Slag Substitution Effect on Features of Alkali-Free Accelerator-Reinforced Cemented Paste Backfill

Abstract

1. Introduction

2. Materials and Methods

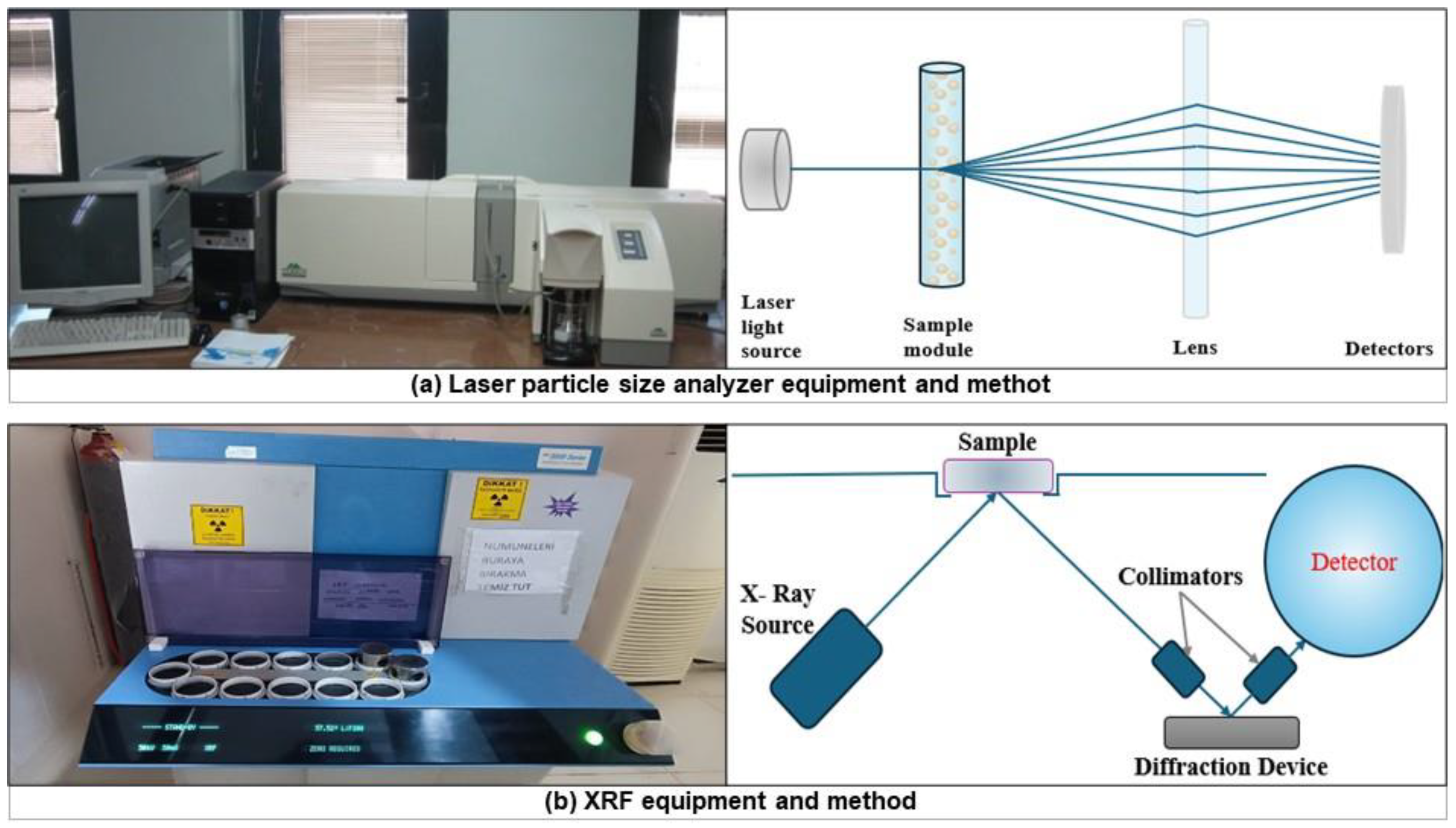

2.1. Materials

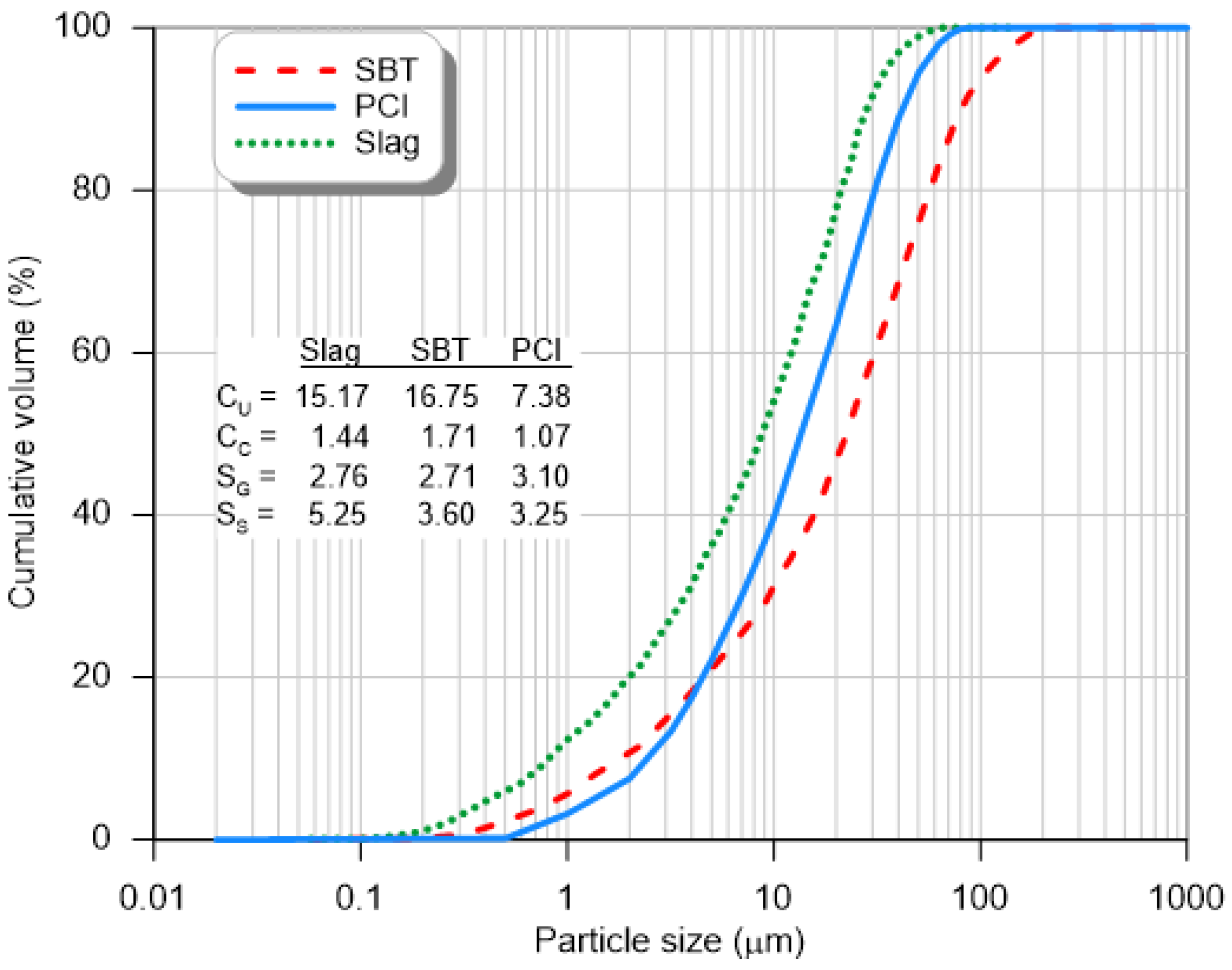

2.1.1. Hydraulic Binders

2.1.2. Tailing

2.1.3. Water and Accelerating Admixture

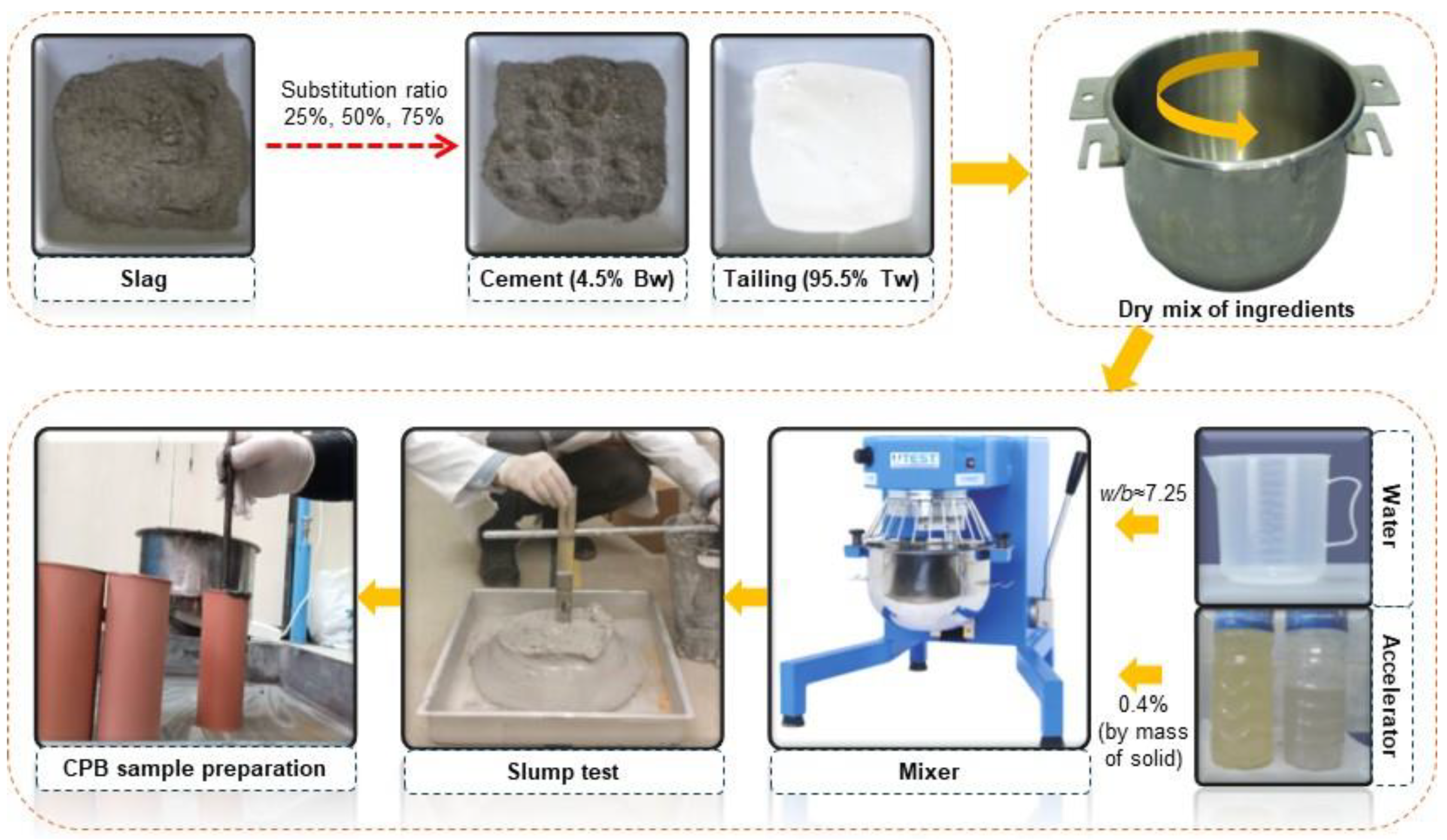

2.2. Sample Preparation

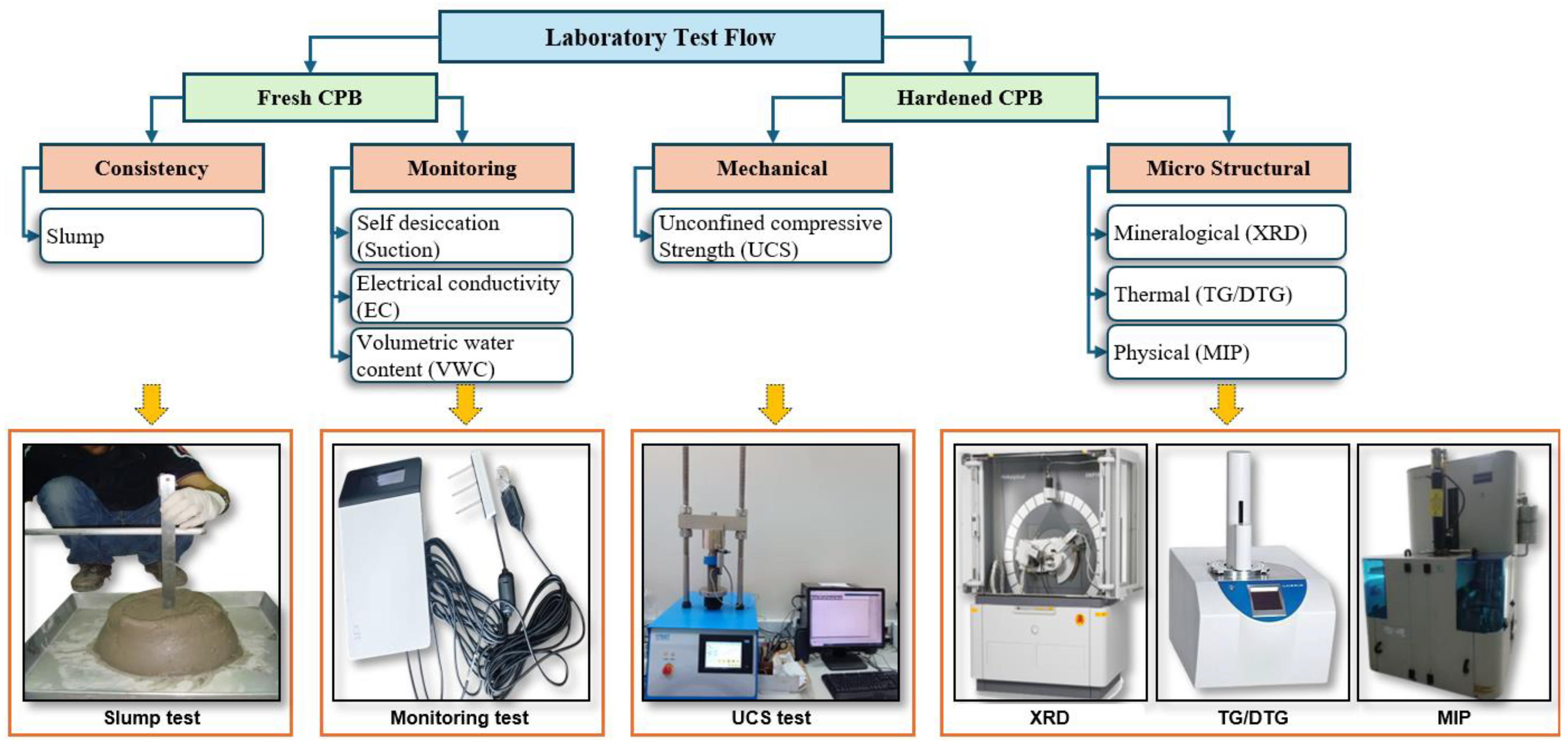

2.3. Testing and Property Monitoring

2.3.1. Slump Test

2.3.2. Monitoring Tests

2.3.3. Unconfined Compressive Strength Tests

2.3.4. Microstructural Analysis

3. Results and Discussion

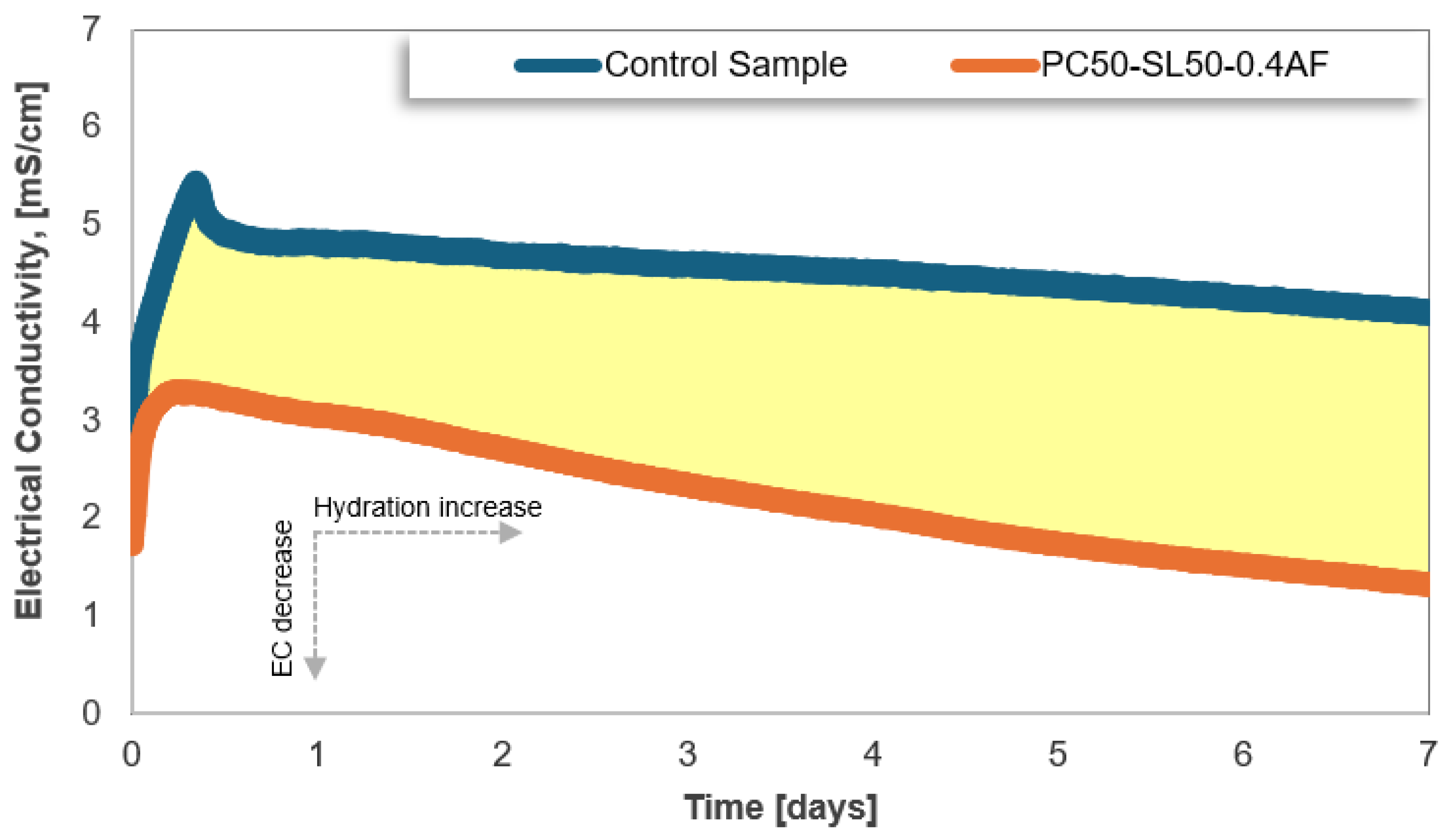

3.1. Influence of Slag Substitution and Addition of AF Accelerator on the Electrical Conductivity of CPB

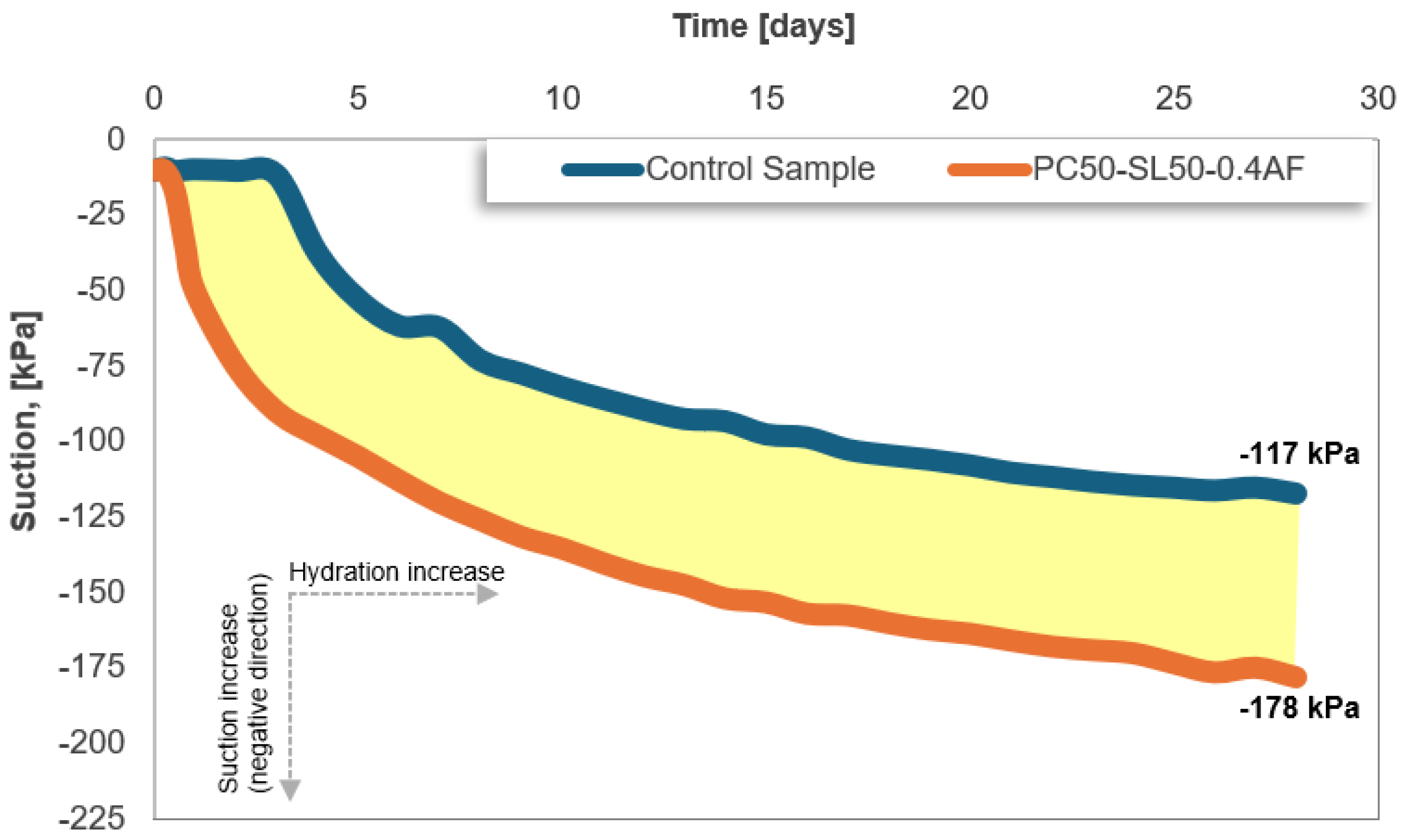

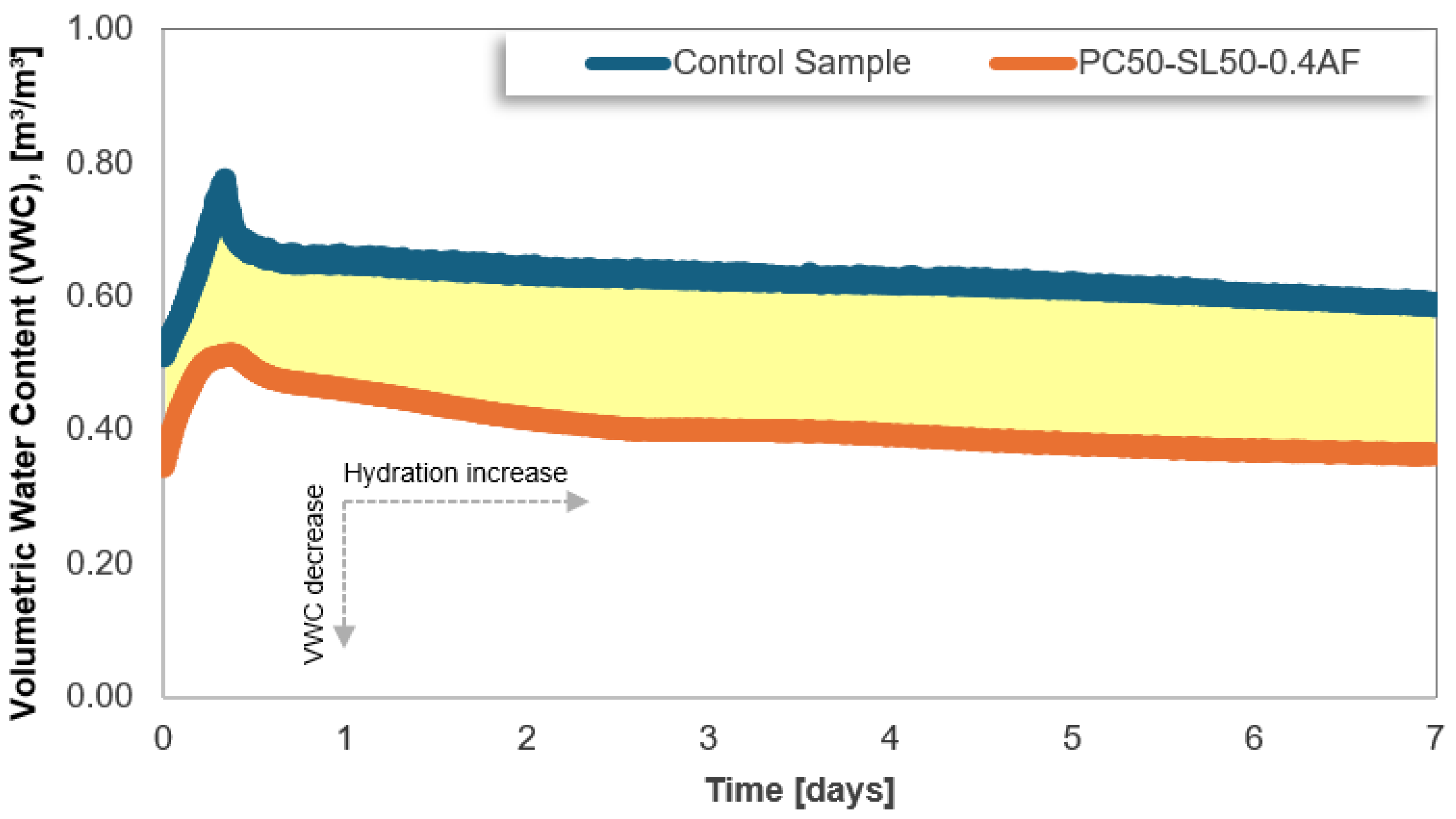

