Mechanical Loading of Barite Rocks: A Nanoscale Perspective

Abstract

1. Introduction

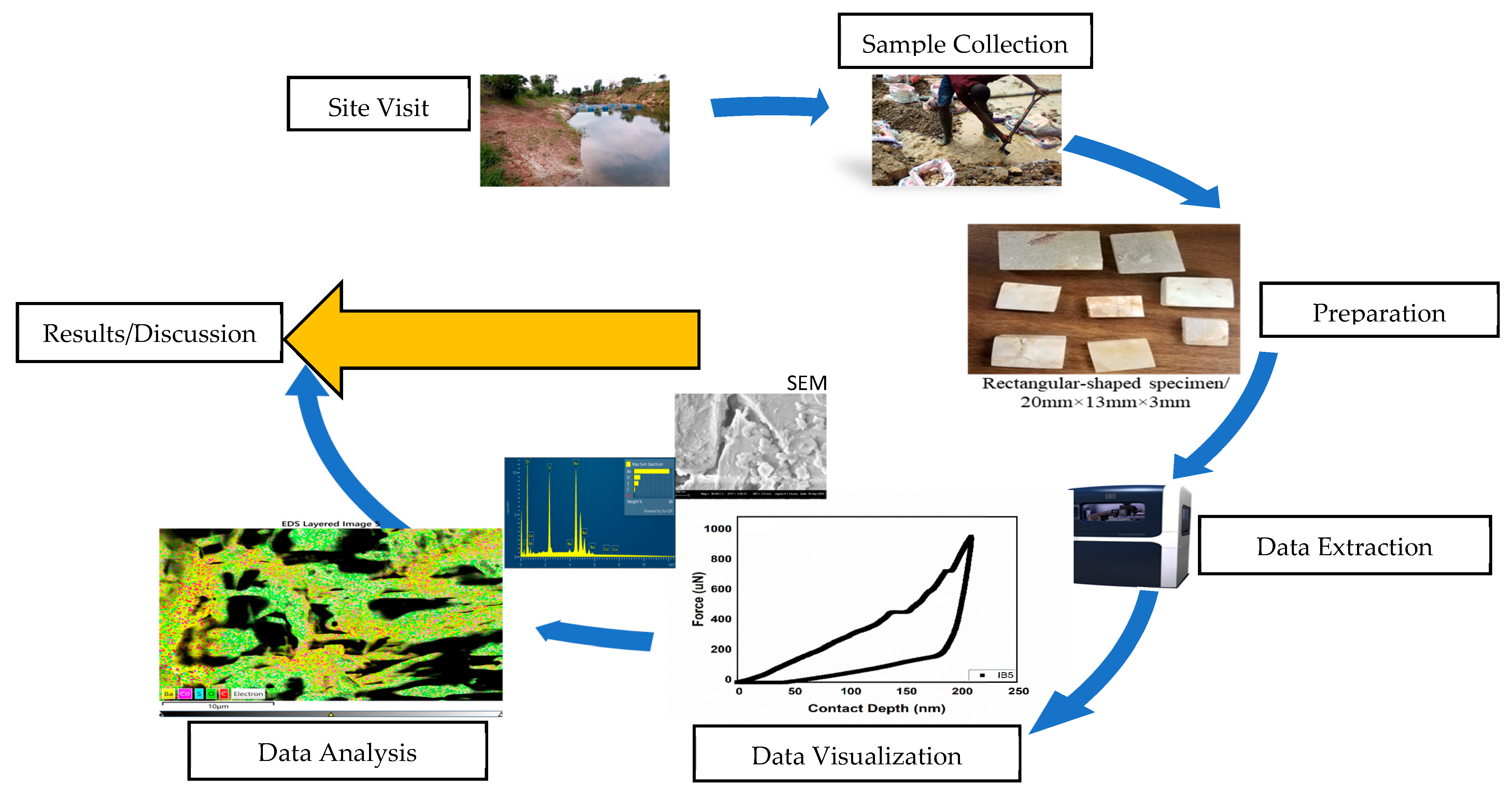

2. Materials and Methods

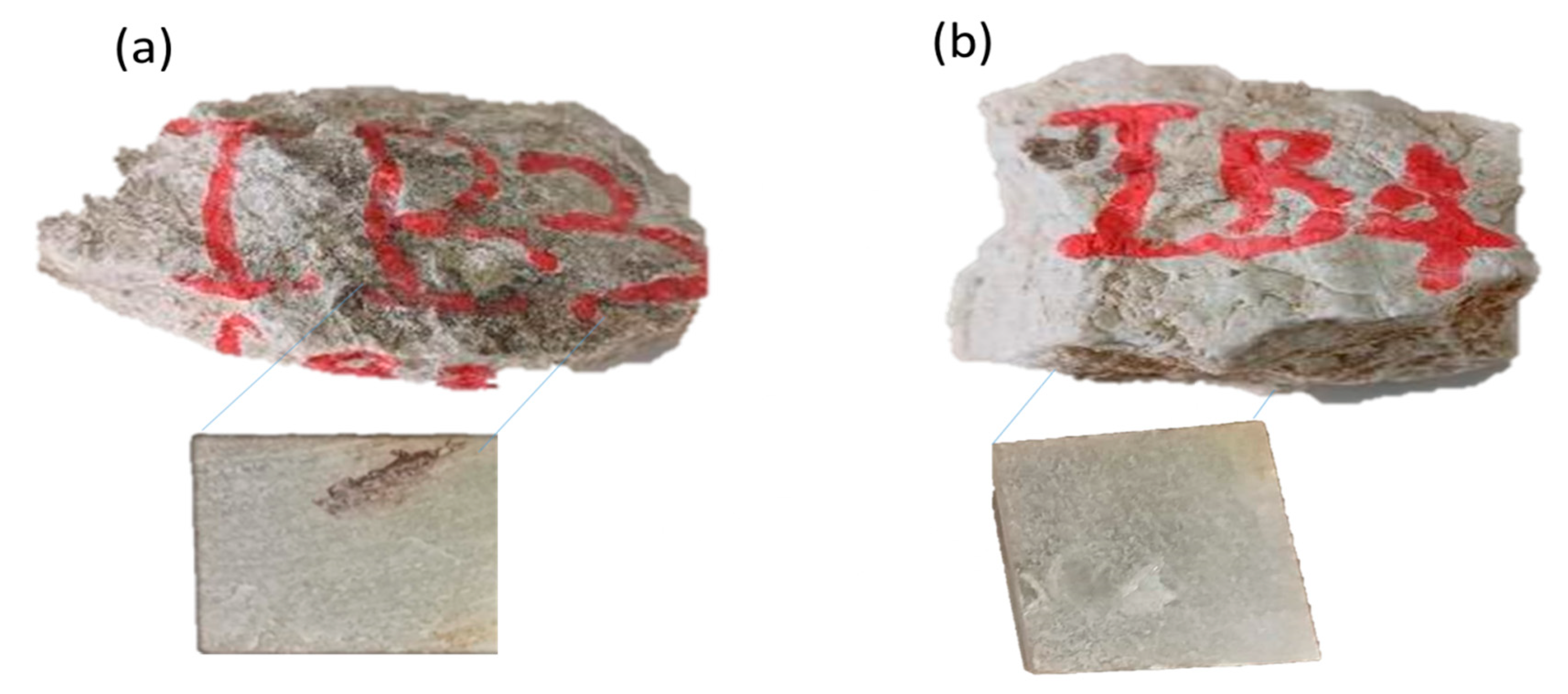

2.1. Materials

2.1.1. Barite Samples

2.1.2. Nanoindentation Equipment

2.1.3. Sample Mounting

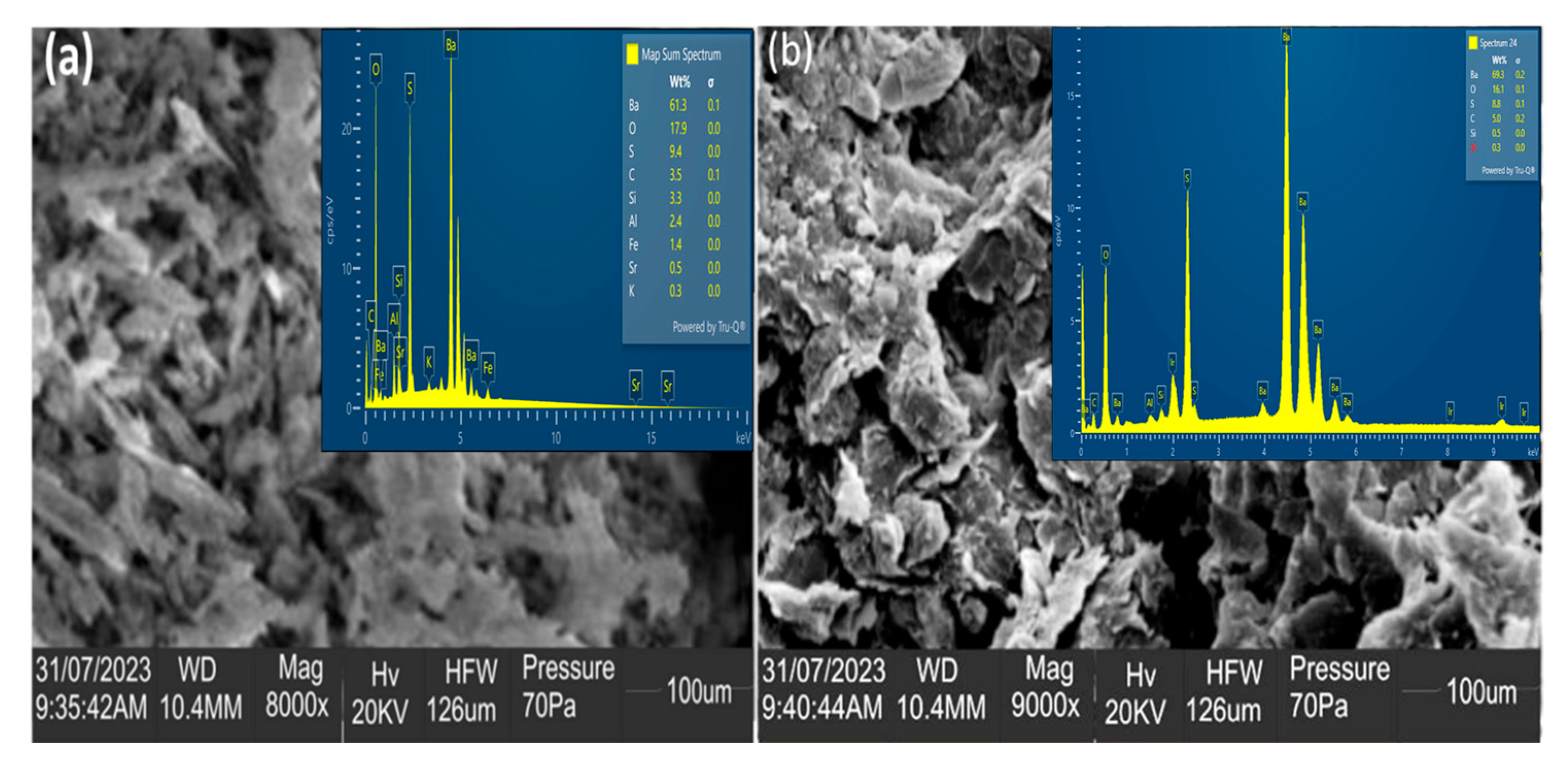

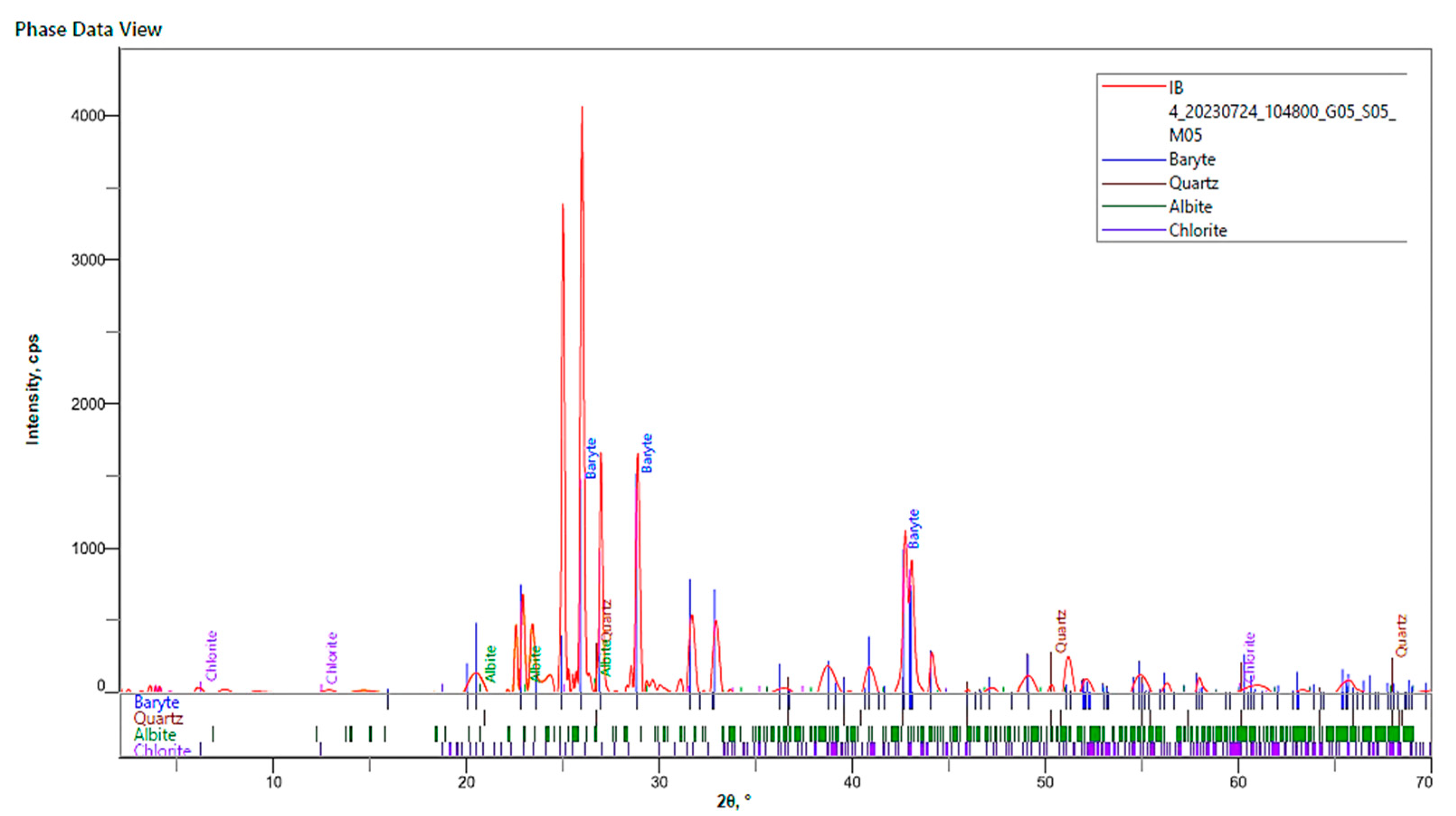

2.2. Characterization Techniques

2.3. Data Generation

2.4. Average Hardness of the Barite Rock Samples

3. Results and Discussion

3.1. Morphology and Elemental Composition of the Indented Barite Rock Sample Surfaces

3.2. XRD Results for Barite Rock Samples

3.3. Nanoindentation Results

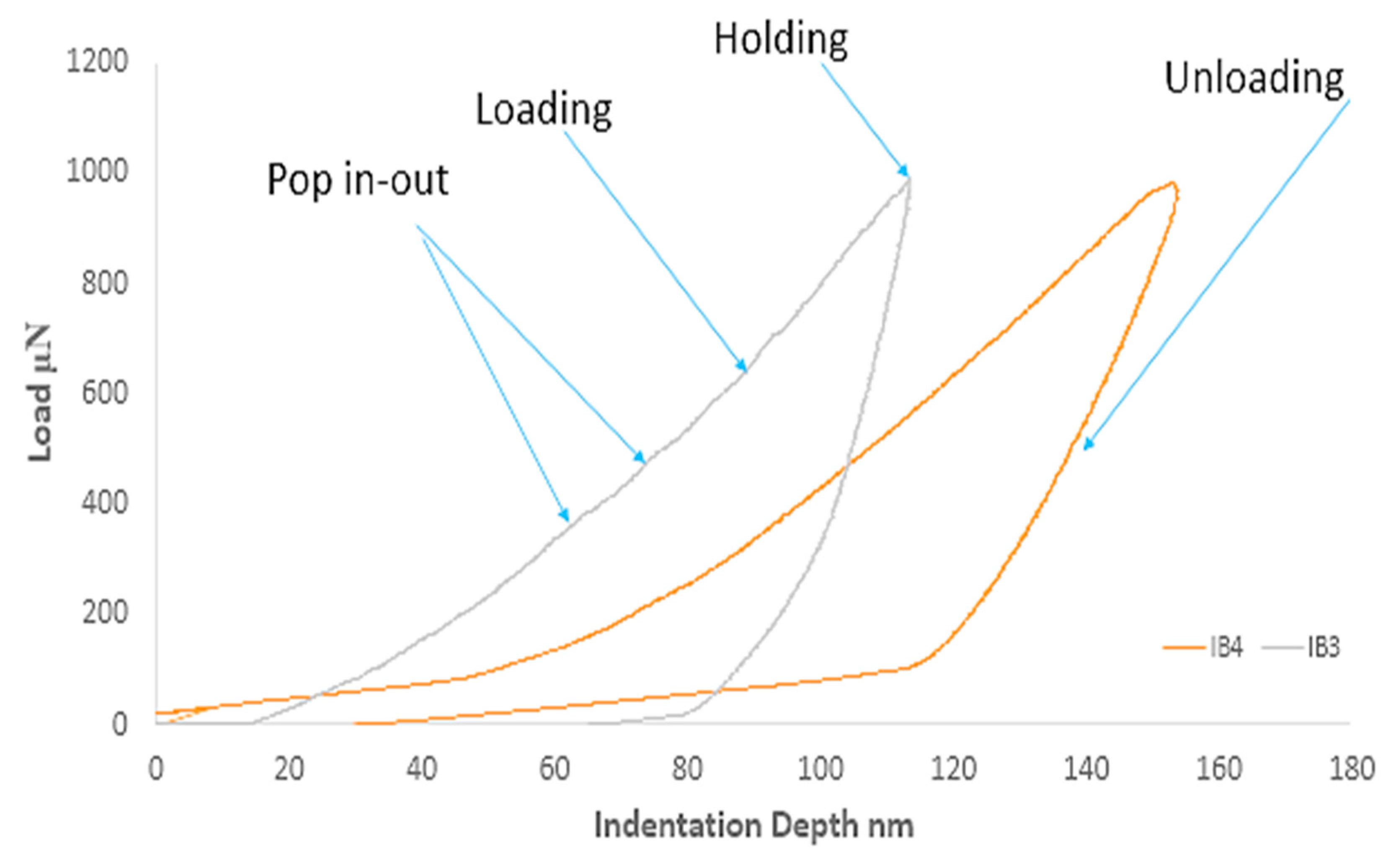

3.3.1. Load–Displacement Curves

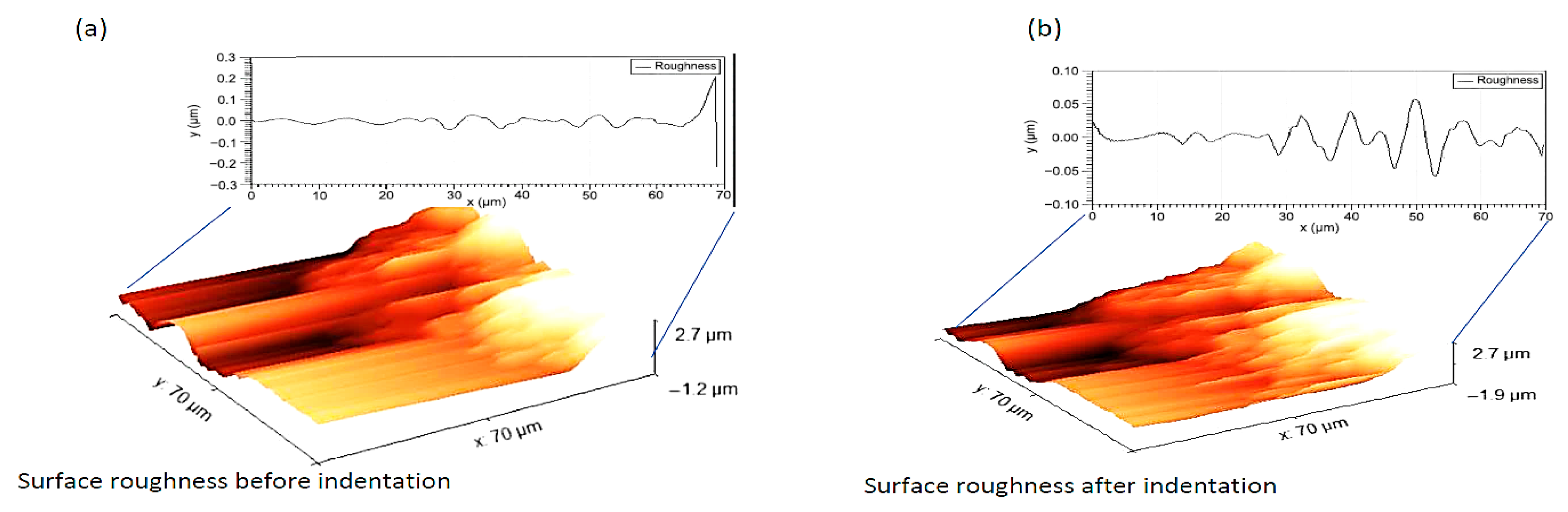

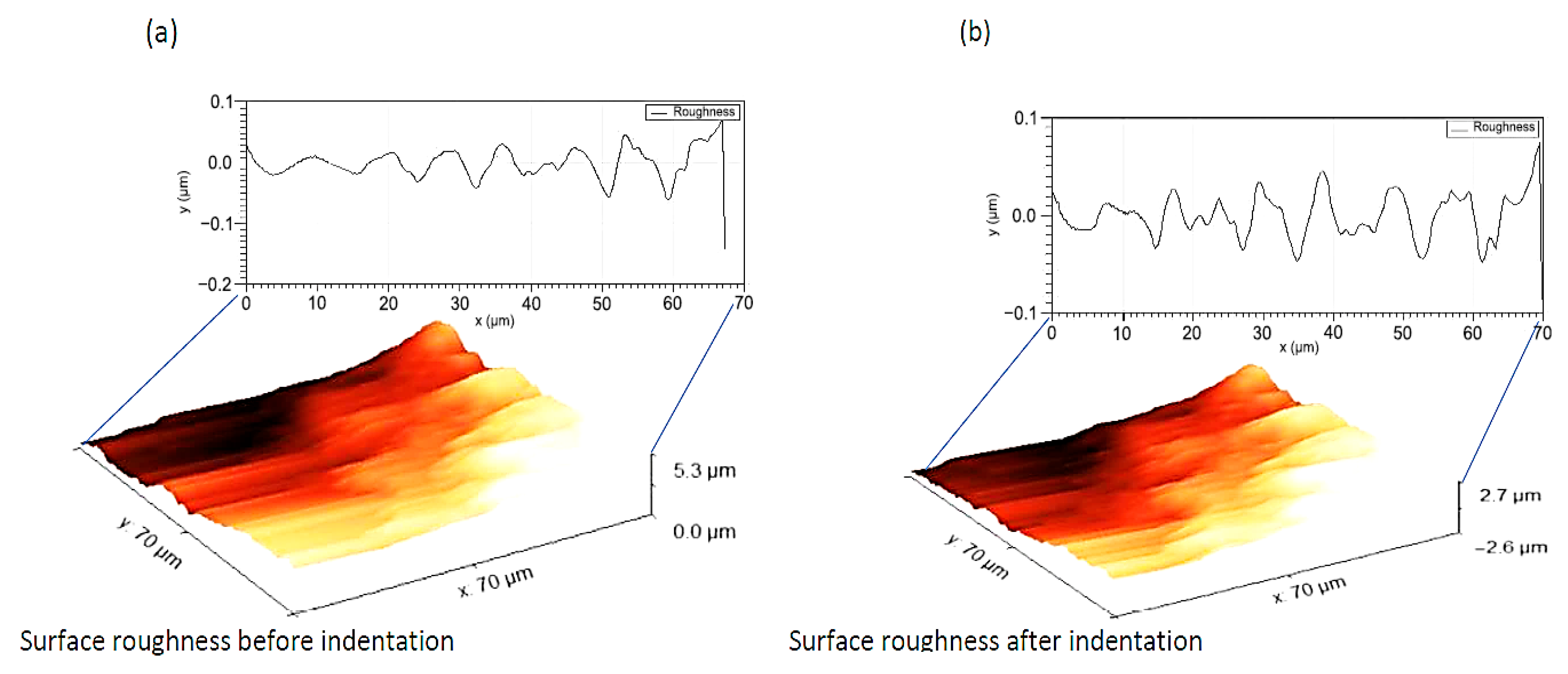

