Nonlinear Dynamic Modeling of a Gear-Bearing Transmission System Based on Dynamic Meshing Parameters

Abstract

1. Introduction

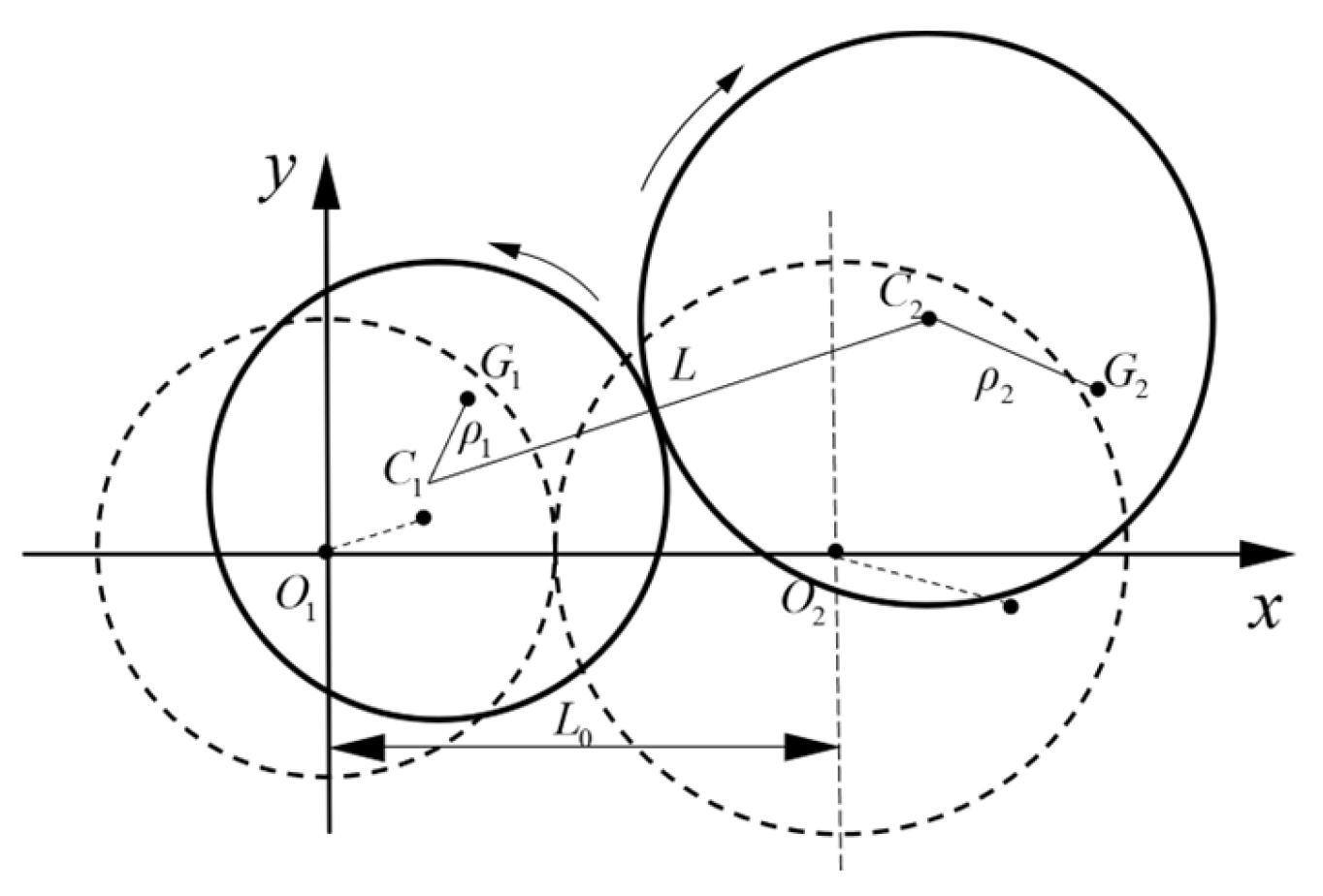

