Fault Diagnosis in a 2 MW Wind Turbine Drive Train by Vibration Analysis: A Case Study

Abstract

1. Introduction

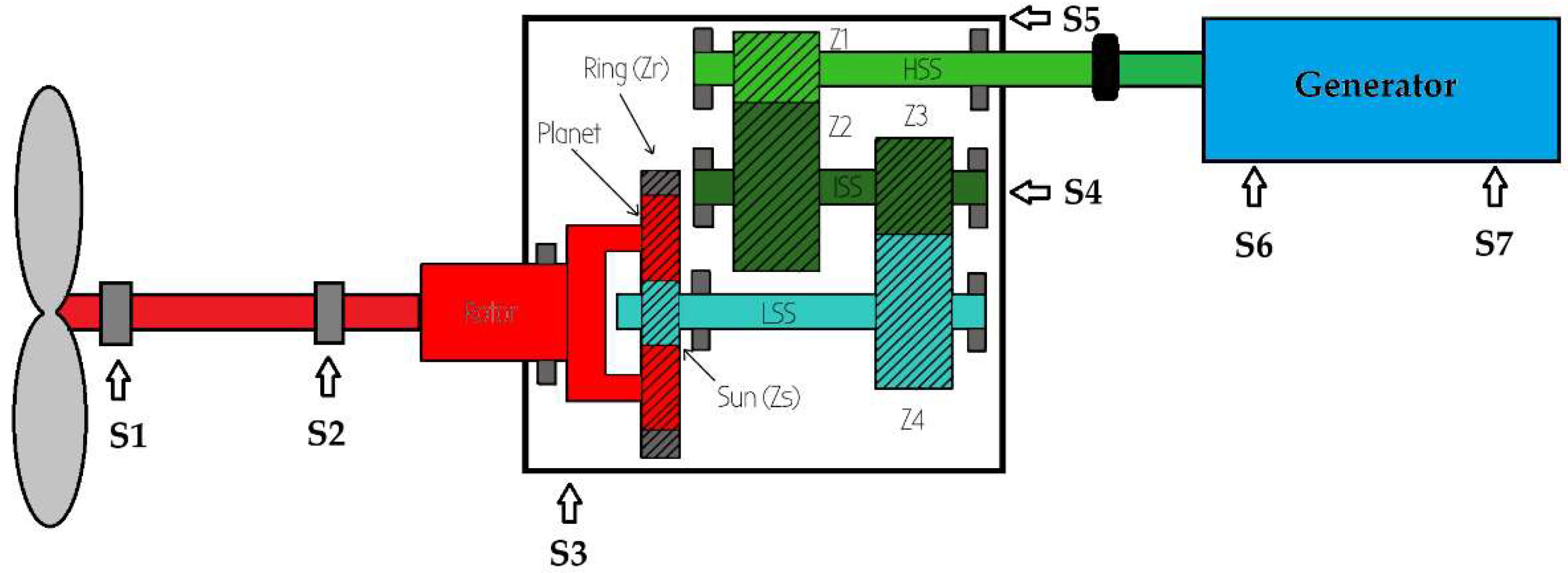

2. Description of the Turbine and Gearbox

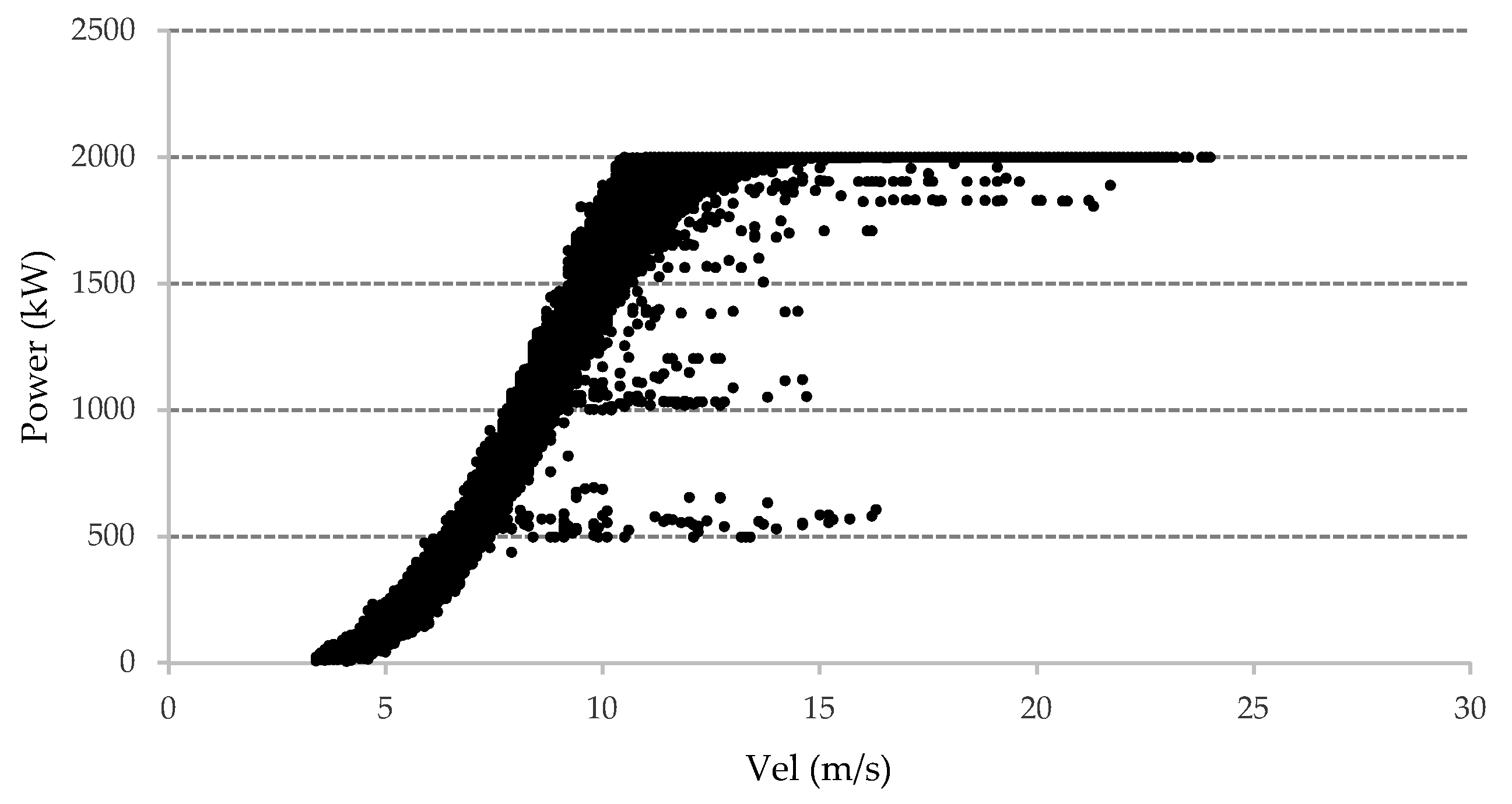

Operating Conditions

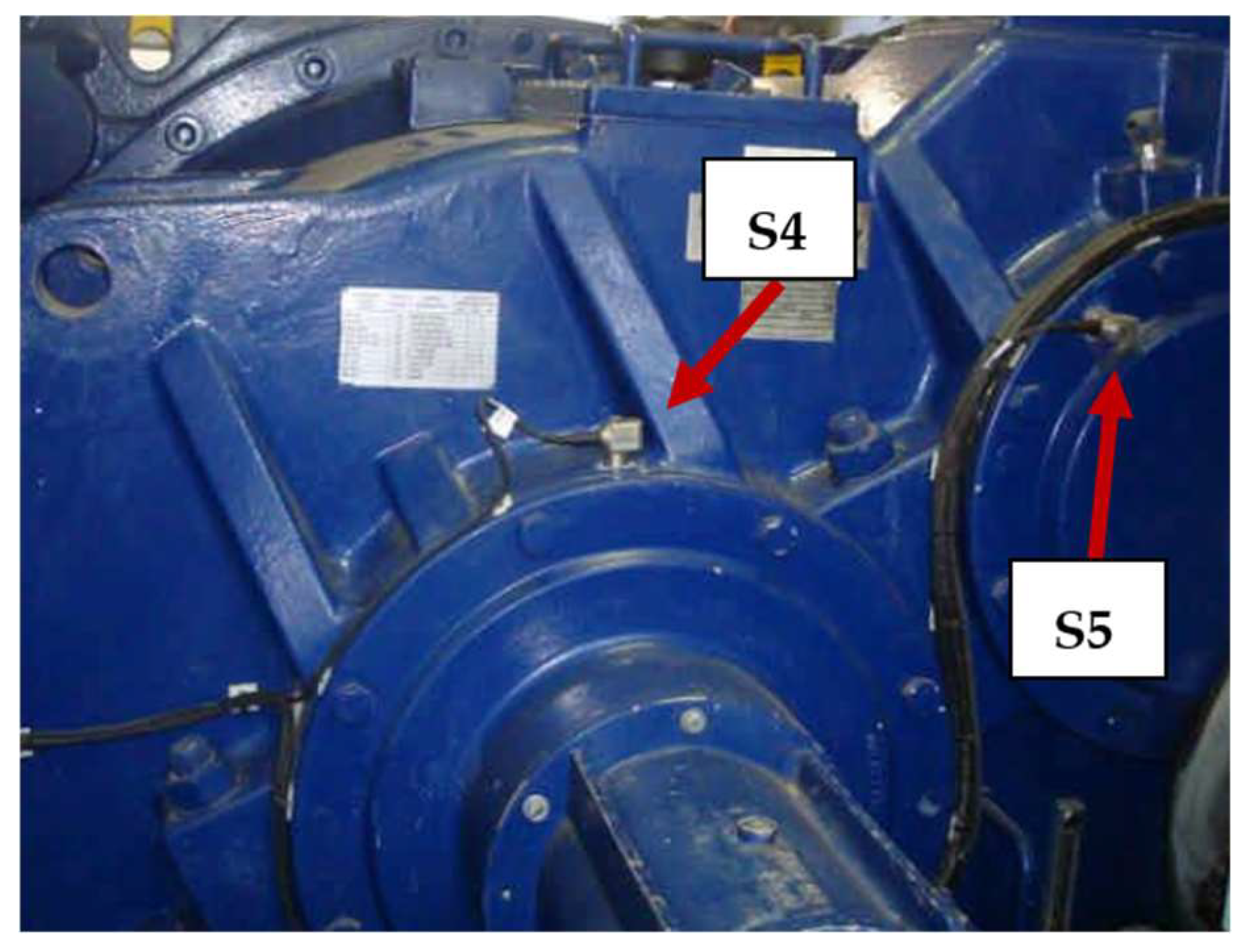

3. Vibration Monitoring System

4. Methodology

- Time-domain waveforms.

- Frequency spectra via Fast Fourier Transform (FFT).

- RMS amplitudes for 12 predefined narrowband frequencies per sensor (including GMFs and bearing-fault frequencies).

- Minimizing transient effects.

- Allowing a comparison of signals at similar power outputs.

