Characterizing Hydraulic Fracture Morphology and Propagation Patterns in Horizontal Well Stimulation via Micro-Seismic Monitoring Analysis

Abstract

1. Introduction

2. Principles and Methods of Earthquake Source Location

2.1. Automatic Identification of Effective Seismic Events

2.2. Automatic Picking Method for Seismic Data

2.2.1. Energy Ratio-Polarization Method

- (1)

- Long–short time window energy ratio method

- (2)

- Polarization analysis

2.2.2. Selection of Threshold Values and Application of Multi-Level Detectors

- (1)

- Threshold value

- (2)

- Utilization of multi-stage detectors

2.2.3. Identification of P- and S-Wave

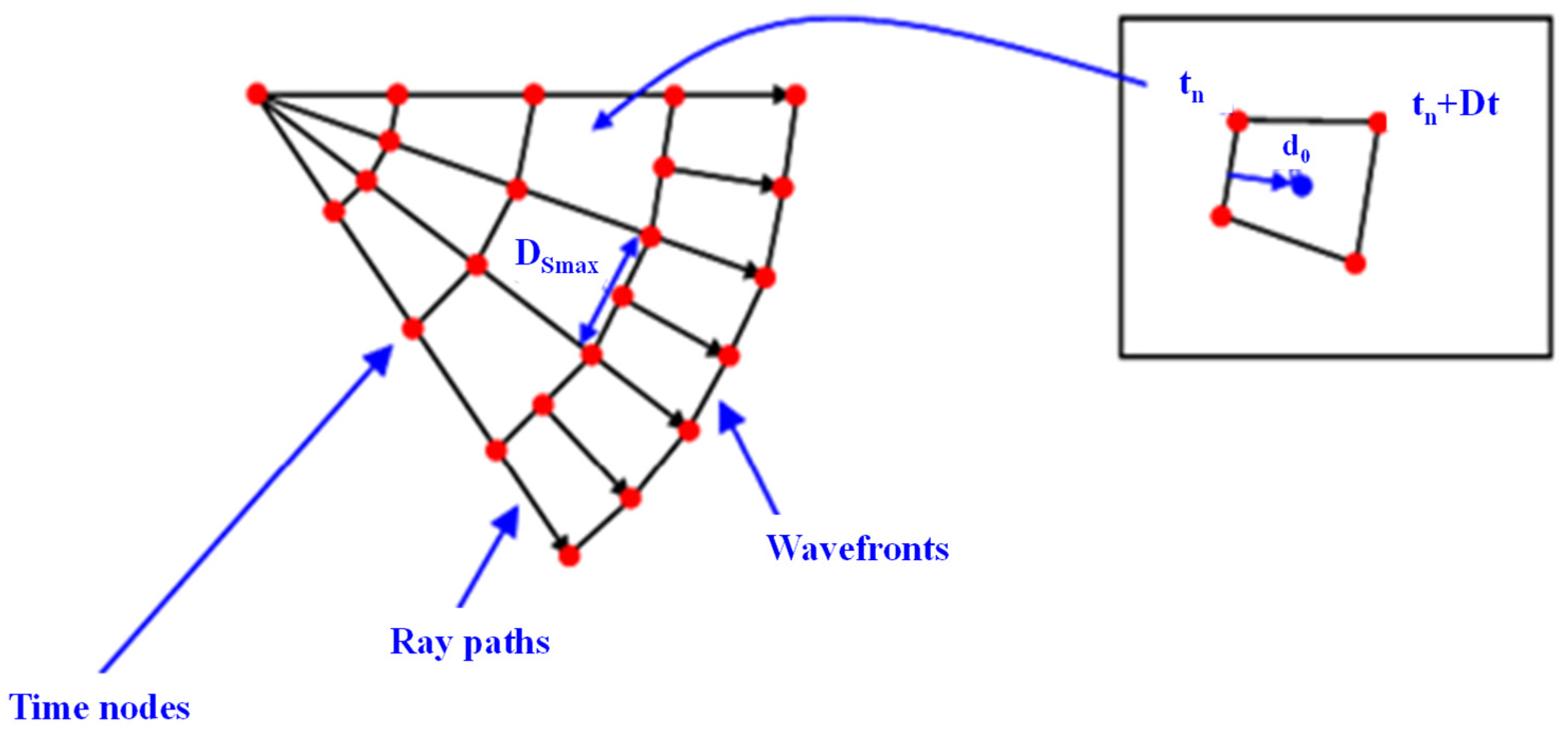

2.3. The Method and Principle of Forward Modeling in Ray Tracing

- (1)

- Raypath determination via numerical integration of emission vectors from source coordinates.

- (2)

- Precision angular adjustment through feedback-controlled iterations to fulfill receiver targeting criteria (Figure 2).

- Divide the medium model into grids with equal spacing.

- Specify the initial point coordinates of the ray and assume an emission angle.

- Starting from the grid containing the initial point, trace the ray to the next grid using the assumed emission angle, and record the position.

- Perturb the recorded grid’s incident edge to determine the next grid, and repeat the calculation until reaching the grid containing the receiving point. Determine whether the ray can reach the receiving point.

- If the receiving point is reached, record the emission angle and output the emission path; otherwise, adjust the emission angle and repeat steps c and d until an emission angle that satisfies the requirements is found.