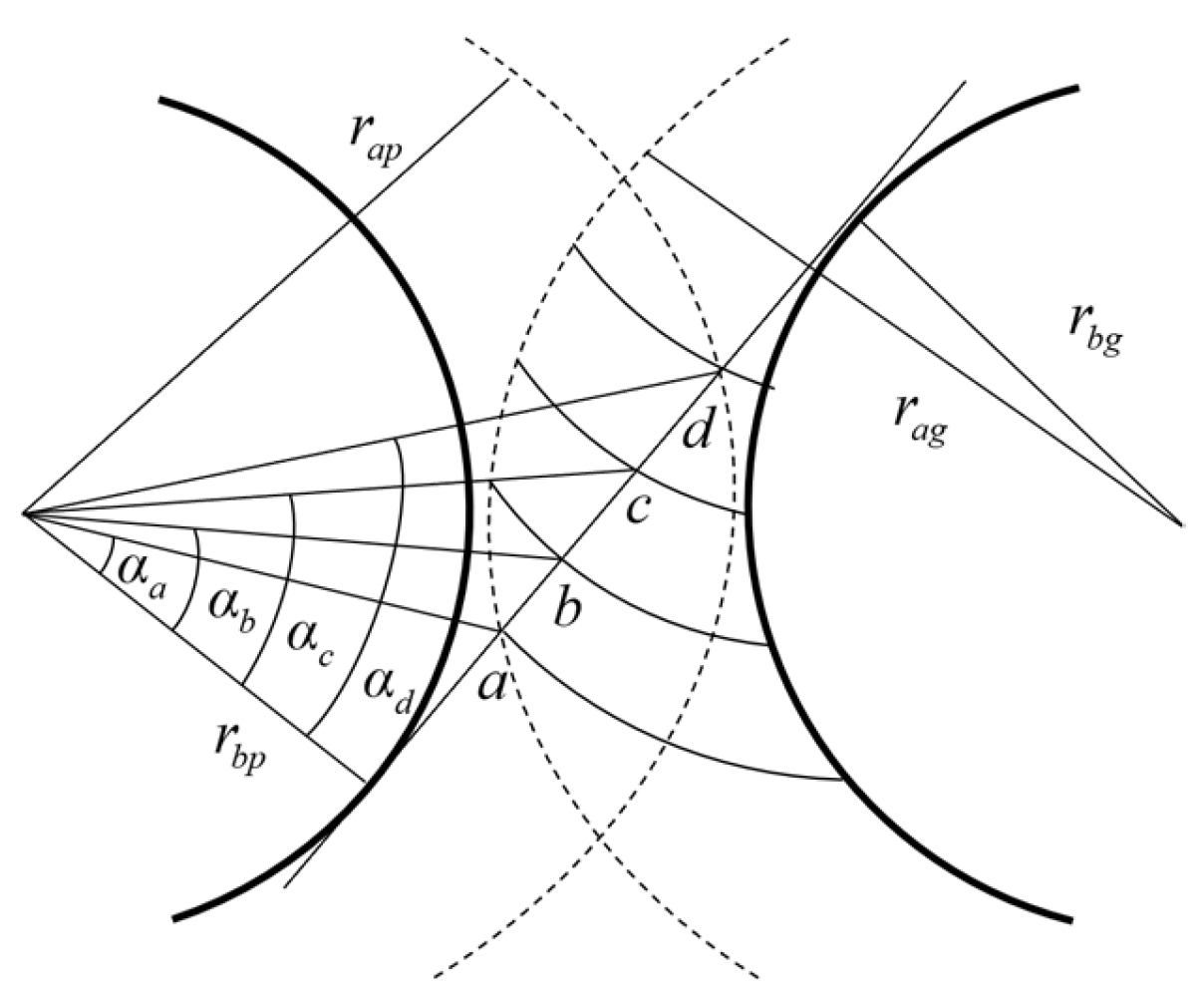

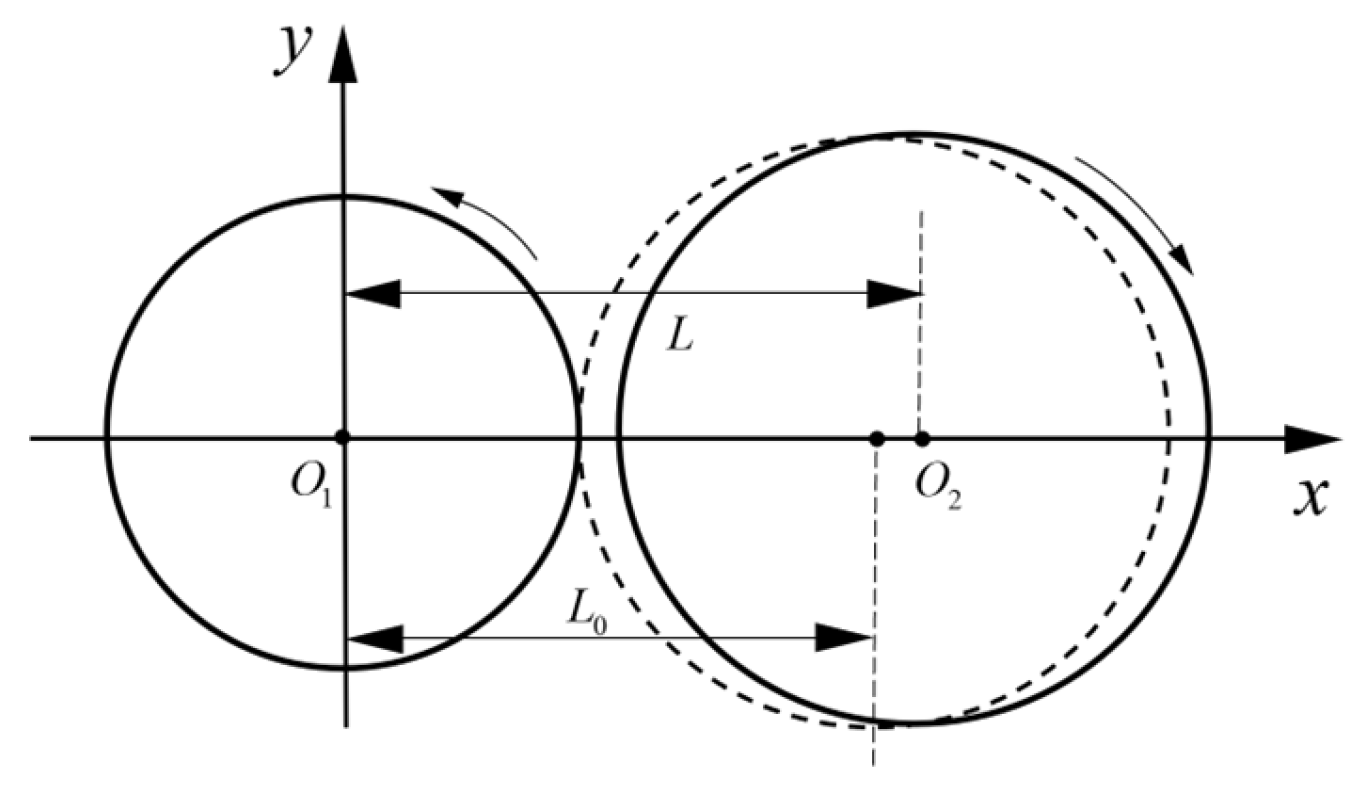

2. Spur Gear Meshing Stiffness Model

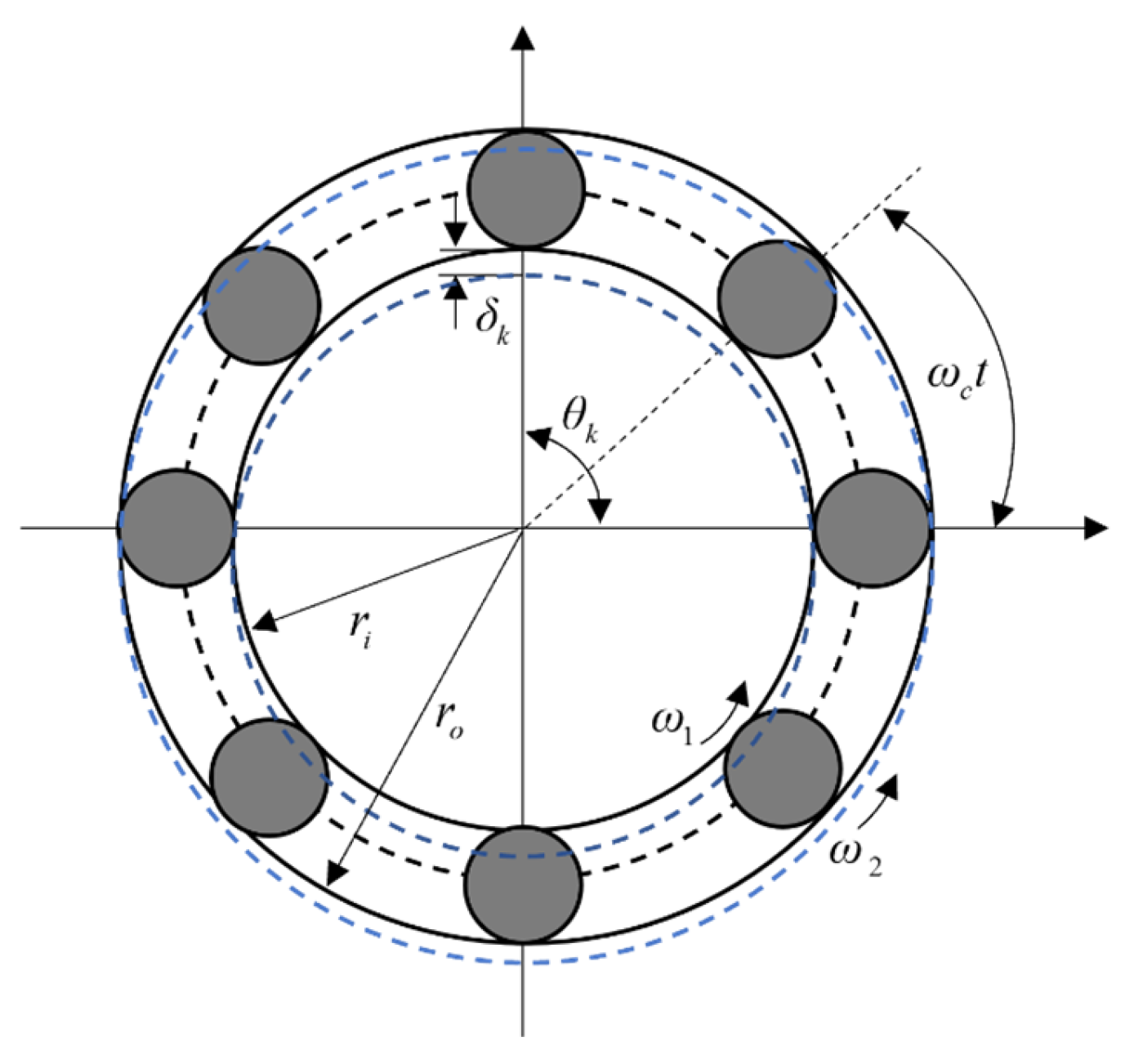

3. Bearing Mechanics Model

