Fuel Consumption Estimation System and Method with Lower Cost

Abstract

:1. Introduction

2. Fuel Consumption Estimation System

2.1. On-Board Unit

- The position module can support a global positioning system (GPS) to receive and analyze satellite signals for estimating the location (i.e., longitude and latitude) and speed of the vehicle.

- The communication module can support the techniques of long term evolution (LTE), and the OBU can connect with the data analysis server through the communication module and cellular networks.

- The middleware module can support hypertext transfer protocol (HTTP) and representational state transfer (REST), and the OBU can periodically call application program interfaces (APIs) and send the movement information (e.g., OBU ID, car type, driver ID, timestamp, longitude, latitude, and vehicle speed) to the data analysis server.

2.2. User Device

- The user interface can be used to input the OBU ID, timestamp, and fuel quantity after refuelling.

- The communication module can support the techniques of LTE, and the connection between a user device and the data analysis server can be built through the communication module.

- The middleware module can support the techniques of HTTP and REST, and the user device can send the information such as OBD ID, timestamp, and fuel quantity to the data analysis server through the middleware module.

2.3. Data Analysis Server

- The middleware module can obtain several REST APIs to receive the movement information (e.g., OBU ID, car type, driver ID, timestamp, longitude, latitude, and vehicle speed) and the fuel quantity information (e.g., OBU ID, timestamp, and fuel quantity) from the OBUs and user devices through HTTP. These data can be stored in a database server.

- The communication module can support Ethernet and build the connections among the data analysis server and other devices (e.g., OBUs, user devices, and a database server).

- The optimized composition module can use the proposed fuel consumption estimation method to collect and analyse the movement information and fuel quantity information for generating the estimated results of fuel consumption.

2.4. Database Server

- The communication module can support Ethernet, and the connection between the database server and the data analysis server can be built by this module.

- The computation module can receive the requests from the data analysis server through the communication module and access the storage module in accordance with the requests.

- The storage module can perform the operations of creation, update, deletion, and query.

