Condition Monitoring of Rolling Bearing Based on Multi-Order FRFT and SSA-DBN

Abstract

:1. Introduction

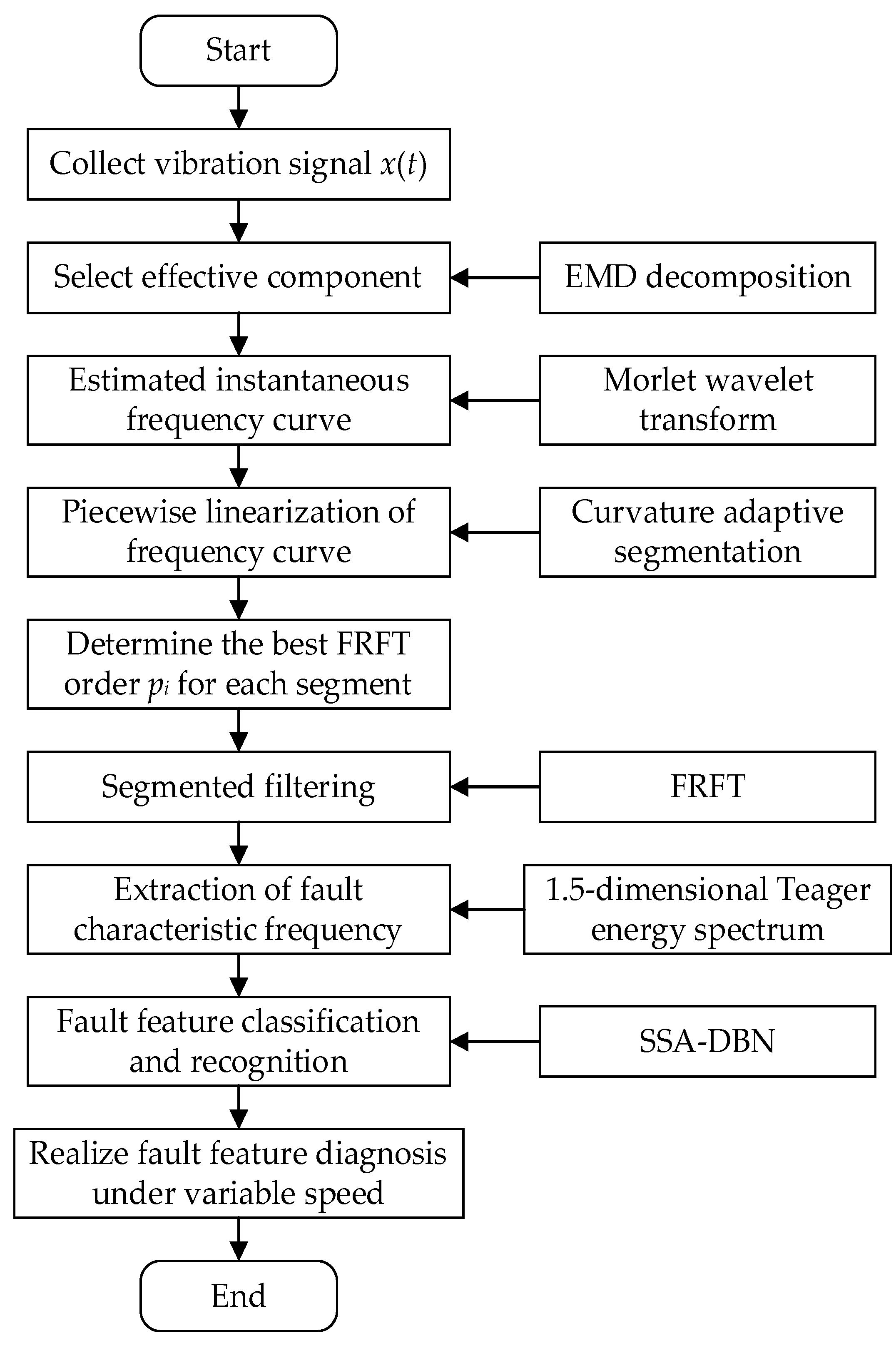

2. Related Theories

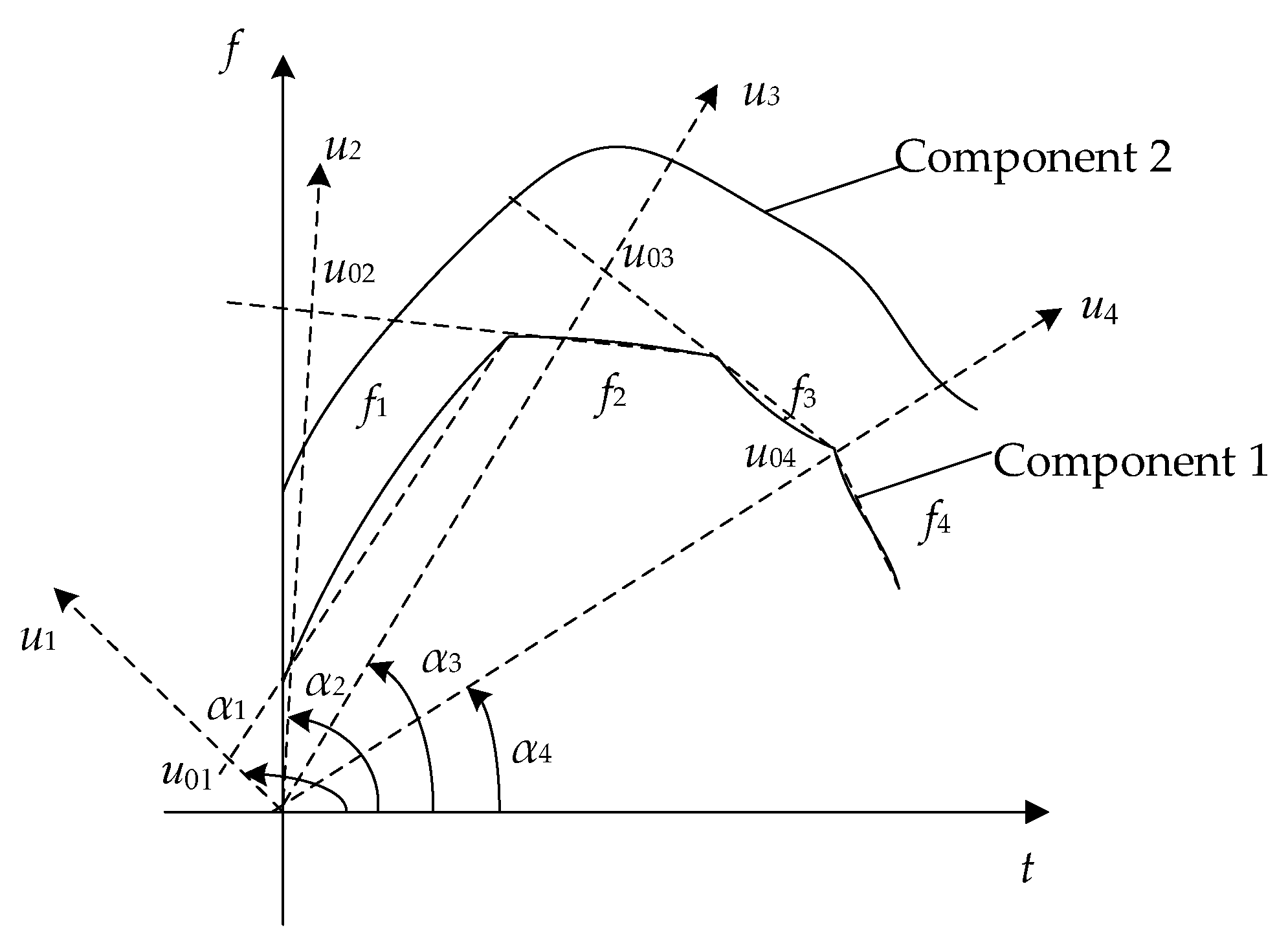

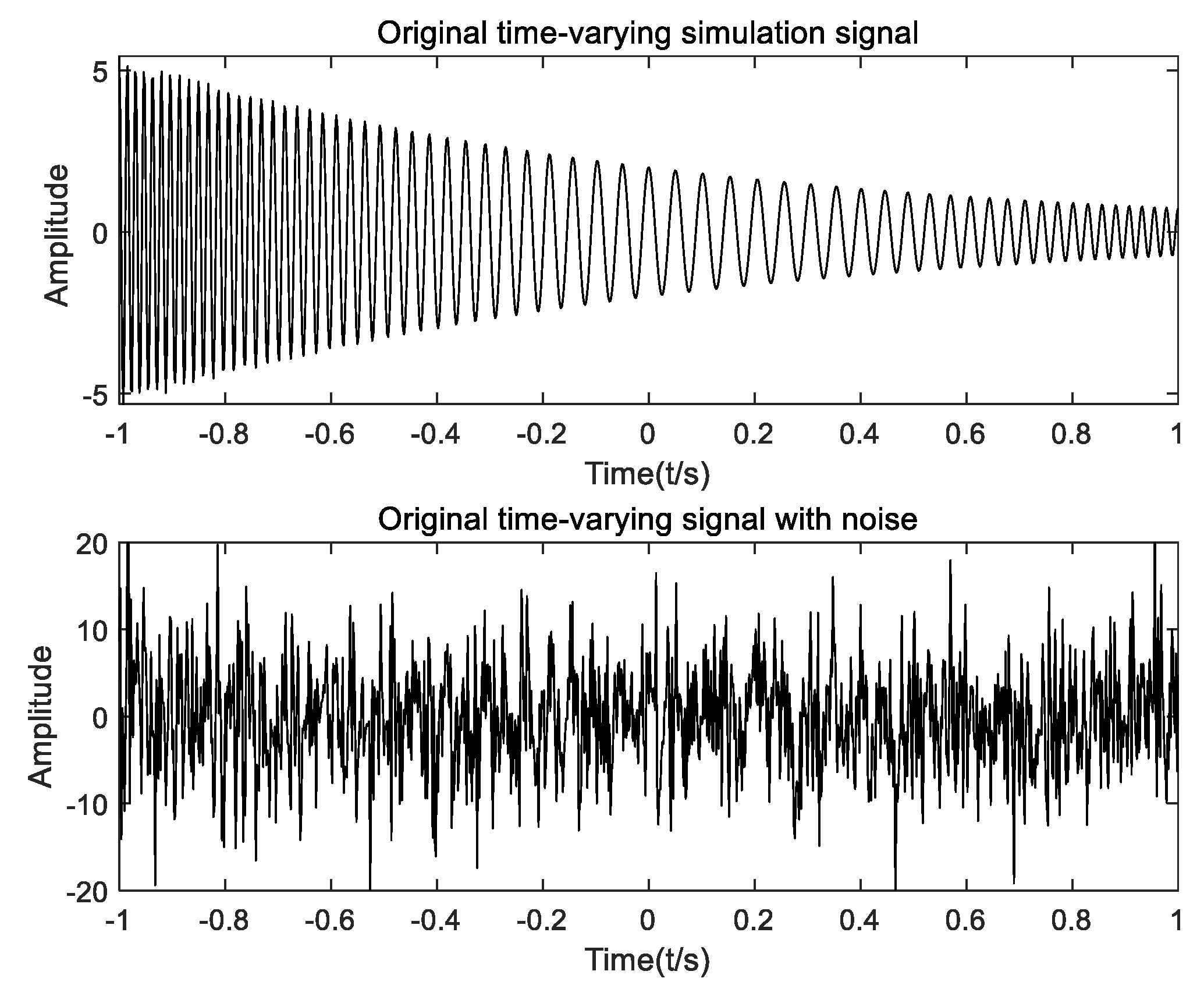

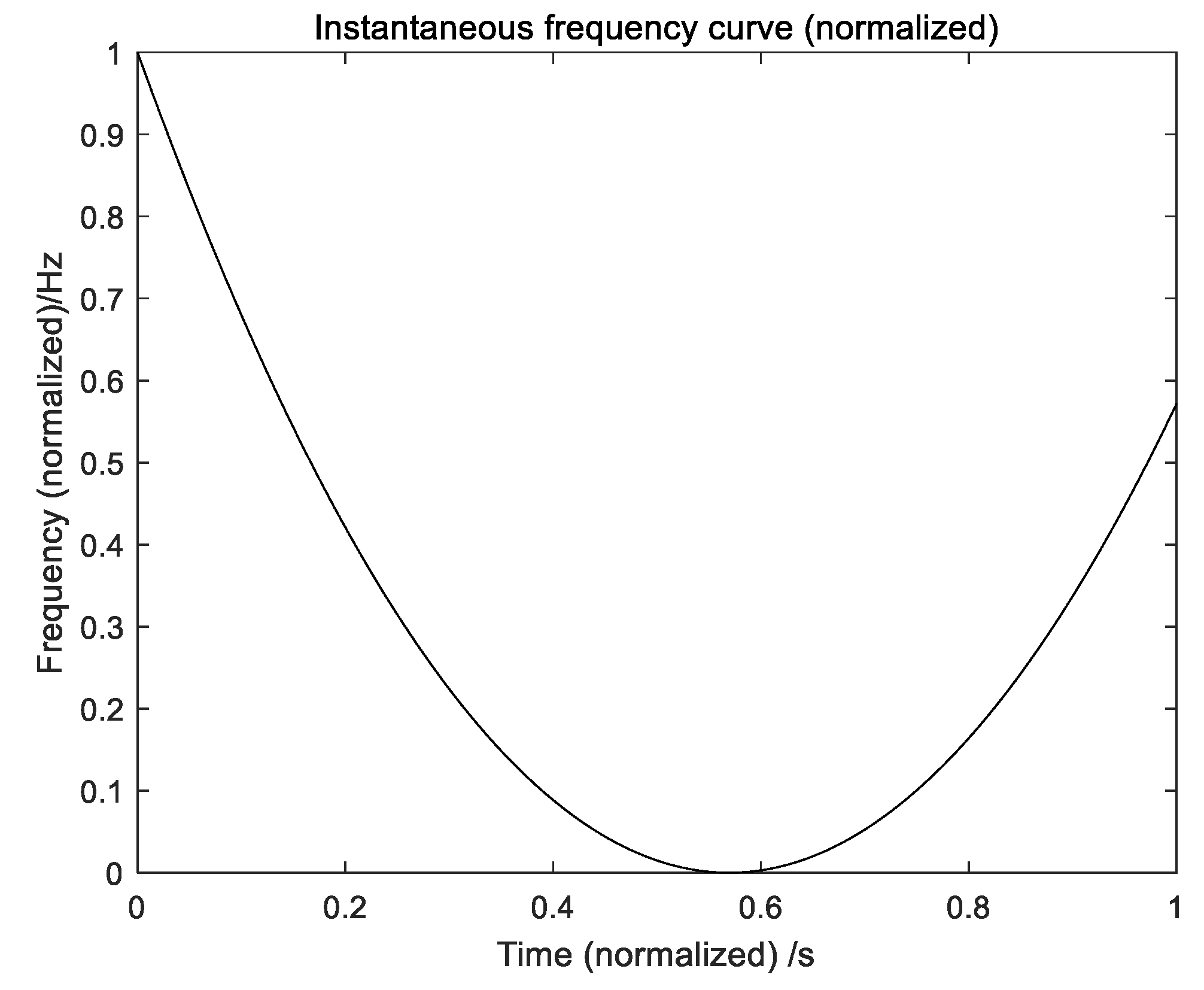

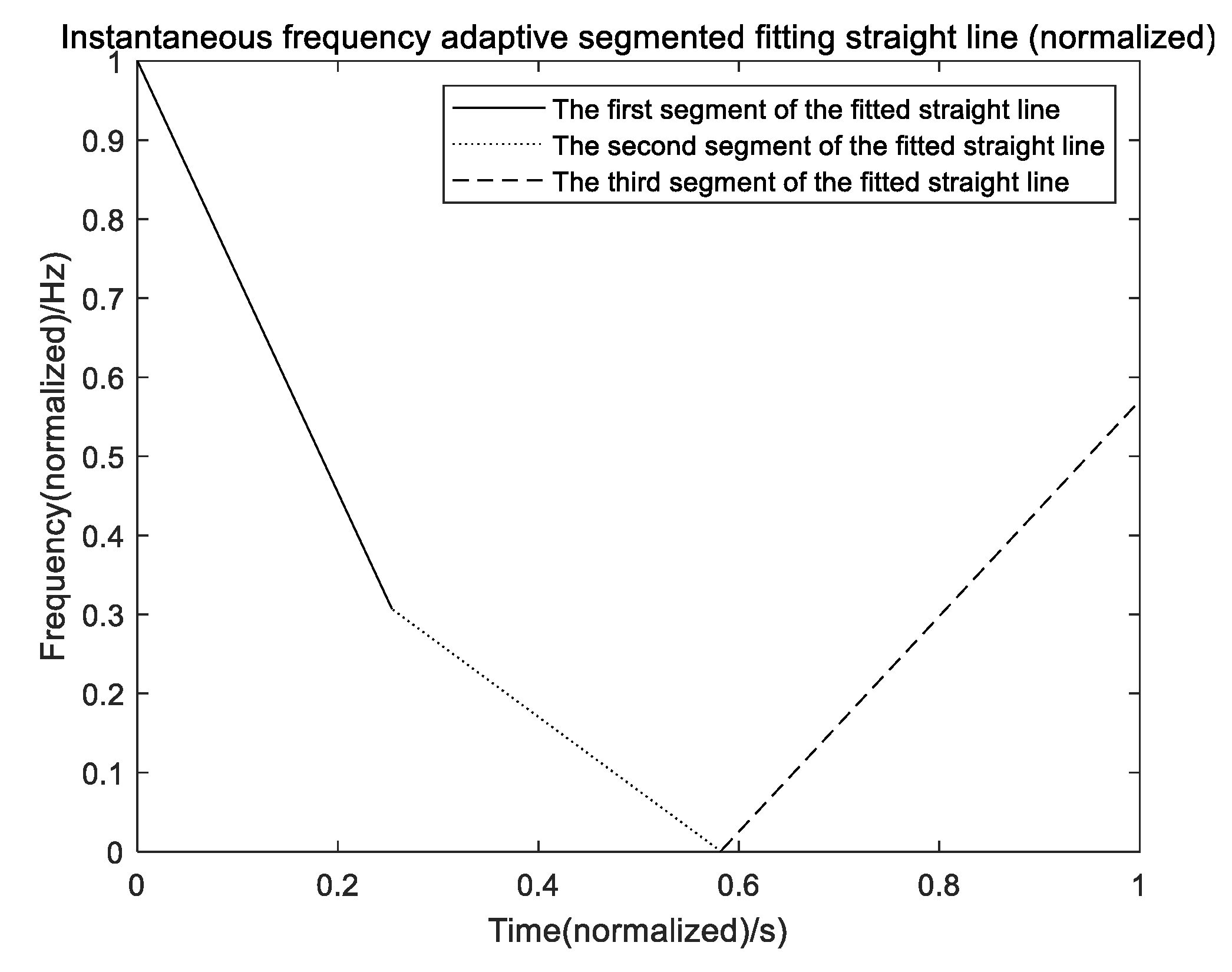

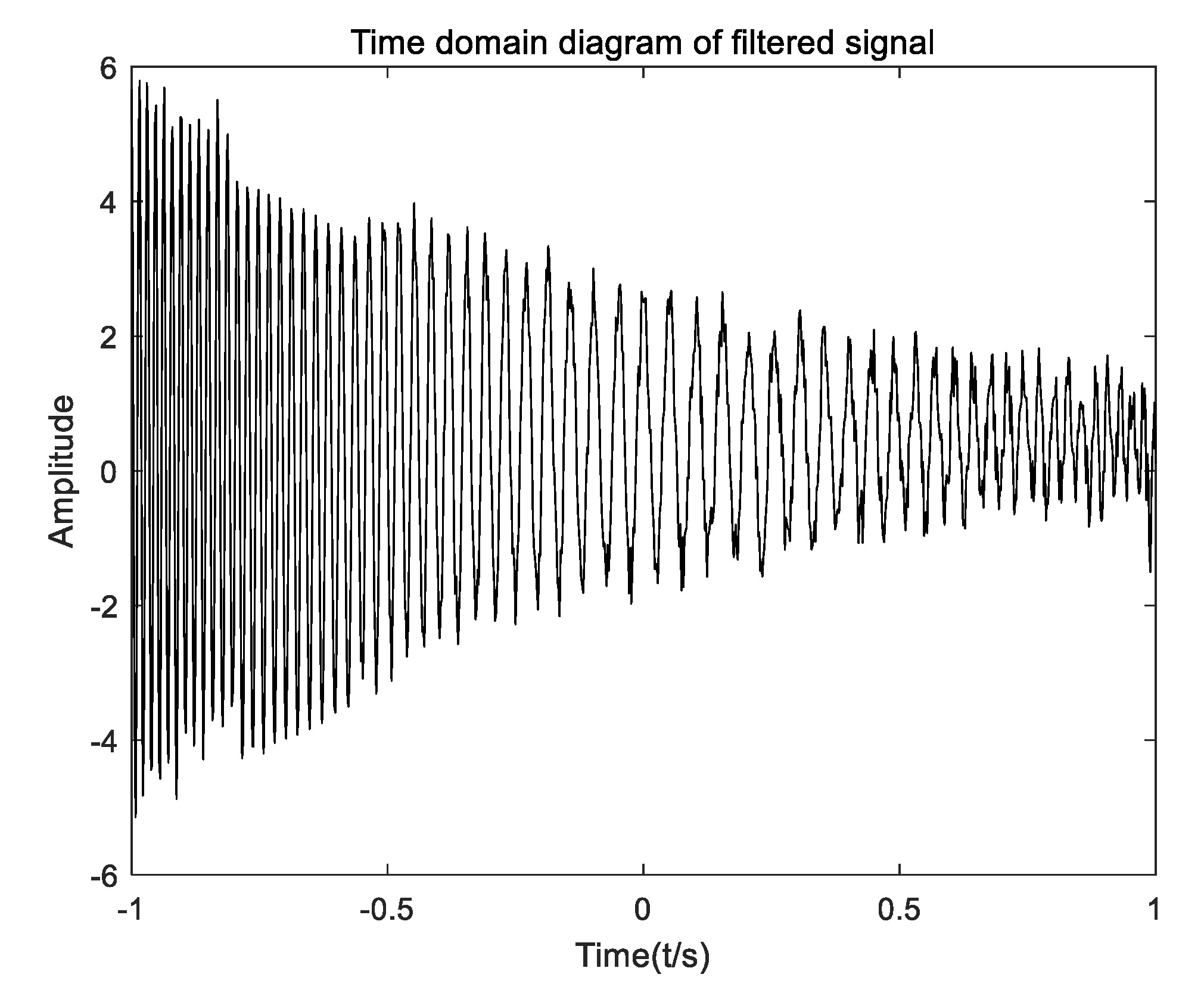

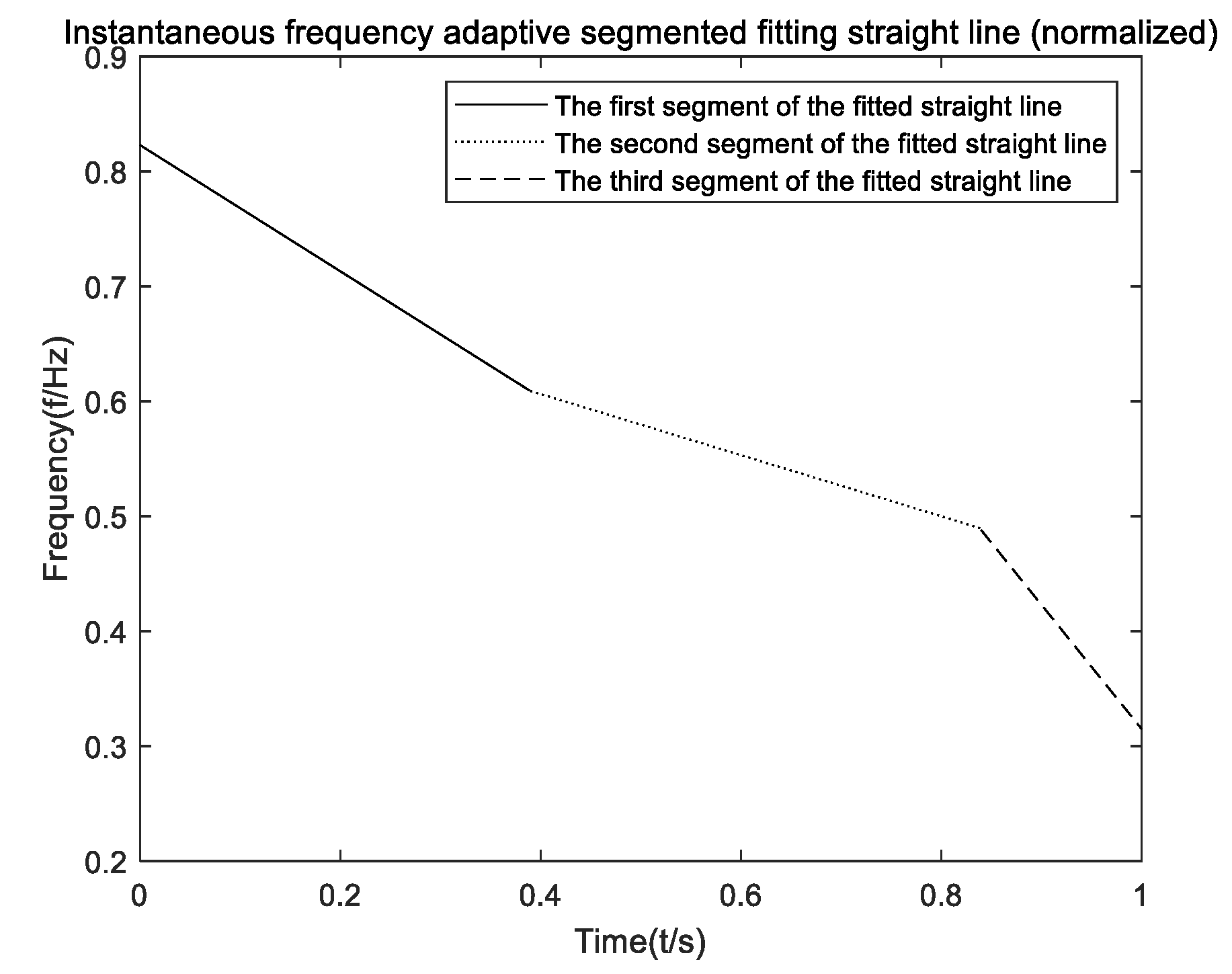

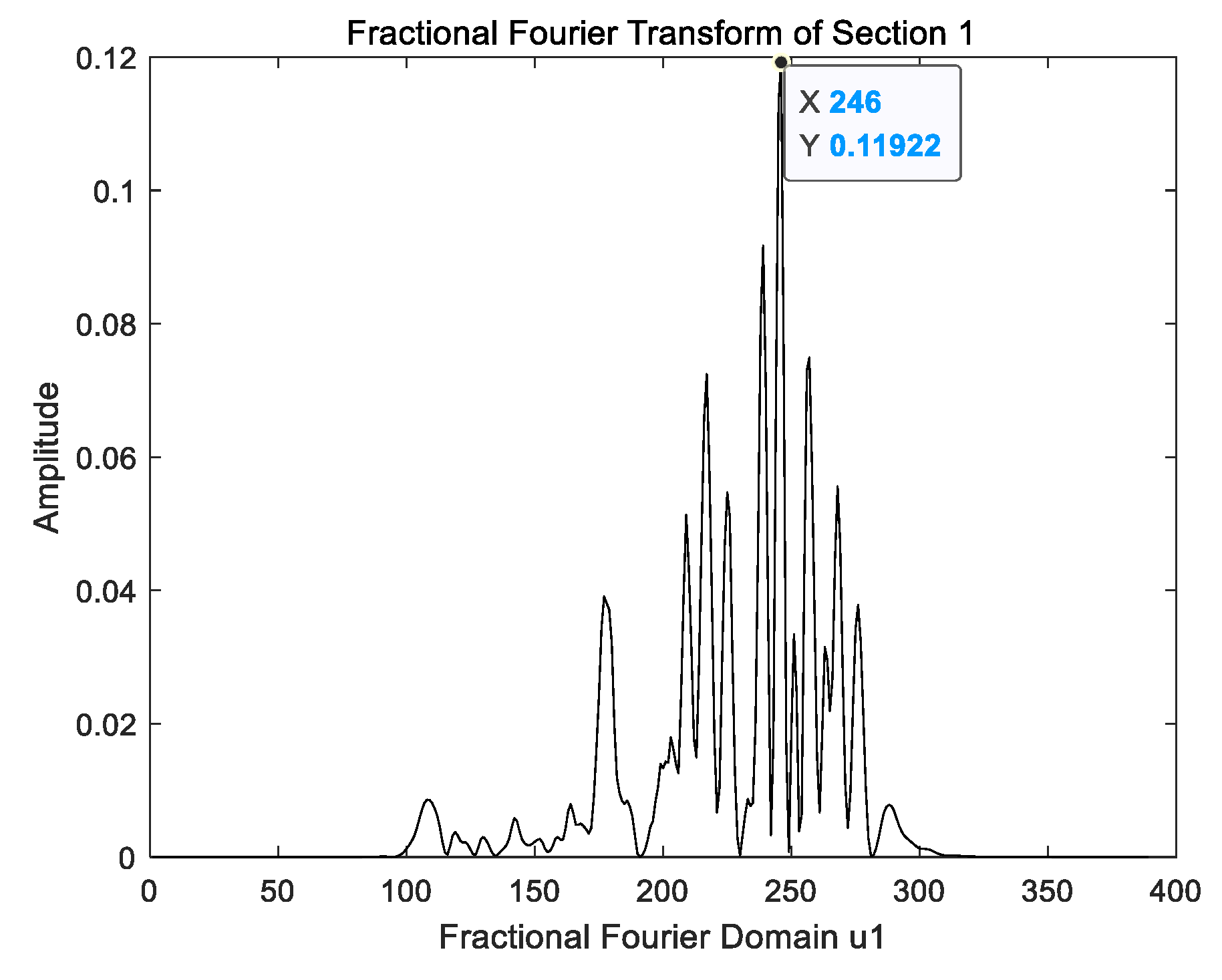

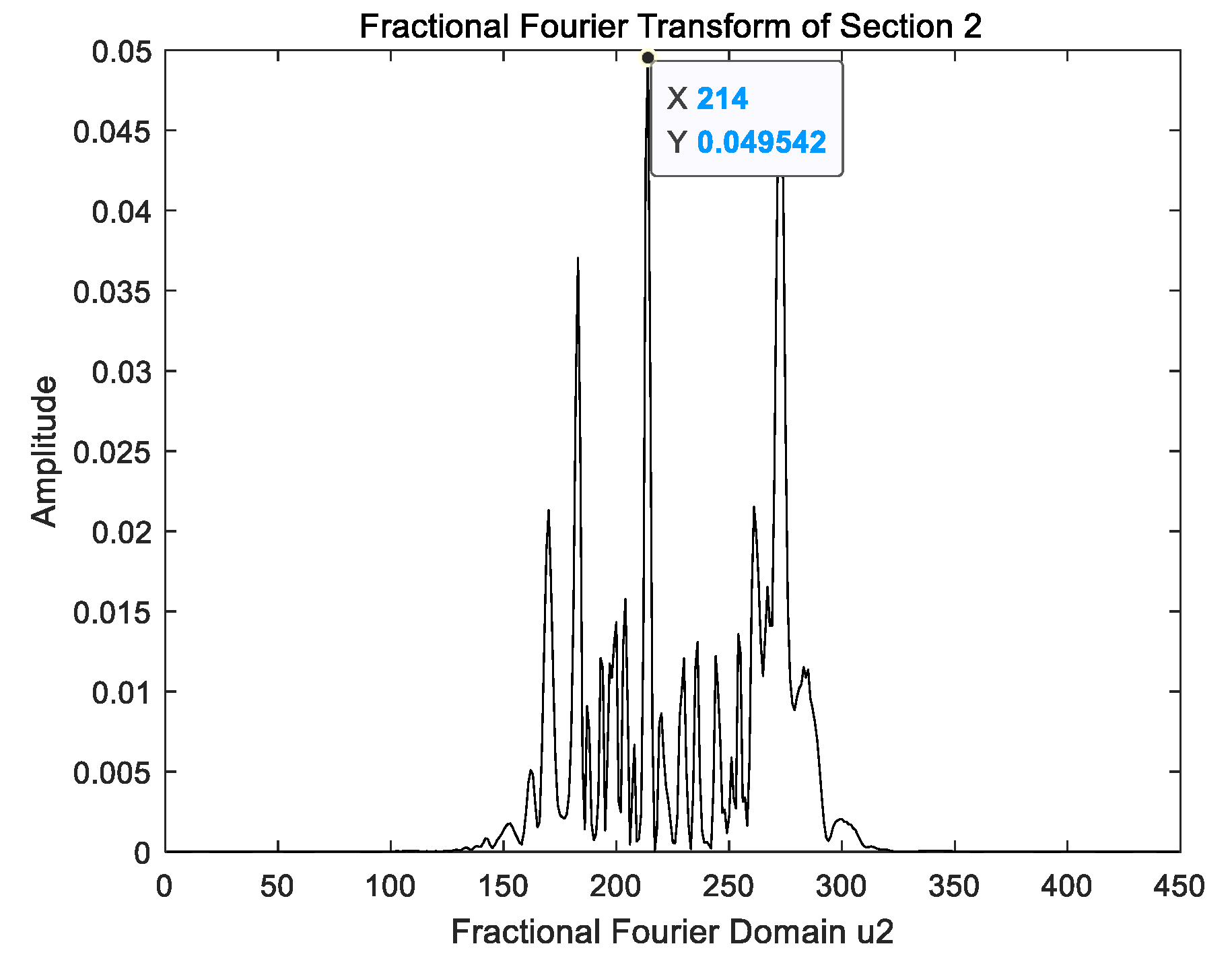

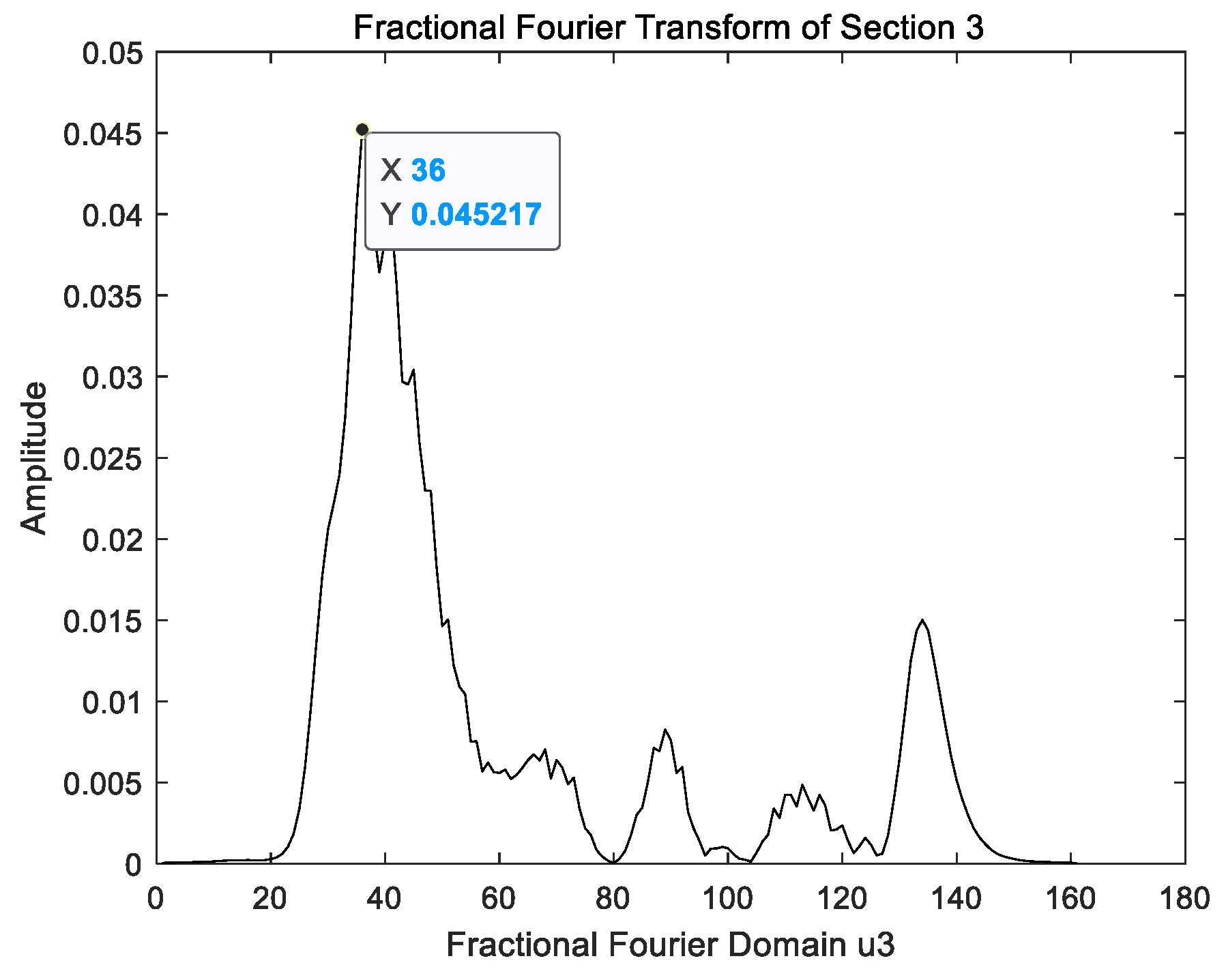

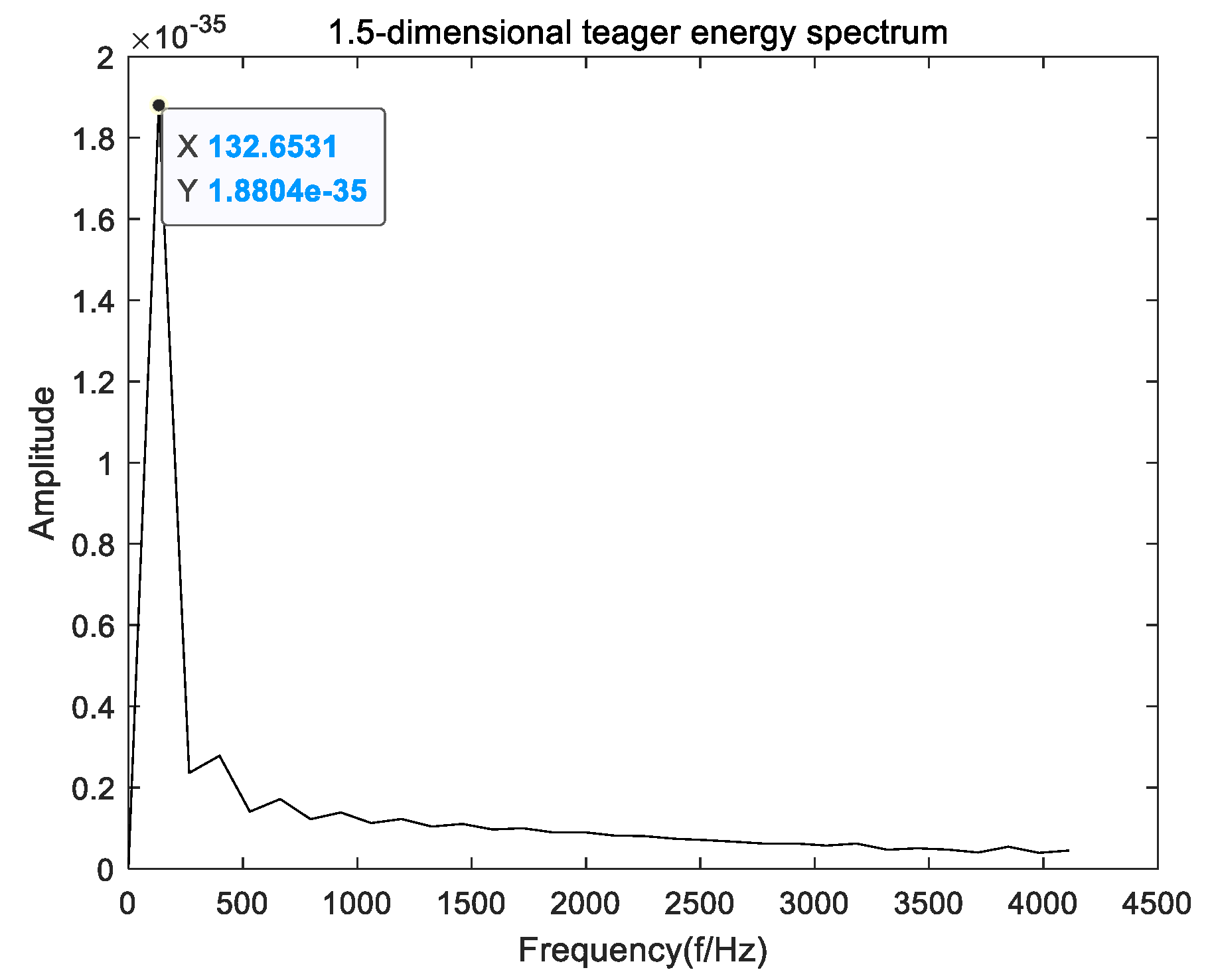

2.1. Signal Filtering Method Based on FRFT

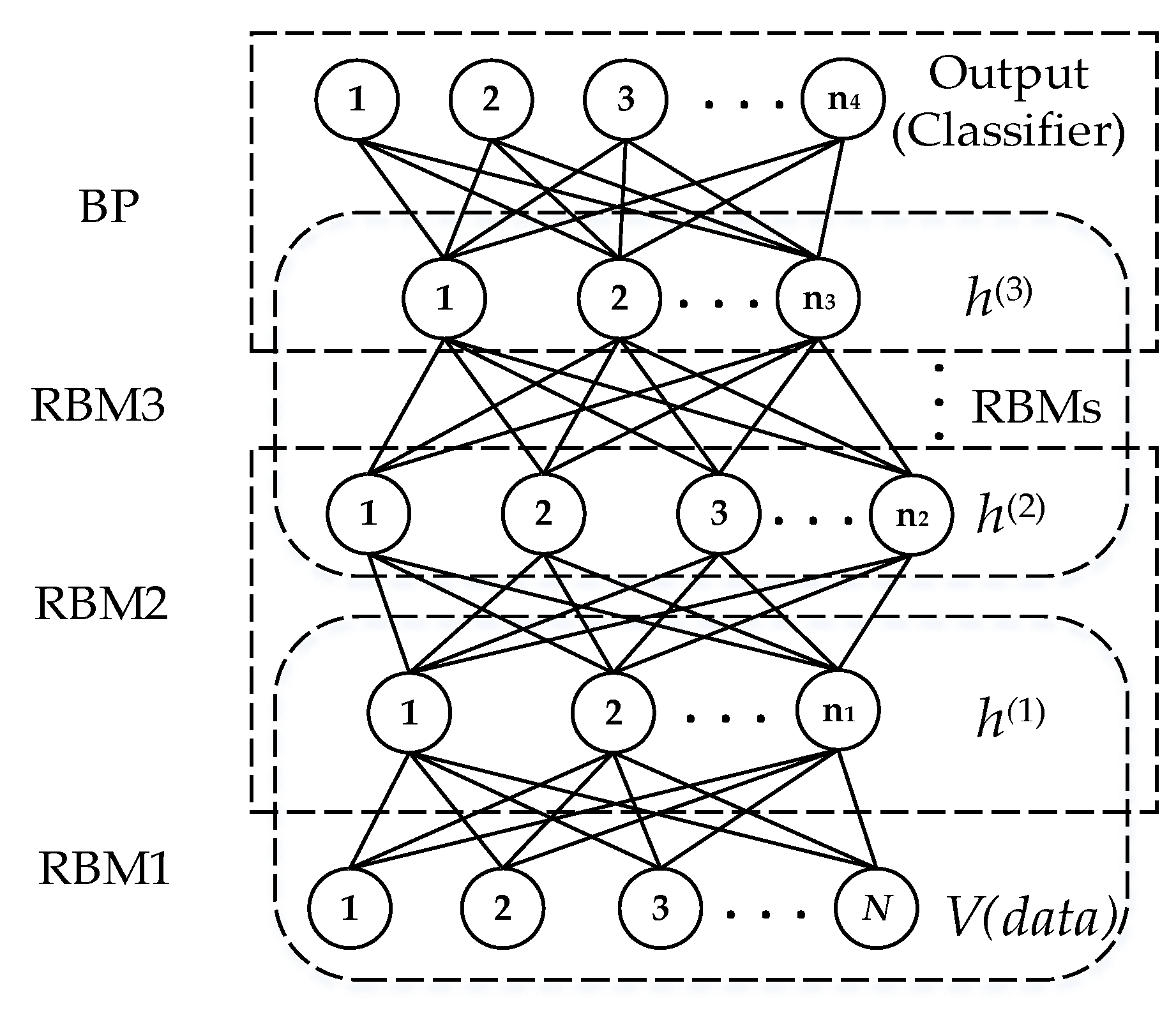

2.2. Fault Feature Classification Based on DBN

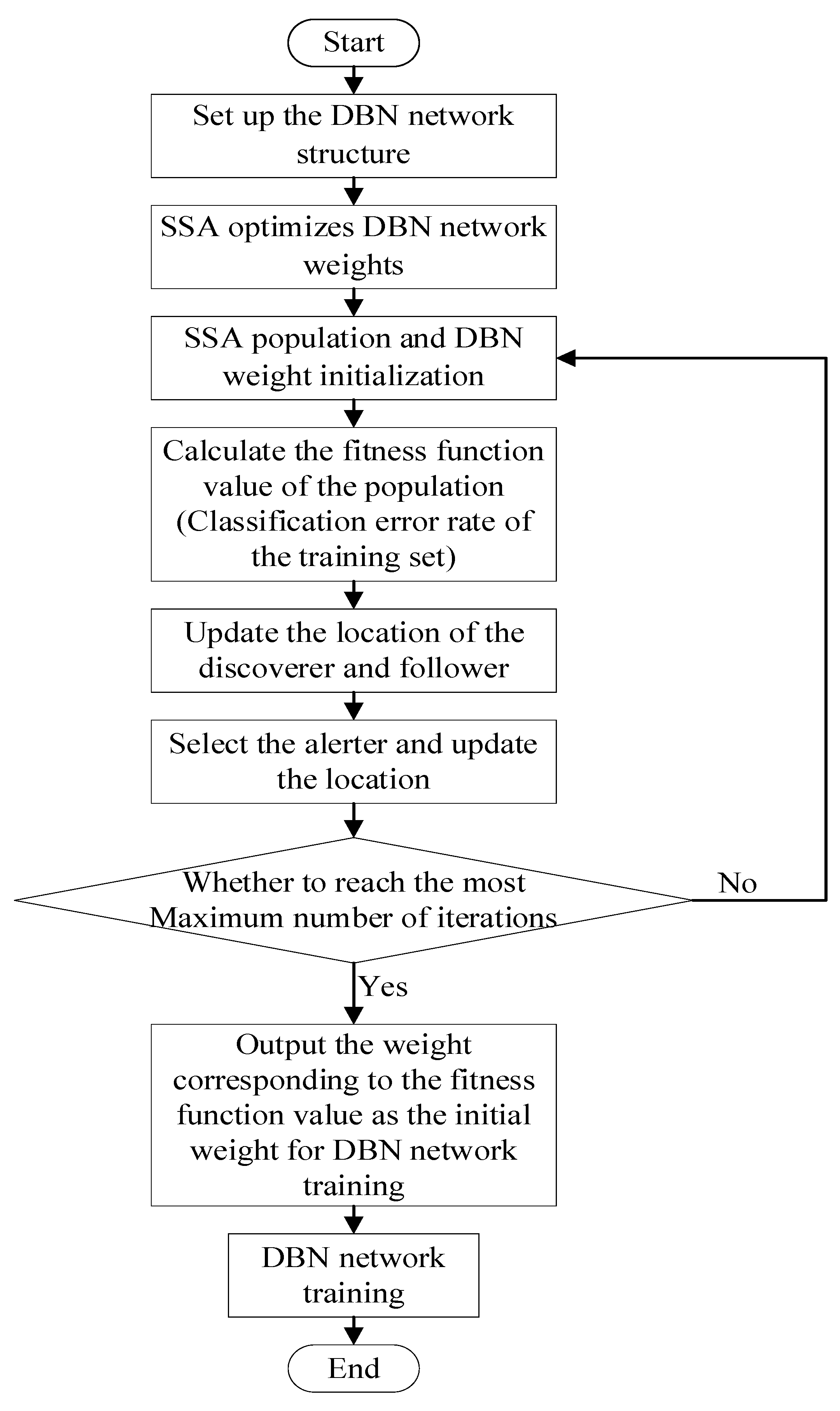

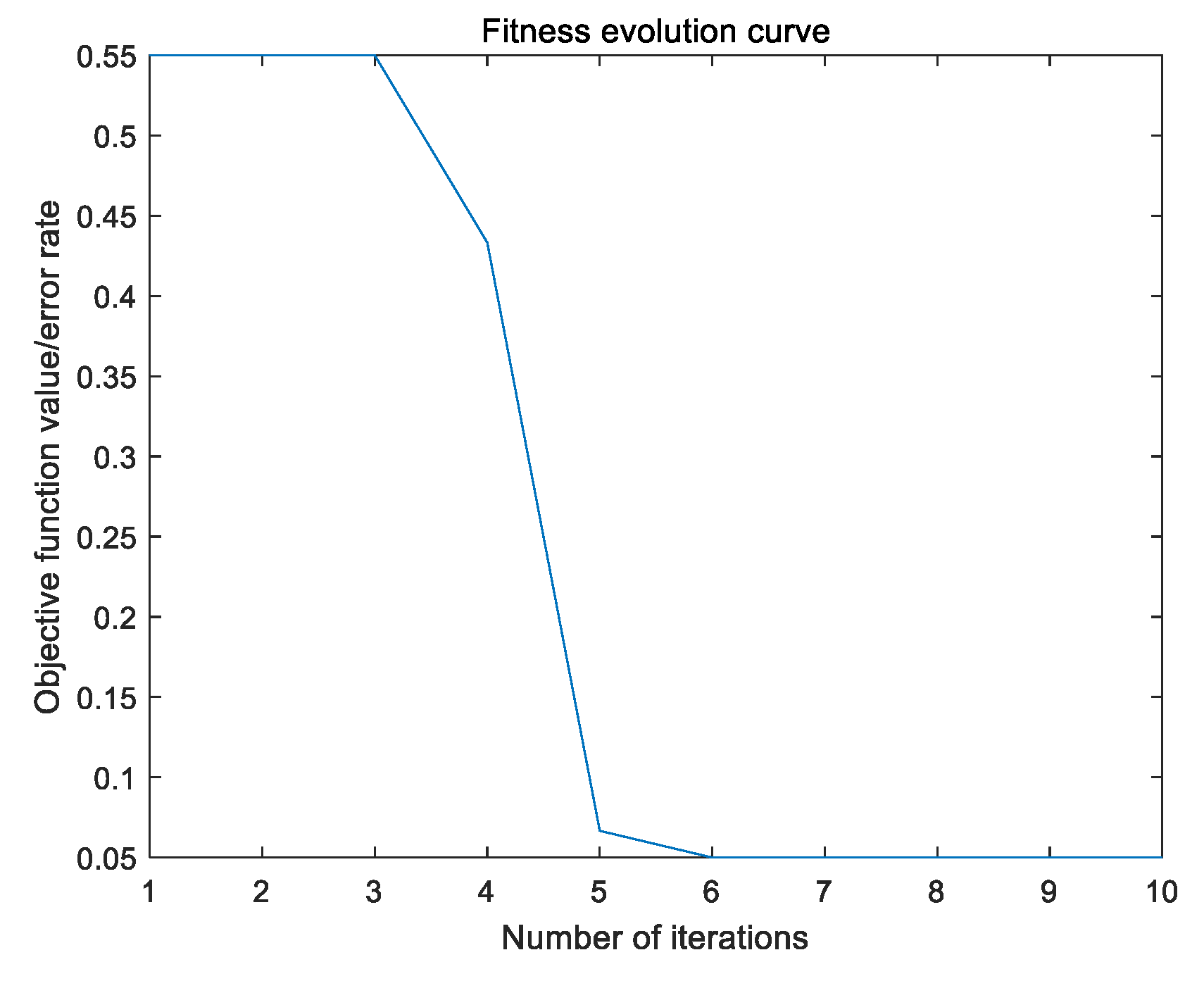

2.3. Fault Feature Classification Based on SSA-DBN

3. Experimental Result

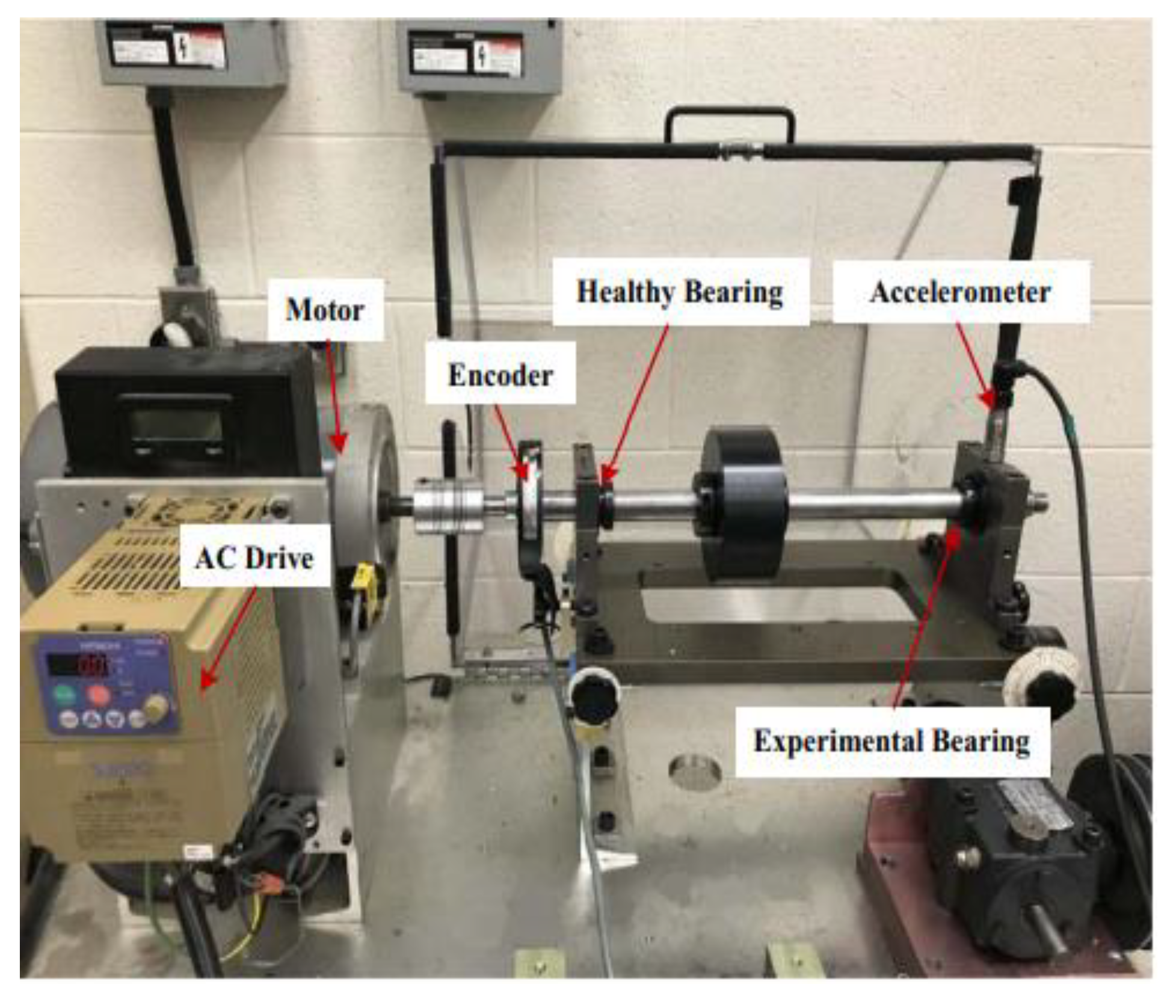

3.1. Data Description

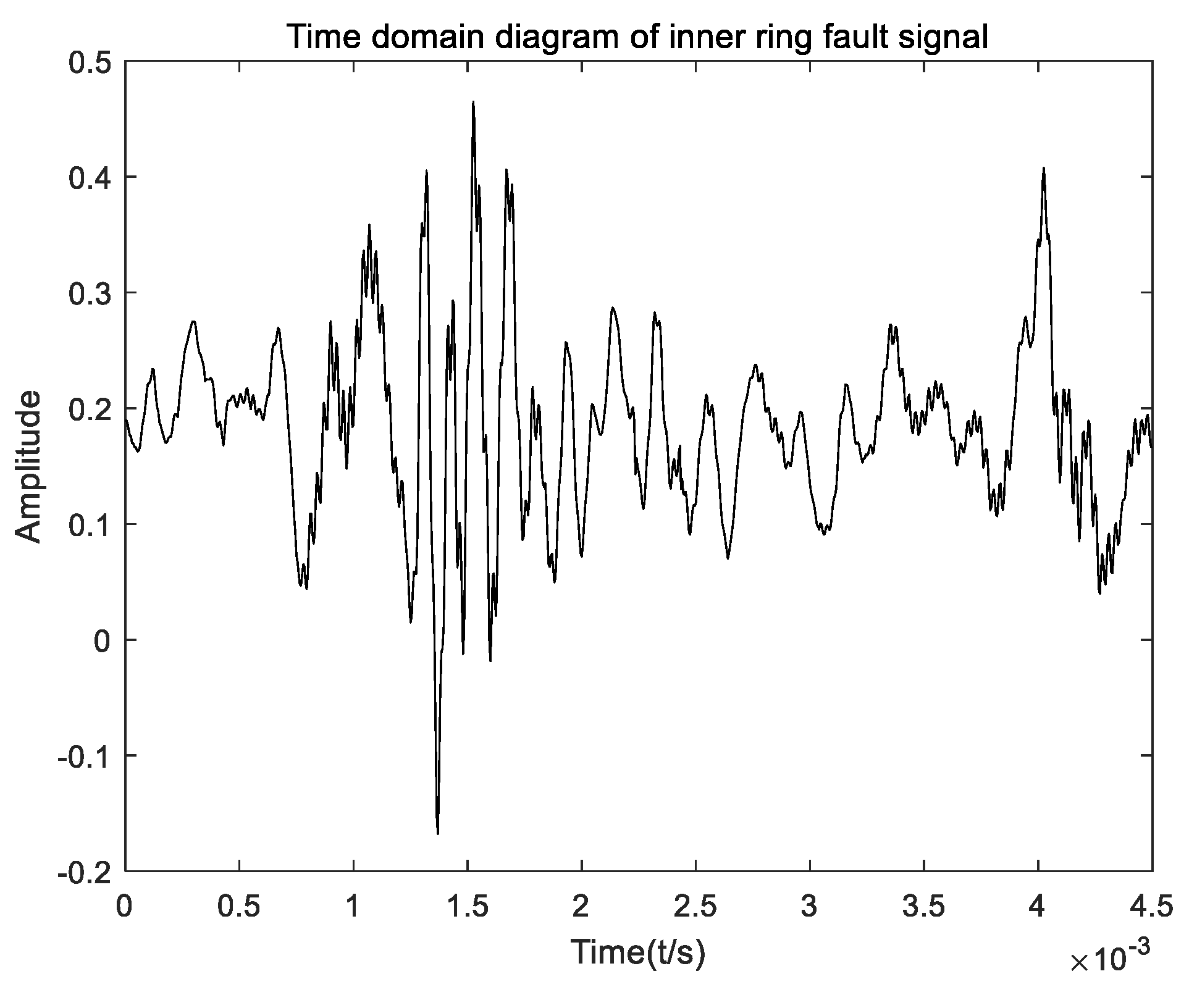

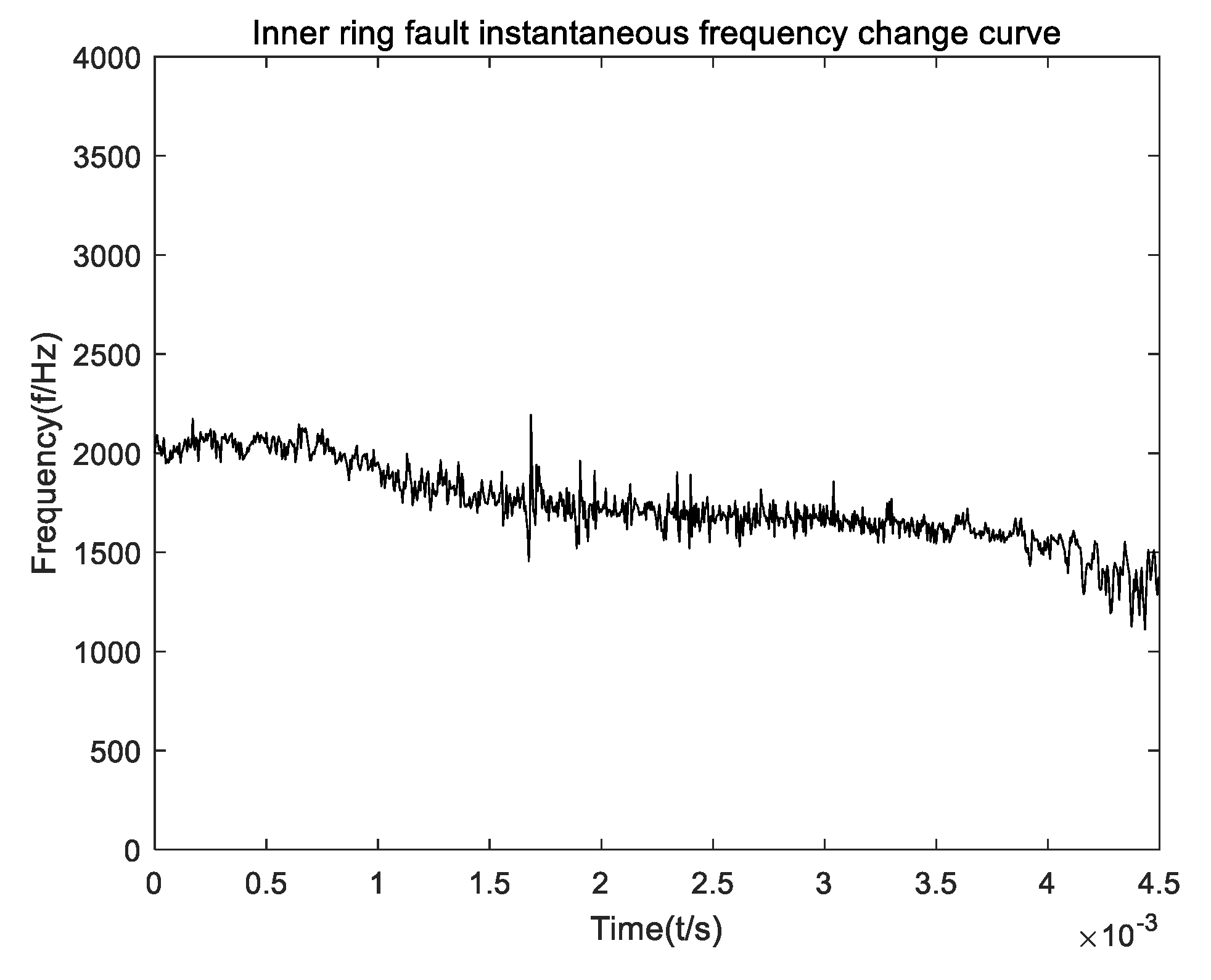

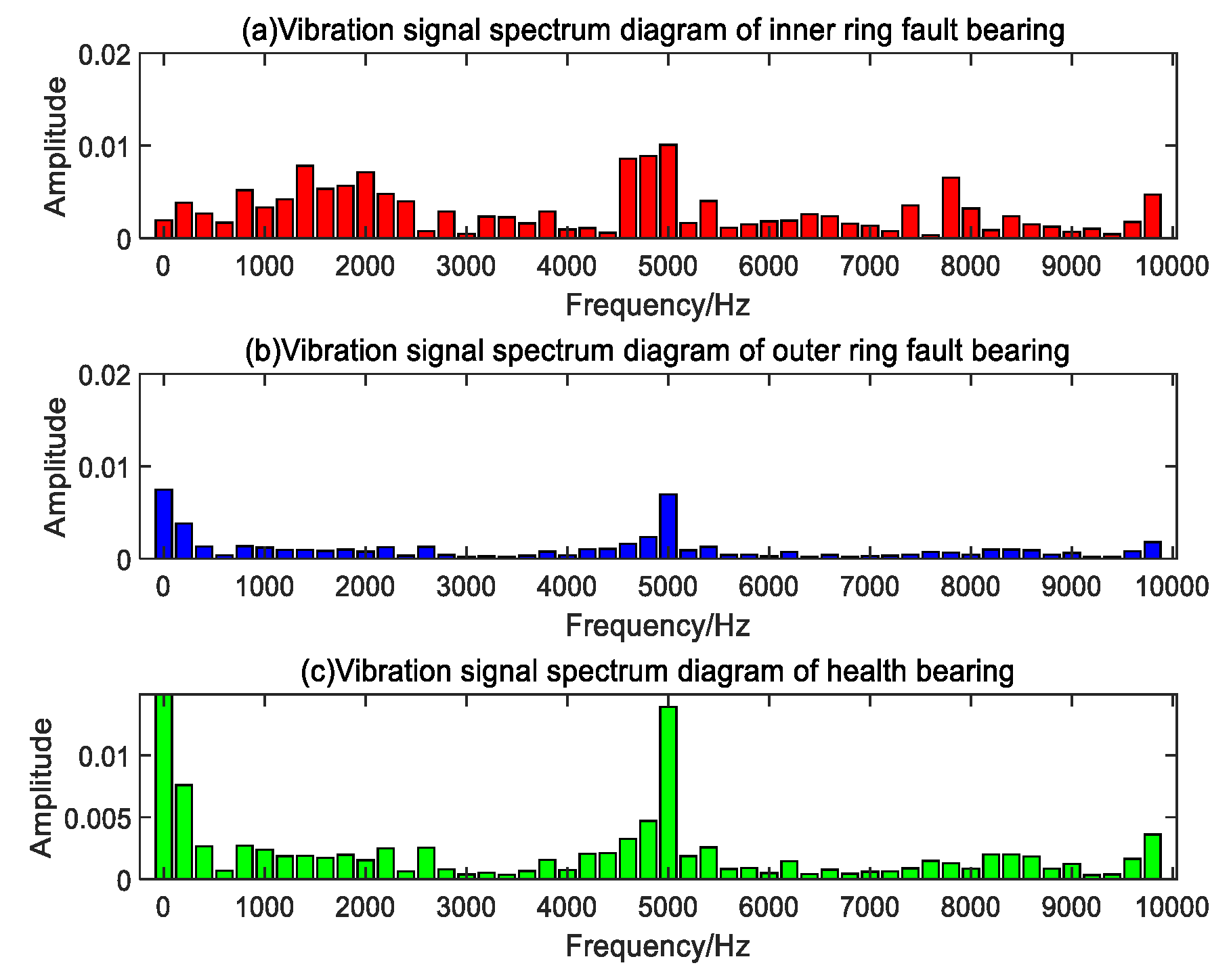

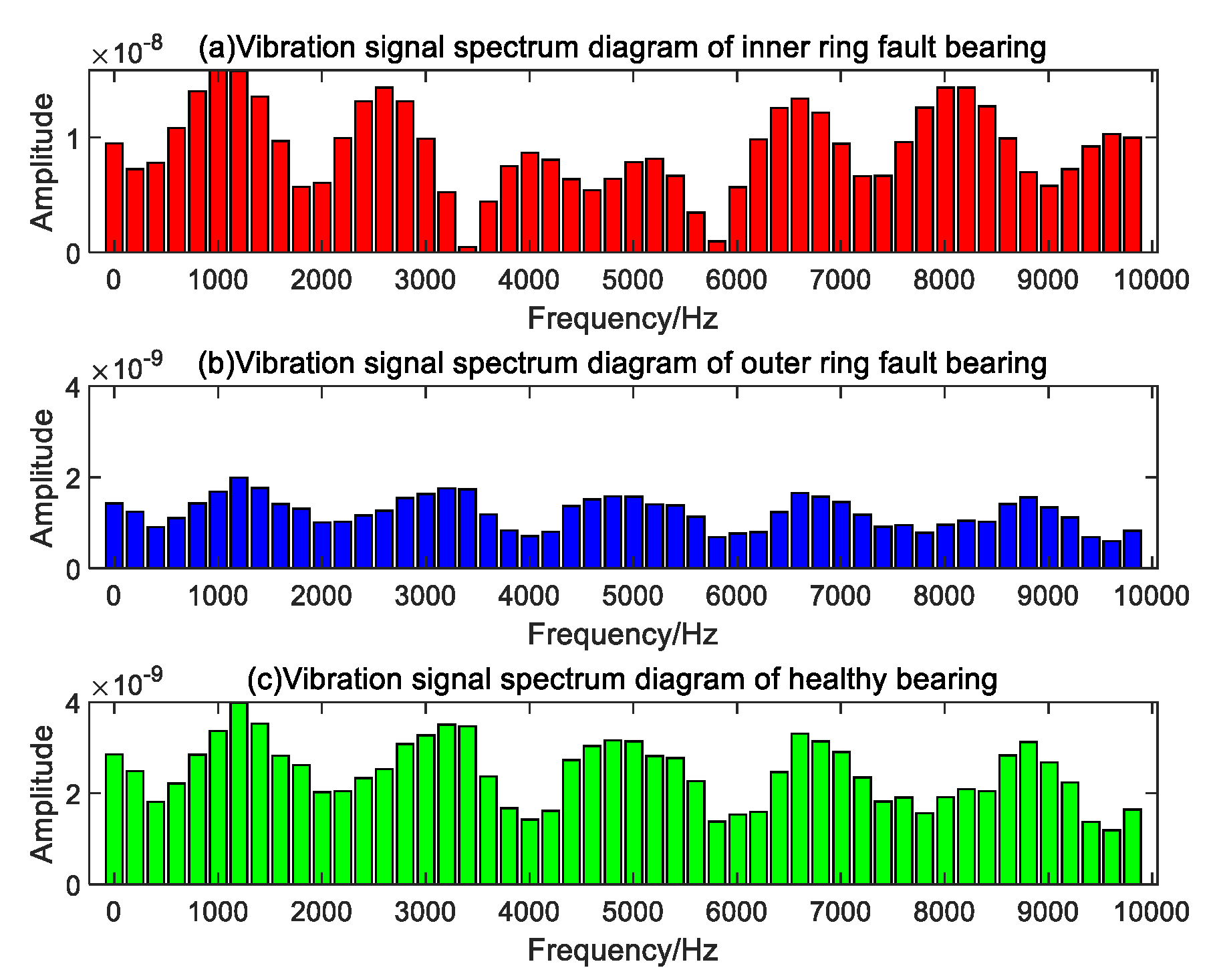

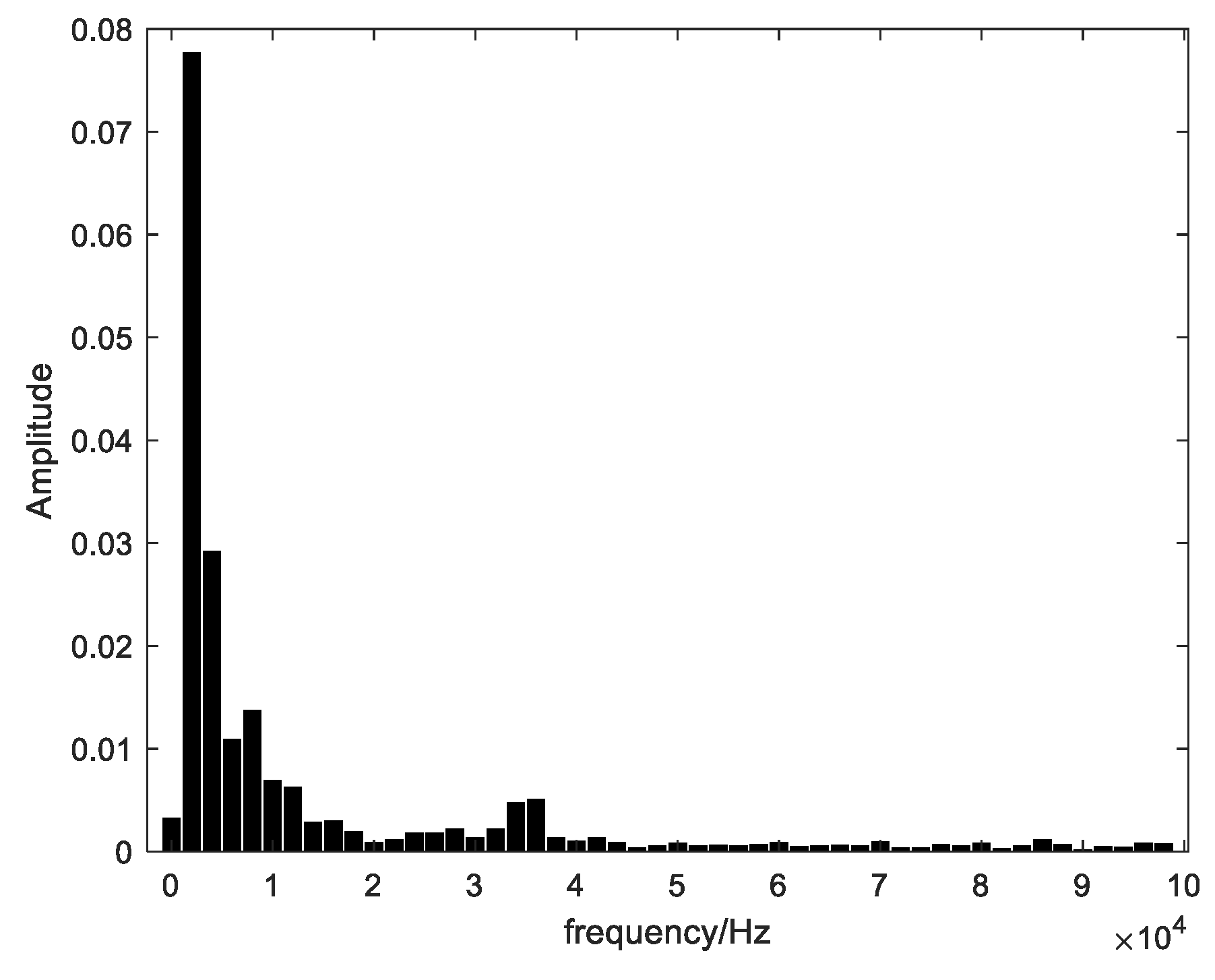

