Active Attitude Stabilization and Power-Constrained Control of Bicycles Based on VSCMG System

Abstract

1. Introduction

Motivation

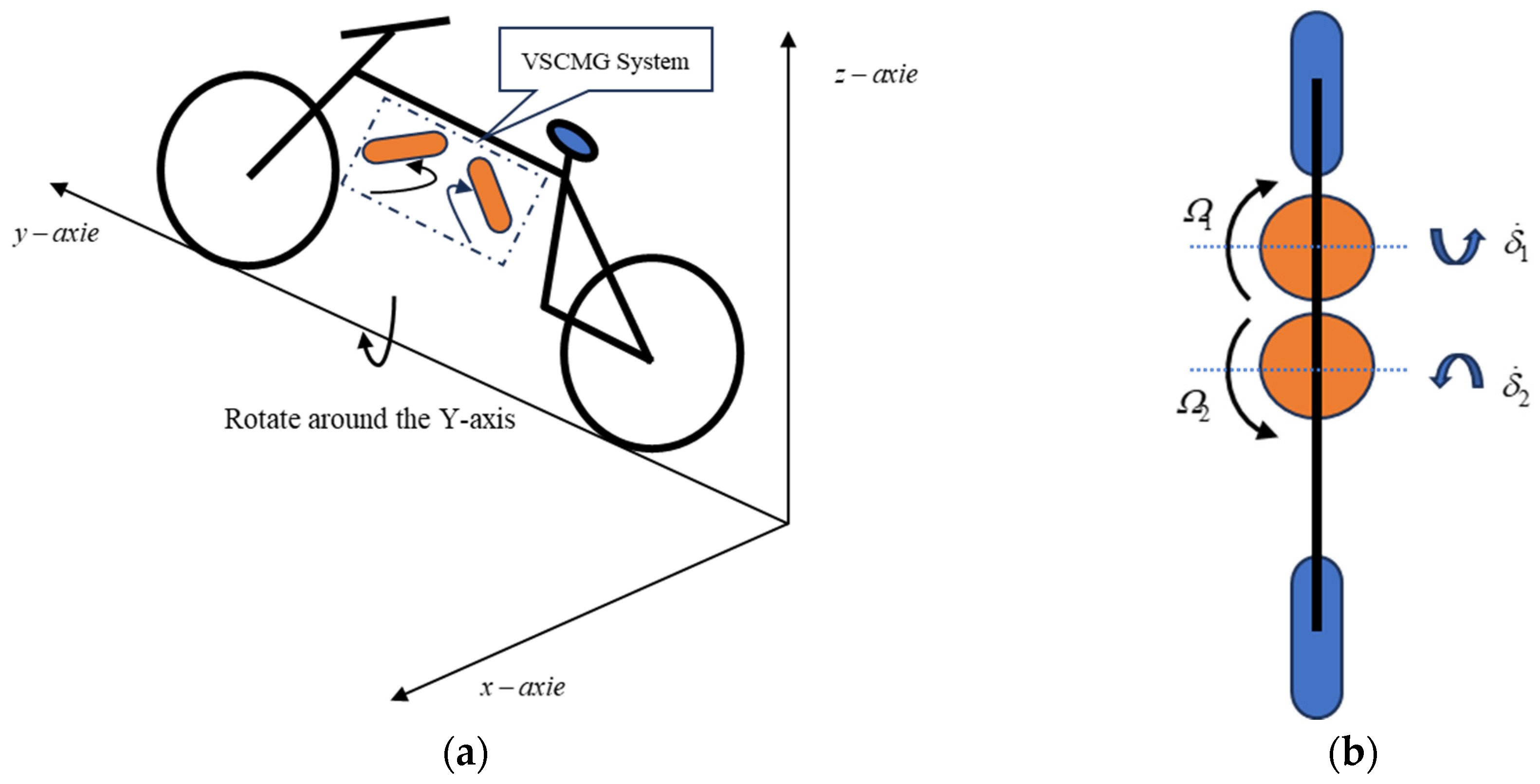

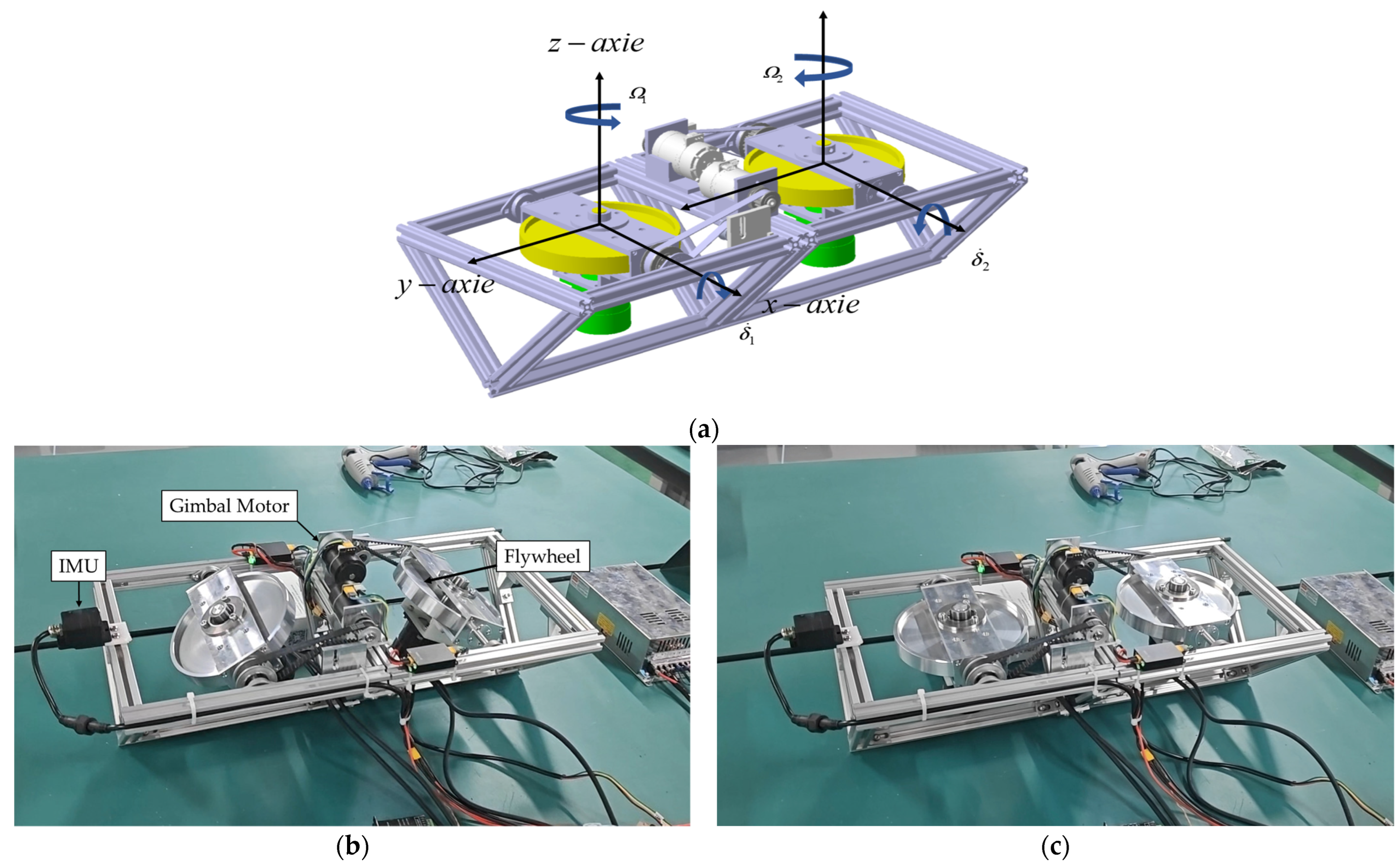

2. Mechanical System

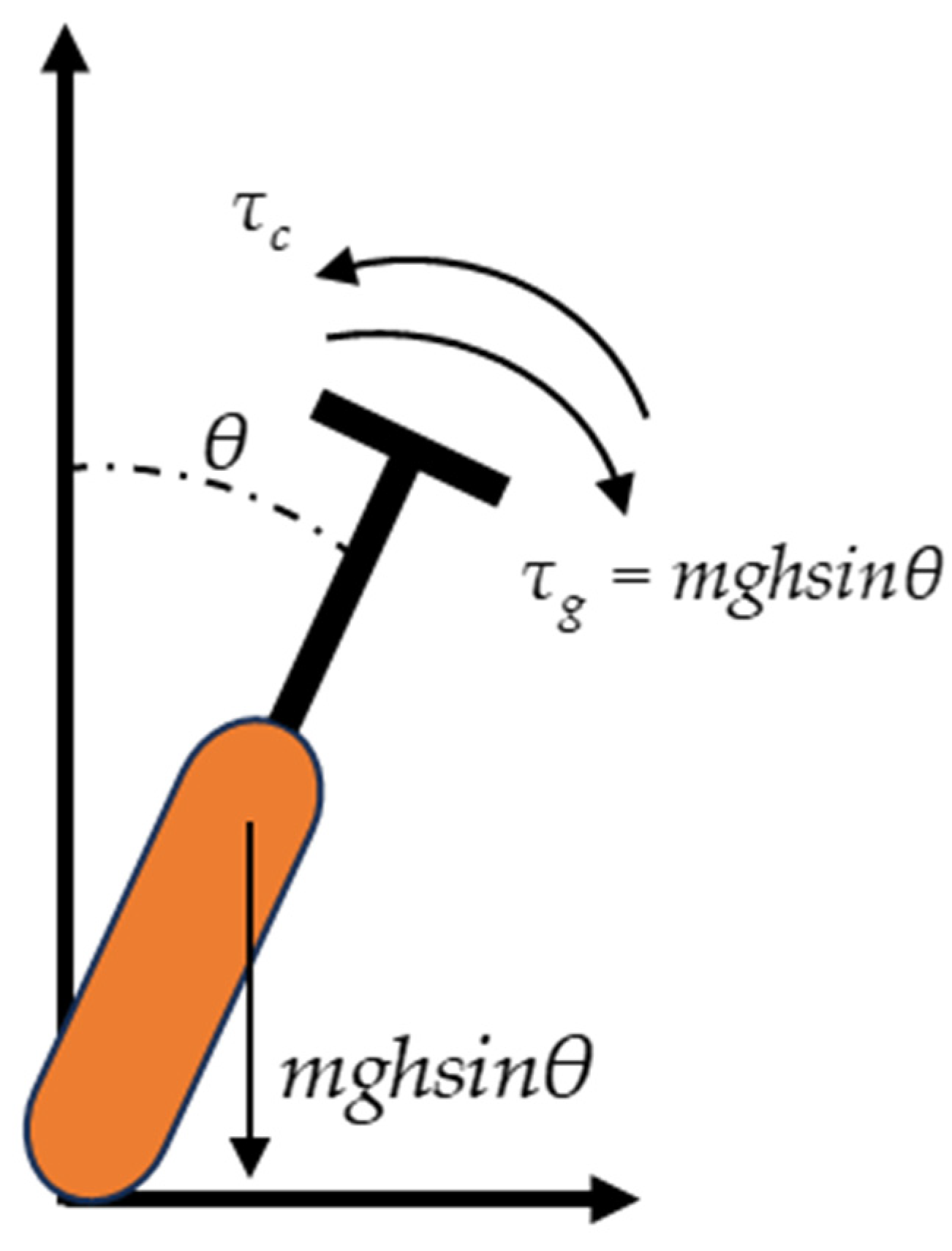

2.1. Dynamics Modeling of the System