3. Fuel Consumption Estimation Method

3.1. Movement Information Collection Method

3.2. Fuel Information Collection Method

3.3. Optimized Composition Method

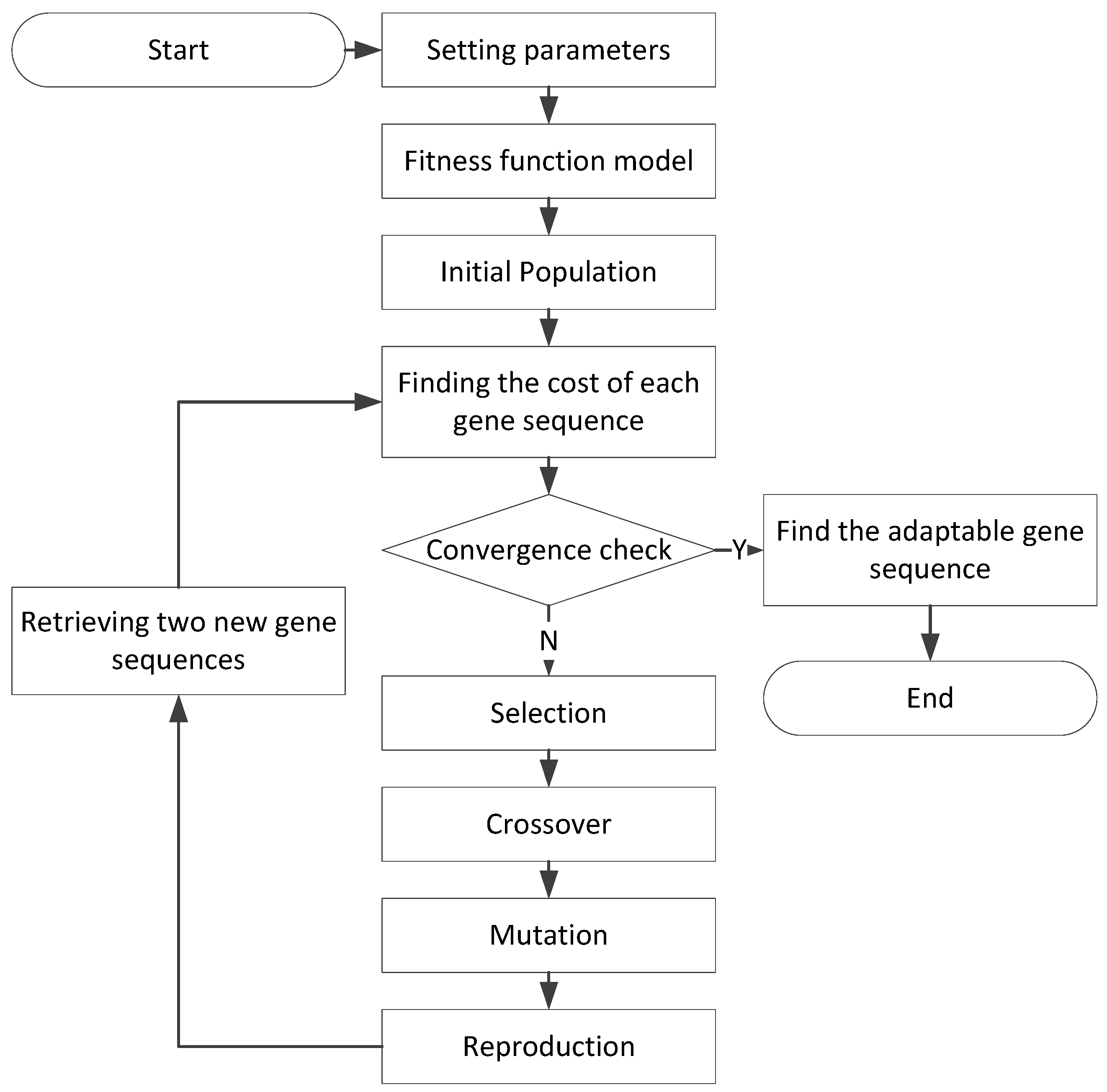

3.3.1. The Process of the Method

- The values of the parameters including the amount of initial maternal DNA (deoxyribonucleic acid) sequences (), the number of evolution times (), the maximum number of iterations (), crossover rate (α), and mutation rate (β) are initially given in this step.

