A New Cable-Driven Model for Under-Actuated Force–Torque Sensitive Mechanisms

Abstract

1. Introduction

- Their convenient disassembly/reassembly;

- Their light-weight structures;

- Their high payload-to-weight ratios.

2. Problem Statement and Proposed Solution

2.1. Da Vinci Robotic Tools (dVRTs)

- Local part: located near the surgeon and controlled directly by the hands of the surgeon;

- Remote part: located near the patient and tele-operated by the local part.

2.2. Problem Statement: Force Feedback in Robotic Surgery

2.3. Proposed Solution: Cable-Driven Force–Torque Sensing Mechanism

- Hybrid System: the mechanism can be used as a sensor and/or actuator;

- Modelling: the model of the mechanism is constituted by an external mobile part connected with cables to an internal fixed structure;

- Application: micro- and macro- applications can be performed with the proposed mechanism;

- Under-actuation: the mechanism is composed of a cable-driven, under-actuated system.

2.3.1. Hybrid System: Sensor and/or Actuator

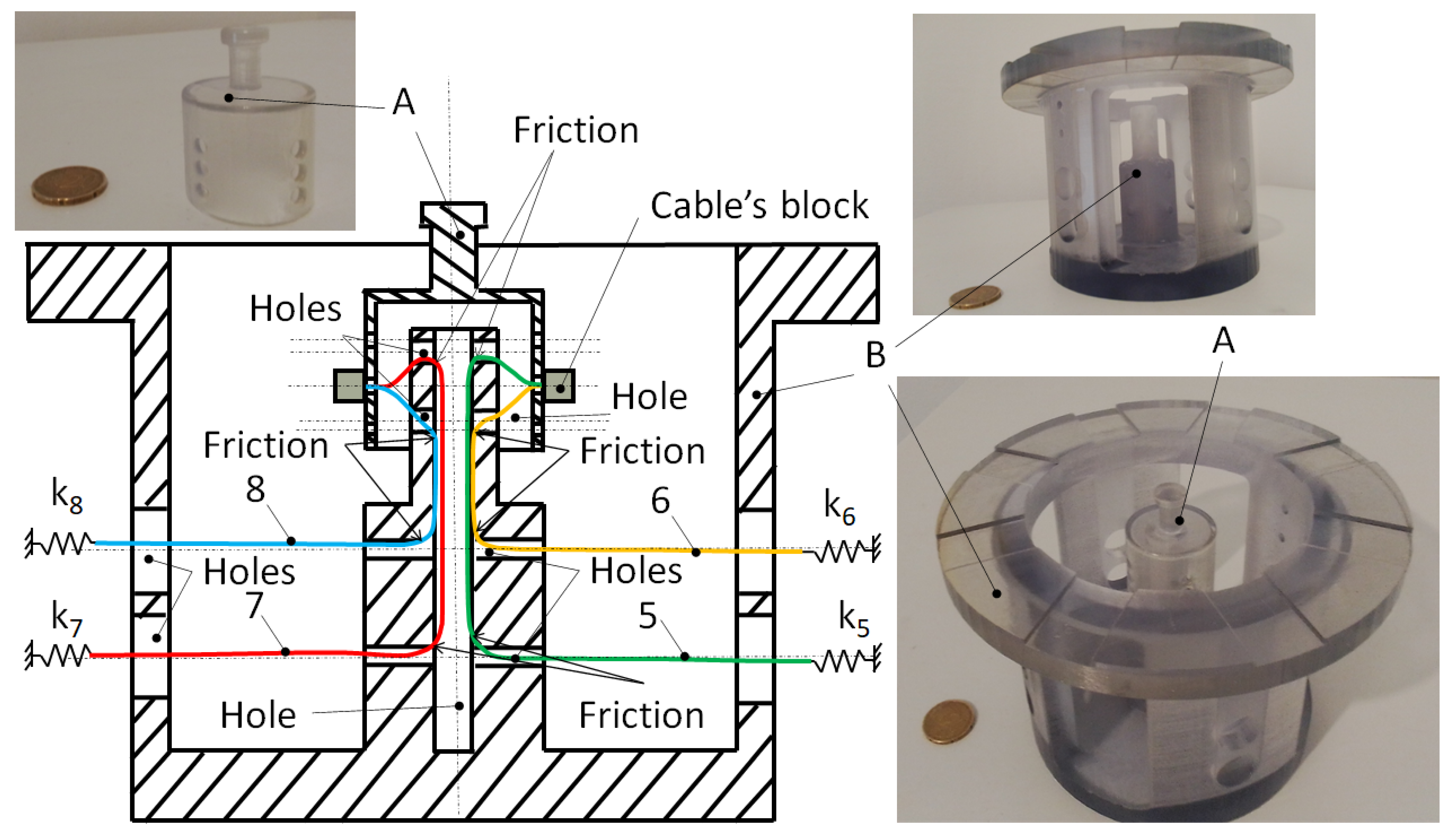

2.3.2. Modelling: An Internal Cable-Driven Fixed Structure

2.3.3. Application: Micro/Macro Cable-Driven Applications

2.3.4. Under-Actuation: Cable-Driven System

3. Analysis of the Mechanism’s Configurations

3.1. Details of the Kinematic Model

3.2. Configuration I

- External forces and torques in condition : ;

- Gravity: ;

- Tension of cables in condition : ;

- Offset in condition : .

3.3. Configuration II

4. Configurations I and II: Comparison and Simulation

- The two matrices and have the same rank, equal to 5;

- .