2.4. Limitations of Micro-Seismic Monitoring Method

3. Design of Micro-Seismic Monitoring

3.1. Selection Principles for Monitoring Wells and Monitoring Horizons

3.1.1. Geological Background of the Ordos Basin and C6 Reservoir

- (1)

- Tectonic and sedimentary setting

- (2)

- Stratigraphic characteristics

- (3)

- Diagenetic evolution and reservoir modification

- (4)

- Hydrocarbon generation and accumulation

3.1.2. Geological Characteristics of the Target Layer C 6

- (1)

- The reservoir petrophysical characteristics of the C 6 formation

- (2)

- Mechanical characteristics of the C 6 formation

- (3)

- The in situ stress characteristics of the reservoir

3.1.3. Selection Principles for Monitoring Wells and Monitoring Horizons

- (1)

- The primary considerations include the well spacing between the monitoring well and the detected well, wellbore conditions, completion method of the monitoring well, proximity to the oil reservoir, and other relevant parameters.

- (2)

- This fracture monitoring is specifically designed for tight reservoirs in Y oilfield, which are characterized by thick sand bodies and locally developed micro-fractures, meeting the requirements for volume fracturing.

- (3)

- Adjacent wells with similar reservoir geological conditions and comparable physical properties can be selected for comparative analysis to evaluate the implementation effects of volume fracturing relative to conventional fracturing.

