Dynamic Performances of Technological Vibrating Machines

Abstract

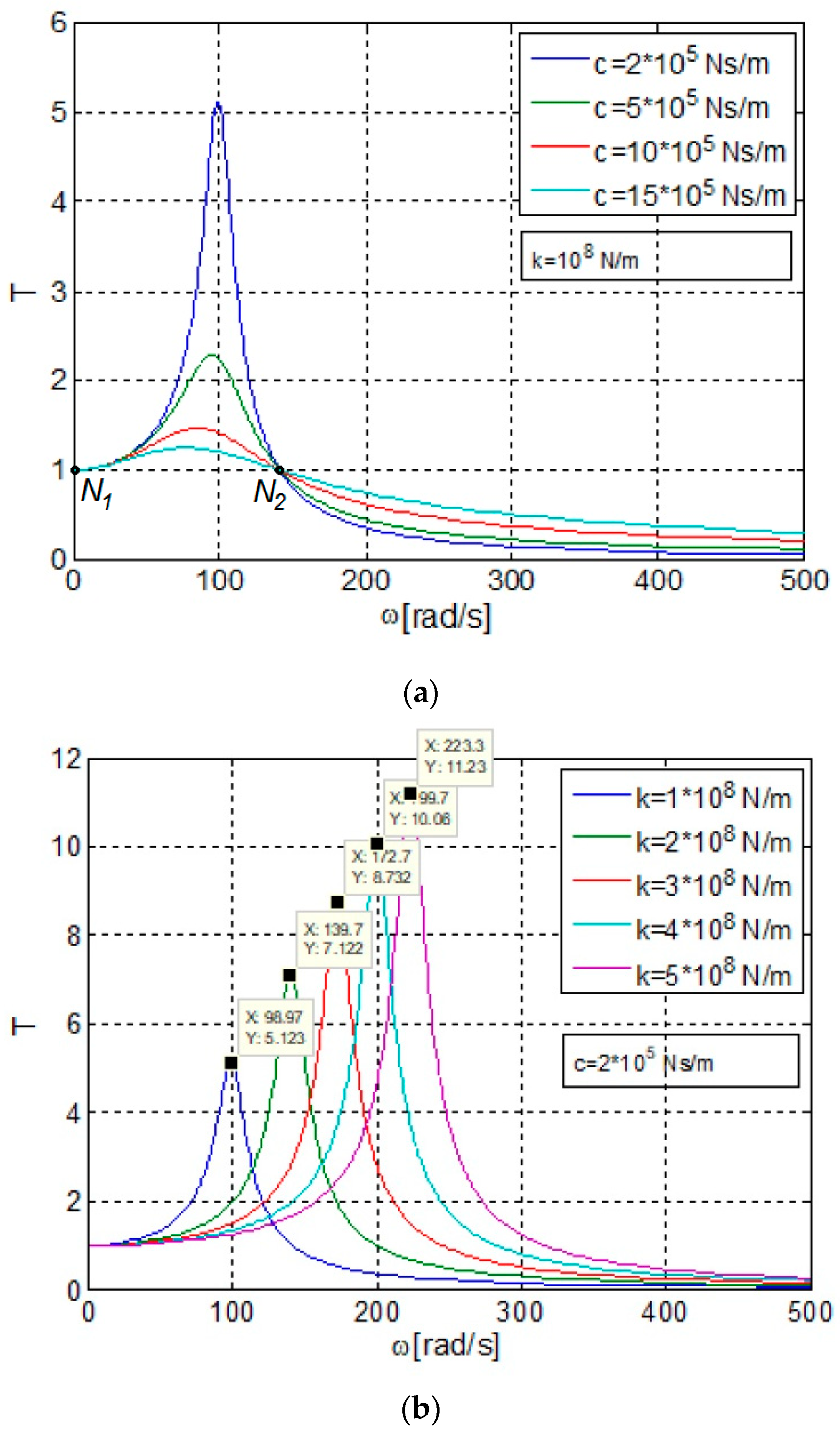

:1. Introduction

- (a)

- (b)

- (c)

