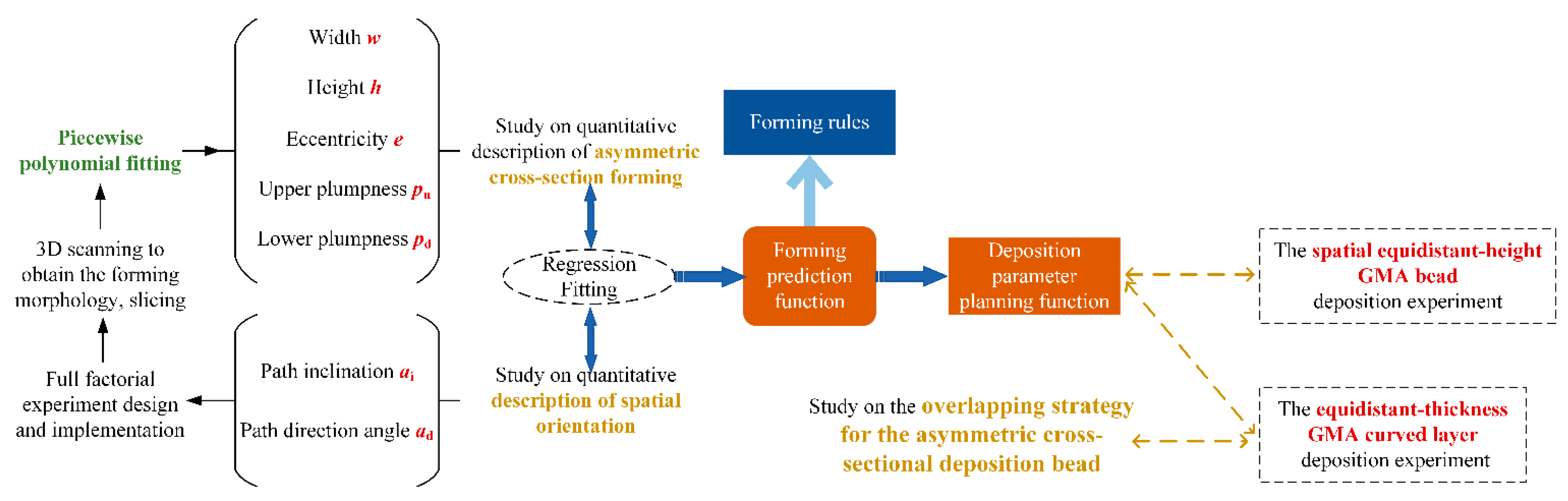

Study on Characterization and Overlapping Strategy of Asymmetric Cross-Section of Spatial Curved GMA Deposition Bead

Abstract

1. Introduction

- (1)

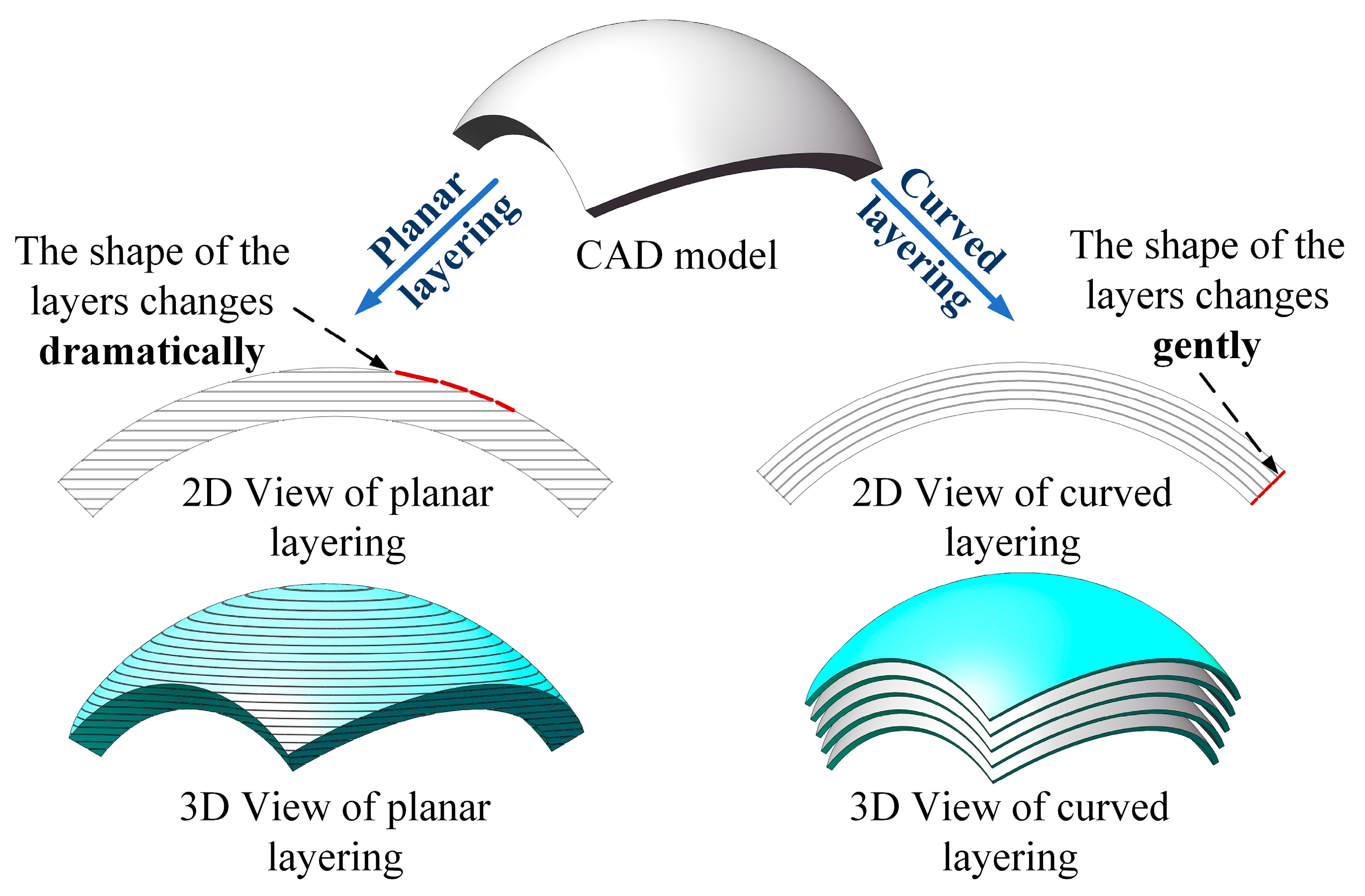

- There is currently a lack of mathematical description of the asymmetric cross-section of the spatial deposition bead on the curved surface, and the modeling research of the cladding bead is still mainly based on the symmetrical bead on the plane.

- (2)

- Although current scholars have noticed the influence of the forming complexity of the spatial deposition path on the GMA-AM based on the curved surface layering and have used simulation methods to predict it, there is a lack of mathematical models to predict the deposition formation and plan the deposition parameters, which limits the application of GMA-AM based on the curved surface layering.

