Lithology and Macroscopic Coal Lithotype Identification of Coal-Bearing Measures Based on Elemental Mud Logging: A Case Study of the Eastern Ordos Basin Coal Seam

Abstract

1. Introduction

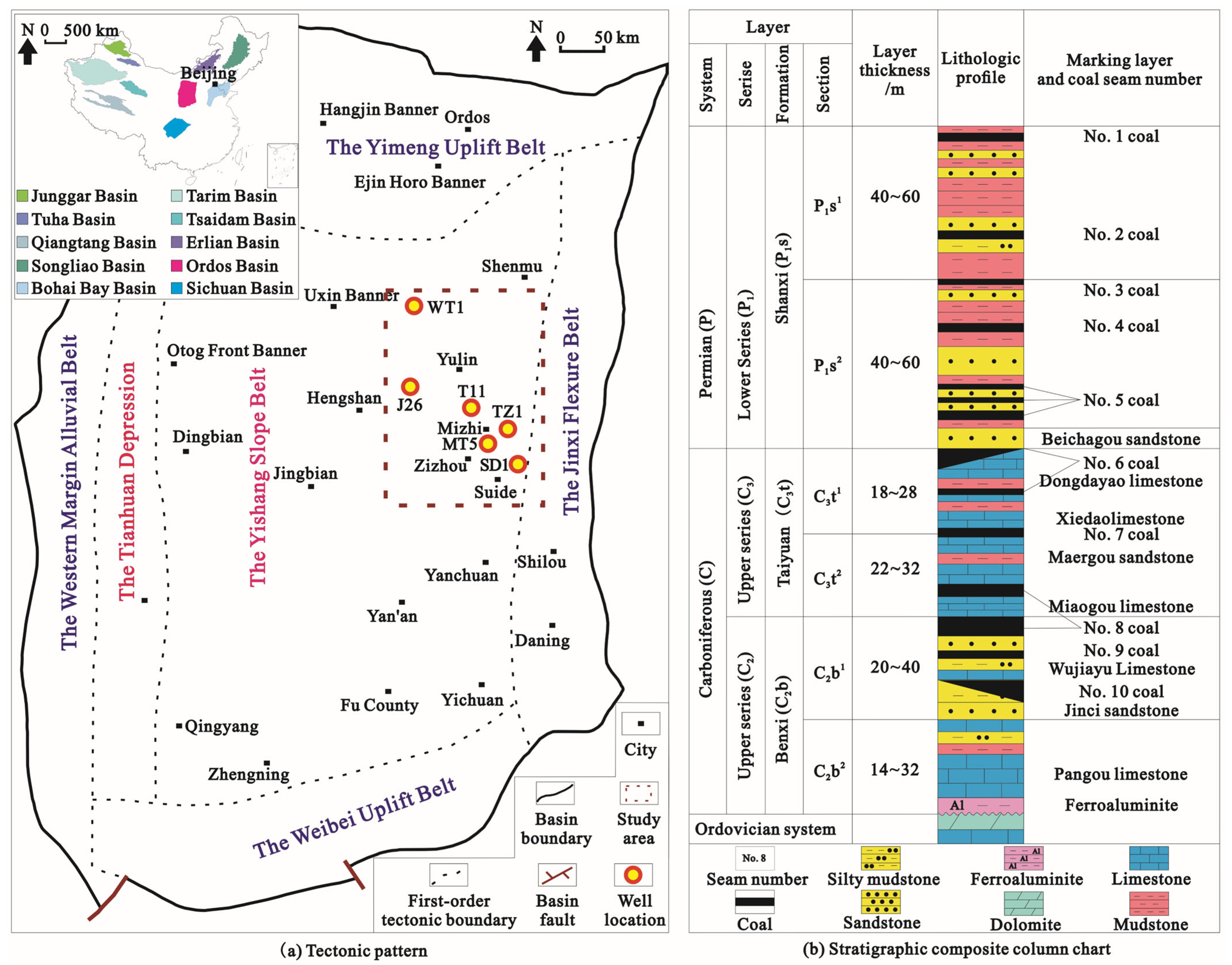

2. Geological Setting