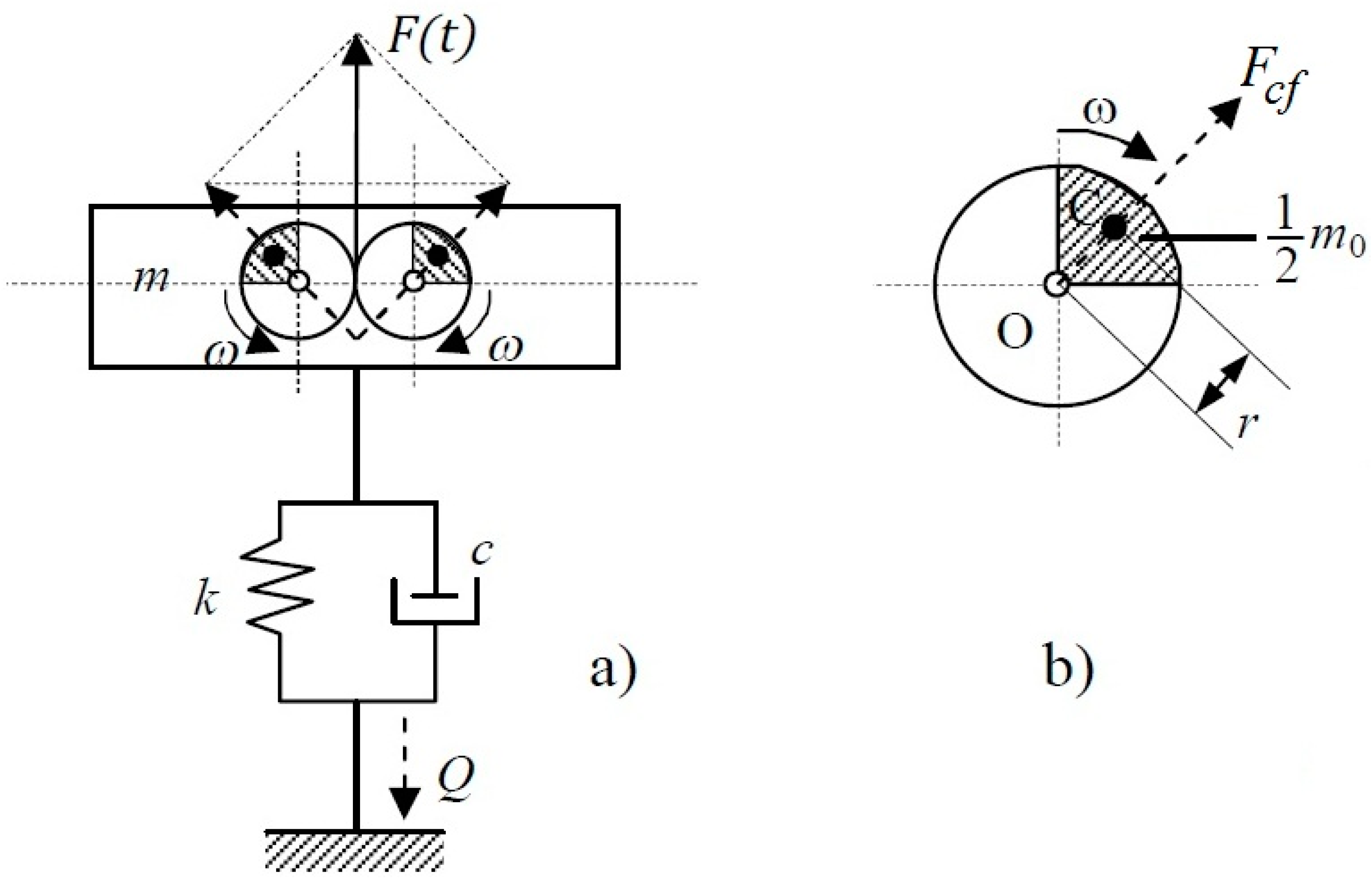

2. Dynamic Calculation Model

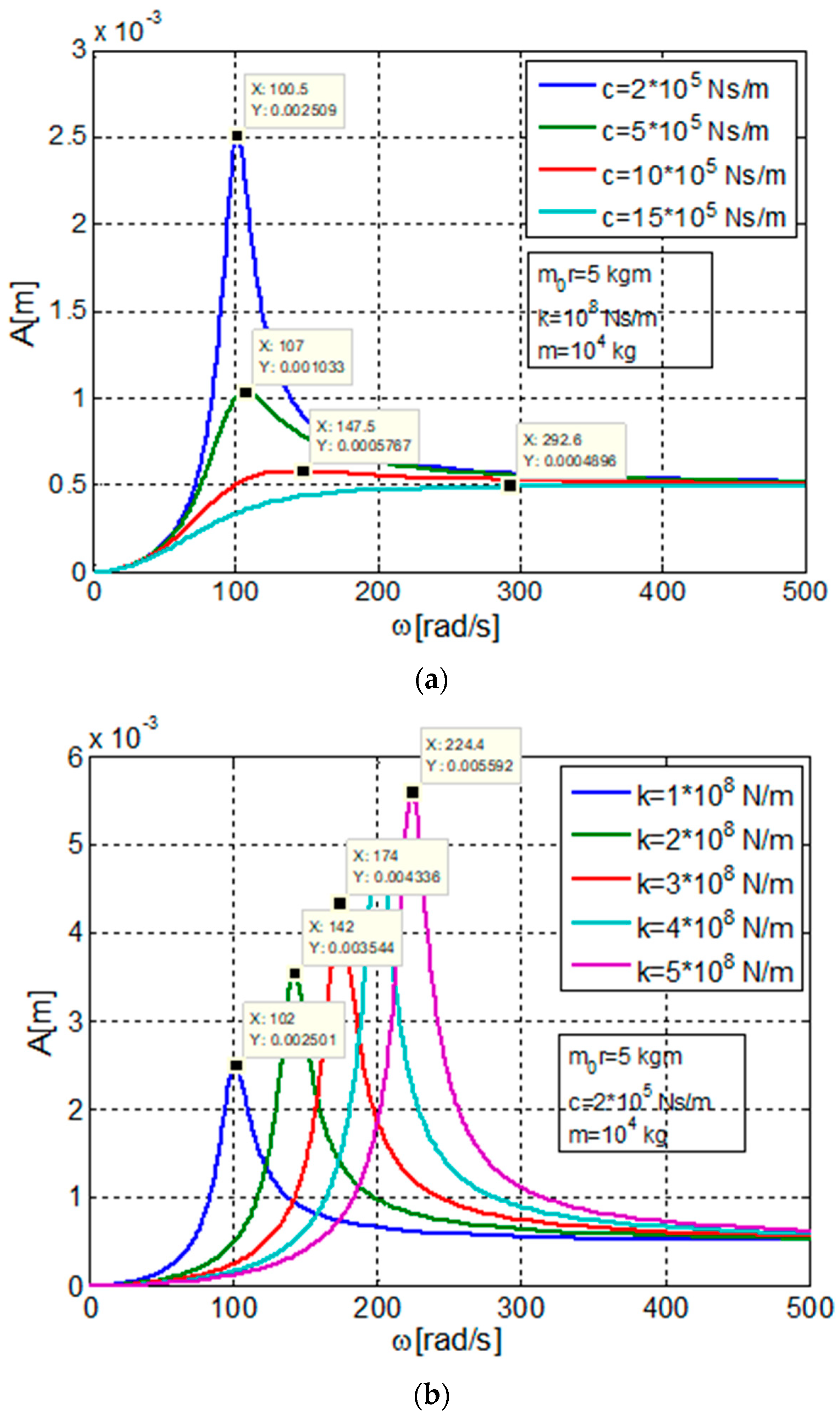

2.1. Dynamic Response of 1DOF System

- (a)

- -relative pulsation;

- (b)

- –the fraction of the critical amortization specific to the linear viscous-elastic systems with discrete viscous dissipators, characterized by the viscous amortization coefficient c.