3.2. Influence of Slag Substitution and Addition of AF Accelerator on the Self-Desiccation of CPB

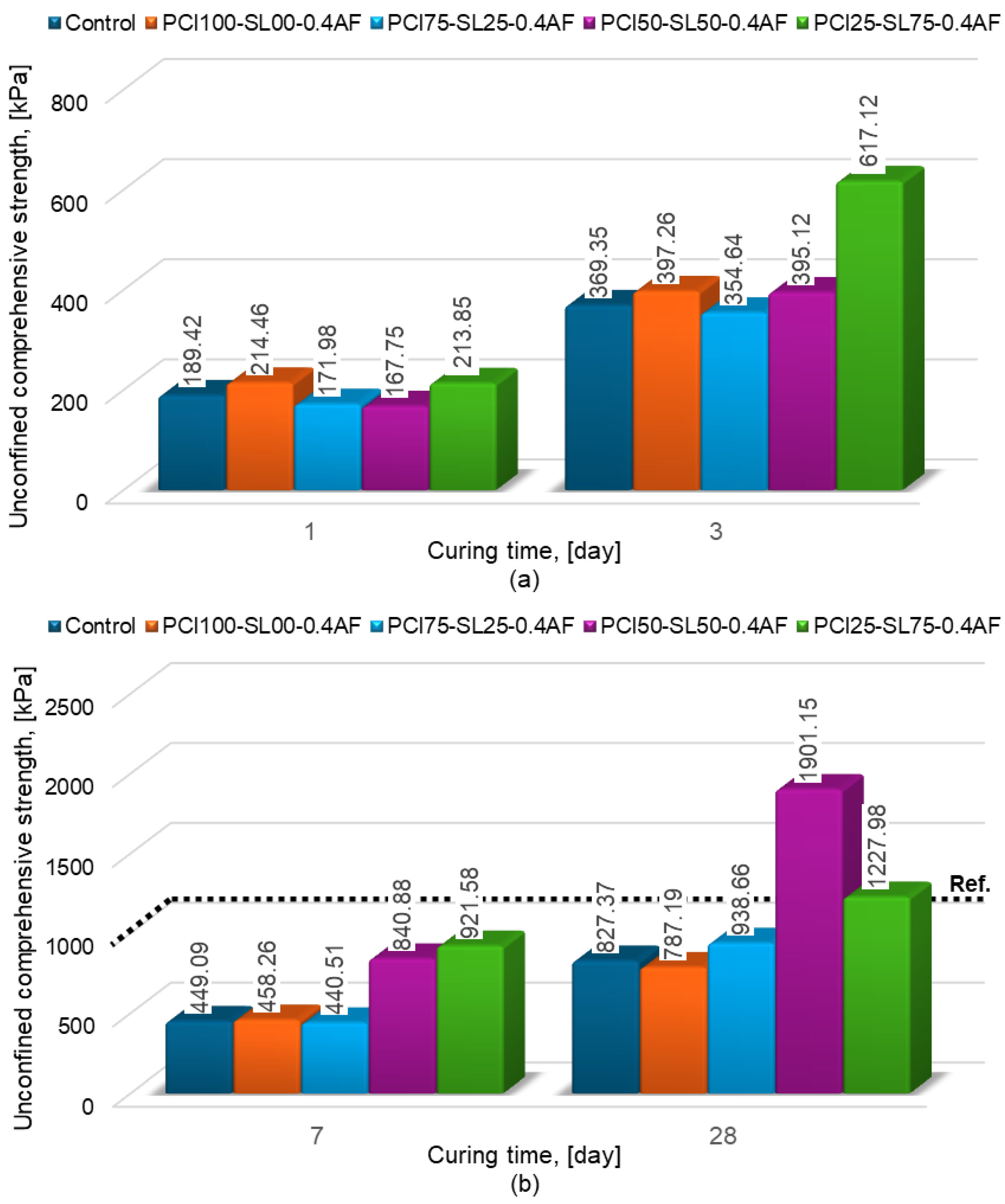

3.3. Influence of Slag Substitution and Addition of AF Accelerator on the Strength Development of CPB

3.4. Effect of Slag and AF Accelerator on the Microstructure of CPB

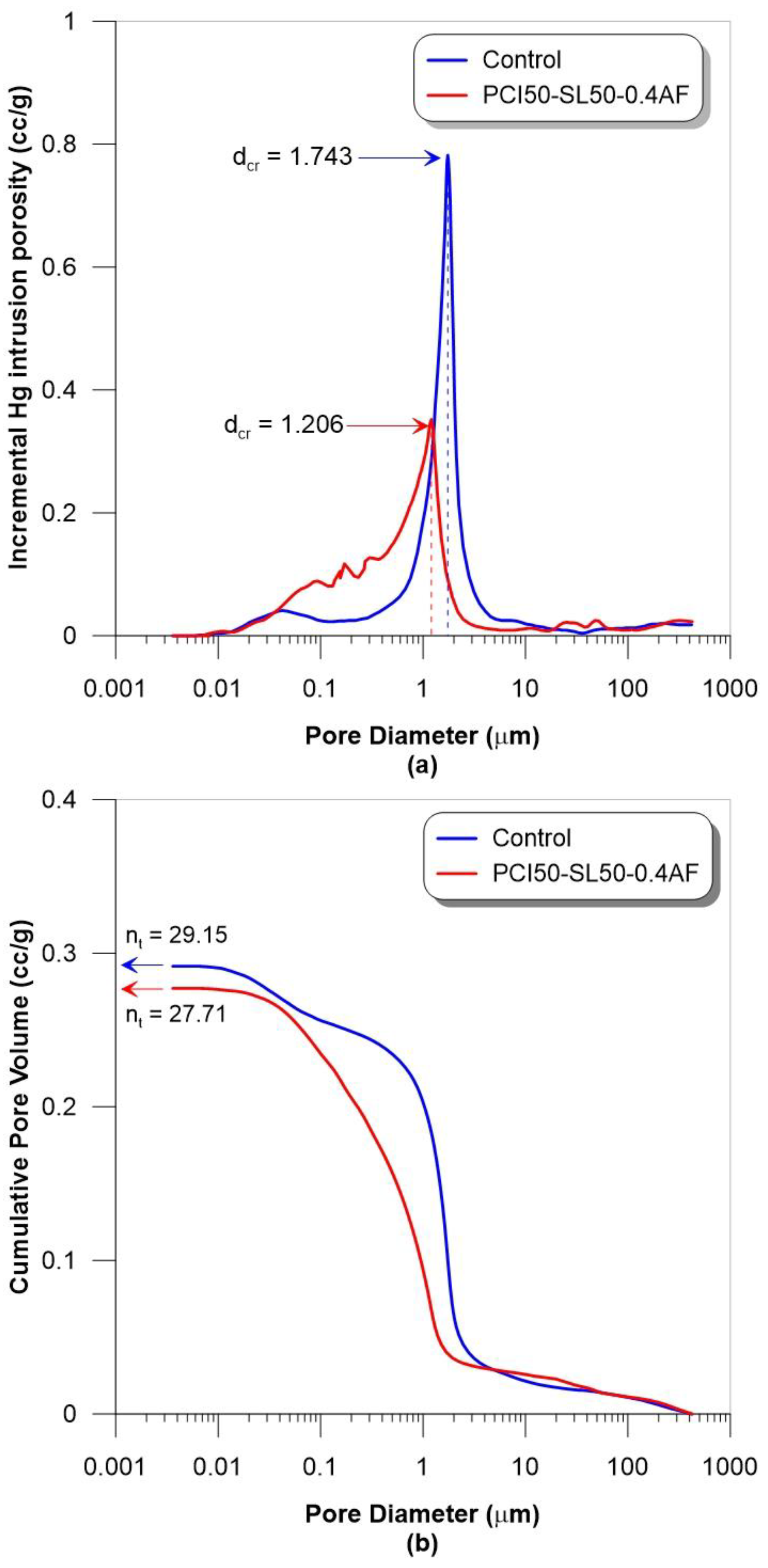

3.4.1. Effect on Pore Structure

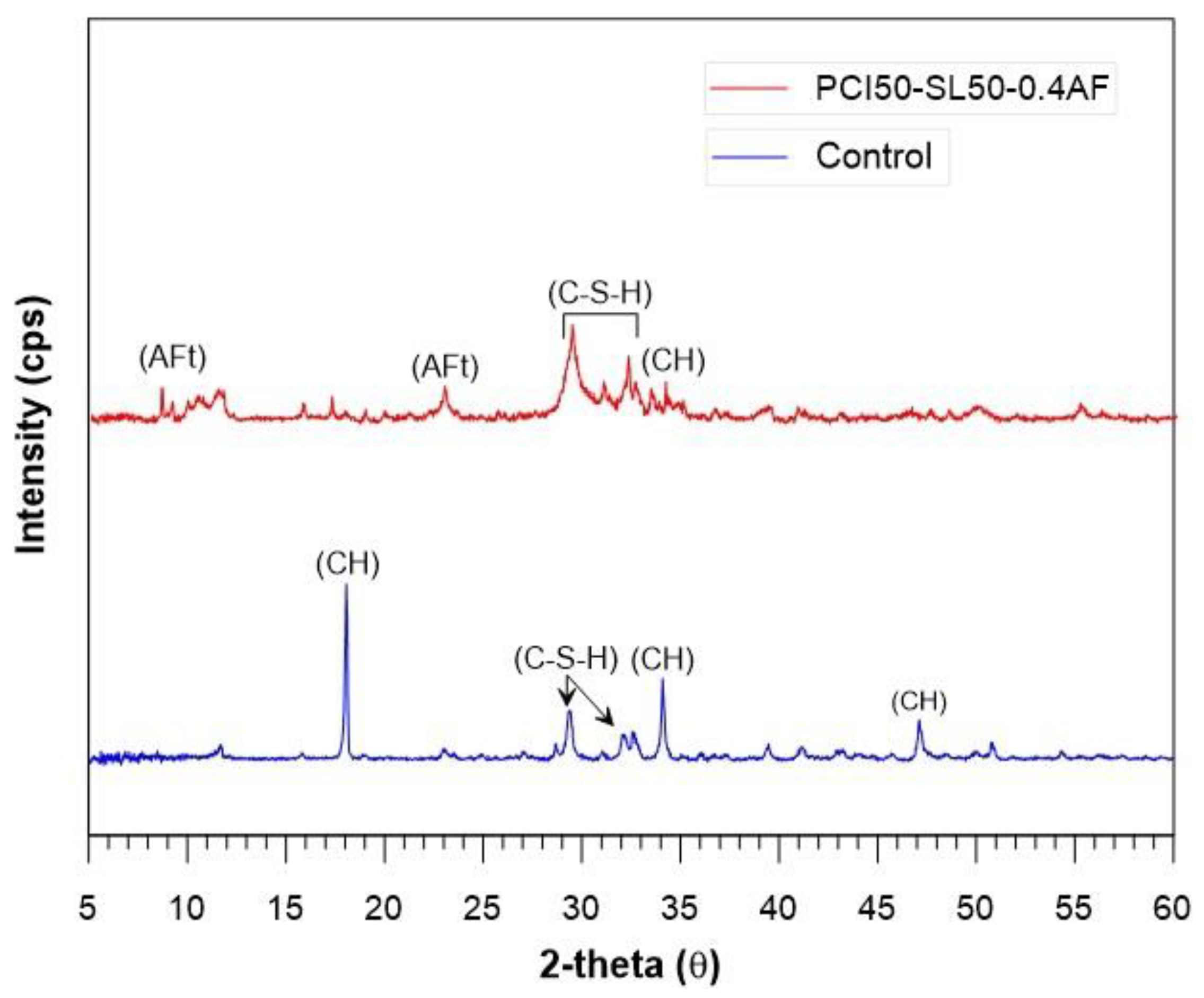

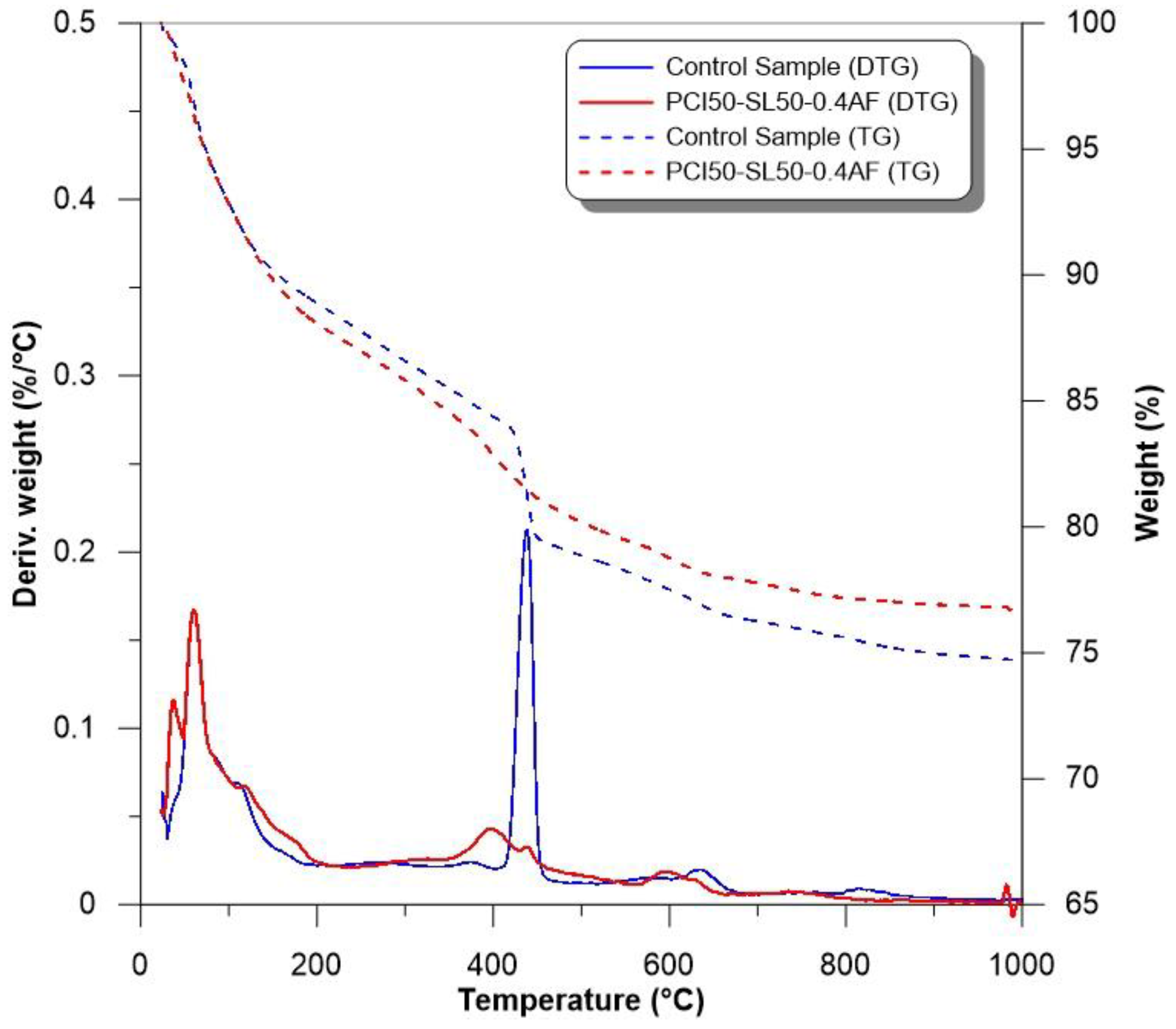

3.4.2. Effect on Hydration Products

4. Conclusions

- Replacing 50% of cement with slag and adding 0.4% AF accelerator shifted the EC peak 2 h earlier than the control sample and reduced the peak EC value from 5.45 mS/cm to 3.30 mS/cm. This indicates lower porosity and reduced ion mobility in the slag-reinforced mixture, which contributes to enhanced durability.