5. Analytical Formulation of Configuration II

5.1. Force Transformation Matrix

5.2. Vector of the Cable’s Tension

6. Model Validation and Physical Implementation with Two Test Bench Prototypes

6.1. Model Validation

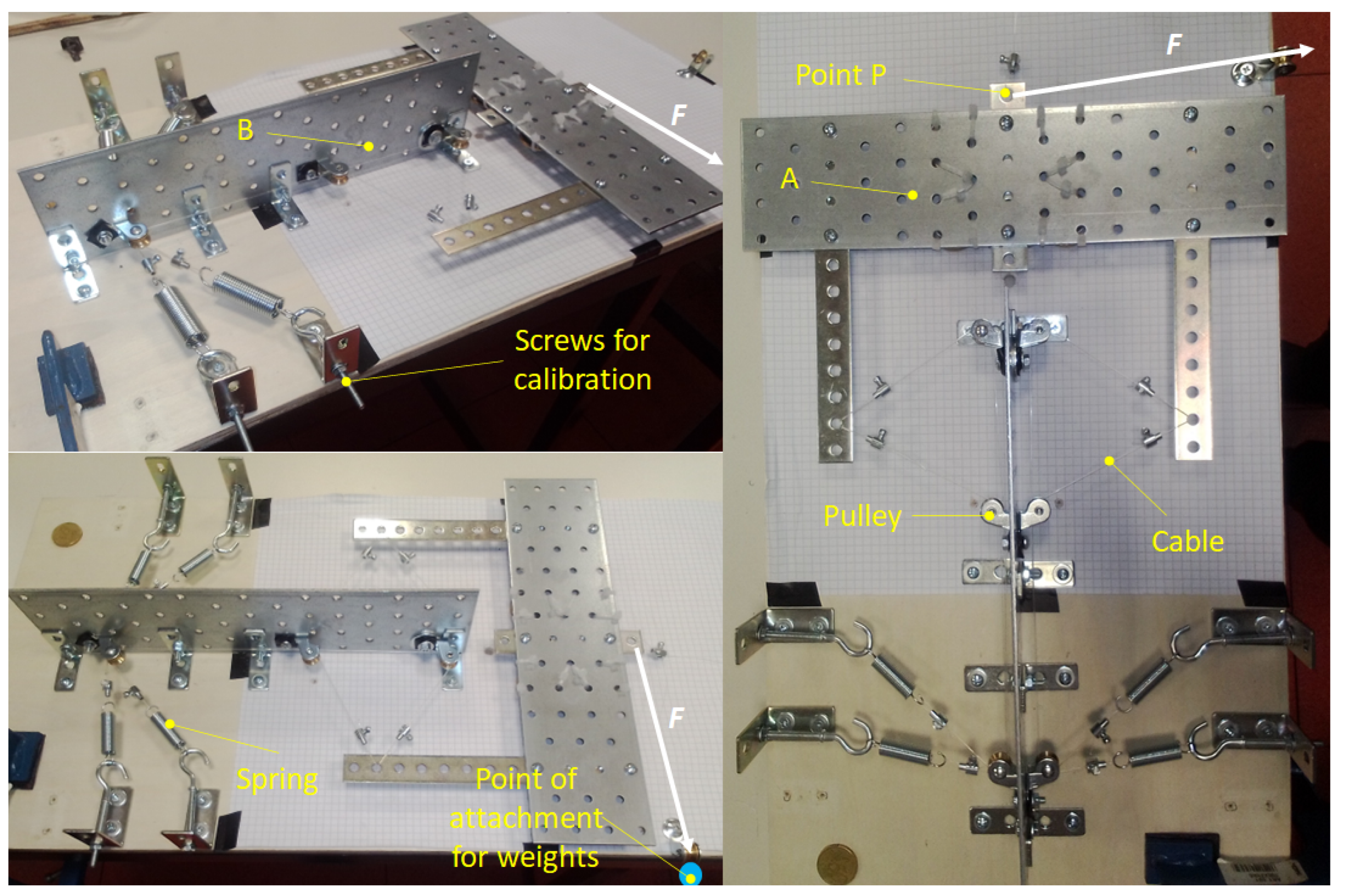

6.2. Planar Test Bench Prototype: TBI

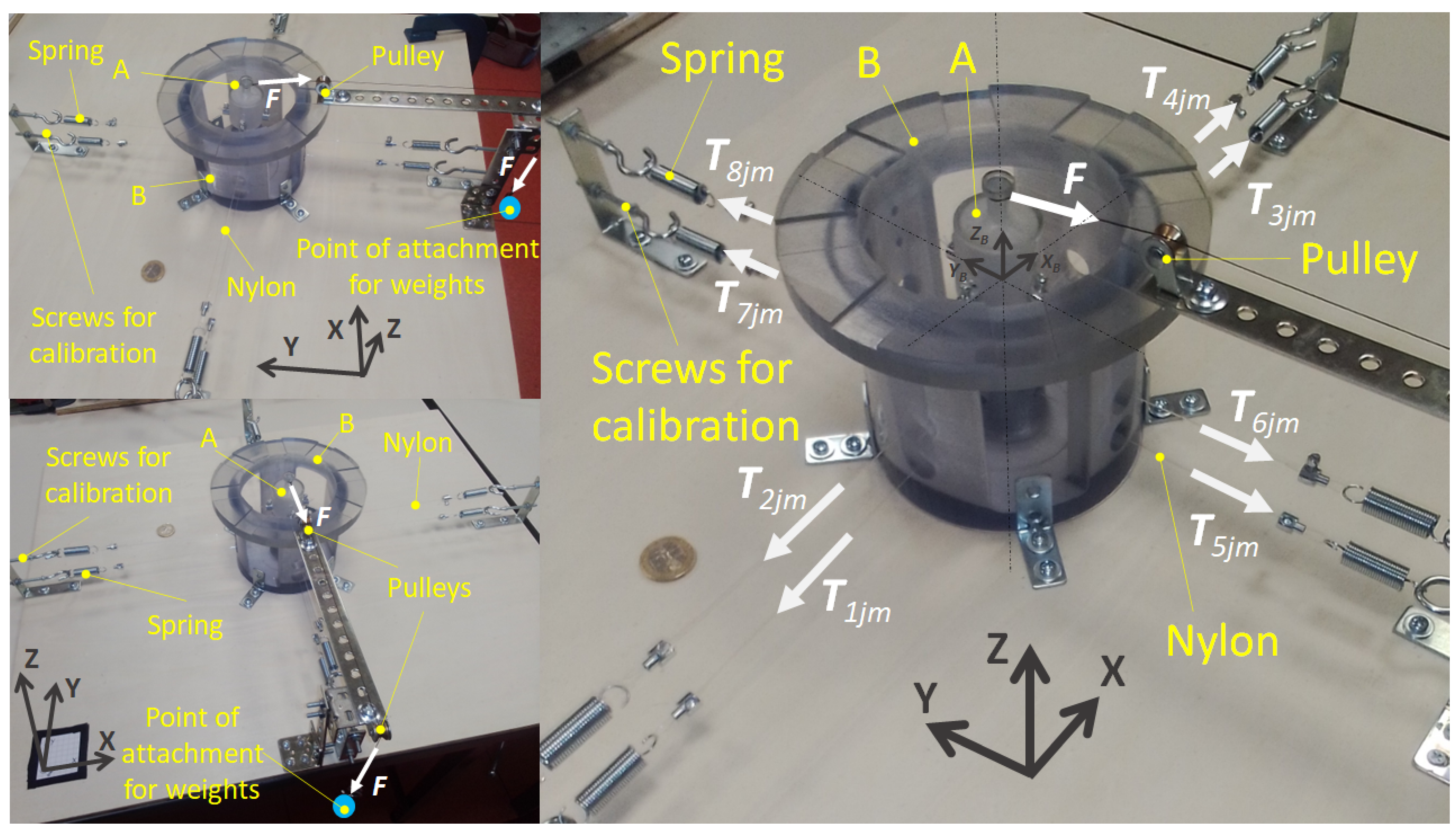

6.3. Spatial Test Bench Prototype: TBII

6.4. Springs and Cables

6.5. Implementation

- 1

- Attachment of the spring to the cable;

- 2

- Attachment of the spring to the fixed part;

- 3

- Centring of part A and calibration using screws in the fixed part;

- 4

- Measuring the spring’s length in the condition ;

- 5

- Applying weights to the point of attachment for the weights;

- 6

- Measuring the spring’s length in the condition .

7. Comparison between Measured and Calculated Forces: Results and Discussion

7.1. Results

7.2. Discussion

8. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| CDPR | cable-driven parallel robots |

| dVRT | da Vinci Robotic Tool |

| MIRS | Minimally Invasive Robotic Surgery |

| dVRA | da Vinci Robotic Arm |