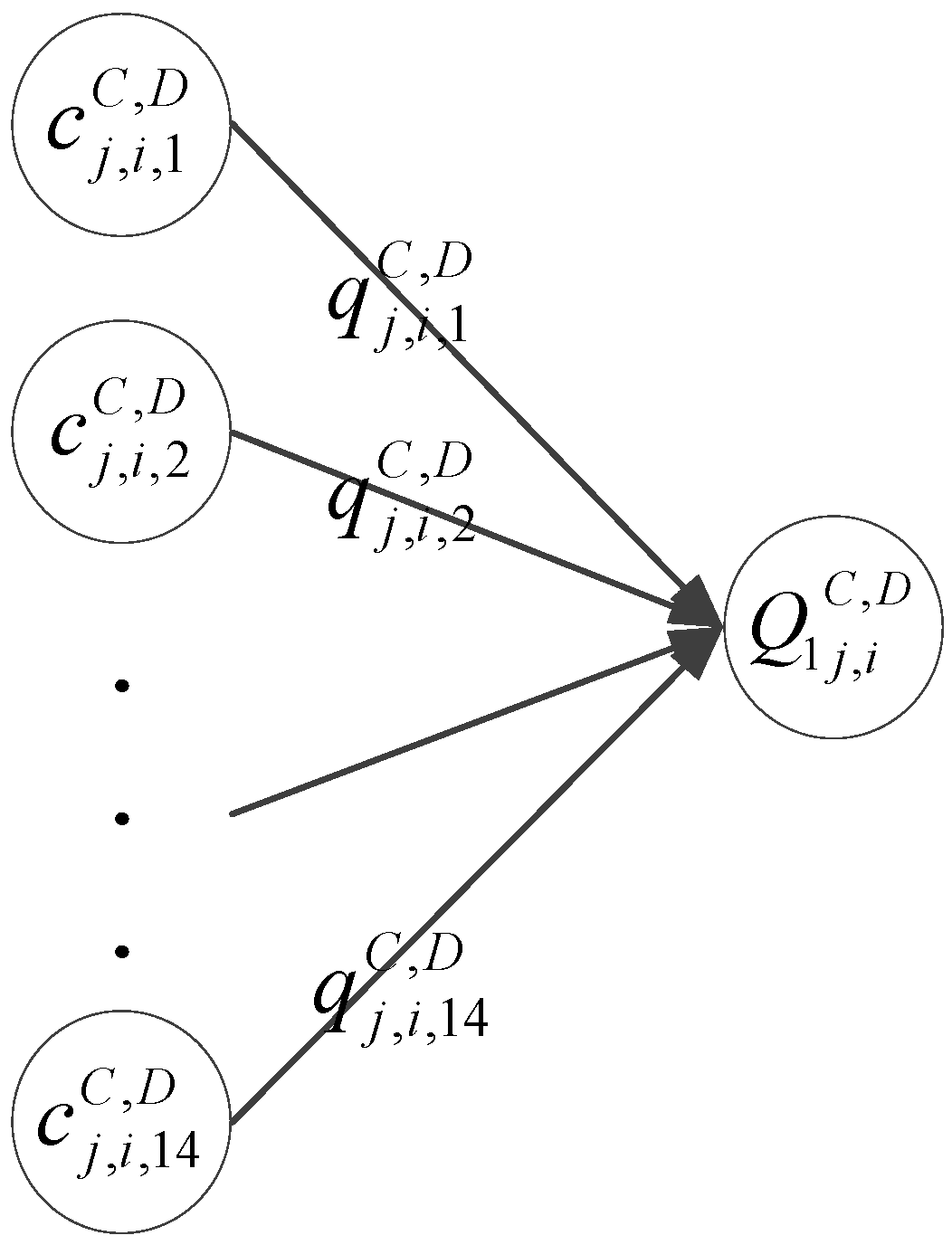

- The model of fitness function is designed for finding the cost of each DNA sequence which includes several chromosomes.

- The process of the initial population can generate maternal DNA sequences.

- Each DNA sequence can be adopted into the model of fitness function for the cost calculation.

- The process of the convergence check can be performed to check the values of the number of evolution times () and the maximum number of iterations (). If the number of evolution times () is equal to the maximum number of iterations (), the adaptable DNA sequence with the lowest cost is outputted as the estimated results of the fuel consumption based on the driver behaviour; otherwise the number of evolution times () is increased by one.

- The process of gene selection can select two of the maternal DNA sequences for crossover and mutation.

- The process of gene crossover can generate a child’s DNA sequences in the first generation in accordance with the crossover rate (α) and the maternal DNA sequences in the first generation.

- The process of gene mutation can generate a child’s DNA sequences in the second generation in accordance with the mutation rate (β) and the maternal DNA sequences in the second generation.

- The process of gene reproduction can support two new generated child’s DNA sequences being substituted for two original maternal DNA sequences which have the highest cost.

- The costs of the two reproduced DNA sequences can be measured by using the model of fitness function, and the GA is performed repeatedly.

3.3.2. A Case Study

4. Practical Experimental Results and Discussions

4.1. Experimental Environments

4.2. Experimental Designs

- Case 1: The fuel consumption estimation method considered the different road types (e.g., urban road and highway). In this case, each DNA sequence included 28 chromosomes.

- Case 2: The fuel consumption estimation method did not consider the different road types. In this case, each DNA sequence included 14 chromosomes.

- Case 3: The significant differences between the results of Case 1 and Case 2 were evaluated.