2. Definition of Asymmetric Cross-Sectional Geometric Characteristics and Contour Fitting Function

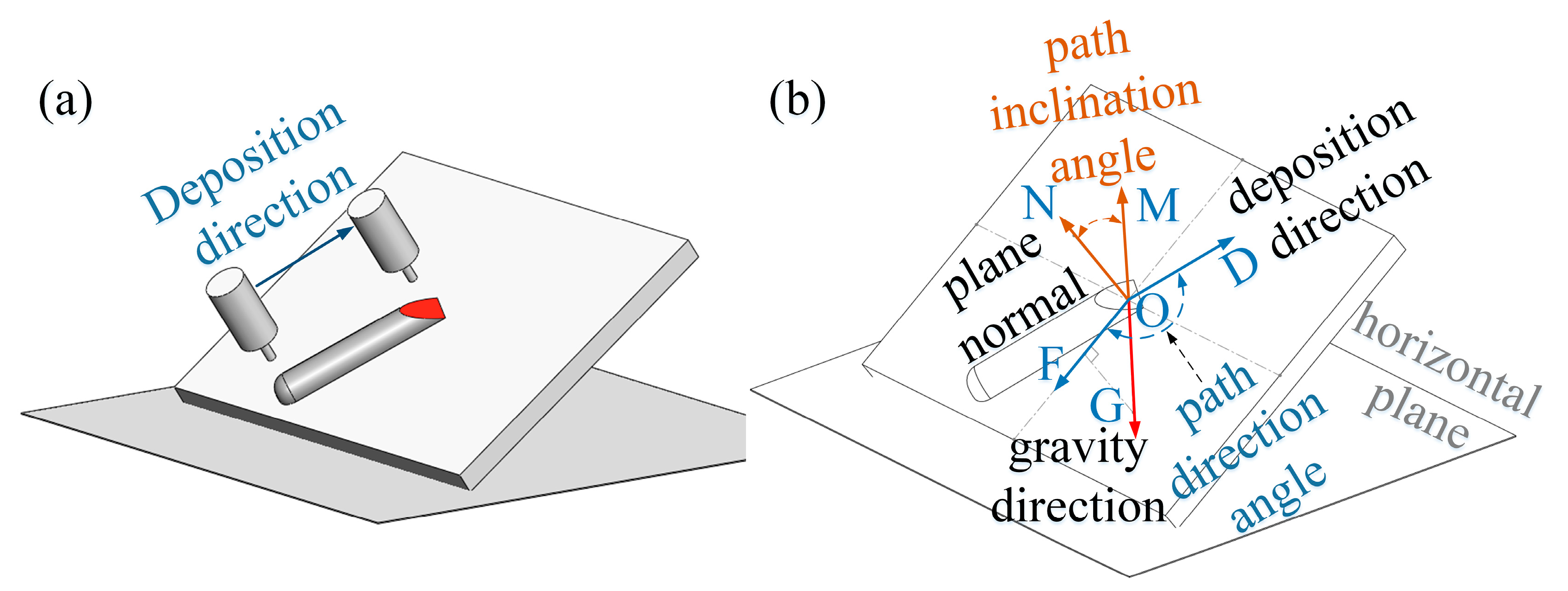

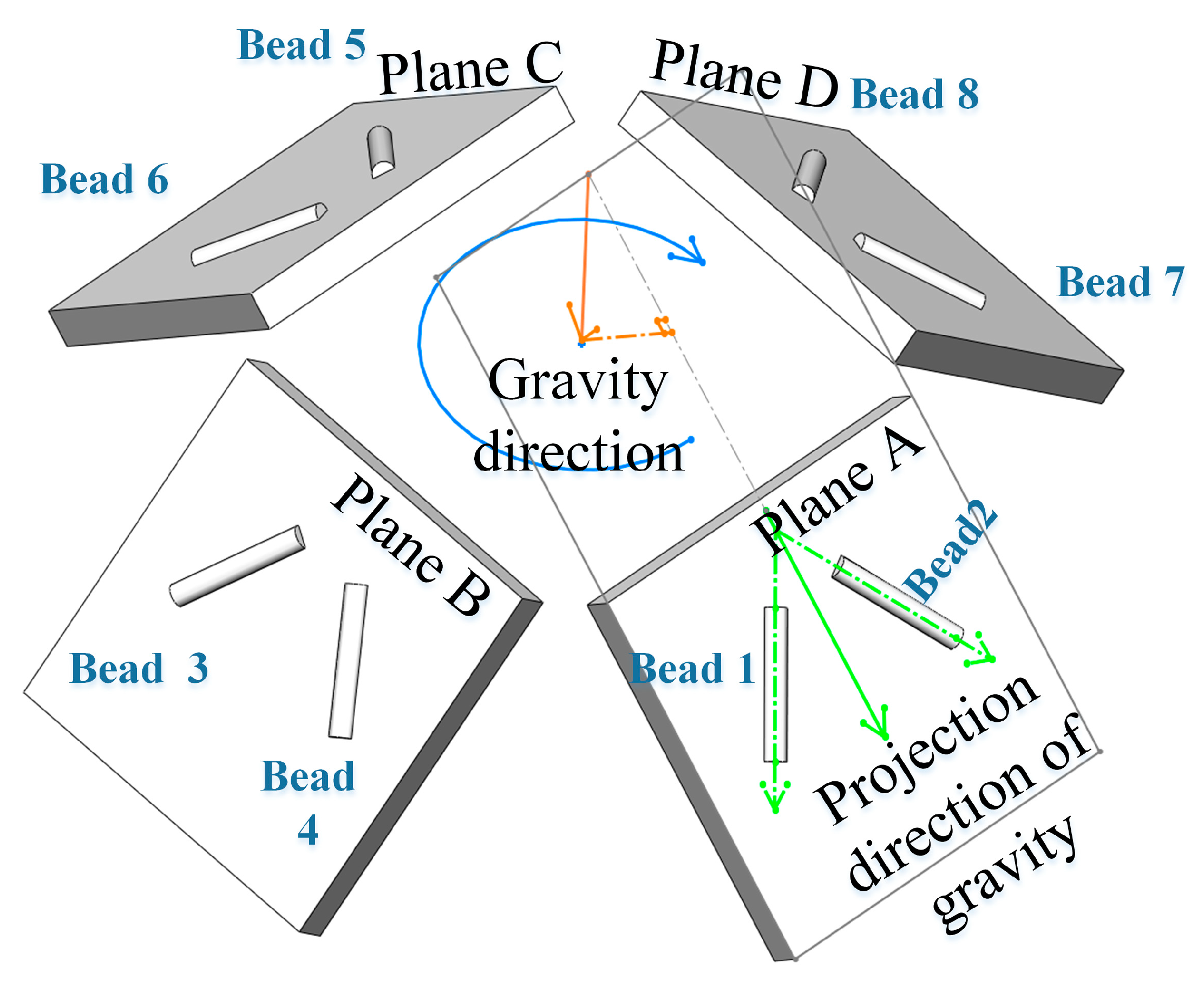

2.1. Description of the Orientation for the Spatial Deposition Bead

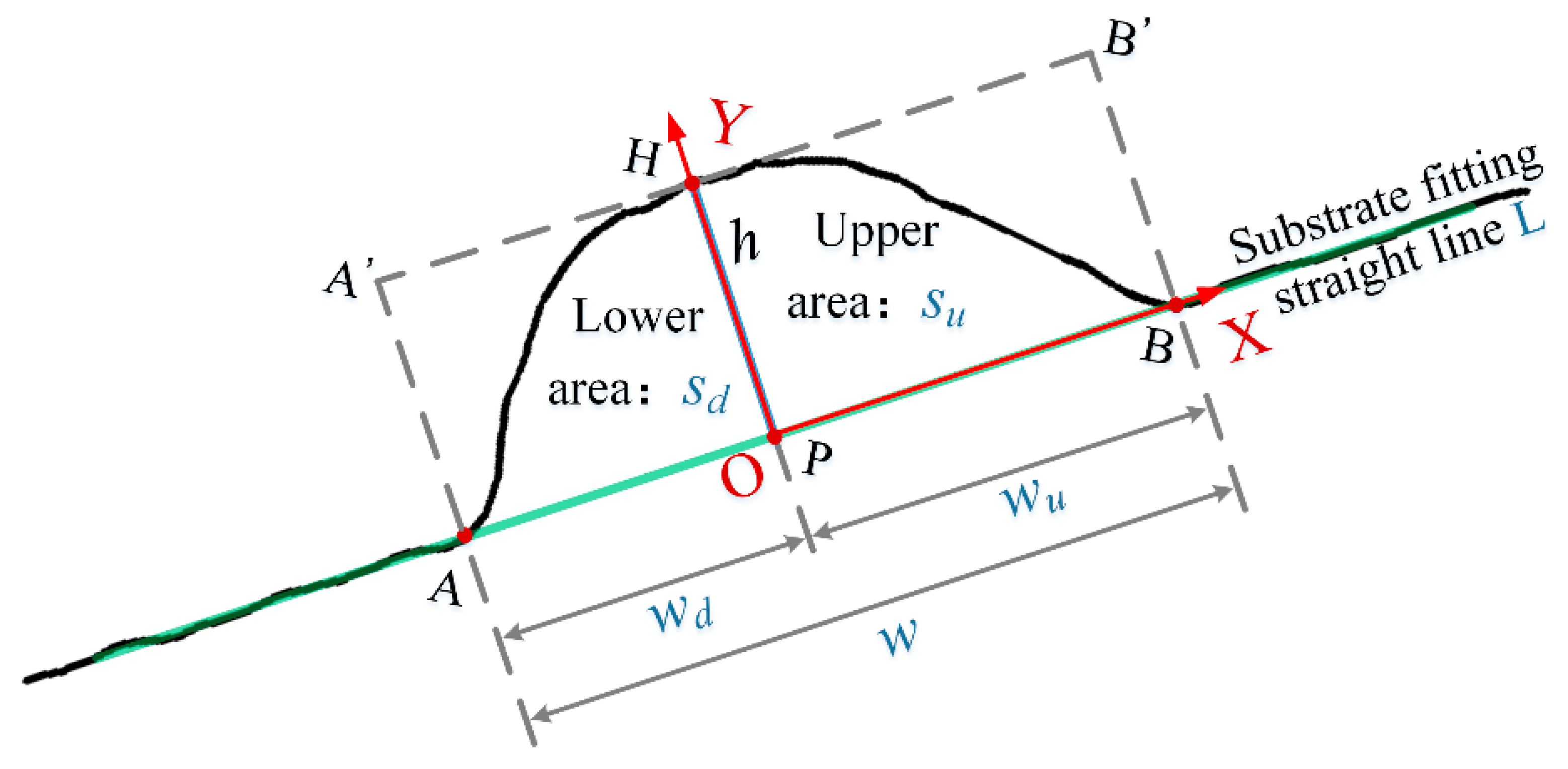

2.2. Geometric Characteristics of the Asymmetric Cross-Sectional Deposition Bead

- (1)

- Using the points on the plane and the least squares method, fit the straight line L;

- (2)

- The point H, which is the farthest from line L among all contour points, is defined as the highest point. The distance from point H to line L is defined as the height of the deposition bead, represented by h. The projection points of point H on the straight-line L are denoted as P;

- (3)

- Calculate the intersection point between the contour of the deposition path and the straight line L, denoted as A and B. Define the distance between points A and B as the width of the deposition path, denoted as w;

- (4)

- The distance between BP is denoted as wu, and the eccentricity is defined as wu/w, represented by e;

- (5)

- The profile is divided into two parts by the line segment HP. The area of the upper part is calculated as su, and the area of the lower part is recorded as sd. The upper plumpness is the ratio of the upper part to the area of the rectangle APHA’ surrounding it, which is su/(wu∗h), denoted as pu; the same applies to the lower plumpness, denoted as pd.

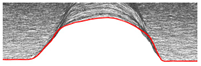

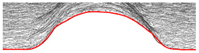