3.3.2. Atomic Force Microscopy (AFM) Images and Surface Roughness

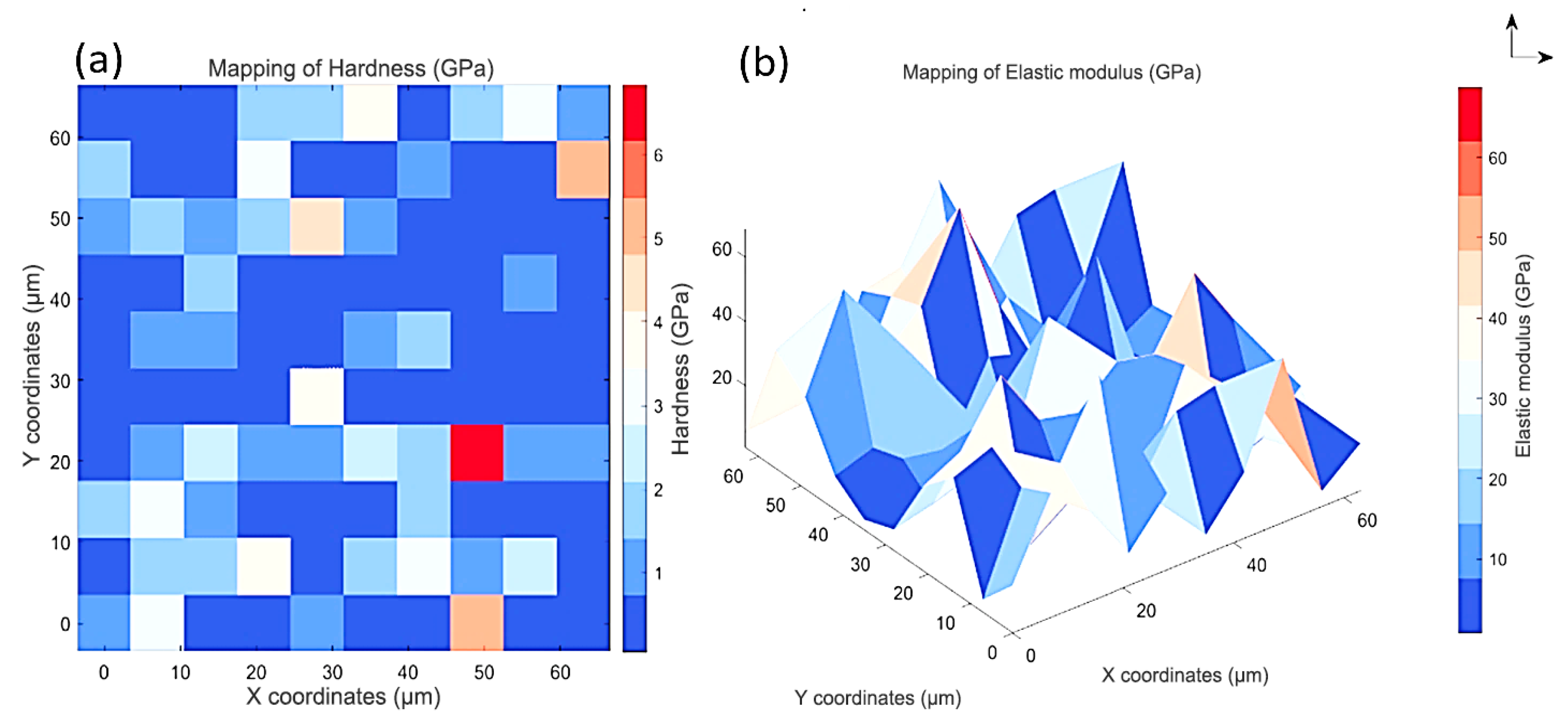

3.4. Hardness and Reduced Elastic Modulus of the Barite Rock Samples

3.5. Elastic Modulus of the Barite Rock Samples

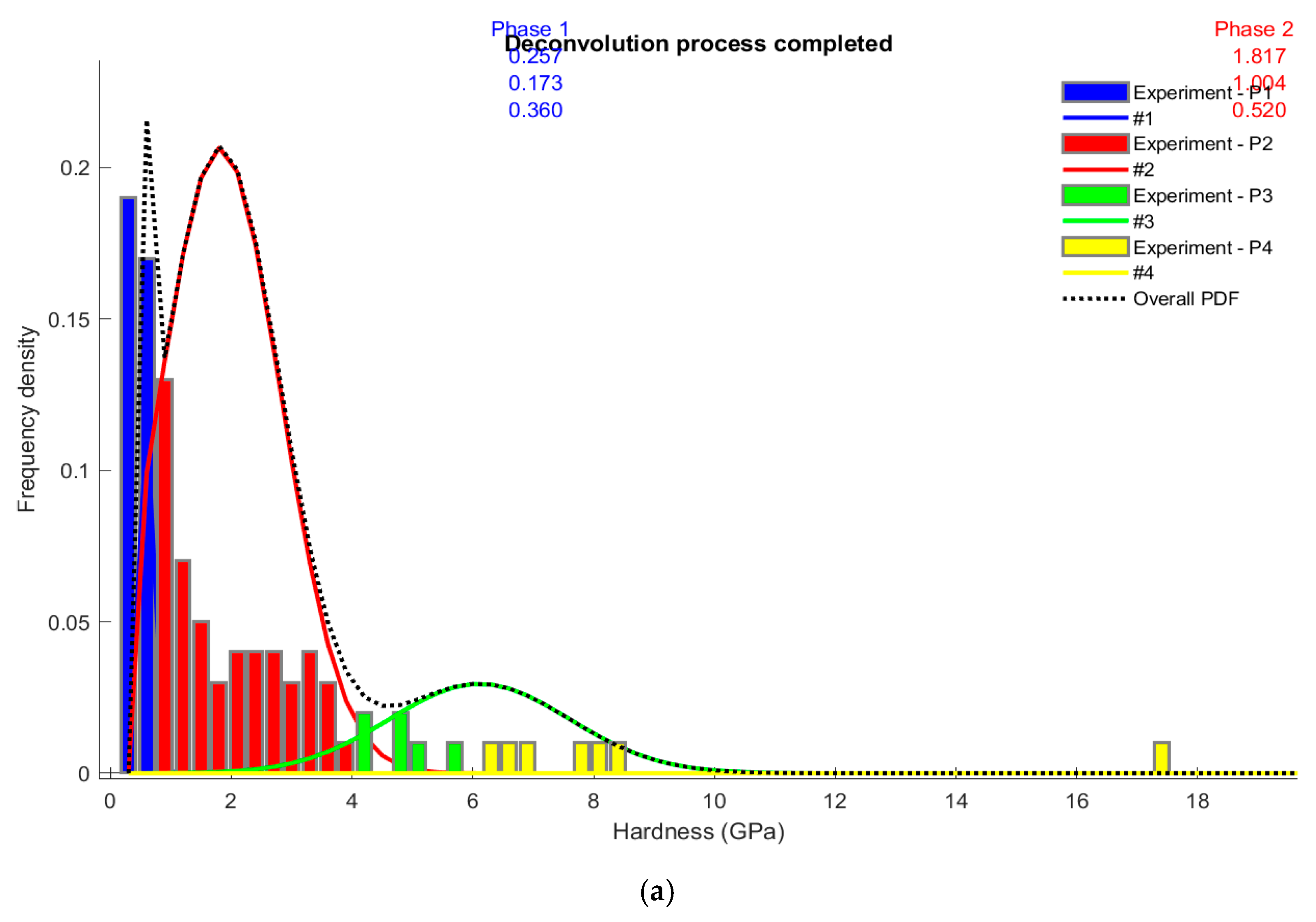

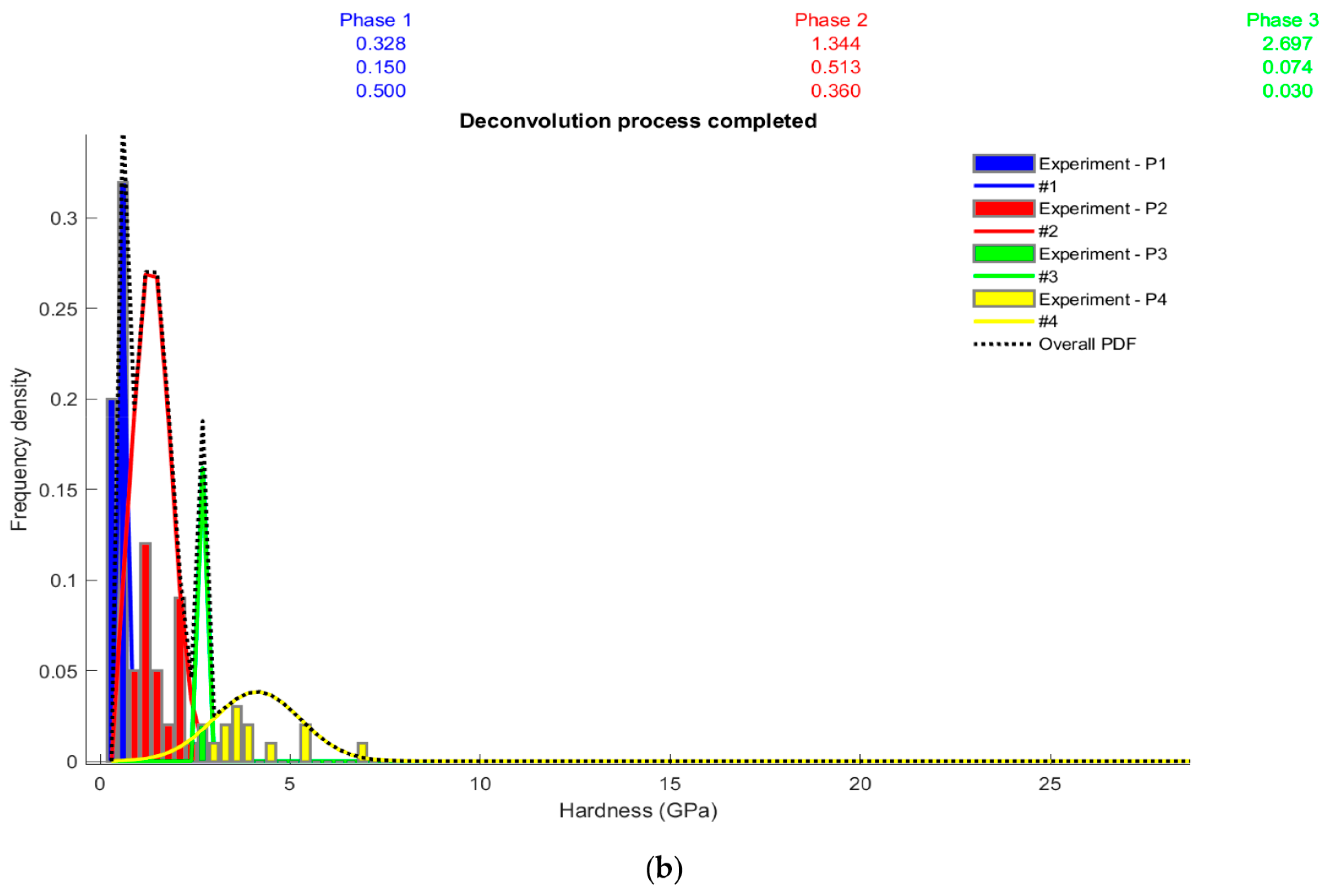

3.6. Statistical Variations in the Mechanical Hardness of Constituents of Barite Rock Samples

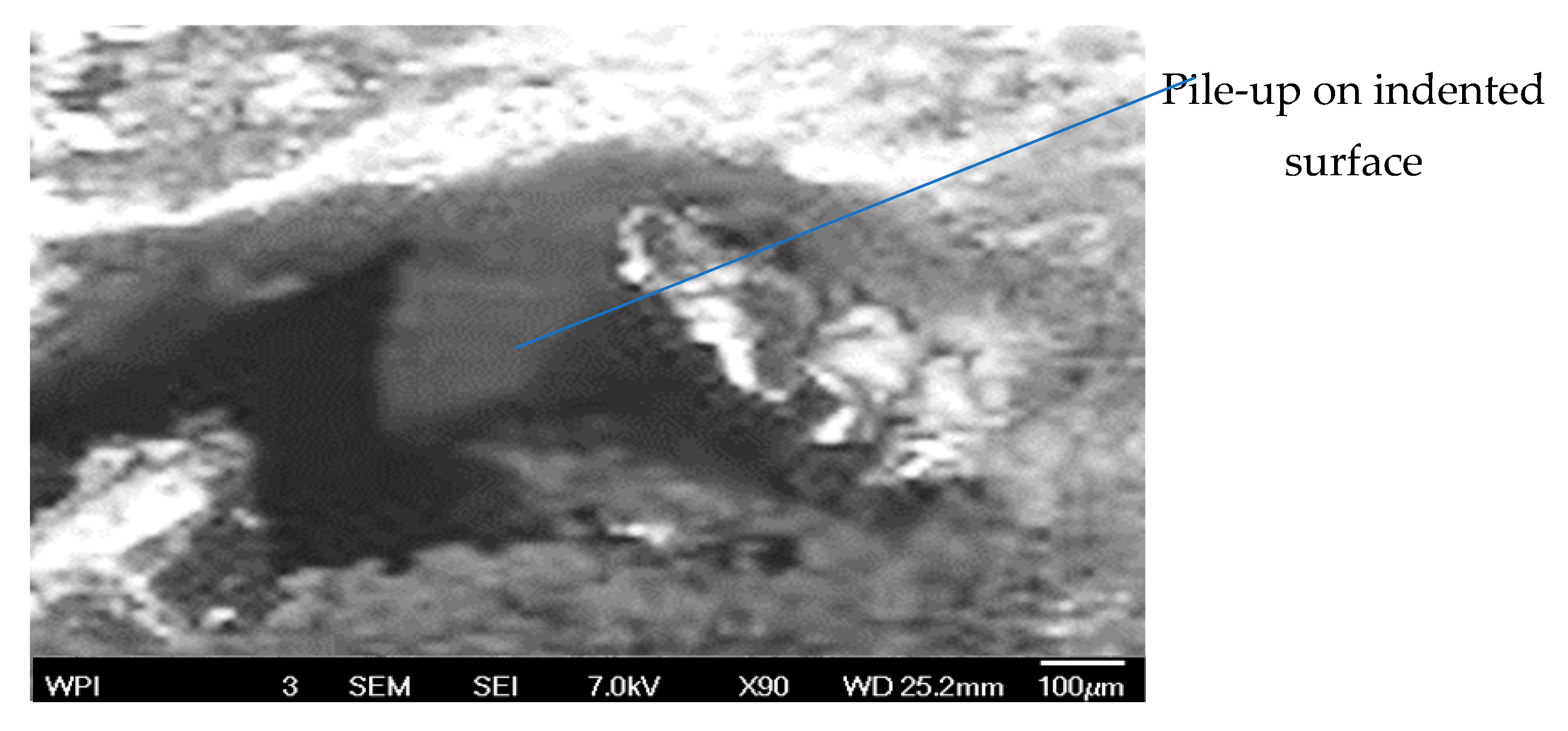

3.7. SEM Image of Indented Barite Rock Surface

3.8. Discussion on Elastic and Plastic Deformation of Barite Rocks

4. Conclusions

- Barite rock samples exhibited both elastic and plastic changes when tested with nanoindentation, indicating they can behave in an elastic–plastic manner, even though they are typically brittle.