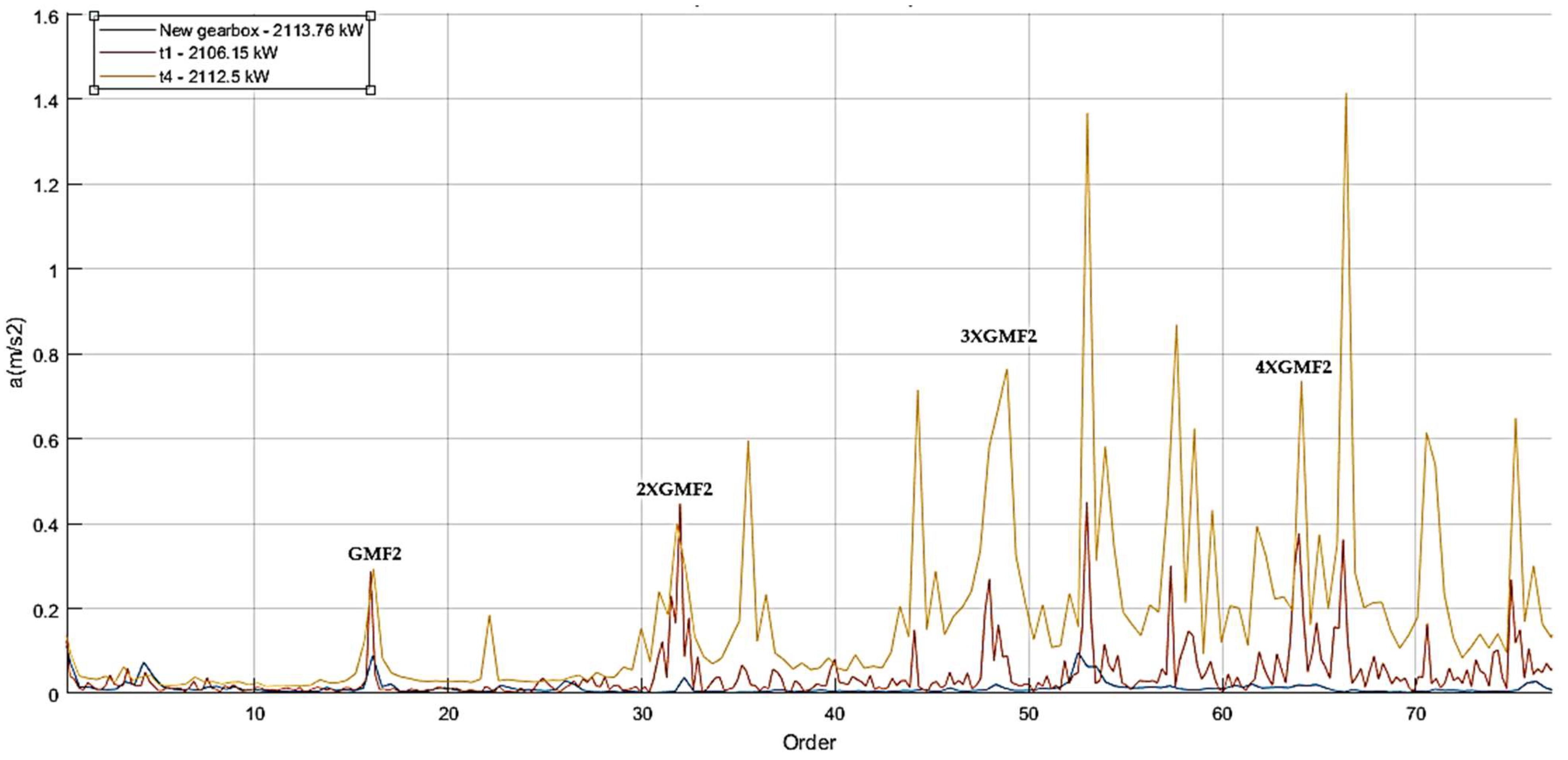

- Focusing on higher harmonics (3XGMF/4XGMF), where fault progression was most evident.