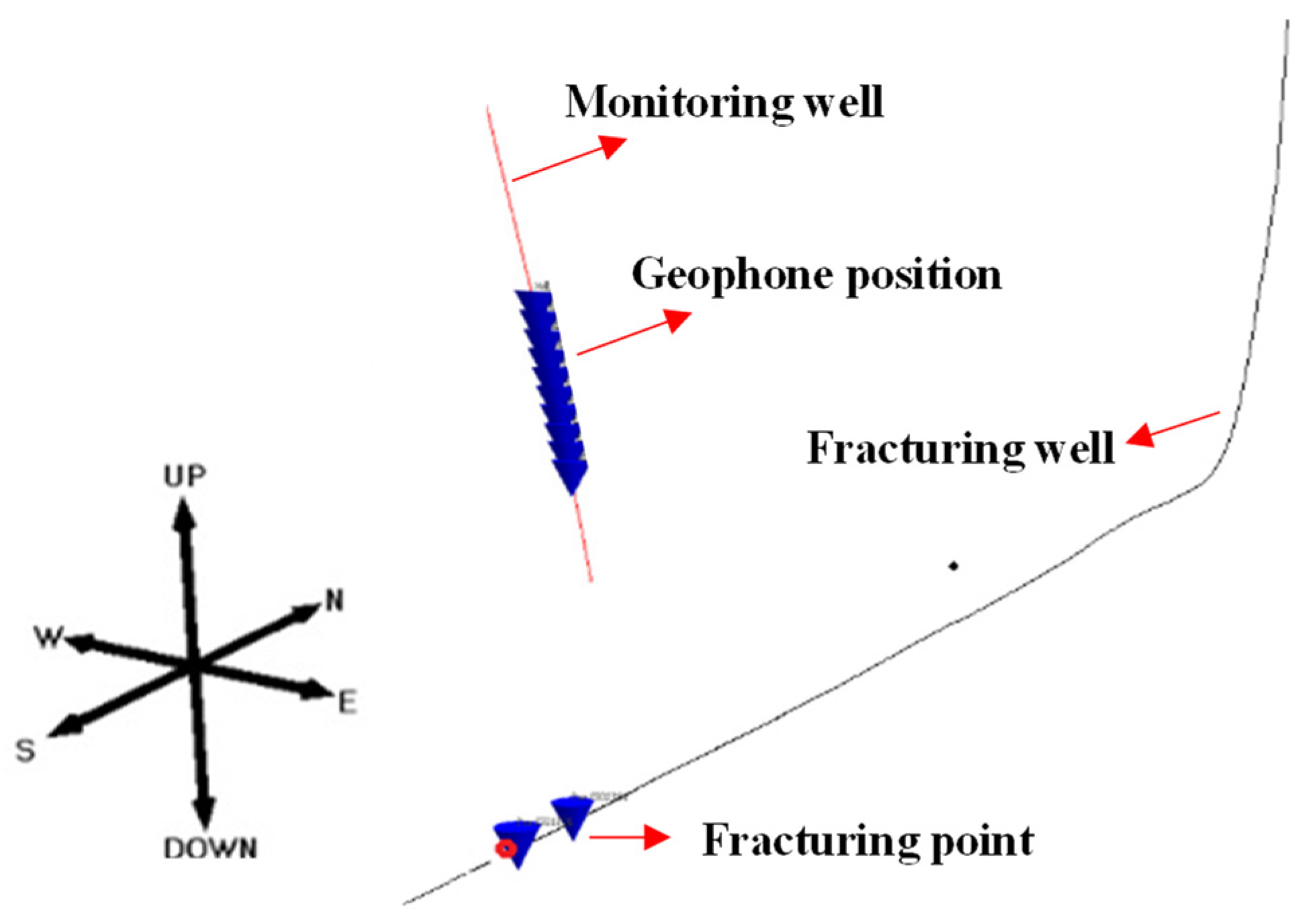

3.2. Design of Monitoring System

3.3. Optimization of Perforation Scheme for Fractured Wells

3.4. Perforation Positioning Analysis

4. Result and Analysis

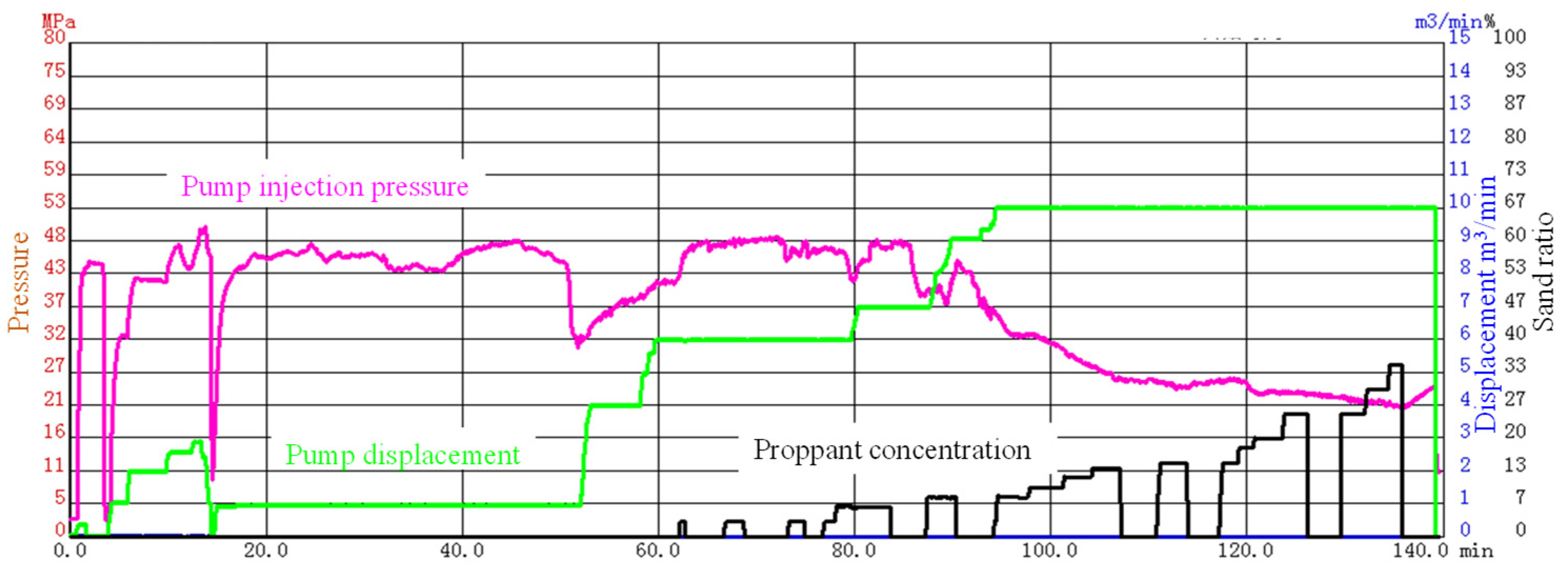

4.1. Fracturing Monitoring Results for Section 1

4.2. Analysis and Discussion

- (1)

- Stress orientation determination

- (2)

- Stress magnitude constraints

- (a)

- Fracture asymmetry ratio (west wing 194 m vs. east wing 117 m).

- (b)

- Branch fracture occurrence threshold (45–65° dip angles).

- (3)

- Stress shadow effects

- (1)

