Arsenic (III) Removal from a High-Concentration Arsenic (III) Solution by Forming Ferric Arsenite on Red Mud Surface

Abstract

1. Introduction

2. Materials and Methods

2.1. Experiment Material

2.2. Arsenic Removal Tests

2.3. Settling Performance Test

2.4. Analytical Techniques

3. Results and Discussion

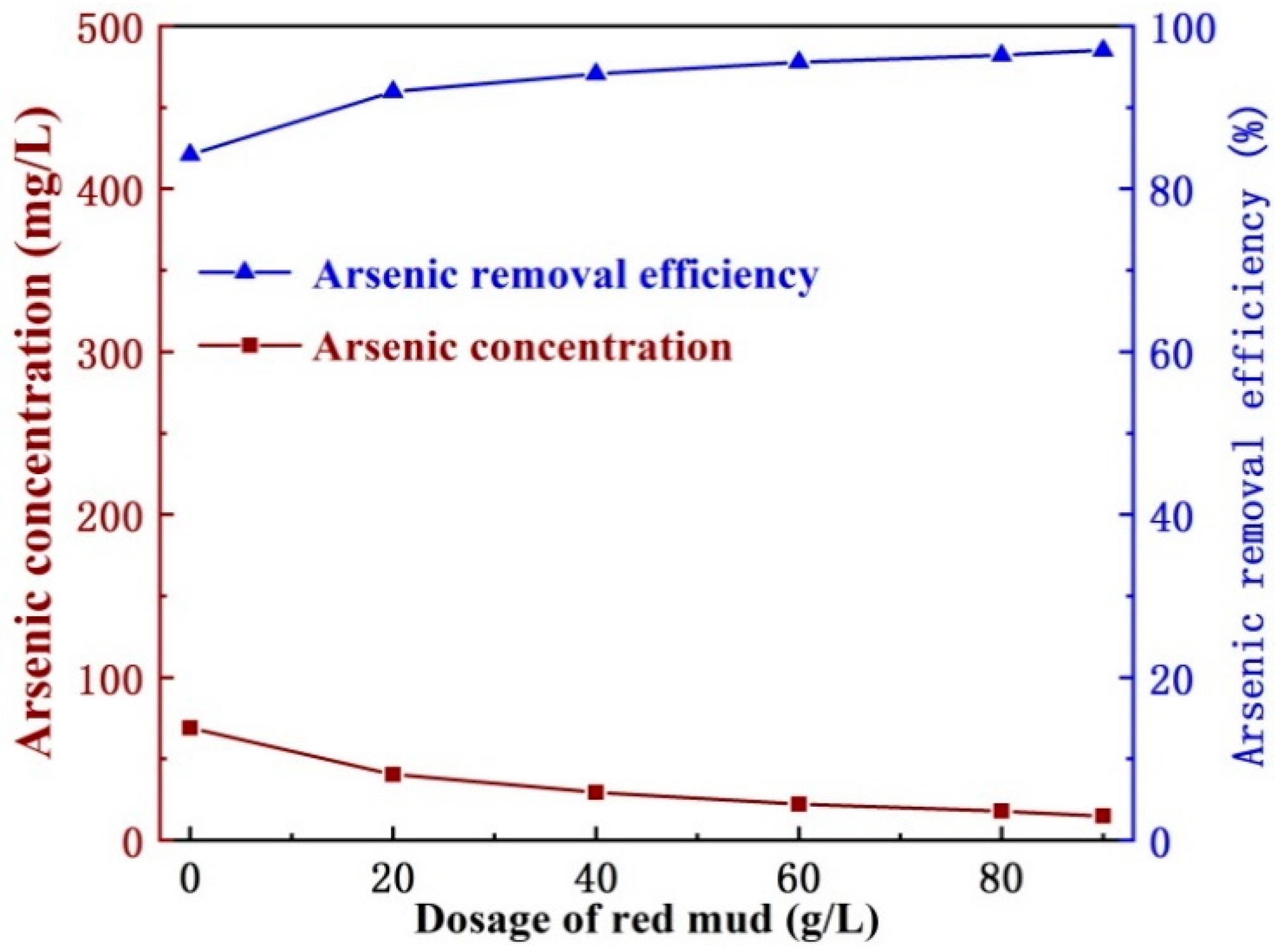

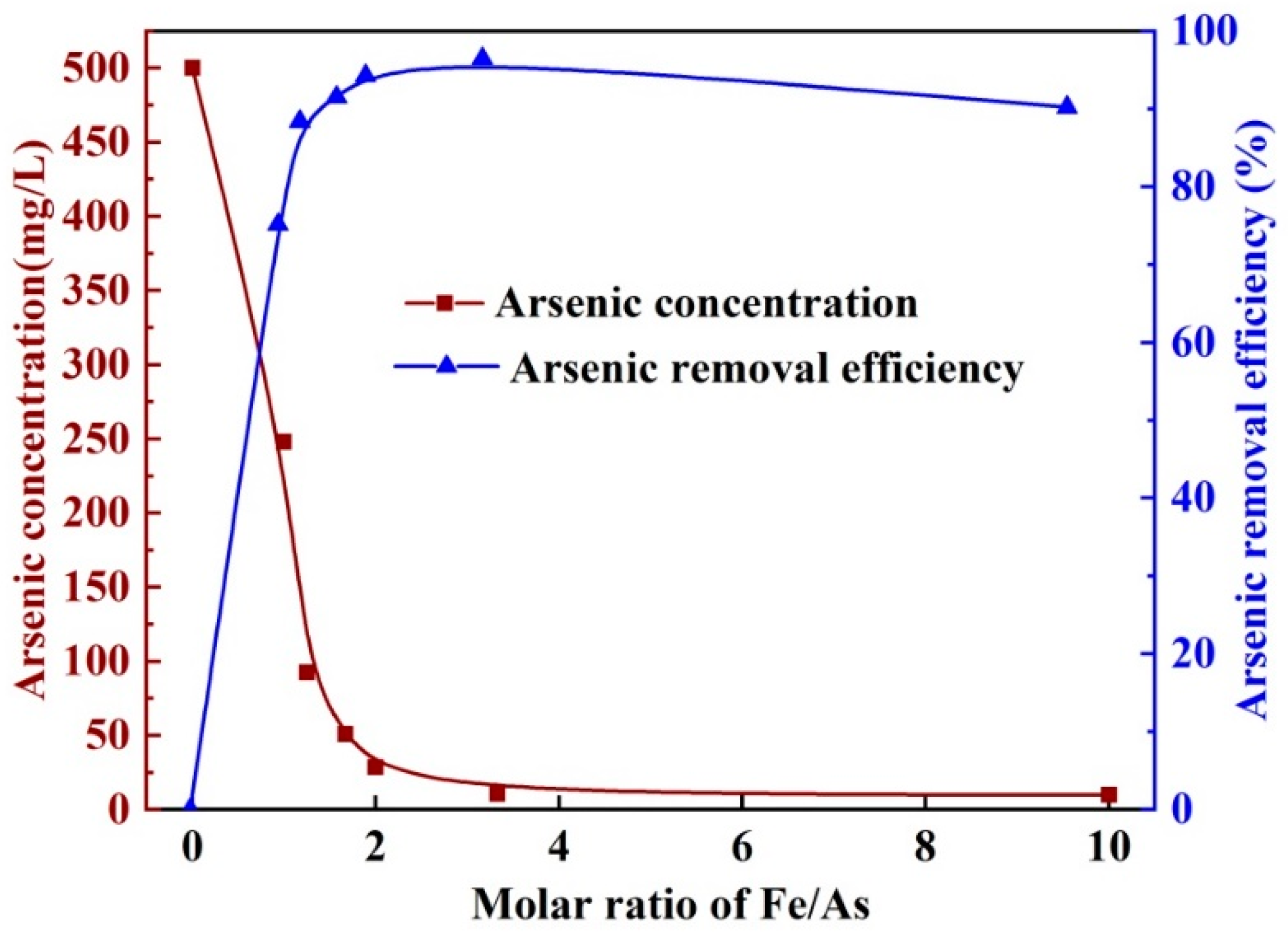

3.1. Arsenic Removal Experiments