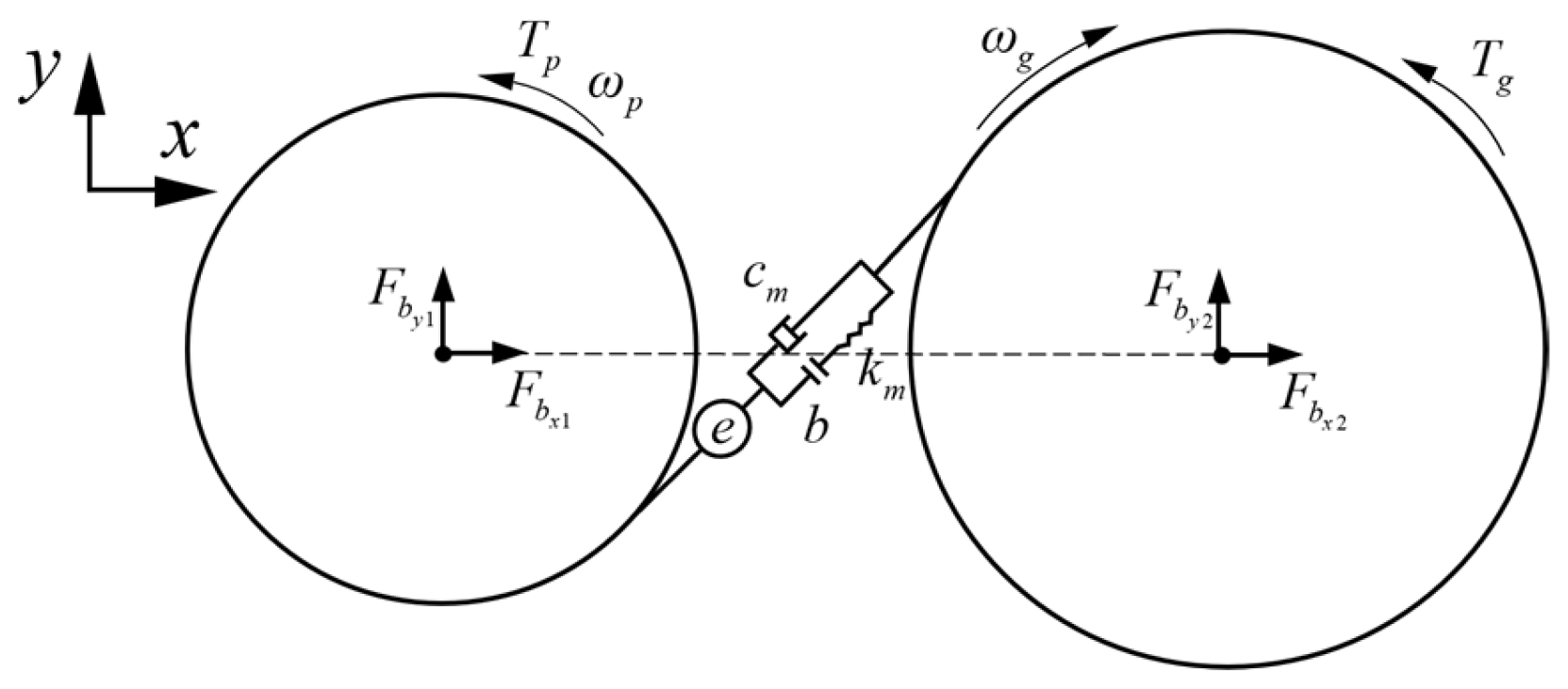

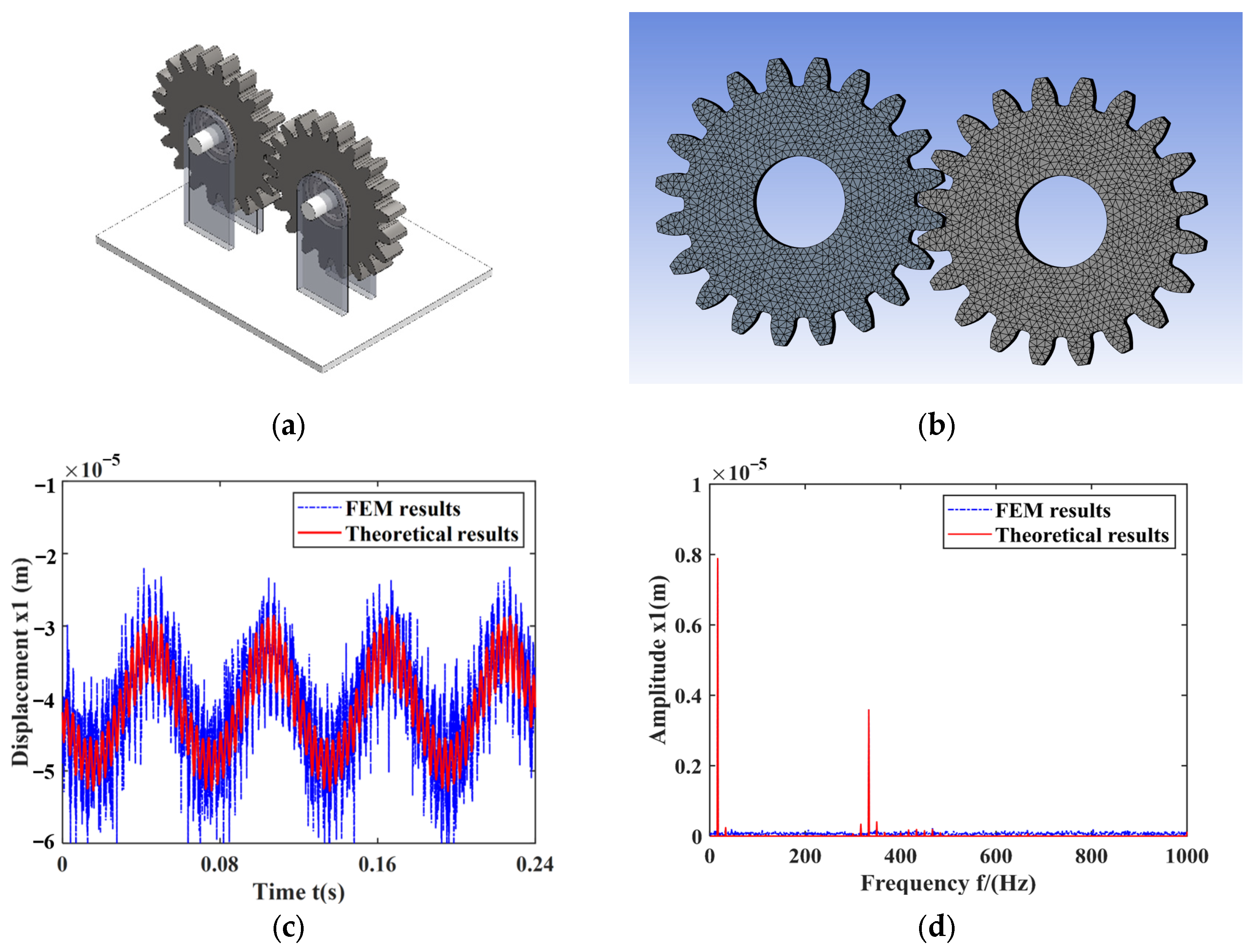

4. Dynamic Modeling of Gear-Bearing Systems

5. Results

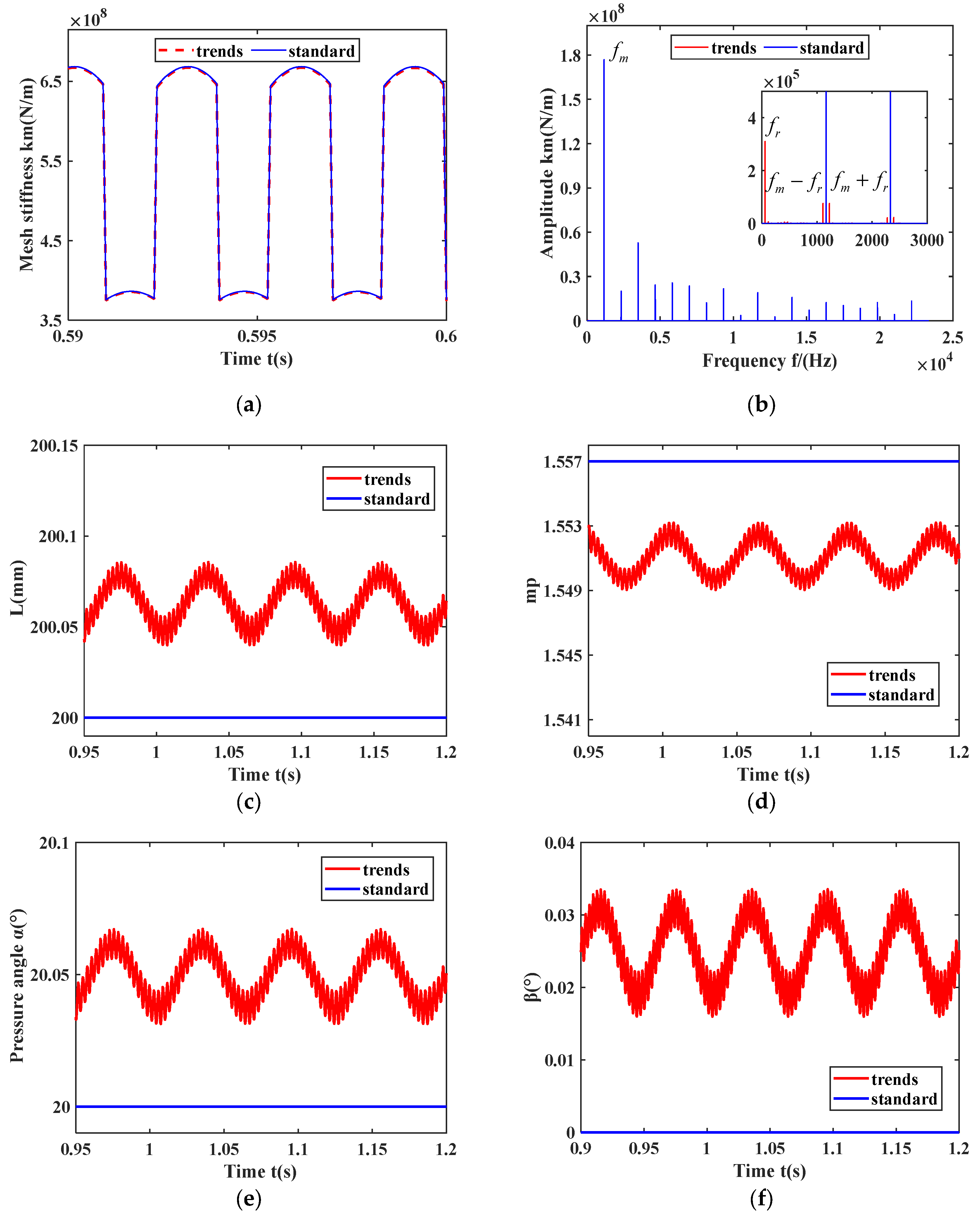