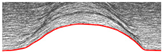

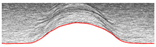

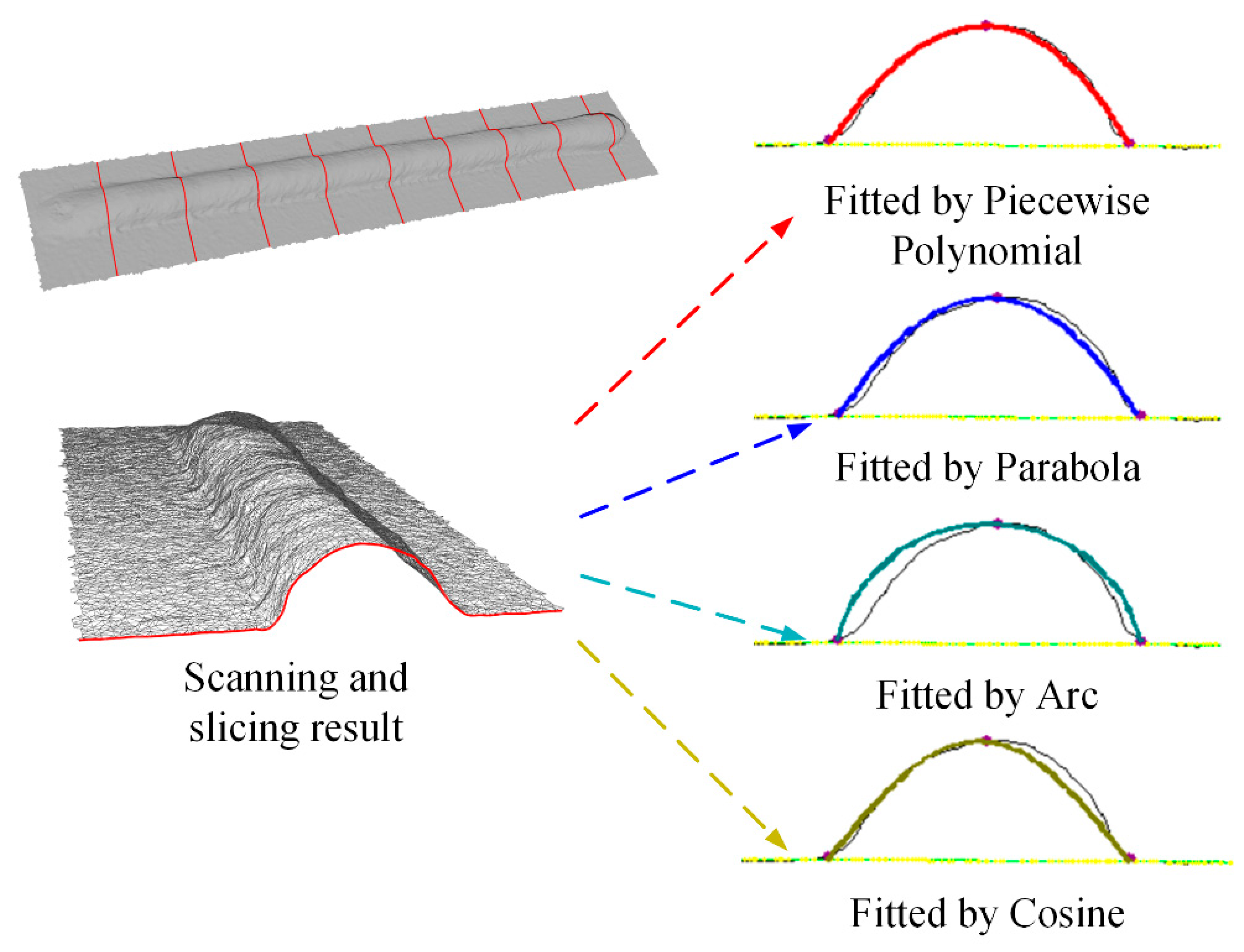

2.3. Contour Fitting Function

3. Forming Law and Modeling of Spatial GMA Deposition Bead

3.1. The Forming Experiment

3.2. Analysis of Forming Law

- (1)

- Height (h): When the path inclination is fixed, as the path direction angle rises, the height of the bead gradually becomes larger, and this trend becomes more and more obvious as the path inclination angle increases. When the path direction angle is fixed and less than 90°, corresponding to a downward welding condition, the height of the bead gradually diminishes as the path inclination increases. However, when the path direction angle exceeds 90°, corresponding to an upward welding condition, the height of the bead gradually expands as the path inclination increases.

- (2)

- Width (w): The width is primarily influenced by the path inclination. As the path inclination increases, the effect of gravity on the molten pool becomes more significant, resulting in an increase in width. When the path inclination is fixed, the width tends to decrease as the path direction angle rises, and this trend is more pronounced at higher path inclinations.

- (3)

- Eccentricity (e): The eccentricity rises with the increase of the path direction angle and path inclination angle and reaches the maximum value near the path direction angle of 90°. The horizontal welding position in the corresponding welding is most likely to cause the eccentricity of the deposition bead.