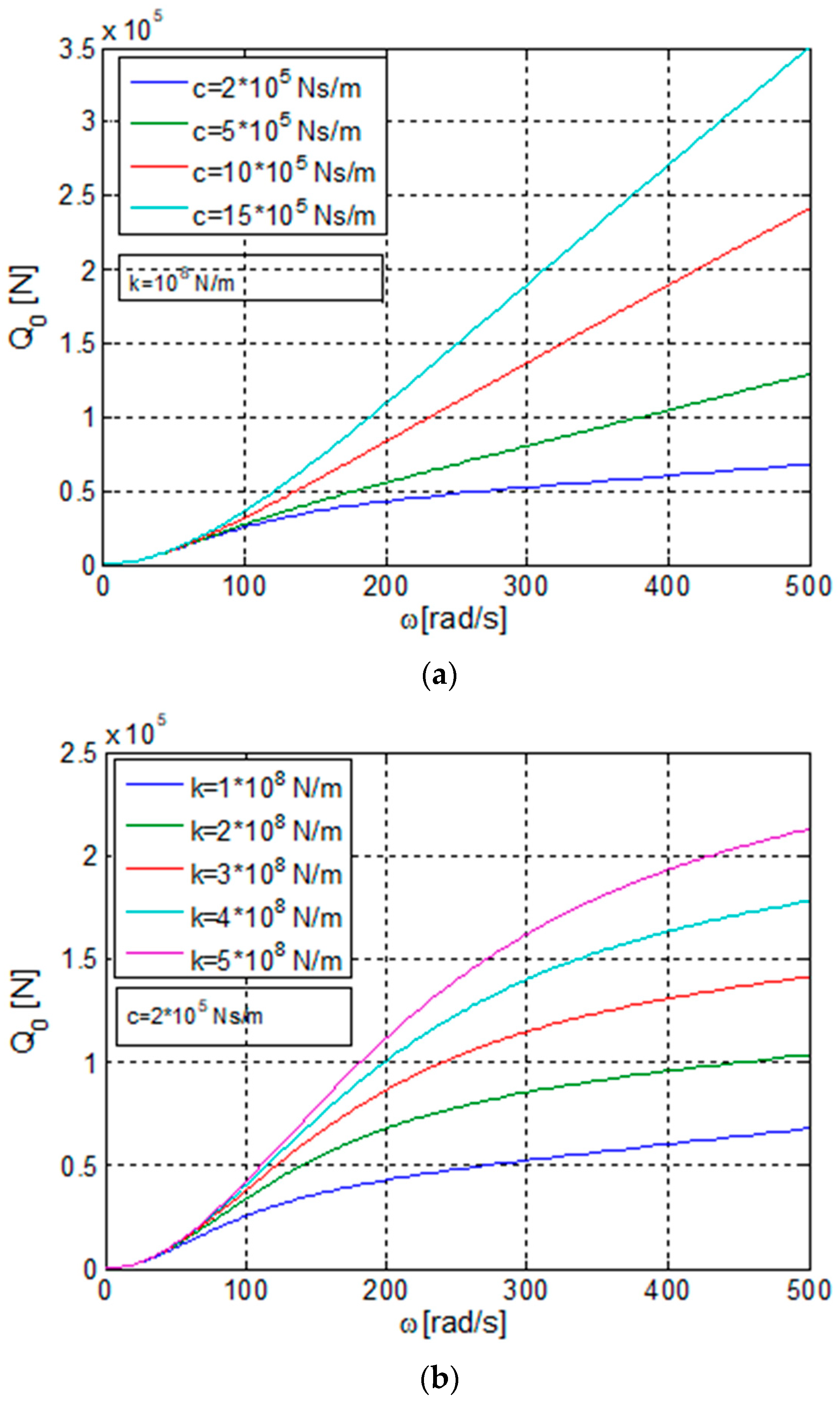

2.2. Transmitted Dynamic Force. Dynamic Force Transmitted in the Time Domain

2.3. Dynamic Insulation Capacity

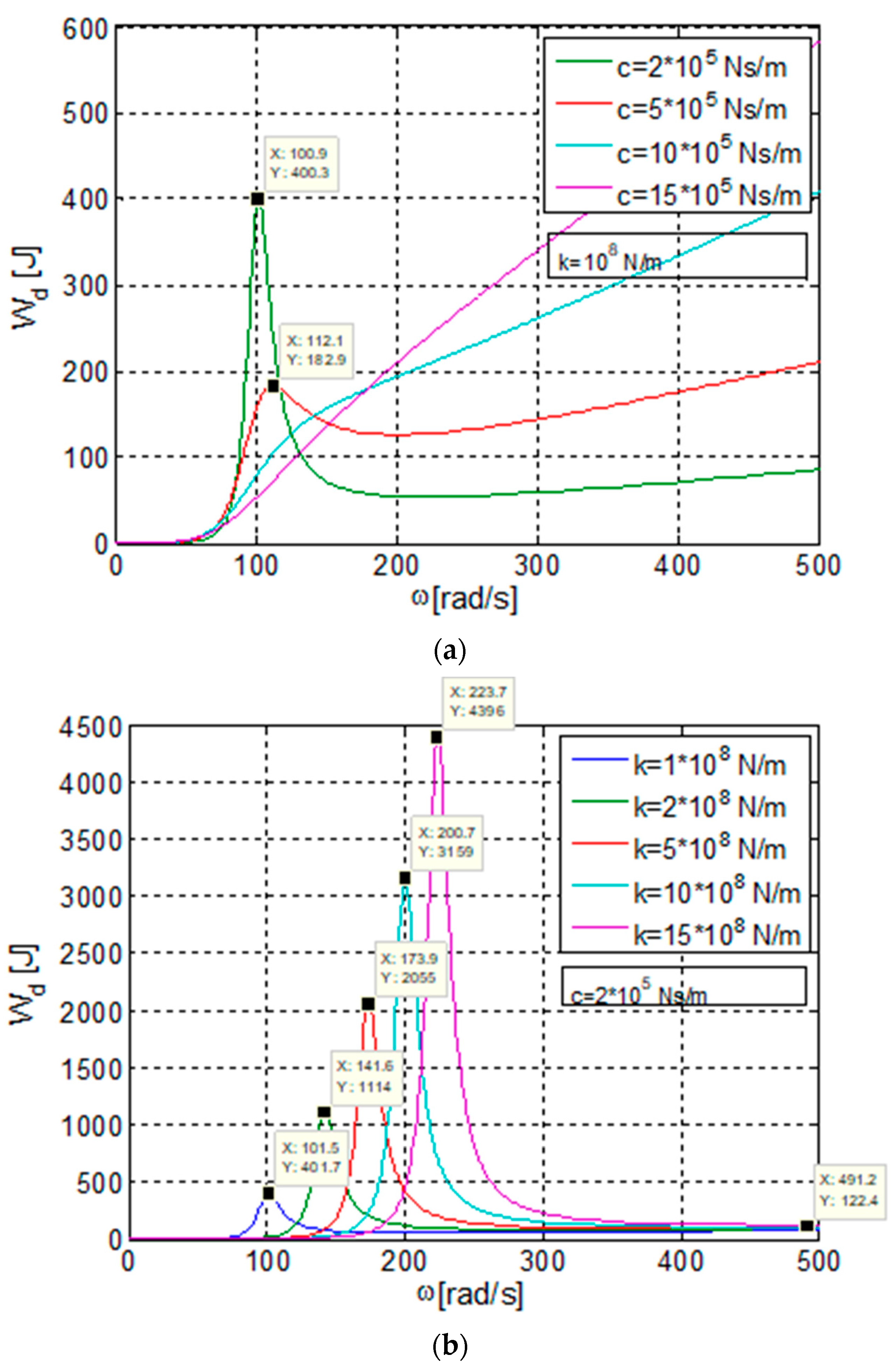

2.4. Dissipated Energy

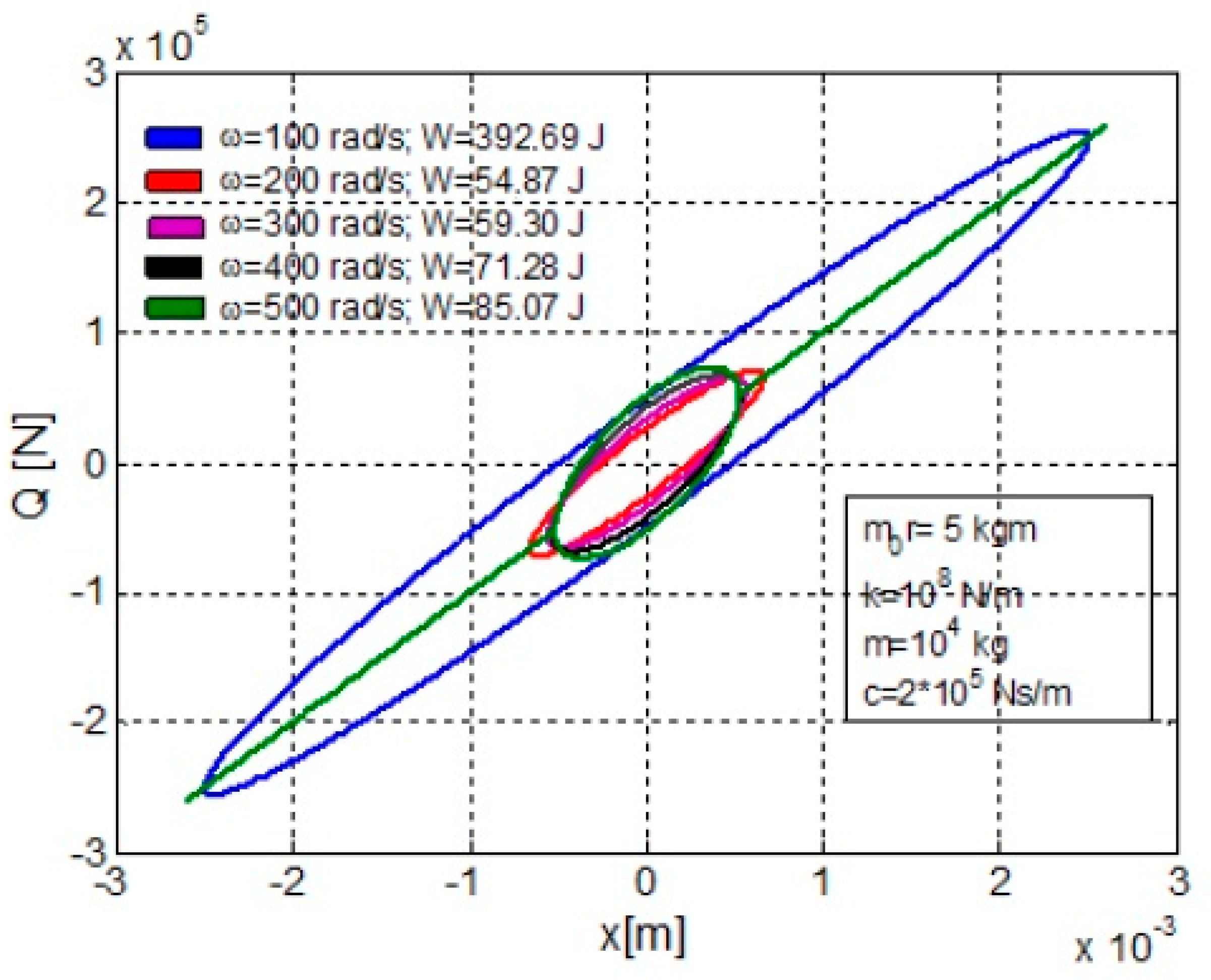

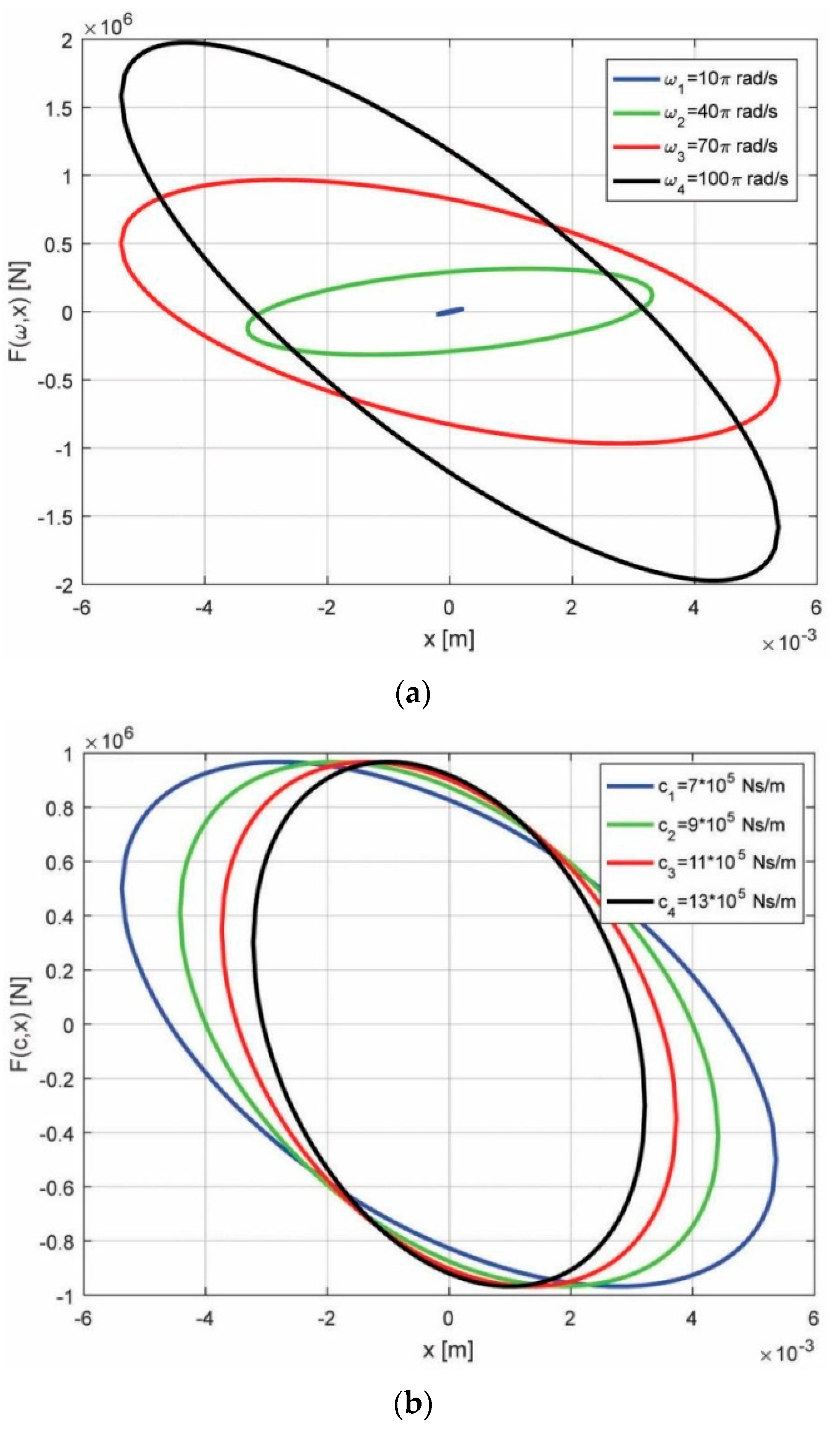

2.5. Representation of the Hysteresis Loop

- hysteresis ellipses are in quadrants II and IV due to the inertial effect of the mass m of the working part of the technological equipment;

- for constant values of stiffness k and damping c, the areas of the hysteresis ellipses at four discrete values of the pulsation ω of the harmonic disturbing force F change significantly; thus, at values of the area of the hysteresis ellipses and, implicitly, the dissipated energy W increase significantly;

- for constant values of the stiffness k and the pulsation ω of the disturbing force F, at the discrete variation of the damping c, distinct values of the areas of the hysteresis ellipses and, implicitly, of the dissipated energies W, are obtained; as the damping coefficient c increases, the hysteresis ellipse rotates clockwise.

3. Conclusions

- the amplitude of the technological vibrations during the postresonance regime is relatively constant, its variation being insignificant for the working process for values of the excitation pulsation ω higher than 2–4 times in relation to the resonance pulsation;

- the modification to the technological values necessary for the work process can be done during the postresonance regime, , using relation from where result the amplitudes , , … for various values of the static moment , , …, at the same value of mobile mass m;

- the force transmitted to the processed material and the energy dissipated by the system at processing for the postresonance regime are given by the calculation relations established and verified in practical cases;

- the hysteresis loops illustrate both the variation of the force in relation to the instantaneous displacement x(t) and the dissipated energy depending on the area of the elliptical surface.

