Towards Customer Outcome Management in Smart Manufacturing

Abstract

1. Introduction

1.1. Context and Goal of This Paper

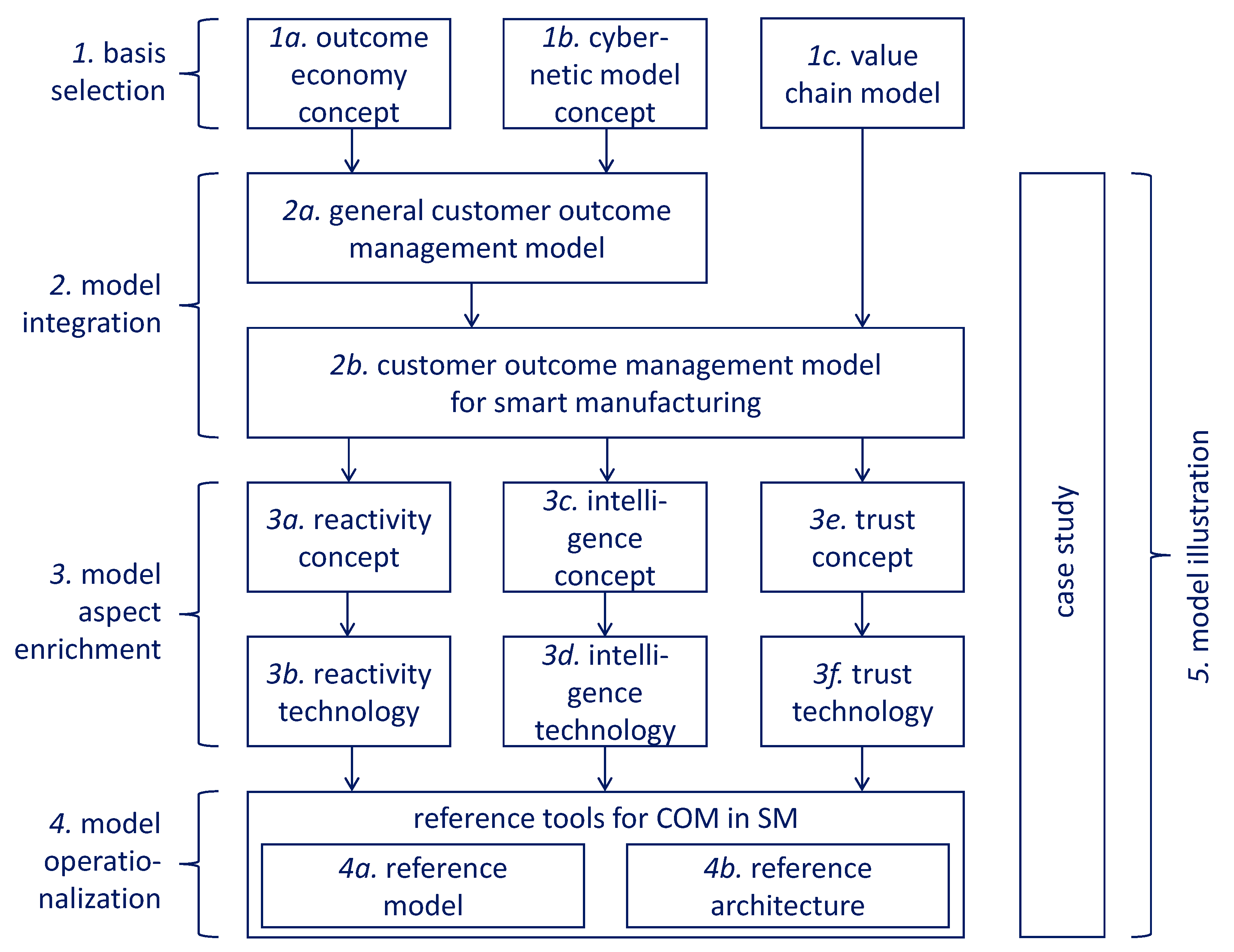

1.2. Approach for and Structure of This Paper

2. Related Work and Positioning

3. The Business Outcome Management Paradigm

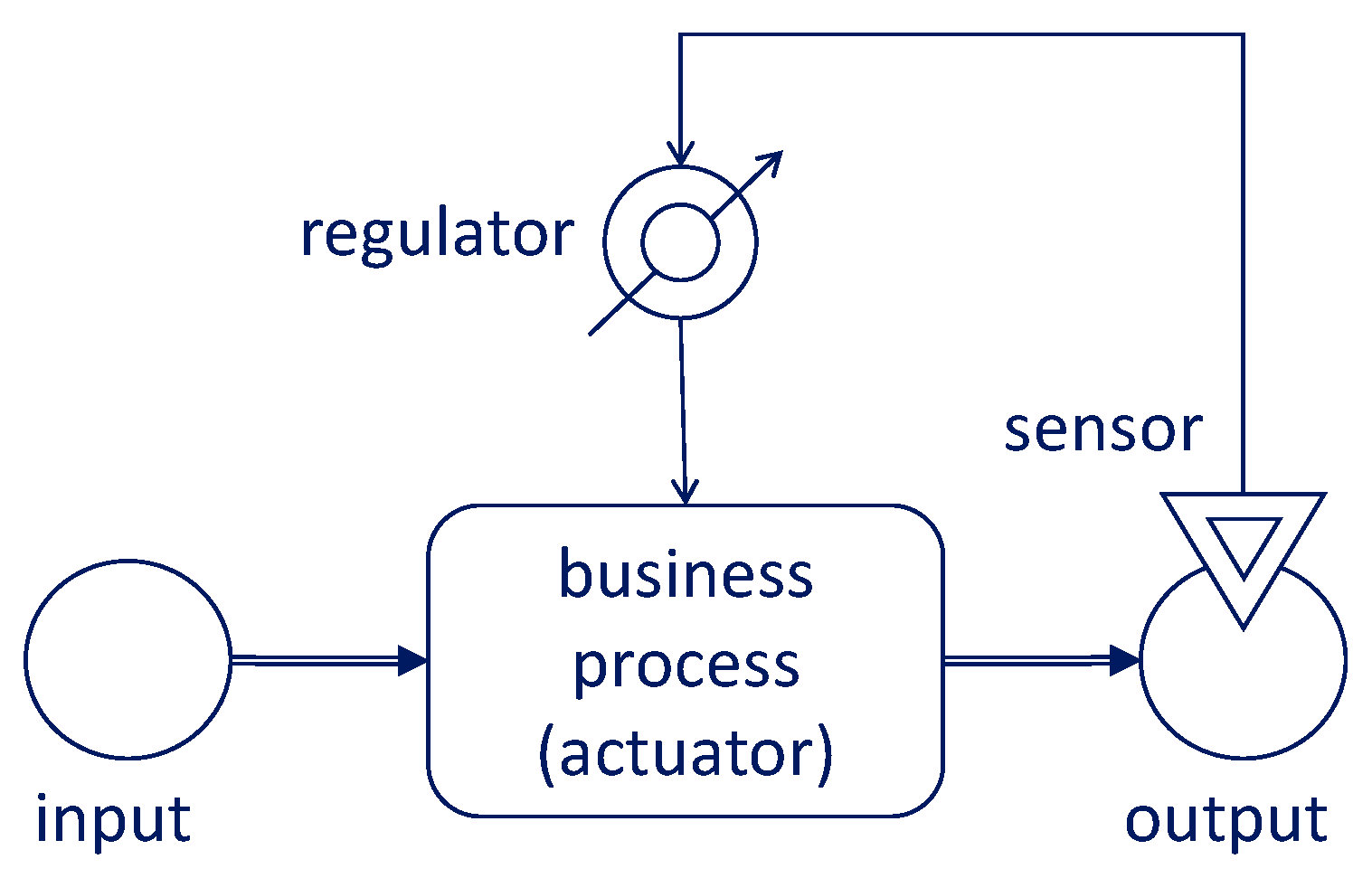

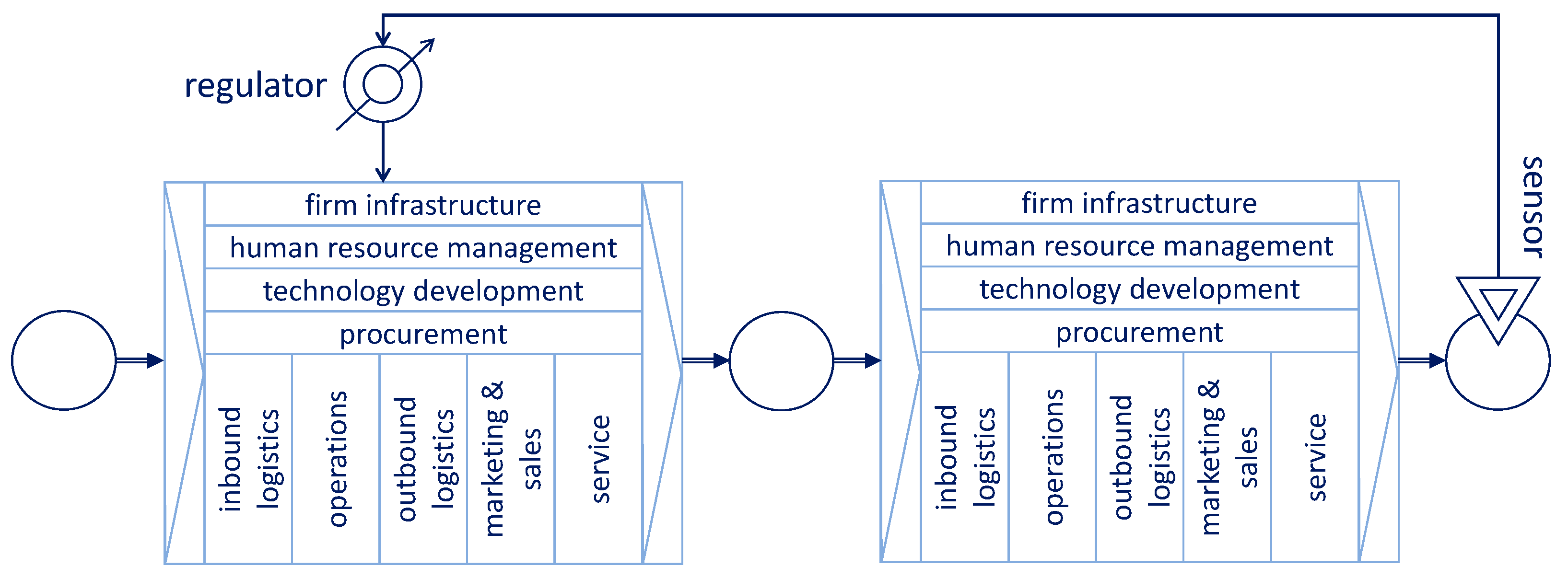

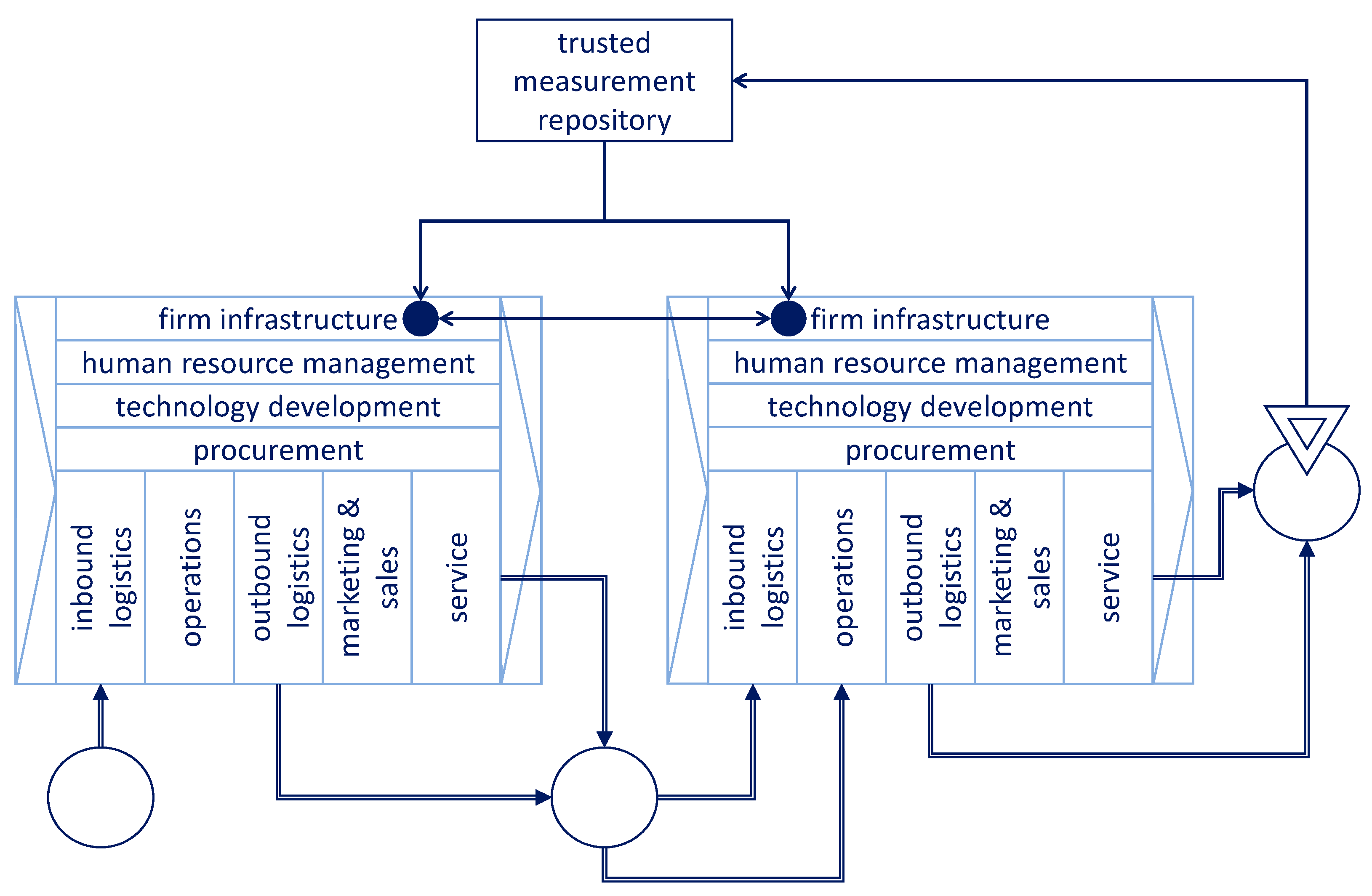

3.1. Single-Stage Cybernetic Model

3.2. Multi-Stage Cybernetic Model

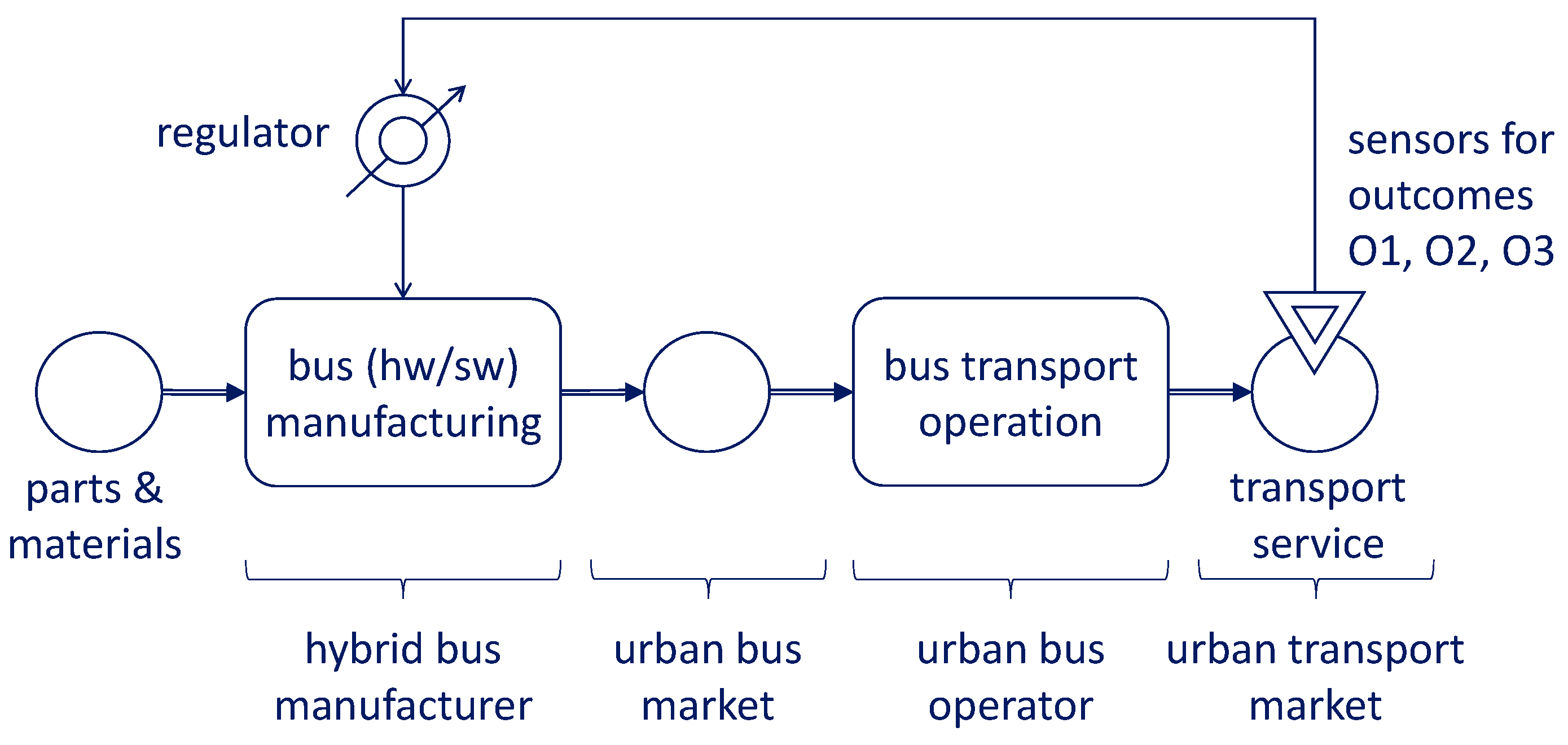

3.3. The Example HBM Case Study

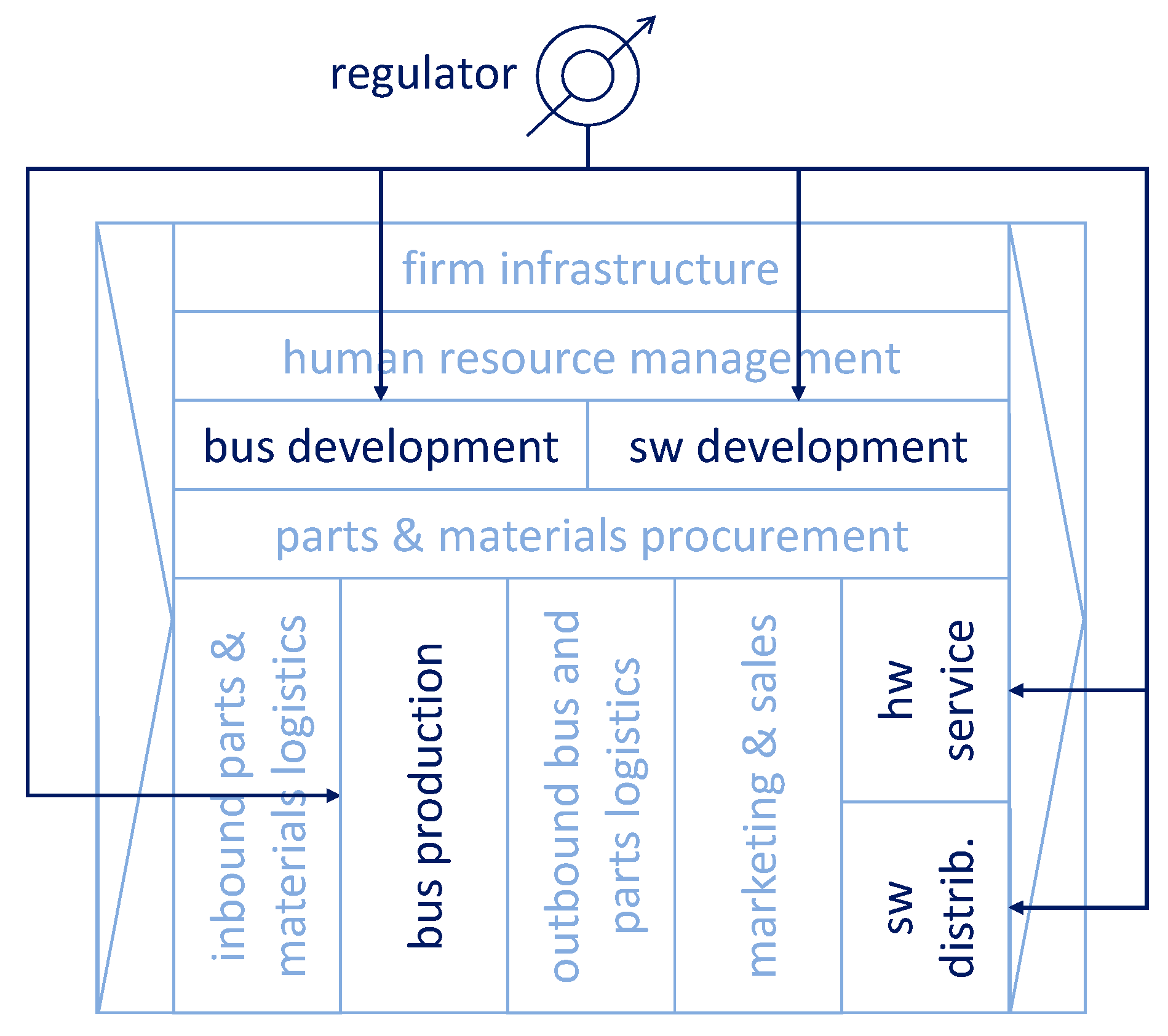

- O1:

- The number of passengers transported per time unit—this reflects the main operational KPI for the operators. HBM can influence this outcome by making their busses more attractive to travelers (e.g., in terms of speed of transport, in terms of operational reliability, or perhaps even in terms of cost of transportation—the latter being influenced by the cost of operating a bus).

- O2:

