Magnetic Properties of Nickel-Titanium Alloy during Martensitic Transformations under Plastic and Elastic Deformation

Abstract

1. Introduction

2. Materials and Methods

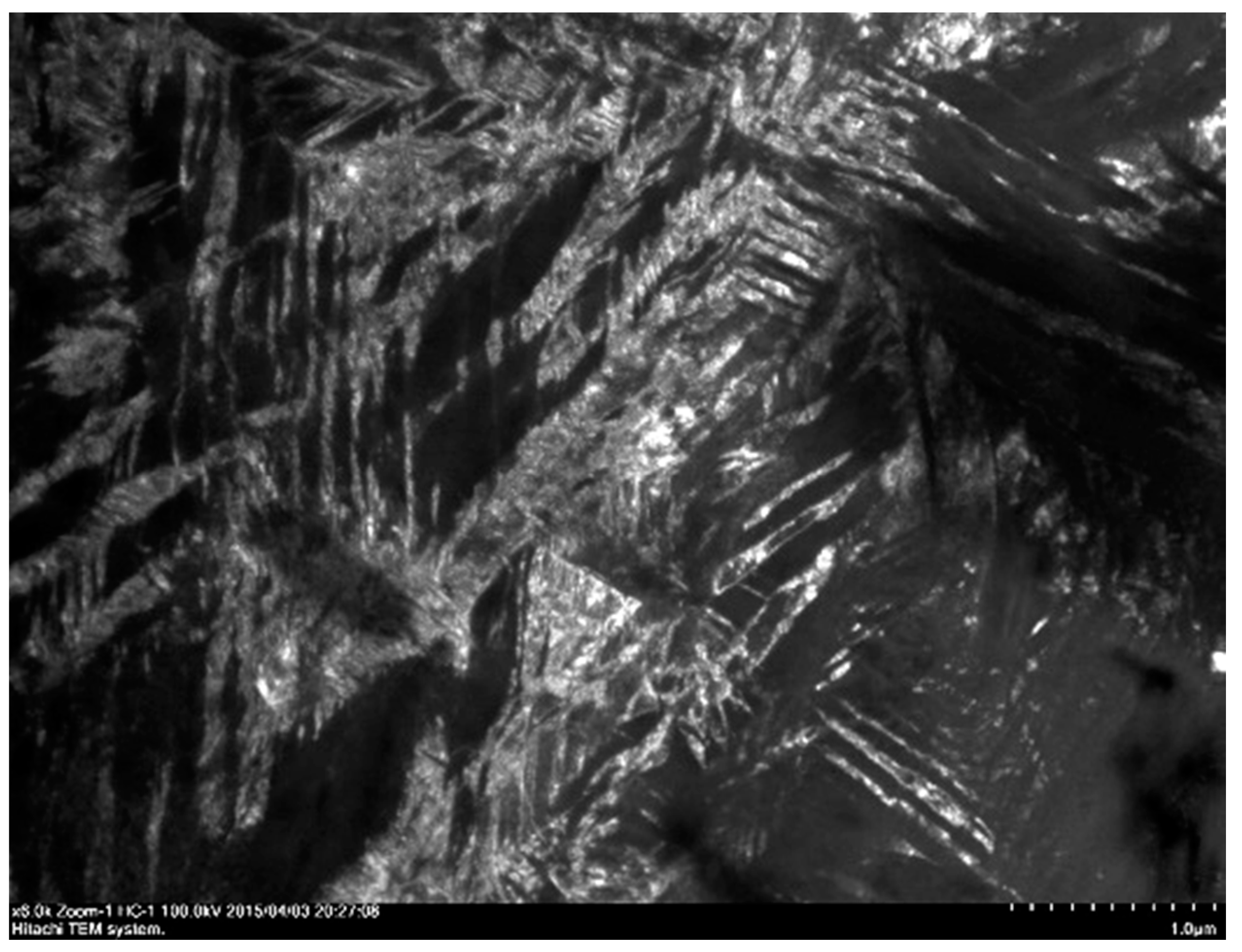