- The AF accelerator significantly accelerated hydration, as evidenced by a sharp decrease in suction values in slag-containing mixtures within 6–7 h compared to 3 days for the control. Lower volumetric water content (VWC) measurements in slag-containing mixtures further confirmed faster water consumption and hydration.

- For slag-free CPB, the AF accelerator improved early-age strength at 1 and 3 days but had minimal influence on the 28-day strength (827.37 kPa for control vs. 787.19 kPa for AF-containing mixtures). However, in slag-containing CPB, the combination of 50% slag and 0.4% AF accelerator dramatically enhanced 28-day strength, achieving 1901.15 kPa, which is 2.3 times higher than the control. This highlights the positive synergy between slag’s pozzolanic activity and AF accelerator in promoting hydration.

- MIP analysis revealed that the PCI50-SL50-0.4AF sample exhibited lower porosity and a finer pore structure compared to the control, contributing to a denser matrix and improved mechanical properties.

- XRD and TG/DTG analyses showed that slag and AF accelerator reduced portlandite content by promoting C-S-H gel formation and increased secondary hydration products such as carbonation compounds. These changes contributed to the long-term durability and stability of the CPB matrix.

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hamraoui, L.; Bergani, A.; Ettoumi, M.; Aboulaich, A.; Taha, Y.; Khalil, A.; Neculita, C.M.; Benzaazoua, M. Towards a Circular Economy in the Mining Industry: Possible Solutions for Water Recovery through Advanced Mineral Tailings Dewatering. Minerals 2024, 14, 319. [Google Scholar] [CrossRef]