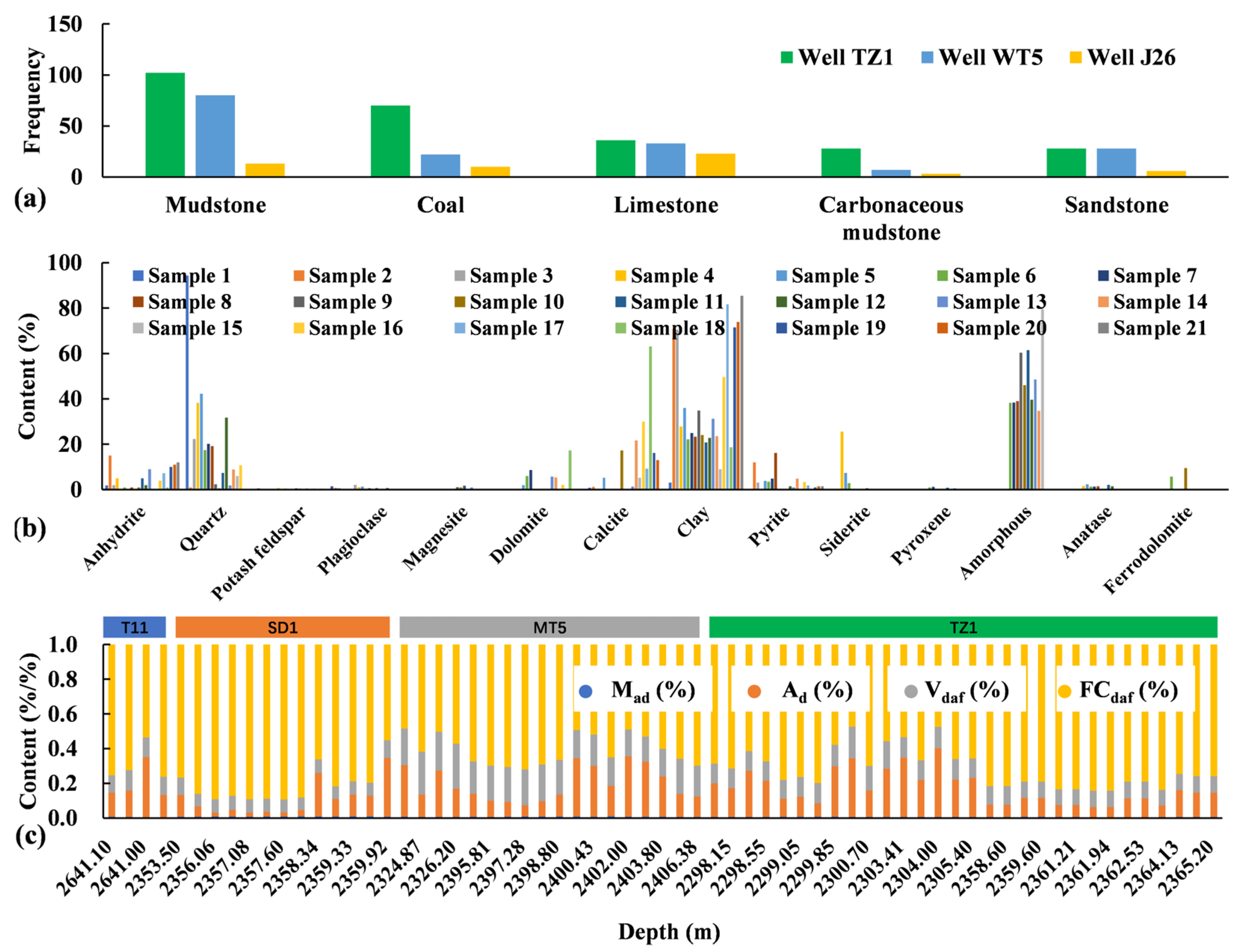

3. Data and Methodology

4. Results and Discussion

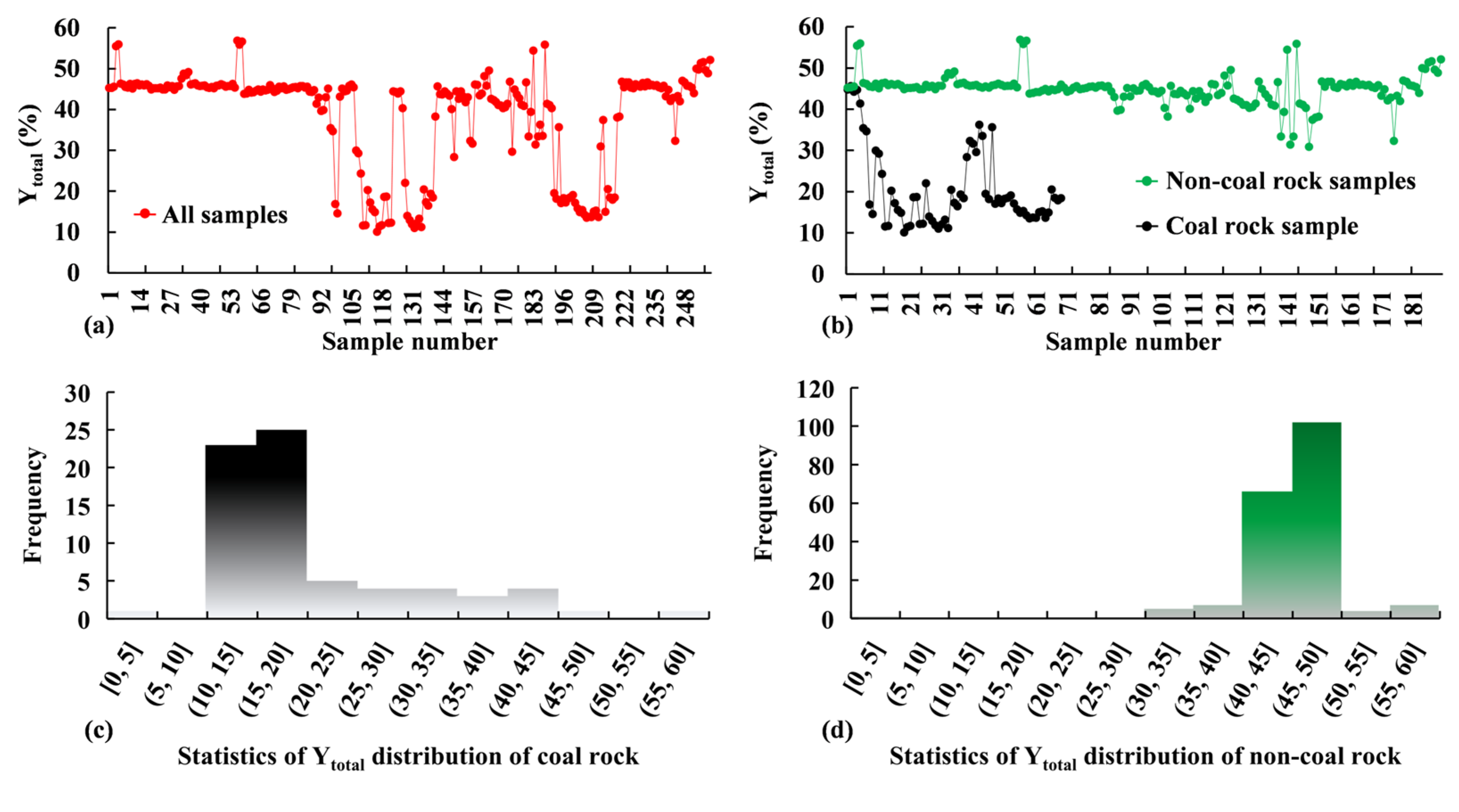

4.1. Coal and Non-Coal Seam Division

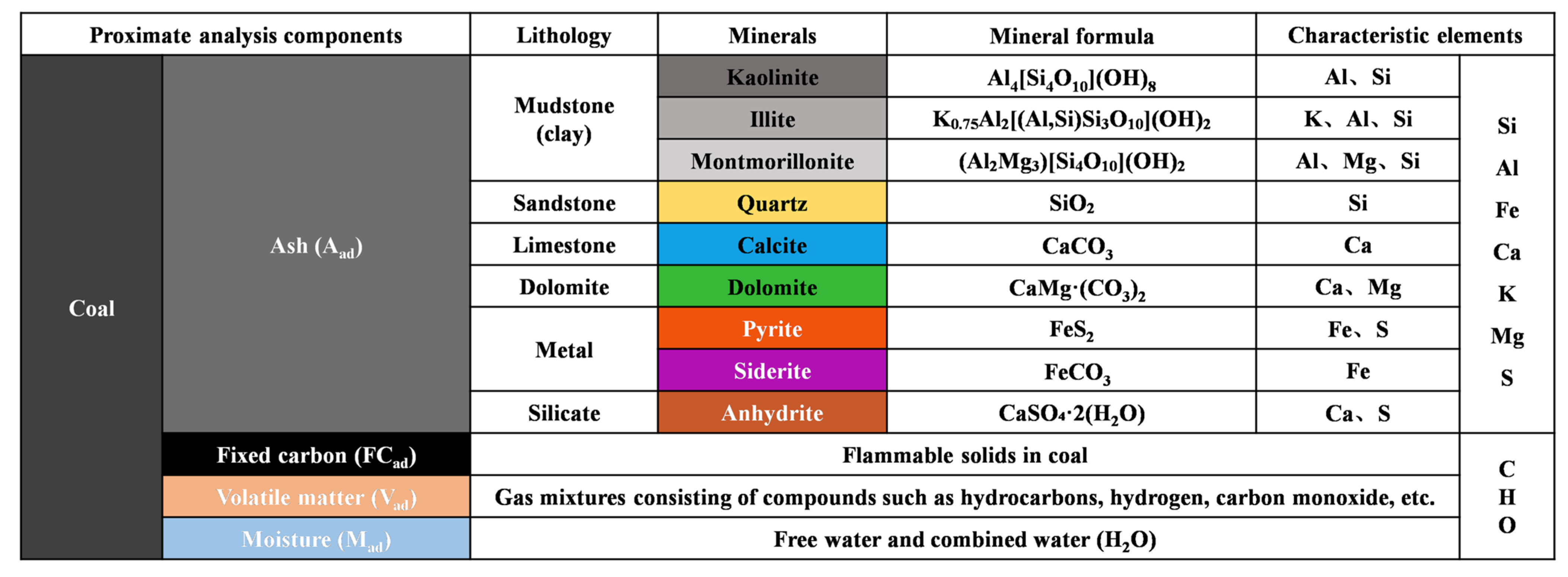

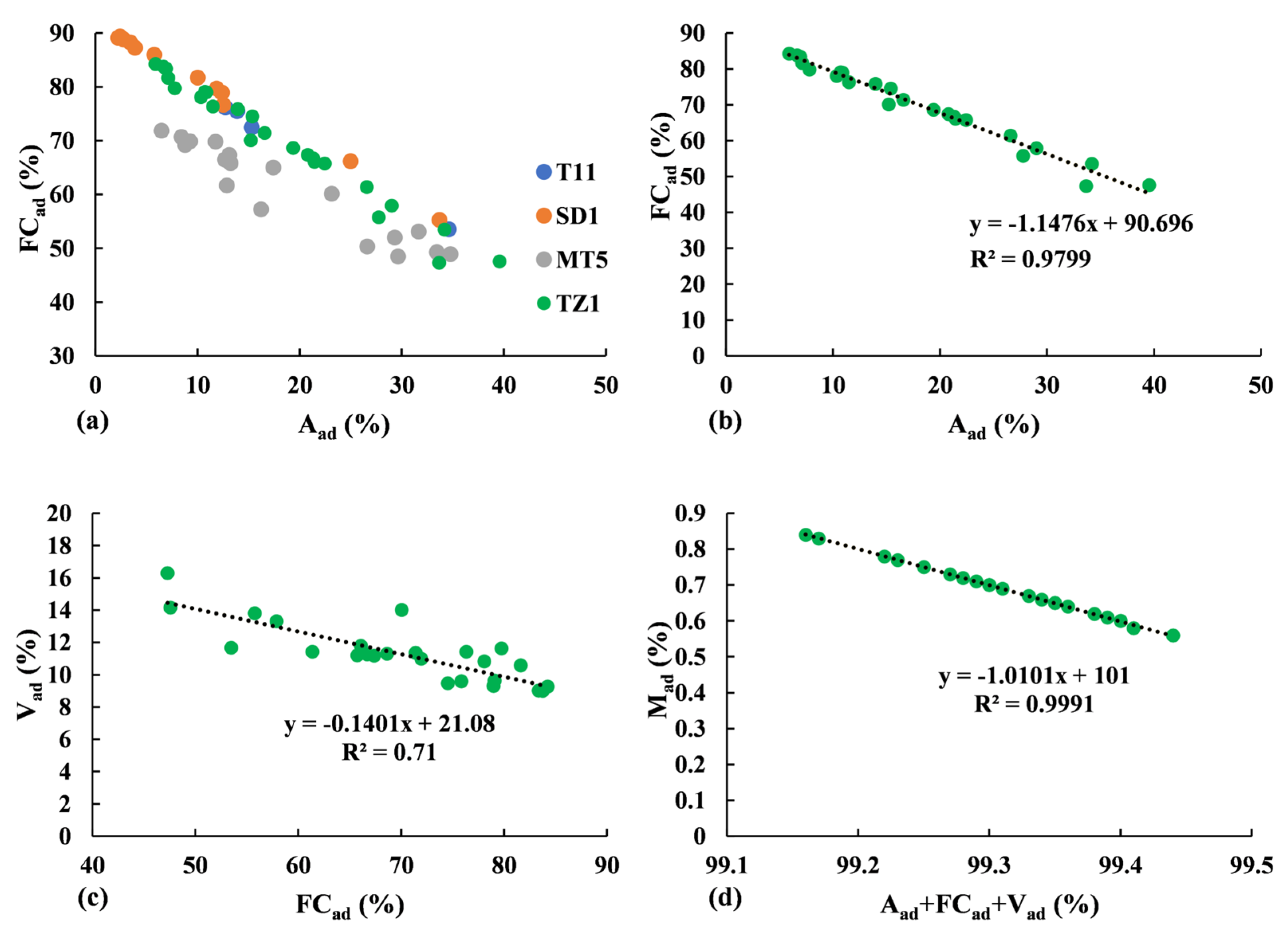

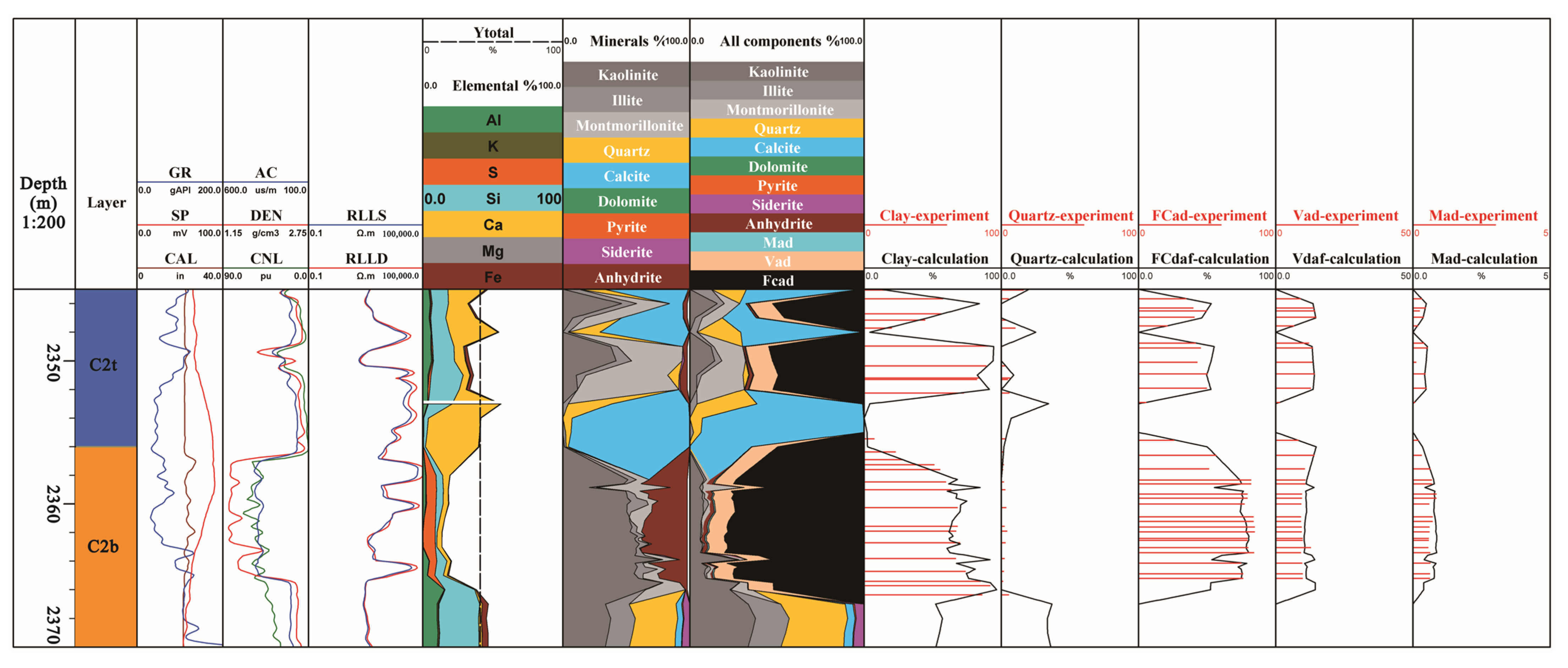