- (4)

- Upper plumpness (pu): Overall, the upper saturation decreases as the path direction angle and the path inclination angle increase. When the path direction angle is fixed and near 0°, the upper saturation shows a positive correlation with the path inclination angle; when the path direction angle is fixed, and near 90°, the upper saturation exhibits a negative correlation with the path inclination angle.

- (5)

- Lower plumpness (pd): The lower plumpness value does not show an opposite trend to the upper plumpness value but is mainly affected by the path inclination, with the maximum value appearing near the maximum path inclination of 45° and the path direction angle of 30°.

- (1)

- As the path direction angle increases, the morphology of the deposition bead changes from short and wide to thin and tall, and this trend becomes more pronounced with the increase of the path inclination angle and the decrease of the speed.

- (2)

- When the path direction angle is near 90°, corresponding to the horizontal welding position in welding, the eccentricity of the deposition path is the largest; that is, the downward tilt phenomenon is the most serious.

- (3)

- The upper and lower plumpness value performance is complex and does not show opposite trends. The figure shows that at maximum eccentricity, the upper plumpness is at a minimum, while the lower plumpness does not reach its maximum. This is because the plumpness value is not only affected by the eccentricity but also by the characteristics of the deposition path formation. For example, compared with the path direction angle of 0° and the path inclination of 45°, the corresponding deposition bead is wider and lower. There is no eccentricity, but the upper and lower plumpness values of the path are greater.

