Automated Kinematic Analysis of Closed-Loop Planar Link Mechanisms

Abstract

1. Introduction

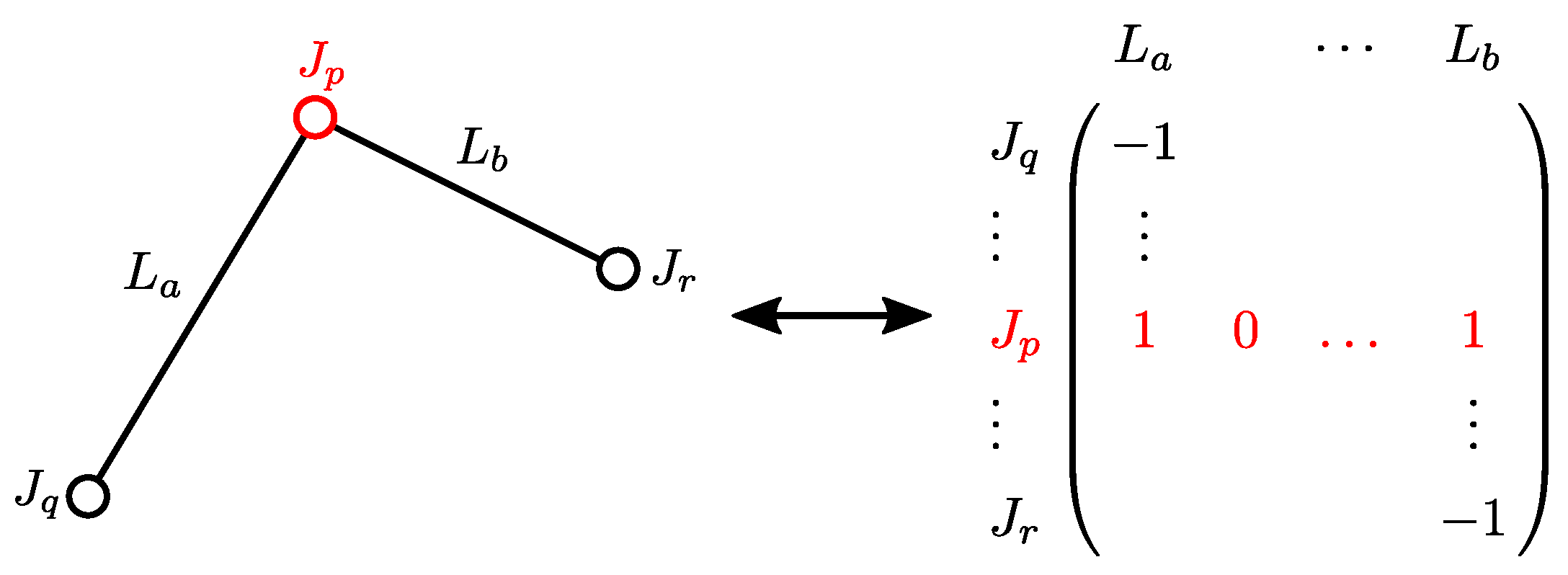