4.3. Experimental Results and Discussions

5. Conclusions and Future Work

Author Contributions

Conflicts of Interest

References

- Iodice, P.; Senatore, A. Road transport emission inventory in a regional area by using experimental two-wheelers emission factors. In Proceedings of the World Congress on Engineering, London, UK, 3–5 July 2013. [Google Scholar]

- Chan, S.Y. The Basic Information of Truck Freight Transportation. Taiwan Institute of Economic Research, 2016. Available online: https://goo.gl/7zZ9ZY (accessed on 2 February 2017).

- Chan, S.Y. The Basic Information of Bus Transportation. Taiwan Institute of Economic Research, 2016. Available online: https://goo.gl/hJnzXe (accessed on 2 February 2017).

- Iodice, P.; Senatore, A. Exhaust emissions of new high-performance motorcycles in hot and cold conditions. Int. J. Environ. Sci. Technol. 2015, 12, 3133–3144. [Google Scholar] [CrossRef]

- Iodice, P.; Senatore, A. Analysis of a Scooter Emission Behavior in Cold and Hot Conditions: Modelling and Experimental Investigations; SAE Technical Paper 2012-01-0881; Society of Automotive Engineers: Warrendale, PN, USA, 2012. [Google Scholar] [CrossRef]

- Zhang, Z.; Yu, X.; Han, W. Investigation of real-time fuel consumption measuring system. Int. J. Hybrid Inf. Technol. 2015, 8, 235–242. [Google Scholar] [CrossRef]

- Zhang, J.; Feng, Y.; Shi, F.; Wang, G.; Ma, B.; Li, R.; Jia, X. Vehicle routing in urban areas based on the oil consumption weight-Dijkstra algorithm. IET Intell. Transp. Syst. 2016, 10, 495–502. [Google Scholar] [CrossRef]

- Zhang, S.; Wu, Y.; Liu, H.; Huang, R.; Un, P.; Zhou, Y.; Fu, L.; Hao, J. Real-world fuel consumption and CO2 (carbon dioxide) emissions by driving conditions for light-duty passenger vehicles in China. Energy 2014, 69, 247–257. [Google Scholar] [CrossRef]

- Chang, C.W.; Kuo, Y.C.; Tsai, Y.Y.; Kuo, Y.L. Vehicle Fuel Consumption Detection System and Detection Method. Patent CN105,628,125, 1 June 2016. [Google Scholar]

- Toledo, G.; Shiftan, Y. Can feedback from in-vehicle data recorders improve driver behavior and reduce fuel consumption. Transp. Res. Part A Policy Pract. 2016, 94, 194–204. [Google Scholar] [CrossRef]

- Silva, J.A.; Moura, F.; Garcia, B.; Vargas, R. Influential vectors in fuel consumption by an urban bus operator: Bus route, driver behavior or vehicle type. Transp. Res. Part D Transp. Environ. 2015, 38, 94–104. [Google Scholar] [CrossRef]

- Castignani, G.; Derrmann, T.; Frank, R.; Engel, T. Driver behavior profiling using smartphones: A low-cost platform for driver monitoring. IEEE Intell. Transp. Syst. Mag. 2015, 7, 91–102. [Google Scholar] [CrossRef]

- Yao, H.H.; Kuo, Y.C.; Shang, T.J. Method for Calculating Fuel Consumption during Driving and Driving Fuel Consumption Calculation System. U.S. Patent 20,130,253,813, 26 September 2013. [Google Scholar]

- Magaña, V.C.; Organero, M.M. GATSF: Genetic algorithm to save fuel. In Proceedings of the 2012 IEEE International Conference on Consumer Electronics-Berlin, Berlin, Germany, 3–5 September 2012. [Google Scholar]

- Bao, Y.; Chen, W. A personalized route search method based on joint driving and vehicular behavior recognition. In Proceedings of the 2016 IEEE MTT-S International Wireless Symposium, Shanghai, China, 14–16 March 2016. [Google Scholar]