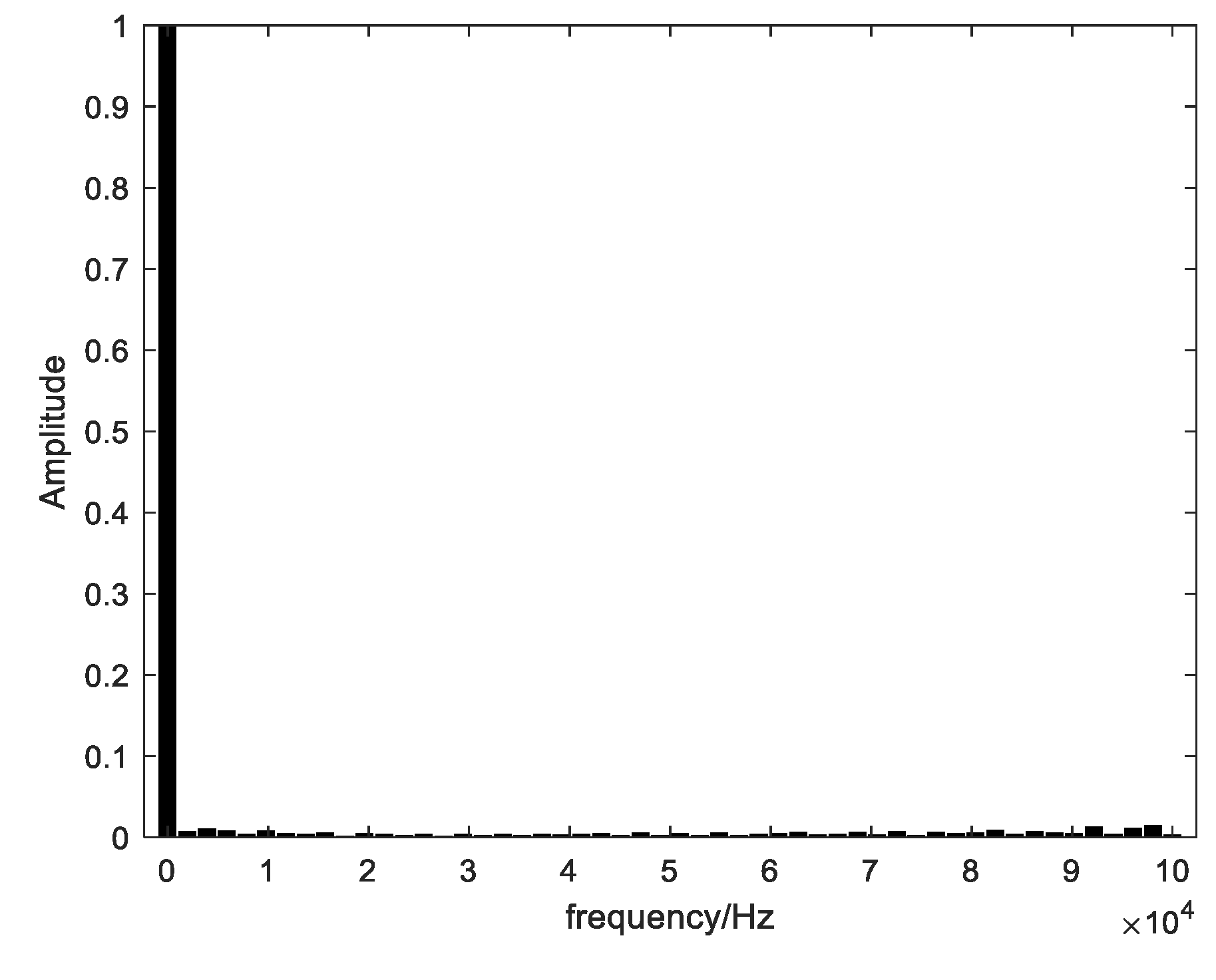

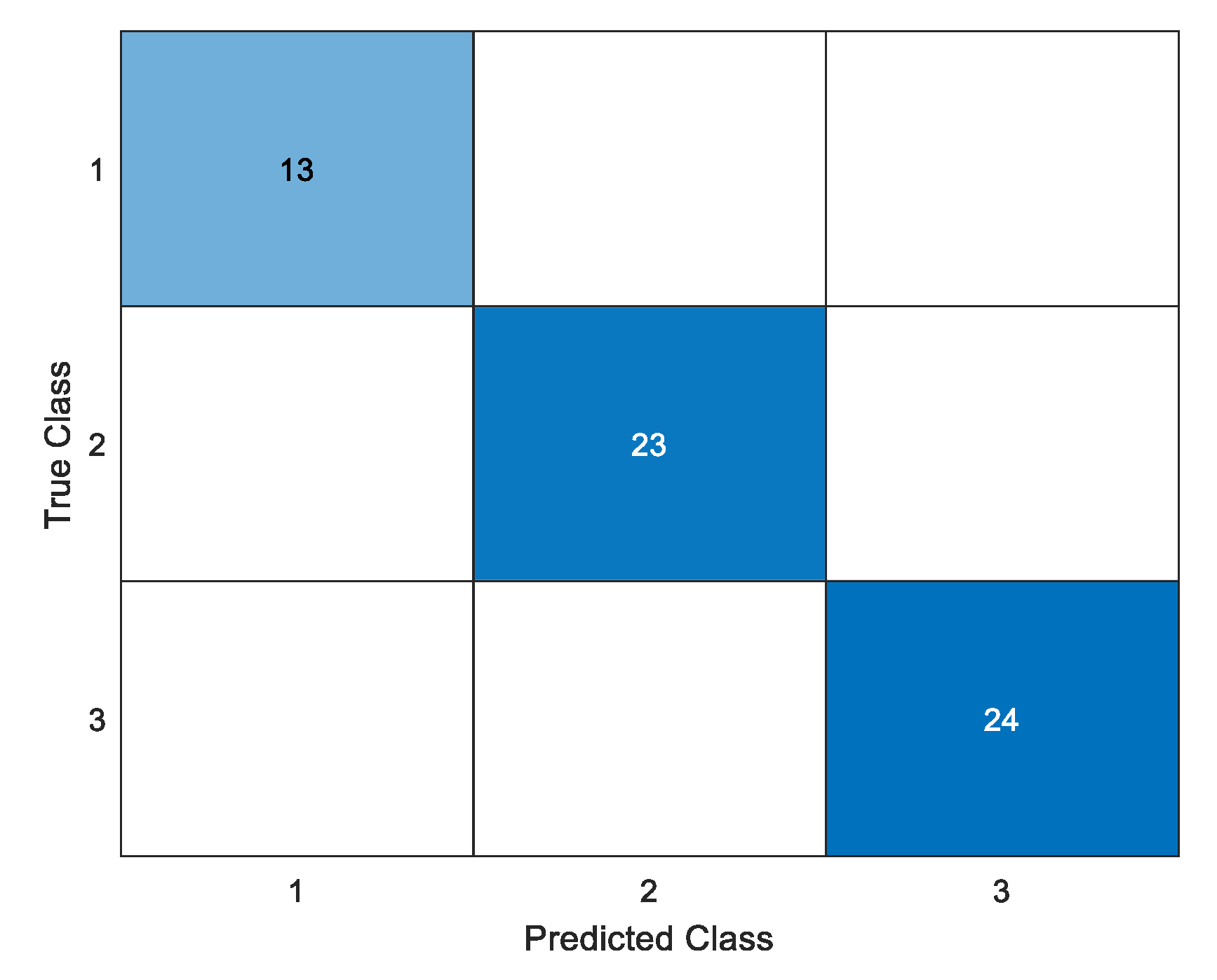

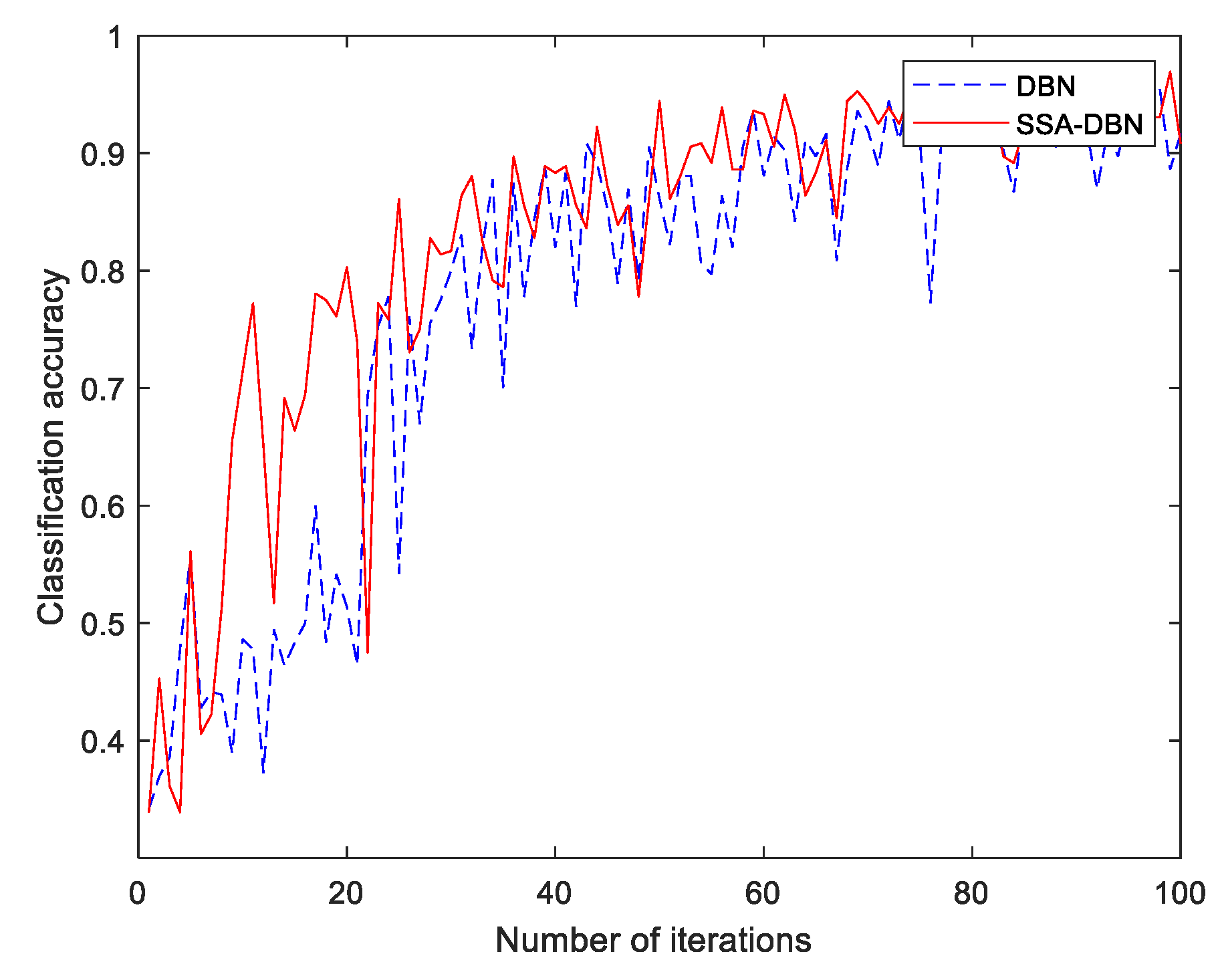

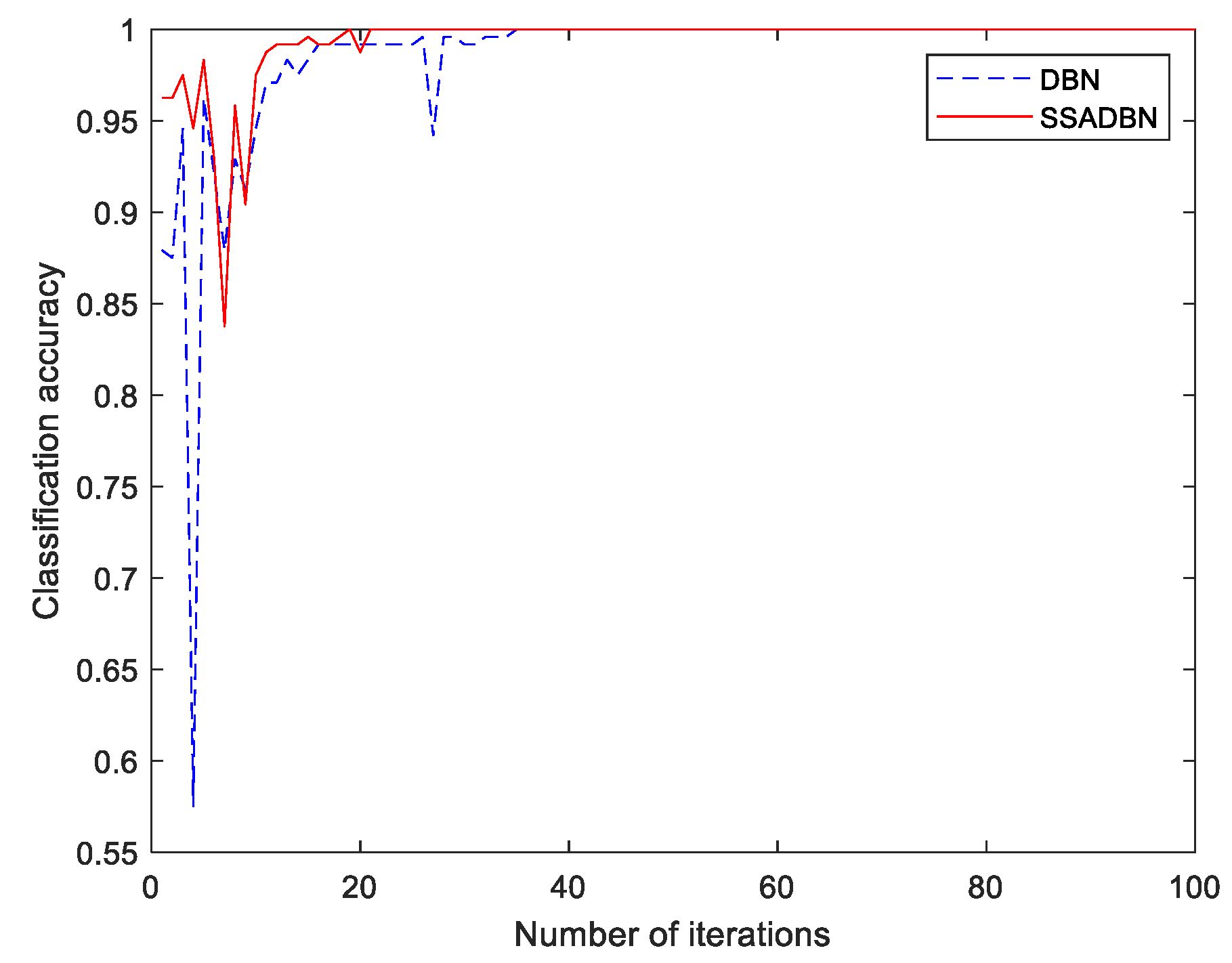

3.2. Condition Monitoring of the Rolling Bearing under Variable Speeds

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ma, J.P.; Zhuo, S.; Li, C.W.; Zhan, L.W.; Zhang, G.Z. An enhanced intrinsic time-scale decomposition method based on adaptive lévy noise and its application in bearing fault diagnosis. Symmetry 2021, 13, 617. [Google Scholar] [CrossRef]

- Gao, S.Z.; Li, T.C.; Zhang, Y.M. Rolling bearing fault diagnosis of PSO-LSSVM based on CEEMD entropy fusion. Trans. Can. Soc. Mech. Eng. 2020, 44, 405–418. [Google Scholar] [CrossRef]

- He, X.; Ma, J. Weak fault diagnosis of rolling bearing based on FRFT and DBN. Syst. Sci. Control Eng. 2020, 8, 57–66. [Google Scholar] [CrossRef]

- Li, C.; Liang, M.; Chen, Z.Q.; Bai, Y. Intelligent Health Management of Rolling Bearing Based on Vibration Signal; Science: Beijing, China, 2018. [Google Scholar]