- The operating efficiency of buses in terms of energy consumption per distance—it is important for bus operators to be “green” [32]. HBM can influence this outcome by improving the physical characteristics of the drive train of their busses or by improving (the parametrization) of the software that controls the drive train.

- O3:

- The average traveler satisfaction with the comfort in buses in a specific period (where comfort is influenced by smooth driving behavior of buses). This is an important strategic KPI for the operators, as it helps obtain more customers in their markets (i.e., passengers).

4. Customer Outcome Management in Smart Manufacturing

4.1. The Product Lifecycle Perspective

- Product design: product design results in the blueprint of the product (including the bill-of-materials or BOM) as well as the blueprint of the process for manufacturing the product (including the bill-of-processes or BOP). This phase is often supported by a product lifecycle management (PLM) system.

- Product manufacturing: product manufacturing uses the BOM and BOP to actually manufacture (physically create) the product. In smart manufacturing, the manufacturing process is typically controlled by a management execution system (MES) or by a manufacturing process management system (MPMS) [36].

- Product delivery: the product delivery phase takes care of sending manufactured products to the customer for deployment in the customer business context, i.e., the context where outcomes are realized.

- Product after-sales servicing: during the use of the manufactured products in the customer context, after-sales services can be deployed to enhance the use of the products and hence the improvement of customer outcomes. Examples are maintenance, product reparameterization or the installation of new versions of firmware into the product.

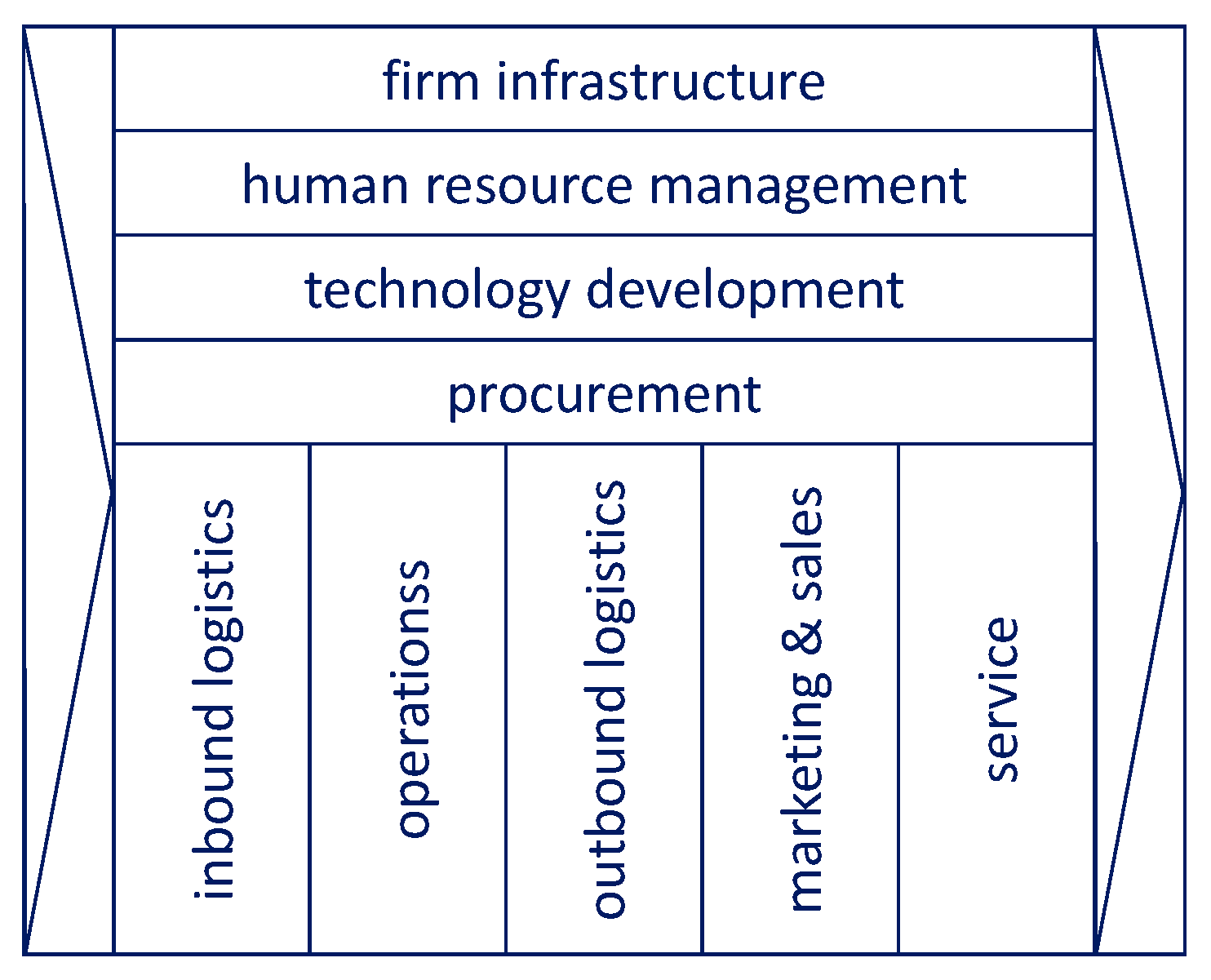

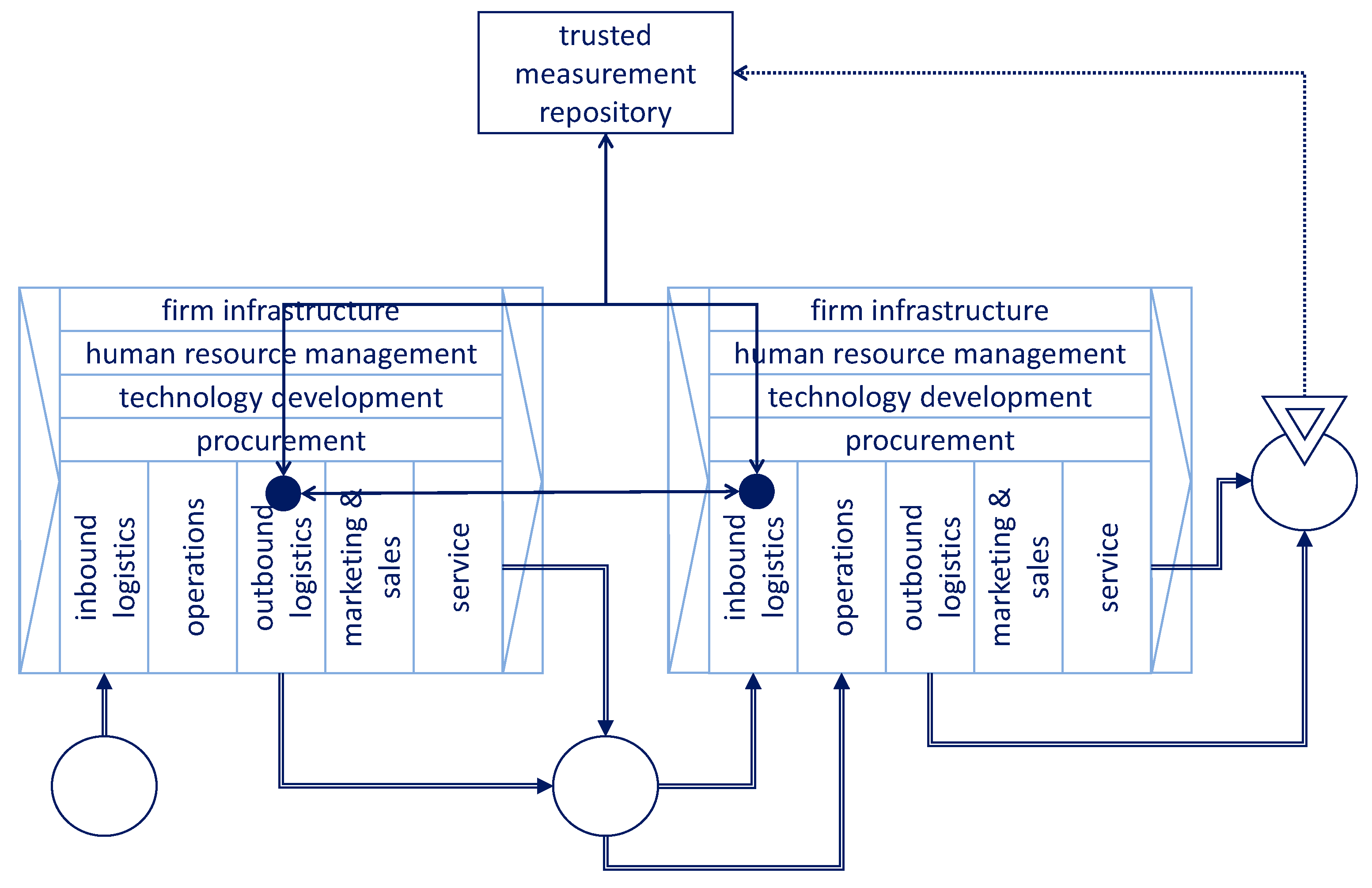

4.2. Adding Porter’s Value Chain Model to Outcome Thinking

- The technology development function of the provider implements the processes related to the product design lifecycle stage.