- The hardness values of the barite samples are within the expected range of 1.7 to 2.0 GPa. The hardness of sample IB3 is slightly higher than that of IB4 but is within the range reported for barite in the literature. However, the materials (rock samples) still contain non-barite minerals that must be removed to improve their potential use in industrial applications such as in drilling fluids for the oil and gas industry, where it is important to resist wear and tear on the oil well walls and drilling rig surfaces.

- The defects observed on the barite rock surfaces revealed the brittle and porous nature of the barite samples. However, the range of dislocations in the sample can be examined using analytical methods complemented by experimental techniques such as transmission electron microscopy (TEM).

- The analysis of the structure and composition provided crucial information relevant to the design of processes and devices required for the efficient extraction of barite mineral and other non-barite minerals of interest.

- Based on the new understanding reported in this work, crush, grind, and process these barite samples to evaluate their effectiveness for specific applications, such as in drilling fluids, radiation protection, or filler materials. This process may involve simulating application-specific conditions and assessing the material’s behaviour under relevant environmental and operational scenarios.

- Future research is recommended to examine the impact of the composition and structure of non-barite minerals on their resistance to plastic, elastic, and lateral deformation. This will involve studying the effects of varying impurity levels or grain sizes on the mechanical properties and fracture-toughening mechanisms.