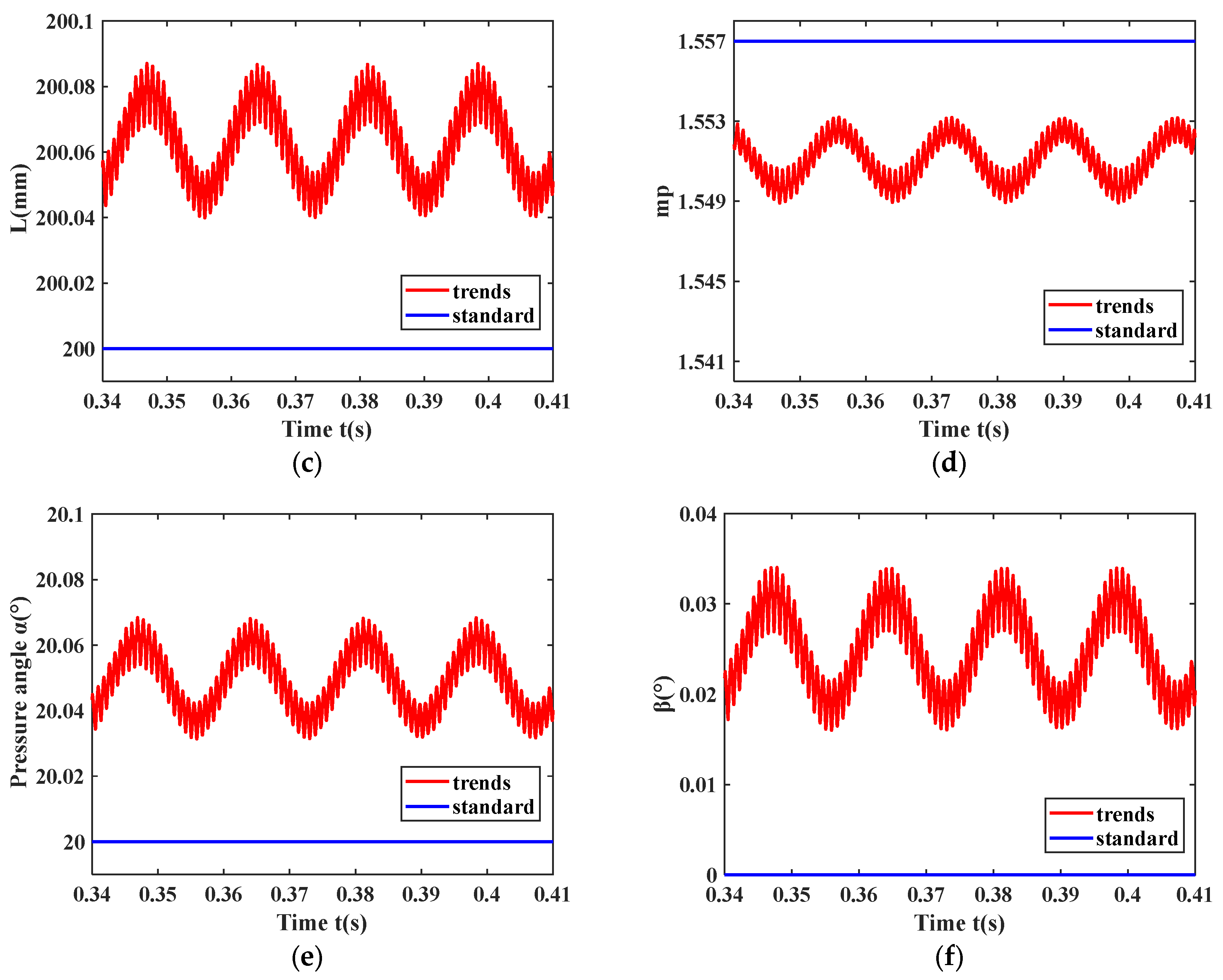

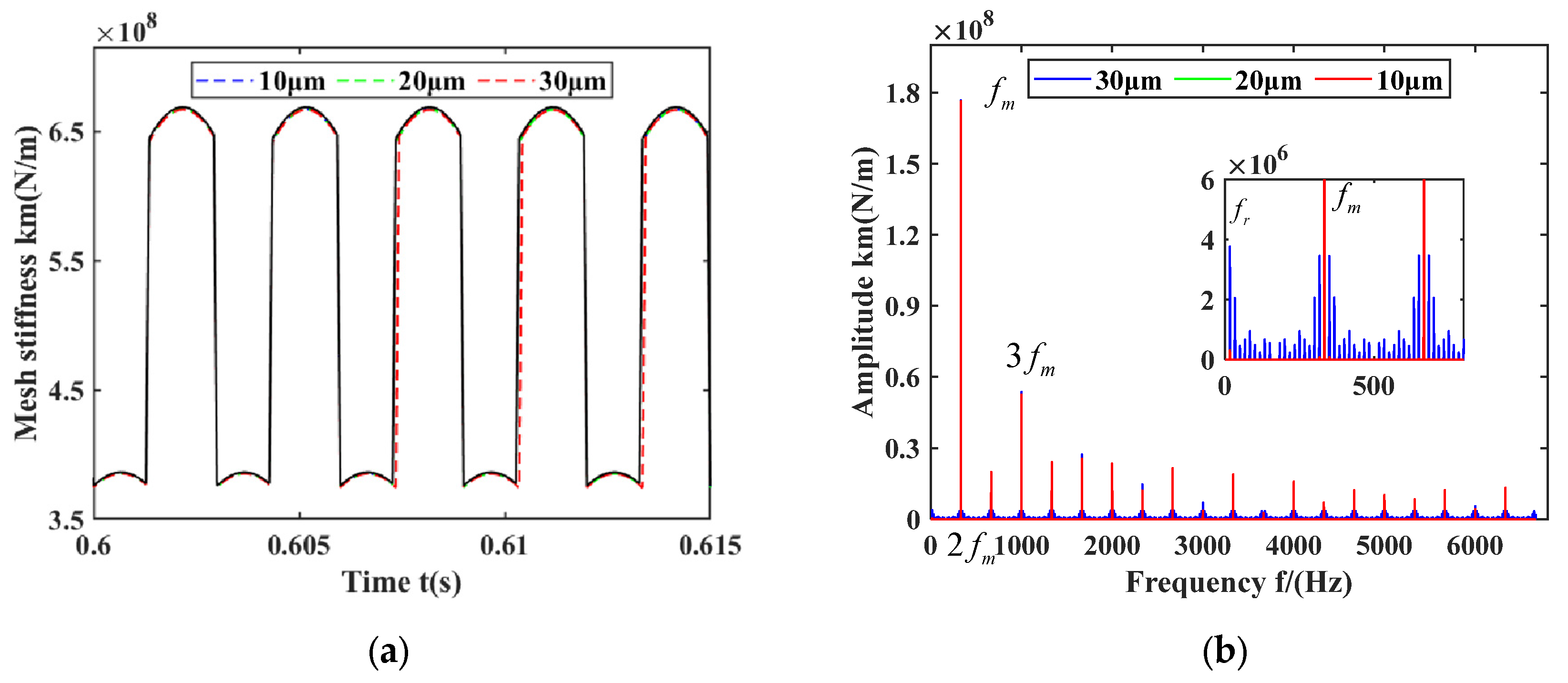

5.1. Gear Mesh Stiffness Calculation Based on Dynamic Meshing Parameters

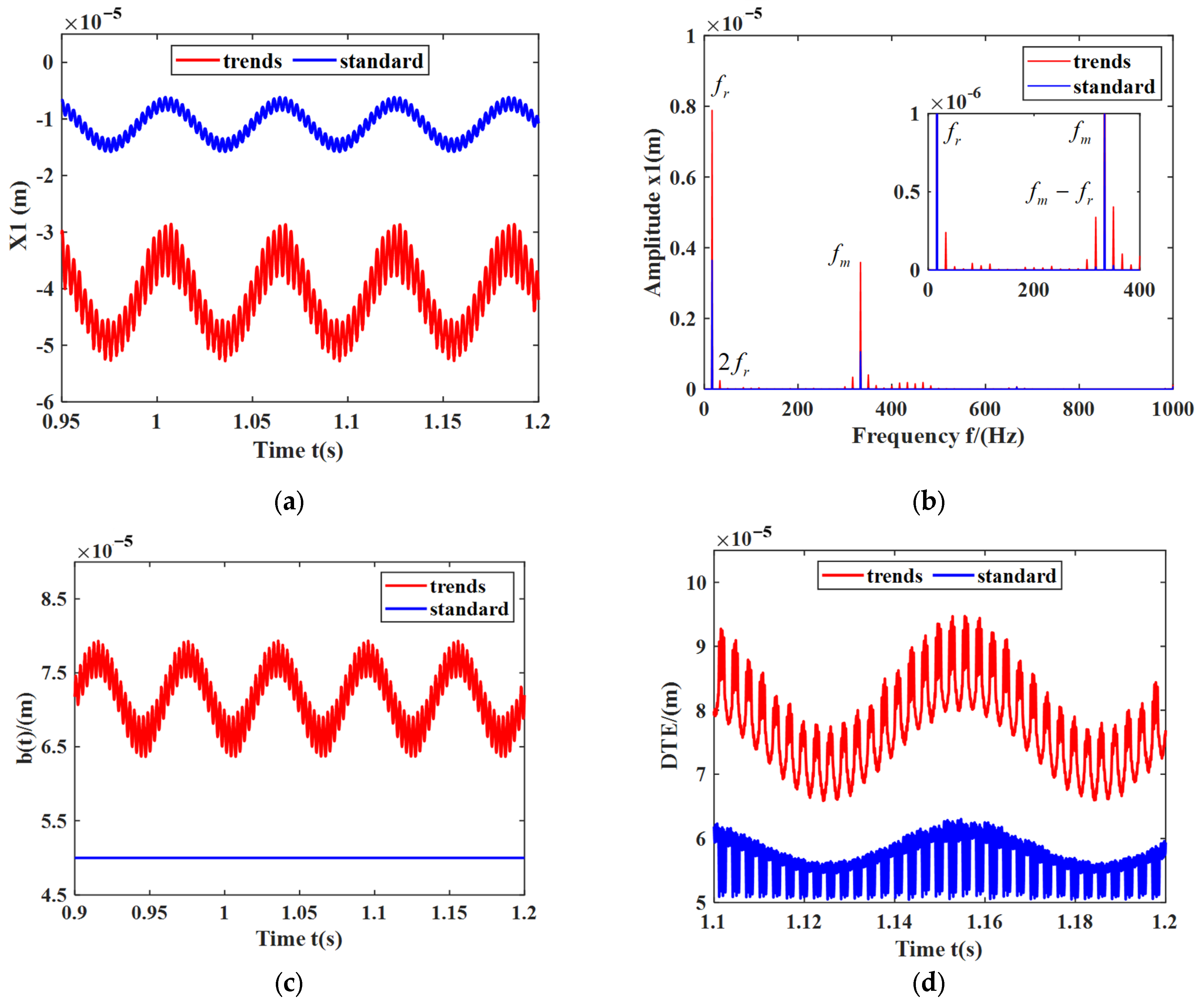