- Rocha, T.V.; Jeanneret, B.; Trigui, R.; Leclercq, L. How simplifying urban driving cycles influence fuel consumption estimation? Procedia-Soc. Behav. Sci. 2012, 48, 1000–1009. [Google Scholar] [CrossRef]

- Whitley, D. A genetic algorithm tutorial. Stat. Comput. 1994, 4, 65–85. [Google Scholar] [CrossRef]

- Rajasekar, N.; Basil, J.; Balasubramanian, K.; Priya, K.; Sangeetha, K.; Babu, T.S. Comparative study of PEM fuel cell parameter extraction using genetic algorithm. Ain Shams Eng. J. 2015, 6, 1187–1194. [Google Scholar] [CrossRef]

- Lee, W.C.; Tsang, K.F.; Chi, H.R.; Hung, F.H.; Wu, C.K.; Chui, K.T.; Lau, W.H.; Leung, Y.W. A high fuel consumption efficiency management scheme for PHEVs using an adaptive genetic algorithm. Sensors 2015, 15, 1245–1251. [Google Scholar] [CrossRef] [PubMed]

- Google. Google Maps; Google Inc.: Mountain View, CA, USA, 2005; Available online: https://maps.google.com (accessed on 30 June 2017).

- The Telecommunication Laboratories. Chunghwa GeoWeb Service; The Telecommunication Laboratories, Chunghwa Telecom Co., Ltd.: Taoyuan, Taiwan, 2007; Available online: http://demo.map.hinet.net/ (accessed on 30 June 2017).

- The Telecommunication Laboratories. eFMS (e-Fleet Management Service); The Telecommunication Laboratories, Chunghwa Telecom Co., Ltd.: Taoyuan, Taiwan, 2014; Available online: http://efms.hinet.net/ (accessed on 9 March 2017).

- Scrucca, L. Package ‘GA’, the Comprehensive R Archive Network. 2016. Available online: https://cran.r-project.org/web/packages/GA/ (accessed on 26 June 2017).

- The Bureau of Energy. Fuel Economy Guide; The Bureau of Energy Ministry of Economic Affairs: Taipei, Taiwan, 2016. Available online: https://goo.gl/YpgQ9Q (accessed on 9 March 2017).

| OBU ID | Car Type | Driver ID | Time | Longitude | Latitude | Speed (km/h) |

|---|---|---|---|---|---|---|

| OBU 1 | Type 1 | Driver 1 | 1 January 2015 06:00:00 | 120.5423383 | 24.09490167 | 44 |

| OBU 1 | Type 1 | Driver 1 | 1 January 2015 06:00:30 | 120.5361317 | 24.09120167 | 39 |

| OBU 1 | Type 1 | Driver 1 | 1 January 2015 06:01:00 | 120.5360417 | 24.09114667 | 2 |

| OBU 1 | Type 1 | Driver 1 | 1 January 2015 06:01:30 | 120.5360383 | 24.09115 | 0 |

| OBU 1 | Type 1 | Driver 1 | 1 January 2015 06:02:00 | 120.536035 | 24.09113833 | 0 |

| OBU 1 | Type 1 | Driver 1 | 1 January 2015 06:02:30 | 120.5356167 | 24.09070333 | 7 |

| OBU 1 | Type 1 | Driver 1 | 1 January 2015 06:03:00 | 120.53052 | 24.09449167 | 48 |

| OBU 1 | Type 1 | Driver 1 | 1 January 2015 06:03:30 | 120.52868 | 24.09591167 | 30 |

| … | ||||||

| OBU CN | Type TN | Driver DN | 31 December 2015 22:00:00 | 121.0601083 | 24.75685833 | 102 |