- Hao, X.Y.; Zheng, Y.; Lu, L.; Pan, H. Reaearch on intelligent fault diagnosis of rolling bearing based on improved deep residual network. Appl. Sci. 2021, 11, 10889. [Google Scholar] [CrossRef]

- Rostaghi, M.; Khatibi, M.M.; Ashory, M.R.; Azami, H. Bearing fault diagnosis using refined composite generalized multiscale dispersion entropy-based skewness and variance and multiclass FCM-ANFIS. Symmetry 2021, 23, 1510. [Google Scholar] [CrossRef]

- Chen, F.F.; Cheng, M.T.; Tang, B.P.; Chen, B.J.; Xiao, W.R. Pattern recognition of a sensitive feature set based on the orthogonal neighborhood preserving embedding and adaboost_SVM algorithm for rolling bearing early fault diagnosis. Meas. Sci. Technol. 2020, 31, 105007. [Google Scholar] [CrossRef]

- Wang, H.; Chen, J.H.; Zhou, Y.W.; Ni, G.X. Early fault diagnosis of rolling bearing based on noise-assisted signal feature enhancement and stochastic resonance for intelligent manufacturing. Int. J. Adv. Manuf. Technol. 2020, 107, 1017–1023. [Google Scholar] [CrossRef]

- Li, Y.B.; Yang, Y.T.; Wang, X.Z.; Liu, X.Z.; Liu, B.B.; Liang, X.H. Early fault diagnosis of rolling bearings based on hierarchical symbol dynamic entropy and binary tree support vector machine. J. Sound. Vib. 2018, 428, 72–86. [Google Scholar] [CrossRef]