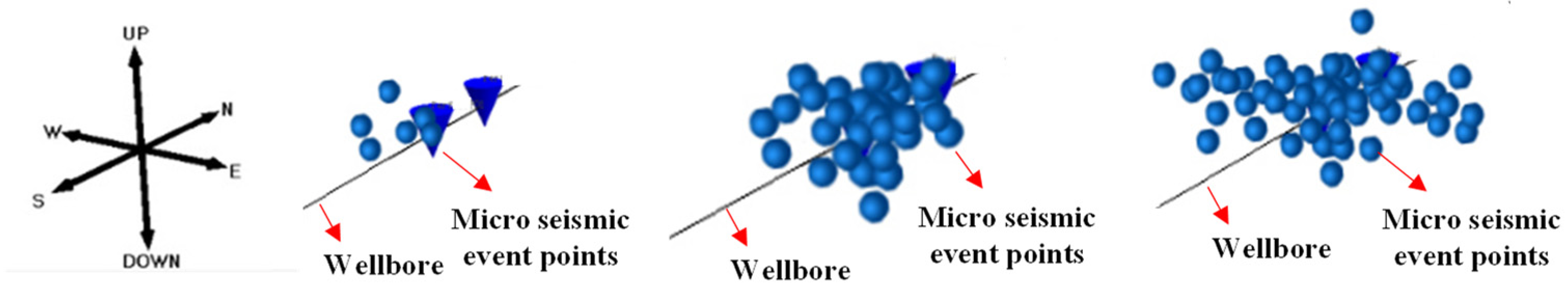

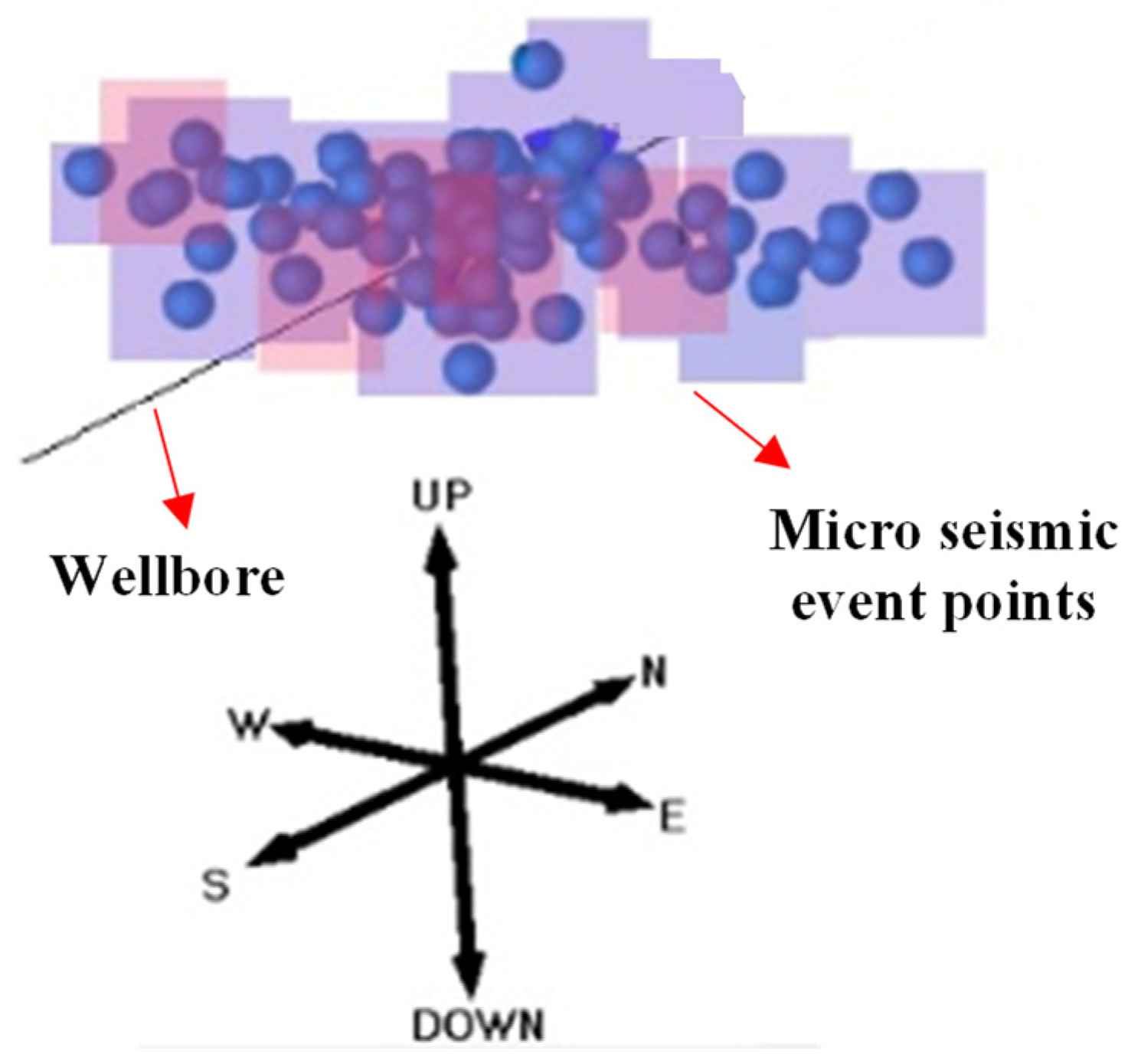

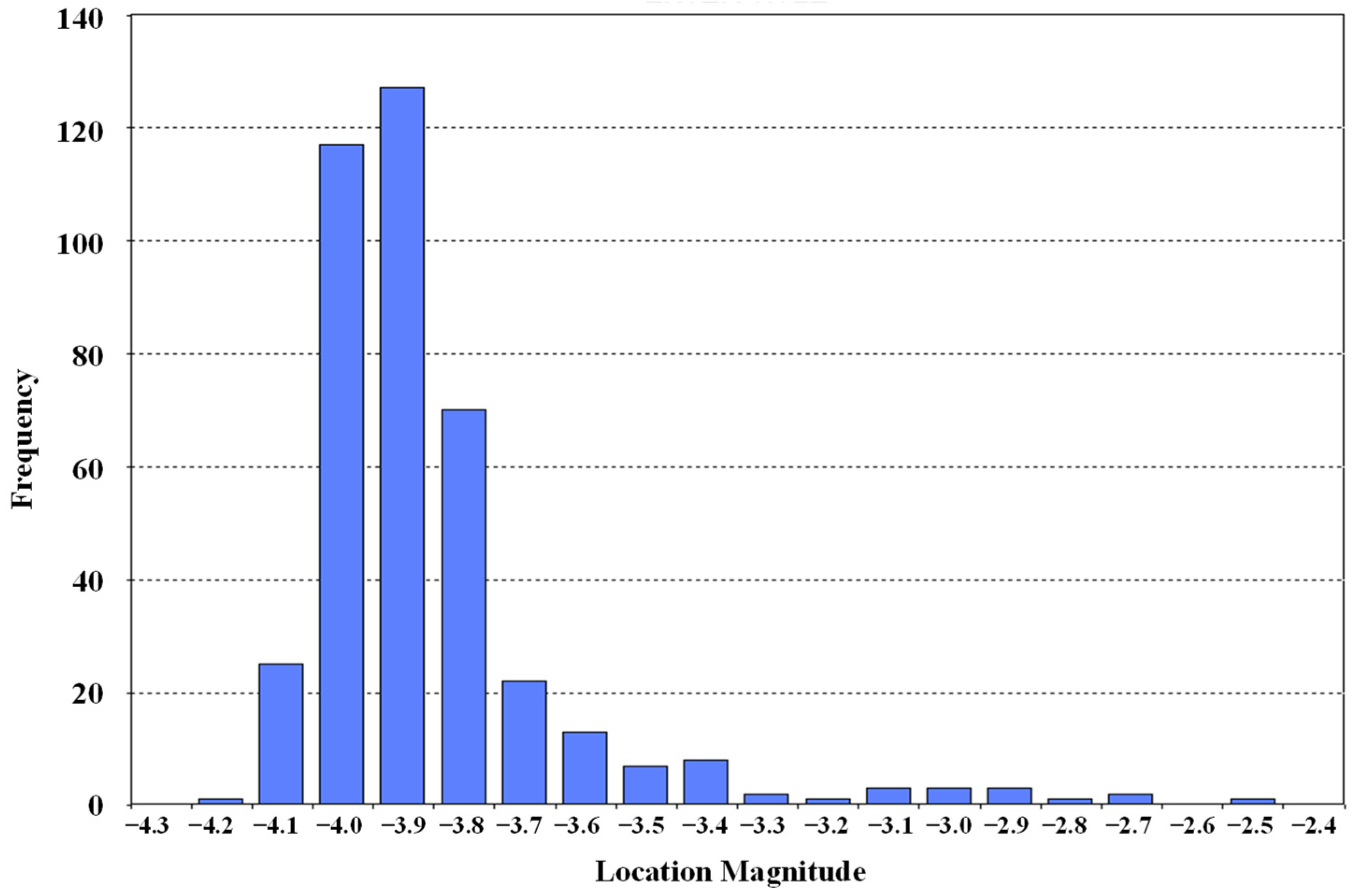

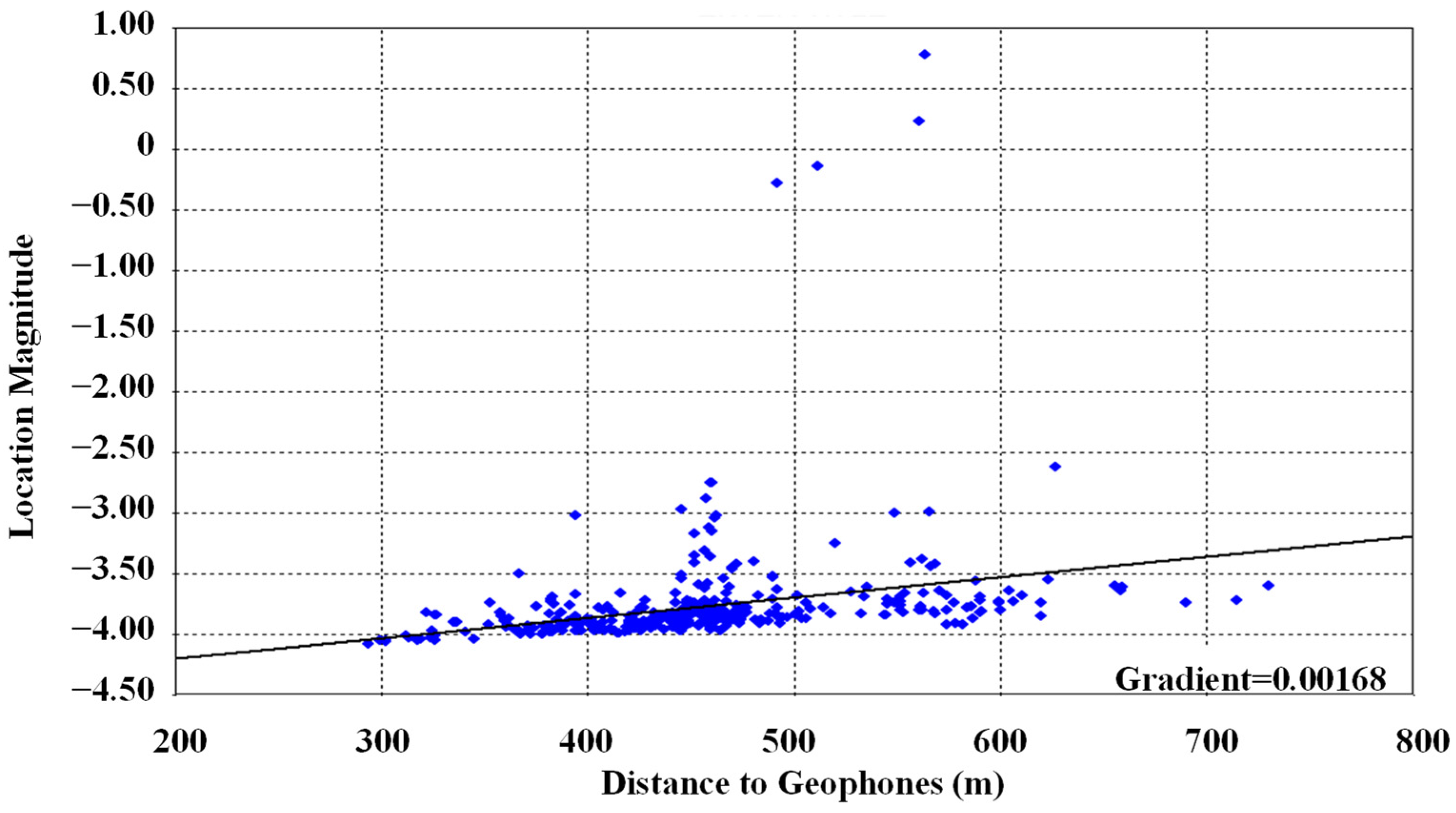

- Effective monitoring was conducted from Stage 1 to Stage 10, during which a total of 405 micro-seismic events were successfully located. The fracture propagation direction is predominantly oriented in the near-east–west direction. Cross-plot analysis revealed that the signal-to-noise ratio (SNR) of micro-seismic signals primarily ranged between 0.49 and 4.82. A positive correlation exists between event magnitude and SNR, with higher magnitudes corresponding to higher SNRs. Micro-seismic magnitudes are mainly concentrated between −4.32 and −2.53. The distance between the events and the geophones generally falls within 290 to 730 m, with closer events exhibiting smaller magnitudes and more distant events showing larger magnitudes.