4. The Overlapping Strategy for the Asymmetric Cross-Sectional Deposition Bead

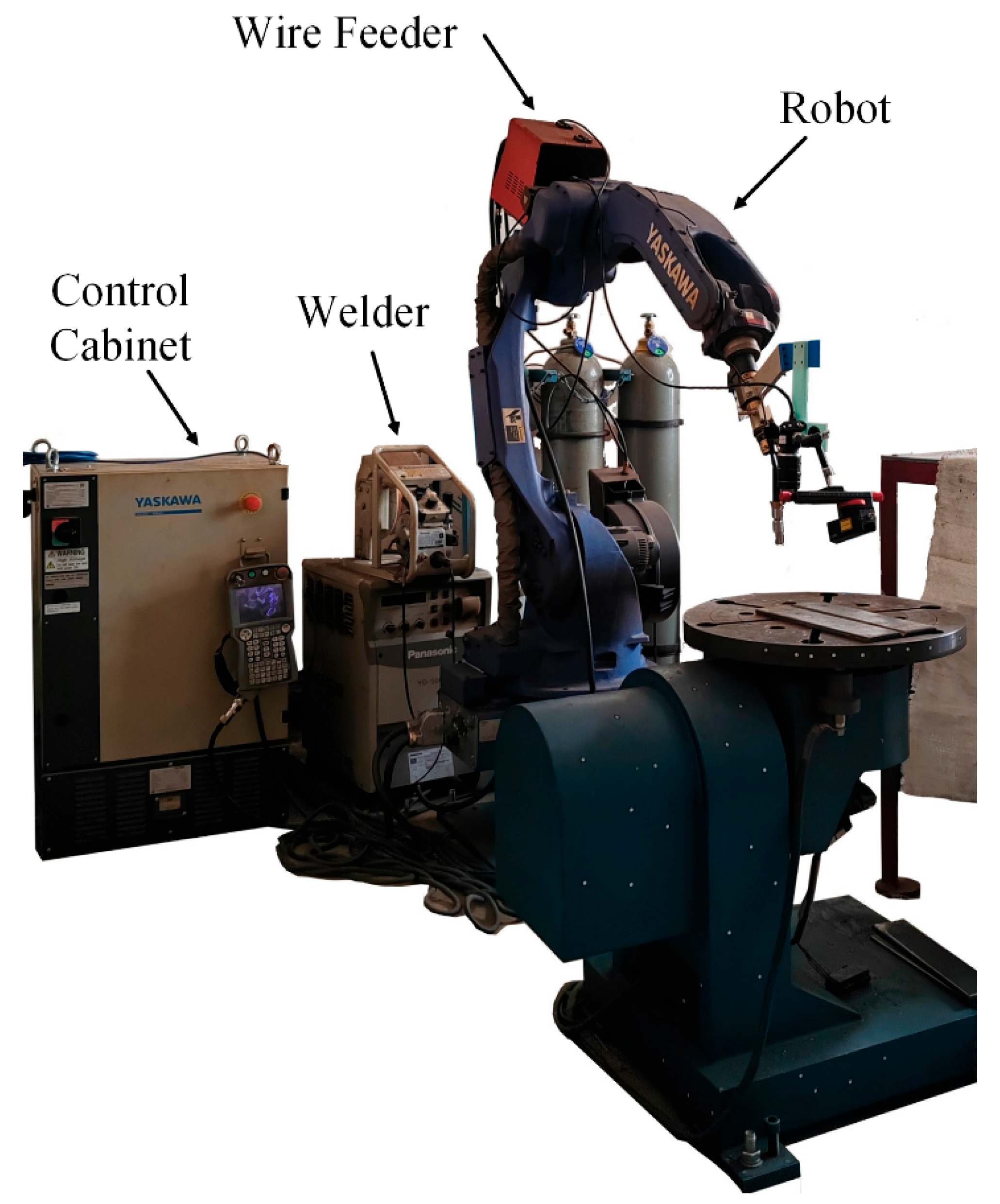

5. Experimental Setup

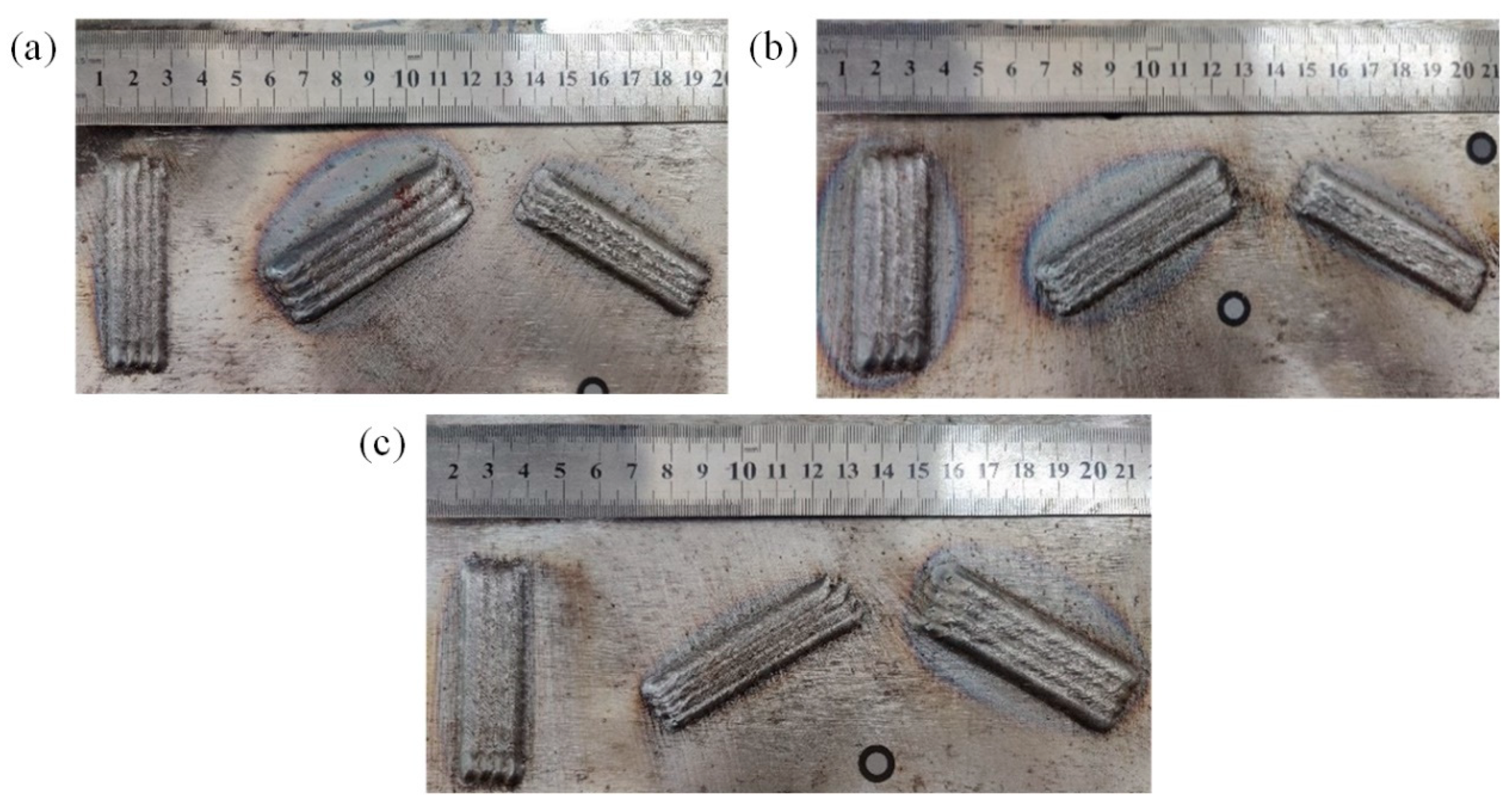

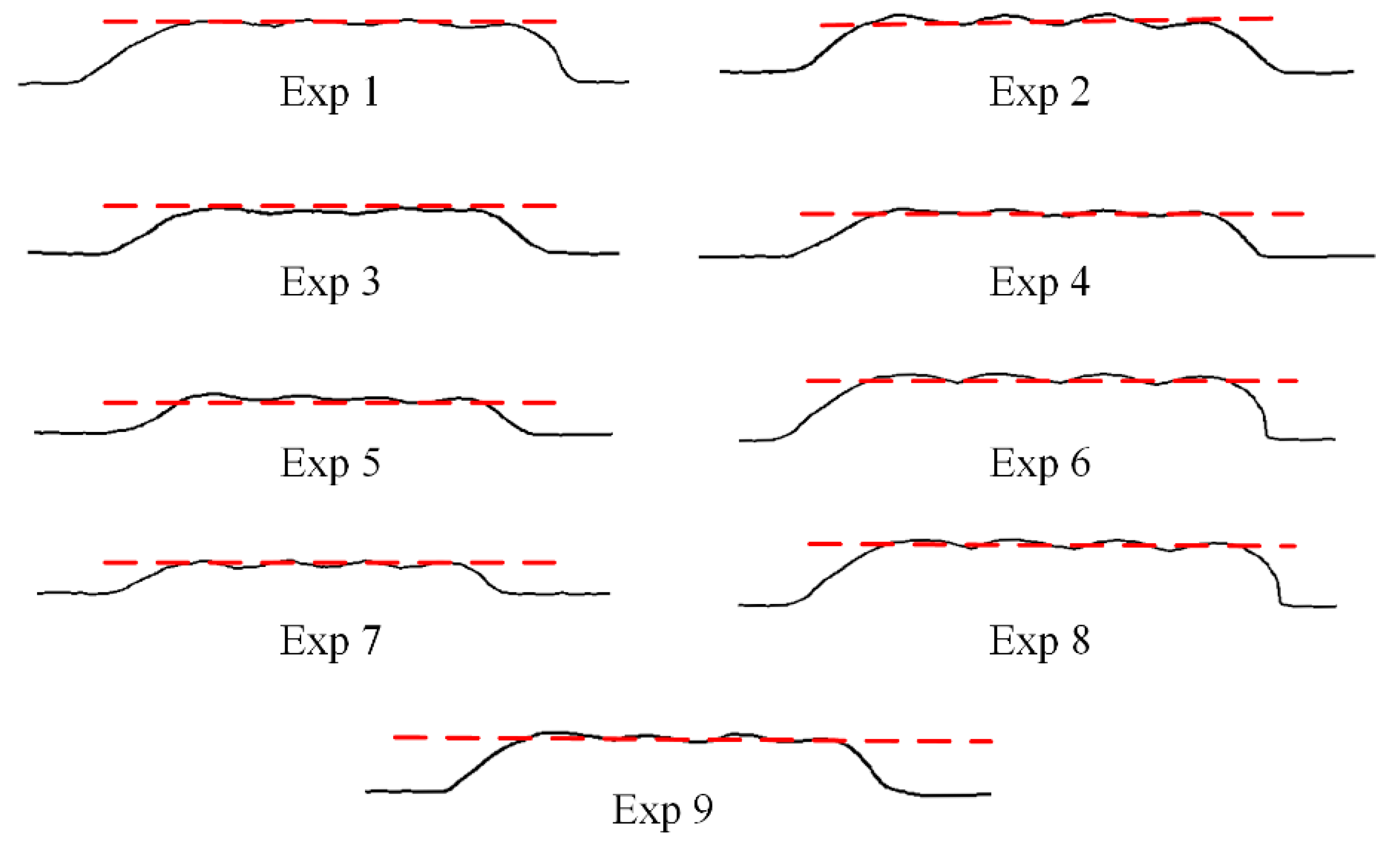

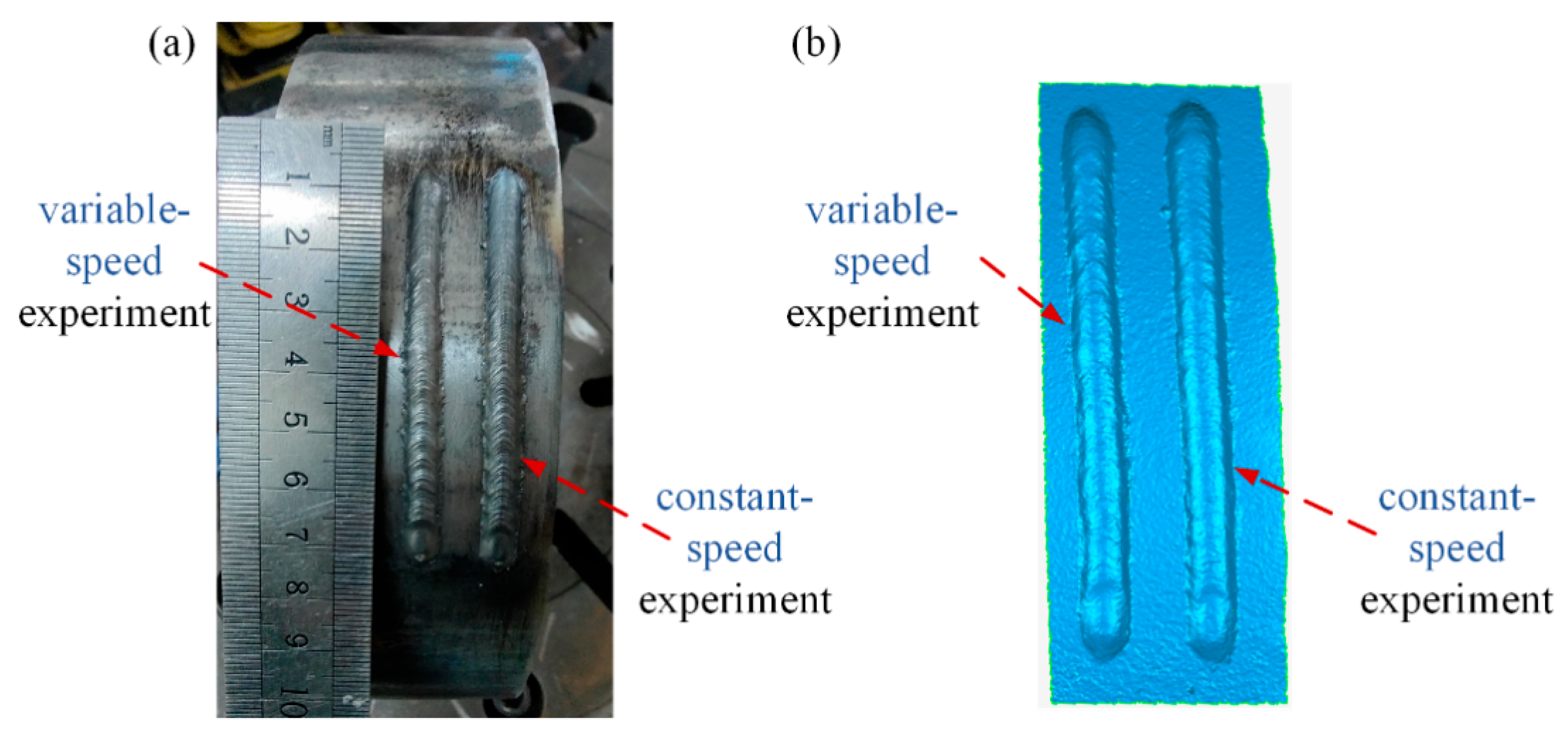

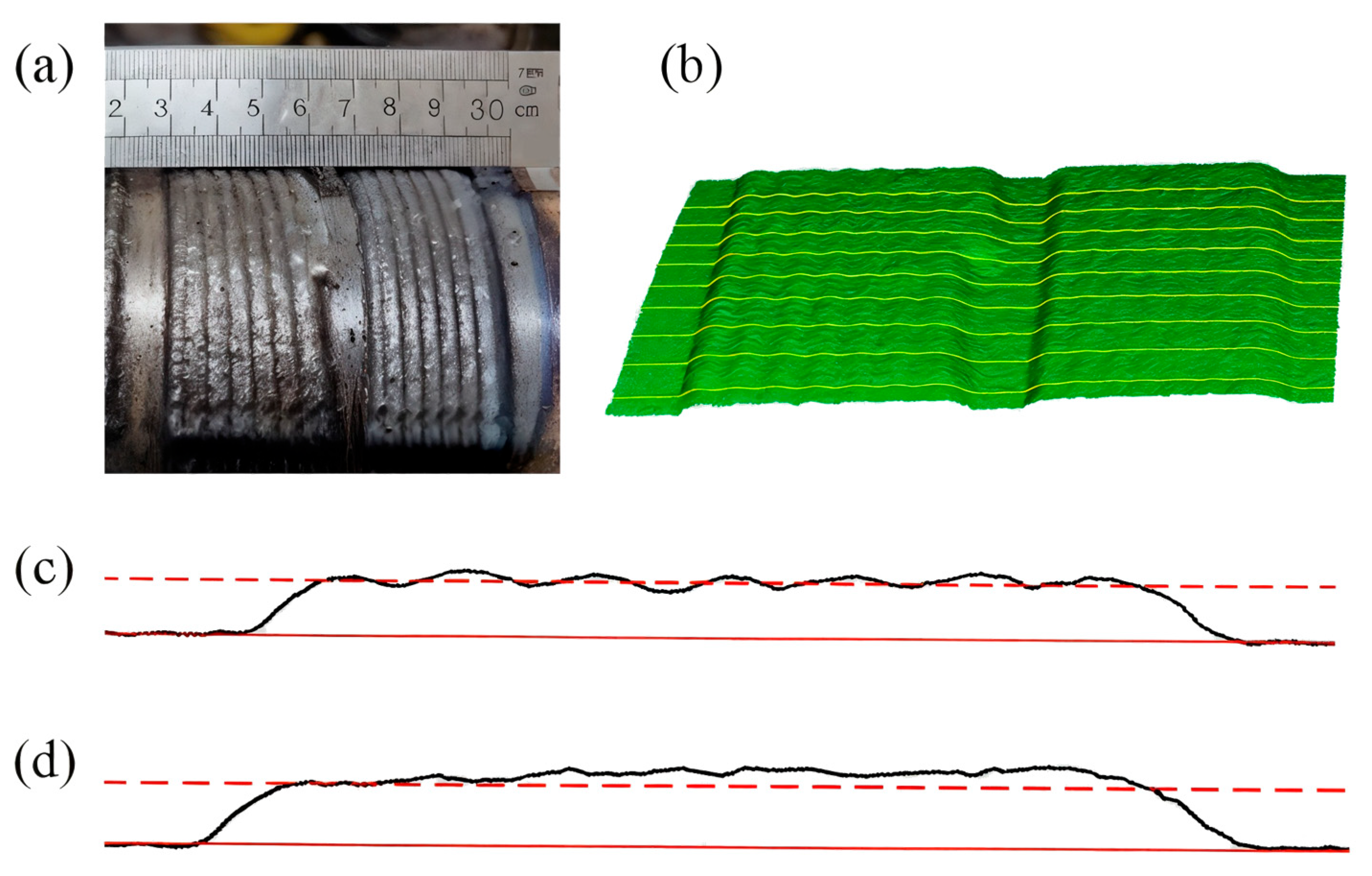

5.1. Deposition Experiment of the Spatial Equidistant-Height GMA Bead

5.2. Deposition Experiment of the Equidistant-Thickness GMA Curved Layer

6. Conclusions

- (1)

- Compared with the traditional contour fitting function, the piecewise polynomial proposed in this paper has better fitting accuracy for the asymmetric cladding channel section. The typical sections are fitted using piecewise polynomial fitting, parabola, arc, and cosine functions. The standard deviations obtained by comparing the fitting curve with the true contour are 0.16 mm, 0.21 mm, 0.44 mm, and 0.22 mm, respectively.

- (2)

- A prediction model for the geometric characteristics of the spatial bead was established. The R2 values of characteristics are all close to 1.0, and the mean relative deviations value fittings were within 2.5%; the fitting effect is good.

- (3)

- A comparative verification test was carried out on a cylinder, and the result showed that by setting different deposition speeds, the height variation range of the obtained spatially curved GMA deposited bead (excluding the arc starting end and the arc ending end) is within 0.2 mm.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

| No. | ai (°) | ad (°) | s (mm/s) | h (mm) | w (mm) | e | pu (%) | pd (%) | Morphology |