3.2. Sedimentation Performance

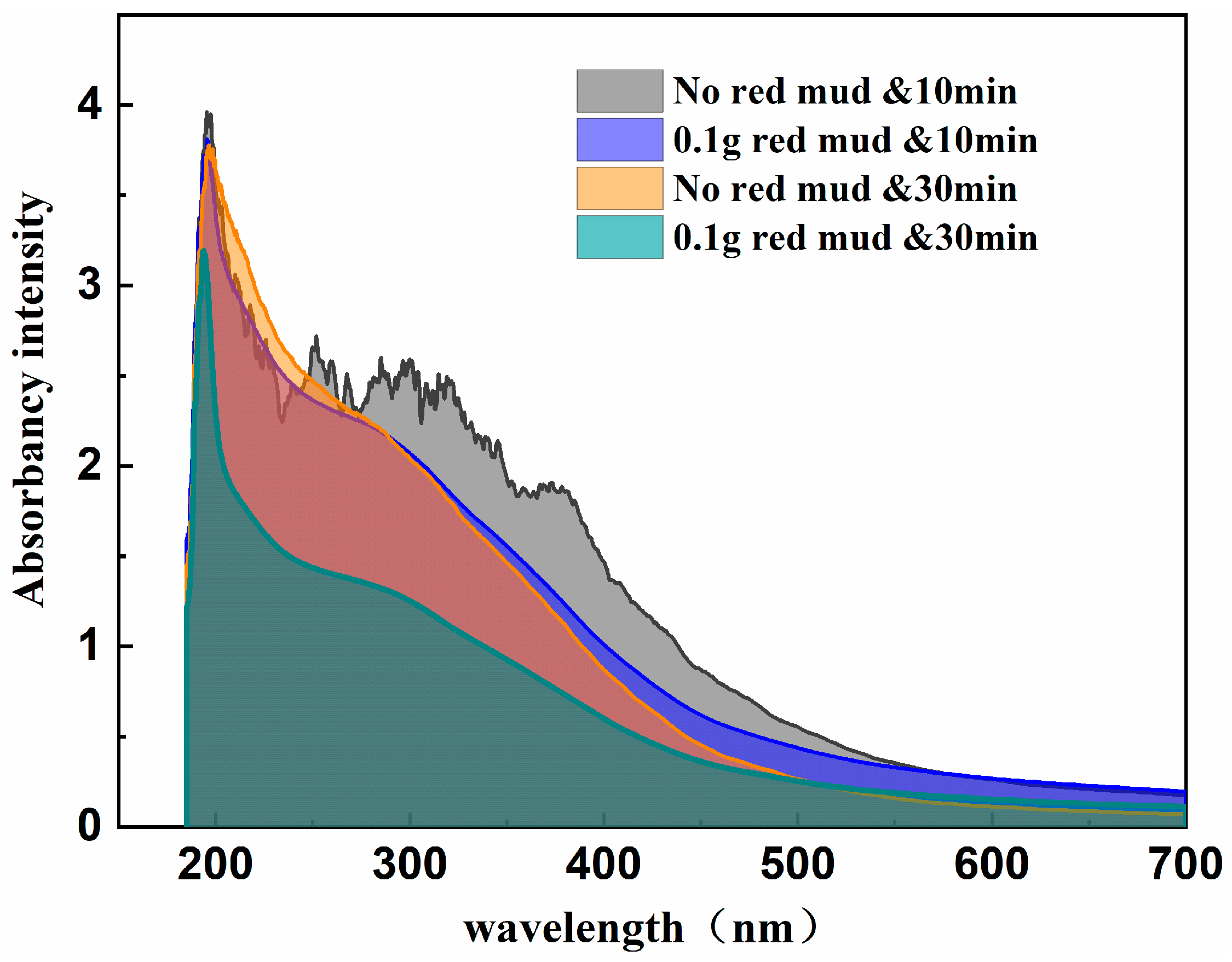

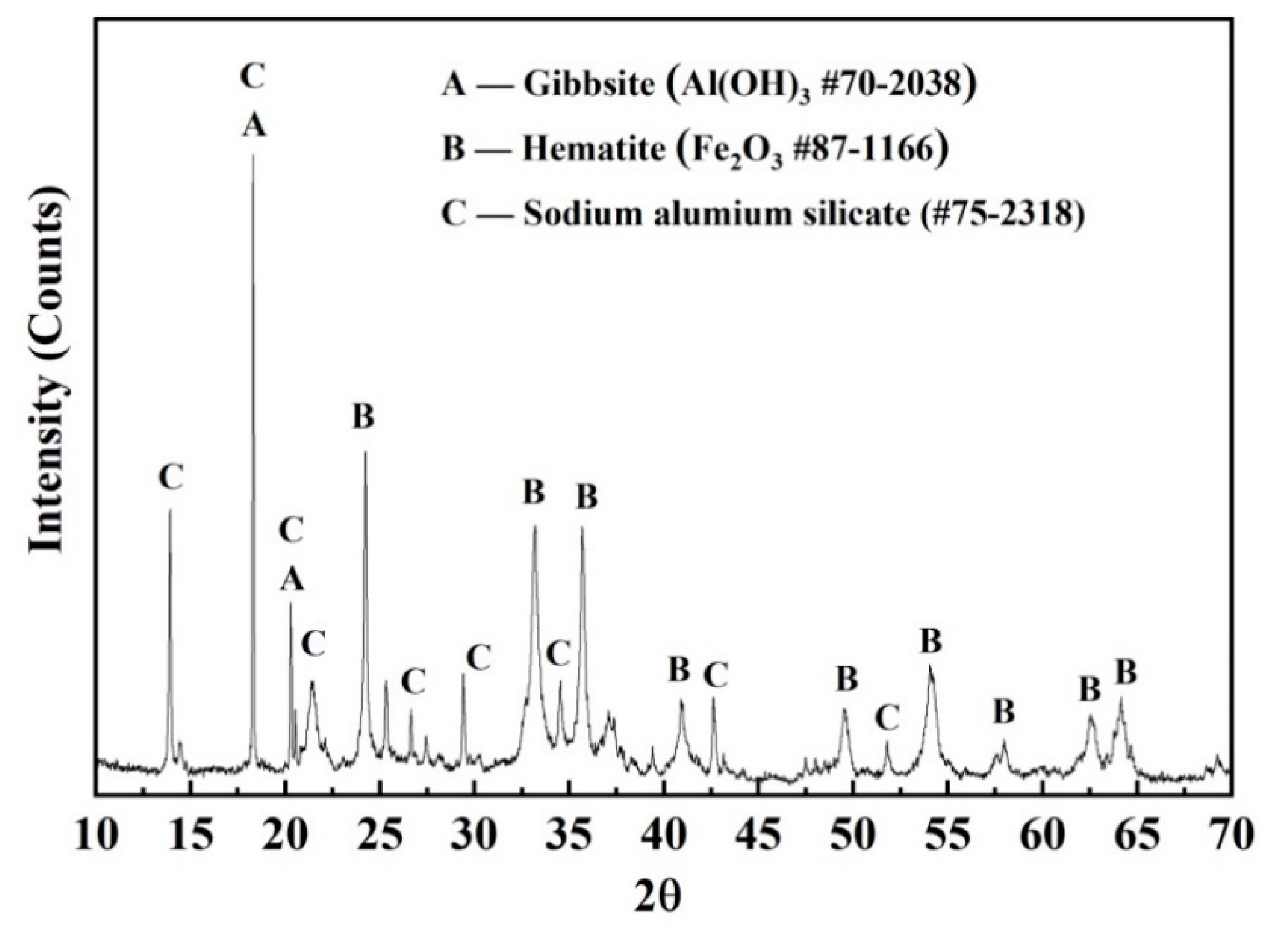

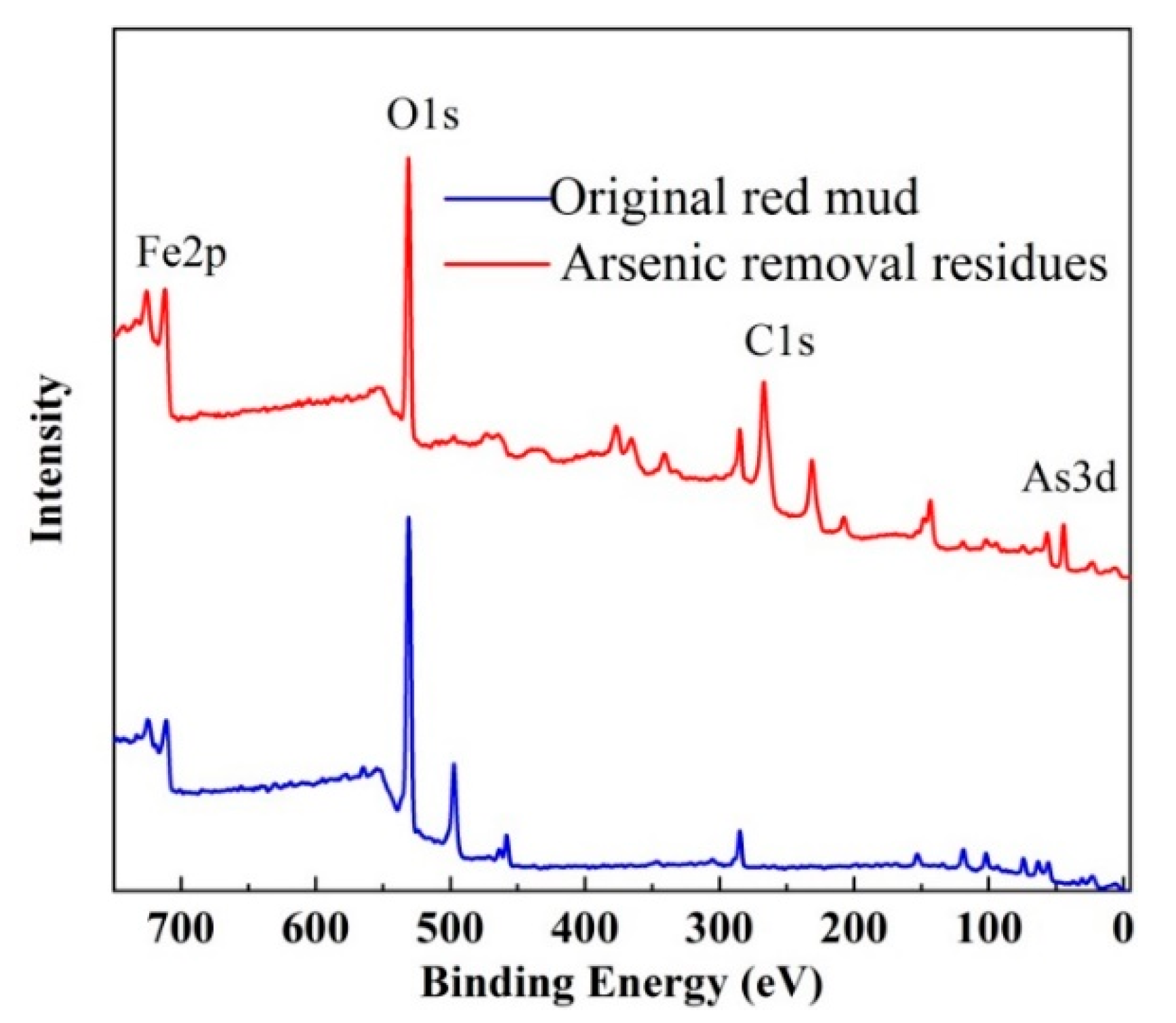

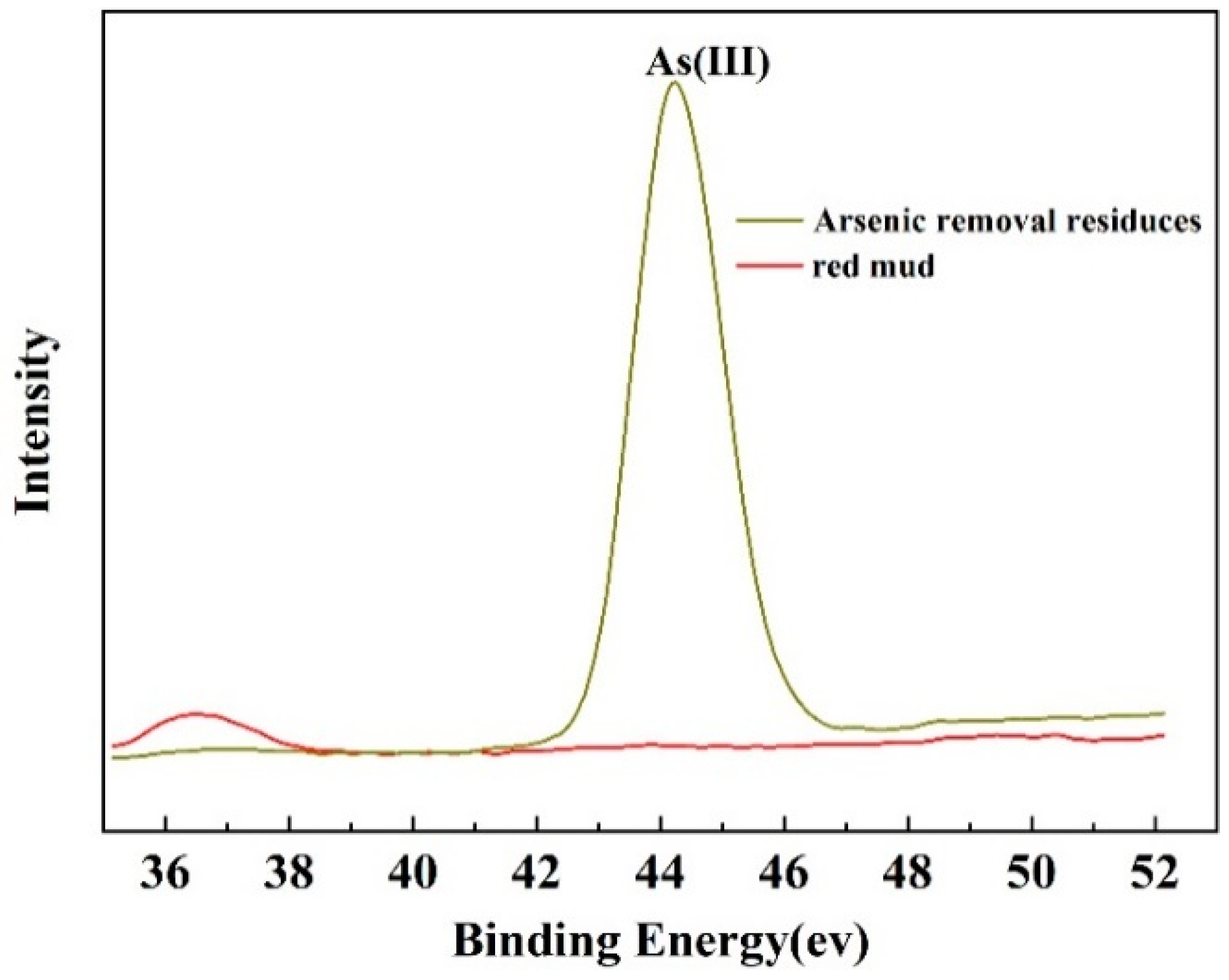

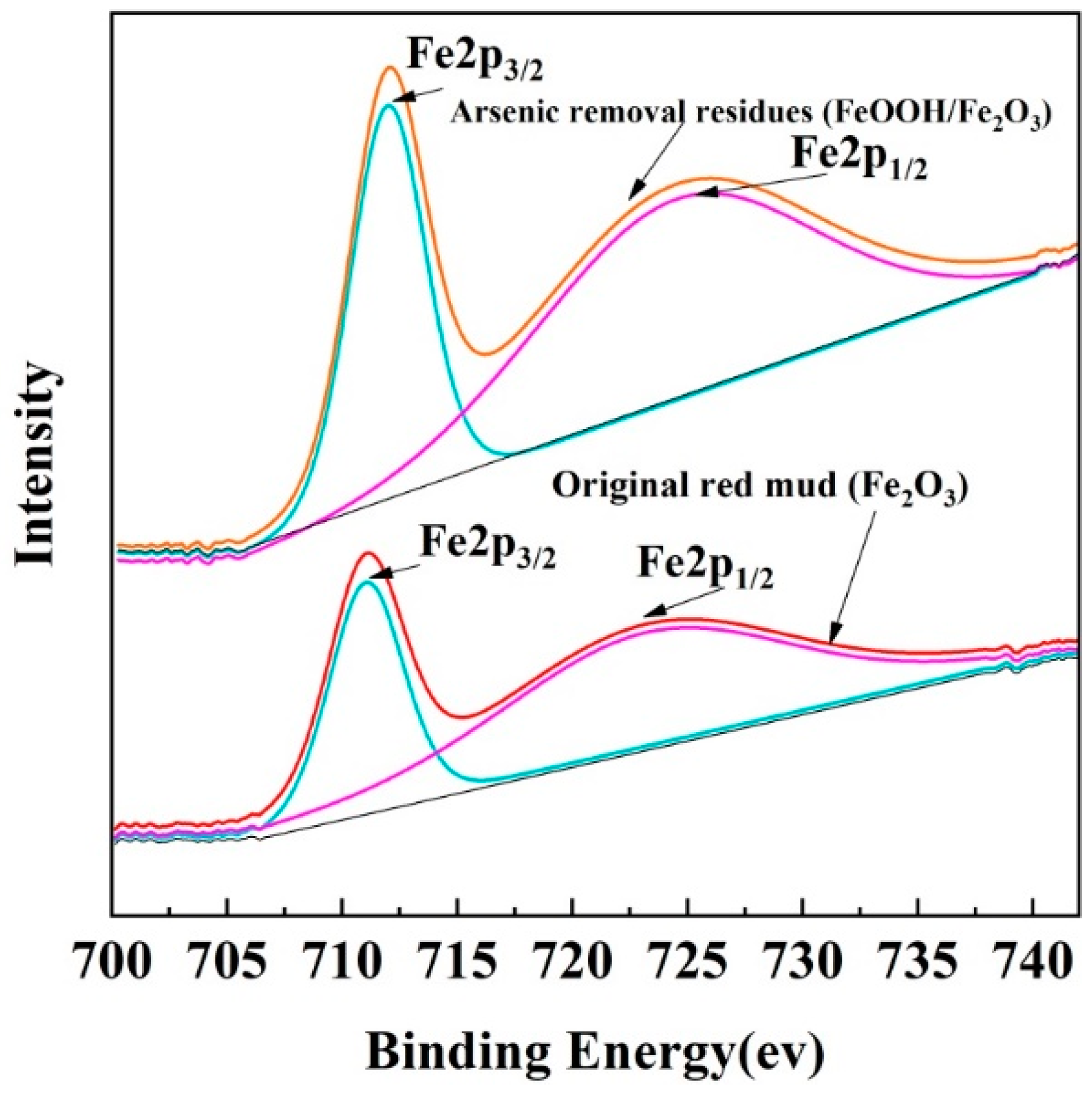

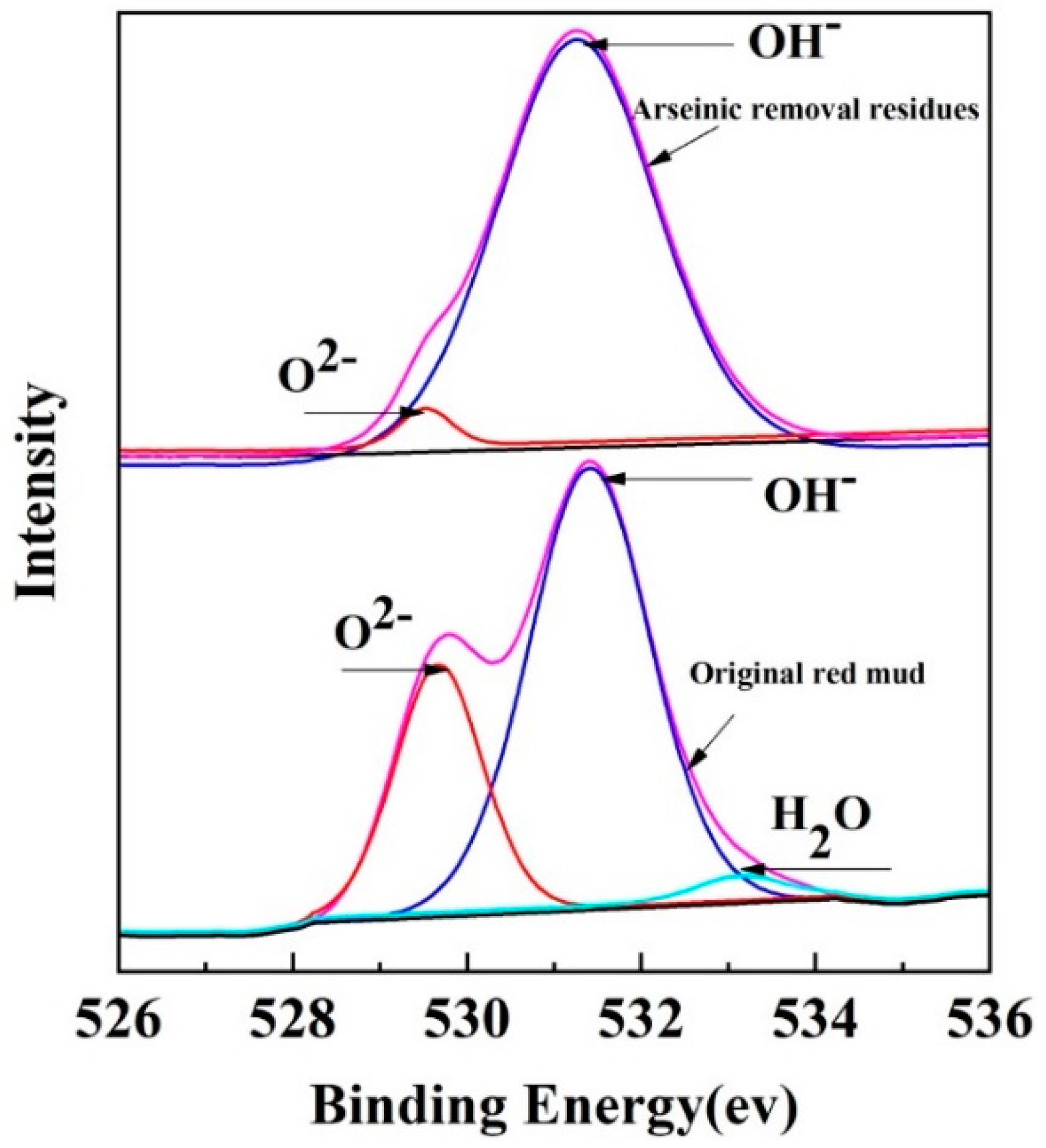

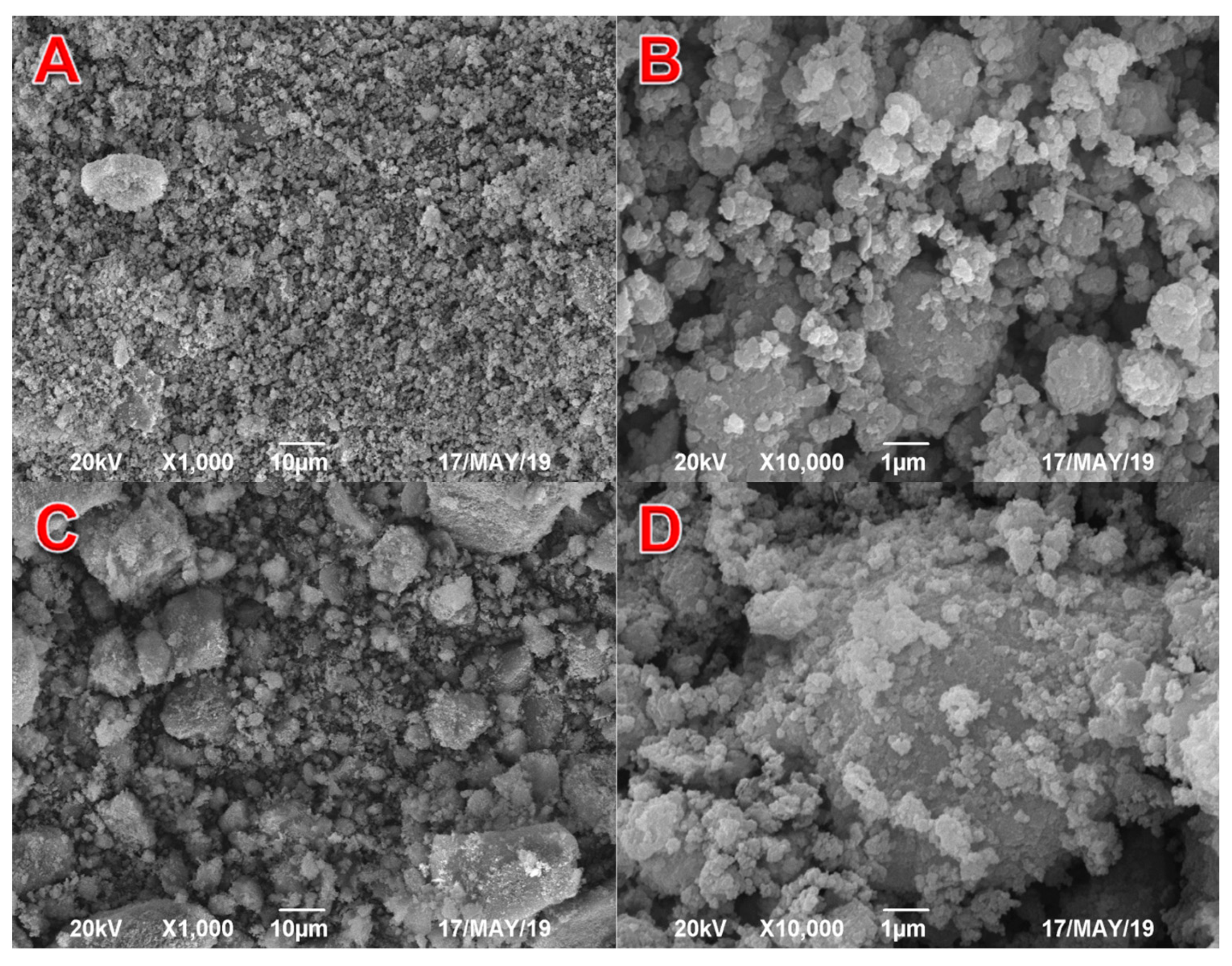

3.3. Characterization of Red Mud and Arsenic Removal Residues

