Integrated Scheduling Algorithm for No-Wait Network Flexible Based on Idle-Time Optimization and Process Rescheduling

Abstract

1. Introduction

2. Problem Description and Mathematical Model

2.1. Problem Description

- (1)

- The processing machine in the machine network can only process one process at a time.

- (2)

- Each process can only be processed by one processing machine, and once a process starts, it cannot be interrupted.

- (3)

- Each process can only start processing after all its preceding procedures have been completed. For processes with no-wait constraints, the completion time of the preceding process is the start time of this process.

- (4)

- There are no identical machines in the machine network, and the processing machine is in a discrete distribution state. To simplify the model and emphasize the optimization of process sequencing and machine idle time, the transportation time between processing machines is not considered in this model. This assumption is reasonable in scenarios where the machine layout is extremely compact or transportation time is much shorter than processing time.

- (5)

- The completion time of the last process of the product is the total processing time of the product.

2.2. Mathematical Model

3. Strategy Analysis

3.1. Reverse Layer Priority Strategy

3.2. Average Reverse Subsequent Path Strategy

3.3. No-Wait Earliest Completion Strategy

3.4. Optimal Completion-Semi-Idle Triggered Insertion Rescheduling Strategy

3.5. Optimal Completion-Full-Idle Adaptive Insertion Scheduling Strategy

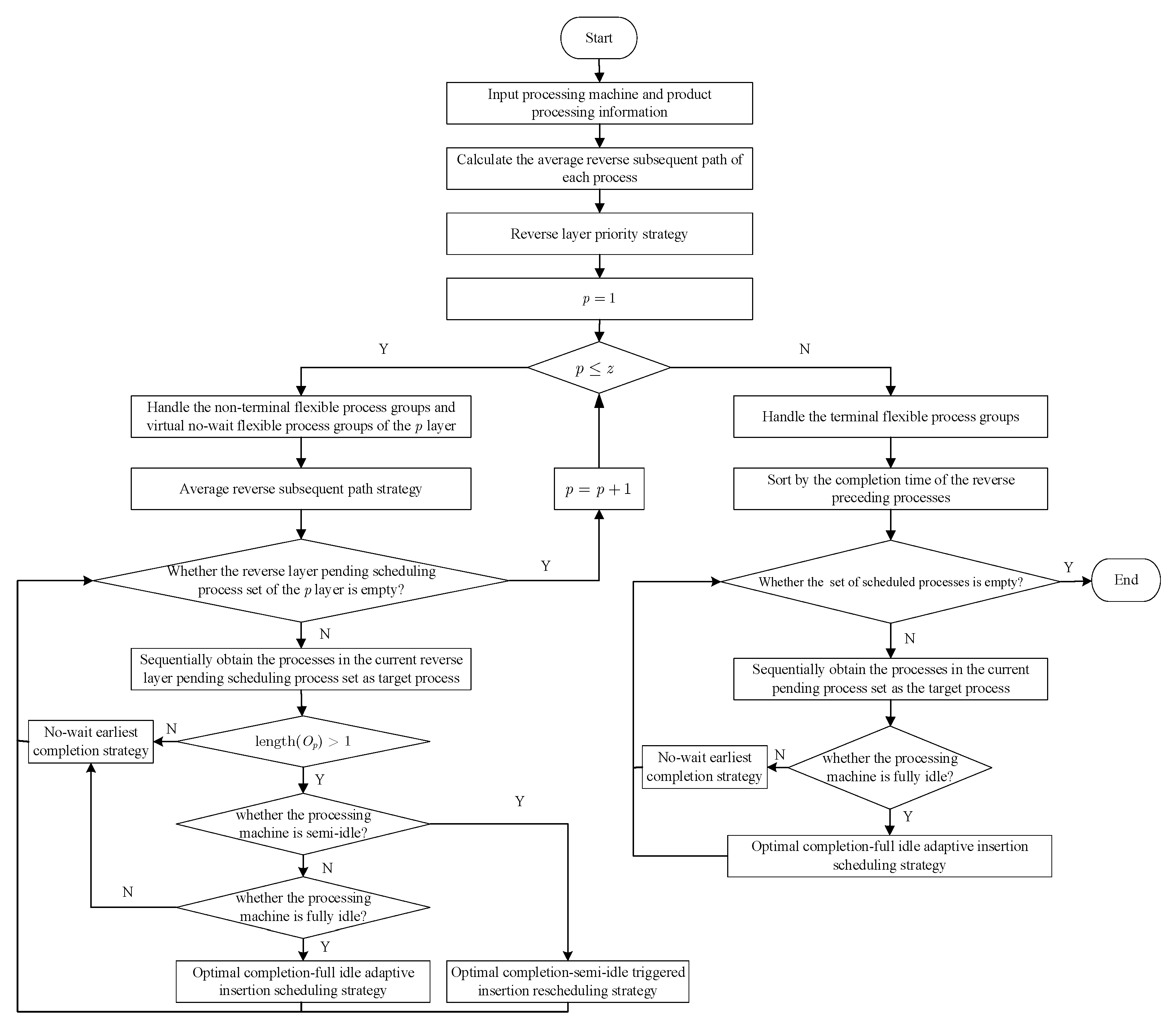

4. Algorithm Design and Complexity Analysis

4.1. Algorithm Design

4.2. Algorithm Pseudo-Code

| Algorithm 1 ITPR-NFIS | |

| Input: product process tree and processing machine information | |

| Output: process scheduling plan and makespan | |

| 1: | Calculate the average reverse subsequent path of each process |

| 2: | Calculate the number of terminal flexible processes F |

| 3: | Perform reverse layering on the process tree, calculate the total number of layers z, and assign the processes to the corresponding set of scheduled processes Op in the reverse layer. The first layer is p = 1 |