- New methods should be developed to improve the processing methods and enhance the mechanical properties and flow characteristics of the barite samples.

- Conduct transmission electron microscopy (TEM) or X-topography to examine mineral dislocations and calculate the material’s dislocation at different length scales. This will provide a complete overview of the plasticity of the rock samples.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| IB3 | Ibi barite sample number 3 |

| IB4 | Ibi barite sample number 4 |

| AFM | Atomic force microscopy |

References

- Olade, M.; Olade, M.A. Solid Mineral Deposits and Mining in Nigeria: A Sector in Transitional Change. Achiev. J. Sci. Res. 2019, 2, 1–16. [Google Scholar] [CrossRef]

- Ericsson, M.; Löf, O. Mining’s contribution to national economies between 1996 and 2016. Gorn. Promyshlennost 2019, 2019, 84–93. [Google Scholar] [CrossRef]

- Caenn, R.; Darley, H.C.H.; Gray, G.R. Drilling Problems Related to Drilling Fluids. In Composition and Properties of Drilling and Completion Fluids; Elsevier: Amsterdam, The Netherlands, 2017. [Google Scholar] [CrossRef]

- Abraham, E.I.; Bayode, B.L.; Olubambi, P.A.; Adetunji, A.R.; Onwualu, A.P. Characterization of barite ores from selected locations in Nigeria for drilling fluid formulation. Sci. Afr. 2021, 14, e01057. [Google Scholar] [CrossRef]

- National Minerals Information Center. Mineral commodity summaries 2024. In Mineral Commodity Summaries; USGS: Reston, VA, USA, 2024; Volume 703, pp. 64–65. Available online: https://pubs.usgs.gov/periodicals/mcs2024/mcs2024-molybdenum.pdf (accessed on 3 April 2025).

