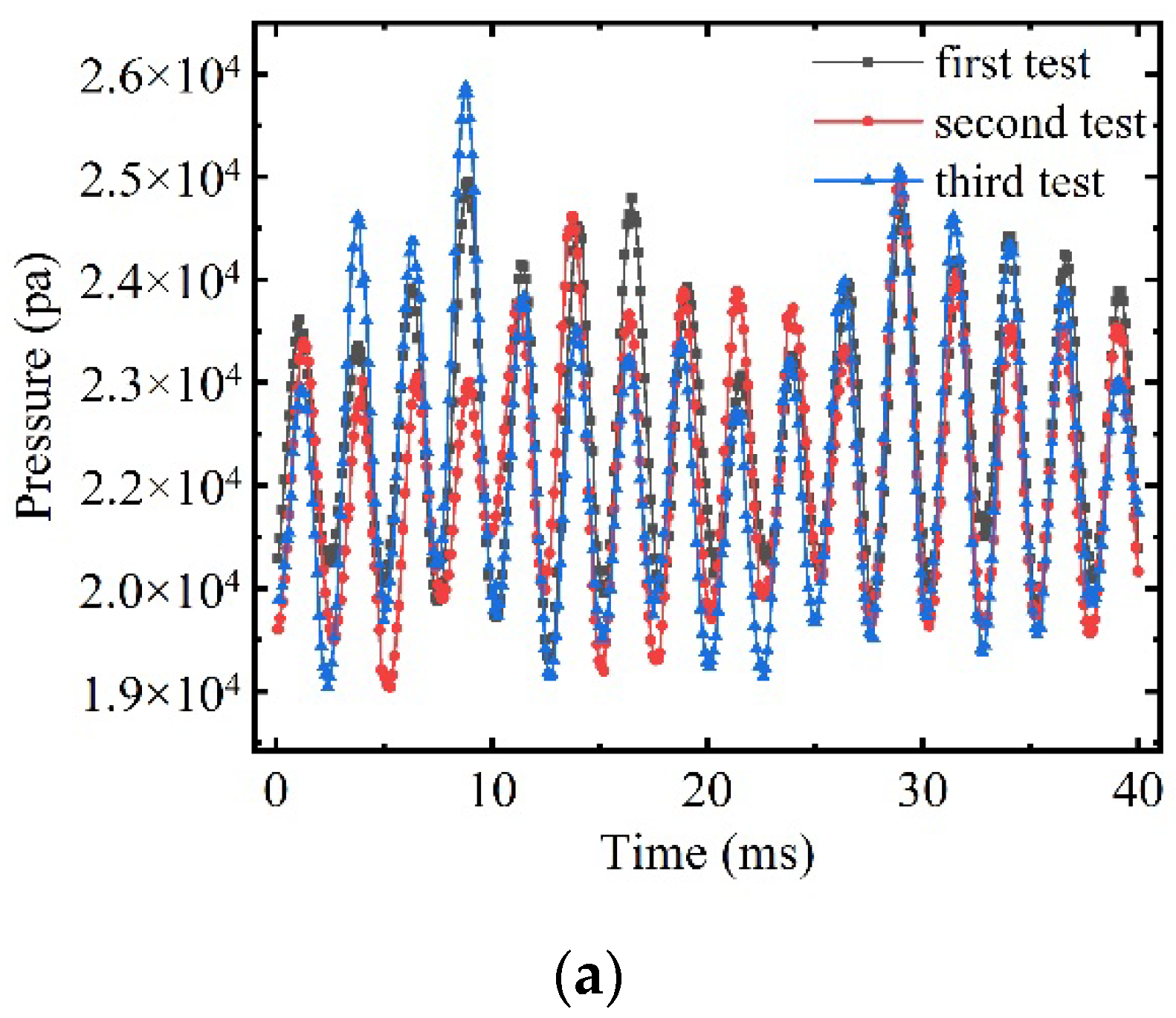

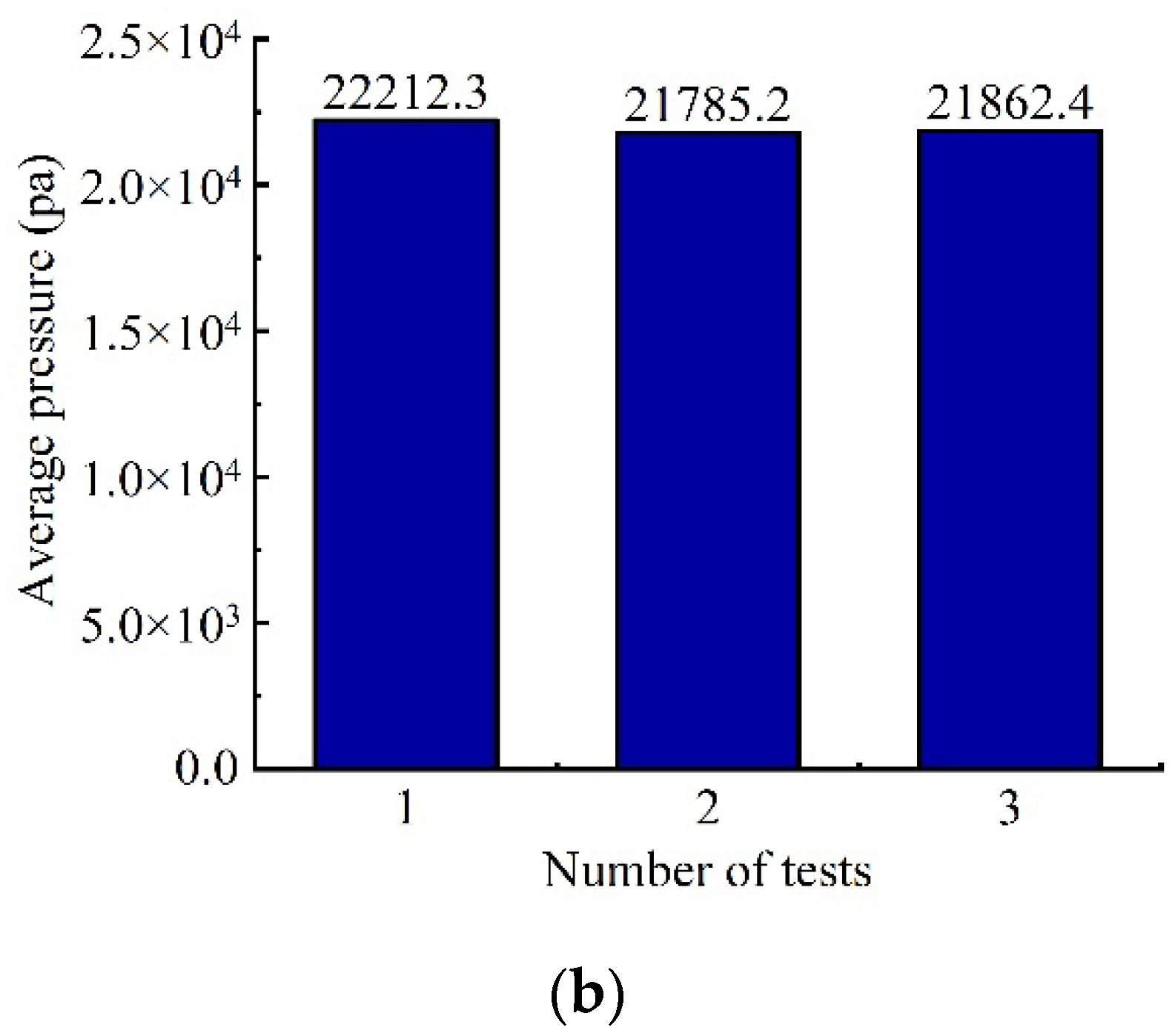

4.1.2. Comparative Analysis of Pressure Fluctuation Average Pressure

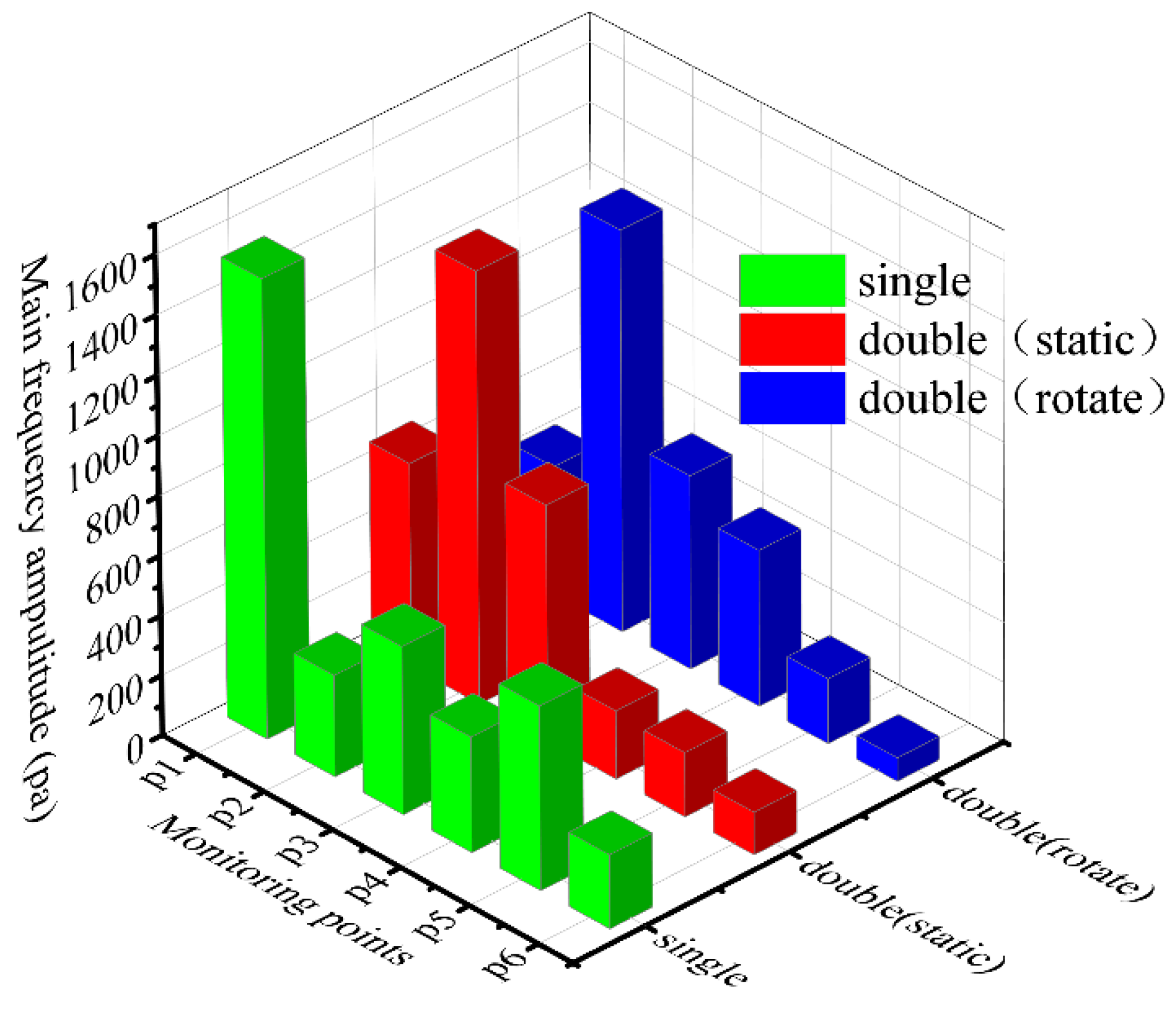

4.1.3. Dominant Frequency Amplitudes of the Pressure Pulsation

4.2. Pressure Pulsation Analysis at Different Impeller Speeds

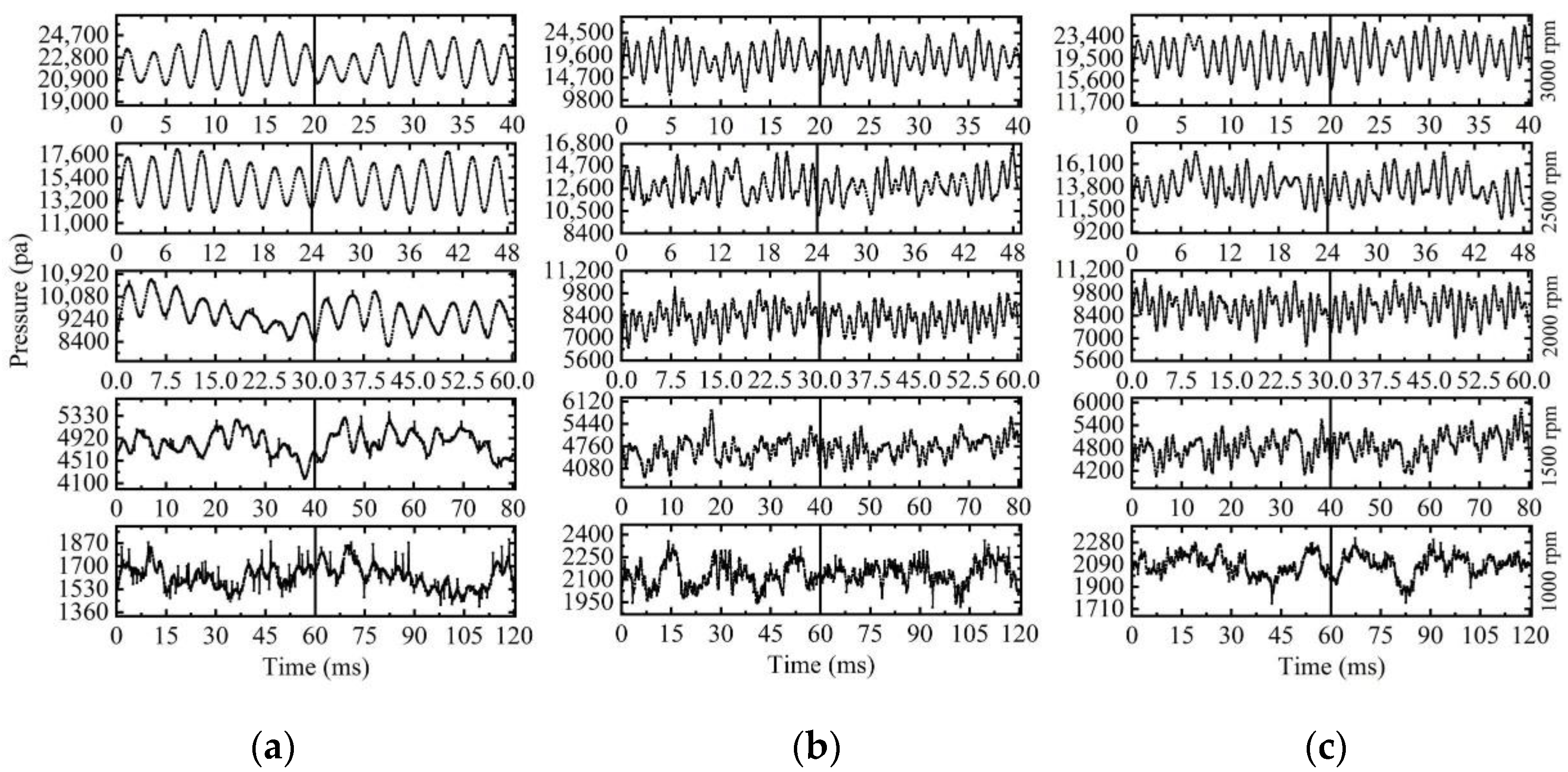

4.2.1. Time–Domain Analysis of Pressure Fluctuation

4.2.2. Frequency–Domain Analysis of Pressure Fluctuation

4.2.3. Dominant Frequency Amplitudes of the Pressure Pulsation

5. Conclusions

- (1)

- Compared with the single-tongue volute and the static double-tongue volute, the average pressure of each monitoring point in the dishwasher pump with a rotating double-tongue volute is