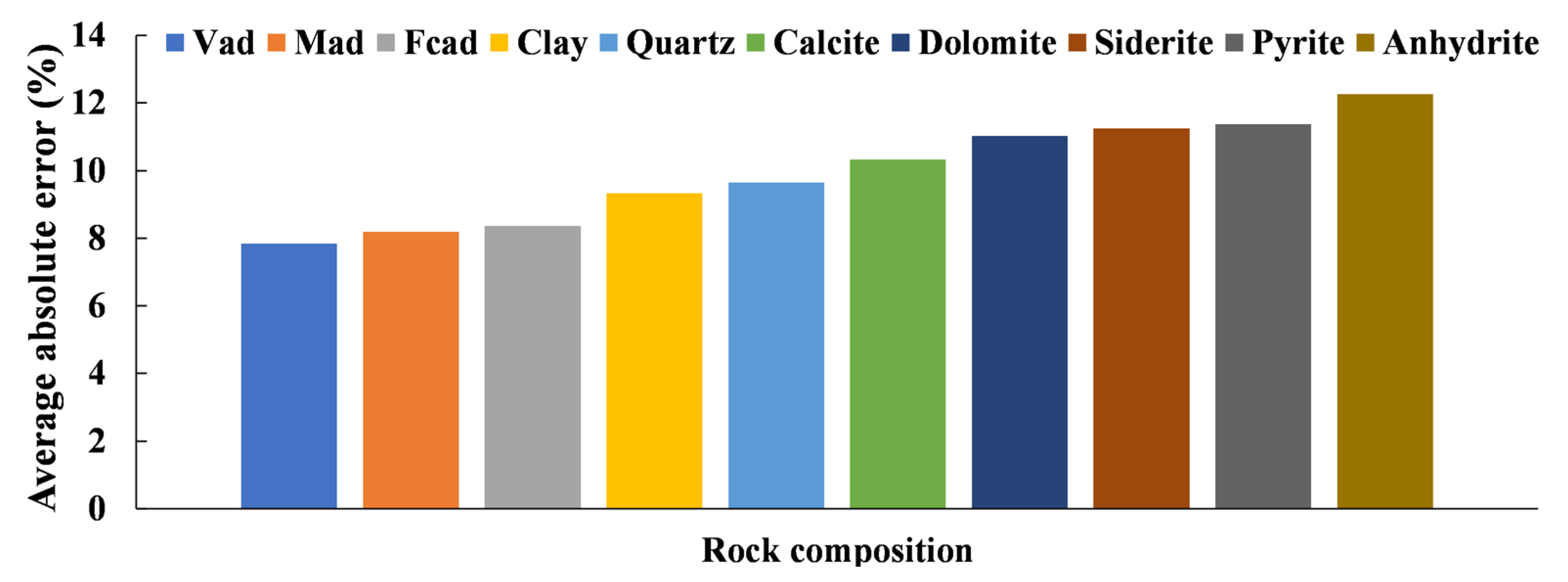

4.2. Calculation of Rock Components

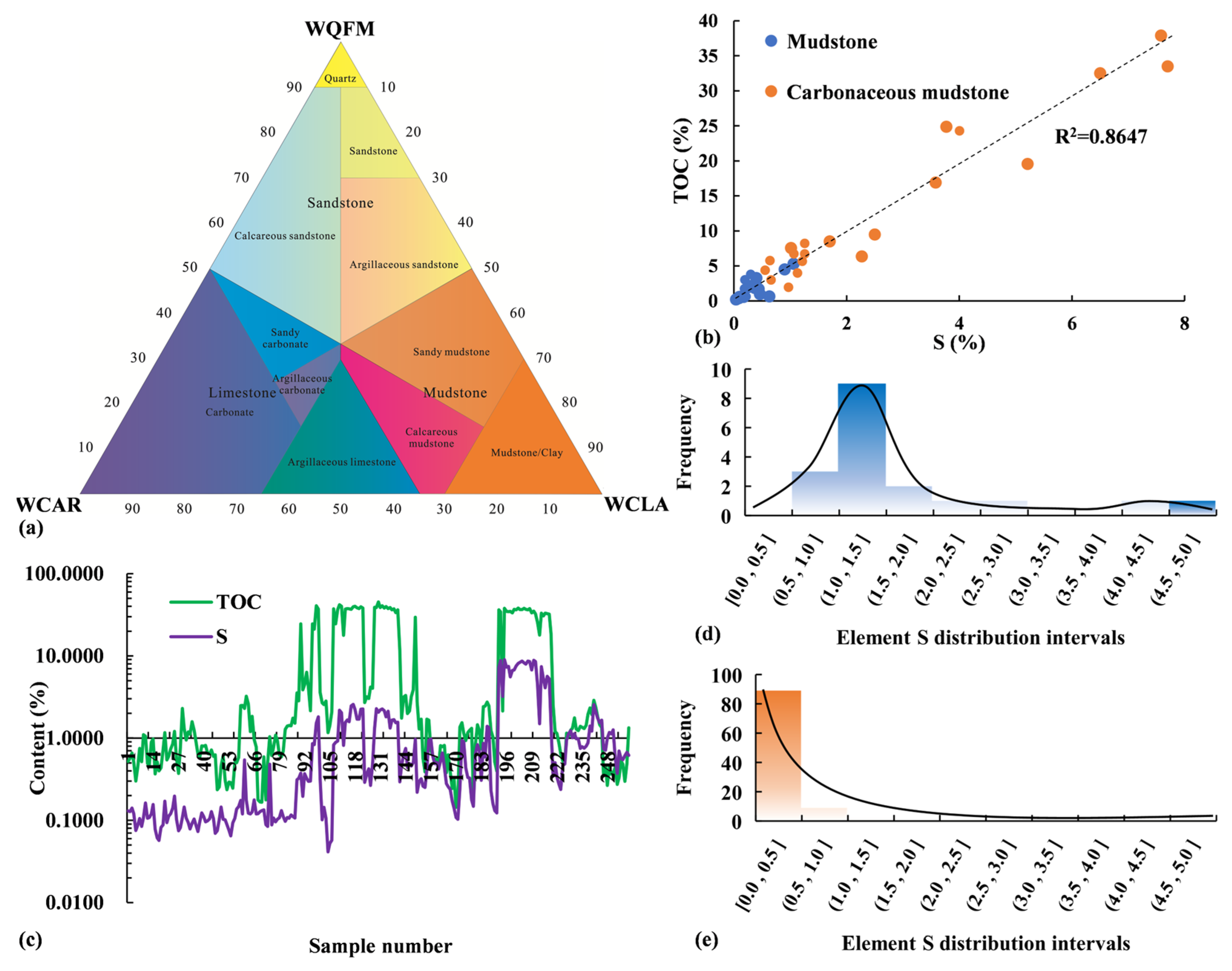

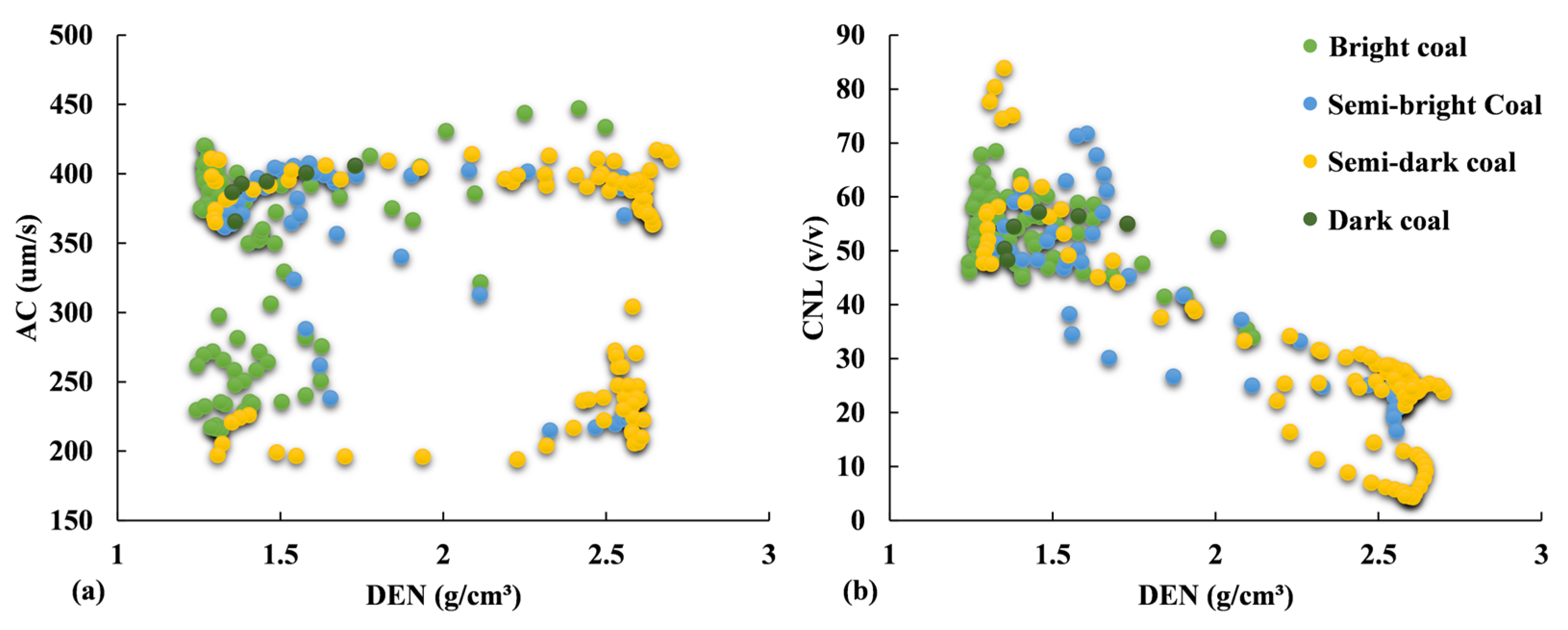

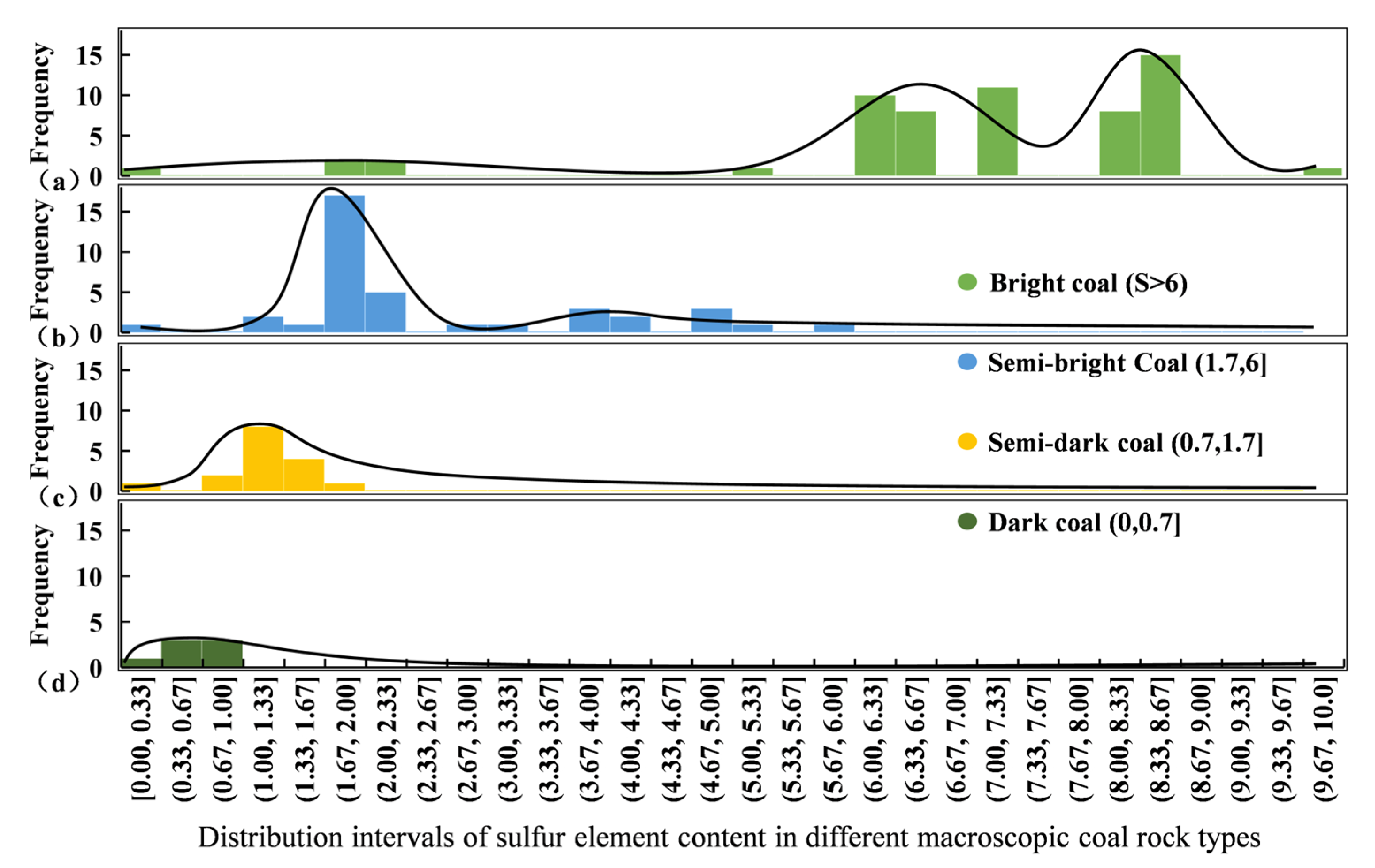

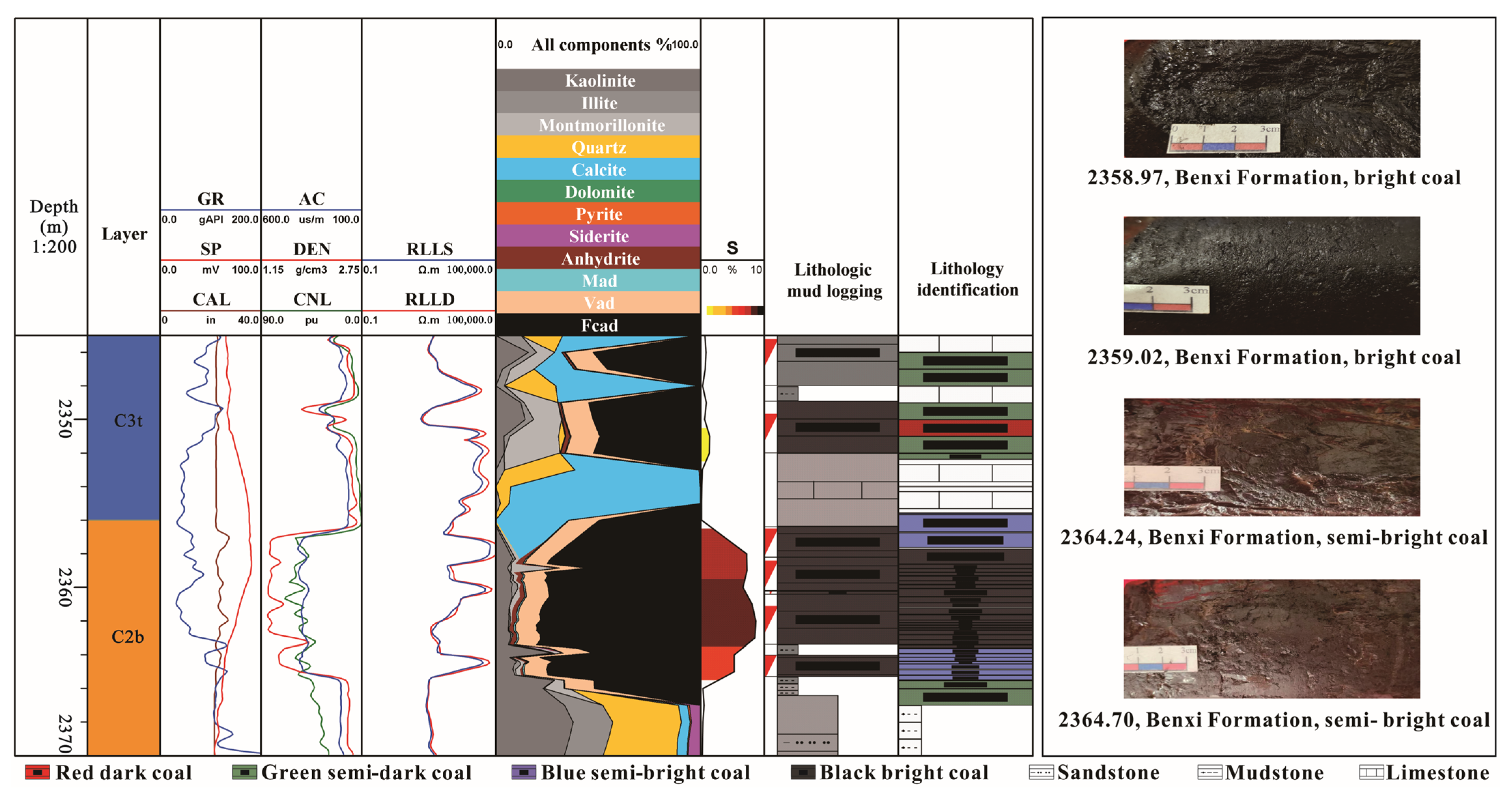