- Li, J.; Zhou, D.H.; Si, X.S.; Chen, M.Y.; Xu, C.H. Review of incipient fault diagnosis methods. Control Theory Appl. 2012, 29, 1517–1528. [Google Scholar]

- Zhao, X.P.; Wang, Y.F.; Zhang, Y.H.; Wu, J.X.; Shi, Y.Q. Weak fault diagnosis of rolling bearing based on improved stochastic resonance. CMC-Comput. Mater. Con. 2020, 64, 571–587. [Google Scholar] [CrossRef]

- Xu, L.; Chatterton, S.; Pennacchi, P. Rolling element bearing diagnosis based on singular value decomposition and composite squared envelope spectrum. Mech. Syst. Signal Pract. 2021, 148, 107174. [Google Scholar] [CrossRef]

- Wen, C.L.; Lv, F.Y.; Bao, Z.J.; Liu, M.Q. A Review of Data Driven-based Incipient Fault Diagnosis. Acta Autom. Sin. 2016, 42, 1286–1299. [Google Scholar]

- Namias, V. The fractional order Fourier transform and its application to quantum mechanics. IMA J. Appl. Math. 1980, 25, 241–265. [Google Scholar] [CrossRef]

- Lin, L.F.; Wang, H.Q.; Lv, W.Y.; Zhong, S.C. A novel parameter-induced stochastic resonance phenomena in fractional Fourier domain. Mech. Syst. Signal Pract. 2016, 76–77, 771–779. [Google Scholar] [CrossRef]