- The operations function of the provider implements the process related to the product manufacturing stage.

- The outbound logistics function of the provider implements the processes related to the product delivery stage, delivering the manufactured product to the inbound logistics function of the customer.

- The service function of the provider implements the processes related to the product after-sales servicing stage. It supports the operations function of the customer in creating products or services that in turn generate the targeted customer outcomes (via the outbound logistics and service functions of the customer, which serve the customer’s market).

- The regulator can decide that the product specification needs to be adapted to enhance the customer outcome and signal this to the technology development function of the provider, for example as a product change request to its PLM system. As an example, the sensor measurements may indicate a too-low uptime of the products, which requires a change to a product parameter.

- The regulator can decide that the customer outcome can be enhanced by improvements to the manufacturing process and hence signals this to the operations function of the provider. As an example, the conclusion of analyzing the sensor readings may be that there is a significant variation in the performance of individual products, which may indicate too much tolerance in the manufacturing process. This can be handled by advice for a change of machine settings in the bill-of-processes (BOP) handled by the manufacturing execution system (MES) of the provider.

- The regulator can decide that the customer outcome can be enhanced by a timelier delivery of products and hence signals this to the outbound logistics function, which may be reflected as a change in its product delivery planning. As an example, sensor readings may indicate lost transactions of the customer because of unavailability of the product manufactured by the provider.

- The regulator can decide that the customer outcome is not optimal because of inadequate after-sales performance and hence signals this to the service function of the provider. As an example, sensor readings may indicate that a deployed product is not always fed the latest version of product parameters that are distributed by the service function (such as embedded software versions) or that maintenance is necessary. Note that maintenance in this context is reactive maintenance from an outcome generation perspective, but may be preventive (i.e., proactive) maintenance from a traditional product perspective. These kinds of regulator decisions should lead to a change in customer service scheduling.