the smallest, and from the pressure monitoring point from p3 to p6, the average pressure changes more gently, and the maximum deviation value is only 1.4%. The amplitude of the main frequency of the pressure pulsation of the double-tongue volute increases first and then decreases from the monitoring point p1 to p6 and reaches the maximum at the monitoring point p2. However, the amplitude of the main frequency of the single-tongue volute changes irregularly, and the maximum amplitude appears at the monitoring point p1. Therefore, for the dishwasher, the volute with the passive rotation has the best results, which can not only reduce the pressure and reduce vibration noise but also perform all-around cleaning, improving dishwasher efficiency.

- (2)

- When the impeller rotates at 3000 rpm, the number of peaks and valleys of the pressure pulsation time domain curve of the single-tongue volute is eight, while that of the double-tongue volute is two. The main frequency of the single-tongue volute is 0.396 kHz, which is concentrated near the blade frequency. The main frequencies of the static double-tongue volute and the rotating double-tongue volute are 0.791 kHz and 0.786, respectively, which are concentrated near the double-blade frequency.

- (3)

- Under the high impeller speeds of 2000, 2500, and 3000 rpm, the pressure pulsation time domain curves present periodicity, and the main frequencies are given priority with the blade frequency and integer times of the blade frequency. At the low impeller speeds of 1000 and 1500 rpm, the pressure pulsation becomes disordered, the periodicity of the time-domain curves disappears, and the main frequency is mainly axial frequency.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, L.; Wang, C.; Zhang, Y.C. Numerical study of coupled flow in blocking pulsed jet on a rotating wall. J. Braz. Soc. Mech. Sci. 2021, 43, 508. [Google Scholar] [CrossRef]

- Wang, H.L.; Qian, Z.D.; Zhang, D. Numerical study of the normal impinging water jet at different impinging height, based on Wray–Agarwal turbulence model. Energies 2020, 13, 1744. [Google Scholar] [CrossRef] [Green Version]

- Li, D.Y.; Wang, H.J.; Qin, Y.L. Numerical simulation of hysteresis characteristic in the hump region of a pump- turbine model. Renew. Energy 2018, 115, 438–447. [Google Scholar] [CrossRef]

- Li, D.Y.; Wang, H.J.; Qin, Y.L. Mechanism of high amplitude low frequency fluctuations in a pump-turbine in pump mode. J. Mech. Sci. Technol. 2018, 126, 668–680. [Google Scholar] [CrossRef]

- Xia, L.S.; Cheng, Y.G.; Cai, F. Pressure pulsation characteristics of a model pump-turbine operating in the S-shaped region: CFD simulations. Int. J. Fluid Mach. Syst. 2017, 10, 287–295. [Google Scholar] [CrossRef] [Green Version]

- Tang, S.N.; Zhu, Y.; Yuan, S.Q. An improved convolutional neural network with an adaptable learning rate towards multi-signal fault diagnosis of hydraulic piston pump. Adv. Eng. Inform. 2021, 50, 101406. [Google Scholar] [CrossRef]