- U.S. Geological Survey. Mineral Commodity Summaries 2023: Barite. 2023. Available online: https://pubs.usgs.gov/periodicals/mcs2023/mcs2023-barite.pdf (accessed on 17 May 2025).

- Akinmosin, A.; Bankole, S.I.; Eyogwe, S.O. Reservoir geology and effects on exploitation of natural bitumen deposits (Nigerian deposits as a case study). J. Pet. Explor. Prod. Technol. 2018, 9, 191–205. [Google Scholar] [CrossRef]

- Olanrewaju, I.H. Evaluation of Some Characteristics of the Barite Deposits in Ribi, Nassarawa State for Industrial Application. Master’s Thesis, AUST, Galadima, Nigeria, 2019. [Google Scholar]

- Auwalu, D. Occurrence and Origin of Baryte Mineralization in the Benue Trough, Nigeria: A Review. Bima J. Sci. Technol. 2022, 4, 389–402. [Google Scholar]

- Eze, C.K. Feasibility Analysis of Commercial Barite Production in Nassarawa State Nigeria. Ph.D. Thesis, AUST, Galadima, Nigeria, 2019. [Google Scholar]

- Otoijamun, I.; Kigozi, M.; Adetunji, A.R.; Onwualu, P.A. Characterization and suitability of nigerian barites for different industrial applications. Minerals 2021, 11, 360. [Google Scholar] [CrossRef]

- Afolayan David, O. Assessment of Beneficiation Process of a Nigerian Barite. Master’s Thesis, African University of Science and Technology, Galadima, Nigeria, 2017. [Google Scholar]

- Xie, L.; Peng, J.W.X.; Lu, Q.; Peng, Q.; Hu, W.; Wang, T.; Yang, D.; Sun, W.; Liu, Q.; Qiao, C.; et al. Surface interaction mechanisms in mineral flotation: Fundamentals, measurements, and perspectives. Adv. Colloid Interface Sci. 2021, 295, 102491. [Google Scholar]

- Molaei, N.; Razavi, H.; Chelgani, S.C. Experimental modeling for upgrading of brown barite ore by different processing methods. Model. Earth Syst. Environ. 2018, 4, 89–96. [Google Scholar] [CrossRef]

- Ighoro, A.; Afolabi, Y.; Ogolo, O.; Rasak, A.; Peter, A. Heliyon Barite as an industrial mineral in Nigeria: Occurrence, utilization, challenges and future prospects. Heliyon 2021, 7, e07365. [Google Scholar] [CrossRef]

- Surendra, G. Froth flotation of barite. In Froth Flotation: A Century of Innovation; Society for Mining, Metallurgy & Exploration: Littleton, CO, USA, 2020; pp. 917–936. [Google Scholar]

- Nayak, A.; Jena, M.S.; Mandre, N.R. Application of Enhanced Gravity Separators for Fine Particle Processing: An Overview. J. Sustain. Metall. 2021, 7, 315–339. [Google Scholar] [CrossRef]

- Benin, S.R.; Selvakumar, G.; Sumathi, M.; Bright, R.J. Influence of barite particulate filler on the mechanical behaviour of carbon fiber reinforced LY556 epoxy matrix composites. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2022, 236, 412–423. [Google Scholar] [CrossRef]

- Ulusoy, U. A Review of Particle Shape Effects on Material Properties for Various Engineering Applications: From Macro to Nanoscale. Minerals 2023, 13, 91. [Google Scholar] [CrossRef]

- Pourghahramani, P. Effects of Grinding Variables on Structural Changes and Energy Conversion During Mechanical Activation Using Line Profile Analysis (LPA). Ph.D. Thesis, Lulea University of Technology, Lulea, Sweden, 2006; p. 163. [Google Scholar]

- Liang, C. Understanding Plastic Deformation: Principles, Mechanisms and Applications. Adv. Mater. Sci. Res. 2024, 152324, 229–230. [Google Scholar] [CrossRef]

- Massam, J.; Browne, N.; Kapilla, M. The Use of Sized Barite as a Weighting Agent for Drilling Fluids. PCT/US2005/019626 International, 22 May 2007. [Google Scholar]

- Workman, L.; Eloranta, J. The effects of blasting on crushing and grinding efficiency and energy consumption. In Proceedings of the Annual Conference on Explosives and Blasting Technique, I, Orlando, FL, USA, 22–23 January 1992; International Society of Explosives Engineers: Warrensville Heights, OH, USA, 2003; pp. 131–140. [Google Scholar]

- Gupta, A.; Yan, D.S.; Gupta, A.; Yan, D. Introduction to Mineral Processing Design and Operation PREFACE; Elsevier: Amsterdam, The Netherlands, 2006; pp. 1–704. [Google Scholar]

- Napier-munn, T. Is progress in energy-efficient comminution doomed? Miner. Eng. 2014, 73, 1–6. [Google Scholar] [CrossRef]

- Oyen, M.L. Nanoindentation of biological and biomimetic materials. Exp. Tech. 2013, 37, 73–87. [Google Scholar] [CrossRef]

- Mahmoud, Z.H.; AL-Salman, H.N.K.; Kianfar, E. Nanoindentation: Introduction and applications of a non-destructive analysis. Nano TransMed. 2024, 3, 100057. [Google Scholar] [CrossRef]

- Zheng, M.; Gu, Z.; Dong, H.; Ma, T.; Wu, Y. Nanoindentation-Based Characterization of Mesoscale Mechanical Behavior in Dolomite Crystals. Processes 2025, 13, 1203. [Google Scholar] [CrossRef]

- Schreiber, D.K.; Schwaiger, R.; Heilmaier, M.; McCormack, S.J. Materials properties characterization in the most extreme environments. MRS Bull. 2022, 47, 1128–1142. [Google Scholar] [CrossRef]

- Zhang, G.; Wei, Z.; Ferrell, R.E. Elastic modulus and hardness of muscovite and rectorite determined by nanoindentation. Appl. Clay Sci. 2009, 43, 271–281. [Google Scholar]

- Huang, C.; Zhu, C.; Ma, Y. Investigating Mechanical Characteristics of Rocks Under Freeze–Thaw Cycles Using Grain-Based Model. Rock Mech. Rock Eng. 2025, 58, 603–622. [Google Scholar] [CrossRef]

- Dong, L.; Zhang, Y.; Wang, L.; Wang, L.; Zhang, S. Temperature dependence of mechanical properties and damage evolution of hot dry rocks under rapid cooling. J. Rock Mech. Geotech. Eng. 2024, 16, 645–660. [Google Scholar] [CrossRef]