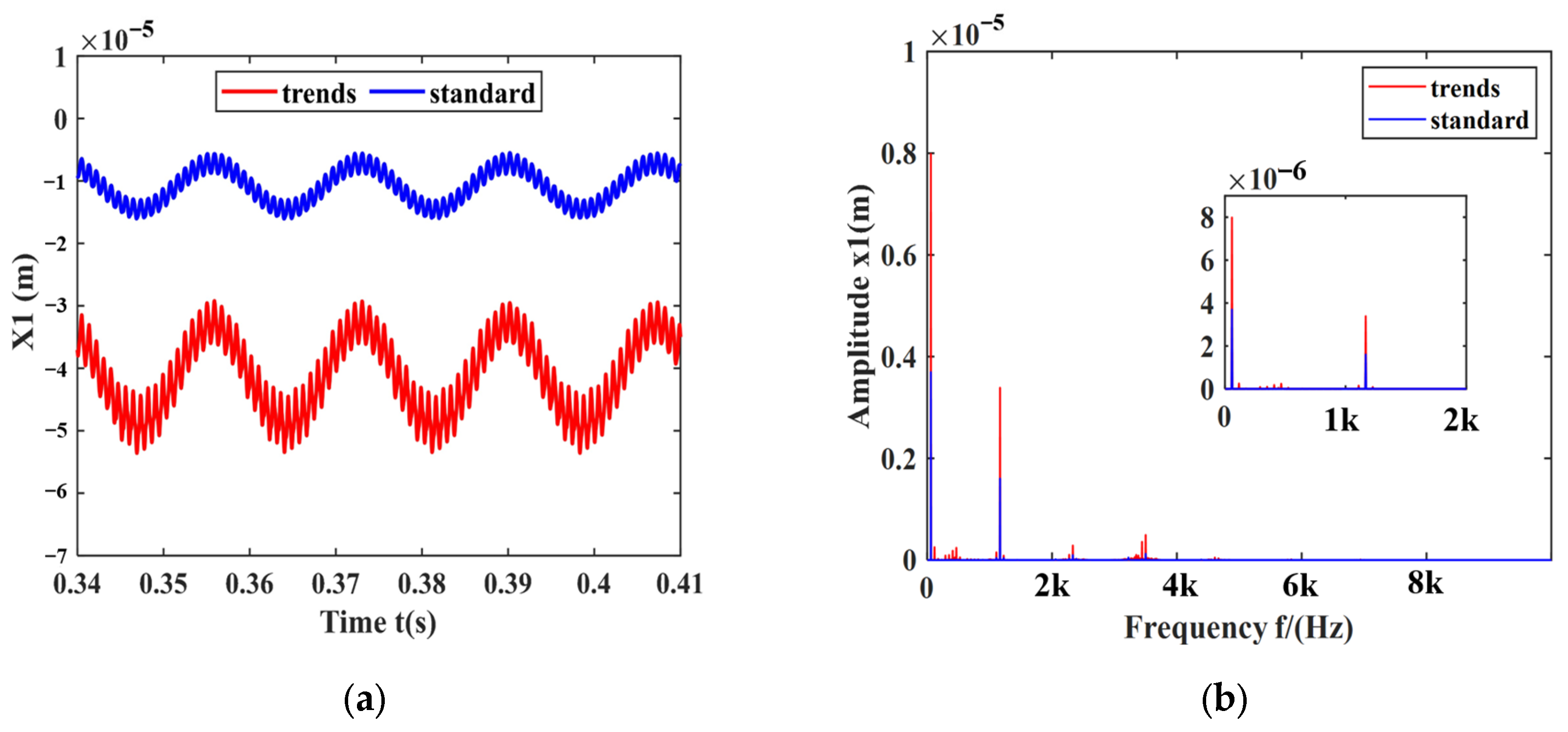

5.2. Calculation of Vibration Characteristics of the Gear-Bearing Transmission Systems Based on Dynamic Meshing Parameters