| OBU ID | Time | Fuel Quantity (L) |

|---|---|---|

| OBU 1 | 5 January 2015 18:51:00 | 43.04 |

| OBU 1 | 6 January 2015 21:11:00 | 47.11 |

| OBU 1 | 8 January 2015 17:49:00 | 31.81 |

| OBU 1 | 10 January 2015 20:35:00 | 21.50 |

| OBU 1 | 12 January 2015 19:59:00 | 41.16 |

| OBU 1 | 14 January 2015 11:36:00 | 34.43 |

| OBU 1 | 15 January 2015 19:18:00 | 27.75 |

| OBU 1 | 16 January 2015 19:15:00 | 38.26 |

| … | ||

| OBU CN | 31 December 2015 23:00:00 | 51.79 |

| OBU ID | Car Type | Driver ID | Time | Longitude | Latitude | Road Type | Speed (km/h) |

|---|---|---|---|---|---|---|---|

| OBU 1 | Type 1 | Driver 1 | 1 January 2015 06:00:00 | 120.5423383 | 24.09490167 | Urban | 44 |

| OBU 1 | Type 1 | Driver 1 | 1 January 2015 06:00:30 | 120.5361317 | 24.09120167 | Urban | 39 |

| OBU 1 | Type 1 | Driver 1 | 1 January 2015 06:01:00 | 120.5360417 | 24.09114667 | Urban | 2 |

| OBU 1 | Type 1 | Driver 1 | 1 January 2015 06:01:30 | 120.5360383 | 24.09115 | Urban | 0 |

| OBU 1 | Type 1 | Driver 1 | 1 January 2015 06:02:00 | 120.536035 | 24.09113833 | Urban | 0 |

| OBU 1 | Type 1 | Driver 1 | 1 January 2015 06:02:30 | 120.5356167 | 24.09070333 | Urban | 7 |

| OBU 1 | Type 1 | Driver 1 | 1 January 2015 06:03:00 | 120.53052 | 24.09449167 | Urban | 48 |

| OBU 1 | Type 1 | Driver 1 | 1 January 2015 06:03:30 | 120.52868 | 24.09591167 | Urban | 30 |

| … | |||||||

| OBU CN | Type TN | Driver DN | 31 December 2015 22:00:00 | 121.0601083 | 24.75685833 | Highway | 102 |