2. General Matrix Representation of Linkages

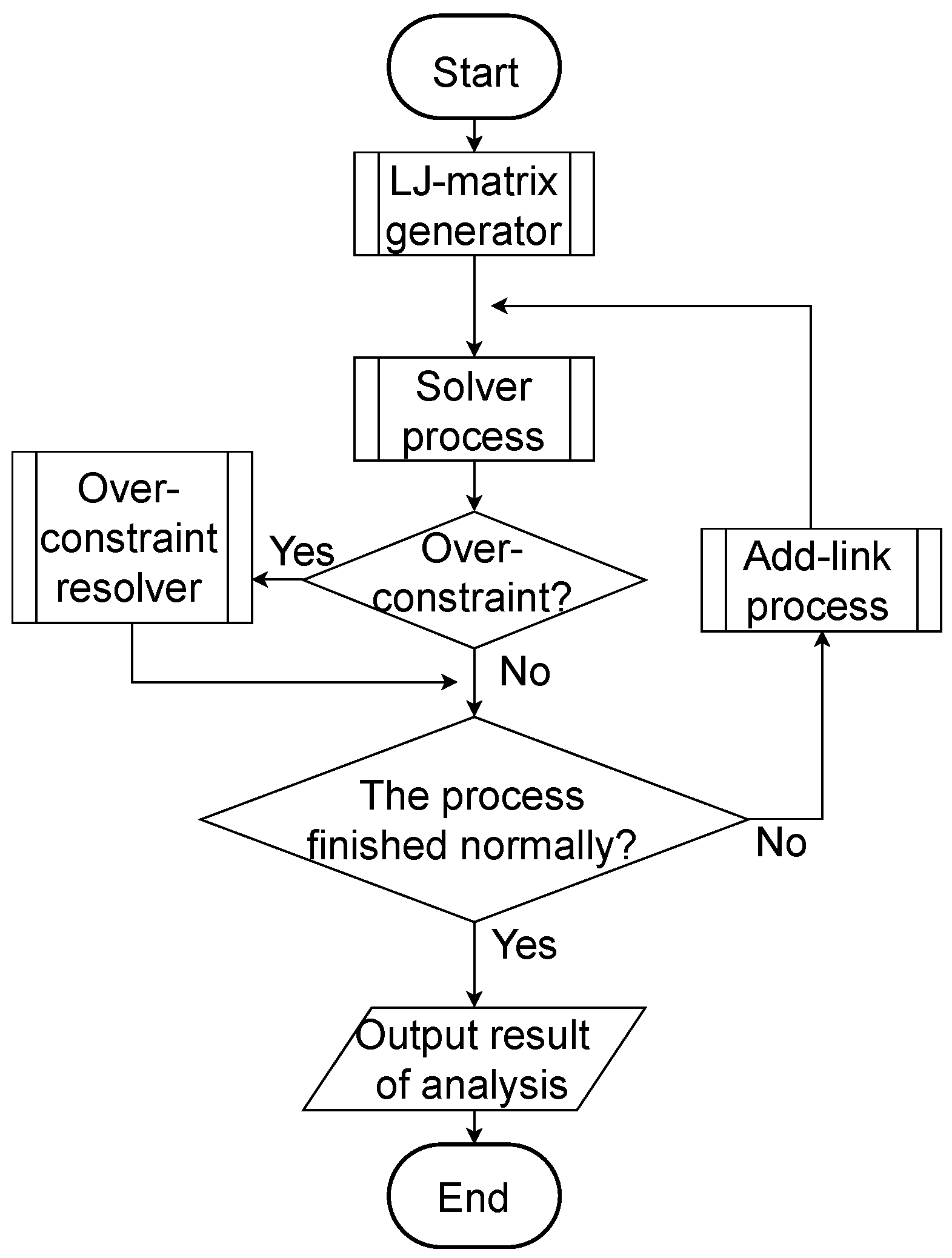

3. Procedure Extraction Algorithm

3.1. Systematic Analysis Based on Two-Link Chains

- (i)