|---|---|---|---|---|---|---|---|---|---|

| 1 | 0 | 0 | 4 | 2.86 | 6.81 | 0.503 | 68.15 | 69.89 |  |

| 2 | 0 | 0 | 6 | 2.27 | 5.84 | 0.508 | 65.06 | 67.32 |  |

| 3 | 0 | 0 | 8 | 1.87 | 5.77 | 0.508 | 62.03 | 62.46 |   |

| 4 | 0 | 0 | 10 | 1.64 | 5.40 | 0.499 | 60.96 | 60.68 |  |

| 5 | 15 | 0 | 4 | 2.73 | 7.13 | 0.520 | 66.47 | 71.93 |  |

| 6 | 15 | 0 | 6 | 2.10 | 6.39 | 0.518 | 64.36 | 69.26 |  |

| 7 | 15 | 0 | 8 | 1.71 | 6.05 | 0.509 | 63.34 | 65.68 |  |

| 8 | 15 | 0 | 10 | 1.49 | 5.60 | 0.498 | 62.61 | 62.39 |  |

| 9 | 15 | 30 | 4 | 2.73 | 7.22 | 0.527 | 65.56 | 72.96 |  |

| 10 | 15 | 30 | 6 | 2.07 | 6.61 | 0.516 | 64.23 | 68.56 |  |

| 11 | 15 | 30 | 8 | 1.73 | 6.40 | 0.522 | 60.10 | 65.53 |  |

| 12 | 15 | 30 | 10 | 1.50 | 5.93 | 0.513 | 59.20 | 62.38 |  |

| 13 | 15 | 60 | 4 | 2.80 | 6.92 | 0.533 | 66.10 | 75.41 |  |

| 14 | 15 | 60 | 6 | 2.13 | 6.31 | 0.518 | 64.18 | 69.05 |  |

| 15 | 15 | 60 | 8 | 1.73 | 6.16 | 0.520 | 60.12 | 64.99 |  |

| 16 | 15 | 60 | 10 | 1.48 | 5.85 | 0.513 | 60.38 | 63.71 |  |

| 17 | 15 | 90 | 4 | 2.74 | 6.99 | 0.520 | 66.15 | 71.68 |  |

| 18 | 15 | 90 | 6 | 2.09 | 6.73 | 0.509 | 61.37 | 63.56 |  |

| 19 | 15 | 90 | 8 | 1.72 | 6.45 | 0.515 | 57.50 | 61.17 |  |

| 20 | 15 | 90 | 10 | 1.45 | 5.92 | 0.511 | 57.85 | 60.42 |  |

| 21 | 15 | 120 | 4 | 2.83 | 7.17 | 0.519 | 64.41 | 69.44 |  |

| 22 | 15 | 120 | 6 | 2.13 | 6.98 | 0.517 | 58.67 | 62.86 |  |

| 23 | 15 | 120 | 8 | 1.75 | 6.51 | 0.514 | 57.06 | 60.40 |  |

| 24 | 15 | 120 | 10 | 1.55 | 6.10 | 0.517 | 55.05 | 59.01 |  |

| 25 | 30 | 0 | 4 | 2.69 | 7.18 | 0.516 | 67.56 | 72.04 |  |

| 26 | 30 | 0 | 6 | 1.99 | 6.76 | 0.517 | 64.22 | 68.73 |  |

| 27 | 30 | 0 | 8 | 1.62 | 6.47 | 0.518 | 62.06 | 66.78 |  |

| 28 | 30 | 0 | 10 | 1.36 | 6.11 | 0.507 | 62.01 | 63.88 |  |

| 29 | 30 | 30 | 4 | 2.70 | 7.31 | 0.528 | 65.52 | 73.47 |  |

| 30 | 30 | 30 | 6 | 1.99 | 6.88 | 0.524 | 63.98 | 70.29 |  |

| 31 | 30 | 30 | 8 | 1.62 | 6.45 | 0.515 | 62.51 | 66.45 |  |

| 32 | 30 | 30 | 10 | 1.37 | 6.04 | 0.507 | 63.30 | 65.19 |  |

| 33 | 30 | 60 | 4 | 2.79 | 6.94 | 0.538 | 64.87 | 75.76 |  |

| 34 | 30 | 60 | 6 | 2.09 | 6.84 | 0.532 | 60.06 | 68.21 |  |

| 35 | 30 | 60 | 8 | 1.69 | 6.30 | 0.518 | 60.85 | 65.46 |  |

| 36 | 30 | 60 | 10 | 1.40 | 6.14 | 0.516 | 59.465 | 63.586 |  |

| 37 | 30 | 90 | 4 | 2.84 | 7.23 | 0.539 | 60.53 | 70.92 |  |

| 38 | 30 | 90 | 6 | 2.13 | 6.99 | 0.528 | 57.36 | 64.15 |  |

| 39 | 30 | 90 | 8 | 1.74 | 6.38 | 0.527 | 57.3054 | 64.0814 |  |

| 40 | 30 | 90 | 10 | 1.47 | 5.93 | 0.522 | 57.46 | 62.74 |  |

| 41 | 30 | 120 | 4 | 2.88 | 6.93 | 0.528 | 64.68 | 72.4 |  |

| 42 | 30 | 120 | 6 | 2.20 | 6.72 | 0.528 | 56.56 | 63.30 |  |

| 43 | 30 | 120 | 8 | 1.82 | 6.36 | 0.515 | 56.26 | 59.77 |  |

| 44 | 30 | 120 | 10 | 1.55 | 5.79 | 0.517 | 56.11 | 60.05 |  |

| 45 | 45 | 0 | 4 | 2.59 | 7.57 | 0.512 | 71.08 | 74.50 |  |

| 46 | 45 | 0 | 6 | 1.94 | 6.93 | 0.506 | 67.60 | 69.20 |  |

| 47 | 45 | 0 | 8 | 1.55 | 6.50 | 0.509 | 66.74 | 69.01 |  |

| 48 | 45 | 0 | 10 | 1.31 | 6.24 | 0.507 | 63.84 | 68.41 |  |

| 49 | 45 | 30 | 4 | 2.62 | 7.63 | 0.536 | 65.71 | 76.06 |  |

| 50 | 45 | 30 | 6 | 1.99 | 7.06 | 0.523 | 64.20 | 70.30 |  |

| 51 | 45 | 30 | 8 | 1.54 | 6.49 | 0.515 | 65.21 | 69.18 |  |

| 52 | 45 | 30 | 10 | 1.32 | 5.99 | 0.526 | 61.89 | 68.55 |  |

| 53 | 45 | 60 | 4 | 2.75 | 7.11 | 0.552 | 63.62 | 78.24 |  |

| 54 | 45 | 60 | 6 | 2.07 | 6.61 | 0.542 | 60.92 | 72.07 |  |

| 55 | 45 | 60 | 8 | 1.67 | 6.46 | 0.532 | 59.29 | 67.31 |  |

| 56 | 45 | 60 | 10 | 1.41 | 6.09 | 0.529 | 58.89 | 66.27 |  |

| 57 | 45 | 90 | 4 | 2.87 | 7.09 | 0.556 | 61.22 | 76.77 |  |

| 58 | 45 | 90 | 6 | 2.15 | 6.88 | 0.535 | 57.91 | 66.62 |  |

| 59 | 45 | 90 | 8 | 1.75 | 6.61 | 0.526 | 56.21 | 62.31 |  |

| 60 | 45 | 90 | 10 | 1.51 | 6.05 | 0.531 | 56.28 | 63.88 |  |

| 61 | 45 | 120 | 4 | 3.05 | 6.83 | 0.557 | 59.41 | 74.73 |  |

| 62 | 45 | 120 | 6 | 2.31 | 6.72 | 0.529 | 55.77 | 62.68 |  |

| 63 | 45 | 120 | 8 | 1.93 | 6.43 | 0.518 | 53.27 | 57.34 |  |

| 64 | 45 | 120 | 10 | 1.65 | 5.77 | 0.510 | 56.03 | 58.41 |  |

References

- Islam, M.K.; Hazell, P.J.; Escobedo, J.P.; Wang, H. Biomimetic armour design strategies for additive manufacturing: A review. Mater. Des. 2021, 205, 109730. [Google Scholar] [CrossRef]

- Ge, T.; Li, Y.; Gao, D.; Yang, C.; Li, F. Hybridizing additive manufacturing and sheet forming process to manufacture complex components with multi-features: A review. J. Manuf. Process. 2024, 124, 345–364. [Google Scholar] [CrossRef]

- Ye, J.; El Desouky, A.; Elwany, A. On the applications of additive manufacturing in semiconductor manufacturing equipment. J. Manuf. Process. 2024, 124, 1065–1079. [Google Scholar] [CrossRef]

- Tanwar, R.S.; Jhavar, S. Ti based alloys for aerospace and biomedical applications fabricated through wire+ arc additive manufacturing (WAAM). Mater. Today Proc. 2024, 98, 226–232. [Google Scholar] [CrossRef]

- Cano-Vicent, A.; Tambuwala, M.M.; Hassan, S.S.; Barh, D.; Aljabali, A.A.; Birkett, M.; Arjunan, A.; Serrano-Aroca, Á. Fused deposition modelling: Current status, methodology, applications and future prospects. Addit. Manuf. 2021, 47, 102378. [Google Scholar] [CrossRef]

- Elser, A.; Königs, M.; Verl, A.; Servos, M. On achieving accuracy and efficiency in Additive Manufacturing: Requirements on a hybrid CAM system. Procedia CIRP 2018, 72, 1512–1517. [Google Scholar] [CrossRef]

- Mansor, M.S.M.; Raja, S.; Yusof, F.; Muhamad, M.R.; Manurung, Y.H.; Adenan, M.S.; Hussein, N.I.S.; Ren, J. Integrated approach to Wire Arc Additive Manufacturing (WAAM) optimization: Harnessing the synergy of process parameters and deposition strategies. J. Mater. Res. Technol. 2024, 30, 2478–2499. [Google Scholar] [CrossRef]

- López-Arrabal, A.; Guzmán-Bautista, Á.; Solórzano-Requejo, W.; Franco-Martínez, F.; Villaverde, M. Axisymmetric non-planar slicing and path planning strategy for robot-based additive manufacturing. Mater. Des. 2024, 241, 112915. [Google Scholar] [CrossRef]