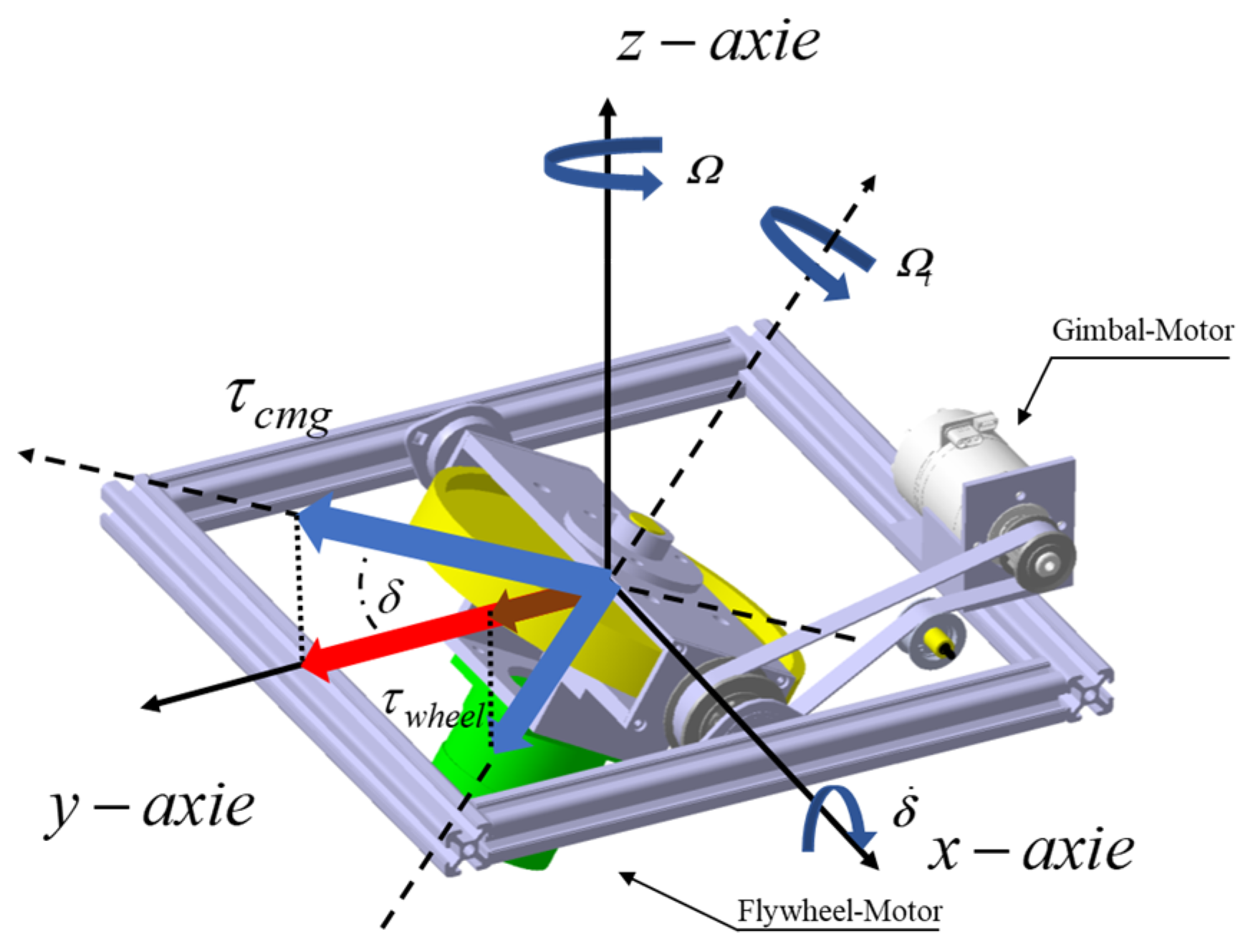

2.2. Torque Output Model of the VSCMG System

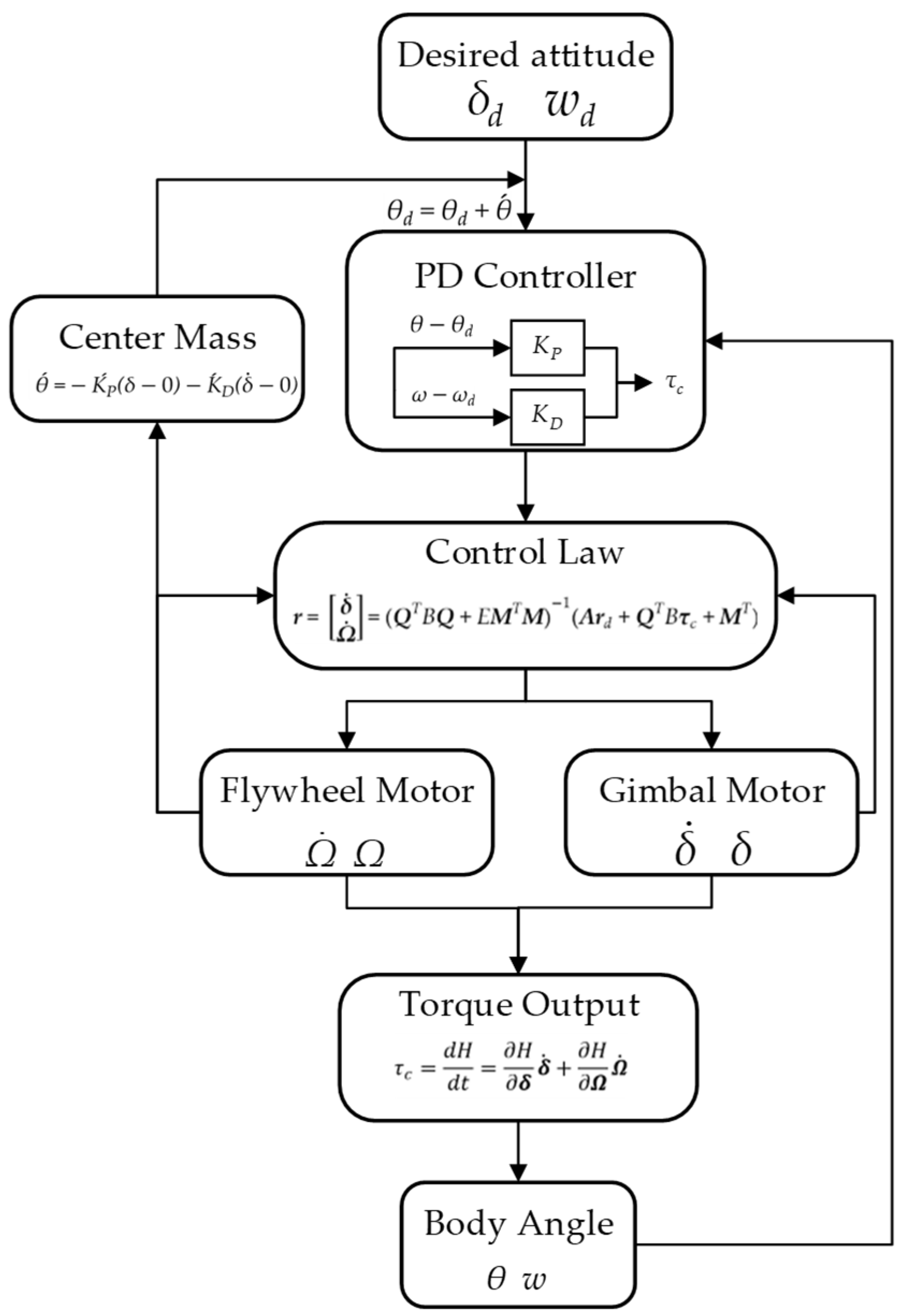

3. Design Controller of Torque

3.1. Torque Output Design by PD Controller

3.2. Control Law Based on VSCMG Power Constraints

3.2.1. Control Law Design for the Desired Flywheel Acceleration

3.2.2. Design of the Control Law for Gimbal Angular Velocity

3.2.3. Real-Time Allocation of Control Law

3.2.4. Center of Mass Alignment and Singularity Avoidance

4. Experiment and Validation

4.1. Experimental Environment Setup

4.2. Experimental Conditions and Phenomena

- Comparison of SGCMG and VSCMG Systems;

- Different power factors ;