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Luong, V.T.; Canas Kurz, E.E.; Hellriegel, U.; Luu, T.L.; Hoinkis, J.; Bundschuh, J. Iron-based subsurface arsenic removal technologies by aeration: A review of the current state and future prospects. Water Res. 2018, 133, 110–122. [Google Scholar] [CrossRef] [PubMed]

- Nidheesh, P.V.; Singh, T.S.A. Arsenic removal by electrocoagulation process: Recent trends and removal mechanism. Chemosphere 2017, 181, 418–432. [Google Scholar] [CrossRef]

- Sarkar, A.; Paul, B. The global menace of arsenic and its conventional remediation—A critical review. Chemosphere 2017, 173, 630–631. [Google Scholar] [CrossRef] [PubMed]

- Sandoval, M.A.; Fuentes, R.; Nava, J.L.; Coreño, O.; Li, Y.; Hernández, J.H. Simultaneous removal of fluoride and arsenic from groundwater by electrocoagulation using a filter-press flow reactor with a three-cell stack. Sep. Purif. Technol. 2019, 208, 208–216. [Google Scholar] [CrossRef]

- Sanjrani, M.A.; Zhou, B.; Zhao, H.; Bhutto, S.A.; Muneer, A.S.; Xia, S.B. Arsenic contaminated groundwater in china and its treatment options, a review. Appl. Ecol. Environ. Res. 2019, 17, 1655–1683. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhao, H.; Zhang, Y.; Liu, H.; Yin, H.; Deng, J.; Qiu, G. Interaction mechanism between marmatite and chalcocite in acidic (microbial) environments. Hydrometallurgy 2020, 191, 105217. [Google Scholar] [CrossRef]

- Tabelin, C.B.; Igarashi, T.; Villacorte-Tabelin, M.; Park, I.; Opiso, E.M.; Ito, M.; Hiroyoshi, N. Arsenic, selenium, boron, lead, cadmium, copper, and zinc in naturally contaminated rocks: A review of their sources, modes of enrichment, mechanisms of release, and mitigation strategies. Sci. Total Environ. 2018, 645, 1522–1553. [Google Scholar] [CrossRef]