| 4: | While p <= z |

| 5: | Obtain the non-terminal flexible process groups and virtual no-wait flexible process groups in the current layer, and sort them in descending order according to the average reverse subsequent path value |

| 6: | if Op is empty |

| 7: | p = p + 1, continue |

| 8: | end |

| 9: | for i = 1 to length(Op) |

| 10: | Sequentially obtain the processes in the current reverse layer pending scheduling process set as target process. |

| 11: | if length(Op) > 1 |

| 12: | if tiw > ITwr and T(Ai) > T(Az) and FTiw < min(EFTik) |

| 13: | Implement the optimal completion-semi-idle triggered insertion rescheduling strategy to determine the processing start time and end time of the target process and the selected processing machine, continue |

| 14: | else if ITwr > = tiw and FTiw < min(EFTik) |

| 15: | Execute the optimal completion-full-idle adaptive insertion scheduling strategy, determine the target process processing start time and end time, as well as the selected processing machine, continue |

| 16: | else |

| 17: | Implement the no-wait earliest completion strategy. If the target process can be fully scheduled on all machines, calculate the earliest completion time of the target process on the flexible machine, continue |

| 18: | end if |

| 19: | end if |

| 20: | end for |

| 21: | p = p + 1 |

| 22: | end while |

| 23: | Calculate the completion time of the reverse preceding processes of the terminal flexible processes in each layer. Schedule the processes with shorter completion times of the reverse preceding processes first, and so on. Sort each process and place the sorted processes in the set of processes to be scheduled. |

| 24: | if the current set of scheduled processes is not empty |

| 25: | if ITwr > = tiw and FTiw < min(EFTik) |

| 26: | Execute the optimal completion-full-idle adaptive insertion scheduling strategy, determine the target process processing start time and end time, as well as the selected processing machine, continue |

| 27: | else |

| 28: | Implement the no-wait earliest completion strategy. If the target process can be fully scheduled on all machines, calculate the earliest completion time of the target process on the flexible machine, continue |