- Qi, L.; Tao, R.; Zhou, S.Q.; Wang, Y. Detection and parameter estimation of multicomponent LFM signals based on fractional Fourier transform. Sci. China Ser. E 2003, 33, 749–759. [Google Scholar] [CrossRef]

- Du, X.W.; Wen, G.R.; Liu, D.; Chen, X.Y.; Zhang, Y.; Luo, J.Q. Fractional iterative variational mode decomposition and its application in fault diagnosis of rotating machinery. Meas. Sci. Technol. 2019, 30, 125009. [Google Scholar] [CrossRef]

- Tang, G.; Huang, Y.J.; Wang, Y.T. Fractional frequency band entropy for bearing fault diagnosis under varying speed conditions. Measurement 2021, 171, 108777. [Google Scholar] [CrossRef]

- Mei, J.M.; Xiao, Y.K. Diagnosis Technology of Fearbox’s Early Fault--Fractional Fourier Transform Principle and Applications; Higher Education Press: Beijing, China, 2016. [Google Scholar]

- Chen, G.Y.; Yan, C.F.; Meng, J.D.; Wang, H.B.; Wu, L.X. Improved VMD-FRFT based on initial center frequency for early fault diagnosis of rolling element bearing. Meas. Sci. Technol. 2021, 32, 115024. [Google Scholar] [CrossRef]