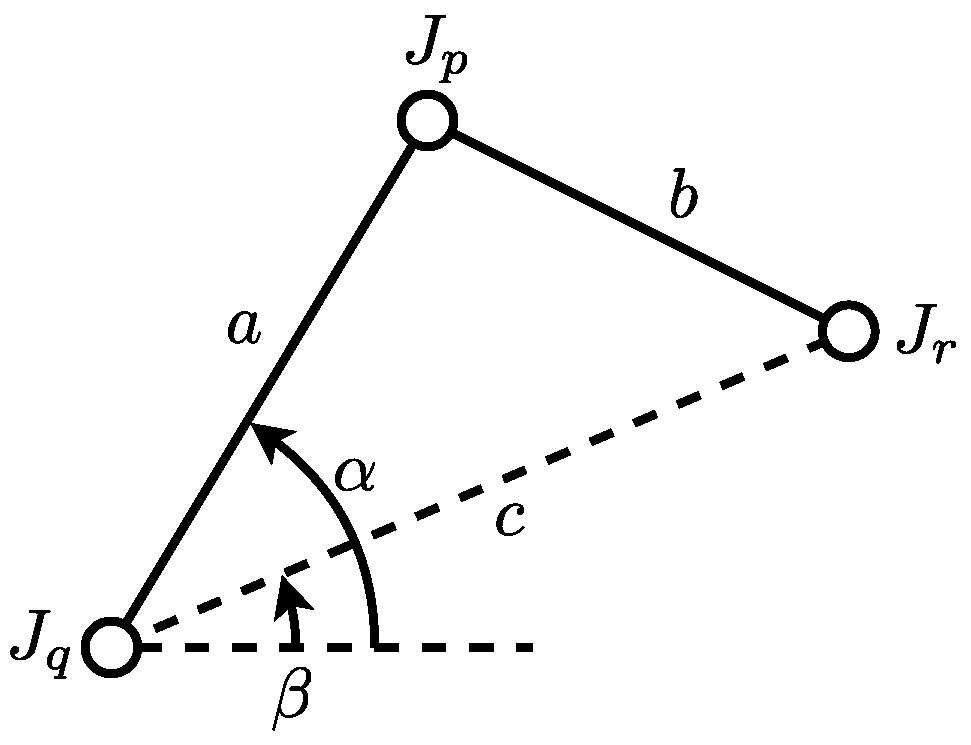

- 3R link chainand are calculated from and with the link length a, b, and time derivatives of them.where , , , , , , , and . Each of and has two solutions. They are symmetric about line connecting and on the -plane.

- (ii)

- 2R1P link chainand are calculated from and with the link direction , the link length b, and time derivatives of them by Equations (3) and (4), where , , , and . Each of and has two solutions. They are symmetric about a line perpendicular to the direction of passing through on the -plane.

- (iii)

- 1R2P link chainand are calculated from and with the pair direction , , and time derivatives of them.where , , , , , , , and .

3.2. Two-Link Chain Searching Algorithm

| Algorithm 1: Solver algorithm. |

| LJ-matrix: while (condition: if such that % Calculate position and velocity of p-th joint with transformation function f % end end |