- (2)

- During fracturing operations in Stages 4, 7, 9, and 10, branch fractures were observed, with some stages exhibiting one or two sets of branch fractures. These branch fractures are either nearly perpendicular or obliquely intersected with the main fracture. A concentration of micro-seismic event points was noted on the eastern wing of Stages 4, 5, 6, 7, 8, and 9, indicating increased micro-seismic activity in these areas.

- (3)

- Reservoir modification volumes in Stages 4, 5, 6, 7, 8, 9, and 10 are relatively large, particularly in sections with overlapping or branched fractures, where the reservoir modification volume significantly increases.

- (4)

- Under conditions of natural fracture deficiency, monitoring data indicate that the distribution of micro-seismic events across the two wings of the fracture exhibits an asymmetric pattern. Compared to the relatively sparse event distribution on the eastern wing, the western wing demonstrates a higher density of fracture events. Furthermore, the fracture extension length on the western wing is greater, indicating that the fracture system formed on both sides of the wellbore during hydraulic fracturing is asymmetric. This asymmetry may be attributed to the closer proximity of the western wing to the geophone location.

- (5)

- Monitoring results from the tenth fracturing stage indicate that increasing the volume of fracturing fluid has a significant effect on extending fracture length but has minimal impact on the width and height of fracture propagation.

- (6)

- According to the statistics of micro-seismic events detected in various segments, the height of the fracturing events is directly proportional to their width, while inversely proportional to their length.

- (7)

- This monitoring suggests that fracturing fractures do not strictly extend along the direction of the maximum principal stress but form a certain angle with the well trajectory. This deviation may be attributed to the preferential opening and connection of natural fractures or changes in in situ stress caused by previously fractured sections, leading to fractures no longer strictly following the direction of the maximum principal stress. Consequently, there is an angle between the fracture orientation and the maximum principal stress, influencing the spatial characteristics of the fractures.

- (8)

- Optimization of segment spacing and cluster spacing: Based on the monitoring results, the coincidence rate of micro-seismic events in each segment is relatively low, and the segment length is close to the fracture network width, indicating that the current segment spacing is appropriate. It is recommended to continue designing segments based on this principle.

4.3. Evaluation and Validation

4.3.1. Validation

- Perforation signal validation

- b.

- Fracture geometry cross-verification

- c.

- Signal-to-noise Ratio (SNR) and magnitude relationships

- d.

- Stimulated reservoir volume (SRV) quantification

- e.

- Stress field and fracture propagation dynamics

- f.

- Comparative analysis with field data

- g.

- Methodological robustness

4.3.2. Applicability Evaluation

- (1)

- Applicability of micro-seismic monitoring

- (2)

- Differentiation Between Natural and Hydraulic Fractures

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Van Der Baan, M.; Eaton, D.; Dusseault, M. Micro-seismic monitoring developments in hydraulic fracture stimulation. In Isrm International Conference for Effective and Sustainable Hydraulic Fracturing; ISRM: Brisbane, Australia, 2013. [Google Scholar]

- He, J.; Dou, L.; Gong, S.; Li, J.; Ma, Z. Rock burst assessment and prediction by dynamic and static stress analysis based on micro-seismic monitoring. Int. J. Rock Mech. Min. Sci. 2017, 93, 46–53. [Google Scholar] [CrossRef]

- Jiang, R.; Dai, F.; Liu, Y.; Li, A. A novel method for automatic identification of rock fracture signals in micro-seismic monitoring. Measurement 2021, 175, 109129. [Google Scholar] [CrossRef]

- Zhao, J.S.; Jiang, Q.; Lu, J.F.; Chen, B.R.; Pei, S.F.; Wang, Z.L. Rock fracturing observation based on micro-seismic monitoring and borehole imaging: In situ investigation in a large underground cavern under high geostress. Tunn. Undergr. Space Technol. 2022, 126, 104549. [Google Scholar] [CrossRef]

- Sellers, E.J.; Kataka, M.O.; Linzer, L.M. Source parameters of acoustic emission events and scaling with mining-induced seismicity. J. Geophys. Res. Solid Earth 2003, 108, 2418. [Google Scholar] [CrossRef]

- Bormann, P.; Wendt, S.; DiGiacomo, D. Seismic sources and source parameters. In New Manual of Seismological Observatory Practice 2 (NMSOP2); Deutsches GeoForschungsZentrum GFZ: Potsdam, Duitsland, 2013; pp. 1–259. [Google Scholar]

- Yousefzadeh, A.; Li, Q.; Aguilera, R. Micro-seismic 101: Monitoring and evaluating hydraulic fracturing to improve the efficiency of oil and gas recovery from unconventional reservoirs. In Proceedings of the SPE Latin America and Caribbean Petroleum Engineering Conference, Quito, Ecuador, 18–20 November 2015; p. D031S023R005. [Google Scholar]

- Eyinla, D.; Henderson, S.K.; Emadi, H.; Thiyagarajan, S.R.; Arora, A. Optimization of hydraulic fracture monitoring approach: A perspective on integrated fiber optics and sonic tools. Geoenergy Sci. Eng. 2023, 231, 212441. [Google Scholar] [CrossRef]

- Temizel, C.; Canbaz, C.H.; Gok, I.M.; Roshankhah, S.; Palabiyik, Y.; Deniz-Paker, M.; Kaya, O.A. A Thorough Review and Latest Advances in Shale Reservoirs: Seismic to Surveillance. In Proceedings of the SPE Latin American and Caribbean Petroleum Engineering Conference, Virtual, 27–31 July 2020. [Google Scholar] [CrossRef]