| MIRT | Minimally Invasive Robotic Tool |

| dVRK | da Vinci Robotic Kit |

| E-E | End-Effector |

| TBI | Test Bench I |

| TBII | Test Bench II |

References

- Muscolo, G.G.; Fiorini, P. force–torque Sensors for Minimally Invasive Surgery Robotic Tools: An overview. IEEE Trans. Med. Robot. Bionics 2023. [Google Scholar] [CrossRef]

- Zhang, T.; Gong, X.; Zhang, L.; Wang, Y.; Liu, Y.; Li, L. A Method for Solving the Additional Stiffness Introduced by Flexible Joints in Stewart Platform Based on FEM Modal Analysi. Machines 2023, 11, 457. [Google Scholar] [CrossRef]

- Dasgupta, B.; Mruthyunjaya, T. The Stewart platform manipulator: A review. Mech. Mach. Theory 2000, 35, 15–40. [Google Scholar] [CrossRef]

- Sorli, M.; Pastorelli, S. Six-axis reticulated structure force/torque sensor with adaptable performances. Mechatronics 1995, 5, 585–601. [Google Scholar] [CrossRef]

- Ranganath, R.; Nair, P.S.; Mruthyunjaya, T.S.; Ghosal, A. A force–torque sensor based on a Stewart Platform in a near-singular configuration. Mech. Mach. Theory 2004, 39, 971–998. [Google Scholar] [CrossRef]

- Kübler, B.; Seibold, U.; Hirzinger, G. Development of actuated and sensor integrated forceps for minimally invasive robotic surger. Int. J. Med. Robot. Comput. Assist. Surg. 2005, 1, 96–107. [Google Scholar] [CrossRef]

- Dai, J.S.; Kerr, D.R. A six-component contact force measurement device based on the Stewart platform. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2000, 214, 687–697. [Google Scholar] [CrossRef]

- Chao, L.P.; Chen, K.T. Shape optimal design and force sensitivity evaluation of six-axis force sensors. Sens. Actuators A Phys. 1997, 63, 105–112. [Google Scholar] [CrossRef]

- Muscolo, G.; Recchiuto, C.; Molfino, R. Dynamic balance optimization in biped robots: Physical modeling, implementation and tests using an innovative formula. Robotica 2015, 33, 2083–2099. [Google Scholar] [CrossRef]

- Zhou, S.; Sun, J.; Gao, F. Influence of flexible spherical joints parameters on accuracy of the six-axis force/torque sensor with three-three orthogonal parallel mechanism. Mech. Mach. Theory 2020, 145, 103697. [Google Scholar] [CrossRef]