| 29: | end if |

| 30: | end if |

| end procedure | |

4.3. Complexity Analysis

5. Comparative Analysis of Example

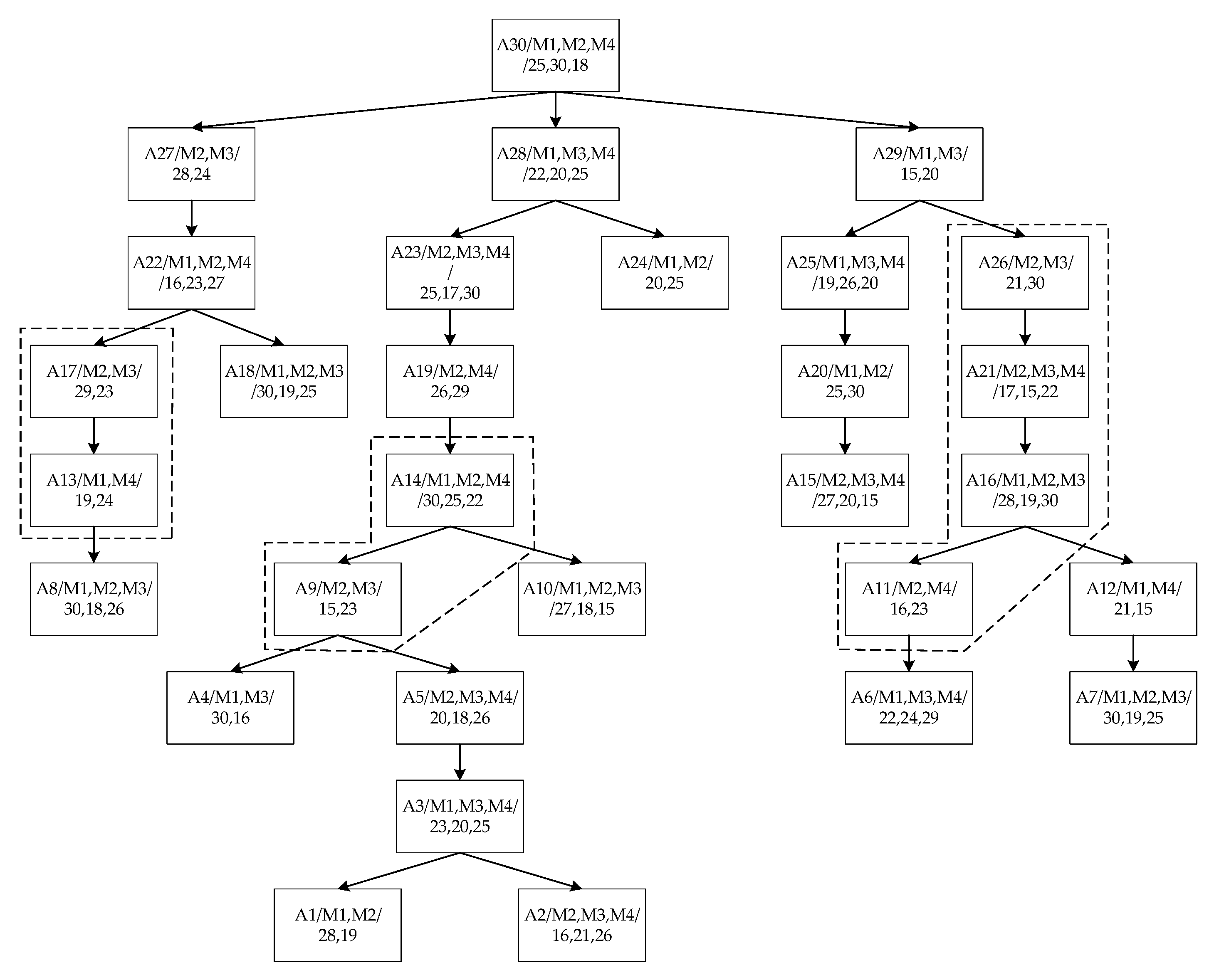

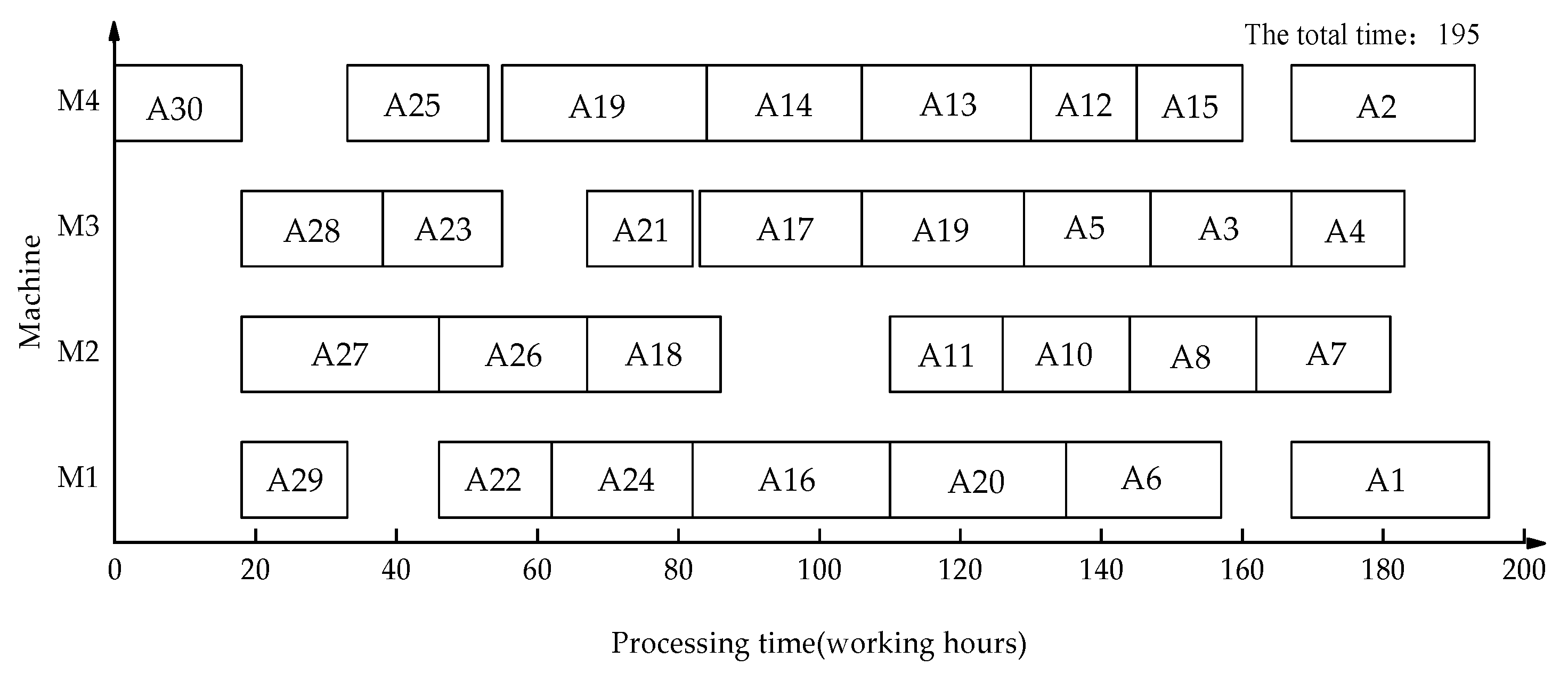

5.1. Example Analysis

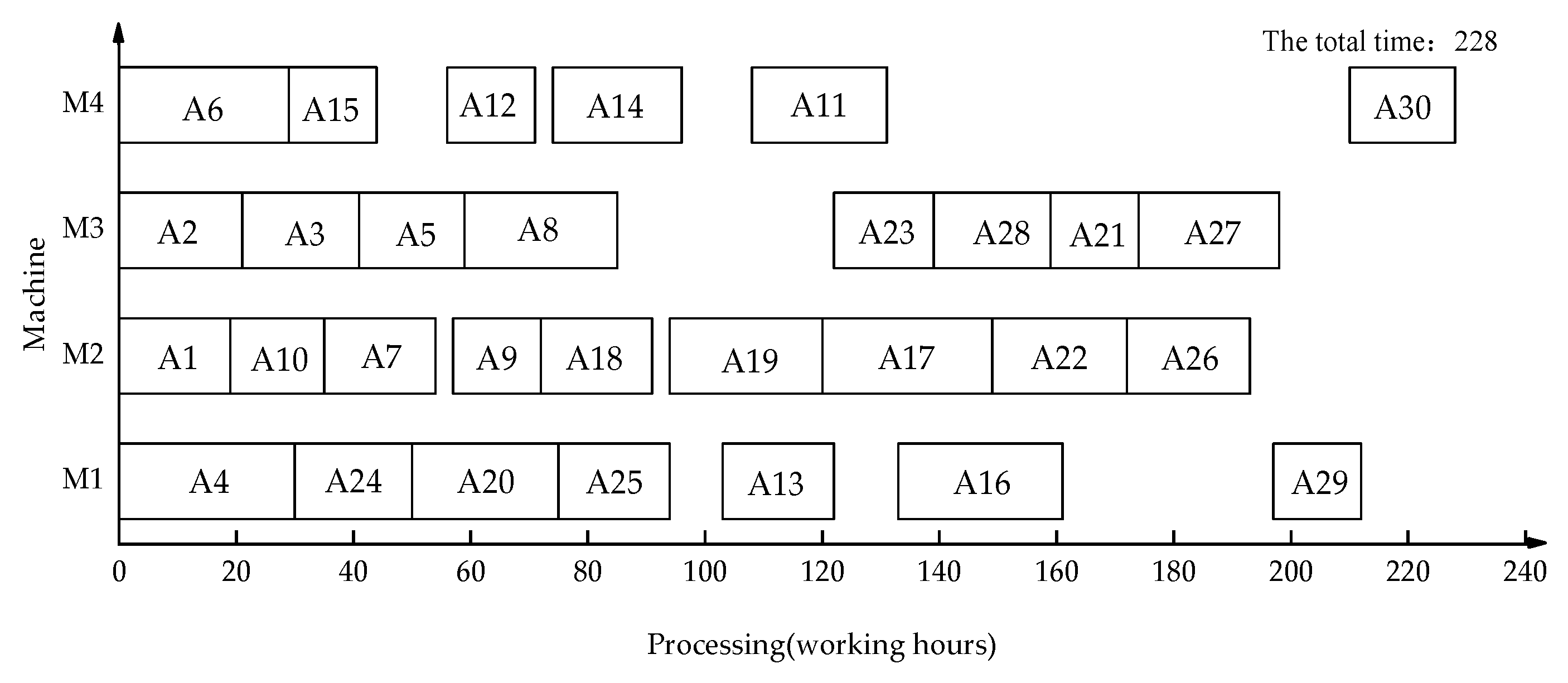

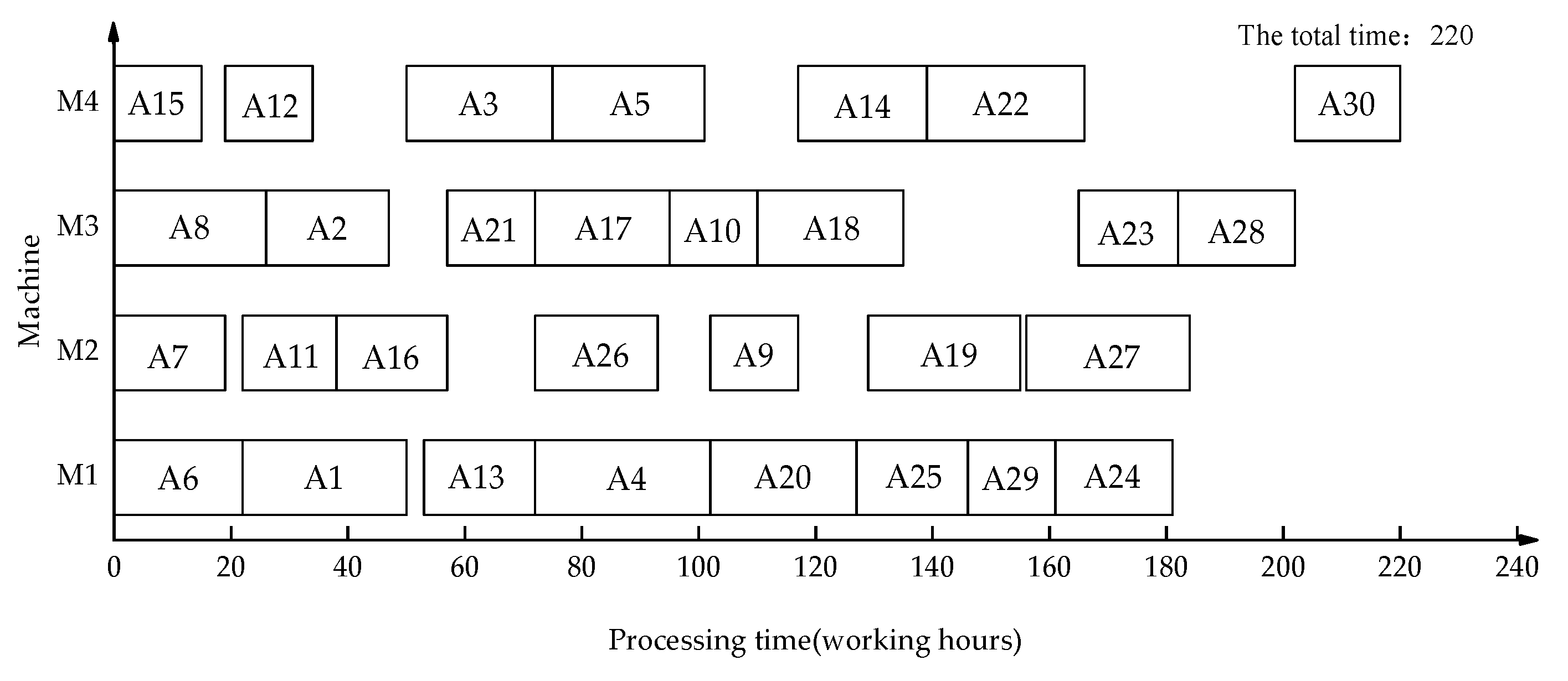

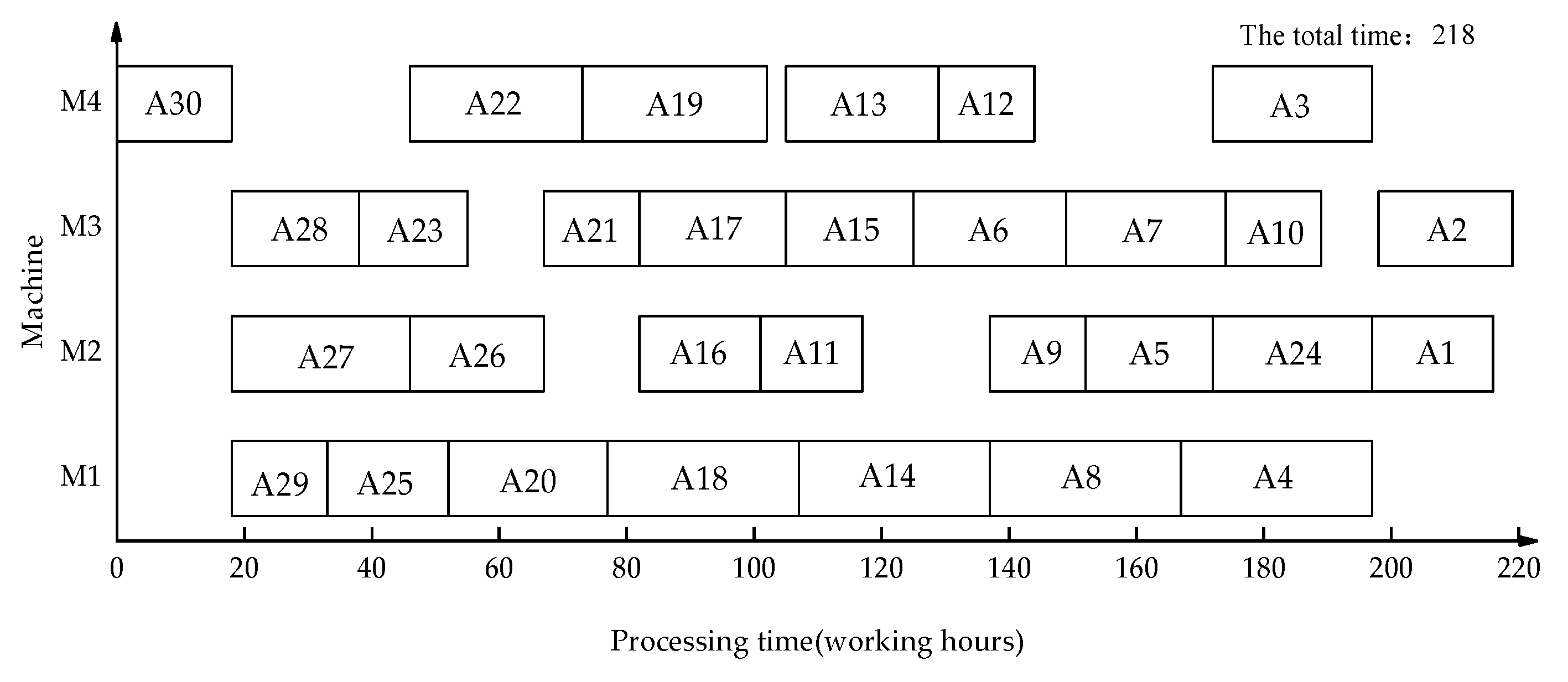

5.2. Performance Comparison Analysis

6. Conclusions and Prospects

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, Y.L.; Liu, A.; Deng, X.D. Integrated scheduling of production and transportation in a distributed heterogeneous hybrid flow shop. Comput. Integr. Manuf. Syst. 2024, 30, 4087–4098. [Google Scholar] [CrossRef]

- Zhang, Y.Z.; Dong, S.D.; Yuan, Z.F.; Wen, T.; Xiao, J.F.; Diao, Z. Meta-relation-based heterogeneous graph neural network with deep reinforcement learning for flexible job shop scheduling. Expert Syst. Appl. 2025, 291, 128411. [Google Scholar] [CrossRef]

- Yu, C.Z.; Zhang, C.J.; Fan, J.X.; Shen, W.M. An integrated mathematical programming and reinforcement learning algorithm for the flexible job shop scheduling with variable lot-sizing. J. Manuf. Syst. 2025, 82, 210–223. [Google Scholar] [CrossRef]