- -

- -

- environment protection: reduction of harmful vibrations transmitted by dynamic action equipment through foundations (passive/active damping in real-time);

- -

- health research: dynamic analysis of the human body modeled as a biomechanical system with (m,c,k) linear characteristics.

- -

- the hypothesis of linearity of damping and elasticities;

- -

- mass/moment of inertia modifications during technological processes;

- -

- a more complex rheological model of the interaction between the vibrating machine and the working environment that can radically change the dynamic response of the system and its operating energy parameters.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Rao, M. Mechanical Vibrations; Addison-Wesley Pub. Co.: Boston, MA, USA, 1986. [Google Scholar]

- Sireteanu, T.; Giuclea, M.; Mitu, A.M. An analitical approach for approximation of experimental hysteretic by Bouc.-Wen model. Procc. Rom. Acad. Ser. A 2009, 10, 43–54. [Google Scholar]

- Nițu, M.C. Parametric evaluation of the vibrating screens for performance assurance in sorting mineral aggregates. ACTA Teh. Napoc. Appl. Math. Mech. Eng. 2020, 63, 331–334. [Google Scholar]

- Stamatiade, C. The influences upon the quality of the mineral aggregates induced by technological vibrations during the sorting process. Rom. J. Acoust. Vib. 2009, VI, 1. [Google Scholar]

- Bratu, P.; Dobrescu, C. Evaluation of the Dissipated Energy in Vicinity of the Resonance, depending on the Nature of Dynamic Excitation. Rom. J. Acoust. Vib. 2019, 16, 66–71. [Google Scholar]

- Vasile, O. Active vibration control for viscoelastic amortization systems under the action of inertial forces. Rom. J. Acoust. Vib. 2017, 14, 54–58. [Google Scholar]

- Bratu, P. Multibody system with elastic connections for dynamic modeling of compactor vibratory rollers. Symmetry 2020, 12, 1617. [Google Scholar] [CrossRef]

- Dragan, N. Nonlinear approach of the systems between the dynamic modeling difficulties and the advantages of using it in mechanical designing. Rom. J. Acoust. Vib. 2010, 2, 2. [Google Scholar]

- Dobrescu, C.F. Analysis of Dynamic Earth Stiffness depending on Structural Parameters in the Process of Vibration Compaction. Rom. J. Acoust. Vib. 2019, 16, 174–177. [Google Scholar]

- Dobrescu, C.F. Dynamic Response of the Newton Voigt–Kelvin Modelled Linear Viscoelastic Systems at Harmonic Actions. Symmetry 2020, 12, 1571. [Google Scholar] [CrossRef]

- Pințoi, R.; Bordos, R.; Braguța, E. Vibration Effects in the Process of Dynamic Compaction of Fresh Concrete and Stabilized Earth. J. Vib. Eng. Technol. 2017, 5, 247–254. [Google Scholar]

- Bejan, S. Dynamic Response Analysis of the Road System Compaction According to the Forced Vibration Mode. Rom. J. Acoust. Vib. 2014, XI, 164–166. [Google Scholar]

- Capatana, G.F. Dynamic simulation of the vibratory roller-terrain interaction using an elastoplastic approach. In Annals of University Dunărea de Jos din Galaţi, XIV, Mechanical Engineering; Galati University Press: Galati, Romania, 2013. [Google Scholar]

- Le Tallec, P. Introduction à la Dynamique des Structures; Cépaduès: Toulouse, France, 2000. [Google Scholar]

- Radeș, M. Mechanical Vibrations; Editura Printech: București, Romania, 2006. [Google Scholar]

- Edincliler, A.; Cabalar, A.F.; Cevik, A. Modelling dynamic behaviour of sand–waste tires mixtures using Neural Networks and Neuro-Fuzzy. Eur. J. Environ. Civ. Eng. 2013, 17, 720–741. [Google Scholar] [CrossRef]

- Inman, D. Vibration with Control; John Wiley & Sons Ltd.: London, UK, 2007. [Google Scholar]

- Adam, D.; Kopf, F. Theoretical Analysis of Dynamically Loaded Soils, European Workshop: Compaction of Soils and Granular Materials; ETC11 of ISSMGE: Paris, France, 2000. [Google Scholar]

- Mooney, M.A.; Rinehart, R.V. In-Situ Soil Response to Vibratory Loading and Its Relationship to Roller-Measured Soil Stiffness. J. Geotech. Geoenviron. Eng. ASCE 2009, 135, 1022–1031. [Google Scholar] [CrossRef] [Green Version]