- Su, Z.; Chen, Q.; Zhang, Q.; Zhang, D. Recycling Lead–Zinc Tailings for Cemented Paste Backfill and Stabilisation of Excessive Metal. Minerals 2019, 9, 710. [Google Scholar] [CrossRef]

- Niroshan, N.; Sivakugan, N.; Veenstrai, R.L. Laboratory Study on Strength Development in Cemented Paste Backfills. J. Mater. Civ. Eng. 2017, 29, 04017027. [Google Scholar] [CrossRef]

- Ajaka, O.E.; Ilunga, O.K.; Omotehinse, O.A. Determining the optimum compressive strength of cemented paste backfill for artificial ground support in underground mines. J. Geol. Min. Res. 2021, 13, 31–41. [Google Scholar] [CrossRef]

- Liu, S.; Fall, M. Fresh and hardened properties of cemented paste backfill: Links to mixing time. Constr. Build. Mater. 2022, 324, 126688. [Google Scholar] [CrossRef]

- Deb, D.; Sreenivas, T.; Dey, G.K.; Panchal, S. Paste Backfill Technology: Essential Characteristics and Assessment of its Application for Mill Rejects of Uranium Ores. Trans. Indian Inst. Met. 2017, 70, 487–495. [Google Scholar] [CrossRef]

- Hassani, F.P.; Mortazavi, A.; Shabani, M. Investigations of mechanics involved in backfill-rock mass behavior in narrow vein mining. J. S. Afr. Inst. Min. Metall. 2008, 108, 463–471. [Google Scholar]

- Yilmaz, E.; Guresci, M. Design and Characterization of Underground Paste Backfill. In Paste Tailings Management, 1st ed; Yilmaz, E., Fall, M., Eds.; Springer International Publishing: Cham, Switzerland, 2017; pp. 111–143. [Google Scholar] [CrossRef]

- Yilmaz, E.; Belem, T.; Benzaazoua, M. Effects of curing and stress conditions on hydromechanical, geotechnical and geochemical properties of cemented paste backfill. Eng. Geol. 2014, 168, 23–37. [Google Scholar] [CrossRef]