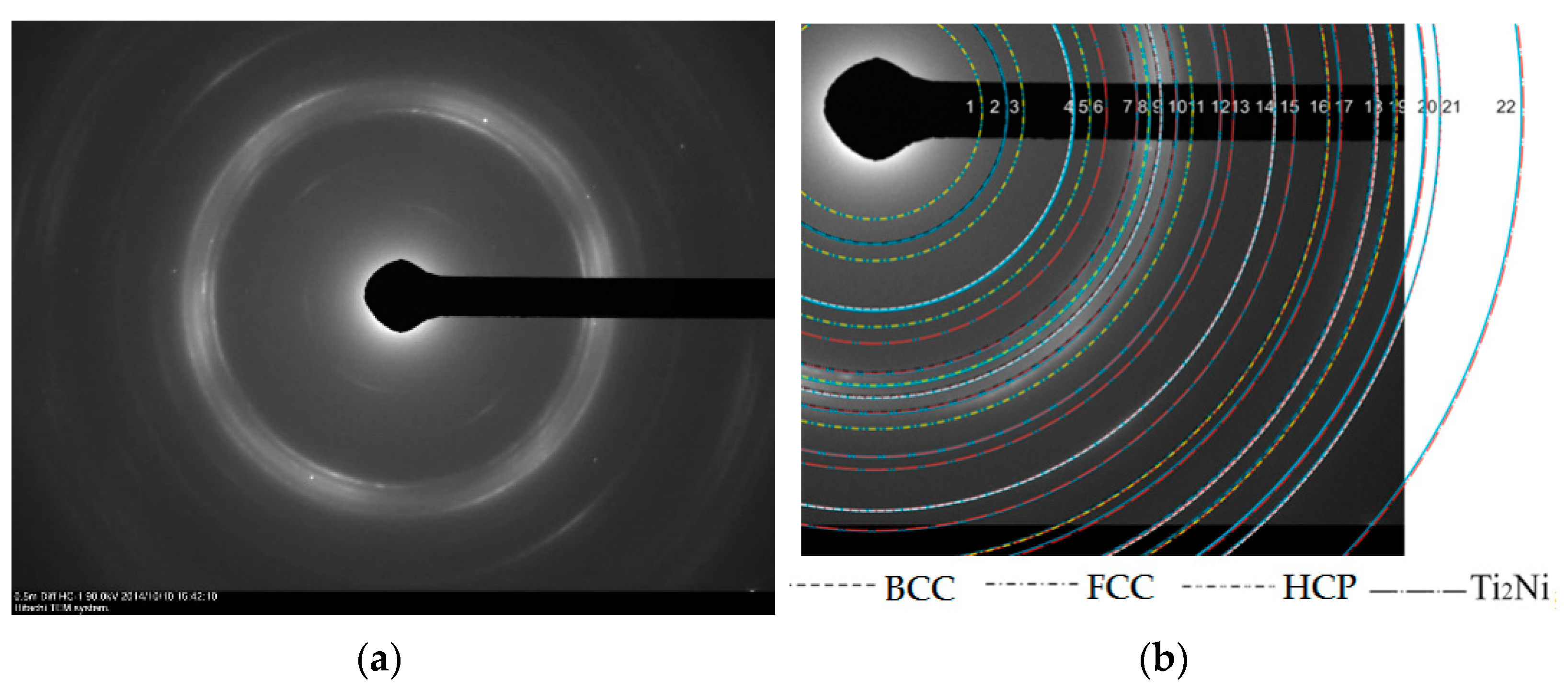

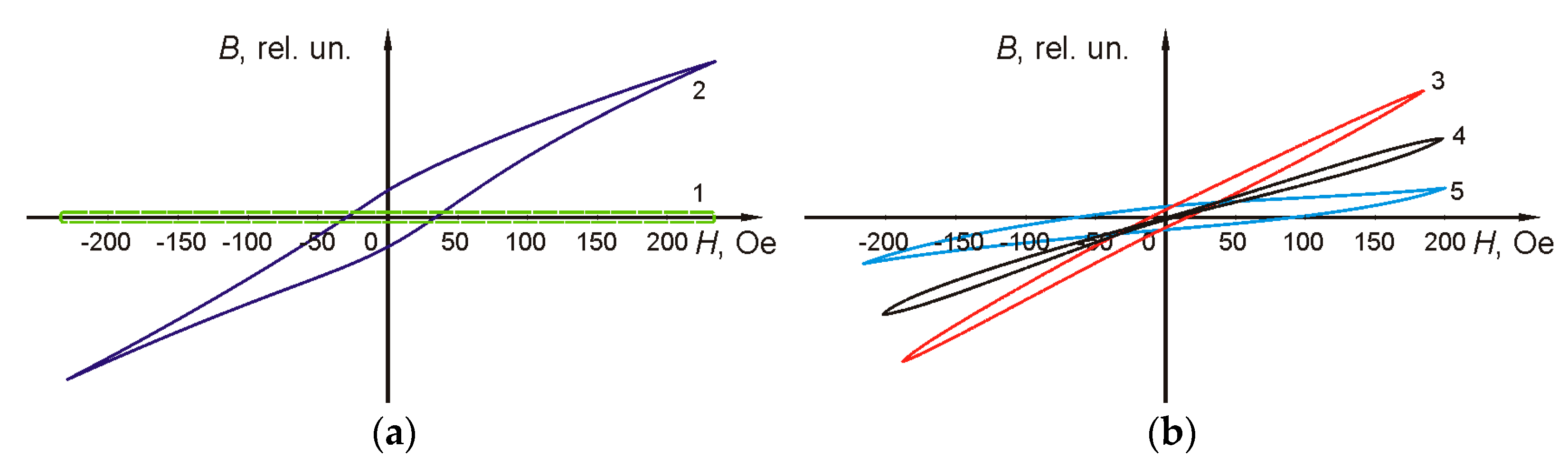

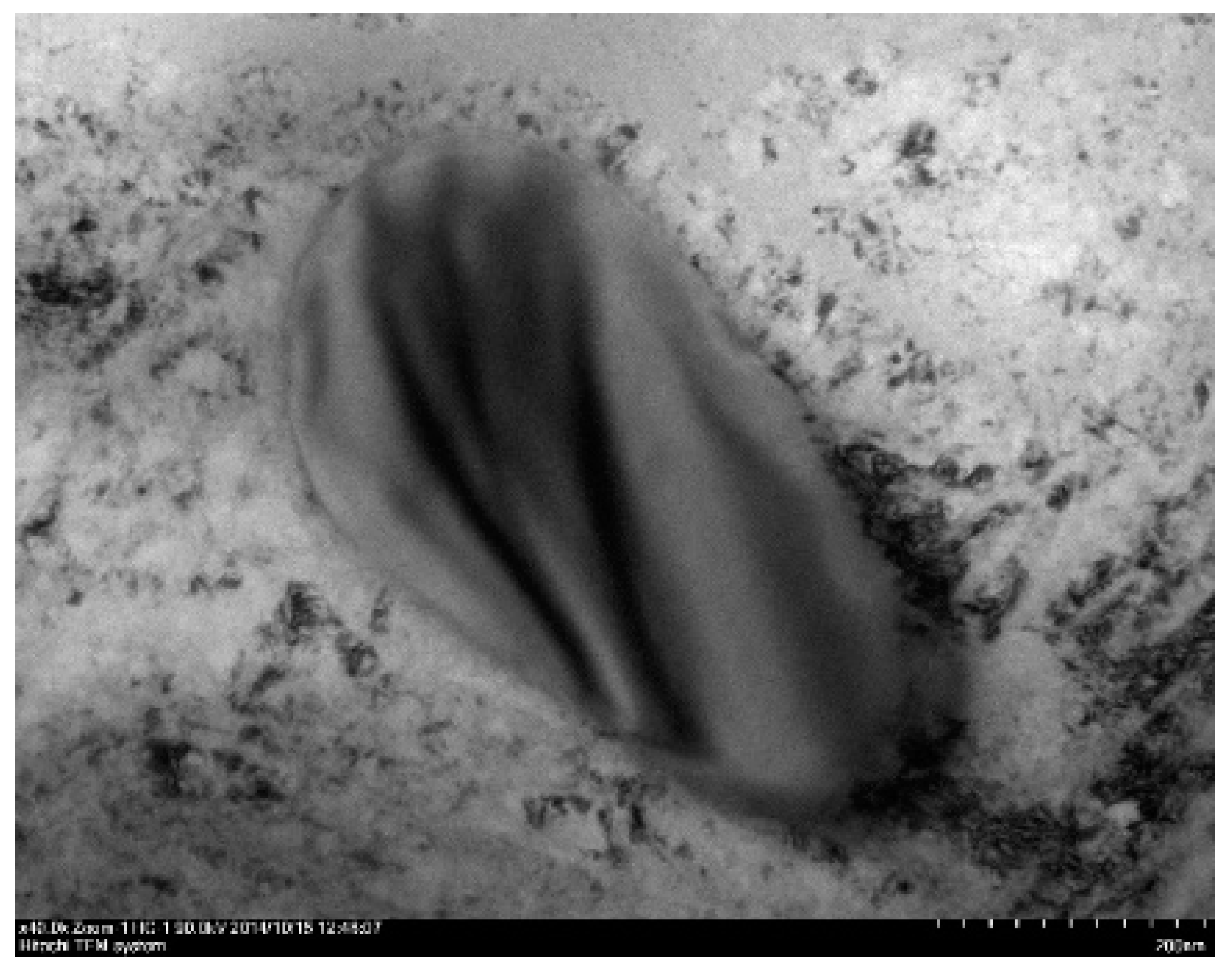

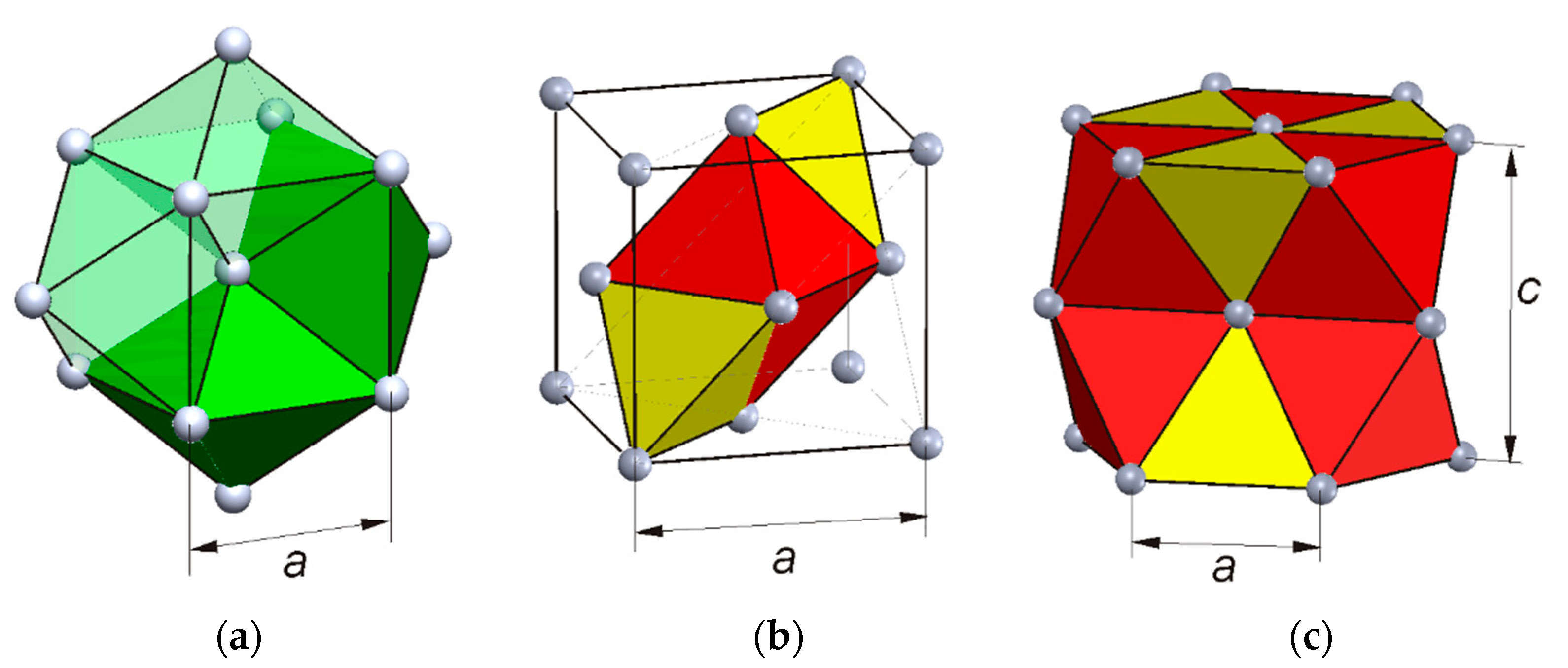

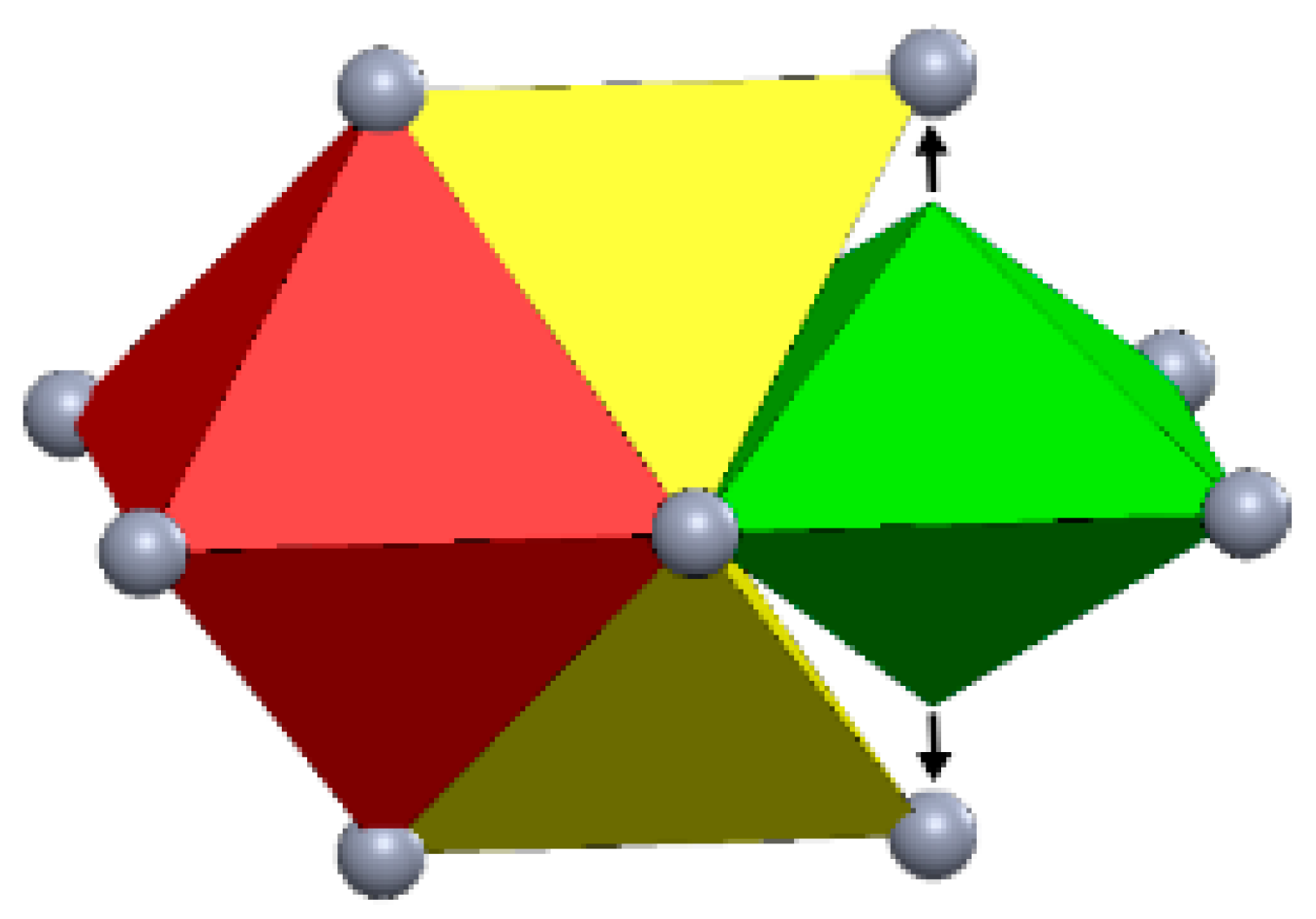

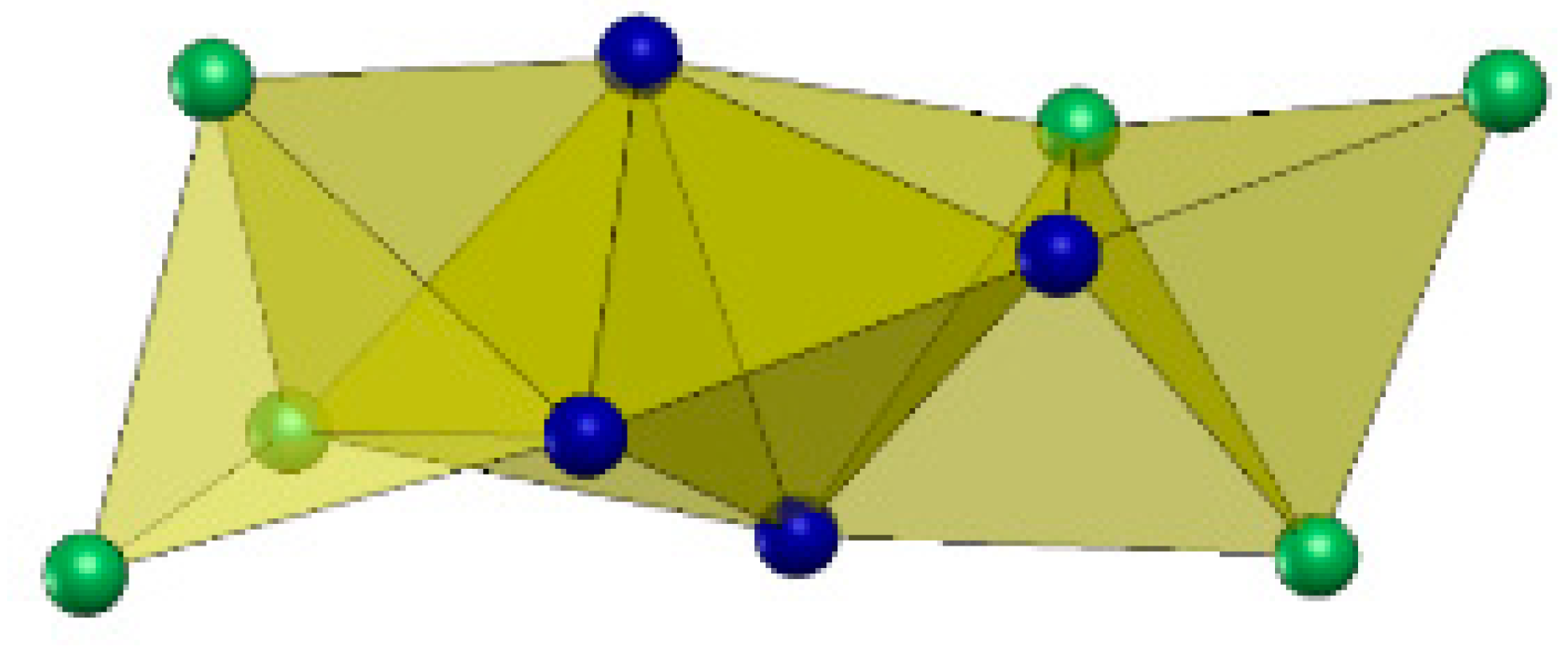