The Limitation of Solver Algorithm

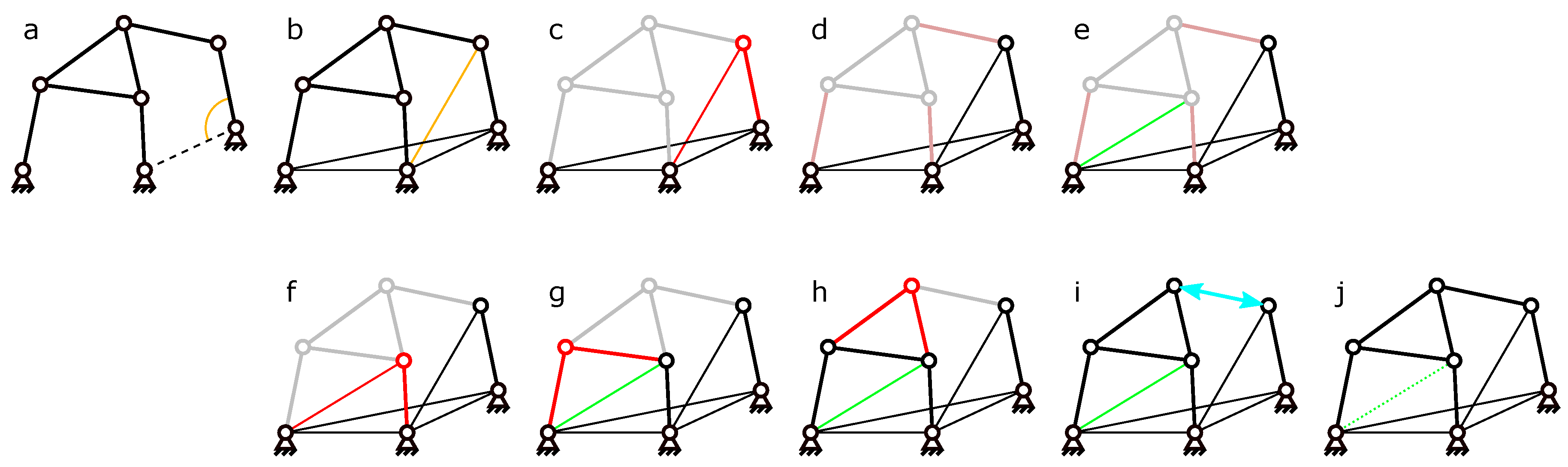

3.3. Auxiliary Process for Dealing with an Unsolvable Mechanism

3.3.1. Additional Temporal Constraint Link

3.3.2. Resolving Over-Constraint

4. Flowchart

5. Results

5.1. Problem 1: A Slider-Crank Mechanism

1 lj_mat = fixed_link(lj_mat,link1);

2 joint3 = RRR_links(link2,link5,joint1,joint2);

3 joint4 = PRR_links(link3,link4,joint3,joint2);