- Performance under external force disturbance

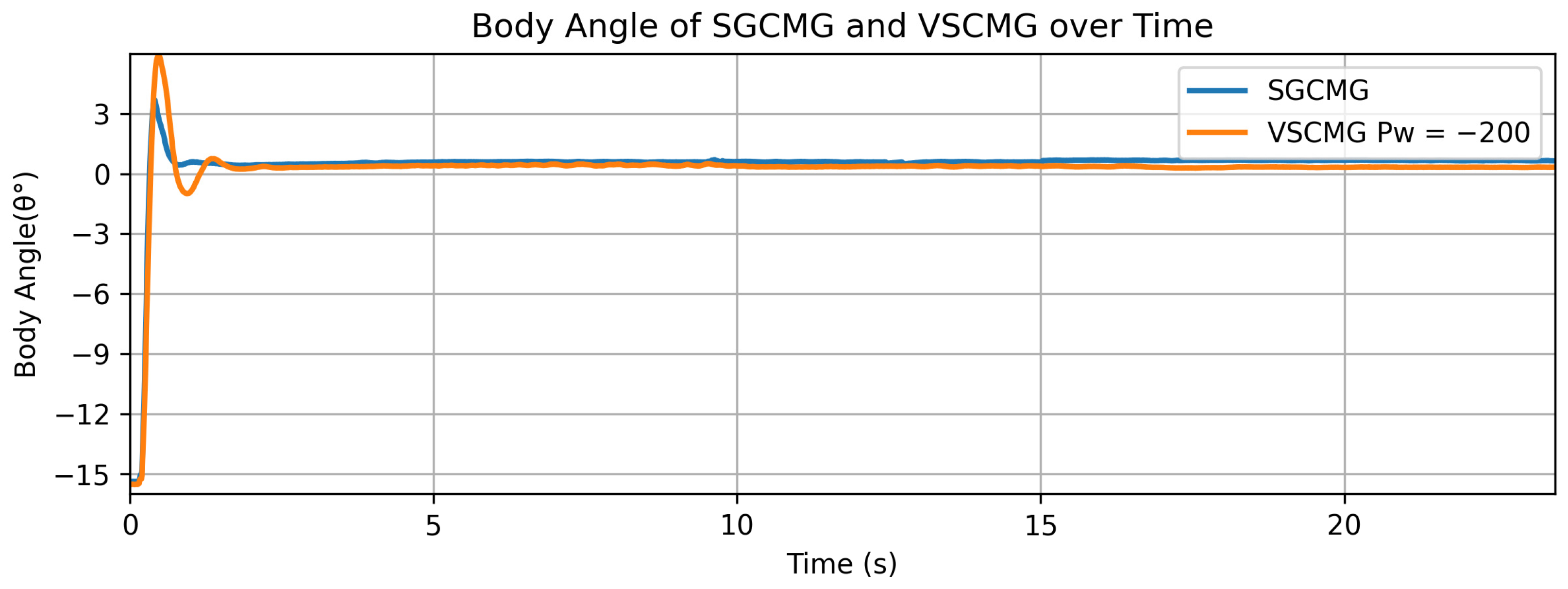

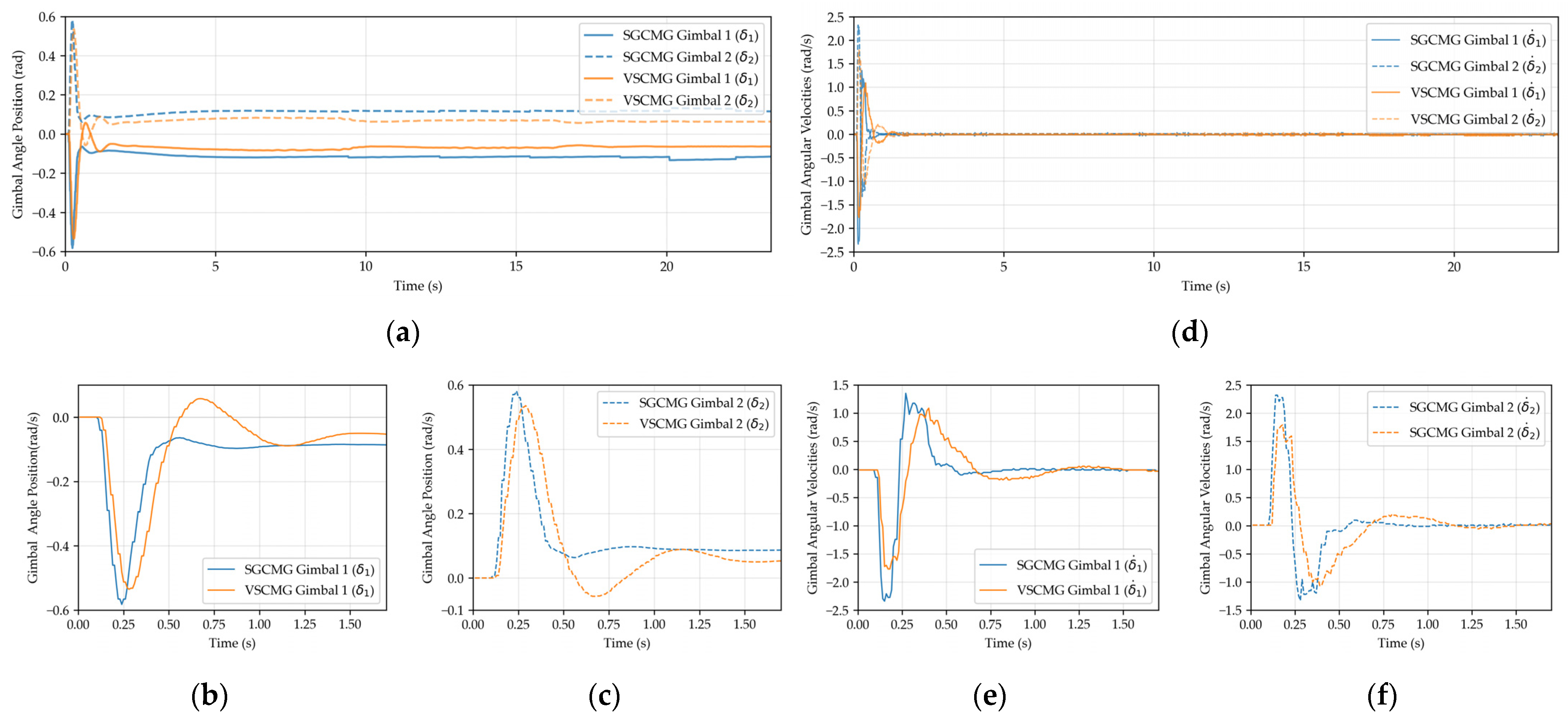

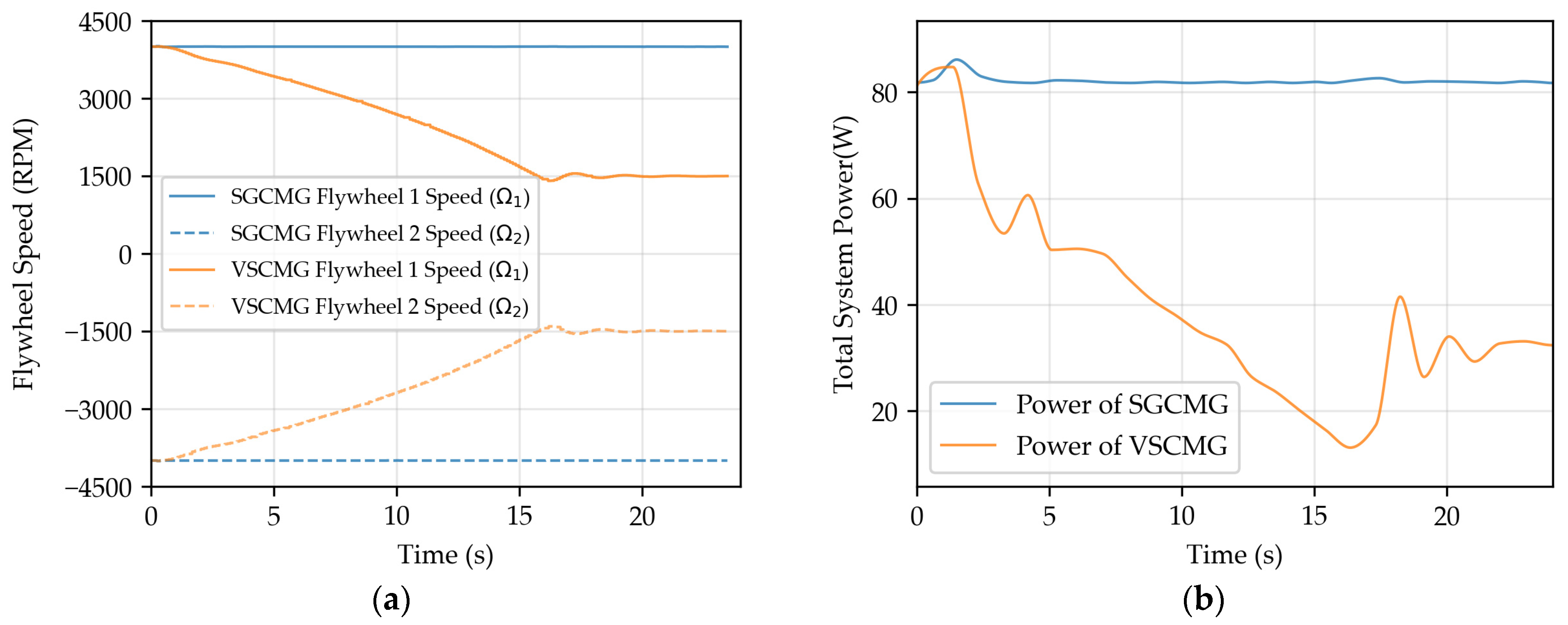

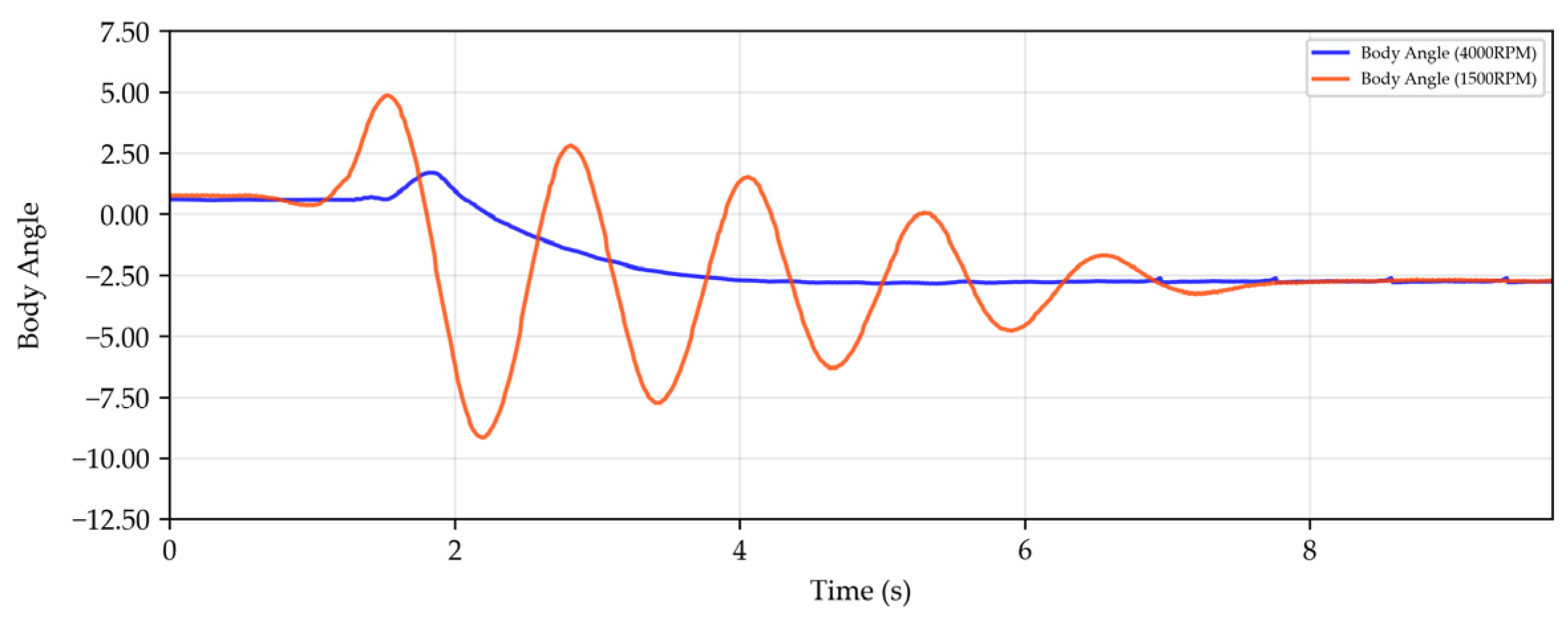

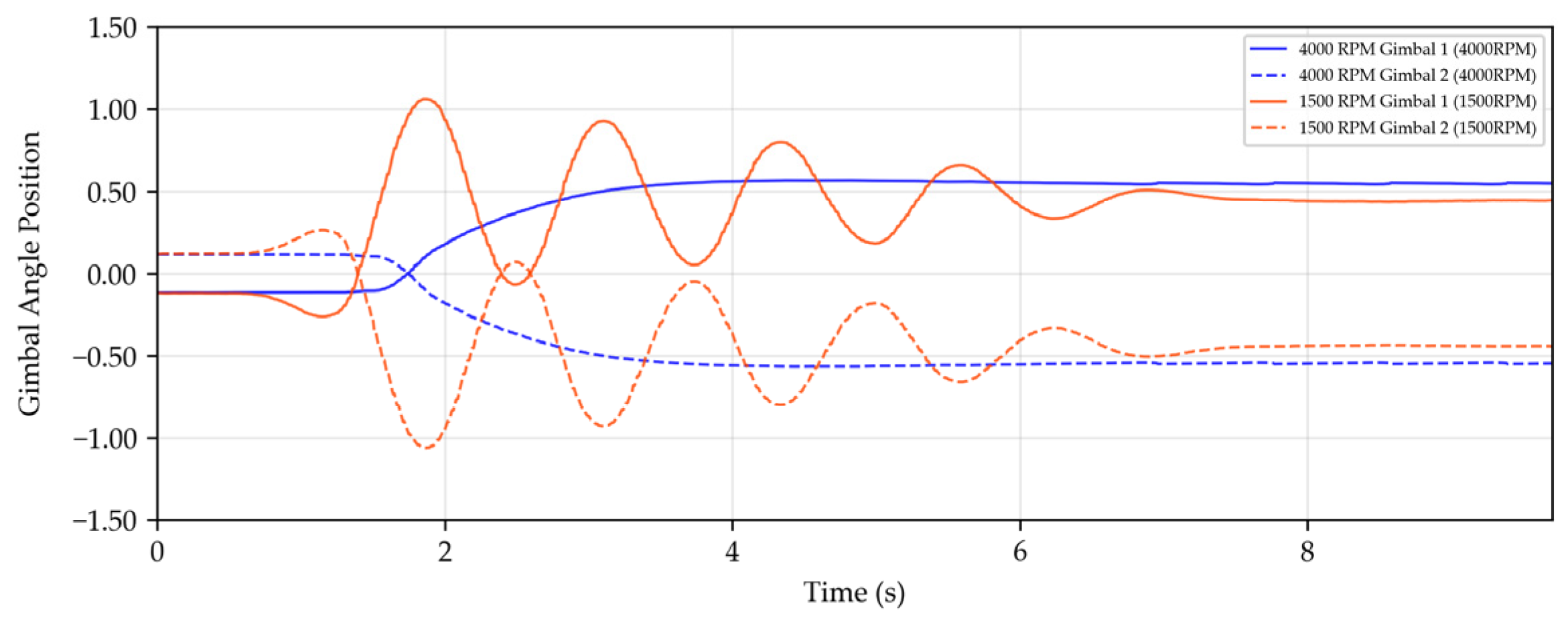

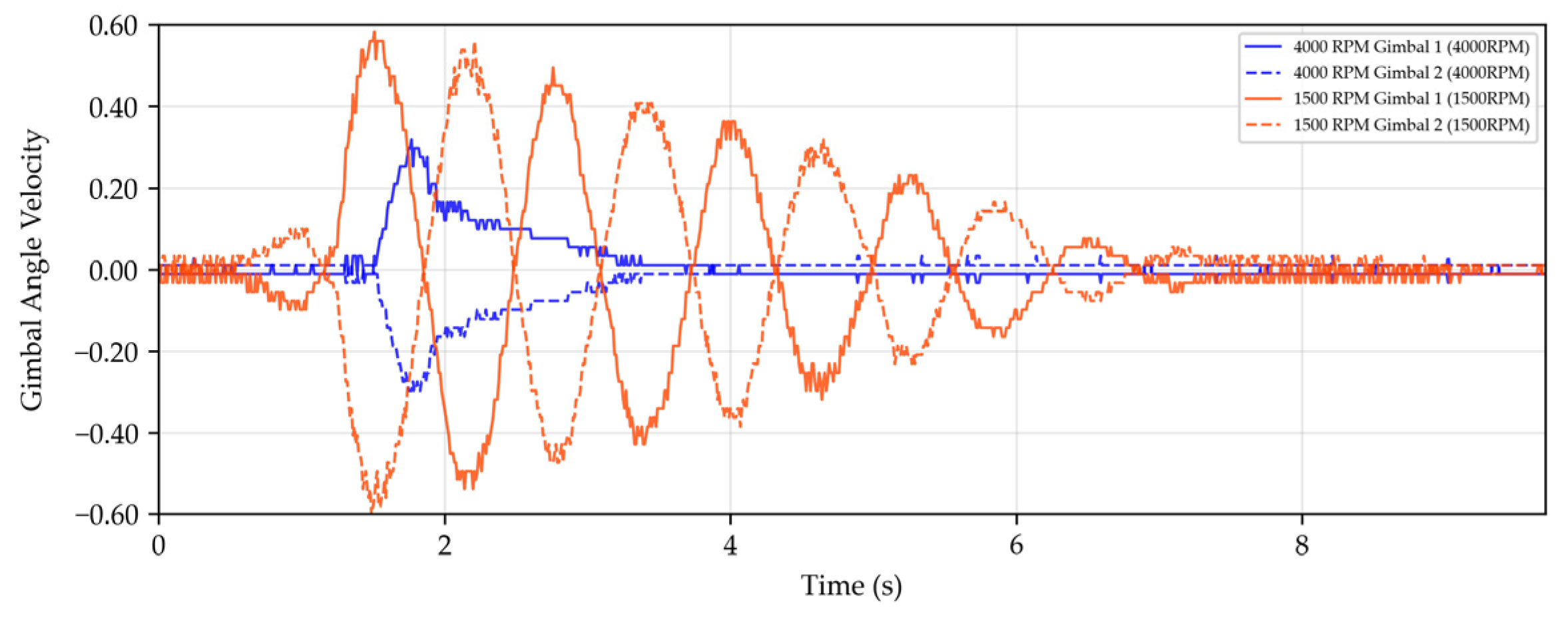

4.2.1. Comparison of SGCMG and VSCMG Systems

4.2.2. Performance Under External Force Disturbance

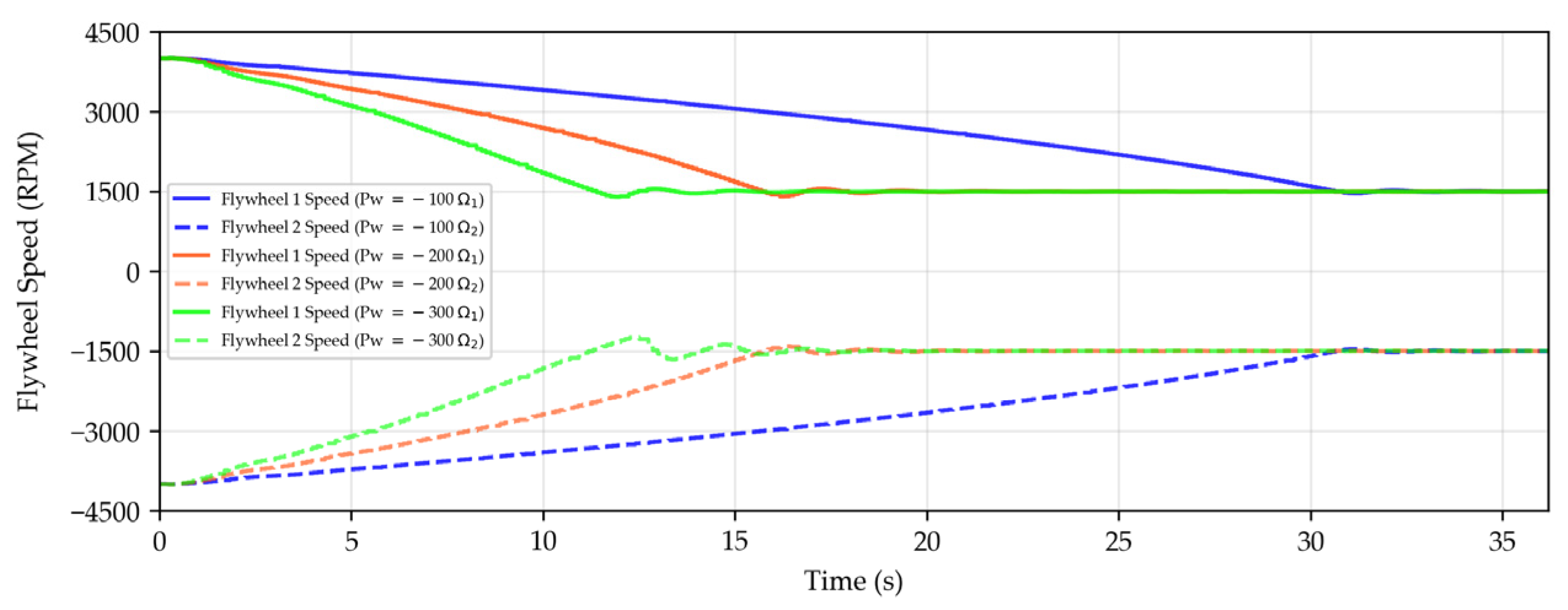

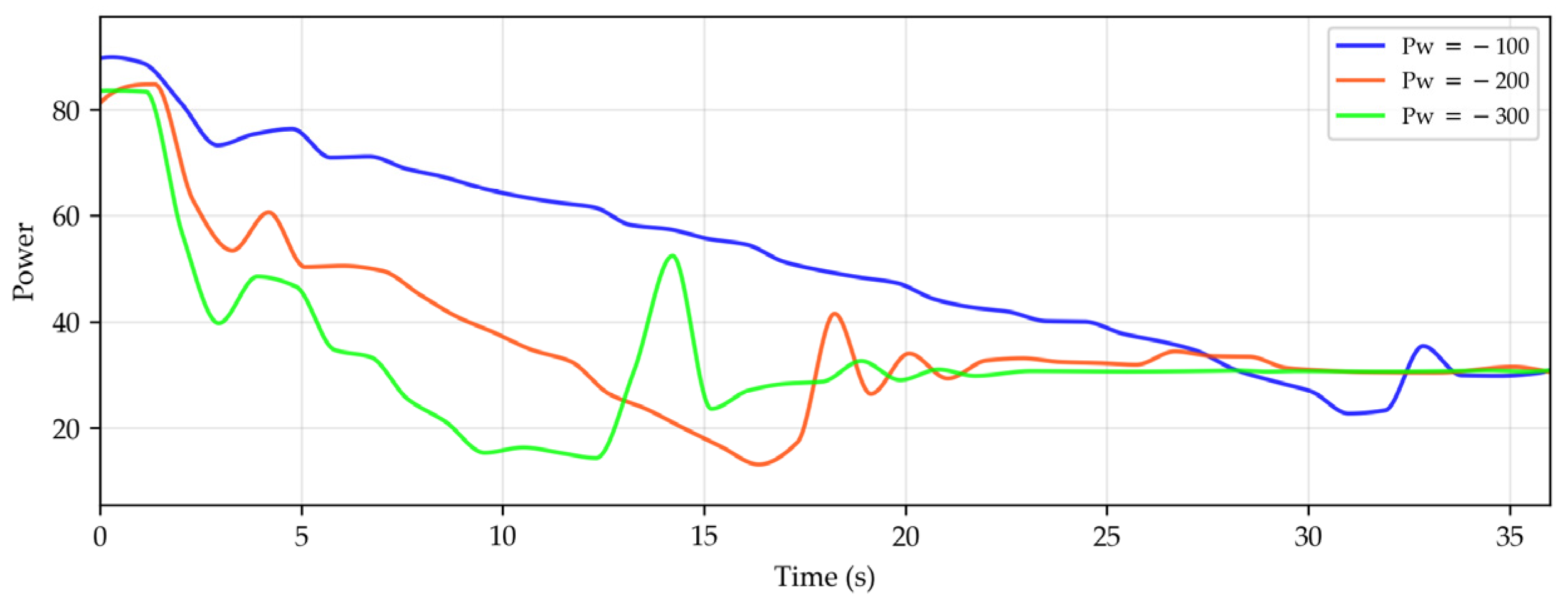

4.2.3. Different Power Factors

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Hartz, F.; Zehnder, P.; Resch, T.; Römmermann, G.; Hartmann, V.; Schwarz, M.; Kirchhoff, C.; Biberthaler, P.; Zyskowski, M. Characteristics of e-scooter and bicycle injuries at a university hospital in a large German city—A one-year analysis. Inj. Epidemiol. 2025, 12, 2. [Google Scholar] [CrossRef] [PubMed]