- Bakku, S.K. Fracture Characterization from Seismic Measurements in a Borehole. Ph.D. Thesis, Massachusetts Institute of Technology, Cambridge, MA, USA, 2015. [Google Scholar]

- Hartog, A.H. Distributed sensors in the oil and gas industry. In Optical Fibre Sensors: Fundamentals for Development of Optimized Devices; Wiley-IEEE Press: Hoboken, NJ, USA, 2020; pp. 151–191. [Google Scholar]

- Hu, Z.F.; Kang, H.X.; Tian, Y.K.; Song, H.J.; Zhou, H.; Ma, Y.Y.; Wang, Y.F. Quantitative comparative analysis of monitoring effect of micro-seismic fracturing borehole and surface. Appl. Geophys. 2023, 20, 507–517. [Google Scholar] [CrossRef]

- Wu, Y.; Zhao, X.P.; Zinno, R.J.; Wu, H.Y.; Vaidya, V.P.; Yang, M.; Qin, J.S. The application of micro-seismic monitoring in unconventional reservoirs. In Unconventional Oil and Gas Resources Handbook; Gulf Professional Publishing: Amsterdam, The Netherlands, 2016; pp. 243–287. [Google Scholar]

- Ou, C.; Liang, C.; Li, Z.; Luo, L.; Yang, X. 3D visualization of hydraulic fractures using micro-seismic monitoring: Methodology and application. Petroleum 2022, 8, 92–101. [Google Scholar] [CrossRef]

- Sun, J.; Li, J.; Chi, B.; Wang, P.; Chu, D.; Wang, Y. Continuous Surface Distributed Acoustic Sensing for Subsurface Hydraulic Fracturing Source Location and Near-surface Scatterer Imaging: A Case Study in Caojiatan Mine. Geophysics 2025, 90, 1–56. [Google Scholar] [CrossRef]

- Taha, B.A.; Addie, A.J.; Haider, A.J.; Osman, S.A.; Ramli, M.Z.; Arsad, N. A review of seismic detection using fiber optic distributed acoustic sensing: From telecommunication cables to earthquake sensors. Nat. Hazards 2025, 121, 13927–13959. [Google Scholar] [CrossRef]

- Li, H.; Wang, H.; Zhang, K.; Jiang, K.; Zhang, X.; Sun, X.; Cai, Y. In-Situ Stress Prediction of Deep Coal Reservoir Considering Anisotropy: A Case Study of the North-Central Zijinshan Block, North China. Processes 2025, 13, 352. [Google Scholar] [CrossRef]

- Kumar, A.; Zorn, E.; Hammack, R.; Harbert, W. Long-period, long-duration seismic events and their probable role in reservoir stimulation and stage productivity. SPE Reserv. Eval. Eng. 2019, 22, 441–457. [Google Scholar] [CrossRef]

- Farge, G. Sounds of Geological Plumbing Systems: How Transient Fluid Circulation Processes in Faults and Volcanoes Shape Sources and Patterns of Micro-Seismicity. Ph.D. Thesis, Université Paris Cité, Paris, France, 2022. [Google Scholar]

- Li, L.; Tan, J.; Wood, D.A.; Zhao, Z.; Becker, D.; Lyu, Q.; Chen, H. A review of the current status of induced seismicity monitoring for hydraulic fracturing in unconventional tight oil and gas reservoirs. Fuel 2019, 242, 195–210. [Google Scholar] [CrossRef]

- Wang, H.; Li, M.; Shang, X. Current developments on micro-seismic data processing. J. Nat. Gas Sci. Eng. 2016, 32, 521–537. [Google Scholar] [CrossRef]

- Jia, J.; Fan, Q.; Jing, J.; Lei, K.; Wang, L. Intelligent hydraulic fracturing under industry 4.0—A survey and future directions. J. Pet. Explor. Prod. Technol. 2024, 14, 3161–3181. [Google Scholar] [CrossRef]

- Ma, Y.; Eaton, D.W.; Wang, C.; Aklilu, A. Characterizing hydraulic fracture growth using distributed acoustic sensing-recorded micro-seismic reflections. Geophysics 2023, 88, WC47–WC57. [Google Scholar] [CrossRef]

- Elenchezhian, M.R.P.; Vadlamudi, V.; Raihan, R.; Reifsnider, K.; Reifsnider, E. Artificial intelligence in real-time diagnostics and prognostics of composite materials and its uncertainties—A review. Smart Mater. Struct. 2021, 30, 083001. [Google Scholar] [CrossRef]

- Nasiri, S.; Khosravani, M.R.; Weinberg, K. Fracture mechanics and mechanical fault detection by artificial intelligence methods: A review. Eng. Fail. Anal. 2017, 81, 270–293. [Google Scholar] [CrossRef]

- Kuang, L.; Liu, H.; Ren, Y.; Luo, K.; Shi, M.; Su, J.; Li, X. Application and development trend of artificial intelligence in petroleum exploration and development. Pet. Explor. Dev. 2021, 48, 1–14. [Google Scholar] [CrossRef]

- Fu, J.; Wang, X.; Li, Z.; Meng, H.; Wang, J.; Wang, W.; Tang, C. Automatic phase-picking method for detecting earthquakes based on the signal-to-noise-ratio concept. Seismol. Res. Lett. 2020, 91, 334–342. [Google Scholar] [CrossRef]

- Leonard, M. Application of Autoregressive processing to the analysis of seismograms. In Methods and Applications of Signal Processing in Seismic Network Operations; Springer: Berlin/Heidelberg, Germany, 2007; pp. 61–78. [Google Scholar]

