Assembly Configuration Representation and Kinematic Modeling for Modular Reconfigurable Robots Based on Graph Theory

Abstract

:1. Introduction

2. Representation of Robot Modules

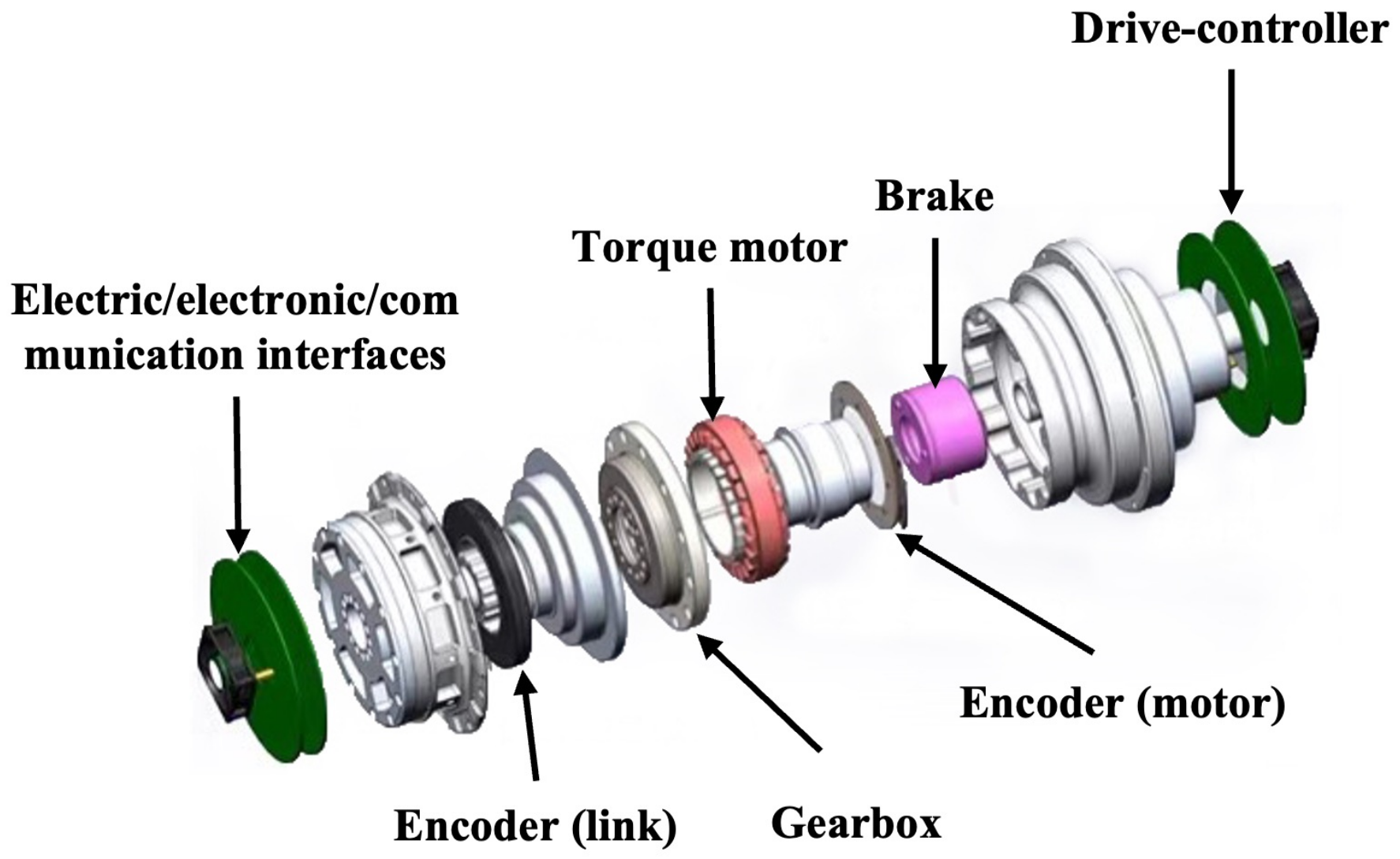

2.1. Revolute Joint Modules

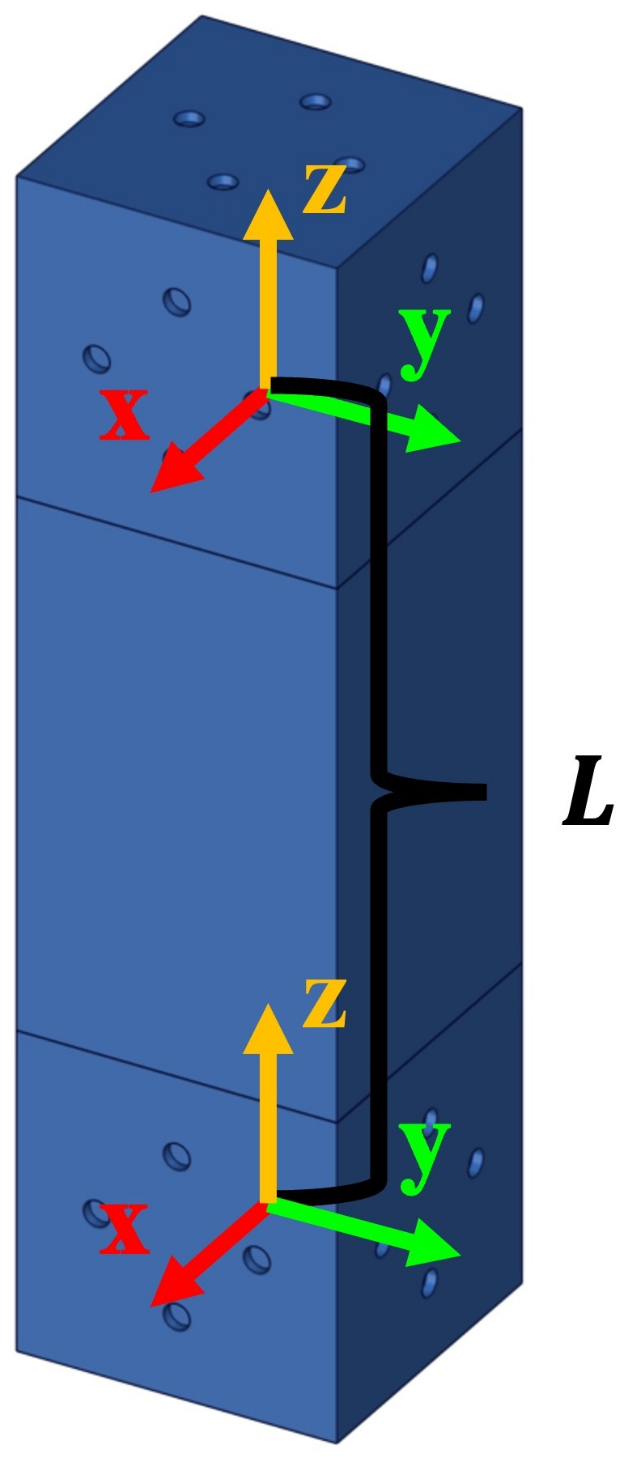

2.2. Link Modules

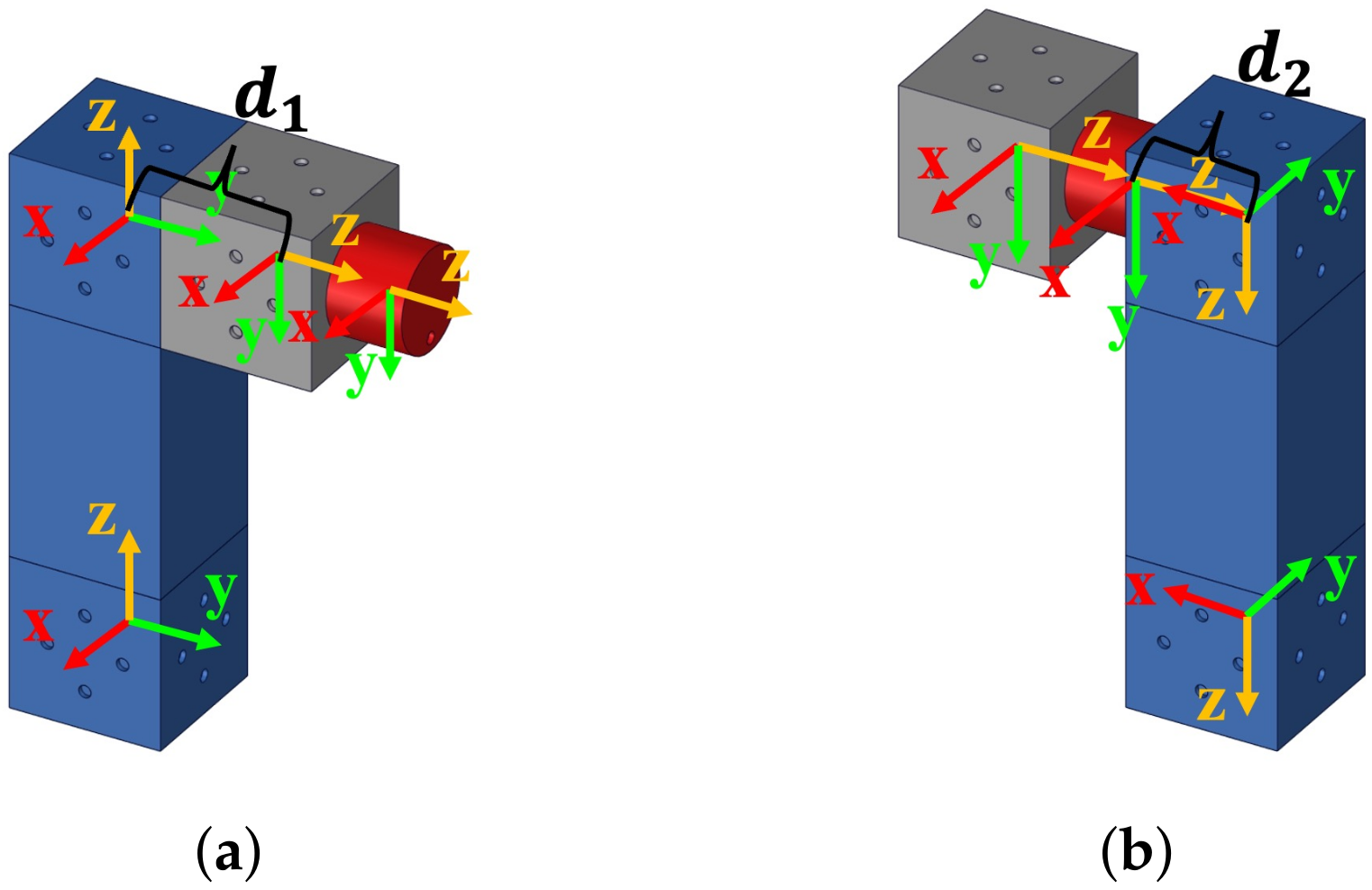

2.3. Unconventional Modules

3. MRR Assembly Configuration Representation

3.1. MRR Assembly Graph

- 1.

- , in which n is the number of vertices;

- 2.

- ;

- 3.

- If the entries in row i of are not all equal to 0, delete column i of ;

- 4.

- is given by the transpose of the resulting .

3.2. Assembly Adjacency Matrix

- Let be the entries of the adjacency matrix, and be the entries of the extend adjacency matrix;

- ;

- which is ’s assignment .

- Let be the entries of the EAM, and be the entries of the AAM;