4.3. Lithologic Identification and Classification of Macroscopic Coal Lithotypes

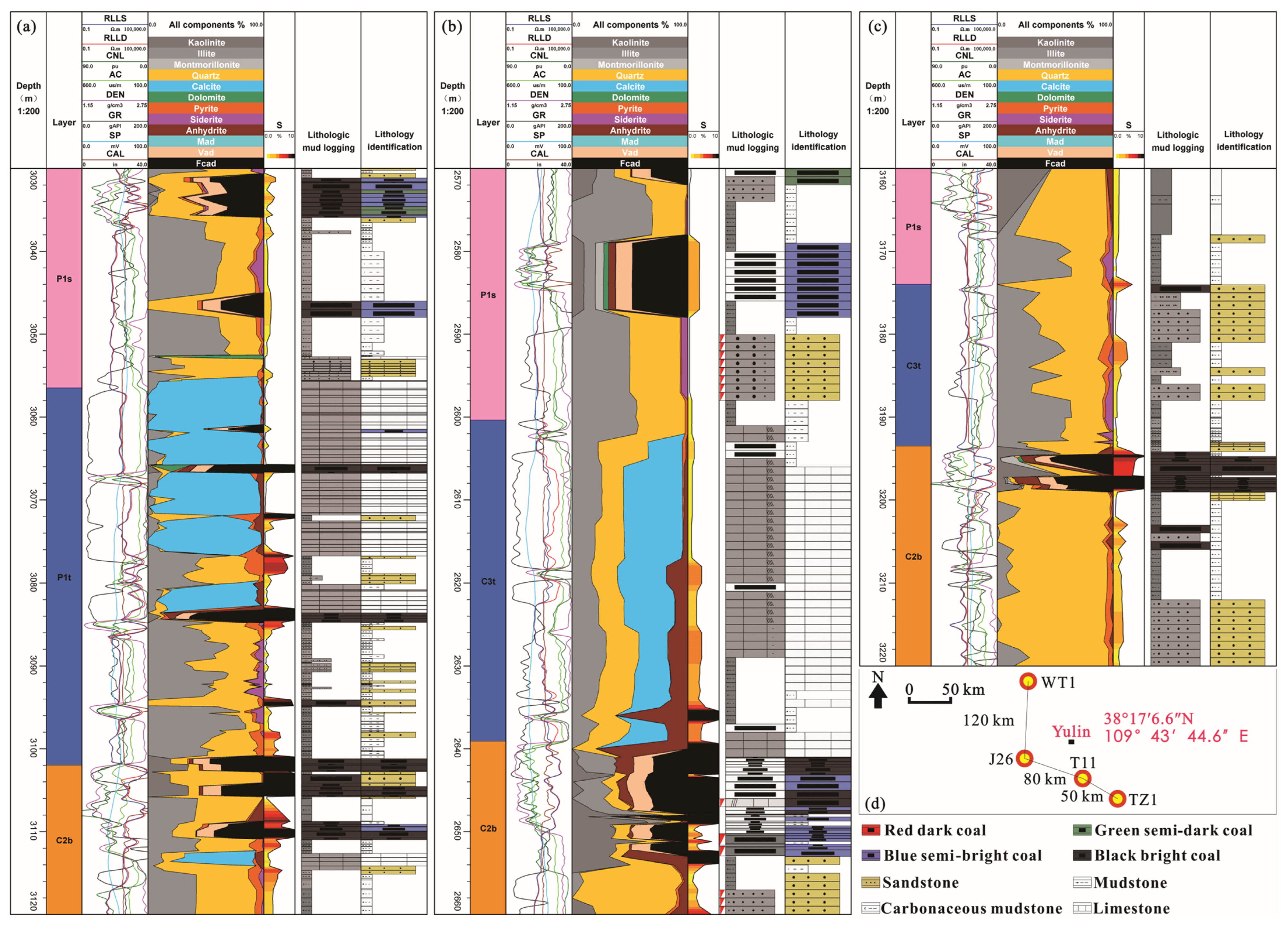

4.4. Method Utilization and Impact Analysis

5. Conclusions

- (1)

- This study constructed the coal seam demarcation line and realized the division of non-coal seams and coal seams. It also established the transformation model between mineral components and proximate analysis components, and realized an accurate calculation with an average error of less than 10%.

- (2)

- Conventional logging curve identification methods do not apply to the identification of non-coal seams lithology and macroscopic coal lithotypes in coal seams in the study area. In this study, based on analyzing the distribution characteristics of S elements, the classification and identification criteria were effectively established.