4.3. Application to the HBM Case Study

5. Adding Reactivity to the COM Model in SM with Sensors

5.1. Sensor Classification

5.2. Application to Example Case Study

6. Adding Intelligence to the COM Model in SM with Data Analytics

6.1. Intelligence Ambition Levels

6.2. Coupling Intelligence Ambition Levels to Manufacturing Functions

6.3. Intelligent Representation of Outcome Data

6.4. Application to Example Case Study

7. Adding Trust to the COM Model in SM with Blockchain and Federated Learning

7.1. Trust between Provider and Customer

7.2. Trust between Customers in Competitive Markets

7.3. Application to the HBM Case

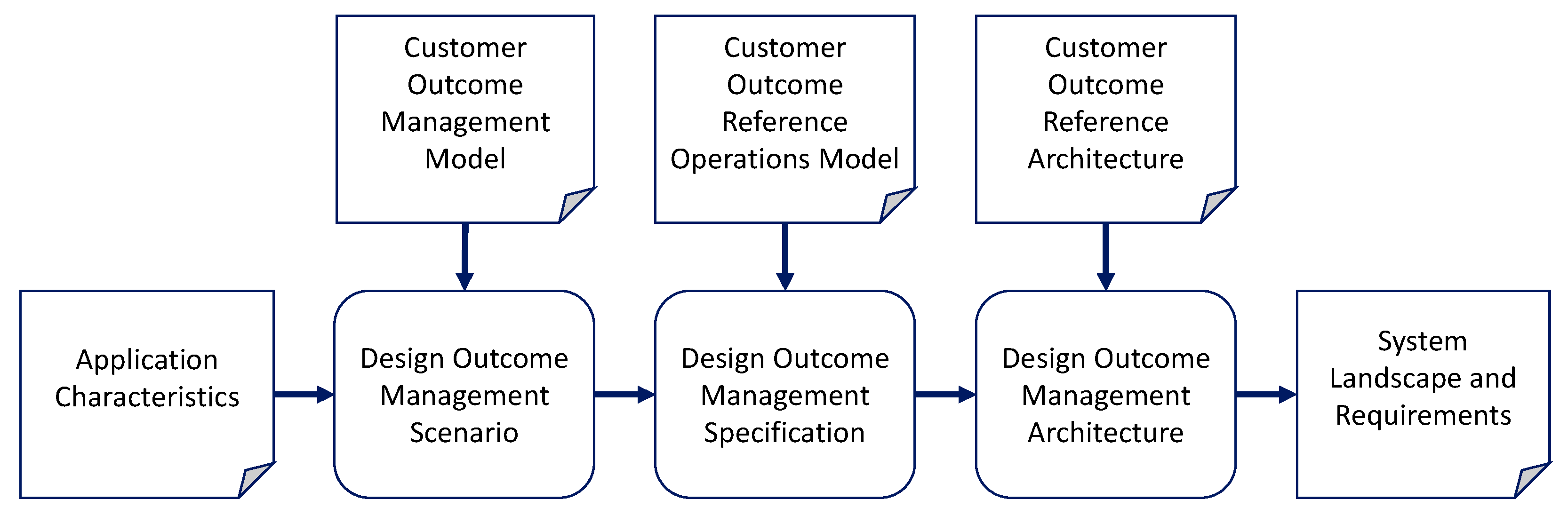

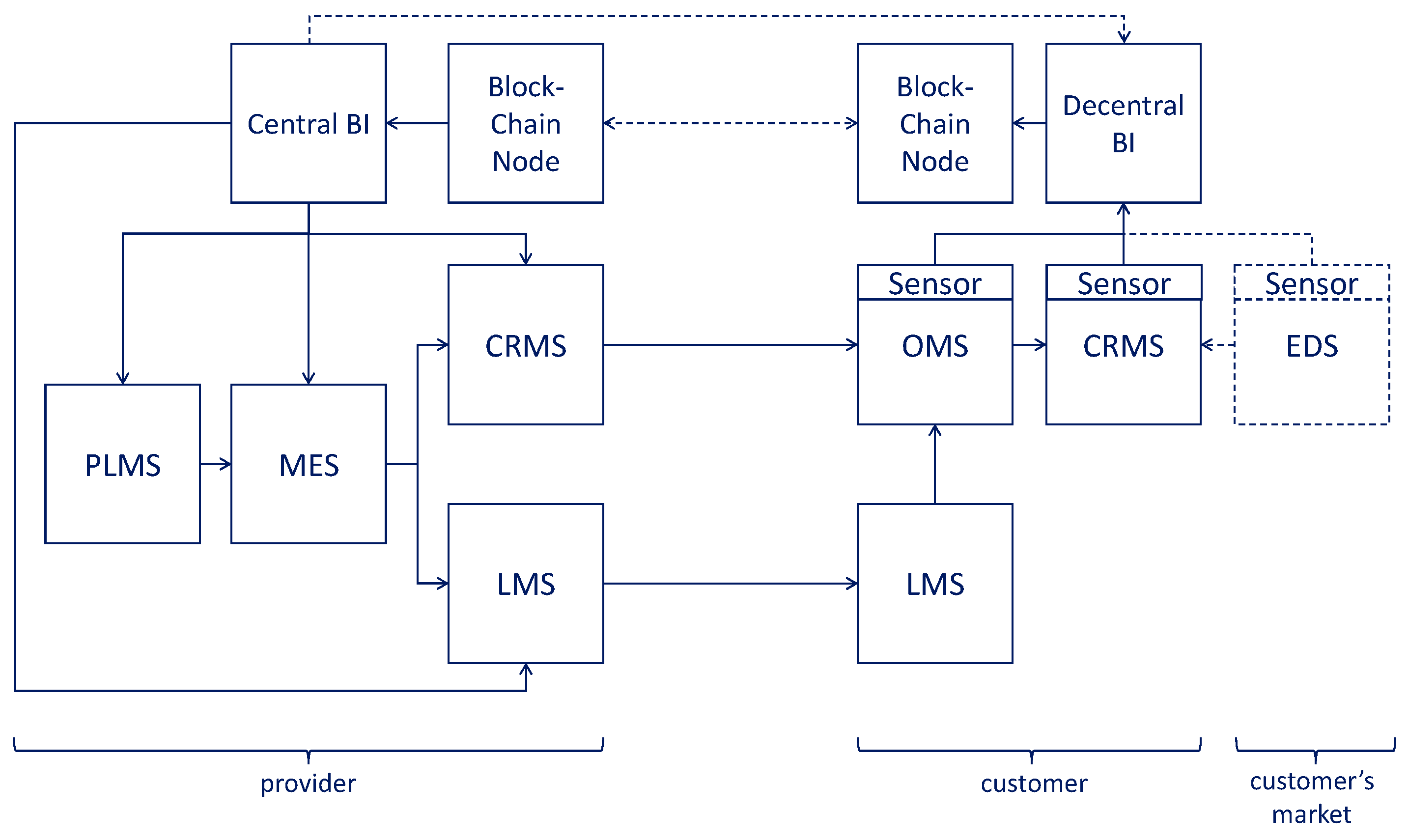

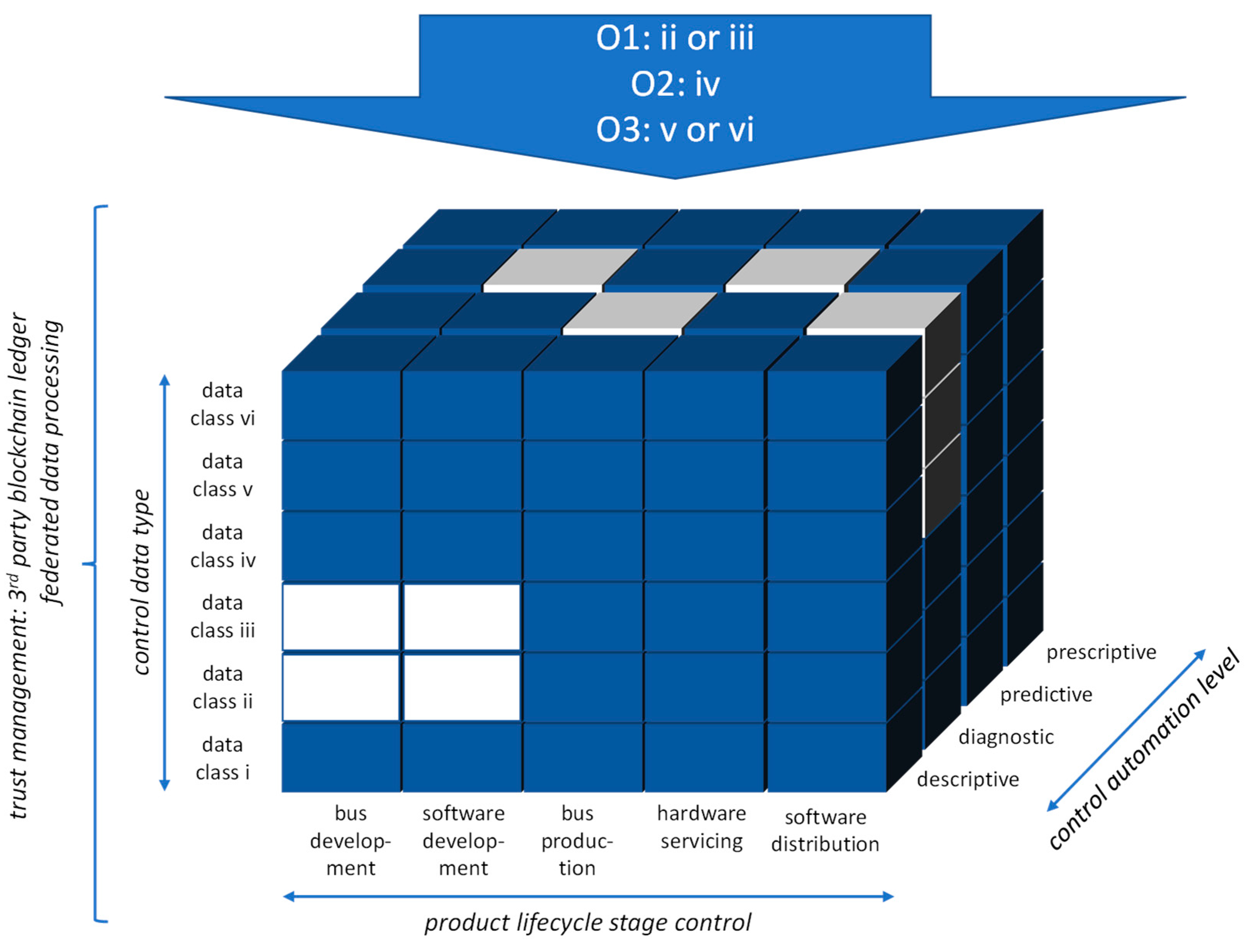

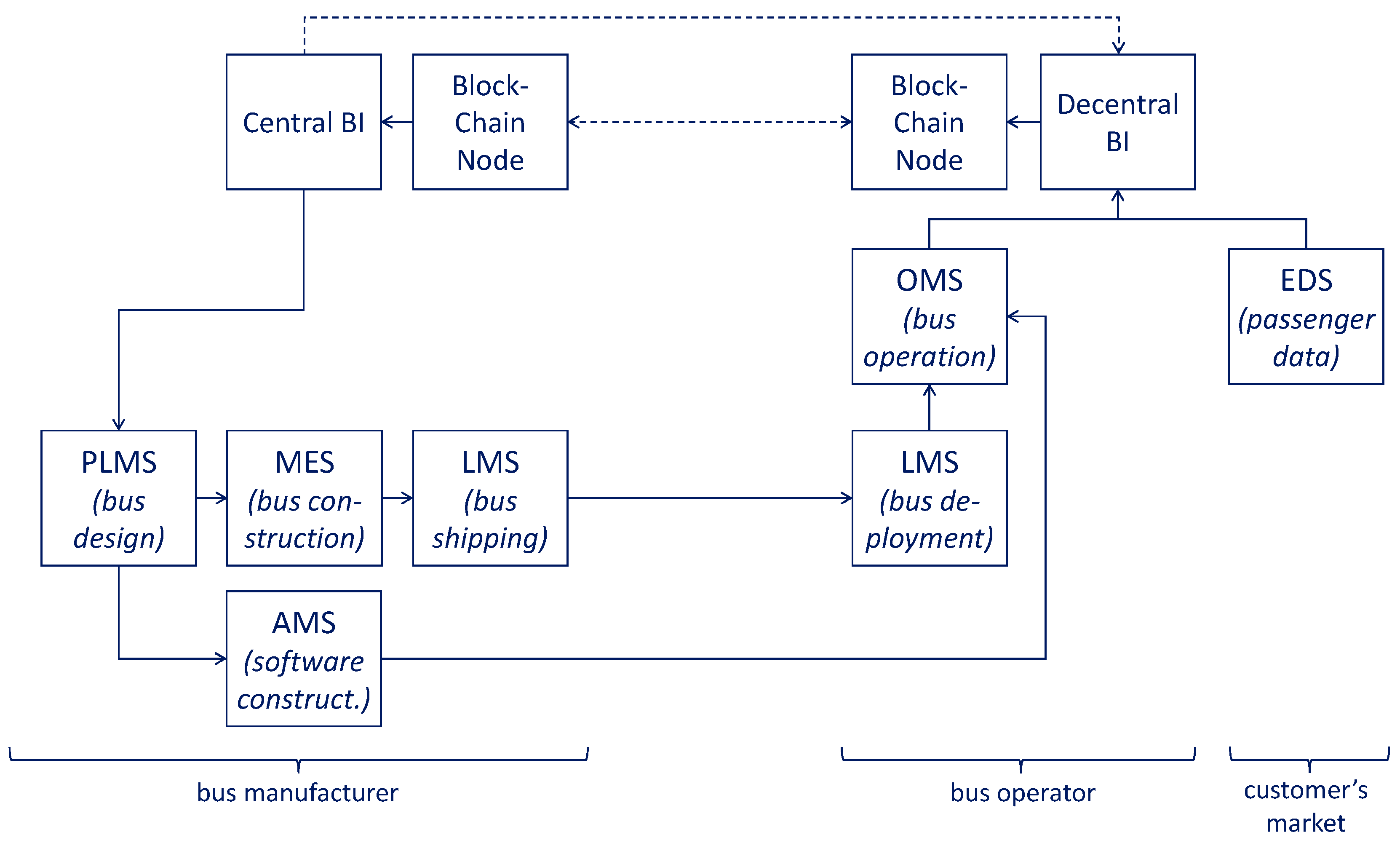

8. A Reference Operations Model and Reference Architecture for COM in SM

8.1. The Reference Operations Model

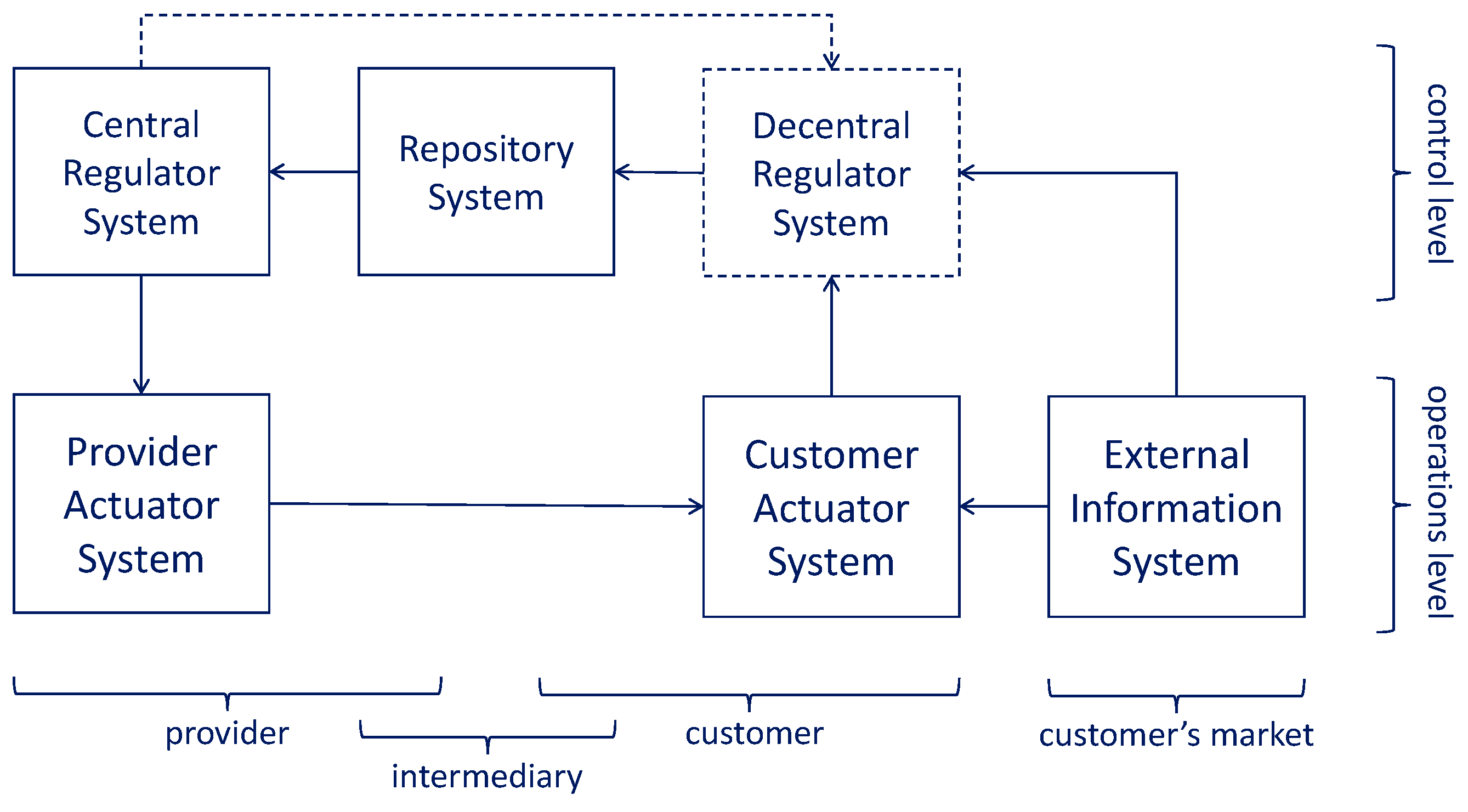

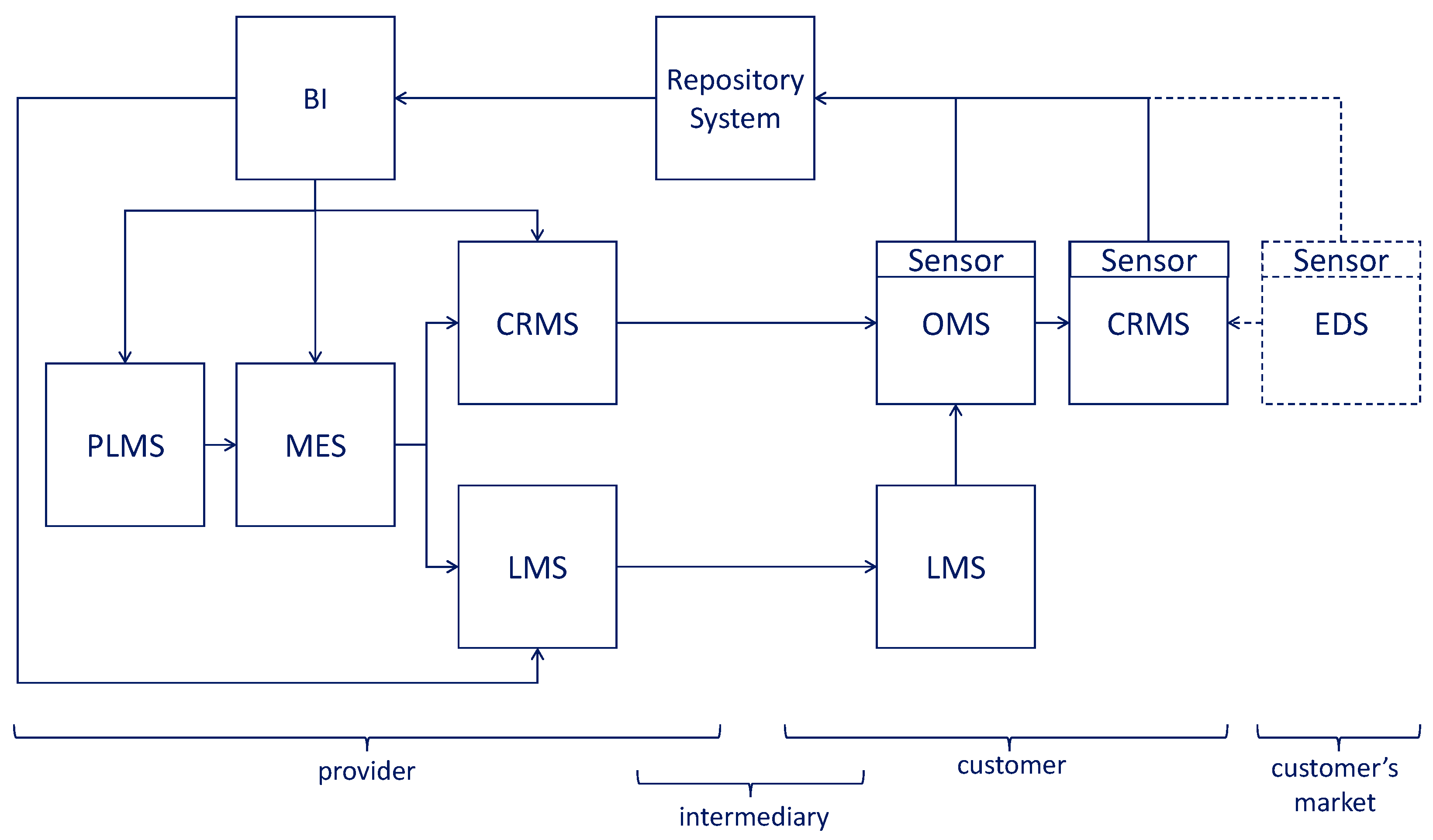

8.2. The Reference Architecture

- A product lifecycle management system (PLMS) supports technology development (product engineering).

- A manufacturing execution system (MES) supports manufacturing shop floor operations.

- A logistics management system (LMS) supports the outbound logistics of manufactured products to the customer.

- A customer relations management system (CRMS) supports service towards the customer.

- A logistics management system (LMS) supports the inbound logistics of manufactured products from the provider.