- ;

- For and , replace with the output port vector of the module, while for and , replace with the input port vector of the module.

4. Automatic Kinematics Modeling

4.1. The Kinematics of Joint Modules

4.2. The Fixed Kinematic Transformation of Link Modules

4.3. The Fixed Kinematic Transformation between Two Assembled Modules

4.4. Automatic Kinematic Modeling Based on AAM

| Algorithm 1 The Kinematics of MRRs | |

| Input: AAM (); Joint angles ; | |

| Output: The pose of the end-effectors relative to the base frame, | |

| 1: | Extract the last row of as and delete the last row of , then set all the non-zero entries to 1 to get the adjacency matrix; |

| 2: | Calculate the path matrix ; |

| 3: | Modify the path matrix () by using the vertices’ subscript to replace the non-zero entries and then deleting the zero entries; |

| 4: | According to , compute the module kinematics set, termed ; |

| 5: | for to row of do |

| 6: | ; |

| 7: | for to row of do |

| 8: | for to column of -1 do |

| 9: | |

| 10: | Get the pair of port vectors , to compute the fixed kinematic transformation between the two assembled modules (); |

| 11: | ; |

| 12: | return |

5. Simulation and Results

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

Abbreviations

| MRR | Modular Reconfigurable Robot |

| AG | Assembly Graph |

| AAM | Assembly Adjacency Matrix |

| POE | Product of Exponentials |

| EAM | Extended Adjacency Matrix |

| D-H | Denavit–Hartenberg |

References

- Althoff, M.; Giusti, A.; Liu, S.B.; Pereira, A. Effortless creation of safe robots from modules through self-programming and self-verification. Sci. Robot. 2019, 4, eaaw1924. [Google Scholar] [CrossRef] [PubMed]