- (3)

- This paper provides a lithology and macroscopic coal lithotypes identification method based on element mud logging data, with an average identification accuracy of 87.48%, which has important guiding significance in the selection of coal seams in coal-bearing measures, development plan design, and improving the economic benefits of coalbed methane.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Amobi, O.J.; Ekpo, M.I.; Emedo, O.C.; Udo, G.I.; Ogbodo, K.U. Coal chemistry, utilization potential, and coalbed methane (CBM) assessment of some coal deposits in Central Benue Trough, north-central Nigeria. Discov. Geosci. 2024, 2, 54. [Google Scholar] [CrossRef]

- Flores, M.R.; Moore, T. Coalbed gas: A review of research directions from the past to the future as facilitated by bibliomet-rics. Int. J. Coal Geol. 2025, 298, 104683. [Google Scholar] [CrossRef]

- Xu, F.; Hou, W.; Xiong, X.; Xu, B.; Wu, P.; Wang, H.; Feng, K.; Yun, J.; Li, S.; Zhang, L.; et al. The status and development strategy of the coalbed methane industry in China. Petro-Leum Explor. Dev. 2023, 50, 765–783. [Google Scholar] [CrossRef]

- Qu, P.R. Broad prospect of scale benefit development of deep coalbed methane in China. China Energy News, 4 November 2024; p. 8. [Google Scholar]

- Yao, P.; Zhang, J.; Lv, D.; Vandeginste, V.; Chang, X.; Zhang, X.; Wang, D.; Han, S.; Liu, Y. Effect of water occurrence in coal reservoirs on the production capacity of coalbed me-thane by using NMR simulation technology and production capacity simulation. Geoenergy Sci. Eng. 2024, 243, 213353. [Google Scholar] [CrossRef]

- Niu, X.; Fan, L.; Yan, X.; Zhou, G.; Zhang, H.; Jing, X.; Zhang, M. Enrichment conditions and resource potential of coal-rock gas in Ordos Basin, NW China. Pet. Explor. Dev. 2024, 51, 972–985. [Google Scholar] [CrossRef]

- Ma, L.; Ji, J.X. Sinopec accelerates research on deep coalbed methane. China Petrochemical News, 26 August 2024; p. 5. [Google Scholar]

- Liu, Y.J.; Lai, F.Q.; Zhang, H.J.; Tan, Z.; Wang, Y.; Zhao, X.; Tan, X. A novel mineral composition inversion method of deep shale gas reservoir in Western Chongqing. J. Pet. Sci. Eng. 2021, 202, 108528. [Google Scholar]

- Lai, F.Q.; Liu, Y.J.; Zhang, H.J.; Wang, H.T.; Mao, H.Y.; Zhang, G.T. Fracturing properties model of deep shale gas reservoir based on digital core simulation. J. China Univ. Pet. Ed. Nat. Sci. 2022, 46, 1–11. [Google Scholar]

- Liu, Y.; Lai, F.; Wang, R.; Wu, Z.; Zhang, X.; Xu, H.; Li, J. Influencing Factors of the Brittleness of Continental Shales Containing Shell Limestone Interlayer. Minerals 2023, 13, 460. [Google Scholar] [CrossRef]

- Bicca, M.; Kalkreuth, W.; Silva, T.; Guerra-Sommer, M.; Degani-Schmidt, I.; Felix, C.; Boardman, D.; Souza, P. Multiproxy-based evidence of wildfire occurrence in the Lower Permian coal-bearing Rio Bonito Formation, Paraná Basin, Brazil. Int. J. Coal Geol. 2025, 306, 104810. [Google Scholar] [CrossRef]

- Wang, D.H.; Liu, J.; Liu, Y.C.; Duan, Y.C.; Li, L.; Li, J.C.; Feng, B. Surface engineering of deep coal-rock gas development: Challenges and solutions. Nat-Ural Gas Ind. 2024, 44, 209–217. [Google Scholar]

- Wei, Q.; Chen, S.; Yi, W.; Gui, H.; Jiang, W.; Li, F.; Li, S. Gas content, geochemical characteristics and implications of coalbed methane from the Deep Area of Qi’Nan Coalmine in Huaibei Coalfield. Sci. Rep. 2024, 14, 28334. [Google Scholar] [CrossRef] [PubMed]

- Šoster, A.; Erlandsson, B.V.; Ajuaba, S.; Šmuc, N.R. Selective trace element uptake in iron sulfides during burial metamorphism of coal: Insights from the coal-bearing Socka Beds, Northeastern Slovenia. Int. J. Coal Geol. 2025, 306, 104805. [Google Scholar] [CrossRef]

- Li, B.; Guo, Y.; Hu, X.; Wang, T.; Wang, R.; Chen, X.; Fan, W.; Deng, Z. Pore Structure and Heterogeneity Characteristics of Deep Coal Reservoirs: A Case Study of the Daning–Jixian Block on the Southeastern Margin of the Ordos Basin. Minerals 2025, 15, 116. [Google Scholar] [CrossRef]

- Ghosh, S.; Chatterjee, R.; Shanker, P. Estimation of ash, moisture content and detection of coal lithofacies from well logs using regression and artificial neural network modelling. Fuel 2016, 177, 279–287. [Google Scholar] [CrossRef]

- Chen, B.; Li, S.; Tang, D.; Pu, Y.; Zhong, G. Evaluation of recoverable potential of deep coalbed methane in the Linxing Block, Eastern Margin of the Ordos Basin. Sci. Rep. 2024, 14, 9192. [Google Scholar] [CrossRef]

- Banerjee, A.; Mukherjee, B.; Sain, K. Machine learning assisted model based petrographic classification: A case study from Bokaro coal field. Acta Geod. Geophys. 2024, 59, 463–490. [Google Scholar] [CrossRef]

- Li, C.; Yang, Z.; Yan, X.; Zhou, G.; Wang, G.; Gao, W.; Liu, C.; Lu, B.; Liang, Y. Distribution Law of Occurrence State and Content Prediction of Deep CBM: A Case Study in the Ordos Basin, China. Nat. Resour. Res. 2024, 33, 1843–1869. [Google Scholar] [CrossRef]

- Maxwell, K.; Rajabi, M.; Esterle, J.; Tivane, M.; Travassos, D. Spatial modelling and classification of altered coal using random forest-based methods at Moatize Basin, Mozambique. J. Afr. Earth Sci. 2024, 215, 105279. [Google Scholar] [CrossRef]

- Yan, T.; Xu, R.; Sun, S.-H.; Hou, Z.-K.; Feng, J.-Y. A real-time intelligent lithology identification method based on a dynamic felling strategy weighted random forest algorithm. Pet. Sci. 2024, 21, 1135–1148. [Google Scholar] [CrossRef]

- Huo, F.; Li, A.; Zhao, X.; Ren, W.; Dong, H.; Yang, J. Novel lithology identification method for drilling cuttings under PDC bit condition. J. Pet. Sci. Eng. 2021, 205, 108898. [Google Scholar] [CrossRef]

- Mu, X.; Zhu, Y.; Dou, K.; Shi, Y.; Huang, M. Logging response prediction of high-lithium coal seam based on K-means clustering algorithm. Front. Earth Sci. 2024, 12, 1443458. [Google Scholar] [CrossRef]

- Ren, P.F.; Xu, H.; Tang, D.Z.; Li, Y.; Sun, C.; Tao, S.; Li, S.; Xin, F.; Cao, L. The identification of coal texture in different rank coal reservoirs by using geophysical logging data in northwest Guizhou, China: Investigation by principal component analysis. Fuel 2018, 230, 258–265. [Google Scholar] [CrossRef]