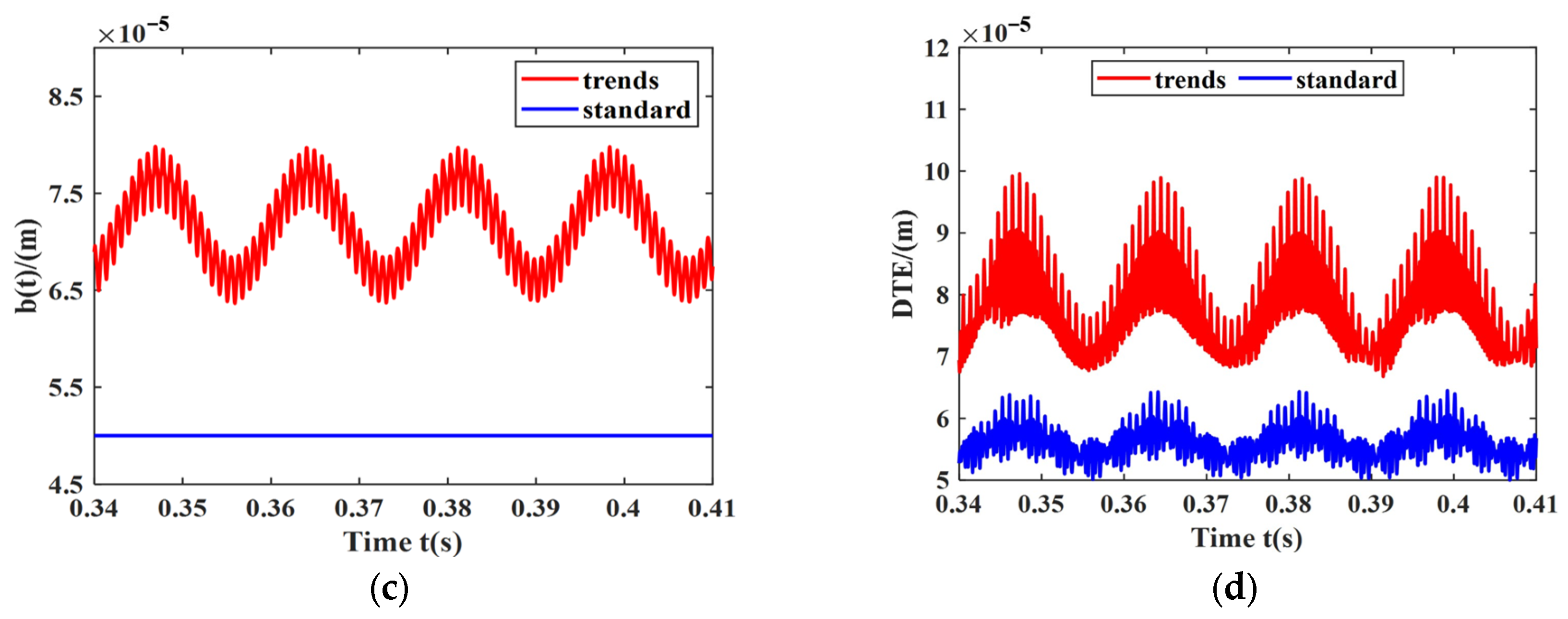

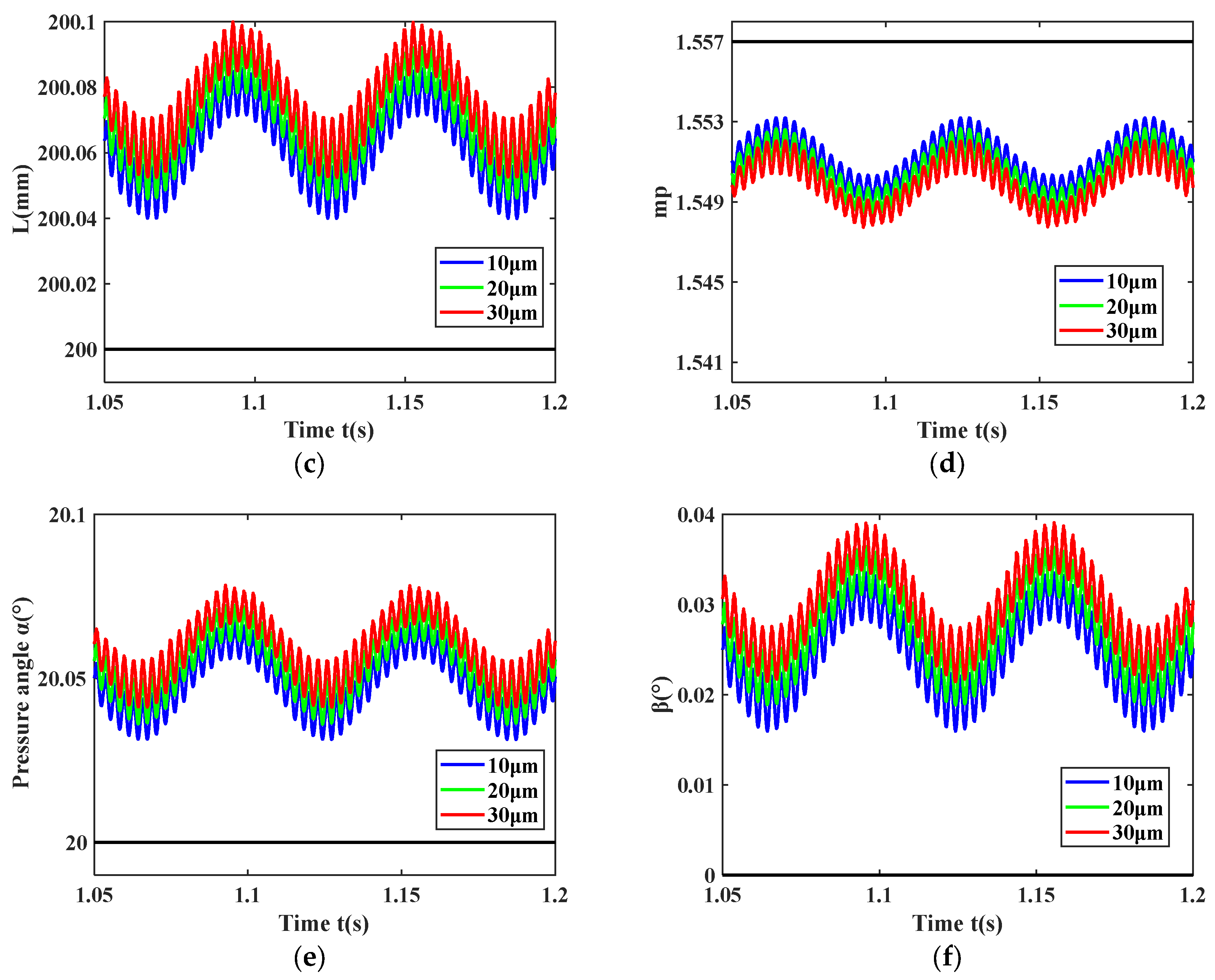

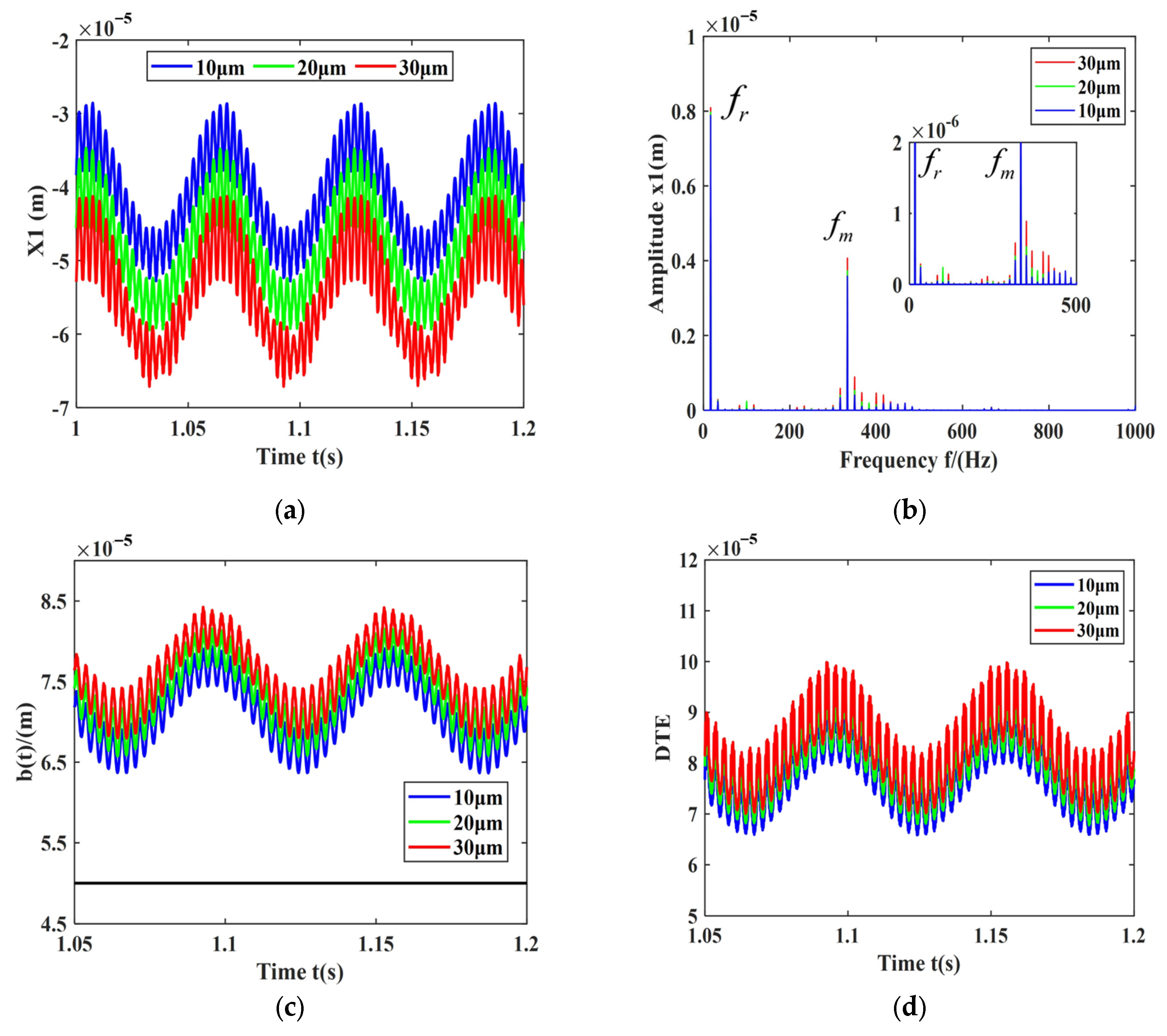

5.3. Influence of Bearing Clearance on Gear-Bearing Systems

6. Conclusions

- (1)

- The variation in the relative positions of the gears leads to changes in the amplitude and range of gear meshing stiffness. This change in relative gear positions is also reflected in the variations in the center distance and contact ratio. As the relative positions of the gears increase, the center distance increases while the contact ratio decreases. The amplitude of meshing stiffness diminishes, while the frequency of gear meshing stiffness increases;

- (2)

- During gear rotation, the meshing parameters of the gear fluctuate over time. As the speed increases, the center distance of the gear, pressure angle, offset angle, contact ratio, and tooth side clearance increase as a whole;

- (3)

- Under the condition of a fixed initial gear backlash, changes in the initial bearing clearance affect the dynamic characteristics of the gear-bearing transmission system. As the initial bearing clearance increases, the amplitudes corresponding to the rotational frequency and meshing frequency gradually increase, and the amplitudes of other frequencies also increase. The center distance, instantaneous pressure angle, deflection angle, lateral displacement of the driving gear, half-tooth side clearance, and contact ratio decrease, while the dynamic tooth engagement (DTE) shows more significant variation.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

Appendix A

Appendix B

References

- Rincon, A.F.D.; Viadero, F.; Iglesias, M.; de-Juan, A.; Garcia, P.; Sancibrian, R. Effect of cracks and pitting defects on gear meshing. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2012, 226, 2805–2815. [Google Scholar] [CrossRef]

- Yang, D.C.H.; Lin, J.Y.; Damping, H. Tooth Friction and Bending Elasticity in Gear Impact Dynamics. J. Mech. Transm. Autom. Des. 1987, 109, 189–196. [Google Scholar] [CrossRef]

- Tian, X.; Zuo, M.J.; Fyfe, K.R. Analysis of the Vibration Response of a Gearbox With Gear Tooth Faults. Am. Soc. Mech. Eng. Digit. Collect. 2008, 785–793. [Google Scholar] [CrossRef]

- Zhou, X.; Shao, Y.; Lei, Y.; Zuo, M. Time-Varying Meshing Stiffness Calculation and Vibration Analysis for a 16DOF Dynamic Model With Linear Crack Growth in a Pinion. J. Vib. Acoust. 2012, 134, 011011. [Google Scholar] [CrossRef]

- Chen, Z.; Shao, Y. Mesh stiffness calculation of a spur gear pair with tooth profile modification and tooth root crack. Mech. Mach. Theory 2013, 62, 63–74. [Google Scholar] [CrossRef]

- Ma, H.; Song, R.; Pang, X.; Wen, B. Time-varying mesh stiffness calculation of cracked spur gears. Eng. Fail. Anal. 2014, 44, 179–194. [Google Scholar] [CrossRef]

- Luo, Y.; Baddour, N.; Liang, M. Effects of gear center distance variation on time varying mesh stiffness of a spur gear pair. Eng. Fail. Anal. 2017, 75, 37–53. [Google Scholar] [CrossRef]

- Dai, H.; Long, X.; Chen, F.; Xun, C. An improved analytical model for gear mesh stiffness calculation. Mech. Mach. Theory 2021, 159, 104262. [Google Scholar] [CrossRef]