- Lau, T.Y.; Chen, L.; He, D.; Li, Z.; Tang, K. Partition-based print sequence planning and adaptive slicing for scalar field-based multi-axis additive manufacturing. Comput. -Aided Des. 2023, 163, 103576. [Google Scholar] [CrossRef]

- Luo, R.C.; Tzou, J.H. Implementation of a new adaptive slicing algorithm for the rapid prototyping manufacturing system. IEEE/ASME Trans. Mechatron. 2004, 9, 593–600. [Google Scholar] [CrossRef]

- Zhang, K.; Li, D.; Gui, H.; Li, Z. An adaptive slicing algorithm for laser cladding remanufacturing of complex components. Int. J. Adv. Manuf. Technol. 2019, 101, 2873–2887. [Google Scholar] [CrossRef]

- Chen, Q.; Xu, J.; Zhang, S. Cylindricity and flatness optimization for mechanical parts in additive manufacturing based on tolerance adaptive slicing. Int. J. Adv. Manuf. Technol. 2021, 115, 3839–3857. [Google Scholar] [CrossRef]

- Pérez-Castillo, J.L.; Cuan-Urquizo, E.; Roman-Flores, A.; Olvera-Silva, O.; Romero-Muñoz, V.; Gómez-Espinosa, A.; Ahmad, R. Curved layered fused filament fabrication: An overview. Addit. Manuf. 2021, 47, 102354. [Google Scholar] [CrossRef]

- Li, Y.; Xiong, J.; Yin, Z. Molten pool stability of thin-wall parts in robotic GMA-based additive manufacturing with various position depositions. Robot. Comput. -Integr. Manuf. 2019, 56, 1–11. [Google Scholar] [CrossRef]

- Liu, H.; Wang, S.; Chen, H.; Xiong, J. Drop and hump behaviors in robotic arc-directed energy deposition with vertical position. Addit. Manuf. 2024, 82, 104049. [Google Scholar] [CrossRef]

- Kazanas, P.; Deherkar, P.; Almeida, P.; Lockett, H.; Williams, S. Fabrication of geometrical features using wire and arc additive manufacture. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2012, 226, 1042–1051. [Google Scholar] [CrossRef]

- Aiyiti, W.; Zhao, W.; Lu, B.; Tang, Y. Investigation of the Overlapping Parameters of MPAW-based Rapid Prototyping. Rapid Prototyp. J. 2006, 12, 165–172. [Google Scholar] [CrossRef]

- Ding, D.; Pan, Z.; Cuiuri, D.; Li, H. A Multi-Bead Overlapping Model for Robotic Wire and Arc Additive Manufacturing (WAAM). Robot. Comput. -Integr. Manuf. 2015, 31, 101–110. [Google Scholar] [CrossRef]

- Han, Q.; Li, X.; Dong, M.; Zhang, G. Enhanced Curve-fitting Model of the Bead Section Profile and the Corresponding Overlapping Model for Twin-electrode Gas Tungsten Arc-based Additive Manufacturing. Int. J. Adv. Manuf. Technol. 2021, 116, 1151–1167. [Google Scholar] [CrossRef]

- Chen, C.; He, H.; Zhou, S.; Lian, G.; Huang, X.; Feng, M. Prediction of multi-bead profile of robotic wire and arc additive manufactured components recursively using axisymmetric drop shape analysis. Virtual Phys. Prototyp. 2023, 18, e2254563. [Google Scholar] [CrossRef]

- Kaščák, Ľ.; Varga, J.; Bidulská, J.; Bidulský, R. Simulation of 316L Stainless Steel Produced the Laser Powder Bed Fusion Process. Materials 2023, 16, 7653. [Google Scholar] [CrossRef] [PubMed]

- Hu, Z.; Hua, L.; Qin, X.; Ni, M.; Ji, F.; Wu, M. Molten pool behaviors and forming appearance of robotic GMAW on complex surface with various welding positions. J. Manuf. Process. 2021, 64, 1359–1376. [Google Scholar] [CrossRef]

- Hu, Z.; Hua, L.; Qin, X.; Ni, M.; Liu, Z.; Liang, C. Region-based path planning method with all horizontal welding position for robotic curved layer wire and arc additive manufacturing. Robot. Comput. -Integr. Manuf. 2022, 74, 102286. [Google Scholar] [CrossRef]

- Cao, H.; Huang, R.; Yi, H.; Liu, M.; Jia, L. Asymmetric molten pool morphology in wire-arc directed energy deposition: Evolution mechanism and suppression strategy. Addit. Manuf. 2022, 59, 103113. [Google Scholar] [CrossRef]

- Ni, M.; Zhou, Y.; Hu, Z.; Qin, X.; Xiong, X.; Ji, F. Forming optimization for WAAM with weaving deposition on curved surfaces. Int. J. Mech. Sci. 2023, 252, 108366. [Google Scholar] [CrossRef]

- Li, X. The Forming Characteristics and Path Planning of Curved Layering Robotic GMA Additive Manufacturing. Doctoral Dissertation, Harbin Institute of Technology, Harbin, China, 2023. [Google Scholar]

| Forming Conditions | Path Inclination (°) | Path Direction Angle (°) | Deposition Velocity (mm/s) |

|---|---|---|---|

| Range | 0~45 | 0~120 | 4~10 |

| Variable | R2 | RMSE | MRE |

|---|---|---|---|

| h | 0.9968 | 0.0286 | 1.10% |

| w | 0.9231 | 0.1384 | 2.05% |

| e | 0.7833 | 0.0057 | 1.12% |

| pu | 0.9032 | 1.1746 | 1.55% |

| pd | 0.915 | 1.4287 | 1.87% |

| No. | Path Inclination ai (°) | Path Direction ad (°) | Deposition Speed s (mm/s) | Offset Distance d (mm) |

|---|---|---|---|---|

| 1 | 15 | 0 | 4 | 4.86 |

| 2 | 15 | 60 | 7 | 4.08 |

| 3 | 15 | 120 | 10 | 3.47 |

| 4 | 30 | 0 | 7 | 4.33 |

| 5 | 30 | 60 | 10 | 3.71 |

| 6 | 30 | 120 | 4 | 4.64 |

| 7 | 45 | 0 | 10 | 4.14 |

| 8 | 45 | 60 | 4 | 5.05 |

| 9 | 45 | 120 | 7 | 3.76 |

| No. | Equipment/Component | Specifications |

|---|---|---|

| 1 | Welder | Panasonic YD-500FR |

| 2 | Robot | Motorman HP20D six-axis robot |

| 3 | Shielding Gas | 95% Ar + 5% CO2, flow rate: 18 ± 0.5 L/min flow rate: 18 ± 0.5 L/min |

| 4 | Welding wire | H08Mn2Si |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, X.; Yan, H.; Li, Y.; Chi, G.; Zhang, G. Study on Characterization and Overlapping Strategy of Asymmetric Cross-Section of Spatial Curved GMA Deposition Bead. Symmetry 2025, 17, 856. https://doi.org/10.3390/sym17060856

Li X, Yan H, Li Y, Chi G, Zhang G. Study on Characterization and Overlapping Strategy of Asymmetric Cross-Section of Spatial Curved GMA Deposition Bead. Symmetry. 2025; 17(6):856. https://doi.org/10.3390/sym17060856

Chicago/Turabian StyleLi, Xinlei, Han Yan, Yongzhe Li, Guanxin Chi, and Guangjun Zhang. 2025. "Study on Characterization and Overlapping Strategy of Asymmetric Cross-Section of Spatial Curved GMA Deposition Bead" Symmetry 17, no. 6: 856. https://doi.org/10.3390/sym17060856

APA StyleLi, X., Yan, H., Li, Y., Chi, G., & Zhang, G. (2025). Study on Characterization and Overlapping Strategy of Asymmetric Cross-Section of Spatial Curved GMA Deposition Bead. Symmetry, 17(6), 856. https://doi.org/10.3390/sym17060856