- Zhu, Y.; Li, G.P.; Wang, R. Intelligent fault diagnosis of hydraulic piston pump combining improved LeNet-5 and PSO hyperparameter optimization. Appl. Acoust. 2021, 183, 108336. [Google Scholar] [CrossRef]

- Jin, J.M.; Jung, K.J.; Kim, Y.H. Effects of gap between impeller and volute tongue on a pressure fluctuation in double-suction pump. J. Mech. Sci. Technol. 2020, 34, 4879–4903. [Google Scholar] [CrossRef]

- Alemi, H.; Nourbakhsh, S.A.; Raisee, M. Effect of the volute tongue profile on the performance of a low specific speed centrifugal pump. Proc. Inst. Mech. Eng. Part A J. Power Energy 2015, 229, 210–220. [Google Scholar] [CrossRef]

- Patil, S.R.; Chavab, S.T.; Jadhav, N.S. Effect of volute tongue clearance variation on performance of centrifugal blower by numerical and experimental analysis. Mater. Today 2018, 5, 3883–3894. [Google Scholar] [CrossRef]

- Shim, H.S.; Afzal, A.; Kim, K.Y. Three-objective optimization of a centrifugal pump with double volute to minimize radial thrust at off-design conditions. Proc. Inst. Mech. Eng. Part A J. Power Energy 2016, 230, 598–615. [Google Scholar] [CrossRef]

- Yang, S.H.; Kong, F.Y.; Chen, B. Research on pump volute design method using CFD. Int. J. Rotating Mach. 2011, 2011, 137860. [Google Scholar] [CrossRef]

- Wang, H.L.; Long, B.; Wang, C. Effects of the impeller blade with a slot structure on the centrifugal pump performance. Energies 2020, 13, 1628. [Google Scholar] [CrossRef]

- Zhou, J.R.; Zhao, M.M.; Wang, C. Optimal design of diversion piers of lateral intake pumping station based on orthogonal test. Shock Vib. 2021, 2021, 6616456. [Google Scholar] [CrossRef]

- Wang, H.L.; Hu, Q.X.; Yang, Y. Performance differences of electrical submersible pump under variable speed schemes. Int. J. Simul. Model. 2021, 20, 76–86. [Google Scholar] [CrossRef]

- Shi, L.J.; Zhu, J.; Tang, F.P. Multi-Disciplinary optimization design of axial-flow pump impellers based on the approximation model. Energies 2020, 13, 779. [Google Scholar] [CrossRef] [Green Version]

- Li, Q.Q.; Li, S.Y.; Wu, P. Investigation on reduction of pressure fluctuation for a double-suction centrifugal pump. Chin. J. Mech. Eng. 2021, 34, 192–209. [Google Scholar] [CrossRef]

- Zhang, J.F.; Appiah, D.; Zhang, F. Experimental and numerical investigations on pressure pulsation in a pump mode operation of a pump as turbine. Energy Sci. Eng. 2019, 7, 1264–1279. [Google Scholar] [CrossRef]

- Tan, L.; Yu, Z.Y.; Xu, Y. Role of blade rotational angle on energy performance and pressure fluctuation of a mixed-flow pump. Proc. Inst. Mech. Eng. Part A J. Power Energy 2017, 231, 227–238. [Google Scholar]

- Meng, L.; Zhang, S.P.; Zhou, L.J. Study on the pressure pulsation inside runner with splitter blades in ultra-high head turbine. IOP Conf. Ser. EES 2014, 22, 032012. [Google Scholar] [CrossRef]

- Xia, L.S.; Cheng, Y.G.; Zhang, X.X. Numerical analysis of rotating stall instabilities of a pump- turbine in pump mode. IOP Conf. Ser. EES 2014, 22, 032020. [Google Scholar] [CrossRef] [Green Version]