- Yao, Y.J.; Li, X.Y.; Gao, L. A dqn-based memetic algorithm for energy-efficient job shop scheduling problem with integrated limited agvs. Swarm Evol. Comput. 2024, 87, 101544. [Google Scholar] [CrossRef]

- He, P.; Jiang, X.C.; Wang, Q.; Zhang, B. Multi-objective human-robot collaborative batch scheduling in distributed hybrid flowshop via automatic design of local search-reconstruction-feedback algorithm. Comput. Ind. Eng. 2025, 203, 110983. [Google Scholar] [CrossRef]

- Hamzadayı, A.; Van, M.G. Greedy randomized adaptive search and benders decomposition algorithms to solve the distributed no-idle permutation flowshop scheduling problem. Swarm Evol. Comput. 2025, 97, 102028. [Google Scholar] [CrossRef]

- Song, H.B.; Lin, J.; Chen, Y.R. An effective two-stage heuristic for scheduling the distributed assembly flowshops with sequence dependent setup times. Comput. Oper. Res. 2025, 173, 106850. [Google Scholar] [CrossRef]

- Ji, Q.H.; Han, Y.Y.; Wang, Y.T.; Gong, D.W.; Gao, K.Z. A Q-learning-driven genetic algorithm for the distributed hybrid flow shop group scheduling problem with delivery time windows. Inf. Sci. 2025, 705, 121971. [Google Scholar] [CrossRef]

- Xie, Z.Q.; Teng, H.K.; Anak Agung, A.P.A.; Yu, X. An integrated scheduling algorithm for the same equipment process sequencing based on the root-subtree vertical and horizontal pre-scheduling. CMES-Comput. Model. Eng. Sci. 2023, 134, 179. [Google Scholar] [CrossRef]

- Ba, Z.Y.; Yuan, Y.P.; Li, M.; Adilanmu, S.T.H. Integrated scheduling algorithm of complex product with hierarchical coupling constraints. Comput. Integr. Manuf. Syst. 2025, 31, 965–983. [Google Scholar] [CrossRef]

- Zhang, J.; Yuan, M.H.; Chen, H.J. Research on welding integrated scheduling based on improved fireworks algorithm. J. Huazhong Univ. Sci. Tech. Nat. Sci. Ed. 2022, 50, 130–137. [Google Scholar] [CrossRef]

- Shi, F.; Zhao, S. Product comprehensive scheduling problems solved by genetic algorithm based on operation constraint chain coding. Chin. Mech. Eng. 2017, 28, 2483–2492. [Google Scholar] [CrossRef]

- Ding, X.Y.; Zhou, W.; Xie, Z.Q.; Sun, M.; Tan, Z.J.; Cao, W.C. Integrated scheduling algorithm based on improved semi-numerical algorithm. Symmetry 2025, 17, 434. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, X.; Cao, Y.; Lai, G. An integrated scheduling algorithm for multi-device-processes with the strategy of exchanging adjacent parallel processes of the same device. EURASIP J. Wirel. Commun. Netw. 2021, 2021, 104. [Google Scholar] [CrossRef]

- Lei, Q.; Guo, W.F.; Song, Y.C. Integrated scheduling algorithm based on an operation relationship matrix table for tree-structured products. Int. J. Prod. Res. 2018, 56, 5437–5456. [Google Scholar] [CrossRef]

- Wang, X.; Song, Y.; Zou, Y.; Guo, W.; Wang, Y. Integrated scheduling algorithm for multiple complex products with due dateconstraints. J. Phys. Conf. Ser. 2021, 1748, 032030. [Google Scholar] [CrossRef]

- Xie, Z.Q.; Liu, D.M. Integrated scheduling algorithm for flexible equipment network considering same layer after process. J. Electron. Inf. Techn. 2024, 46, 2961–2969. [Google Scholar] [CrossRef]

- Li, X.; Ren, X.Y.; Zhou, Y.B.; Zhang, J. Research on flexible integrated scheduling under stochastic processing times based on improved D3QN algorithm. J. Syst. Simul. 2025, 37, 474–486. [Google Scholar] [CrossRef]

- Yang, D.; Xie, Z.Q.; Liu, Q.; Yu, X. A signal-driven based flexible integrated scheduling algorithm with bidirectional coordination mechanism. Multimed. Tools Appl. 2023, 82, 34029–34051. [Google Scholar] [CrossRef]

- Gui, Z.Y.; Zhang, Z.; Wang, Q.; Jiang, L.L. Reversed flexible integrated scheduling algorithm based on device driving and essential path. Mod. Inf. Technol. 2024, 8, 152–156. [Google Scholar]

- Xie, Z.Q.; Wang, Q. Flexible integrated scheduling algorithm based on reverse order layer priority. J. Electron. Inf. Technol. 2022, 44, 1554–1562. [Google Scholar] [CrossRef]

- Zhou, W.; Ding, X.Y.; Xie, Z.Q. An integrated scheduling algorithm considering the processing capacity of flexible equipment. J. South China Norm. Univ. Nat. Sci. Ed. 2024, 56, 110–118. [Google Scholar] [CrossRef]

- Rajendran, C. A no-wait flowshop scheduling heuristic to minimize makespan. J. Oper. Res. Soc. 1994, 45, 472–478. [Google Scholar] [CrossRef]