| Movement | … | ||||||

|---|---|---|---|---|---|---|---|

| OBU ID and Driver ID | |||||||

| Driver 1 drove OBU 1 | … | ||||||

| Driver 2 drove OBU 1 | … | ||||||

| … | … | … | … | … | … | … | |

| Driver 1 drove OBU 2 | … | ||||||

| … | … | … | … | … | … | … | |

| Driver DN drove OBU CN | … | ||||||

| Chromosome | Chromosome 1 | Chromosome 2 | … | Chromosome 14 | |

|---|---|---|---|---|---|

| DNA Sequences | |||||

| DNA Sequence 1 () | … | ||||

| DNA Sequence 2 () | … | ||||

| … | |||||

| DNA Sequence 14 () | … | ||||

| Chromosome | Chromosome 1 | Chromosome 2 | … | Chromosome 14 | |

|---|---|---|---|---|---|

| DNA Sequences | |||||

| DNA Sequence 1 () | 0.013249146 | 0.018487159 | … | 0.551971137 | |

| DNA Sequence 2 () | 0.016574516 | 0.02331678 | … | 0.553625064 | |

| … | |||||

| DNA Sequence 14 () | 0.01539256 | 0.021892833 | … | 0.555117159 | |

| Chromosome | Chromosome 1 | Chromosome 2 | … | Chromosome 14 | |

|---|---|---|---|---|---|

| DNA Sequences | |||||

| DNA Sequence 1 () | 0.013249146 | 0.018487159 | … | 0.551971137 | |

| DNA Sequence 2 () | 0.016574516 | 0.02331678 | … | 0.553625064 | |

| Chromosome | Chromosome 1 | Chromosome 2 | … | Chromosome 14 | |

|---|---|---|---|---|---|

| DNA Sequences | |||||

| DNA Sequence 1 | 0.013249146 | 0.02331678 | … | 0.553625064 | |

| DNA Sequence 2 | 0.016574516 | 0.018487159 | … | 0.551971137 | |

| Chromosome | Chromosome 1 | Chromosome 2 | … | Chromosome 14 | |

|---|---|---|---|---|---|

| DNA Sequences | |||||

| DNA Sequence 1 | 0.013249146 | 0.02331678 | … | 0.553625064 | |

| DNA Sequence 2 | 0.016574516 | 0.018487159 | … | 0.551971137 | |

| Chromosome | Chromosome 1 | Chromosome 2 | … | Chromosome 14 | |

|---|---|---|---|---|---|

| DNA Sequences | |||||

| DNA Sequence 1 | 0.011241019 | 0.02331678 | … | 0.553625064 | |

| DNA Sequence 2 | 0.012500034 | 0.018487159 | … | 0.551971137 | |

| Chromosome | Chromosome 1 | Chromosome 2 | … | Chromosome 14 | |

|---|---|---|---|---|---|

| DNA Sequences | |||||

| DNA Sequence 1 () | 0.013249146 | 0.018487159 | … | 0.551971137 | |

| DNA Sequence 2 () | 0.011241019 | 0.02331678 | … | 0.553625064 | |

| … | |||||

| DNA Sequence 14 () | 0.012500034 | 0.018487159 | … | 0.551971137 | |

| OBU ID | November 2016 (i.e., Training Data) | December 2016 (i.e., Testing Data) | ||

|---|---|---|---|---|

| The Number of Movement Records | Driving Mileage (km) | The Number of Movement Records | Driving Mileage (km) | |

| 1 | 29,115 | 10,636 | 33,546 | 13,548 |

| 2 | 39,957 | 11,598 | 39,573 | 12,500 |

| 3 | 29,289 | 7897 | 28,097 | 6825 |

| 4 | 18,980 | 2844 | 15,313 | 2211 |

| 5 | 23,514 | 5928 | 22,015 | 5418 |

| 6 | 26,422 | 4880 | 28,820 | 5964 |

| 7 | 32,345 | 9404 | 34,440 | 10,258 |

| 8 | 30,859 | 6707 | 29,066 | 6195 |

| 9 | 36,165 | 10,316 | 34,445 | 10,229 |

| 10 | 30,046 | 6419 | 28,199 | 6367 |

| 11 | 26,074 | 5884 | 26,301 | 5917 |

| 12 | 19,258 | 5340 | 19,191 | 5337 |

| 13 | 26,106 | 5720 | 26,353 | 6067 |

| 14 | 24,620 | 5475 | 24,252 | 5066 |

| 15 | 27,923 | 6520 | 25,187 | 5749 |

| Summary | 420,673 | 105,569 | 414,798 | 107,651 |

| OBU ID | November 2016 (i.e., Training Data) | December 2016 (i.e., Testing Data) | ||

|---|---|---|---|---|

| The Number of Refuelling Times | Fuel Quantity (L) | The Number of Refuelling Times | Fuel Quantity (L) | |

| 1 | 20 | 3619.020 | 25 | 4582.252 |

| 2 | 21 | 3820.000 | 24 | 4180.871 |

| 3 | 16 | 2704.016 | 15 | 2425.483 |

| 4 | 15 | 581.154 | 11 | 479.641 |

| 5 | 23 | 1031.828 | 25 | 975.490 |

| 6 | 26 | 838.163 | 30 | 896.126 |

| 7 | 16 | 3222.007 | 18 | 3578.000 |

| 8 | 14 | 2440.178 | 14 | 2331.264 |

| 9 | 23 | 3662.796 | 22 | 3691.831 |

| 10 | 17 | 2334.016 | 18 | 2350.214 |

| 11 | 11 | 2100.003 | 12 | 2241.000 |

| 12 | 30 | 897.420 | 25 | 874.300 |

| 13 | 15 | 2166.003 | 16 | 2296.017 |

| 14 | 20 | 1690.028 | 20 | 1782.006 |

| 15 | 13 | 581.154 | 11 | 479.641 |

| Summary | 280 | 31,687.786 | 286 | 33,164.136 |

| OBU ID | The Proposed Method | Fuel Economy Guide [24] | ||

|---|---|---|---|---|

| Accuracy of Training Data | Accuracy of Testing Data | Accuracy of Training Data | Accuracy of Testing Data | |