- An operations management system (OMS) manages the core business process of the customer (the actuator in our model that directly generates the outcomes). The precise nature of the OMS is heavily dependent on the business domain of the customer. The OMS may consist of a number of more specific systems. It can include sensor(s) of types i to iv.

- A customer relations management system (CRMS) that is faced towards the market of the customer and is involved in collecting outcome measurements from that market. It can include sensor(s) of types i and ii.

- An optional external data system (EDS), which is not in the domain of the customer, but provides external customer outcome measurements. If present, it includes sensor(s) of types v and vi.

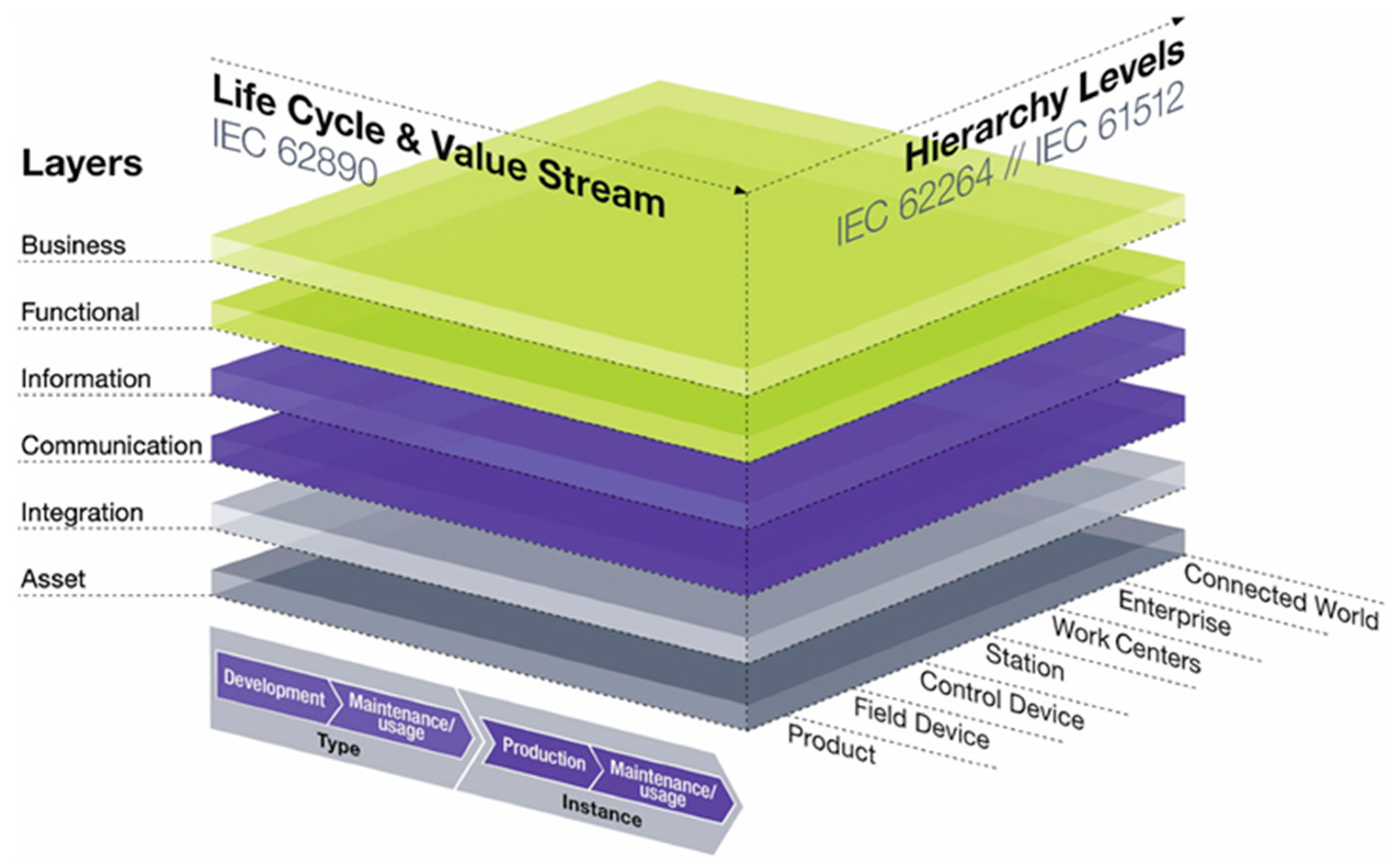

8.3. Positioning in RAMI4.0 and OT-IT Connection

8.4. Application to Case Study

- the considerations in Section 4.3 for the mapping of outcomes to business functions (leading to the details of the product lifecycle stage control dimension of the reference model);

- the considerations in Section 5.2 for the mapping to the control data type (leading to the selection of data types in the vertical dimension of the reference model);

- the considerations in Section 6.4 for the mapping to control automation levels in the respective dimension of the reference model;

- the considerations in Section 7.3 for the selection of trust management characteristics governing the exchange of outcome data, as shown in the left side of the reference model.