- Wu, Y.; Tao, S.; Bi, C.; Tang, S.; Men, X. Pore-fracture and permeability heterogeneity of different marcolithotypes of medium-rank coals in Jixi Basin, China. Geoenergy Sci. Eng. 2023, 231, 212395. [Google Scholar] [CrossRef]

- Chang, X.; Han, R.; Zhang, J.; Vandeginste, V.; Zhang, X.; Liu, Y.; Han, S. Prediction of Coal Body Structure of Deep Coal Reservoirs Using Logging Curves: Principal Component Analysis and Evaluation of Factors Influencing Coal Body Structure Distribution. Nat. Resour. Res. 2024, 34, 1023–1044. [Google Scholar] [CrossRef]

- Hussein, S.H.; Ondřej, B.; Howri, M.; Salahadin, S. Outcrop-to-subsurface correlation and sequence stratigraphy of a mixed carbonate–siliciclastic ramp using element geochemistry and well logging; Upper Cretaceous Kometan Formation, Zagros Foreland, NE Iraq. Sediment. Geol. 2024, 459, 106547. [Google Scholar] [CrossRef]

- Xia, W.; Tang, Y.; Li, G.; Yue, C.; Han, Y.; Wu, X.; Fan, S. Wellbore stability prediction method based on intelligent analysis model of drilling cut-tings logging images. Geoenergy Sci. Eng. 2025, 252, 213961. [Google Scholar] [CrossRef]

- Gan, Y.Y.; Zhang, K.L.; Yao, H.P. Discussion on potential joint mining of coal measures gases resources in Ordos area, Inner Mongolia. J. China Coal Soc. 2018, 43, 1661–1668. [Google Scholar]

- Zhao, Z.; Xu, W.; Zhao, Z.; Yi, S.; Yang, W.; Zhang, Y.; Sun, W.; Shi, Y.; Zhang, C.; Gao, J. Geological characteristics and exploration breakthroughs of coal rock gas in Carbonif-erous Benxi Formation, Ordos Basin, NW China. Pet. Explor. Dev. 2024, 51, 262–278. [Google Scholar] [CrossRef]

- Xu, F.Y.; Nie, Z.H.; Sun, W.; Xiong, X.Y.; Xu, B.Y.; Zhang, L.; Shi, X.S.; Liu, Y.; Liu, S.U.; Zhao, Z.P.; et al. Theoretical and technological system for Highly efficient development of deep coalbed methane in the Eastern edge of Erdos Basin. J. China Coal Soc. 2024, 49, 528–544. [Google Scholar]

- Li, Y.; Xu, F.Y.; Tang, S.H.; Wang, Y.B.; Meng, S.Z.; Xu, Q. Progress and development direction of coalbed methane (coal-rock gas) exploration and development in the Ordos Basin. Nat. Gas Ind. 2024, 44, 63–79. [Google Scholar]

- Grau, J.A.; Schweitzer, J.S. Elemental concentration from thermal neutron capture gamma ray spectra in geological for-mation. Nucl. Geophys. 1989, 2, 1–9. [Google Scholar]

- Huang, Q.J. Research on Inversion Mineral Method and Application by XRF. Master’s Thesis, China University of Petroleum (East China), Qingdao, China, 2020. [Google Scholar]

- Herron, M.M.; Herron, L.S. Geological applications of geochemical well logging. Geol. Soc. 1990, 48, 165–175. [Google Scholar] [CrossRef]

- Shan, Y.P.; Wang, H.J.; Zhang, L.J.; Bai, Z.H.; Sy, P.H.; He, Y.X.; Meng, W.K.; Liu, H.Y.; Cheng, M.W. The Principle and Fast Drawing of Ternary Plots and Their Application in Sandstone Classification. Acta Sedimentol. Sin. 2022, 40, 1095–1108. [Google Scholar]

- SY/T 5735-2019; Geochemical Method for Source Rock Evaluation. National Energy Administratio: Beijing, China, 2019.

- GB/T 18023-2000; Classification of Macrolithotype for Bituminous Coal. The State Bureau of Quality and Technical Supervision: Beijing, China, 2000.

- Li, C.; Yang, Z.; Tian, W.; Peng, L.; Liu, L.; Liu, C.; Lu, B.; Liang, Y.; Gu, J. Accurate Prediction of the Macrolithotype of a High-Rank Coal Reservoir by Logging Interpretation: A Case Study of the Junlian Block, Sichuan Province. Chin. Nat. Resour. Res. 2023, 32, 2289–2311. [Google Scholar] [CrossRef]

| Mineral | Si | Al | Ca | Mg | K | Fe | S |

| Quartz | 0.467 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 |

| Calcite | 0.000 | 0.000 | 0.395 | 0.004 | 0.000 | 0.000 | 0.000 |

| Dolomite | 0.000 | 0.000 | 0.213 | 0.129 | 0.000 | 0.000 | 0.000 |

| Siderite | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.482 | 0.000 |

| Kaolinite | 0.210 | 0.204 | 0.001 | 0.001 | 0.001 | 0.008 | 0.000 |

| Illite | 0.249 | 0.105 | 0.012 | 0.012 | 0.045 | 0.048 | 0.000 |

| Montmorillonite | 0.264 | 0.091 | 0.013 | 0.020 | 0.006 | 0.020 | 0.000 |

| Pyrite | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.466 | 0.535 |

| Anhydrite | 0.000 | 0.000 | 0.294 | 0.000 | 0.000 | 0.000 | 0.240 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Y.; Zhang, W.; Lai, F.; Zhang, M.; Sun, H.; Zhou, Z.; Sun, J.; Wang, R.; Zheng, S. Lithology and Macroscopic Coal Lithotype Identification of Coal-Bearing Measures Based on Elemental Mud Logging: A Case Study of the Eastern Ordos Basin Coal Seam. Minerals 2025, 15, 616. https://doi.org/10.3390/min15060616

Liu Y, Zhang W, Lai F, Zhang M, Sun H, Zhou Z, Sun J, Wang R, Zheng S. Lithology and Macroscopic Coal Lithotype Identification of Coal-Bearing Measures Based on Elemental Mud Logging: A Case Study of the Eastern Ordos Basin Coal Seam. Minerals. 2025; 15(6):616. https://doi.org/10.3390/min15060616

Chicago/Turabian StyleLiu, Yuejiao, Wenya Zhang, Fuqiang Lai, Mingyang Zhang, Honghua Sun, Zongsheng Zhou, Jianmeng Sun, Ruyue Wang, and Shanshan Zheng. 2025. "Lithology and Macroscopic Coal Lithotype Identification of Coal-Bearing Measures Based on Elemental Mud Logging: A Case Study of the Eastern Ordos Basin Coal Seam" Minerals 15, no. 6: 616. https://doi.org/10.3390/min15060616

APA StyleLiu, Y., Zhang, W., Lai, F., Zhang, M., Sun, H., Zhou, Z., Sun, J., Wang, R., & Zheng, S. (2025). Lithology and Macroscopic Coal Lithotype Identification of Coal-Bearing Measures Based on Elemental Mud Logging: A Case Study of the Eastern Ordos Basin Coal Seam. Minerals, 15(6), 616. https://doi.org/10.3390/min15060616