- Luukkonen, T.; Runtti, H.; Niskanen, M.; Tolonen, E.T.; Sarkkinen, M.; Kemppainen, K.; Ramo, J.; Lassi, U. Simultaneous removal of Ni(Ⅱ), As(III), and Sb(III) from spiked mine effluent with metakaolin and blast-furnace-slag geopolymers. J. Environ. Manag. 2016, 166, 579–588. [Google Scholar] [CrossRef]

- Kobya, M.; Gebologlu, U.; Ulu, F.; Oncel, S.; Demirbas, E. Removal of arsenic from drinking water by the electrocoagulation using fe and al electrodes. Electrochim. Acta 2011, 56, 5060–5070. [Google Scholar] [CrossRef]

- Dutta, P.K.P.S.O.; Sharma, V.K. Photocatalytic oxidation of arsenic (III): Evidence of hydroxyl radicals. Environ. Sci. Technol. 2005, 39, 1827–1834. [Google Scholar] [CrossRef]

- Leupin, O.X.; Hug, S.J. Oxidation and removal of arsenic (III) from aerated groundwater by filtration through sand and zero-valent iron. Water Res. 2005, 39, 1729–1740. [Google Scholar] [CrossRef]

- Gallagher, P.A.S.C.A.; Parks, A. Preservation of As (III) and As (V) in drinking water supply samples from across the united states using edta and acetic acid as a means of minimizing iron-arsenic coprecipitation. Environ. Sci. Technol. 2004, 38, 2919–2927. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.-J.; Gong, W.-X.; Liu, R.-P.; Liu, H.-J.; Qu, J.-H. Treatment of high arsenic content wastewater by a combined physical–chemical process. Colloids Surf. A Physicochem. Eng. Asp. 2011, 379, 116–120. [Google Scholar] [CrossRef]

- He, Z.; Tian, S.; Ning, P. Adsorption of arsenate and arsenite from aqueous solutions by cerium-loaded cation exchange resin. J. Rare Earths 2012, 30, 563–572. [Google Scholar] [CrossRef]

- Kim, J.; Benjamin, M.M. Modeling a novel ion exchange process for arsenic and nitrate removal. Water Res. 2004, 38, 2053–2062. [Google Scholar] [CrossRef]

- Sabbatini, P.; Yrazu, F.; Rossi, F.; Thern, G.; Marajofsky, A.; Fidalgo de Cortalezzi, M.M. Fabrication and characterization of iron oxide ceramic membranes for arsenic removal. Water Res. 2010, 44, 5702–5712. [Google Scholar] [CrossRef]

- Yu, Y.; Zhao, C.; Wang, Y.; Fan, W.; Luan, Z. Effects of ion concentration and natural organic matter on arsenic(V) removal by nanofiltration under different transmembrane pressures. J. Environ. Sci. 2013, 25, 302–307. [Google Scholar] [CrossRef]

- Gallegos-Garcia, M.; Ramírez-Muñiz, K.; Song, S. Arsenic removal from water by adsorption using iron oxide minerals as adsorbents: A review. Miner. Process. Extr. Metall. Rev. 2012, 33, 301–315. [Google Scholar] [CrossRef]

- Guan, X.; Du, J.; Meng, X.; Sun, Y.; Sun, B.; Hu, Q. Application of titanium dioxide in arsenic removal from water: A review. J. Hazard Mater. 2012, 215–216, 1–16. [Google Scholar] [CrossRef]

- Mohan, D.; Pittman, C.U., Jr. Arsenic removal from water/wastewater using adsorbents—A critical review. J. Hazard. Mater. 2007, 142, 1–53. [Google Scholar] [CrossRef]

- Srivastava, P.K.; Vaish, A.; Dwivedi, S.; Chakrabarty, D.; Singh, N.; Tripathi, R.D. Biological removal of arsenic pollution by soil fungi. Sci. Total Environ. 2011, 409, 2430–2442. [Google Scholar] [CrossRef]

- Niazi, N.K.; Bibi, I.; Shahid, M.; Ok, Y.S.; Burton, E.D.; Wang, H.; Shaheen, S.M.; Rinklebe, J.; Luttge, A. Arsenic removal by perilla leaf biochar in aqueous solutions and groundwater: An integrated spectroscopic and microscopic examination. Environ. Pollut. 2018, 232, 31–41. [Google Scholar] [CrossRef]

- Nazari, A.M.; Radzinski, R.; Ghahreman, A. Review of arsenic metallurgy: Treatment of arsenical minerals and the immobilization of arsenic. Hydrometallurgy 2017, 174, 258–281. [Google Scholar] [CrossRef]

- Yue, T.; Niu, Z.; Hu, Y.; Han, H.; Sun, W.; Tian, J.; Xu, Z.; Wang, L.; Yang, Y. Arsenic(V) adsorption on ferric oxyhydroxide gel at high alkalinity for securely recycling of arsenic-bearing copper slag. Appl. Surf. Sci. 2019, 478, 213–220. [Google Scholar] [CrossRef]

- Nikbin, I.M.; Aliaghazadeh, M.; Charkhtab, S.H.; Fathollahpour, A. Environmental impacts and mechanical properties of lightweight concrete containing bauxite residue (red mud). J. Clean. Prod. 2018, 172, 2683–2694. [Google Scholar] [CrossRef]

- Tabelin, C.B.; Corpuz, R.D.; Igarashi, T.; Villacorte-Tabelin, M.; Alorro, R.D.; Yoo, K.; Raval, S.; Ito, M.; Hiroyoshi, N. Acid mine drainage formation and arsenic mobility under strongly acidic conditions: Importance of soluble phases, iron oxyhydroxides/oxides and nature of oxidation layer on pyrite. J. Hazard. Mater. 2020, 399, 122844. [Google Scholar] [CrossRef] [PubMed]

- Bhatnagar, A.; Vilar, V.J.; Botelho, C.M.; Boaventura, R.A. A review of the use of red mud as adsorbent for the removal of toxic pollutants from water and wastewater. Environ. Technol. 2011, 32, 231–249. [Google Scholar] [CrossRef] [PubMed]

- Li, N.S.Z.M.; Run, F.H.; Du, D.Y. The mechanism of arsenic (III) removal by ferric chloride. CIESC J. 2012, 63, 2224–2228. [Google Scholar]