- Kelmar, L.; Khosla, P. Automatic generation of kinematics for a reconfigurable modular manipulator system. In Proceedings of the 1988 IEEE International Conference on Robotics and Automation, Philadelphia, PA, USA, 24–29 April 1988; Volume 2, pp. 663–668. [Google Scholar] [CrossRef]

- Paredis, C.; Brown, H.; Khosla, P. A rapidly deployable manipulator system. Proc. IEEE Int. Conf. Robot. Autom. 1996, 2, 1434–1439. [Google Scholar] [CrossRef]

- Patel, H.; Singh, C.; Liu, G. Safe robot operation alongside humans using spring-assisted modular and reconfigurable robot. In Proceedings of the 2017 IEEE International Conference on Mechatronics and Automation (ICMA), Takamatsu, Japan, 6–9 August 2017; pp. 787–792. [Google Scholar] [CrossRef]

- Singh, C.; Liu, G. On Task-Specific Redundant Actuation of Spring-Assisted Modular and Reconfigurable Robot. In Proceedings of the 2020 IEEE International Conference on Mechatronics and Automation (ICMA), Beijing, China, 13–16 October 2020; pp. 1191–1196. [Google Scholar] [CrossRef]

- Liu, C.; Yim, M. A Quadratic Programming Approach to Modular Robot Control and Motion Planning. In Proceedings of the 2020 Fourth IEEE International Conference on Robotic Computing (IRC), Taichung, Taiwan, 9–11 November 2020; pp. 1–8. [Google Scholar] [CrossRef]

- Liu, C.; Yu, S.; Yim, M. A Fast Configuration Space Algorithm for Variable Topology Truss Modular Robots. In Proceedings of the 2020 IEEE International Conference on Robotics and Automation (ICRA), Paris, France, 31 May–31 August 2020; pp. 8260–8266. [Google Scholar] [CrossRef]

- Zhao, S.; Zhao, J.; Sui, D.; Wang, T.; Zheng, T.; Zhao, C.; Zhu, Y. Modular Robotic Limbs for Astronaut Activities Assistance. Sensors 2021, 21, 6305. [Google Scholar] [CrossRef] [PubMed]

- Memar, A.H.; Esfahani, E.T. Modeling and Dynamic Parameter Identification of the SCHUNK Powerball Robotic Arm. In Proceedings of the ASME 2015 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Boston, MA, USA, 2–5 August 2015; Volume 5C: 39th Mechanisms and Robotics Conference. [Google Scholar] [CrossRef] [Green Version]

- Dogra, A.; Padhee, S.S.; Singla, E. Optimal Architecture Planning of Modules for Reconfigurable Manipulators. Robotica 2020, 1–15. [Google Scholar] [CrossRef]

- Dogra, A.; Sekhar Padhee, S.; Singla, E. An Optimal Architectural Design for Unconventional Modular Reconfigurable Manipulation System. J. Mech. Des. 2020, 143, 063303. [Google Scholar] [CrossRef]

- Yun, A.; Moon, D.; Ha, J.; Kang, S.; Lee, W. ModMan: An Advanced Reconfigurable Manipulator System with Genderless Connector and Automatic Kinematic Modeling Algorithm. IEEE Robot. Autom. Lett. 2020, 5, 4225–4232. [Google Scholar] [CrossRef]

- Romiti, E.; Malzahn, J.; Kashiri, N.; Iacobelli, F.; Ruzzon, M.; Laurenzi, A.; Hoffman, E.M.; Muratore, L.; Margan, A.; Baccelliere, L.; et al. Toward a Plug-and-Work Reconfigurable Cobot. IEEE/ASME Trans. Mechatron. 2021, 1–13. [Google Scholar] [CrossRef]

- Chen, I.M.; Yang, G. Configuration independent kinematics for modular robots. Proc. IEEE Int. Conf. Robot. Autom. 1996, 2, 1440–1445. [Google Scholar] [CrossRef]

- Zhao, J.; Tang, S.F.; Zhu, Y.H.; Cui, X.D. Topological description method of UBot self-reconfigurable robot. Harbin Gongye Daxue Xuebao/J. Harbin Inst. Technol. 2011, 43, 46–49+55. [Google Scholar]

- Nainer, C.; Feder, M.; Giusti, A. Automatic Generation of Kinematics and Dynamics Model Descriptions for Modular Reconfigurable Robot Manipulators. In Proceedings of the 2021 IEEE 17th International Conference on Automation Science and Engineering (CASE), Lyon, France, 23–27 August 2021; pp. 45–52. [Google Scholar] [CrossRef]