- Jiang, H.; Han, J.; Li, Y.; Yilmaz, E.; Sun, Q.; Liu, J. Relationship between ultrasonic pulse velocity and uniaxial compressive strength for cemented paste backfill with alkali-activated slag. Nondestruct. Test. Eval. 2019, 35, 359–377. [Google Scholar] [CrossRef]

- Yilmaz, E. Stope depth effect on field behaviour and performance of cemented paste backfills. Int. J. Min. Reclam. Environ. 2017, 32, 273–296. [Google Scholar] [CrossRef]

- Meng, J.; Fall, M.; Pour, H.M. Deeper Understanding of the Strength Evolution and Deformation Characteristics of Sodium Silicate–Cemented Paste Tailing Material. Minerals 2023, 13, 1382. [Google Scholar] [CrossRef]

- Cao, S.; Xue, G.; Yilmaz, E.; Yin, Z. Assessment of rheological and sedimentation characteristics of fresh cemented tailings backfill slurry. Int. J. Min. Reclam. Environ. 2021, 35, 319–335. [Google Scholar] [CrossRef]

- Xiao, B.; Wen, Z.; Miao, S.; Gao, Q. Utilization of steel slag for cemented tailings backfill: Hydration, strength, pore structure, and cost analysis. Case Stud. Constr. Mater. 2021, 15, e00621. [Google Scholar] [CrossRef]

- Jiang, H.; Qi, Z.; Yilmaz, E.; Han, J.; Qiu, J.; Dong, C. Effectiveness of alkali-activated slag as alternative binder on workability and early age compressive strength of cemented paste backfills. Constr. Build. Mater. 2019, 218, 689–700. [Google Scholar] [CrossRef]

- Akkaya, U.G.; Cinku, K.; Yilmaz, E. Characterization of strength and quality of cemented mine backfill made up of lead-zinc processing tailings. Front. Mater. 2021, 8, 740116. [Google Scholar] [CrossRef]

- Qiu, J.; Zhao, Y.; Xing, J.; Sun, X. Fly ash/blast furnace slag-based geopolymer as a potential binder for mine backfilling: Effect of binder type and activator concentration. Adv. Mater. Sci. Eng. 2019, 2028109. [Google Scholar] [CrossRef]

- Nidheesh, P.; Kumar, M.S. An overview of environmental sustainability in cement and steel production. J. Clean. Prod. 2019, 231, 856–871. [Google Scholar] [CrossRef]

- Dong, Q.; Liang, B.; Jia, L.; Jiang, L. Effect of sulfide on the long-term strength of lead-zinc tailings cemented paste backfill. Constr. Build. Mater. 2019, 200, 436–446. [Google Scholar] [CrossRef]

- Wang, Y.; Cao, Y.; Cui, L.; Si, Z.; Wang, H. Effect of external sulfate attack on the mechanical behavior of cemented paste backfill. Constr. Build. Mater. 2020, 263, 120968. [Google Scholar] [CrossRef]

- Li, J.J.; Cao, S.; Yilmaz, E.; Liu, Y.P. Compressive fatigue behavior and failure evolution of additive fiber-reinforced cemented tailings composites. Int. J. Miner. Metall. Mater. 2022, 29, 345–355. [Google Scholar] [CrossRef]

- Koohestani, B.; Darban, A.K.; Darezereshki, E.; Mokhtari, P.; Yilmaz, E.; Yilmaz, E. The influence of sodium and sulfate ions on total solidification and encapsulation potential of iron-rich acid mine drainage in silica gel. J. Environ. Chem. Eng. 2018, 6, 3520–3527. [Google Scholar] [CrossRef]

- Sari, M.; Yilmaz, E.; Kasap, T.; Guner, N.U. Strength and microstructure evolution in cemented mine backfill with low and high pH pyritic tailings: Effect of mineral admixtures. Constr. Build. Mater. 2022, 328, 127109. [Google Scholar] [CrossRef]

- Ercikdi, B.; Cihangir, F.; Kesimal, A.; Deveci, H.; Alp, İ. Utilization of industrial waste products as pozzolanic material in cemented paste backfill of high sulphide mill tailings. J. Hazard. Mater. 2009, 168, 848–856. [Google Scholar] [CrossRef]

- Liu, H.; Zhang, J.; Li, B.; Zhou, N.; Xiao, X.; Li, M.; Zhu, C. Environmental behavior of construction and demolition waste as recycled aggregates for backfilling in mines: Leaching toxicity and surface subsidence studies. J. Hazard. Mater. 2020, 389, 121870. [Google Scholar] [CrossRef]

- Behera, S.K.; Mishra, D.P.; Singh, P.; Mishra, K.; Mandal, S.K.; Ghosh, C.N.; Kumar, R.; Mandal, P.K. Utilization of mill tailings, fly ash and slag as mine paste backfill material: Review and future perspective. Constr. Build. Mater. 2021, 309, 125120. [Google Scholar] [CrossRef]

- Kou, Y.; Jiang, H.; Ren, L.; Yilmaz, E.; Li, Y. Rheological Properties of Cemented Paste Backfill with Alkali-Activated Slag. Minerals. 2020, 10, 288. [Google Scholar] [CrossRef]

- Zhang, S.; Yang, L.; Ren, F.; Qiu, J.; Ding, H. Rheological and mechanical properties of cemented foam backfill: Effect of mineral admixture type and dosage. Cem. Concr. Compos. 2020, 112, 103689. [Google Scholar] [CrossRef]

- Li, W.; Fall, M. Strength and self-desiccation of slag-cemented paste backfill at early ages: Link to initial sulphate concentration. Cem. Concr. Compos. 2018, 89, 160–168. [Google Scholar] [CrossRef]

- Cihangir, F.; Ercikdi, B.; Kesimal, A.; Ocak, S.; Akyol, Y. Effect of Sodium-Silicate Activated Slag at Different Silicate Modulus on the Strength and Microstructural Properties of Full and Coarse Sulphidic Tailings Paste Backfill. Constr. Build. Mater. 2018, 185, 555–566. [Google Scholar] [CrossRef]

- Zhao, Y.; Taheri, A.; Karakus, M.; Chen, Z.; Deng, A. Effects of water content, water type and temperature on the rheological behaviour of slag-cement and fly ash-cement paste backfill. Int. J. Min. Sci. Technol. 2020, 30, 271–278. [Google Scholar] [CrossRef]

- He, Y.; Zhang, Q.; Chen, Q.; Bian, J.; Qi, C.; Kang, Q.; Feng, Y. Mechanical and environmental characteristics of cemented paste backfill containing lithium slag-blended binder. Constr. Build. Mater. 2021, 271, 121567. [Google Scholar] [CrossRef]

- El-Wafa, M.A.; Fukuzawa, K. Optimization of alkali-activated municipal slag composite performance by substituting varying ratios of fly ash for fine aggregate. Materials 2021, 14, 6299. [Google Scholar] [CrossRef] [PubMed]

- Nasir, O.; Fall, M. Shear behaviour of cemented pastefill-rock interfaces. Eng. Geol. 2008, 101, 146–153. [Google Scholar] [CrossRef]

- Fall, M.; Pokharel, M. Coupled effects of sulphate and temperature on the strength development of cemented tailings backfills: Portland cement-paste backfill. Cem. Concr. Compos. 2010, 32, 819–828. [Google Scholar] [CrossRef]

- Cavusoglu, I.; Yilmaz, E.; Yilmaz, A.O. Sodium silicate effect on setting properties, strength behavior and microstructure of cemented coal fly ash backfill. Powder Technol. 2021, 384, 17–28. [Google Scholar] [CrossRef]

- Cavusoglu, I. Potential Use of Flyash as a Backfill Material: A Case Study (Çayırhan). Sci. Min. J. 2008, 47, 3–13. [Google Scholar]