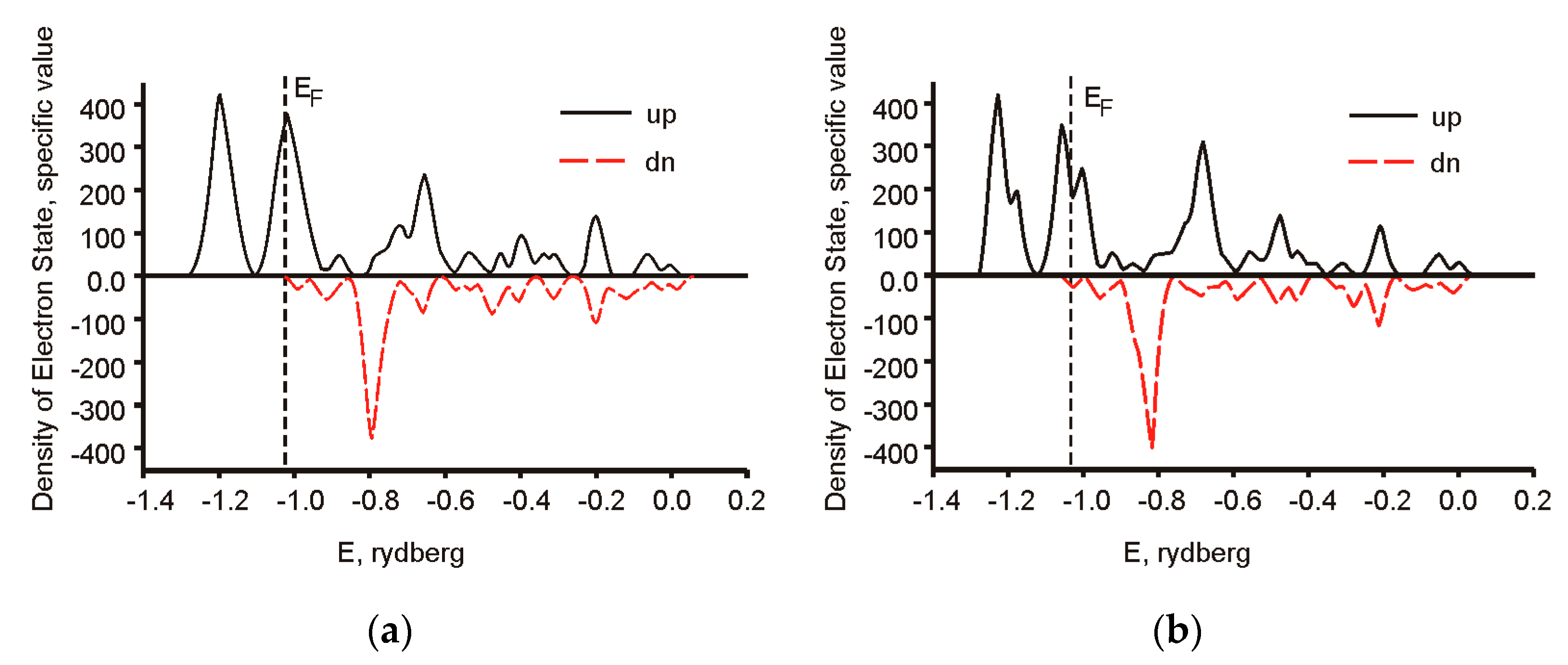

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Otsuka, K.; Wayman, C.M. Shape Memory Materials; Cambridge University Press: Cambridge, UK, 1999. [Google Scholar]

- Lagoudas, D.C. Shape Memory Alloys: Modeling and Engineering Applications; Springer: Berlin, Germany, 2008. [Google Scholar]

- Yamauchi, K.; Ohkata, I.; Tsuchiya, K.; Miyazaki, S. Shape Memory and Superelastic Alloys: Applications and Technologies; Woodhead Publishing: Cambridge, UK, 2011. [Google Scholar]

- Likhachev, V.A.; Kuz’min, S.L.; Kamentsova, Z.P. Effect Shape Memory; Leningrad State University: Leningrad, Russia, 1987. [Google Scholar]

- Pogrebnjak, A.D.; Bratushka, S.N.; Beresnev, V.M.; Levintant-Zayonts, N. Shape memory effect and superelasticity of titanium nickelide alloys implanted with high ion doses. Rus. Chem. Rev. 2013, 82, 1135–1159. [Google Scholar] [CrossRef]