5. Results and Discussion

5.1. Data Acquisition and Processing

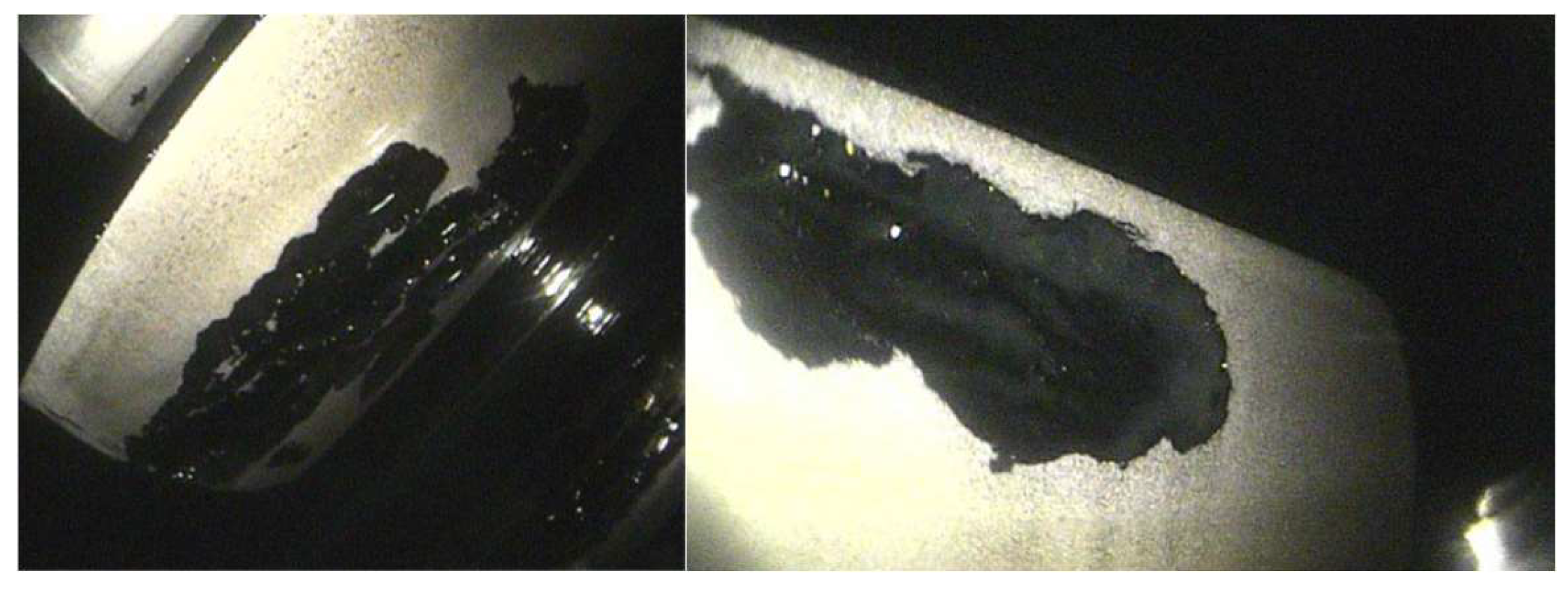

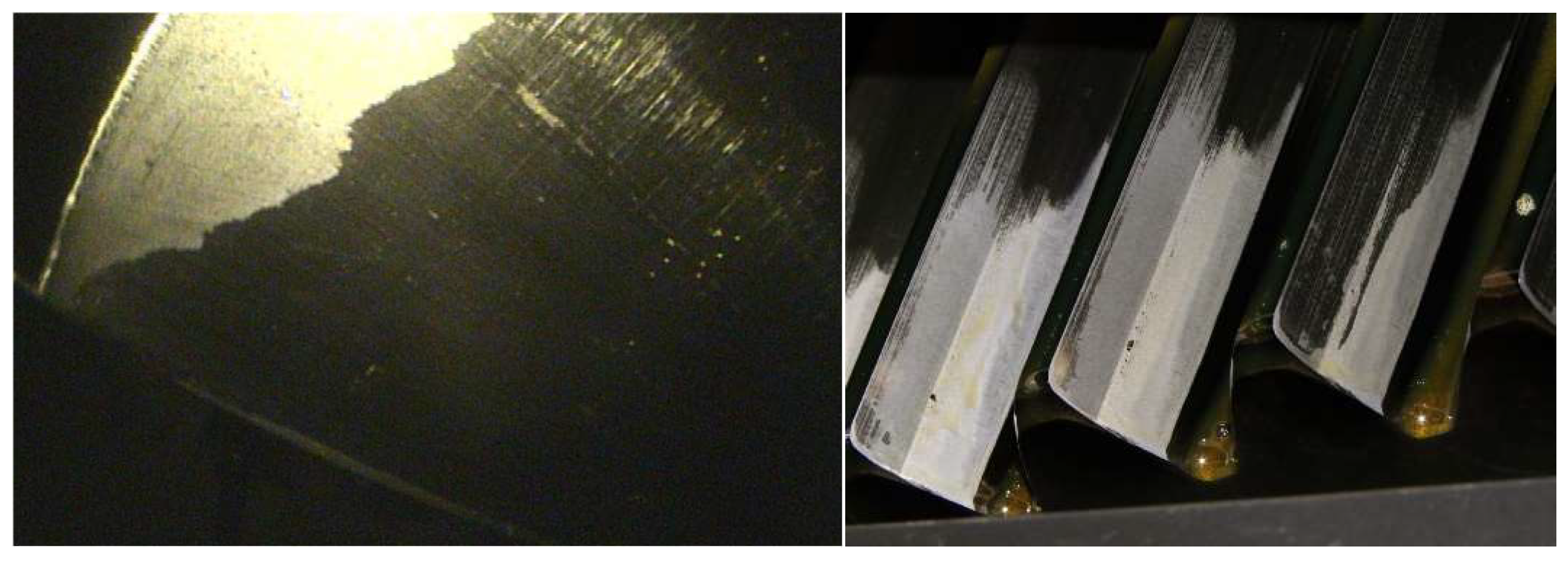

5.2. Pitting and Spalling

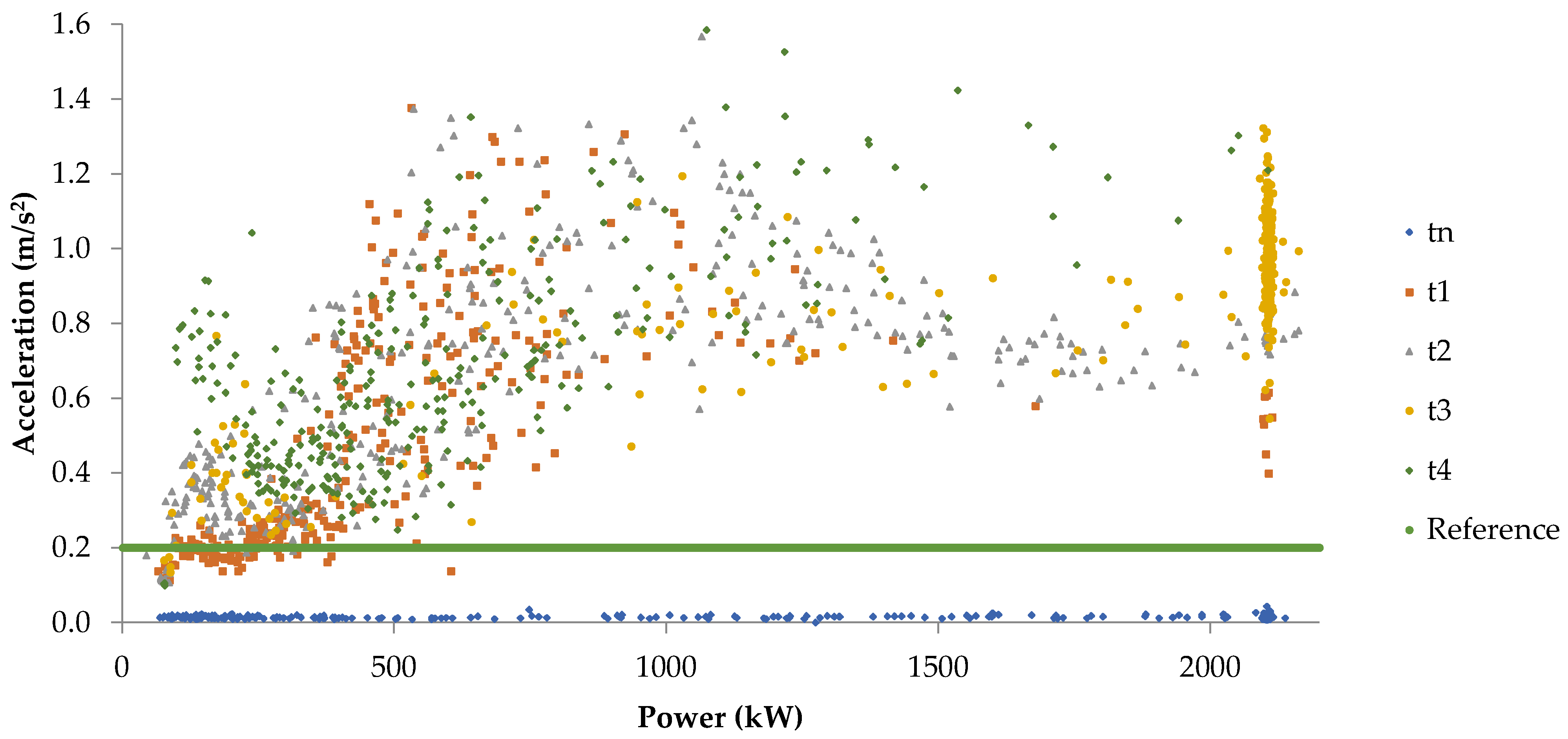

5.2.1. Sensor S4

5.2.2. Sensor S5

5.2.3. Sensor S6

5.2.4. Comparison Between Sensors S4 and S5

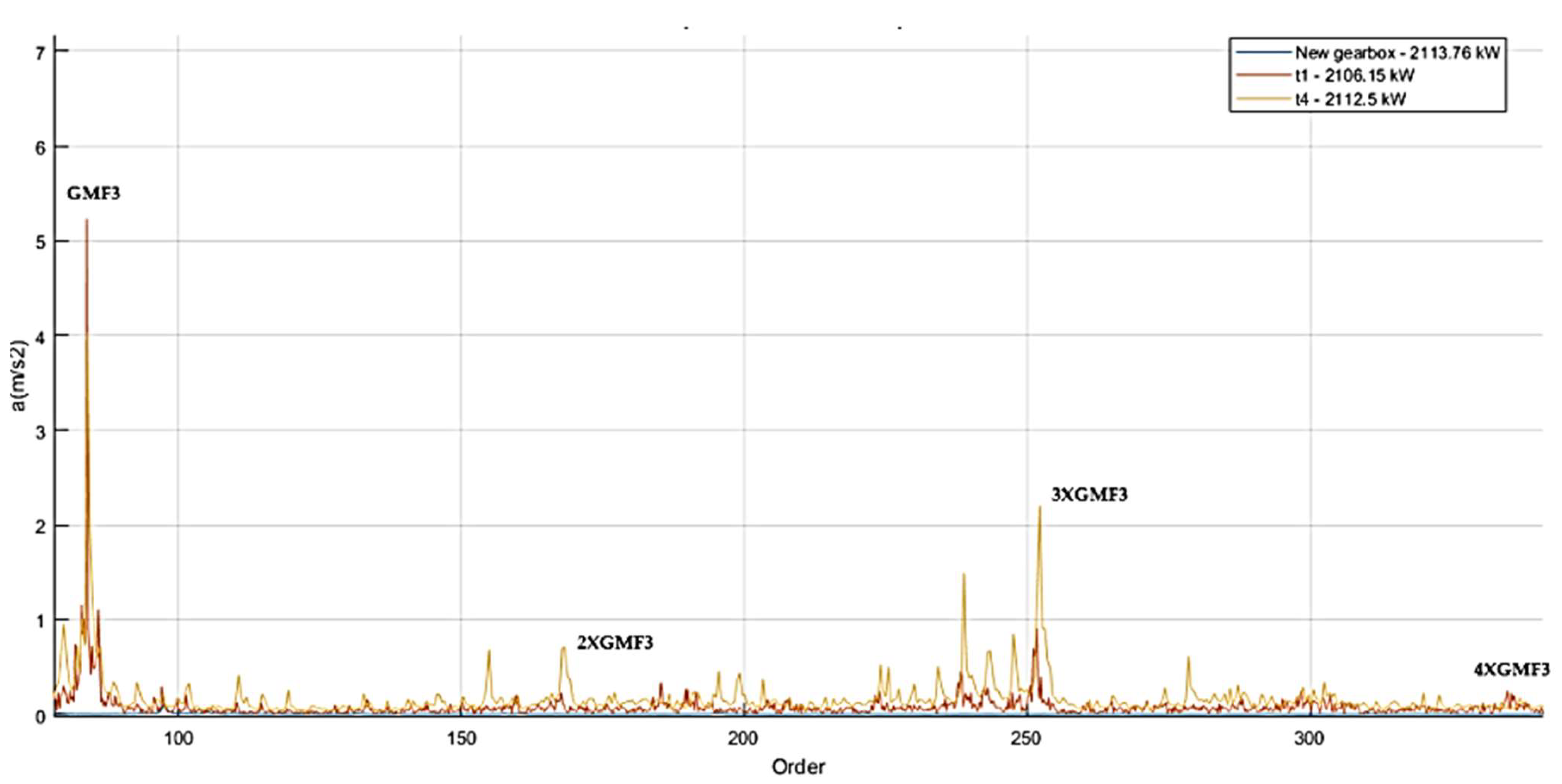