- Shao, Y. The application of fractional Fourier transform algorithm in signal analysis. Master’s thesis, Harbin University of Science and Technology, Harbin, China, 2016. [Google Scholar]

- Zhu, J.; Hu, T.Z.; Jiang, B.; Yang, X. Intelligent bearing fault diagnosis using PCA-DBN framework. Neural. Comput. Appl. 2020, 32, 10773–10781. [Google Scholar] [CrossRef]

- Qin, Y.; Wang, X.; Zou, J.Q. The Optimized Deep Belief Networks With Improved Logistic Sigmoid Units and Their Application in Fault Diagnosis for Planetary Gearboxes of Wind Turbines. IEEE Trans. Ind. Electr. 2019, 66, 3814–3824. [Google Scholar] [CrossRef]

- Zhang, Y.H.; Zhang, Y.S.; Wen, L.B.; Cui, Z.M.; Liu, G.S. Power Grid Fault Diagnosis Based on Improved Deep Belief Network. J. Phys. Conf. Ser. 2020, 1585, 012021. [Google Scholar] [CrossRef]

- Xu, F.; Fang, Y.J.; Wang, D.; Liang, J.Q. Combining DBN and FCM for Fault Diagnosis of Roller Element Bearings without Using Data Labels. Hindawi 2018, 2018, 1–12. [Google Scholar] [CrossRef]

- Hinton, G.E.; Salakhutdinov, R.R. Reducing the dimensionality of data with neural networks. Science 2006, 313, 504–507. [Google Scholar] [CrossRef] [Green Version]