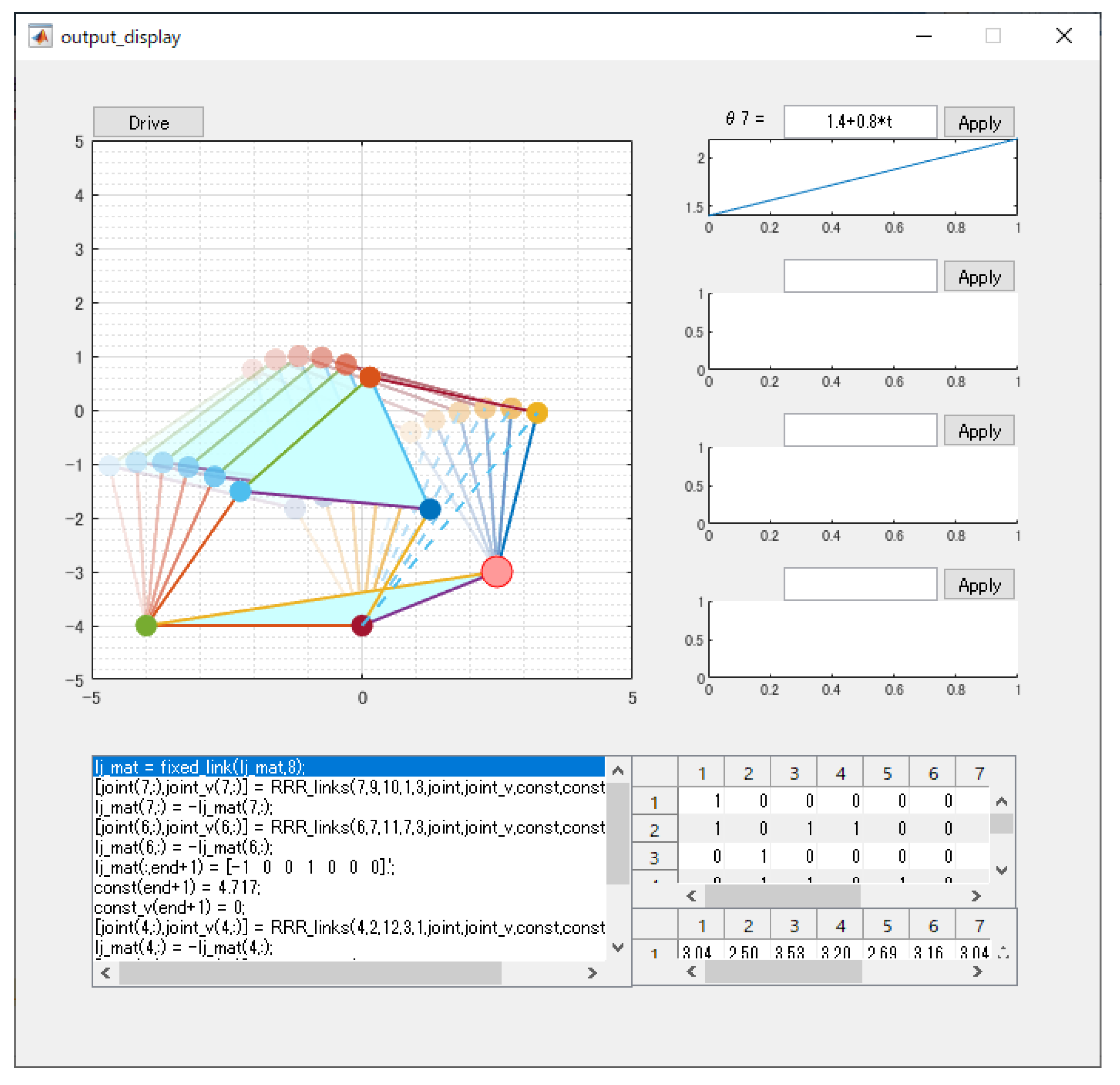

5.2. Problem 2: A Six-Bar Linkage Mechanism

1 lj_mat = fixed_link(lj_mat,link8,link9,link10); 2 joint6 = RRR_links(link7,link11,joint7,joint3); 3 additional_link(joint1,joint4); 4 joint4 = RRR_links(link2,link12,joint3,joint1); 5 joint2 = RRR_links(link1,link3,joint1,joint4); 6 joint5 = RRR_links(link4,link5,joint2,joint4); 7 add_link_optimizer(target_link[6],add-link[12]);

6. Processing Time of the Algorithm Depending on Add-Link Choice

7. Conclusion and Future Works

7.1. Conclusions

- (1)

- LJ-matrix that represents the relationship between links and joints, classification of pairs which are known or unknown has been proposed.

- (2)

- An algorithm for automatically searching two-links chains and extracting the analysis procedure has been established.

- (3)

- This method does not require many kinds of transformation function but is based only on one transformation function.

- (4)

- For a mechanism not analyzed by only the two-links chain based calculations, the analysis is achieved by installing temporally over-constraints as additional links.

- (5)

- The proposed algorithm generates the procedure manual and MATLAB program for the analysis.

- (6)

- The generated procedure manual explicitly reveals the process of analysis.

- (7)

- For several mechanisms, their analysis procedures are extracted and their motions are analyzed with the extracted procedures.

- (8)

- It is shown that the best Add-link candidate that minimizes the processing time of the analysis program is found by assessing the norm of function values to obtain proper Add-links before executing the Over-constraint resolver.

7.2. Future Works

Author Contributions

Funding

Conflicts of Interest

References

- Wampler, C.W. Solving the kinematics of planar mechanisms. J. Mech. Des. 1999, 121, 387–391. [Google Scholar] [CrossRef]

- Nielsen, J.; Roth, B. Solving the Input/Output problem for Planar Mechanisms. J. Mech. Des. 1999, 121, 206–211. [Google Scholar] [CrossRef]

- Dixon, A.L. The Eliminant of Three Quantics in Two Independent Variables. Proc. Lond. Math. Soc. 1909, 2–7, 49–69. [Google Scholar] [CrossRef]

- Dassault Systèmes SOLIDWORKS Corp. Available online: https://www.solidworks.com/ (accessed on 27 May 2020).

- Autodesk Inc. Available online: https://www.autodesk.com/products/fusion-360/overview (accessed on 27 May 2020).

- OPEN CASCADE SAS. Available online: https://www.opencascade.com/ (accessed on 27 May 2020).