5.2.5. Spectra Comparison

5.3. Pitting and Wear

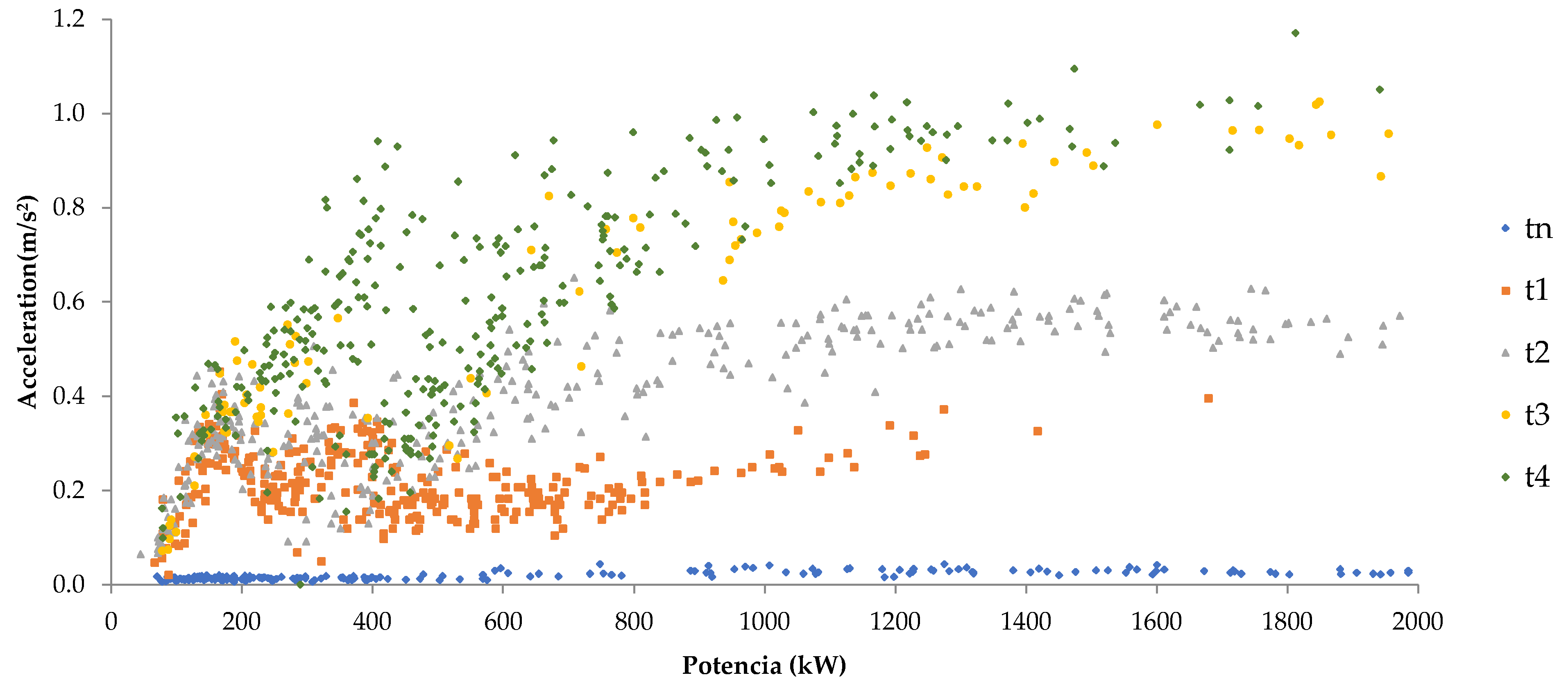

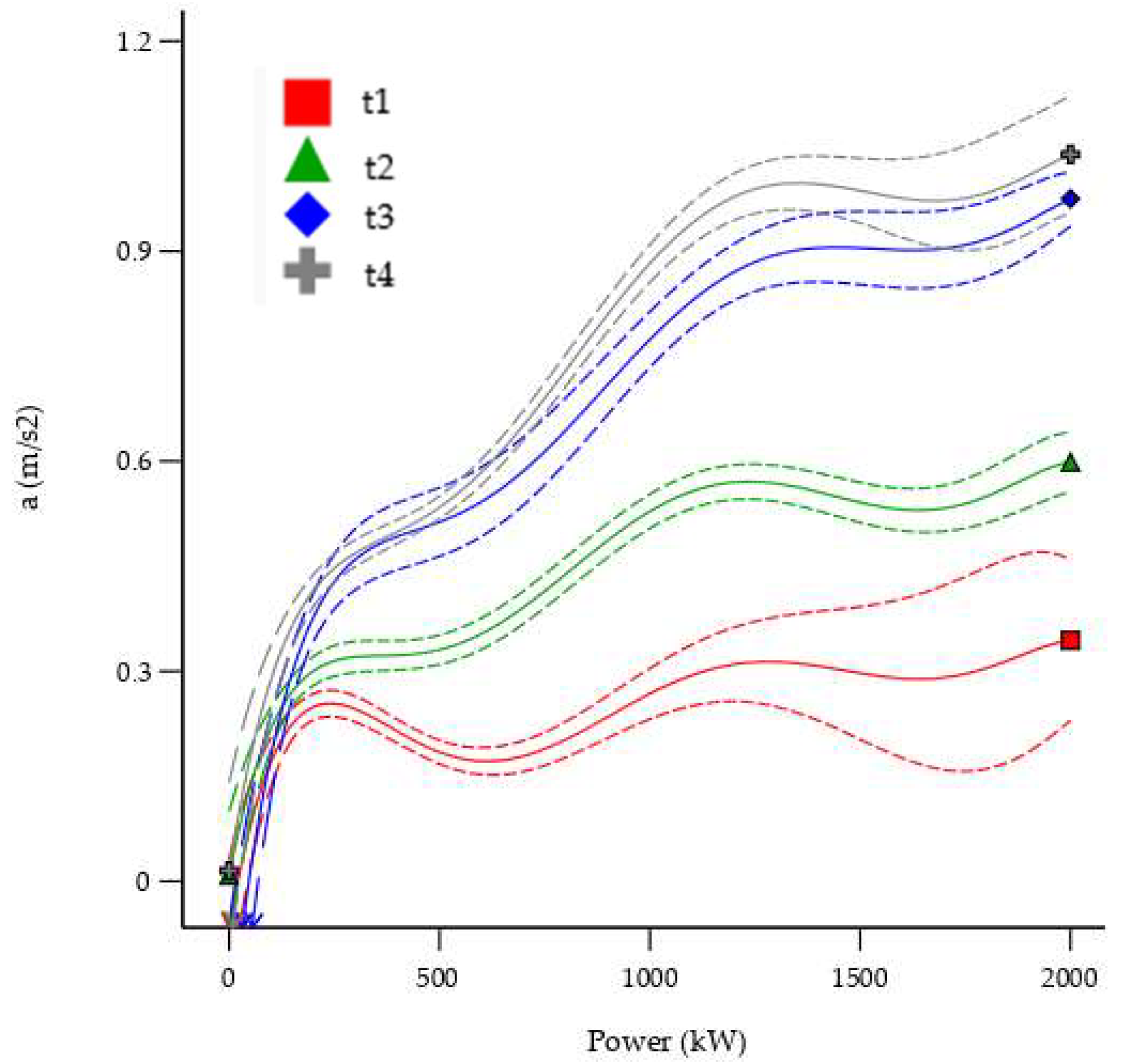

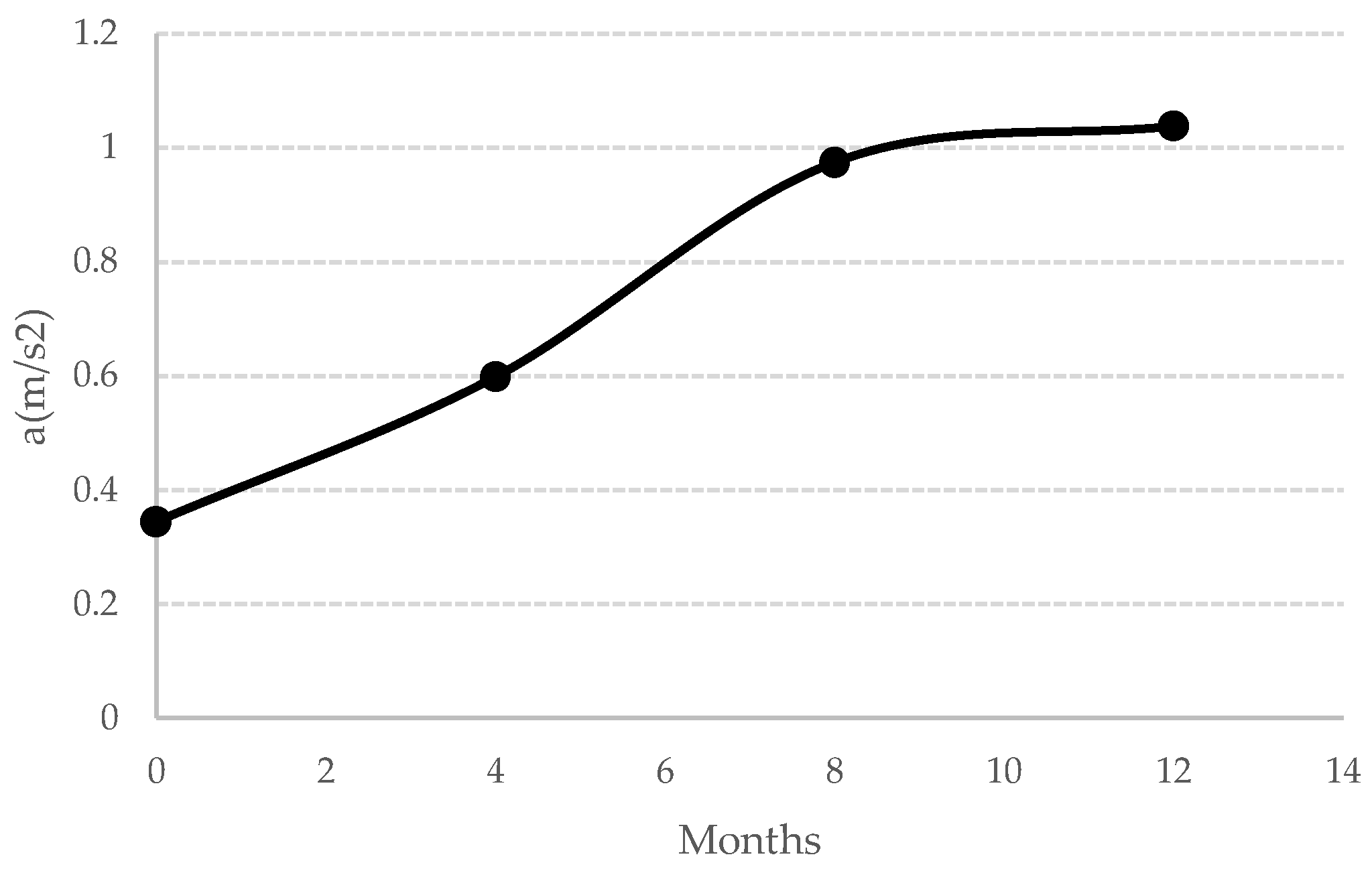

5.3.1. Sensor S4

5.3.2. Sensor S5

5.3.3. Sensor S6

5.3.4. Spectra Comparison

5.4. Sensor Data Relationships and Optimization Implications

5.4.1. Multi-Sensor Correlation Analysis

5.4.2. Fault-Specific Sensor Efficacy

- For HSS-ISS gear-pair damage (pitting/spalling), S5 (axial) outperformed S4 (vertical) in detecting 2XGMF3 and 3XGMF3 harmonics.

- For ISS-LSS gear wear, S5’s 3XGMF2 and 4XGMF2 harmonics exhibited clear progression trends (Figure 11), while S4’s GMF2/2XGMF2 data were inconclusive.

- Sensor S6 (generator-bearing) was less relevant for gear faults but highlighted risks of frequency aliasing (e.g., GMF2 overlapping with BPFO).

5.4.3. Implications for Sensor Optimization:

- Axial sensors are critical for helical-gear fault detection, as they capture axial load variations from tooth wear/pitting.

- Sensor placement should avoid spectral overlaps (e.g., gear and bearing frequencies) to reduce false alarms.