- Guo, W.F.; Lie, Q.; Song, Y.C.; Lü, X.F.; Li, L. Integrated scheduling algorithm of complex product with no-wait constraint based on virtual component. J. Mech. Eng. 2020, 56, 246–257. [Google Scholar] [CrossRef]

- Xie, Z.Q.; Li, Z.M.; Hao, S.Z.; Tan, G.Y. Study on complex product scheduling problem with no-wait constraint between operations. Acta Autom. Sin. 2009, 35, 983–989. [Google Scholar] [CrossRef]

- Xie, Z.Q.; Teng, Y.Z.; Yang, J. Integrated scheduling algorithm with no-wait constraint operation group. Acta Autom. Sin. 2011, 37, 371–379. [Google Scholar] [CrossRef]

- Guo, W.F.; Song, Y.C.; Zhou, F.; Lie, Q.; Lü, X.F. Integrated scheduling algorithm of complex product with no-wait constraint based on reversed virtual component. Comput. Integr. Manuf. Syst. 2020, 26, 3313–3328. [Google Scholar] [CrossRef]

- Xie, Z.Q.; Xin, Y.; Yang, J. No-wait integrated scheduling algorithm based on reversed order signal-driven. J. Comput. Res. Dev. 2013, 50, 1710–1721. [Google Scholar]

- Xie, Z.Q.; Su, W.X.; Guo, H.; Chen, D.Y.; Xin, Y.; Teng, Y.Z. The integrated flexible scheduling algorithm of complex product with no-wait constraint between procedures. In Proceedings of the 11th International Forum on Strategic Technology, Novosibirsk, Russia, 1–3 June 2016; pp. 249–253. [Google Scholar] [CrossRef]

- Topcuoglu, H.; Hariri, S.; Wu, M.Y. Performance-effective and low-complexity task scheduling for heterogeneous computing. IEEE Trans. Parallel Distrib. Syst. 2002, 13, 260–274. [Google Scholar] [CrossRef]

| Abbreviation | Full Name |

|---|---|

| O-NPS | Study on the complex product scheduling problem with no-wait constraint between operations |

| OG-NIS | Integrated scheduling algorithm with no-wait constraint operation group |

| ROSD-NIS | No-wait integrated scheduling algorithm based on reversed order signal-driven |

| P-NIFS | The integrated flexible scheduling algorithm of complex products with no-wait constraint between procedures |

| ITPR-NFIS | Integrated scheduling algorithm for no-wait network flexible based on idle-time optimization and process rescheduling |

| Symbol | Definition |

|---|---|

| n | total number of processes |

| m | total number of processing machines |

| Ai | the i-th process of the product, i = 1, 2, …, n |

| Mj | the j-th device, j = 1, 2, …, m |

| si | start processing time of process Ai |

| fi | completion time of process Ai |

| ti | processing time of process Ai |

| AFTij | actual completion time of process Ai on processing machine Mj |

| tij | processing time of process Ai on processing machine Mj |

| Hij | decision variable, whether process Ai is processed on processing machine Mj |

| Process Set | Process | EST | EFT | Selected Processing | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| M1 | M2 | M3 | M4 | M1 | M2 | M3 | M4 | Machine | ||

| NF1 | A30 | 0 | 0 | - | 0 | 25 | 30 | - | 18 | M4 |

| NF3, NF4, NF2 | A28 | 18 | - | 18 | 18 | 40 | - | 38 | 43 | M3 |

| A29 | 18 | - | 38 | - | 33 | - | 58 | - | M1 | |

| A27 | - | 18 | 38 | - | - | 46 | 52 | - | M2 | |

| NF6, V9, NF5, NF8 | A23 | - | 46 | 38 | 38 | - | 71 | 55 | 68 | M3 |

| A26 | - | 46 | 55 | - | - | 67 | 85 | - | M2 (A26 meets no-wait constraints.) | |

| A21 | - | 67 | 67 | 67 | - | 84 | 82 | 89 | M3 (A21 meets no-wait constraints.) | |

| A16 | 82 | 82 | 82 | - | 110 | 101 | 112 | - | M2 (A16 meets no-wait constraints.) | |

| A11 | - | 101 | - | 101 | - | 117 | - | 124 | M2 (A11 meets no-wait constraints.) | |

| A22 | 46 | 67 | - | 46 | 62 | 90 | - | 73 | M1 | |

| A25 | 62 | - | 82 | 33 | 81 | - | 108 | 53 | M4 | |

| NF12, V10, NF13, NF15 | A19 | - | 67 | - | 55 | - | 93 | - | 84 | M4 |

| A17 | - | 67 | 82 | - | - | 96 | 105 | - | M2 (A17 meets the semi-idle insertion condition on machine M2 and is inserted. A17 meets no-wait constraints. The affected processes are A16 and A11.) | |

| A13 | 96 | - | - | 96 | 115 | - | - | 120 | M1 (A13 meets no-wait constraints.) | |

| A16 | 82 | 96 | 82 | - | 110 | 115 | 112 | - | M1 (A16 rescheduling. A16 meets the semi-idle insertion condition on machine M1 and is inserted. A16 meets no-wait constraints. The affected process is A13.) | |

| A11 | - | 110 | - | 110 | - | 126 | - | 133 | M2 (A11 rescheduling. A11 meets no-wait constraints.) | |