- Kermani, M.; Hassani, F.P.; Aflaki, E.; Benzaazoua, M.; Nokken, M. Evaluation of the effect of sodium silicate addition to mine backfill, Gelfill—Part 1. J. Rock Mech. Geotech. Eng. 2015, 7, 266–272. [Google Scholar] [CrossRef]

- Kermani, M.; Hassani, F.P.; Aflaki, E.; Benzaazoua, M.; Nokken, M. Evaluation of the effect of sodium silicate addition to mine backfill, Gelfill—Part 2: Effects of mixing time and curing temperature. J. Rock Mech. Geotech. Eng. 2015, 7, 668–673. [Google Scholar] [CrossRef]

- Abdul-Hussain, N.; Fall, M. Unsaturated hydraulic properties of cemented tailings backfill that contains sodium silicate. Eng. Geol. 2011, 123, 288–301. [Google Scholar] [CrossRef]

- Wang, Y.; Fall, M.; Wu, A. Initial temperature-dependence of strength development and self-desiccation in cemented paste backfill that contains sodium silicate. Cem. Concr. Compos. 2016, 67, 101–110. [Google Scholar] [CrossRef]

- Abdul-Hussain, N.; Fall, M. Thermo-hydro-mechanical behaviour of sodium silicate-cemented paste tailings in column experiments. Tunn. Undergr. Space Technol. 2012, 29, 85–93. [Google Scholar] [CrossRef]

- ASTM C143/C143M; Standard Test Method for Slump of Hydraulic-Cement Concrete. ASTM International: West Conshohocken, PA, USA, 2015.

- ASTM C39; Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. ASTM International: West Conshohocken, PA, USA, 2016.

- Rajabipour, F.; Weiss, J. Electrical conductivity of drying cement paste. Mater. Struct. 2007, 40, 1143–1160. [Google Scholar] [CrossRef]

- Liang, K.; Zeng, X.; Zhou, X.; Qu, F.; Wang, P. A new model for the electrical conductivity of cement-based material by considering pore size distribution. Mag. Concr. Res. 2017, 69, 1067–1078. [Google Scholar] [CrossRef]

- Topu, I.B.; Uygunoğlu, T.; Hocaoğlu, I. Electrical conductivity of setting cement paste with different mineral admixtures. Constr. Build. Mater. 2012, 28, 414–420. [Google Scholar] [CrossRef]

- Ali, G.; Fall, M.; Alainachi, I. Time-and temperature-dependence of rheological properties of cemented tailings backfill with sodium silicate. J. Mater. Civ. Eng. 2021, 33, 04020498. [Google Scholar] [CrossRef]

- Cavusoglu, I.; Fall, M. Engineering properties of cemented paste backfill with full-range water-reducing admixture. Int. J. Civ. Eng. 2023, 21, 1567–1582. [Google Scholar] [CrossRef]

- Xiao, B.; Fall, M.; Roshani, A. Towards Understanding the Rheological Properties of Slag-Cemented Paste Backfill. Int. J. Min. Reclam. Environ. 2020, 35, 268–290. [Google Scholar] [CrossRef]

- Rhoades, J.D.; Raats, P.A.C.; Prather, R.J. Effects of liquid-phase electrical conductivity, water content, and surface conductivity on bulk soil electrical conductivity. Soil Sci. Soc. Am. J. 1976, 40, 651–655. [Google Scholar] [CrossRef]

- Li, W.; Fall, M. Sulphate effect on the early age strength and self-desiccation of cemented paste backfill. Constr. Build. Mater. 2016, 106, 296–304. [Google Scholar] [CrossRef]

- Wan, Z.; He, T.; Zheng, B.; Qu, Q.; Qiu, H.; Xue, R.; Xie, X. Influence of fly ash and granulated blast furnace slag on autogenous shrinkage and drying shrinkage of cement-based materials mixed with alkali accelerator and alkali-free accelerator. Dry. Technol. 2024, 42, 2137–2154. [Google Scholar] [CrossRef]

- Klein, K.; Simon, D. Effect of specimen composition on the strength development in cemented paste backfill. Can. Geotech. J. 2006, 43, 310–324. [Google Scholar] [CrossRef]

- Zhang, G.; Li, K.; Like, L.; Huawei, S.; Chen, C.; Yuan, C. Influence Mechanism of Accelerator on the Hydration and Microstructural Properties of Portland Cement. Buildings 2024, 14, 3201. [Google Scholar] [CrossRef]

- Wang, W.; Zeng, L.; Du, S.; Qiao, M.; Chen, J.; Zhu, B. The Influence of Alkali-Free Shotcrete Accelerators on Early Age Hydration and Property Development within Cement Systems. Materials 2022, 15, 6907. [Google Scholar] [CrossRef]

- Li, G.; Zhang, J.; Niu, M.; Song, Z. The mechanism of alkali-free liquid accelerator on the hydration of cement pastes. Constr. Build. Mater. 2020, 233, 117296. [Google Scholar] [CrossRef]

- Salvador, R.P.; Cavalaro, S.H.P.; Segura, I.; Figueiredo, A.D.; Pérez, J. Early age hydration of cement pastes with alkaline and alkali-free accelerators for sprayed concrete. Constr. Build. Mater. 2016, 111, 386–398. [Google Scholar]

| Element | PCI (%) | Slag (%) |

|---|---|---|

| SiO2 | 19.02 | 34.32 |

| Al2O3 | 4.64 | 9.54 |

| Fe2O3 | 3.09 | - |

| CaO | 62.98 | 40.84 |

| MgO | 2.89 | 9.79 |

| SO3 | 3.03 | 3.91 |

| Element | SBTs (%) |

|---|---|

| SiO2 | 99.8 |

| Al2O3 | 0.05 |

| Fe2O3 | 0.035 |

| K2O | 0.02 |

| TiO2 | 0.02 |

| CaO | <0.01 |

| MgO | <0.01 |

| Na2O | <0.01 |

| Form | Density at 20 °C | pH (1:1 Water Solution) | Viscosity | Chloride Content | Na2Oe, by Mass |

|---|---|---|---|---|---|

| Suspension | 1.47 ± 0.30 kg/L | 2.7 ± 0.5 | 750 ± 250 mPa.s | <0.1% | <1% |

| Mix Name | Admixture Content | Binder Content | Slag Content | Solid Content | Water/Binder Ratio | Slump |

|---|---|---|---|---|---|---|

| (wt. %) | (wt. %) | (wt. %) | (wt. %) | (w/b) | (cm) | |

| Control | - | 4.5 | 0 | 76.22 | 7.25 | ≈20 |

| PCI100-SL00-0.4AF | 0.4 | 4.5 | 0 | 75.98 | 7.25 | ≈20 |

| PCI75-SL25-0.4AF | 0.4 | 4.5 | 25 | 75.98 | 7.25 | ≈20 |

| PCI50-SL50-0.4AF | 0.4 | 4.5 | 50 | 75.98 | 7.25 | ≈20 |

| PCI25-SL75-0.4AF | 0.4 | 4.5 | 75 | 75.98 | 7.25 | ≈20 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cavusoglu, I. Slag Substitution Effect on Features of Alkali-Free Accelerator-Reinforced Cemented Paste Backfill. Minerals 2025, 15, 135. https://doi.org/10.3390/min15020135

Cavusoglu I. Slag Substitution Effect on Features of Alkali-Free Accelerator-Reinforced Cemented Paste Backfill. Minerals. 2025; 15(2):135. https://doi.org/10.3390/min15020135

Chicago/Turabian StyleCavusoglu, Ibrahim. 2025. "Slag Substitution Effect on Features of Alkali-Free Accelerator-Reinforced Cemented Paste Backfill" Minerals 15, no. 2: 135. https://doi.org/10.3390/min15020135

APA StyleCavusoglu, I. (2025). Slag Substitution Effect on Features of Alkali-Free Accelerator-Reinforced Cemented Paste Backfill. Minerals, 15(2), 135. https://doi.org/10.3390/min15020135