- Chen, B.; Fei, X.; Fan, Y.; Dan, Y.; Huang, Z. Frame Angular Velocity Control Design of SGCMG for Unmanned Two-Wheeled Motorcycle. Machines 2023, 11, 371. [Google Scholar] [CrossRef]

- Yetkin, H.; Kalouche, S.; Vernier, M.; Colvin, G.; Redmill, K.; Ozguner, U. Gyroscopic stabilization of an unmanned bicycle. In Proceedings of the 2014 American Control Conference, Portland, OR, USA, 4–6 June 2014; pp. 4549–4554. [Google Scholar] [CrossRef]

- Hou, Z.; Geng, Y.; Wu, B.; Huang, S. Spacecraft angular velocity trajectory planning for SGCMG singularity avoidance. Acta Astronaut. 2018, 151, 284–295. [Google Scholar] [CrossRef]

- Wang, L.; Guo, Y.; Wu, L.; Chen, Q. Improved optimal steering law for SGCMG and adaptive attitude control of flexible spacecraft. J. Syst. Eng. Electron. 2015, 26, 1268–1276. [Google Scholar] [CrossRef]

- Chen, C.; Liu, X.; Cong, B.; Jin, Y. Dynamical sliding mode control of spacecraft attitude using SGCMG systems. In Proceedings of the 29th Chinese Control Conference, Beijing, China, 29–31 July 2010; pp. 2240–2244. [Google Scholar]

- Wardle, D.; Gregory, T.; Cazzolato, B. Electronic training wheels: An automated cycling track stand. In Proceedings of the Australasian Conference on Robotics and Automation, The University of Melbourne, Melbourne, Australia, 2–4 December 2014. [Google Scholar]

- Chen, C.-K.; Chu, T.-D.; Zhang, X.-D. Modeling and Control of an Active Stabilizing Assistant System for a Bicycle. Sensors 2019, 19, 248. [Google Scholar] [CrossRef] [PubMed]

- Uematsu, E.; Ueno, S.; Higuchi, T. Sub-Optimal Control Law for Minimum Energy Attitude Maneuver using CMGs. Trans. Jpn. Soc. Aeronaut. Space Sci. Aerosp. Technol. Jpn. 2014, 12, Pd_19–Pd_25. [Google Scholar] [CrossRef] [PubMed]

- Meijaard, J.; Papadopoulos, J.M.; Ruina, A.; Schwab, A. Linearized dynamics equations for the balance and steer of a bicycle: A benchmark and review. Proc. R. Soc. A Math. Phys. Eng. Sci. 2007, 463, 1955–1982. [Google Scholar] [CrossRef]

- Guan, R.; Li, C.; Lv, Q. VSCMG System Model Based on Euler Kinematics Equation. In Innovative Computing: Proceedings of the 4th International Conference on Innovative Computing (IC 2021); Springer: Singapore, 2022; pp. 409–416. [Google Scholar] [CrossRef]