- Zhenlin, J.; Feng, G.; Xiaohui, Z. Design and analysis of a novel isotropic six-component force/torque sensor. Sens. Actuators A Phys. 2003, 109, 17–20. [Google Scholar] [CrossRef]

- Kim, J.H.; Kang, D.I.; Shin, H.H.; Park, Y.K. Design and analysis of a column type multi-component force/moment sensor. Measurement 2003, 33, 213–219. [Google Scholar] [CrossRef]

- Franchi, V.; Di Rito, G.; Galatolo, R.; Cannella, F.; Caldwell, D.; Muscolo, G.G. Modelling and control design of a novel robotic membrane. Int. J. Mech. Control 2019, 20, 113–122. [Google Scholar]

- Franchi, V.; Di Rito, G.; Galatolo, R.; Cannella, F.; Caldwell, D.; Muscolo, G.G. Multibody Analysis and Design of an Electromechanical System Simulating Hyperelastic Membranes. In Multibody Dynamics 2019, ECCOMAS 2019; Computational Methods in Applied Sciences; Kecskeméthy, A., Geu Flores, F., Eds.; Springer: Cham, Switzerland, 2020; Volume 53. [Google Scholar]

- Mannella, D.; Bellusci, M.; Graziani, F.; Ferraresi, C.; Muscolo, G.G. Modelling, design and control of a new seat-cushion for pressure ulcers prevention. Proc. Inst. Mech. Eng. Part H J. Eng. Med. 2022, 236, 592–602. [Google Scholar] [CrossRef] [PubMed]

- Bottero, S.; Muscolo, G.G.; Ferraresi, C. A New Soft RCC Device with Pneumatic Regulation. Robotics 2020, 9, 98. [Google Scholar] [CrossRef]

- Muscolo, G.G.; Fontana, M. A novel linear pneumatic actuator with tunable-compliance constraint. Int. J. Mech. Control 2020, 21, 73–86. [Google Scholar]

- Xiong, H.; Diao, X. A review of cable-driven rehabilitation devices. Disabil. Rehabil. Assist. Technol. 2020, 15, 885–897. [Google Scholar] [CrossRef]

- Paterna, M.; Magnetti Gisolo, S.; De Benedictis, C.; Muscolo, G.G.; Ferraresi, C. A passive upper-limb exoskeleton for industrial application based on pneumatic artificial muscles. Mech. Sci. 2022, 13, 387–398. [Google Scholar] [CrossRef]

- Pott, A.; Mütherich, H.; Kraus, W.; Schmidt, V.; Miermeister, P.; Verl, A. IPAnema: A family of Cable-Driven Parallel Robots for Industrial Applications. In Cable-Driven Parallel Robots; Mechanisms and Machine Science; Bruckmann, T., Pott, A., Eds.; Springer: Berlin/Heidelberg, Germany, 2013; Volume 12. [Google Scholar]

- Cheng, Y.; Ren, G.; Dai, S. The multi-body system modelling of the Gough–Stewart platform for vibration control. J. Sound Vib. 2004, 271, 599–614. [Google Scholar] [CrossRef]

- Gosselin, C. Cable-driven parallel mechanisms: State of the art and perspectives. Mech. Eng. Rev. 2014, 1, DSM0004. [Google Scholar] [CrossRef]

- Piao, J.; Kim, E.S.; Choi, H.; Moon, C.B.; Choi, E.; Park, J.O.; Kim, C.S. Indirect force control of a cable-driven parallel robot: Tension estimation using artificial neural network trained by force sensor measurements. Sensors 2019, 19, 2520. [Google Scholar] [CrossRef] [PubMed]

- Müller, M.S.; Hoffmann, L.; Christopher Buck, T.; Walter Koch, A. Fiber Bragg grating-based force–torque sensor with six degrees of freedom. Int. J. Optomechatron. 2009, 3, 201–214. [Google Scholar] [CrossRef]

- He, C.; Wang, S.; Sang, H.; Li, J.; Zhang, L. Force sensing of multiple-DOF cable-driven instruments for minimally invasive robotic surgery. Int. J. Med. Robot. Comput. Assist. Surg. 2014, 10, 314–324. [Google Scholar] [CrossRef] [PubMed]