- Liu, Y.L.; Yang, D.L. Bearing Fault Diagnosis Based on Deep Belief Network and Multisensor Information Fusion. Hindawi 2016, 2016, 1–9. [Google Scholar]

- Xue, J.K.; Shen, B. A novel swarm intelligence optimization approach: Sparrow search algorithm. Syst. Sci. Contr. Eng. 2020, 8, 22–34. [Google Scholar] [CrossRef]

- Lv, J.; Sun, W.L.; Wang, H.W.; Zhang, F. Coordinated Approach Fusing RCMDE and Sparrow Search Algorithm-Based SVM for Fault Diagnosis of Rolling Bearings. Sensors 2021, 21, 5297. [Google Scholar] [CrossRef]

- Huang, H.; Baddour, N. Bearing vibration data collected under time-varying rotational speed conditions. Data Brief 2018, 21, 1745–1749. [Google Scholar] [CrossRef] [PubMed]

| Bearing Type | Pitch Diameter | Rolling Element Diameter | Number of Balls | FCCi 1 | FCCo 2 |

|---|---|---|---|---|---|

| ER16K | 38.53 mm | 7.94 mm | 9 | 5.43fr | 3.57fr |

| Dataset Number | Fault Type | Number of Training Samples | Number of Test Samples | Fault Tag |

|---|---|---|---|---|

| 1 | Inner ring fault | 240 | 60 | 001 |

| 2 | Outer ring fault | 240 | 60 | 010 |

| 3 | Healthy bearing | 240 | 60 | 100 |