- Yang, H.; Shi, W.; Chen, Z.; Guo, N. An improved analytical method for mesh stiffness calculation of helical gear pair considering time-varying backlash. Mech. Syst. Signal Proc. 2022, 170, 108882. [Google Scholar] [CrossRef]

- Liu, Z.; Jiang, Y.; Luo, R.; Wu, Y.; Huang, J.; Feng, N.; Li, K. Improved analytical model for calculating mesh stiffness and transmission error of helical gears considering root curve: Theoretical analysis and experiments. Adv. Mech. Eng. 2024, 16, 16878132241228196. [Google Scholar] [CrossRef]

- Guo, Y.; Parker, R.G. Analytical determination of back-side contact gear mesh stiffness. Mech. Mach. Theory 2014, 78, 263–271. [Google Scholar] [CrossRef]

- Cheng, G.; Xiao, K.; Wang, J.; Pu, W.; Han, Y. Calculation of Gear Meshing Stiffness Considering Lubrication. J. Tribol. Trans. ASME 2020, 142, 031602. [Google Scholar] [CrossRef]

- Blankenship, G.W.; Kahraman, A. Steady state forced response of a mechanical oscillator with combined parametric excitation and clearance type non-linearity. J. Sound Vib. 1995, 185, 743–765. [Google Scholar] [CrossRef]

- Al-shyyab, A.; Kahraman, A. Non-linear dynamic analysis of a multi-mesh gear train using multi-term harmonic balance method: Sub-harmonic motions. J. Sound Vib. 2005, 279, 417–451. [Google Scholar] [CrossRef]

- Chen, Q.; Ma, Y.; Huang, S.; Zhai, H. Research on gears’ dynamic performance influenced by gear backlash based on fractal theory. Appl. Surf. Sci. 2014, 313, 325–332. [Google Scholar] [CrossRef]

- Cao, Z.; Shao, Y.; Rao, M.; Yu, W. Effects of the gear eccentricities on the dynamic performance of a planetary gear set. Nonlinear Dyn. 2018, 91, 1–15. [Google Scholar] [CrossRef]

- Zhao, B.; Huangfu, Y.; Ma, H.; Zhao, Z.; Wang, K. The influence of the geometric eccentricity on the dynamic behaviors of helical gear systems. Eng. Fail. Anal. 2020, 118, 104907. [Google Scholar] [CrossRef]

- Han, J.; Liang, L.; Zhang, H.; Zhao, Y. Dynamics Modeling and Experimental Investigation of Gear Mechanism with Coupled Small Clearances. Entropy 2021, 23, 834. [Google Scholar] [CrossRef]

- Liu, Z.; Liu, Z.; Zhao, J.; Zhang, G. Study on interactions between tooth backlash and journal bearing clearance nonlinearity in spur gear pair system. Mech. Mach. Theory 2017, 107, 229–245. [Google Scholar] [CrossRef]

- Meng, Z.; Shi, G.; Wang, F. Vibration response and fault characteristics analysis of gear based on time-varying mesh stiffness. Mech. Mach. Theory 2020, 148, 103786. [Google Scholar] [CrossRef]

- Han, Y.; Chen, X.; Xiao, J.; Gu, J.X.; Xu, M. An Improved Coupled Dynamic Modeling for Exploring Gearbox Vibrations Considering Local Defects. J. Dyn. Monit. Diagn. 2023, 262–274. [Google Scholar] [CrossRef]

- Fukata, S.; Gad, E.; Kondou, T.; Ayabe, T.; Tamura, H. On the Radial Vibration of Ball-Bearings—Computer-Simulation. Bull. Jsme-Jpn. Soc. Mech. Eng. 1985, 28, 899–904. [Google Scholar] [CrossRef]

- Sawalhi, N.; Randall, R.B. Simulating gear and bearing interactions in the presence of faults—Part II: Simulation of the vibrations produced by extended bearing faults. Mech. Syst. Signal Proc. 2008, 22, 1952–1966. [Google Scholar] [CrossRef]

- Tu, W.; Shao, Y.; Mechefske, C.K. An analytical model to investigate skidding in rolling element bearings during acceleration. J. Mech. Sci. Technol. 2012, 26, 2451–2458. [Google Scholar] [CrossRef]