- Mooney, M.A.; Rinehart, R.V.; White, D.J.; Vennapusa, P.K.; Facas, N.W.; Musimbi, O.M. Intelligent Soil Compaction Systems; NCHRP project 21-09 final report; Transportation Research Board: Washington, DC, USA, 2010. [Google Scholar]

- Adam, D. Continuous Compaction Control (CCC) with Vibratory Roller, GeoEnvironment Revue; Balkema Rotterdam: Bouazza, Morocco, 1997. [Google Scholar]

- Adam, D.; Kopf, F. Sophisticated Roller Compaction Technologies and Roller-Integrated Compaction Control, Compaction of Soils-Granulates and Powders; Editura Kolymbas & Fellin: Rotterdam, The Netherlands, 2000. [Google Scholar]

- Forssblad, L. Vibratory Soil and Rock Fill Compaction; Robert Olsson Tryckeri AB: Stockholm, Sweden, 1981. [Google Scholar]

- Floss, R.; Kloubert, H.-J. Newest Developments in Compaction Technology. In Proceedings of the European Workshop Compaction of Soils and Granular Materials, Presses Ponts et Chaussées, Paris, France, 19 May 2000; pp. 247–261. [Google Scholar]

- Capatana, G.F. Dynamic behaviour of complex interaction between vibratory drum equipment and natural terrain based on rheological evaluations. In Proceedings of the 10th HSTAM International Congress on Mechanics Chania, Crete, Greece, 25–27 May 2013. [Google Scholar]

- Adam, D.; Kopf, F. Operational Devices for Compaction Optimization and Quality Control (Continuous Compaction Control & Light Falling Weight Device). In Proceedings of the International Seminar on Geotechnics in Pavement and Railway Design and Construction, Athens, Greece, 16–17 December 2004; pp. 97–106. [Google Scholar]

- Anderegg, R. ACE Ammann Compaction Expert–Automatic Control of the Compaction. In Proceedings of the European Workshop Compaction of Soils and Granular Materials, Paris, France, 19 May 2000; pp. 229–236. [Google Scholar]

- Bratu, P. Hysteretic Loops in Correlation with the Maximum Dissipated Energy, for Linear Dynamic Systems. Symmetry 2019, 11, 315. [Google Scholar] [CrossRef] [Green Version]

- Brandl, H.; Adam, D. Sophisticated continuous compaction control of soils and granular materials. In Proceedings of the 14th International Conference on Soil Mechanics & Foundation Engineering, Hamburg, Germany, 6–12 September 1997; Volume 1, pp. 31–36. [Google Scholar]

- Mooney, M.A.; Rinehart, R.V. Field Monitoring of Roller Vibration During Compaction of Subgrade Soil. J. Geotech. Geoenviron. Eng. ASCE 2007, 133, 257–265. [Google Scholar] [CrossRef]

- Tonciu, O. Parametric analysis of vibrating equipment for the insertion of piles into the ground. ACTA Tech. Napoc. Appl. Math. Mech. Eng. 2020, 63, 95–100. [Google Scholar]

- Bejan, S. Rheological Models of the Materials for the Road System in the Compaction Process. Rom. J. Acoust. Vib. 2014, XI, 67. [Google Scholar]

- Capatana, G.F. Analysis of the Dynamics of Vibratory Compactor Rollers for Road Works. Doctoral Thesis, “Dunarea de Jos” University of Galati, Galați, Romania, 2014. [Google Scholar]

- Pinţoi, R. Dependence of the Concrete Strength on the Duration of the Compaction by Vibration Process. Rom. J. Acoust. Vib. 2015, 11, 67. [Google Scholar]

- Spanu (Stefan), G.C.; Capatana, G.F.; Potirniche, A. Analysis of the Transmissibility Ratio and the Isolation Degree of the Vibration for 1DOF Mechanical Systems with Zener Viscous Damping Model. Synth. Theor. Appl. Mech. 2019, 10, 43–46. [Google Scholar]

- Thakur, N.; Han, C.Y. An Ambient Intelligence-Based Human Behavior Monitoring Framework for Ubiquitous Environments. Information 2021, 12, 81. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bratu, P.; Drăgan, N.; Dobrescu, C. Dynamic Performances of Technological Vibrating Machines. Symmetry 2022, 14, 539. https://doi.org/10.3390/sym14030539

Bratu P, Drăgan N, Dobrescu C. Dynamic Performances of Technological Vibrating Machines. Symmetry. 2022; 14(3):539. https://doi.org/10.3390/sym14030539

Chicago/Turabian StyleBratu, Polidor, Nicușor Drăgan, and Cornelia Dobrescu. 2022. "Dynamic Performances of Technological Vibrating Machines" Symmetry 14, no. 3: 539. https://doi.org/10.3390/sym14030539

APA StyleBratu, P., Drăgan, N., & Dobrescu, C. (2022). Dynamic Performances of Technological Vibrating Machines. Symmetry, 14(3), 539. https://doi.org/10.3390/sym14030539