- The Japan Society of Mechanical Engineers (Ed.) JSME Textbook Series Kinematics of Machinery; JSME: Tokyo, Japan, 2007; pp. 57–60. (In Japanese) [Google Scholar]

- McCarthy, J.M.; Soh, G.S. Geometric Design of Linkages, 2nd ed.; Springer: New York, NY, UAS, 2010. [Google Scholar]

- Mitsi, S.; Bouzakis, K.-D.; Mansour, G.; Popescu, I. Position analysis in polynomial form of planar mechanisms with Assur groups of class 3 including revolute and prismatic joints. Mech. Mach. Theory 2003, 38, 1325–1344. [Google Scholar] [CrossRef]

- Chung, W.-Y. The position analysis of Assur kinematic chain with five links. Mech. Mach. Theory 2005, 40, 1015–1029. [Google Scholar] [CrossRef]

- Han, L.; Liao, Q.; Liang, C. Closed-form displacement analysis for a nine-link Barranov truss or a eight-link Assur group. Mech. Mach. Theory 2000, 35, 379–390. [Google Scholar] [CrossRef]

- Innocenti, C. Polynomial solution to the position analysis of the 7-link assur kinematic chain with one quaternary link. Mech. Mach. Theory 1995, 30, 1295–1303. [Google Scholar] [CrossRef]

- Galletti, C.U. A note on modular approaches to planar linkage kinematic analysis. Mech. Mach. Theory 1986, 21, 385–391. [Google Scholar] [CrossRef]

- Funabashi, H.; Ogawa, K.; Hara, T. A Systematic Analysis of Planar Multilink Mechanisms. Bull. JSME 1977, 20, 343. [Google Scholar] [CrossRef][Green Version]

- Erdman, A.G.; Sandor, G.N. Mechanism Design: Analysis and Synthesis; Prentice-Hall: Englewood Cliffs, NJ, USA, 1997; pp. 135–137. [Google Scholar]

- Müller, M.; Mannheim, T.; Hüsing, M.; Corves, B. MechDev—A New Software for Developing Planar Mechanisms. In Interdisciplinary Applications of Kinematics, Proceedings of the Third International Conference (IAK); Springer: Cham, Switzerland, 2019; pp. 167–175. [Google Scholar]

- Yamamoto, T.; Nobuyuki, I.; Ikuma, I. Automated kinematic analysis of planar link mechanisms. In Proceedings of the 25th Jc-IFToMM Symposium, Kanagawa, Japan, 25–26 October 2019. [Google Scholar]

- Li, D.; Zhang, Z.; McCarthy, J.M. A Constraint Graph Representation of Metamorphic Linkages. Mech. Mach. Theory 2011, 46, 228–238. [Google Scholar] [CrossRef]

- Woo, L.S. Type Synthesis of Planar Linkages. ASME J. Eng. Ind. 1967, 89, 159–172. [Google Scholar] [CrossRef]

- Li, S.; Dai, J.S. Augmented Adjacency Matrix for Topological Configuration of the Metamorphic Mechanisms. J. Adv. Mech. Des. Syst. Manuf. 2011, 5, 187–198. [Google Scholar] [CrossRef]

- Dai, J.S.; Rees Jones, J. Matrix Representation of Topological Configuration Transformation of Metamorphic Mechanisms. ASME J. Mech. Des. 2005, 127, 837–840. [Google Scholar] [CrossRef]

| Is | Revolute Pair | Prismatic Pair |

|---|---|---|

| Known | a = −1 | a = −2 |

| Unknown | a = 1 | a = 2 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yamamoto, T.; Iwatsuki, N.; Ikeda, I. Automated Kinematic Analysis of Closed-Loop Planar Link Mechanisms. Machines 2020, 8, 41. https://doi.org/10.3390/machines8030041

Yamamoto T, Iwatsuki N, Ikeda I. Automated Kinematic Analysis of Closed-Loop Planar Link Mechanisms. Machines. 2020; 8(3):41. https://doi.org/10.3390/machines8030041

Chicago/Turabian StyleYamamoto, Tatsuya, Nobuyuki Iwatsuki, and Ikuma Ikeda. 2020. "Automated Kinematic Analysis of Closed-Loop Planar Link Mechanisms" Machines 8, no. 3: 41. https://doi.org/10.3390/machines8030041

APA StyleYamamoto, T., Iwatsuki, N., & Ikeda, I. (2020). Automated Kinematic Analysis of Closed-Loop Planar Link Mechanisms. Machines, 8(3), 41. https://doi.org/10.3390/machines8030041