- Wu, D.H.; Ren, Y.; Mou, J.G. Investigation of pressure pulsations and flow instabilities in a centrifugal pump at part-load conditions. Int. J. Fluid Mach. Syst. 2017, 10, 355–362. [Google Scholar] [CrossRef]

- Shi, L.J.; Yuan, Y.; Jiao, H.F. Numerical investigation and experiment on pressure pulsation characteristics in a full tubular pump. Renew. Energy 2021, 163, 987–1000. [Google Scholar] [CrossRef]

- Zhang, F.; Lowys, P.Y.; Houdeline, J.B. Pump-turbine rotor-stator interaction induced vibration: Problem resolution and experience. IOP Conf. Ser. EES 2021, 774, 012124. [Google Scholar] [CrossRef]

- Song, X.J.; Liu, C. Experimental investigation of pressure pulsation induced by the floor-attached vortex in an axial flow pump. Adv. Mech. Eng. 2019, 11, 1–13. [Google Scholar] [CrossRef] [Green Version]

- Liu, Y.P.; Li, X.J.; Li, B.W. Influence of impeller sinusoidal tubercle trailing-edge on pressure pulsation in a centrifugal pump at nominal flow rate. J. Fluids Eng. 2021, 143, 091205. [Google Scholar]

- Duan, X.H.; Tang, F.P.; Duan, W.Y.; Zhou, W.; Shi, L. Experimental investigation on the correlation of pressure pulsation and vibration of axial flow pump. Adv. Mech. Eng. 2019, 11, 1–11. [Google Scholar] [CrossRef] [Green Version]

- Ni, D.; Zhang, N.; Gao, B. Dynamic measurements on unsteady pressure pulsations and flow distributions in a nuclear reactor coolant pump. Energy 2020, 198, 117305. [Google Scholar] [CrossRef]

- Zhang, N.; Yang, M.G.; Gao, B. Experimental and numerical analysis of unsteady pressure pulsation in a centrifugal pump with slope volute. J. Mech. Sci. Technol. 2015, 29, 4231–4238. [Google Scholar] [CrossRef]

- Wang, W.J.; Pei, J.; Yuan, S.Q. Experimental investigation on clocking effect of vaned diffuser on performance characteristics and pressure pulsations in a centrifugal pump. Energy 2018, 90, 286–298. [Google Scholar] [CrossRef]

- Allen, J.B. Short term spectral analysis, synthesis, and modification by discrete Fourier transform. IEEE Trans. Acoust. Speech Signal Process. 1977, 25, 235–238. [Google Scholar] [CrossRef]

- Sun, T.Z.; Zhang, X.S.; Zhang, J.Y. Experimental study on the unsteady natural cloud cavities: Influence of cavitation number on cavity evolution and pressure pulsations. J. Mar. Sci. Eng. 2021, 9, 1-13. [Google Scholar] [CrossRef]

- Wang, C.; Zhang, Y.X.; Li, Z.W. Pressure fluctuation–vortex interaction in an ultra-low specific-speed centrifugal pump. J. Low Freq. Noise Vib. Act. Control. 2019, 38, 527–543. [Google Scholar] [CrossRef] [Green Version]

- Bai, L.; Zhou, L.; Han, C.; Zhu, Y.; Shi, W. Numerical study of pressure fluctuation and unsteady flow in a centrifugal pump. Processes 2019, 7, 354. [Google Scholar] [CrossRef] [Green Version]

- Bosioc, A.I.; Tanasa, C.; Muntean, S. Unsteady pressure measurements and numerical investigation of the jet control method in a conical differ with swirling flow. IOP Conf. Ser. EES 2010, 12, 012017. [Google Scholar] [CrossRef] [Green Version]

- Zhou, Q.; Zhao, X.W.; Pei, L. Investigation on pressure pulsation and modal behavior of the impeller in a nuclear reactor coolant pump. Energy Sci. Eng. 2021, 9, 1440–1449. [Google Scholar] [CrossRef]