- Lim, Y.Y.; Munawar Chaudhri, M. Indentation of elastic solids with a rigid Vickers pyramidal indenter. Mech. Mater. 2006, 38, 1213–1228. [Google Scholar] [CrossRef]

- Fischer-Cripps, A.C. Factors Affecting Nanoindentation Test Data. In Nanoindentation; Springer: Berlin/Heidelberg, Germany, 2004. [Google Scholar] [CrossRef]

- Singh, B.; Saxena, K.K.; Dagwa, I.M.; Singhal, P.; Malik, V. Optimization of Machining Characteristics of Titanium-Based Biomaterials: Approach to Optimize Surface Integrity for Implants Applications. Surf. Rev. Lett. 2023, 32, 2340008. [Google Scholar]

- Ezenwafor, T.; Anye, V.; Madukwe, J.; Amin, S.; Obayemi, J.; Odusanya, O.; Soboyejo, W. Nanoindentation study of the viscoelastic properties of human triple negative breast cancer tissues: Implications for mechanical biomarkers. Acta Biomater. 2023, 158, 374–392. [Google Scholar]

- Zhao, F.; Shi, Z.; Yu, S.; Zheng, H. A review of fracture mechanic behaviors of rocks containing various defects. Undergr. Space 2023, 12, 102–115. [Google Scholar]

- Oliver, W.C.; Pharr, G.M. Improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar]

- Tsvirkun, D.; Revilloud, J.; Giannetti, A.; Verdier, C. The intriguing role of collagen on the rheology of cancer cell spheroids. J. Biomech. 2022, 141, 111229. [Google Scholar]

- Menčík, J.; He, L.H.; Němeček, J. Characterization of viscoelastic-plastic properties of solid polymers by instrumented indentation. Polym. Test. 2011, 30, 101–109. [Google Scholar] [CrossRef]

- Rao, X.; Zhang, F.; Luo, X.; Ding, F. Characterization of hardness, elastic modulus and fracture toughness of RB-SiC ceramics at elevated temperature by Vickers test. Mater. Sci. Eng. A 2019, 744, 426–435. [Google Scholar] [CrossRef]

- Li, X.; Wang, M.; Xu, L.; Xu, T.; Wu, W.; Pan, S.; Wang, C.; Zhang, W.; Cai, X. Progress in indentation test for material characterization: A systematic review. Results Surf. Interfaces 2024, 17, 100358. [Google Scholar] [CrossRef]

- Constantinides, G.; Chandran, K.S.R.; Ulm, F.J.; Van Vliet, K.J. Grid indentation analysis of composite microstructure and mechanics: Principles and validation. Mater. Sci. Eng. A 2006, 430, 189–202. [Google Scholar]

- ISO/FDIS 14577-1; Metallic Materials—Instrumented Indentation Test for Hardness and Material Parameter, Part 1: Test Method. ISO—International Organization for Standardization: Geneve, Switzerland, 2002.

- Oyen, M.L.; Cook, R.F. A practical guide for analysis of nanoindentation data. J. Mech. Behav. Biomed Mater. 2009, 2, 396–407. [Google Scholar]

- Hay, J.C.; Pharr, G.M. Critical issues in measuring the mechanical properties of hard films on soft substrates by nanoindentation techniques. MRS Proc. 1997, 505, 65–70. [Google Scholar] [CrossRef]

- Ali, A.; Zhang, N.; Santos, R.M. Mineral Characterization Using Scanning Electron Microscopy (SEM): A Review of the Fundamentals, Advancements, and Research Directions. Appl. Sci. 2023, 13, 12600. [Google Scholar] [CrossRef]

- Jamal, M.; Morgan, M.N. Materials characterization part I: Contact area of the Berkovich indenter for nanoindentation tests. Int. J. Adv. Manuf. Technol. 2017, 92, 361–370. [Google Scholar] [CrossRef]

- Joslin, D.L.; Oliver, W.C. A New Method for Analyzing Data from Continuous Depth Sensing Microindentation Tests. J. Mater. Res. 1990, 5, 123–126. [Google Scholar]

- Tsui, T.Y.; Pharr, G.M.; Oliver, W.C.; Bhatia, C.S.; White, R.L.; Anders, A.; Brown, I.G. Nanoindentation and Nanoscratching of Hard Carbon Coatings for Magnetic Disks. MRS Proc. 1994, 356, 767. [Google Scholar]

- Finkin, E.F. Examination of abrasion Resistance Criteria for Some Ductile Metals. J. Lubr. Technol. 1974, 96, 210–214. [Google Scholar]

- Kuksenko, V.; Roberts, S. The hardness and modulus of polycrystalline beryllium from nano-indentation. Int. J. Plast. 2019, 116, 62–80. [Google Scholar] [CrossRef]

- Li, M.; Liang, Y.; Deng, B.; Chen, B. Evolution of mesomechanical properties of granite minerals after high-temperature exposure. Phys. Fluids 2025, 37, 057111. [Google Scholar] [CrossRef]

- Afolayan, D.O.; Adetunji, A.R.; Peter, A.; Oghenerume, O.; Amankwah, R.K. Characterization of barite reserves in Nigeria for use as weighting agent in drilling fluid. J. Pet. Explor. Prod. 2021, 11, 2157–2178. [Google Scholar] [CrossRef]

- Pintaude, G. Introduction of the Ratio of the Hardness to the Reduced Elastic Modulus for Abrasion. In Tribology—Fundamentals and Advancements; InTech: Rijeka, Croatia, 2013. [Google Scholar] [CrossRef]

- Phakey, P.P.; Aly, A.M. Direct observation of dislocations in natural barite (BaSO4). Philos. Mag. 1970, 22, 1217–1225. [Google Scholar] [CrossRef]

- Asenjo, A.; Rojo, J.M. Dislocation generation and motion at the incipient stages of surface plasticity in barite. Philos. Mag. 2007, 87, 3959–3966. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Adamu, H.A.; Olajuyi, S.I.; Bello, A.; Onwualu, P.A.; Ogunmodimu, O.S.O.; Afolayan, D.O. Mechanical Loading of Barite Rocks: A Nanoscale Perspective. Minerals 2025, 15, 779. https://doi.org/10.3390/min15080779

Adamu HA, Olajuyi SI, Bello A, Onwualu PA, Ogunmodimu OSO, Afolayan DO. Mechanical Loading of Barite Rocks: A Nanoscale Perspective. Minerals. 2025; 15(8):779. https://doi.org/10.3390/min15080779

Chicago/Turabian StyleAdamu, Hassan Abubakar, Seun Isaiah Olajuyi, Abdulhakeem Bello, Peter Azikiwe Onwualu, Olumide Samuel Oluwaseun Ogunmodimu, and David Oluwasegun Afolayan. 2025. "Mechanical Loading of Barite Rocks: A Nanoscale Perspective" Minerals 15, no. 8: 779. https://doi.org/10.3390/min15080779

APA StyleAdamu, H. A., Olajuyi, S. I., Bello, A., Onwualu, P. A., Ogunmodimu, O. S. O., & Afolayan, D. O. (2025). Mechanical Loading of Barite Rocks: A Nanoscale Perspective. Minerals, 15(8), 779. https://doi.org/10.3390/min15080779