- Honerkamp, D.; Welschehold, T.; Valada, A. Learning Kinematic Feasibility for Mobile Manipulation Through Deep Reinforcement Learning. IEEE Robot. Autom. Lett. 2021, 6, 6289–6296. [Google Scholar] [CrossRef]

- Mahkam, N.; Özcan, O. A framework for dynamic modeling of legged modular miniature robots with soft backbones. Robot. Auton. Syst. 2021, 144, 103841. [Google Scholar] [CrossRef]

- Dalla Libera, A.; Castaman, N.; Ghidoni, S.; Carli, R. Autonomous Learning of the Robot Kinematic Model. IEEE Trans. Robot. 2021, 37, 877–892. [Google Scholar] [CrossRef]

- Denavit, J.; Hartenberg, R.S. A Kinematic Notation for Lower-Pair Mechanisms. J. Appl. Mech. 1955, 22, 215–221. [Google Scholar] [CrossRef]

- Chen, I.M. Theory and Applications of Modular Reconfigurable Robotic System. Ph.D. Thesis, California Institute of Technology, Pasadena, CA, USA, 1994. [Google Scholar]

- Yang, G.; Chen, I.M. A novel kinematic calibration algorithm for reconfigurable robotic systems. Proc. Int. Conf. Robot. Autom. 1997, 4, 3197–3202. [Google Scholar] [CrossRef]

- Chen, I.M.; Yang, G. Automatic Model Generation for Modular Reconfigurable Robot Dynamics. J. Dyn. Syst. Meas. Control 1998, 120, 346. [Google Scholar] [CrossRef]

- Yang, G. Kinematics, Dynamics, Calibration, and Configuration Optimization of Modular Reconfigurable Robots. Ph.D. Thesis, School of Mechanical and Production Engineering, Nanyang Technological University, Singapore, 1999. [Google Scholar]

- Brockett, R.W. Robotic manipulators and the product of exponentials formula. In Mathematical Theory of Networks and Systems; Fuhrmann, P.A., Ed.; Springer: Berlin/Heidelberg, Germany, 1984; pp. 120–129. [Google Scholar]

- Park, F.C.; Kim, B.; Jang, C.; Hong, J. Geometric Algorithms for Robot Dynamics: A Tutorial Review. Appl. Mech. Rev. 2018, 70, 010803. [Google Scholar] [CrossRef]

- Kollmorgen. Available online: https://www.kollmorgen.com/sites/default/files/public_downloads/RGM_UserManual_PDF.pdf (accessed on 15 December 2021).

| Column | Value |

|---|---|

| 1 | , |

| 2 | , , , |

| 3 | , , |

| 4 | , , |

| 5 | , , |

| 6 | , , |

| 7 | , , |

| 8 | , , |

| 9 | , , |

| 10 | , , |

| 11 | , , |

| 12 | , , |

| 13 | , |

| 14 | , |

| Value | |

|---|---|

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, T.; Du, Q.; Yang, G.; Wang, C.; Chen, C.-Y.; Zhang, C.; Chen, S.; Fang, Z. Assembly Configuration Representation and Kinematic Modeling for Modular Reconfigurable Robots Based on Graph Theory. Symmetry 2022, 14, 433. https://doi.org/10.3390/sym14030433

Zhang T, Du Q, Yang G, Wang C, Chen C-Y, Zhang C, Chen S, Fang Z. Assembly Configuration Representation and Kinematic Modeling for Modular Reconfigurable Robots Based on Graph Theory. Symmetry. 2022; 14(3):433. https://doi.org/10.3390/sym14030433

Chicago/Turabian StyleZhang, Tuopu, Qinghao Du, Guilin Yang, Chongchong Wang, Chin-Yin Chen, Chi Zhang, Silu Chen, and Zaojun Fang. 2022. "Assembly Configuration Representation and Kinematic Modeling for Modular Reconfigurable Robots Based on Graph Theory" Symmetry 14, no. 3: 433. https://doi.org/10.3390/sym14030433

APA StyleZhang, T., Du, Q., Yang, G., Wang, C., Chen, C.-Y., Zhang, C., Chen, S., & Fang, Z. (2022). Assembly Configuration Representation and Kinematic Modeling for Modular Reconfigurable Robots Based on Graph Theory. Symmetry, 14(3), 433. https://doi.org/10.3390/sym14030433