- Gibbons, S.J.; Kværna, T.; Harris, D.B.; Dodge, D.A. Iterative strategies for aftershock classification in automatic seismic processing pipelines. Seismol. Res. Lett. 2016, 87, 919–929. [Google Scholar] [CrossRef]

- Yang, Y.; Ritzwoller, M.H. Characteristics of ambient seismic noise as a source for surface wave tomography. Geochem. Geophys. Geosystems 2008, 9. [Google Scholar] [CrossRef]

- Deflandre, J.P.; Dubesset, M. Identification of P/S-wave successions for application in microseismicity. Pure Appl. Geophys. 1992, 139, 405–420. [Google Scholar] [CrossRef]

| Series | Number of Perforation Clusters | Perforation Top (m) | Perforation Bottom (m) | Perforation Cluster Length (m) | Hole Density (Holes/m) |

|---|---|---|---|---|---|

| First stage | 1 | 2578 | 2580 | 2 | 16 |

| 2 | 2553 | 2555 | |||

| Second stage | 1 | 2525 | 2528 | 3 | 12 |

| 2 | 2502 | 2505 | |||

| 3 | 2486 | 2489 | |||

| Third stage | 1 | 2458 | 2461 | 3 | 12 |

| 2 | 2438 | 2441 | |||

| 3 | 2417 | 2420 | |||

| Fourth stage | 1 | 2377 | 2380 | 3 | 12 |

| 2 | 2357 | 2360 | |||

| 3 | 2338 | 2341 | |||

| Fifth stage | 1 | 2308 | 2311 | 3 | 12 |

| 2 | 2278 | 2281 | |||

| 3 | 2262 | 2266 | |||

| Sixth stage | 1 | 2247 | 2350 | 3 | 12 |

| 2 | 2219 | 2222 | |||

| 3 | 2199 | 2200 | |||

| Seventh stage | 1 | 2136 | 2138 | 2 | 12 |

| 2 | 2121 | 2122 | |||

| 3 | 2105 | 2107 | |||

| Eighth stage | 1 | 2000 | 2002 | 2 | 16 |

| 2 | 1973 | 1975 | |||

| Ninth stage | 1 | 1860 | 1862 | 2 | 16 |

| 2 | 1830 | 1832 | |||

| Tenth stage | 1 | 1805 | 1807 | 2 | 16 |

| 2 | 1780 | 1782 |

| Monitoring Project | Fracture Network Length (m) | Bandwidth (m) | Fracture Height (m) | Orientation (°) | Number of Events | |

|---|---|---|---|---|---|---|

| East Wing | West Wing | |||||

| Monitoring results | 117 | 194 | 44 | 20 | 89 | 51 |

| Fracturing Section | Fracture Network Length (m) | Bandwidth (m) | Fracture Height (m) | Orientation (°) | Number of Events | Reservoir Modification Volume (104 m3) | |

|---|---|---|---|---|---|---|---|

| East Wing | West Wing | ||||||

| No. 1 | 117 | 194 | 44 | 20 | 89 | 51 | 13.37 |

| No. 2 | 98 | 177 | 47 | 24 | 87 | 47 | 11.74 |

| No. 3 | 102 | 178 | 46 | 22 | 82 | 39 | 12.48 |

| No. 4 | 111 | 172 | 48 | 22 | 83 | 37 | 13.82 |

| No. 5 | 101 | 155 | 48 | 26 | 79 | 38 | 11.84 |

| No. 6 | 106 | 183 | 43 | 21 | 87 | 30 | 12.25 |

| No. 7 | 118 | 185 | 48 | 22 | 78 | 40 | 18.43 |

| No. 8 | 101 | 177 | 47 | 24 | 86 | 37 | 13.42 |

| No. 9 | 128 | 192 | 50 | 23 | 85 | 39 | 19.41 |

| No. 10 | 98 | 202 | 48 | 23 | 87 | 47 | 17.93 |

| Parameter | Value | Validation Method |

|---|---|---|

| σH direction | N87°E ± 5° | 402/405 event moment tensors |

| σv gradient | 1.08 psi/ft | Fracture height containment |

| σH/σh ratio | 1.15–1.25 | Fracture length/width correlation (R2 = 0.81) |

| Stress rotation | 5–15° | Stage-to-stage fracture azimuth variation |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lin, L.; Xiong, X.; Xu, Z.; Yan, X.; Wang, Y. Characterizing Hydraulic Fracture Morphology and Propagation Patterns in Horizontal Well Stimulation via Micro-Seismic Monitoring Analysis. Symmetry 2025, 17, 1732. https://doi.org/10.3390/sym17101732

Lin L, Xiong X, Xu Z, Yan X, Wang Y. Characterizing Hydraulic Fracture Morphology and Propagation Patterns in Horizontal Well Stimulation via Micro-Seismic Monitoring Analysis. Symmetry. 2025; 17(10):1732. https://doi.org/10.3390/sym17101732

Chicago/Turabian StyleLin, Longbo, Xiaojun Xiong, Zhiyuan Xu, Xiaohua Yan, and Yifan Wang. 2025. "Characterizing Hydraulic Fracture Morphology and Propagation Patterns in Horizontal Well Stimulation via Micro-Seismic Monitoring Analysis" Symmetry 17, no. 10: 1732. https://doi.org/10.3390/sym17101732

APA StyleLin, L., Xiong, X., Xu, Z., Yan, X., & Wang, Y. (2025). Characterizing Hydraulic Fracture Morphology and Propagation Patterns in Horizontal Well Stimulation via Micro-Seismic Monitoring Analysis. Symmetry, 17(10), 1732. https://doi.org/10.3390/sym17101732