| A13 | 110 | - | - | 96 | 129 | - | - | 120 | M4 (A13 rescheduling. A13 meets no-wait constraints.) | |

| A20 | 110 | 126 | - | - | 135 | 156 | - | - | M1 | |

| A12 | 135 | - | - | 120 | 156 | - | - | 135 | M4 | |

| V17 | A14 | 135 | 96 | - | 84 | 165 | 121 | - | 106 | M4 (A14 meets the semi-idle insertion condition on machine M4 and is inserted. A14 meets no-wait constraints. The affected process is A13.) |

| A9 | - | 126 | 106 | - | - | 141 | 129 | - | M3 (A9 meets no-wait constraints.) | |

| A13 | 135 | - | - | 106 | 154 | - | - | 130 | M4 (A13 rescheduling. A13 meets the semi-idle insertion condition on machine M4 and is inserted. A13 does not meet the no-wait constraint. Reschedule A17 to ensure that A13 meets the no-wait constraint. The affected processes are A12 and A17.) | |

| A17 | - | 77 | 83 | - | - | 106 | 106 | - | M3 (A17 rescheduling. The completion time of A17 on M2 and M3 is the same, but the processing time on M3 is shorter, so M3 is chosen. A17 meets the full-idle insertion condition on machine M3 and is inserted. A17 and A13 meet no-wait constraints.) | |

| A12 | 135 | - | - | 130 | 156 | - | - | 145 | M4 (A12 rescheduling.) | |

| NF21 | A5 | - | 129 | 129 | 145 | - | 159 | 147 | 171 | M3 |

| NF23 | A3 | 147 | - | 147 | 147 | 170 | - | 167 | 172 | M3 |

| F7, F11, F22, F14, F20, F16, F18, F19, F24, F25 | A24 | 62 | 67 | - | - | 82 | 92 | - | - | M1 (A24 meets the full-idle insertion condition on machine M1 and is inserted. No affected processes.) |

| A18 | 135 | 67 | 167 | - | 165 | 86 | 192 | - | M2 (A18 meets the full-idle insertion condition on machine M2 and is inserted. No affected processes.) | |

| A10 | 135 | 126 | 167 | - | 162 | 144 | 182 | - | M2 | |

| A6 | 135 | - | 167 | 145 | 157 | - | 191 | 174 | M1 | |

| A4 | 157 | - | 167 | - | 187 | - | 183 | - | M3 | |

| A8 | 157 | 144 | 183 | - | 187 | 162 | 209 | - | M2 | |

| A15 | - | 162 | 183 | 145 | - | 189 | 203 | 160 | M4 | |

| A7 | 157 | 162 | 183 | - | 187 | 181 | 208 | - | M2 | |

| A1 | 167 | 181 | - | - | 195 | 200 | - | - | M1 | |

| A2 | - | 181 | 183 | 167 | - | 197 | 205 | 193 | M4 | |

| Algorithm | Scheduling Strategy | Optimization Objective | No-Wait Constraints | Idle Time |

|---|---|---|---|---|

| IO-NPS | average allied critical path method, best fit scheduling method, movement and exchange algorithm, and no-wait earliest completion strategy | Minimize makespan | Yes | Not optimized |

| IOG-NIS | first fit scheduling method for unified linkage of no-wait process groups, average allied critical path method, and no-wait earliest completion strategy | Minimize makespan | Yes | Not optimized |

| IROSD-NIS | biggest parallelism chosen policy, frontier greedy policy, and reverse order signal-driven | Minimize makespan | Yes | Not optimized |

| P-NIFS | allied critical path method, adaptive flexible scheduling strategy, equipment balanced strategy, optimization strategy of procedure scheduling | Minimize makespan | Yes | Not optimized |

| ITPR-NFIS | reverse layer priority strategy, average reverse subsequent path strategy, no-wait earliest completion strategy, optimal completion-semi-idle triggered insertion rescheduling strategy, optimal completion-full-idle adaptive insertion scheduling strategy | Minimize makespan | Yes | Optimized |

| Algorithm | Makespan (Working Hours) | Relative Reduction Ratio of Makespan of ITPR-NFIS Algorithm |

|---|---|---|

| IO-NPS | 228 | 14.47% |

| IOG-NIS | 220 | 11.36% |

| IROSD-NIS | 218 | 10.55% |

| P-NIFS | 220 | 11.36% |

| ITPR-NFIS | 195 | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, D.; Xie, Z. Integrated Scheduling Algorithm for No-Wait Network Flexible Based on Idle-Time Optimization and Process Rescheduling. Symmetry 2025, 17, 2053. https://doi.org/10.3390/sym17122053

Liu D, Xie Z. Integrated Scheduling Algorithm for No-Wait Network Flexible Based on Idle-Time Optimization and Process Rescheduling. Symmetry. 2025; 17(12):2053. https://doi.org/10.3390/sym17122053

Chicago/Turabian StyleLiu, Dongmei, and Zhiqiang Xie. 2025. "Integrated Scheduling Algorithm for No-Wait Network Flexible Based on Idle-Time Optimization and Process Rescheduling" Symmetry 17, no. 12: 2053. https://doi.org/10.3390/sym17122053

APA StyleLiu, D., & Xie, Z. (2025). Integrated Scheduling Algorithm for No-Wait Network Flexible Based on Idle-Time Optimization and Process Rescheduling. Symmetry, 17(12), 2053. https://doi.org/10.3390/sym17122053