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Machado, M.R.; Dutkiewicz, M. Wind turbine vibration management: An integrated analysis of existing solutions, products, and Open-source developments. Energy Rep. 2024, 11, 3756–3791. [Google Scholar] [CrossRef]

- Orsted. What Is the Carbon Footprint of Offshore Wind? 2022. Available online: https://orsted.com/en/what-we-do/insights/the-fact-file/what-is-the-carbon-footprint-of-offshore-wind (accessed on 1 February 2025).

- Lee, J.; Zhao, F. Global Wind Report 2024. 2024. Available online: https://img.saurenergy.com/2024/05/gwr-2024_digital-version_final-1-compressed.pdf (accessed on 27 November 2024).

- Smoucha, E.A.; Fitzpatrick, K. Life Cycle Analysis of the Embodied Carbon Emissions from 14 Wind Turbines with Rated Powers between 50 Kw and 3.4 Mw. J. Fundam. Renew. Energy Appl. 2016, 6, 1000211. [Google Scholar] [CrossRef]

- Stehly, T.; Duffy, P. 2020 Cost of Wind Energy Review. 2020. Available online: www.nrel.gov/publications (accessed on 13 May 2025).

- Teng, W.; Ding, X.; Tang, S.; Xu, J.; Shi, B.; Liu, Y. Vibration analysis for fault detection of wind turbine drivetrains—A comprehensive investigation. Sensors 2021, 21, 1686. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.; Zhang, L. A review of failure modes, condition monitoring and fault diagnosis methods for large-scale wind turbine bearings. Measurement 2020, 149, 107002. [Google Scholar] [CrossRef]

- Castellani, F.; Garibaldi, L.; Daga, A.P.; Astolfi, D.; Natili, F. Diagnosis of faulty wind turbine bearings using tower vibration measurements. Energies 2020, 13, 1474. [Google Scholar] [CrossRef]

- Siegel, D.; Zhao, W.; Lapira, E.; Abuali, M.; Lee, J. A comparative study on vibration-based condition monitoring algorithms for wind turbine drive trains. Wind Energy 2014, 17, 695–714. [Google Scholar] [CrossRef]

- Srikanth, P.; Sekhar, A.S. Dynamic analysis of wind turbine drive train subjected to nonstationary wind load excitation. Proc. Inst. Mech. Eng. C J. Mech. Eng. Sci. 2015, 229, 429–446. [Google Scholar] [CrossRef]

- Gayatri, C.V.H.; Sekhar, A.S. Dynamic analysis and characterization of two stage epicyclic gear box in wind turbine drive train. AIP Conf. Proc. 2018, 2044, 020018. [Google Scholar] [CrossRef]

- Jian, T.; Cao, J.; Liu, W.; Xu, G.; Zhong, J. A novel wind turbine fault diagnosis method based on compressive sensing and lightweight SqueezeNet model. Expert Syst. Appl. 2025, 260, 125440. [Google Scholar] [CrossRef]

- Wei, H.; Zhang, Q.; Shang, M.; Gu, Y. Extreme learning Machine-based classifier for fault diagnosis of rotating Machinery using a residual network and continuous wavelet transform. Measurement 2021, 183, 109864. [Google Scholar] [CrossRef]

- Dibaj, A.; Ettefagh, M.M.; Hassannejad, R.; Ehghaghi, M.B. A hybrid fine-tuned VMD and CNN scheme for untrained compound fault diagnosis of rotating machinery with unequal-severity faults. Expert Syst. Appl. 2021, 167, 114094. [Google Scholar] [CrossRef]

- Yang, J.; Delpha, C. An incipient fault diagnosis methodology using local Mahalanobis distance: Fault isolation and fault severity estimation. Signal Process. 2022, 200, 108657. [Google Scholar] [CrossRef]

- Escaler, X.; Mebarki, T. Full-scale wind turbine vibration signature analysis. Machines 2018, 6, 63. [Google Scholar] [CrossRef]

- Nejad, A.R.; Odgaard, P.F.; Gao, Z.; Moan, T. A prognostic method for fault detection in wind turbine drivetrains. Eng. Fail. Anal. 2014, 42, 324–336. [Google Scholar] [CrossRef]

- Zhong, Q.; Liu, S.; Liu, C.; Liu, W.; Liu, S.; Zhao, Y.; Wu, Y. Fault Diagnosis of Wind Turbine Gearboxes Based on Multisource Signal Fusion. IEEE Trans. Instrum. Meas. 2025, 74, 3526413. [Google Scholar] [CrossRef]

- Wu, J.; Wei, P.; Zhu, C.; Zhang, P.; Liu, H. Development and application of high strength gears. Int. J. Adv. Manuf. Technol. 2024, 132, 3123–3148. [Google Scholar] [CrossRef]

- Bußkamp, P.; Jacobs, G.; Röder, J. Multiobjective wind turbine gearbox design optimization to reduce component damage risk during grid faults. Forsch. Ingenieurwes. 2025, 89, 48. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tuirán, R.; Águila, H.; Jou, E.; Escaler, X.; Mebarki, T. Fault Diagnosis in a 2 MW Wind Turbine Drive Train by Vibration Analysis: A Case Study. Machines 2025, 13, 434. https://doi.org/10.3390/machines13050434

Tuirán R, Águila H, Jou E, Escaler X, Mebarki T. Fault Diagnosis in a 2 MW Wind Turbine Drive Train by Vibration Analysis: A Case Study. Machines. 2025; 13(5):434. https://doi.org/10.3390/machines13050434

Chicago/Turabian StyleTuirán, Rafael, Héctor Águila, Esteve Jou, Xavier Escaler, and Toufik Mebarki. 2025. "Fault Diagnosis in a 2 MW Wind Turbine Drive Train by Vibration Analysis: A Case Study" Machines 13, no. 5: 434. https://doi.org/10.3390/machines13050434

APA StyleTuirán, R., Águila, H., Jou, E., Escaler, X., & Mebarki, T. (2025). Fault Diagnosis in a 2 MW Wind Turbine Drive Train by Vibration Analysis: A Case Study. Machines, 13(5), 434. https://doi.org/10.3390/machines13050434