- Buehler, W.J.; Gilfrich, J.V.; Wiley, R.C. Effect of low-temperature phase changes on the mechanical properties of alloys near composition TiNi. J. Appl. Phys. 1963, 34, 1475–1477. [Google Scholar] [CrossRef]

- Malygin, G.A. Diffuse martensitic transitions and the plasticity of crystals with a shape memory effect. Usp. Fiz. Nauk 2001, 171, 187–212. [Google Scholar] [CrossRef]

- Potekaev, A.I.; Glezer, A.M.; Kulagin, V.V.; Starostenkov, M.D.; Klopotov, A.A. Structure and Properties of Intermetallics in Pre-Transitional Low-Stability States; CRC Press, Taylor Francis Group: Boca Raton, FL, USA; London, UK; New York, NY, USA, 2020. [Google Scholar]

- Otsuka, K.; Ren, X. Physical metallurgy of Ti-Ni-based shape memory alloys. Prog. Mat. Sci. 2005, 50, 511–678. [Google Scholar] [CrossRef]

- Fadlallah, A.S.; El-Bagoury, N.; Gad, E.-R.M.S.; Ahmed, A.R.; El-Ousamii, G. An overview of NiTi shape memory alloy: Corrosion resistance and antibacterial inhibition for dental application. J. Alloys Compd. 2014, 583, 455–464. [Google Scholar] [CrossRef]

- Shabalovskaya, A.S. On the nature of the biocompatibility and on medical applications of NiTi shape memory and superelastic alloys. Biomed. Mater. Eng. 1996, 6, 267–289. [Google Scholar] [CrossRef] [PubMed]

- Khoo, Z.X.; Liu, Y.; An, J.; Chua, C.K.; Shen, Y.F.; Kuo, C.N. A review of selective laser melted NiTi shape memory alloy. Materials 2018, 11, 519. [Google Scholar] [CrossRef]

- Rupérez, E.; Manero, J.M.; Bravo-González, L.-A.; Espinar, E.; Gil, F.J. Development of biomimetic NiTi Alloy: Influence of thermo-chemical treatment on the physical, mechanical and biological behavior. Materials 2016, 9, 402. [Google Scholar] [CrossRef]

- Cayron, C. What EBSD and TKD tell us about the crystallography of the martensitic B2-B19′ transformation in NiTi shape memory alloys. Crystals 2020, 10, 562. [Google Scholar] [CrossRef]

- Wang, M.; Jiang, S.; Zhang, Y. Phase transformation, twinning, and detwinning of NiTi shape-memory alloy subject to a shock wave based on molecular-dynamics simulation. Materials 2018, 11, 2334. [Google Scholar] [CrossRef]

- Chang, S.-H.; Lin, K.-H.; Wu, S.-K. Effects of cold-rolling/aging treatments on the shape memory properties of Ti49.3Ni50.7 shape memory alloy. Materials 2017, 10, 704. [Google Scholar] [CrossRef]

- Fan, G.; Zhoua, Y.; Chena, W.; Yanga, S.; Rena, X.; Otsuka, K. Precipitation kinetics of Ti3Ni4 in polycrystalline Ni-rich TiNi alloys and its relation to abnormal multi-stage transformation behavior. Mater. Sci. Eng. A 2006, 438–440, 622–626. [Google Scholar] [CrossRef]

- Tyumentsev, A.N.; Surikova, N.S.; Lysenko, O.V.; Litovchenko, I.Y. Regularities and mechanisms of mechanical twinning in alloys based on titanium nickelide. Phys. Mesomech. 2007, 10, 53–66. [Google Scholar] [CrossRef]

- Zolotukhin, Y.S.; Lotkov, A.I.; Klopotov, A.A.; Grishkov, V.N. Structure of domains formed upon martensitic transformations B2 → B19 and B2 → B19’ in alloys with a B2 superstructure. Phys. Met. Metallogr. 2011, 111, 431–440. [Google Scholar] [CrossRef]

- Zolotukin, Y.S.; Lotkov, A.I.; Klopotov, A.A.; Grishkov, V.N. Symmetry of pretransition structures in alloys with a B2-type superstructure. Phys. Met. Metallogr. 2012, 113, 438–447. [Google Scholar] [CrossRef]

- Sitepul, H.; Schmahll, W.W.; Stalick, J.K. Correction of intensities for preferred orientation in neutron-diffraction data of NiTi shape-memory alloy using the generalized spherical-harmonic description. Appl. Phys. A 2002, 74, S1719–S1721. [Google Scholar] [CrossRef]

- Biront, V.S. Theory of Thermal Processing of Metals. Hardening, Aging and Tempering; GATsMiZ: Krasnoyarsk, Russia, 1998. [Google Scholar]