- Prabhakaran, V.S.; Sanyal, A.K.; Leve, F.; McClamroch, N.H. Geometric Mechanics Based Modeling of the Attitude Dynamics and Control of Spacecraft with Variable Speed Control Moment Gyroscopes. In Proceedings of the ASME 2013 Dynamic Systems and Control Conference, Palo Alto, CA, USA, 21–23 October 2013; Volume 56123. [Google Scholar] [CrossRef]

- Biggs, J.D.; Brisotto, S. Robust spacecraft rendezvous using a variable speed control moment gyro and thruster. Aerosp. Sci. Technol. 2021, 112, 106644. [Google Scholar] [CrossRef]

- Guo, J.; Chen, X.; Zhu, M.; Zhou, Q. Integrated Control of Attitude Maneuver and Vibration Suppression Using Pyramid-Type SGCMGs. IEEE Trans. Aerosp. Electron. Syst. 2022, 58, 17–26. [Google Scholar] [CrossRef]

- Meng, Q.; Yang, H.; Jiang, B. Attitude control reconfigurability analysis of 4-CMGs pyramid configuration spacecraft. In Proceedings of the 2019 12th Asian Control Conference (ASCC), Kitakyushu, Japan, 9–12 June 2019; pp. 1478–1482. [Google Scholar]

- Liu, F.; Lyu, K. The Singularity Avoidance Analysis and Designed Steering Law for VSCMG. In Proceedings of the 2022 41st Chinese Control Conference (CCC), Hefei, China, 25–27 July 2022; pp. 2791–2796. [Google Scholar] [CrossRef]

- Schaub, H.; Junkins, J. CMG singularity avoidance using VSCMG null motion. In Proceedings of the AIAA/AAS Astrodynamics Specialist Conference and Exhibit, Boston, MA, USA, 10–12 August 1998. [Google Scholar] [CrossRef]

- Cheng, Z.; Qin, D.; Wang, D.; Zhang, Z.; Peng, R. Reconfigurability Evaluation of VSCMG Based on Power Consumption Constraint. In Proceedings of the 2023 China Automation Congress (CAC), Chongqing, China, 17–19 November 2023; IEEE: Piscataway, NJ, USA, 2023; pp. 9085–9090. [Google Scholar] [CrossRef]

- Fausz, J.; Richie, D. Flywheel simultaneous attitude control and energy storage using a VSCMG configuration. In Proceedings of the IEEE International Conference on Control Applications. Conference Proceedings (Cat. No. 00CH37162), Anchorage, AK, USA, 27 September 2000; IEEE: Piscataway, NJ, USA, 2000. [Google Scholar] [CrossRef]

- Richie, D.J.; Lappas, V.J.; Asghar, S. Constrained singularity avoidance using VSCMGs for combined attitude and power tracking. In Proceedings of the 2007 European Control Conference (ECC), Kos, Greece, 2–5 July 2007; IEEE: Piscataway, NJ, USA, 2007. [Google Scholar] [CrossRef]

- Altay, A.; Ozan, T. Spacecraft energy storage and attitude control. In Proceedings of the 2nd International Conference on Recent Advances in Space Technologies, 2005. RAST 2005, Istanbul, Turkey, 9–11 June 2005; IEEE: Piscataway, NJ, USA, 2005. [Google Scholar]

- Xie, R.Q.; Yao, Y.; He, F.H.; Ma, K.M. Simultaneous attitude stabilization and power tracking for a spacecraft with two VSCMGs. In Proceedings of the 2008 IEEE International Conference on Control Applications, San Antonio, TX, USA, 3–5 September 2008; IEEE: Piscataway, NJ, USA, 2008. [Google Scholar]

- Yoon, H.; Panagiotis, T. Spacecraft adaptive attitude and power tracking with variable speed control moment gyroscopes. J. Guid. Control Dyn. 2002, 25, 1081–1090. [Google Scholar] [CrossRef]

- Yoshihara, H.; Takahashi, M.; Noumi, A.; Kanzawa, T.; Haruki, M.; Gui, H.; Vukovich, G.; Xu, S.; Wu, Y.-H.; Han, F.; et al. Optimal power management considering attitude control and battery deterioration control for spacecraft with VSCMG/IPACS. In Proceedings of the AIAA SciTech 2020 Forum, Orlando, FL, USA, 6–10 January 2020. [Google Scholar] [CrossRef]

- Liu, F.; Gao, F.; Zhang, W.; Zhang, B.; He, J. The optimization design with minimum power for variable speed control moment gyroscopes with integrated power and attitude control. Aerosp. Sci. Technol. 2019, 88, 287–297. [Google Scholar] [CrossRef]

- Badgujar, C.; Mohite, S. Design, analysis and implementation of control moment gyroscope (CMG) mechanism to self-balance a moped bike. Mater. Today Proc. 2022, 72, 1517–1523. [Google Scholar] [CrossRef]

- El-Aal, A.A.; Roustom, M.; Hegaze, M.M.; Ibrahim, M. Modeling and control of unstable mechanical systems using control moment gyro (CMG). IOP Conf. Ser. Mater. Sci. Eng. 2019, 610, 012053. [Google Scholar] [CrossRef]

| Parameters | Value | Description |

|---|---|---|

| I | 0.5 | System’s moment of inertia |

| J | Flywheel’s moment of inertia | |

| h | 0.25 m | System center of mass height |

| Attitude controller proportional gain | ||

| 0.4 | Attitude controller derivative gain | |

| 0.2 | Offset angle controller proportional gain | |

| 0.01 | Offset angle controller derivative gain | |

| Total Reduction Ratio | 25.32 | Servo motor and belt |

| Model | Rated Voltage | Rated Speed | Rated Power | Rated Current | Pole Number |

|---|---|---|---|---|---|

| AK57BL55-230-060 | 24 V | 4000 RPM | 60 W | 4 A | 4 |

| Model | Rated Voltage | Rated Speed | Reduction Ratio | Rated Current | Pole Number |

|---|---|---|---|---|---|

| DM3519 | 24 V | 395 RPM | 1:19.2 | 9.2 A | 14 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kang, H.; Chen, X.; Wang, Z.; Zhu, J.; Xia, G. Active Attitude Stabilization and Power-Constrained Control of Bicycles Based on VSCMG System. Machines 2025, 13, 459. https://doi.org/10.3390/machines13060459

Kang H, Chen X, Wang Z, Zhu J, Xia G. Active Attitude Stabilization and Power-Constrained Control of Bicycles Based on VSCMG System. Machines. 2025; 13(6):459. https://doi.org/10.3390/machines13060459

Chicago/Turabian StyleKang, Huifeng, Xiangqiu Chen, Zehui Wang, Jifa Zhu, and Guangqing Xia. 2025. "Active Attitude Stabilization and Power-Constrained Control of Bicycles Based on VSCMG System" Machines 13, no. 6: 459. https://doi.org/10.3390/machines13060459

APA StyleKang, H., Chen, X., Wang, Z., Zhu, J., & Xia, G. (2025). Active Attitude Stabilization and Power-Constrained Control of Bicycles Based on VSCMG System. Machines, 13(6), 459. https://doi.org/10.3390/machines13060459