9. Outlook and Conclusions

- Traditionally, markets were based on selling products (such as cars in the automotive market)

- Then, markets (partially) transformed into selling period-based usage contracts (such as lease contracts in the automotive market)

- Next, mechanisms were developed to shift to pay-per-use models (such as pay-as-you-go models in the automotive markets, e.g., ShareNow (https://www.share-now.com, accessed on 23 February 2023))

- Finally, in outcome-based thinking, we move to not being paid for the product or the use of the product, but for the value that the use of the product brings (such as actual transport performance in the automotive market)

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Accenture. Digital Business Era: Stretch Your Boundaries. In Accenture Technology Vision 2015; Accenture: Dublin, Ireland, 2015. [Google Scholar]

- Connerty, M.; Navales, E.; Kenney, C.; Bhatia, T. Manufacturing Companies Need to Sell Outcomes, Not Products. In Harvard Business Review; Harvard Business Publishing: Cambridge, MA, USA, 2016. [Google Scholar]

- Grefen, P.; Ludwig, H.; Tata, S.; Dijkman, R.; Baracaldo, N.; Wilbik, A.; D’Hondt, T. Complex Collaborative Physical Process Management: A Position on the Trinity of BPM, IoT and DA. In Proceedings of the 19th IFIP WG 5.5 Working Conference on Virtual Enterprises, PRO-VE 2018, Cardiff, UK, 17–19 September 2018; pp. 244–253. [Google Scholar] [CrossRef]

- D’Hondt, T.; Wilbik, A.; Grefen, P.; Ludwig, H.; Baracaldo, N.; Anwar, A. Using BPM Technology to Deploy and Manage Distributed Analytics in Collaborative IoT-Driven Business Scenarios. In Proceedings of the 9th International Conference on the Internet of Things, Bilbao, Spain, 22–25 October 2019; p. 19. [Google Scholar] [CrossRef]

- Grefen, P. Beyond E-Business: Towards Networked Structures; Routledge: Abingdon, UK, 2016. [Google Scholar]

- Barkai, J. The Outcome Economy: How the Industrial Internet of Things is Transforming Every Business; Createspace: Scotts Valley, CA, USA, 2016. [Google Scholar]

- Ng, I.; Xin Ding, D.; Yip, N. Outcome-Based Contracts as New Business Model. Ind. Mark. Manag. 2013, 42, 730–743. [Google Scholar] [CrossRef]

- Sjödin, D.; Parida, V.; Jovanovic, M.; Visnjic, I. Value Creation and Value Capture Alignment in Business Model Innovation: A Process View on Outcome-Based Business Models. J. Prod. Innov. Manag. 2020, 37, 158–183. [Google Scholar] [CrossRef]

- Grefen, P.; Wilbik, A.; Kuitems, F.; Blanken, M. Outcome-Based Business Design in IoT-Enabled Digital Supply Chain Transformation. In Proceedings of the 2021 IEEE International Conference on Internet of Things and Intelligence Systems (IoTaIS), Bandung, Indonesia, 23–24 November 2021; pp. 28–34. [Google Scholar] [CrossRef]

- Van Asseldonk, M. A Process Mining-Based Approach to Accounts Payable Recovery Audit; Eindhoven University of Technology: Eindhoven, The Netherlands, 2020. [Google Scholar]

- Atos. Smart Connected Vessels: Commercial Model. In Atos Codex IoT Services CT-200402; Atos: Bezons, France, 2021. [Google Scholar]

- IBM. The Customer-Activated Enterprise: Insights from the Global C-Suite Study; IBM Institute for Business Value: Armonk, NY, USA, 2013. [Google Scholar]

- Tao, F.; Qi, Q.; Liu, A.; Kusiak, A. Data-driven smart manufacturing. J. Manuf. Syst. 2018, 48, 157–169. [Google Scholar] [CrossRef]

- Industrial Internet of Things. Available online: https://en.wikipedia.org/wiki/Industrial_internet_of_things (accessed on 23 February 2023).

- World Economic Forum. Industrial Internet of Things: Unleashing the Potential of Connected Products and Services; World Economic Forum: Cologny, Switzerland, 2015. [Google Scholar]

- Gierej, S. The Framework of Business Model in the Context of Industrial Internet of Things. Procedia Eng. 2017, 182, 206–212. [Google Scholar] [CrossRef]

- Ren, G.; Nakamura, Y.; Ludwig, H. Service Value Modeling: A Systematic Method to Unveil the Business Value of Industry Solutions. In Proceedings of the 2014 Annual SRII Global Conference, San Jose, CA, USA, 23–25 April 2014; pp. 82–89. [Google Scholar] [CrossRef]

- Hankel, M.; Rexroth, B. The Reference Architectural Model Industrie 4.0 (RAMI4.0); German Electrical and Electronic Manufac-turers’ Association: Frankfurt, Germany, 2015. [Google Scholar]

- IEC. Enterprise-Control System Integration—Part 1: Models and Terminology, 2nd ed.; The International Electrotechnical Commission (IEC): Geneva, Switzerland, 2013. [Google Scholar]

- Blanchard, B.; Fabrycky, W. Systems Engineering and Analysis, 4th ed.; Prentice Hall: Upper Saddle River, NJ, USA, 2006. [Google Scholar]

- ‘t Veld, J. Analyse van Bedrijfsprocessen: Een Toepassing van Denken in Systemen; Wolters-Noordhoff: Groningen, The Netherlands, 2019. (In Dutch) [Google Scholar]

- Erasmus, J.; Vanderfeesten, I.; Traganos, K.; Grefen, P. Using business process models for the specification of manufacturing operations. Comput. Ind. 2020, 123, 103297. [Google Scholar] [CrossRef]

- Erasmus, J.; Vanderfeesten, I.; Traganos, K.; Keulen, R.; Grefen, P. The HORSE Project: The Application of Business Process Management for Flexibility in Smart Manufacturing. Appl. Sci. 2020, 10, 4145. [Google Scholar] [CrossRef]

- van Looy, A.; Shafagatova, A. Business process performance measurement: A structured literature review of indicators, measures and metrics. SpringerPlus 2016, 5, 1797. [Google Scholar] [CrossRef]

- Kang, N.; Zhao, C.; Li, J.; Horst, J.A. A Hierarchical structure of key performance indicators for operation management and continuous improvement in production systems. Int. J. Prod. Res. 2016, 54, 6333–6350. [Google Scholar] [CrossRef]

- Varisco, M.; Johnsson, C.; Mejvik, J.; Schiraldi, M.M.; Zhu, L. KPIs for Manufacturing Operations Management: Driving the ISO22400 standard towards practical applicability. IFAC-PapersOnLine 2018, 51, 7–12. [Google Scholar] [CrossRef]

- Tummers, A.; Grefen, P. Projecting a Complex IT Legacy Landscape onto Future Strategic Scenarios in the High-Tech Manufacturing Industry in Capital Goods. In Proceedings of the 7th International Conference on Information Systems, Logistics and Supply Chain, Lyon, France, 8–11 July 2018; pp. 230–239. [Google Scholar]

- Grefen, P.; Vanderfeesten, I.; Traganos, K.; Domagala-Schmidt, Z.; van der Vleuten, J. Advancing Smart Manufacturing in Europe: Experiences from Two Decades of Research and Innovation Projects. Machines 2022, 10, 45. [Google Scholar] [CrossRef]

- Grefen, P.; Türetken, O.; Razavian, M. Awareness Initiative for Agile Business Models in the Dutch Mobility Sector: An Experience Report; Beta Working Papers; Eindhoven University of Technology: Eindhoven, The Netherlands, 2016; p. 505. [Google Scholar]

- Türetken, O.; Grefen, P.; Gilsing, R.; Adali, O. Service-Dominant Business Model Design for Digital Innovation in Smart Mobility. Bus. Inf. Syst. Eng. 2019, 61, 9–29. [Google Scholar] [CrossRef]

- Molander, S.; Fellesson, M.; Friman, M.; Skålén, P. Market Orientation in Public Transport Research—A Review. Transp. Rev. 2012, 32, 155–180. [Google Scholar] [CrossRef]

- Shah, K.; Pan, S.Y.; Lee, I.; Kim, H.; You, Z.; Zheng, J.M.; Chiang, P.C. Green transportation for sustainability: Review of current barriers, strategies, and innovative technologies. Clean. Prod. 2021, 326, 129392. [Google Scholar] [CrossRef]

- Porter, M. Competitive Advantage: Creating and Sustaining Superior Performance; Free Press: New York, NY, USA, 1985. [Google Scholar]

- Nadisa, F. Implementing Green PLM to Reach Sustainability Goals: Challenges and Opportunities; TUE: Eindhoven, The Netherlands, 2023. [Google Scholar]

- Tao, F.; Cheng, J.; Qi, Q.; Zhang, M.; Zhang, H.; Sui, F. Digital twin-driven product design, manufacturing and service with big data. Int. J. Adv. Manuf. Technol. 2017, 94, 3563–3576. [Google Scholar] [CrossRef]

- Traganos, K.; Grefen, P.; Vanderfeesten, I.; Erasmus, J.; Boultadakis, G.; Bouklis, P. The HORSE framework: A reference architecture for cyber-physical systems in hybrid smart manufacturing. J. Manuf. Syst. 2021, 61, 461–494. [Google Scholar] [CrossRef]

- Zhang, Y.; Ren, S.; Liu, Y.; Sakao, T.; Huisingh, D. A framework for Big Data driven product lifecycle management. J. Clean. Prod. 2017, 159, 229–240. [Google Scholar] [CrossRef]

- Grefen, P.; Boultadakis, G. Designing an Integrated System for Smart Industry: The Development of the HORSE Architecture; Independently Published: Eindhoven, The Netherlands, 2021. [Google Scholar]

- Dumas, M.; La Rosa, M.; Mendling, J.; Reijers, H. Fundamentals of Business Process Management, 2nd ed.; Springer: Berlin, Germany, 2018. [Google Scholar]

- Mota, A.; Azam, S.; Shanmugam, B.; Yeo, K.; Kannoorpatti, K. Comparative analysis of different techniques of encryption for secured data transmission. In Proceedings of the 2017 IEEE International Conference on Power, Control, Signals and Instrumentation Engineering (ICPCSI), Chennai, India, 21–22 September 2017; pp. 231–237. [Google Scholar] [CrossRef]

- Madziel, M.; Campisi, T. Energy Consumption of Electric Vehicles: Analysis of Selected Parameters Based on Created Database. Energies 2023, 16, 1437. [Google Scholar] [CrossRef]