- Chen, Q.; Lin, Q.; Wei, G.; Ren, L. Tension vector and structure matrix associated force sensitivity of a 6-DOF cable-driven parallel robot. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2022, 236, 100–114. [Google Scholar] [CrossRef]

- Shimachi, S.; Hirunyanitiwatna, S.; Fujiwara, Y.; Hashimoto, A.; Hakozaki, Y. Adapter for contact force sensing of the da Vinci® robot. Int. J. Med. Robot. Comput. Assist. Surg. 2008, 4, 121–130. [Google Scholar] [CrossRef]

- Moradi Dalv, M.; Shirinzadeh, B.; Shamdani, A.H.; Smith, J.; Zhong, Y. An actuated force feedback-enabled laparoscopic instrument for robotic-assisted surgery. Int. J. Med. Robot. Comput. Assist. Surg. 2014, 10, 11–21. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, D.; Chen, B.; Yu, L.; Qian, J.; Zi, B. A clamping force estimation method based on a joint torque disturbance observer using PSO-BPNN for cable-driven surgical robot end-effectors. Sensors 2019, 19, 5291. [Google Scholar] [CrossRef]

- Sang, H.; Yun, J.; Monfaredi, R.; Wilson, E.; Fooladi, H.; Cleary, K. External force estimation and implementation in robotically assisted minimally invasive surgery. Int. J. Med. Robot. Comput. Assist. Surg. 2017, 13, e1824. [Google Scholar] [CrossRef]

- Shi, C.; Lai, D.; Tang, Z.; Yang, Z. Development of an optic fiber-based torque sensor with a torsion-translation conversion flexure. IEEE Sens. J. 2021, 22, 344–351. [Google Scholar] [CrossRef]

- Kim, U.; Kim, Y.B.; So, J.; Seok, D.Y.; Choi, H.R. Sensorized surgical forceps for robotic-assisted minimally invasive surgery. IEEE Trans. Ind. Electron. 2018, 65, 9604–9613. [Google Scholar] [CrossRef]

- Klema, V.; Laub, A. The singular value decomposition: Its computation and some applications. IEEE Trans. Autom. Control 1980, 25, 164–176. [Google Scholar] [CrossRef]

- Shooter, K.V.; Tabor, D. The frictional properties of plastics. Proc. Phys. Soc. Sect. B 1952, 65, 661. [Google Scholar] [CrossRef]

| (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | ||

|---|---|---|---|---|---|---|---|

| TBI | 23 | 85 | 100 | 43 | 7 | 82 | 0 |

| TBII | 16 | 8.75 | 13.5 | 11.8 | 12 | 2.5 | 0.3; 0.25 [34] |

| (mm) | d (mm) | (mm) | k (N/mm) | ||

|---|---|---|---|---|---|

| Spring | 9.4 | 1 | 24.8 | 25 | 0.6786 |

| 1 (N) | 2 (N) | 3 (N) | 4 (N) | 5 (N) | 6 (N) | 7 (N) | |

|---|---|---|---|---|---|---|---|

| TBI | 6.46 | 7.48 | 8.49 | 9.85 | 10.94 | ||

| TBII | 3.25 | 4.26 | 5.27 | 6.46 | 7.48 | 8.49 | 9.57 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Muscolo, G.G.; Fiorini, P. A New Cable-Driven Model for Under-Actuated Force–Torque Sensitive Mechanisms. Machines 2023, 11, 617. https://doi.org/10.3390/machines11060617

Muscolo GG, Fiorini P. A New Cable-Driven Model for Under-Actuated Force–Torque Sensitive Mechanisms. Machines. 2023; 11(6):617. https://doi.org/10.3390/machines11060617

Chicago/Turabian StyleMuscolo, Giovanni Gerardo, and Paolo Fiorini. 2023. "A New Cable-Driven Model for Under-Actuated Force–Torque Sensitive Mechanisms" Machines 11, no. 6: 617. https://doi.org/10.3390/machines11060617

APA StyleMuscolo, G. G., & Fiorini, P. (2023). A New Cable-Driven Model for Under-Actuated Force–Torque Sensitive Mechanisms. Machines, 11(6), 617. https://doi.org/10.3390/machines11060617