- Chaudhry, S.I.S.S.A. Iron oxide and its modified forms as an adsorbent for arsenic removal: A comprehensive recent advancement. Process Saf. Environ. Prot. 2017, 111, 592–626. [Google Scholar]

- Demopoulos, D.F.G.P. Arsenic immobilization by controlled scorodite precipitation. JOM 1997, 49, 52–55. [Google Scholar]

- Donald Langmuir, J.M.; Anjali Macdonald, J.R. Predicting arsenic concentrations in the porewaters of buried uranium mill tailings. Geochim. Cosmochim. Acta 1999, 63, 3379–3394. [Google Scholar] [CrossRef]

- Langmuir, D.; Mahoney, J.; Rowson, J. Solubility products of amorphous ferric arsenate and crystalline scorodite (FeAsO4·2H2O) and their application to arsenic behavior in buried mine tailings. Geochim. Cosmochim. Acta 2006, 70, 2942–2956. [Google Scholar] [CrossRef]

- Park, I.; Tabelin, C.B.; Seno, K.; Jeon, S.; Inano, H.; Ito, M.; Hiroyoshi, N. Carrier-microencapsulation of arsenopyrite using al-catecholate complex: Nature of oxidation products, effects on anodic and cathodic reactions, and coating stability under simulated weathering conditions. Heliyon 2020, 6, e03189. [Google Scholar] [CrossRef]

- Wei, Y.; Liao, A.; Wang, L.; Wang, X.; Wang, D.; Zhou, Y.; Zou, Z. Room temperature surface modification of ultrathin feooh cocatalysts on Fe2O3 photoanodes for high photoelectrochemical water splitting. J. Nanomater. 2020, 2020, 1–7. [Google Scholar] [CrossRef]

- Liu, J.; Deng, S.; Zhao, F.; Cheng, H.; Frost, R.L. Spectroscopic characterization and solubility investigation on the effects of As(V) on mineral structure tooeleite (Fe6(AsO3)2SO4(OH)2.H2O). Spectrochim. Acta A Mol. Biomol. Spectrosc. 2015, 134, 428–433. [Google Scholar] [CrossRef]

- Ghahremaninezhad, A.; Dixon, D.G.; Asselin, E. Electrochemical and xps analysis of chalcopyrite (CuFeS2) dissolution in sulfuric acid solution. Electrochim. Acta 2013, 87, 97–112. [Google Scholar] [CrossRef]

- Zhao, H.; Zhang, Y.; Sun, M.; Ou, P.; Zhang, Y.; Liao, R.; Qiu, G. Catalytic mechanism of silver in the oxidative dissolution process of chalcopyrite: Experiment and dft calculation. Hydrometallurgy 2019, 187, 18–29. [Google Scholar] [CrossRef]

| Element | Al2O3 | CaO | Fe2O3 | TiO2 | Na2O | SiO2 |

|---|---|---|---|---|---|---|

| Content/% | 20.57 | 2.10 | 33.1 | 5.77 | 9.79 | 15.10 |

| Agent Addition Sequence | Fe3+ + NaOH | Fe3+ + Red Mud | Red Mud + Fe3+ | NaOH + Fe3+ |

|---|---|---|---|---|

| As concentration after reaction (mg/L) | 11.98 ± 0.23 | 13.14 ± 0.31 | 29.79 ± 0.82 | 49.54 ± 1.52 |

| Arsenic removal (%) | 97.60% | 97.37% | 94.04% | 90.09% |

| Element | O | Na | Al | Si | P | S | Ti | Fe | As |

|---|---|---|---|---|---|---|---|---|---|

| arsenic removal residues | 26.87 | 0.93 | 3.85 | 2.62 | 0.05 | 0.24 | 1.75 | 41.61 | 21.45 |

| Original Red Mud | Arsenic Removal Residues | |||

|---|---|---|---|---|

| Name | Peak BE (eV) | Atomic (%) | Peak BE (eV) | Atomic (%) |

| C1s | 284.8 | 20.28 | 284.8 | 22.71 |

| O1s | 531.18 | 70.76 | 530.9 | 52.41 |

| Fe2p | 710.6 | 8.96 | 711.51 | 14.76 |

| As3d | - | - | 44.39 | 10.11 |

| Spectral Peak | Binding Energy (eV) | FWHM | Chemical States |

|---|---|---|---|

| Fe 2p3/2 Fe 2p3/2 Fe 2p1/2 Fe 2p1/2 | 711.98 711.04 724.51 723.22 | 3.85 3.78 14.60 14.72 | FeOOH Fe2O3 FeOOH Fe2O3 |

| As 3d5/2 | 44.39 | 1.67 | As(III)–O |

| O 1s | 529.5 | 1.25/0.7 | Lattice oxygen (O2– ) |

| O 1s | 531.2 | 1.62/2.15 | Hydroxyl oxygen (OH– ) |

| O 1s | 532.9 | 1.50 | Attached water (H2O) |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, D.; Xiong, Y.; Wang, L.; Sun, W.; Liu, R.; Yue, T. Arsenic (III) Removal from a High-Concentration Arsenic (III) Solution by Forming Ferric Arsenite on Red Mud Surface. Minerals 2020, 10, 583. https://doi.org/10.3390/min10070583

He D, Xiong Y, Wang L, Sun W, Liu R, Yue T. Arsenic (III) Removal from a High-Concentration Arsenic (III) Solution by Forming Ferric Arsenite on Red Mud Surface. Minerals. 2020; 10(7):583. https://doi.org/10.3390/min10070583

Chicago/Turabian StyleHe, Dongdong, Yuming Xiong, Li Wang, Wei Sun, Runqing Liu, and Tong Yue. 2020. "Arsenic (III) Removal from a High-Concentration Arsenic (III) Solution by Forming Ferric Arsenite on Red Mud Surface" Minerals 10, no. 7: 583. https://doi.org/10.3390/min10070583

APA StyleHe, D., Xiong, Y., Wang, L., Sun, W., Liu, R., & Yue, T. (2020). Arsenic (III) Removal from a High-Concentration Arsenic (III) Solution by Forming Ferric Arsenite on Red Mud Surface. Minerals, 10(7), 583. https://doi.org/10.3390/min10070583