- Gartner. Magic Quadrant for BI Platforms—Analytics Value Escalator; Gartner: Stamford, CT, USA, 2012. [Google Scholar]

- Cui, W. Visual Analytics: A Comprehensive Overview. IEEE Access 2019, 7, 81555–81573. [Google Scholar] [CrossRef]

- Pearl, J. Causal inference in statistics: An overview. Stat. Surv. 2009, 3, 96–146. [Google Scholar] [CrossRef]

- Lepenioti, K.; Bousdekis, A.; Apostolou, D.; Mentzas, G. Prescriptive analytics: Literature review and research challenges. Int. J. Inf. Manag. 2020, 50, 57–70. [Google Scholar] [CrossRef]

- Mitchell, T. Machine Learning; McGraw-Hill: New York, NY, USA, 2007; Volume 1. [Google Scholar]

- GM, H.; Gourisaria, M.; Pandey, M.; Rautaray, S. A comprehensive survey and analysis of generative models in machine learning. Comput. Sci. Rev. 2020, 38, 100285. [Google Scholar] [CrossRef]

- Schuh, G.; Gützlaff, A.; Sauermann, F.; Maibaum, J. Digital Shadows as an Enabler for the Internet of Production. In Proceedings of the 2020 APMS: IFIP International Conference on Advances in Production Management Systems, Novi Sad, Serbia, 30 August–3 September 2020. [Google Scholar]

- Hartmann, D.; Van der Auweraer, H. Digital Twins. In Progress in Industrial Mathematics: Success Stories; Springer: Berlin, Germany, 2021. [Google Scholar]

- Vater, J.; Harscheidt, L.; Knoll, A. Smart Manufacturing with Prescriptive Analytics. In Proceedings of the 2019 8th International Conference on Industrial Technology and Management (ICITM), Cambridge, UK, 2–4 March 2019. [Google Scholar]

- Erasmus, J.; Grefen, P.; Vanderfeesten, I.; Traganos, K. Smart Hybrid Manufacturing Control Using Cloud Computing and the Internet-of-Things. Machines 2018, 6, 62. [Google Scholar] [CrossRef]

- Antunes, A.; Cardoso, E.; Barateiro, J. Incorporation of Ontologies in Data Warehouse/Business Intelligence Systems—A Systematic Literature Review. Int. J. Inf. Manag. Data Insights 2022, 2, 100131. [Google Scholar] [CrossRef]

- Breslin, G.; O’Sullivan, D.; Passant, A.; Visiliu, L. Semantic Web computing in industry. Comput. Ind. 2010, 61, 729–741. [Google Scholar] [CrossRef]

- Yahya, M.; Breslin, J.; Ali, M. Semantic web and knowledge graphs for industry 4.0. Appl. Sci. 2021, 11, 5110. [Google Scholar] [CrossRef]

- Killeen, P.; Ding, B.; Kiringa, I.; Yeap, T. IoT-based predictive maintenance for fleet management. Procedia Comput. Sci. 2019, 151, 607–613. [Google Scholar] [CrossRef]

- Comuzzi, M.; Grefen, P.; Meroni, G. Blockchain for Business: IT Principles into Practice; Routledge: Abingdon, UK, 2023. [Google Scholar]

- Minoli, D.; Occhiogrosso, B. Blockchain mechanisms for IoT security. Internet Things 2018, 1–2, 1–13. [Google Scholar] [CrossRef]

- Silvano, W.F.; Marcelino, R. Iota tangle: A cryptocurrency to communicate internet-of-things. Future Gener. Comput. Syst. 2020, 112, 307–319. [Google Scholar] [CrossRef]

- Ludwig, H.; Baracaldo, N. Federated Learning: A Comprehensive Overview of Methods and Applications; Springer: Berlin, Germany, 2022. [Google Scholar]

- Kairouz, P.; McMahan, H.B.; Avent, B.; Bellet, A.; Bennis, M.; Bhagoji, A.N.; Bonawitz, K.; Charles, Z.; Cormode, G.; Cummings, R.; et al. Advances and open problems in federated learning. Found. Trends Mach. Learn. 2021, 4, 1–210. [Google Scholar] [CrossRef]

- Stallmann, M.; Wilbik, A. On a Framework for Federated Cluster Analysis. Appl. Sci. 2022, 12, 10455. [Google Scholar] [CrossRef]

- Lindell, Y. Secure multiparty computation. Commun. ACM 2020, 64, 86–96. [Google Scholar] [CrossRef]

- Wei, K.; Li, J.; Ding, M.; Ma, C.; Yang, H.H.; Farokhi, F.; Jin, S.; Quek, T.Q.; Poor, H.V. Federated Learning with Differential Privacy: Algorithms and Performance Analysis. IEEE Trans. Inf. Forensics Secur. 2020, 15, 3454–3469. [Google Scholar] [CrossRef]

- Angelov, S.; Grefen, P.; Greefhorst, D. A framework for analysis and design of software reference architectures. Inf. Softw. Technol. 2012, 54, 417–431. [Google Scholar] [CrossRef]

- Zheng, P.; Wang, H.; Sang, Z.; Zhong, R.Y.; Liu, Y.; Liu, C.; Mubarok, K.; Yu, S.; Xu, X. Smart manufacturing systems for Industry 4.0: Conceptual framework, scenarios, and future perspectives. Front. Mech. Eng. 2018, 13, 137–150. [Google Scholar] [CrossRef]

- Wang, Y.; Ma, H.; Yang, J.; Wang, K. Industry 4.0: A way from mass customization to mass personalization production. Adv. Manuf. 2017, 5, 311–320. [Google Scholar] [CrossRef]

- Pech, M.; Vrchota, J. The Product Customization Process in Relation to Industry 4.0 and Digitalization. Processes 2022, 10, 539. [Google Scholar] [CrossRef]

| Outcome | OPI | Reporting Interval |

|---|---|---|

| O1 | nr. of passengers/(hr × route) | Minute |

| O2 | nr. of KJ/km | Second |

| O3 | NPS | Day |

| Product Lifecycle Phases [35] | Relevant for Current Paper? | Included and Label |

|---|---|---|

| product concept | No, outside outcome scope | No |

| design | Yes | Product design |

| raw material purchase | Yes, secondary importance | No |

| manufacturing | Yes | Product manufacturing |

| transportation | Yes | Product delivery |

| sale | No, outside outcome scope | No |

| utilization | Yes, but implicit to provider | No |

| after-sale service | Yes | Product after-sales servicing |

| recycle/disposal | No, outside outcome scope | No |

| Bus Development | Software Development | Bus Production | Hardware Servicing | Software Distribution | |

|---|---|---|---|---|---|

| O1 | ✓ | ✓ | |||

| O2 | ✓ | ✓ | ✓ | ||

| O3 | ✓ | ✓ |

| Push | Pull | |

|---|---|---|

| Recorded data | (i) data provisioning software module | (ii) data query interface |

| Physical data | (iii) active IoT device or CPS | (iv) passive IoT device or CPS |

| External data | (v) external system with data stream subscription | (vi) external system with data query interface |

| Sensor Class | Sensing Frequency | Implementation Aspects | |

|---|---|---|---|

| O1 | ii or iii | minute scale | Class ii: coupling to HBM ticketing system; Class iii: physical sensors in buses—buffering of measurements may be required |

| O2 | iv | sub-second scale | Class iv: coupling to bus engine management system—buffering of measurements is required |

| O3 | v or vi | day scale | Class v: coupling to external passenger survey system; Class vi: coupling to social media-based sentiment analysis system |

| Type of Regulator | Level of Complexity | Level of Control Automation | Typical Techniques and Technology Used |

|---|---|---|---|

| (a) Descriptive | Low | Low | Dashboards, visual analytics [43] (e.g., with Power BI (https://powerbi.microsoft.com, accessed on 23 February 2023)), statistical analysis (e.g., with SPSS (https://www.ibm.com/products/spss-statistics, accessed on 23 February 2023)) |

| (b) Diagnostic | Low-Medium | Medium | Statistical analysis (e.g., correlation analysis), causal analysis [44] |

| (c) Predictive | Medium-High | Medium | Classification models, regression models [45], neural networks [46], SciKit Learn (https://scikit-learn.org/stable/, accessed on 23 February 2023), PyTorch (https://pytorch.org/, accessed on 23 February 2023) |

| (d) Prescriptive | High | High | Optimization models, advanced machine learning, generative models [47] |

| Bus Development | Software Development | Bus Production | Hardware Servicing | Software Distribution | |

|---|---|---|---|---|---|

| O1 | Descriptive | Descriptive | |||

| O2 | Predictive | Prescriptive | Diagnostic | ||

| O3 | Diagnostic | Predictive |

| Product Deployment | Internal Outcome Realization | External Outcome Realization | |

|---|---|---|---|

| product development | X | ||

| product manufacturing | X | ||

| product logistics | |||

| product servicing | X |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Grefen, P.; Vanderfeesten, I.; Wilbik, A.; Comuzzi, M.; Ludwig, H.; Serral, E.; Kuitems, F.; Blanken, M.; Pietrasik, M. Towards Customer Outcome Management in Smart Manufacturing. Machines 2023, 11, 636. https://doi.org/10.3390/machines11060636

Grefen P, Vanderfeesten I, Wilbik A, Comuzzi M, Ludwig H, Serral E, Kuitems F, Blanken M, Pietrasik M. Towards Customer Outcome Management in Smart Manufacturing. Machines. 2023; 11(6):636. https://doi.org/10.3390/machines11060636

Chicago/Turabian StyleGrefen, Paul, Irene Vanderfeesten, Anna Wilbik, Marco Comuzzi, Heiko Ludwig, Estefania Serral, Frank Kuitems, Menno Blanken, and Marcin Pietrasik. 2023. "Towards Customer Outcome Management in Smart Manufacturing" Machines 11, no. 6: 636. https://doi.org/10.3390/machines11060636

APA StyleGrefen, P., Vanderfeesten, I., Wilbik, A., Comuzzi, M., Ludwig, H., Serral, E., Kuitems, F., Blanken, M., & Pietrasik, M. (2023). Towards Customer Outcome Management in Smart Manufacturing. Machines, 11(6), 636. https://doi.org/10.3390/machines11060636