| 1 | 99.73% | 91.55% | 16.89% | 16.99% |

| 2 | 99.70% | 92.66% | 17.45% | 17.18% |

| 3 | 99.28% | 93.60% | 16.78% | 16.17% |

| 4 | 99.49% | 94.90% | 28.12% | 26.49% |

| 5 | 99.95% | 97.12% | 33.02% | 31.92% |

| 6 | 98.76% | 95.48% | 33.46% | 38.25% |

| 7 | 99.34% | 97.29% | 16.77% | 16.48% |

| 8 | 99.80% | 99.37% | 15.80% | 15.27% |

| 9 | 99.62% | 97.89% | 16.19% | 15.92% |

| 10 | 99.00% | 95.30% | 15.81% | 15.57% |

| 11 | 99.68% | 96.09% | 16.10% | 15.17% |

| 12 | 99.47% | 97.22% | 34.20% | 35.08% |

| 13 | 99.65% | 95.41% | 15.18% | 15.19% |

| 14 | 94.36% | 96.56% | 18.62% | 16.34% |

| 15 | 99.39% | 92.71% | 64.48% | 68.89% |

| Mean | 99.15% | 95.54% | 23.92% | 24.06% |

| OBU ID | The proposed Method | Fuel Economy Guide [24] | ||

|---|---|---|---|---|

| Accuracy of Training Data | Accuracy of Testing Data | Accuracy of Training Data | Accuracy of Testing Data | |

| 1 | 99.54% | 92.19% | 16.89% | 16.99% |

| 2 | 98.99% | 91.59% | 17.45% | 17.18% |

| 3 | 98.86% | 96.81% | 16.78% | 16.17% |

| 4 | 97.26% | 97.70% | 28.12% | 26.49% |

| 5 | 99.79% | 98.71% | 33.02% | 31.92% |

| 6 | 98.24% | 95.61% | 33.46% | 38.25% |

| 7 | 99.77% | 95.74% | 16.77% | 16.48% |

| 8 | 99.71% | 98.44% | 15.80% | 15.27% |

| 9 | 98.90% | 96.59% | 16.19% | 15.92% |

| 10 | 99.02% | 97.81% | 15.81% | 15.57% |

| 11 | 99.04% | 93.26% | 16.10% | 15.17% |

| 12 | 99.88% | 99.05% | 34.20% | 35.08% |

| 13 | 96.85% | 89.22% | 15.18% | 15.19% |

| 14 | 97.23% | 99.28% | 18.62% | 16.34% |

| 15 | 98.77% | 96.12% | 64.48% | 68.89% |

| Mean | 98.79% | 95.87% | 23.92% | 24.06% |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lo, C.-L.; Chen, C.-H.; Kuan, T.-S.; Lo, K.-R.; Cho, H.-J. Fuel Consumption Estimation System and Method with Lower Cost. Symmetry 2017, 9, 105. https://doi.org/10.3390/sym9070105

Lo C-L, Chen C-H, Kuan T-S, Lo K-R, Cho H-J. Fuel Consumption Estimation System and Method with Lower Cost. Symmetry. 2017; 9(7):105. https://doi.org/10.3390/sym9070105

Chicago/Turabian StyleLo, Chi-Lun, Chi-Hua Chen, Ta-Sheng Kuan, Kuen-Rong Lo, and Hsun-Jung Cho. 2017. "Fuel Consumption Estimation System and Method with Lower Cost" Symmetry 9, no. 7: 105. https://doi.org/10.3390/sym9070105

APA StyleLo, C.-L., Chen, C.-H., Kuan, T.-S., Lo, K.-R., & Cho, H.-J. (2017). Fuel Consumption Estimation System and Method with Lower Cost. Symmetry, 9(7), 105. https://doi.org/10.3390/sym9070105