- Zhang, X.; Han, Q.; Peng, Z.; Chu, F. Stability analysis of a rotor-bearing system with time-varying bearing stiffness due to finite number of balls and unbalanced force. J. Sound Vibr. 2013, 332, 6768–6784. [Google Scholar] [CrossRef]

- Bizarre, L.; Nonato, F.; Cavalca, K.L. Formulation of five degrees of freedom ball bearing model accounting for the nonlinear stiffness and damping of elastohydrodynamic point contacts. Mech. Mach. Theory 2018, 124, 179–196. [Google Scholar] [CrossRef]

- Xu, H.; Wang, P.; Yang, Y.; Ma, H.; Luo, Z.; Han, Q.; Wen, B. Effects of supporting stiffness of deep groove ball bearings with raceway misalignment on vibration behaviors of a gear-rotor system. Mech. Mach. Theory 2022, 177, 105041. [Google Scholar] [CrossRef]

- Corral, E.; Moreno, R.G.; García, M.J.G.; Castejón, C. Nonlinear phenomena of contact in multibody systems dynamics: A review. Nonlinear Dyn. 2021, 104, 1269–1295. [Google Scholar] [CrossRef]

- Moreno, R.G.; Marques, F.; Abad, E.C.; Alonso, J.M.; Flores, P.; Castejon, C. Enhanced modelling of planar radial-loaded deep groove ball bearings with smooth-contact formulation. Multibody Syst. Dyn. 2024, 60, 121–159. [Google Scholar]

- Kim, W.; Yoo, H.H.; Chung, J. Dynamic analysis for a pair of spur gears with translational motion due to bearing deformation. J. Sound Vib. 2010, 329, 4409–4421. [Google Scholar] [CrossRef]

- Yi, Y.; Huang, K.; Xiong, Y.; Sang, M. Nonlinear dynamic modelling and analysis for a spur gear system with time-varying pressure angle and gear backlash. Mech. Syst. Signal Process. 2019, 132, 18–34. [Google Scholar] [CrossRef]

- Kong, X.; Ding, H.; Tang, J.; Hu, Z.; Chen, S. Bearing internal load analysis and fatigue life estimation based on nonlinear dynamic model of a gear system. J. Vib. Control 2022, 28, 1635–1642. [Google Scholar] [CrossRef]

- Guo, Y.; Parker, R.G. Dynamic Analysis of Planetary Gears With Bearing Clearance. J. Comput. Nonlinear Dyn. 2012, 7, 041002. [Google Scholar] [CrossRef]

- Liu, P.; Zhu, L.; Gou, X.; Shi, J.; Jin, G. Modeling and analyzing of nonlinear dynamics for spur gear pair with pitch deviation under multi-state meshing. Mech. Mach. Theory 2021, 163, 104378. [Google Scholar] [CrossRef]

- Zhang, C.; Wei, J.; Wang, F.; Hou, S.; Zhang, A.; Lim, T.C. Dynamic model and load sharing performance of planetary gear system with journal bearing. Mech. Mach. Theory 2020, 151, 103898. [Google Scholar] [CrossRef]

- Xu, M.; Han, Y.; Sun, X.; Shao, Y.; Gu, F.; Ball, A.D. Vibration characteristics and condition monitoring of internal radial clearance within a ball bearing in a gear-shaft-bearing system. Mech. Syst. Signal Process. 2022, 165, 108280. [Google Scholar] [CrossRef]

- Li, H.; Chen, S.; Tang, J.; Sun, Z.; Hu, Y. Nonlinear dynamic modeling and analysis of spur gear based on gear compatibility conditions. Mech. Mach. Theory 2022, 171, 104767. [Google Scholar] [CrossRef]

- Zeng, Q.; Liu, Y.; Du, W.; Jiang, L.; Yu, W. Dynamic characteristic analysis of a gear-rotor-bearing coupling system considering bearing fit. Nonlinear Dyn. 2024, 113, 2131–2154. [Google Scholar] [CrossRef]

- Tian, G.; Gao, Z.; Liu, P.; Bian, Y. Dynamic Modeling and Stability Analysis for a Spur Gear System Considering Gear Backlash and Bearing Clearance. Machines 2022, 10, 439. [Google Scholar] [CrossRef]

- Xu, Z.; Yu, W.; Xu, H.; Li, J. Dynamic modeling of spur gear system considering the coupling effect between bearing deflection and gear mesh stiffness. Proc. Inst. Mech. Eng. Part C-J. Eng. Mech. Eng. Sci. 2024, 238, 6725–6737. [Google Scholar] [CrossRef]

- Guan, H. Study on dynamic characteristics of the gear-dual-rotor system with multi-position rubbing. Mech. Mach. Theory 2024. [Google Scholar] [CrossRef]

- Ma, H.; Pang, X.; Feng, R.; Song, R.; Wen, B. Fault features analysis of cracked gear considering the effects of the extended tooth contact. Eng. Fail. Anal. 2015, 48, 105–120. [Google Scholar] [CrossRef]

- Chen, Y.; Hou, L.; Chen, G.; Song, H.; Lin, R.; Jin, Y.; Chen, Y. Nonlinear dynamics analysis of a dual-rotor-bearing-casing system based on a modified HB-AFT method. Mech. Syst. Signal Process. 2023, 185. [Google Scholar] [CrossRef]

- Bahan, D. Nonlinear Vibration Analysis of Rotors Supported by Ball Bearings. Master’s Thesis, Middle East Technical University, Ankara, Turkey, 2019. [Google Scholar]

- Niu, Q.; Li, Y.; Zhu, Y.; Pei, S.; Yin, Y.; Wang, D. Analytical Determination and Influence Analysis of Stiffness Matrix of Ball Bearing under Different Load Conditions. Machines 2022, 10, 238. [Google Scholar] [CrossRef]

- Anoopnath, P.R.; Babu, V.S.; Vishwanath, A.K. Hertz Contact Stress of Deep Groove Ball Bearing. In Materials Today-Proceedings; Elsevier: Amsterdam, The Netherlands, 2018. [Google Scholar]

| Physical Parameters | Variable | Value |

|---|---|---|

| Number of teeth of wheel | 20 | |

| Modulus (mm) | 10 | |

| Elastic modulus (GPa) | 206 | |

| Standard pressure angle (°) | 20 | |

| Tooth width (mm) | 30 | |

| Standard center distance (mm) | 200 | |

| Static transmission error amplitude (μm) | 20 | |

| Mass of wheel (kg) | 6.57 | |

| ) | 0.0365 | |

| Damping factor | 0.07 | |

| Torque average (N·m) | 300 | |

| Torque amplitude (N·m) | 100 | |

| Initial half-tooth clearance measurement (μm) | 50 |

| Physical Parameters | Variable | Value |

|---|---|---|

| Inner circle radius (mm) | 10 | |

| Outer circle radius (mm) | 23.5 | |

| Bearing widths (mm) | B | 14 |

| Number of balls | 10 | |

| Bearing damping (N·s/m) | 512.64 | |

| Hertz contact stiffness (N/m) | 2 × 108 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Song, J.; Hou, L.; Ma, R.; Li, Z.; Lin, R.; Chen, Y.; Chen, Y.; Saeed, N.A. Nonlinear Dynamic Modeling of a Gear-Bearing Transmission System Based on Dynamic Meshing Parameters. Machines 2025, 13, 230. https://doi.org/10.3390/machines13030230

Song J, Hou L, Ma R, Li Z, Lin R, Chen Y, Chen Y, Saeed NA. Nonlinear Dynamic Modeling of a Gear-Bearing Transmission System Based on Dynamic Meshing Parameters. Machines. 2025; 13(3):230. https://doi.org/10.3390/machines13030230

Chicago/Turabian StyleSong, Jinzhou, Lei Hou, Rui Ma, Zhonggang Li, Rongzhou Lin, Yi Chen, Yushu Chen, and Nasser A. Saeed. 2025. "Nonlinear Dynamic Modeling of a Gear-Bearing Transmission System Based on Dynamic Meshing Parameters" Machines 13, no. 3: 230. https://doi.org/10.3390/machines13030230

APA StyleSong, J., Hou, L., Ma, R., Li, Z., Lin, R., Chen, Y., Chen, Y., & Saeed, N. A. (2025). Nonlinear Dynamic Modeling of a Gear-Bearing Transmission System Based on Dynamic Meshing Parameters. Machines, 13(3), 230. https://doi.org/10.3390/machines13030230