- Yang, J.; Liu, J.; Liu, X.H. Numerical study of pressure pulsation of centrifugal pumps with the compressible mode. J. Therm. Sci. 2019, 28, 106–114. [Google Scholar] [CrossRef]

- Gao, Y.S.; Cheng, J.; Huang, J.H. Simulation analysis and experiment of variable-displacement asymmetric axial piston pump. Appl. Sci. 2017, 7, 328. [Google Scholar] [CrossRef] [Green Version]

- Yang, Y.; Zhou, L.; Shi, W.D. Interstage difference of pressure pulsation in a three-stage electrical submersible pump. J. Petrol. Sci. Eng. 2021, 196, 107683. [Google Scholar] [CrossRef]

- Zhou, Q.; Li, H.K.; Pei, L. Research on non-uniform pressure pulsation of the diffuser in a nuclear reactor coolant pump. Nucl. Eng. Technol. 2020, 53, 1020–1028. [Google Scholar] [CrossRef]

- Muntean, S.; Tanasa, C.; Bosioc, A.I. Investigation of the plunging pressure pulsation in a swirling flow with precessing vortex rope in a straight diffuser. IOP Conf. Ser. EES 2016, 49, 082010. [Google Scholar] [CrossRef]

| Parameter | Value | |

|---|---|---|

| Impeller | Impeller inlet diameter Din (mm) | 32 |

| Impeller outlet width b1 (mm) | 14.15 | |

| Impeller outlet diameter Dout (mm) | 43.3 | |

| Number of blades Z | 8 | |

| Volute | Volute inlet width b3 (mm) | 17.8 |

| Volute base circle diameter D3 (mm) | 46 | |

| Volute tongue angle θ (º) | 34 |

| Variable | Frequency/kHz | ||||

|---|---|---|---|---|---|

| 3000 rpm | 2500 rpm | 2000 rpm | 1500 rpm | 1000 rpm | |

| fn | 0.05 | 0.042 | 0.033 | 0.025 | 0.017 |

| fBPF | 0.4 | 0.333 | 0.267 | 0.2 | 0.133 |

| Volute Condition | Frequency/kHz | ||||

|---|---|---|---|---|---|

| 3000 rpm | 2500 rpm | 2000 rpm | 1500 rpm | 1000 rpm | |

| Single-tongue volute | 0.396 | 0.339 | 0.265 | 0.024 | 0.016 |

| Double-tongue volute (static) | 0.791 | 0.662 | 0.793 | 0.199 | 0.016 |

| Double-tongue volute (rotate) | 0.784 | 0.658 | 0.793 | 0.198 | 0.016 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, Y.; Zhang, J.; Li, Y.; Huang, P.; Xu, H.; Zheng, F. Experimental Investigation of Unsteady Pressure Pulsation in New Type Dishwasher Pump with Special Double-Tongue Volute. Machines 2021, 9, 288. https://doi.org/10.3390/machines9110288

Zhu Y, Zhang J, Li Y, Huang P, Xu H, Zheng F. Experimental Investigation of Unsteady Pressure Pulsation in New Type Dishwasher Pump with Special Double-Tongue Volute. Machines. 2021; 9(11):288. https://doi.org/10.3390/machines9110288

Chicago/Turabian StyleZhu, Yilei, Jinfeng Zhang, Yalin Li, Ping Huang, Hui Xu, and Feng Zheng. 2021. "Experimental Investigation of Unsteady Pressure Pulsation in New Type Dishwasher Pump with Special Double-Tongue Volute" Machines 9, no. 11: 288. https://doi.org/10.3390/machines9110288

APA StyleZhu, Y., Zhang, J., Li, Y., Huang, P., Xu, H., & Zheng, F. (2021). Experimental Investigation of Unsteady Pressure Pulsation in New Type Dishwasher Pump with Special Double-Tongue Volute. Machines, 9(11), 288. https://doi.org/10.3390/machines9110288