| Input Sample | SSA-DBN | DBN | BP | SVM | ||||

|---|---|---|---|---|---|---|---|---|

| Accuracy | Time | Accuracy | Time | Accuracy | Time | Accuracy | Time | |

| Spectrum of original signal | 95% | 106.57 s | 91.2% | 99.48 s | 70% | 0.61 s | 55% | 1.04 s |

| Spectrum of multi-order FRFT filtered signal | 100% | 104.54 s | 96.38% | 104.21 s | 98.33% | 3.48 s | 83.33% | 0.53 s |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, J.; Li, S.; Wang, X. Condition Monitoring of Rolling Bearing Based on Multi-Order FRFT and SSA-DBN. Symmetry 2022, 14, 320. https://doi.org/10.3390/sym14020320

Ma J, Li S, Wang X. Condition Monitoring of Rolling Bearing Based on Multi-Order FRFT and SSA-DBN. Symmetry. 2022; 14(2):320. https://doi.org/10.3390/sym14020320

Chicago/Turabian StyleMa, Jie, Shule Li, and Xinyu Wang. 2022. "Condition Monitoring of Rolling Bearing Based on Multi-Order FRFT and SSA-DBN" Symmetry 14, no. 2: 320. https://doi.org/10.3390/sym14020320

APA StyleMa, J., Li, S., & Wang, X. (2022). Condition Monitoring of Rolling Bearing Based on Multi-Order FRFT and SSA-DBN. Symmetry, 14(2), 320. https://doi.org/10.3390/sym14020320