- Kassan-Ogly, F.A.; Naish, V.E.; Sagaradze, I.V. Diffuse scattering in metals with a BCC lattice and crystal geometry of martensitic phase transitions BCC-FCC and BCC-HCP. Phys. Met. Metallogr. 1988, 65, 481–492. [Google Scholar]

- Lekston, Z.; Naish, V.E.; Novoselova, T.V.; Sagaradze, I.V. Structure and symmetry of the trigonal R-phase of titanium nickelide. Phys. Met. Metallogr. 1999, 87, 5–12. [Google Scholar]

- Lobodyuk, V.A.; Koval’, Y.N.; Pushin, V.G. Crystal-structural features of pretransition phenomena and thermoelastic martensitic transformations in alloys of nonferrous metals. Phys. Met. Metallogr. 2011, 111, 165–189. [Google Scholar] [CrossRef]

- Pearson, W.B. The Crystal Chemistry and Physics of Metals and Alloys; Wiley-Interscience: New York, NY, USA, 1972. [Google Scholar]

- Bulienkov, N.A.; Tytik, D.L. Modular design of icosahedral metal clusters. Russ. Bull. Chem. 2001, 50, 1–19. [Google Scholar] [CrossRef]

- Kraposhin, V.S.; Talis, A.L.; Lam, H.T.; Dubois, J.-M. Model for the transformation of anicosahedral phase into a B2 crystallinephase. J. Phys. Condens. Matter. 2008, 20, 235215. [Google Scholar] [CrossRef]

- Kablov, D.E.; Kraposhin, V.S.; Talis, A.L. Crystallographic mechanism of local lattice turn under growth of single crystals of refractory nickel alloys. Met. Sci. Heat Treat. 2017, 58, 712–718. [Google Scholar] [CrossRef]

- Kraposhin, V.; Schastlivtsev, V.; Jakovleva, I.; Talis, A. New model for carbon distribution in austenite and steel transformation products. Mater. Today Proc. 2015, 2, S557–S560. [Google Scholar] [CrossRef]

- Kraposhin, V.S.; Jakovleva, I.L.; Karkina, L.E.; Nuzhny, G.A.; Zubkova, T.A.; Talis, A.L. Microtwinning as a common mechanism for the martensitic and pearlitic transformations. J. Alloys Compd. 2013, 577S, 30–36. [Google Scholar] [CrossRef]

- Kuznetsov, A.R.; Gornostyrev, Y.N. Structural Transformations at Grain Boundaries. Phase and Structural Transformations in Steels; Magnitogorsk State Technical University: Magnitogorsk, Russia, 2003. [Google Scholar]

- Pynko, V.G.; Kveglis, L.I.; Korchmar, V.S. Epitaxial growth of Ti, V, Cr, V films on LiF and NaCl. Sov. Phys. Solid State 1971, 13, 3334–3337. [Google Scholar]

- Abylkalykova, R.B.; Tazhibaeva, G.B.; Noskov, F.M.; Kveglis, L.I. The features of the martensitic transformation in Titanium Nickelide. Bull. Russ. Acad. Sci. Phys. 2009, 73, 1542–1544. [Google Scholar] [CrossRef]

- Kurdjumow, G.; Sachs, G. Über den mechanismus der stahlhärtung. Z. Physik 1930, 64, 325–343. [Google Scholar] [CrossRef]

- Kulkova, S.E.; Valujsky, D.V.; Smolin, I.Y. Changes in the electronic structure upon the B2-B19’ martensitic transformation in titanium-nickel. Phys. Solid State 2001, 43, 737–745. [Google Scholar] [CrossRef]

- Takacs, L. Mechanochemistry and the other branches of chemistry: Similarities and dierences. Acta Phys. Pol. A 2012, 121, 711–714. [Google Scholar] [CrossRef]

- Khomskii, D.I.; Kugel, K.I.; Sboychakov, A.O.; Streltsov, S.V. Role of local geometry in the spin and orbital structure of transition metal compounds. J. Exp. Theor. Phys. 2016, 122, 484–498. [Google Scholar] [CrossRef]

- Goodenough, J.B. Magnetism and the Chemical Bond; Wiley Interscience: New York, NY, USA, 1963. [Google Scholar]

- Panin, V.E.; Egorushkin, V.E. Curvature solitons as generalized structural wave carriers of plastic deformation and fracture. Phys. Mesomech. 2013, 16, 267–286. [Google Scholar] [CrossRef]

- Panin, V.E.; Egorushkin, V.E. Fundamental role of local curvature of crystal structure in plastic deformation and fracture of solids. AIP Conf. Proc. 2014, 1623, 475–478. [Google Scholar]

- Zhigalov, V.S. Methods of Obtaining Magnetic Layers and Studies of Their Physical Properties: Textbook; SibGAU: Krasnoyarsk, Russia, 2008. [Google Scholar]

- Nyavro, A.V. Evolution of Electronic States: Atom-Molecule-Cluster-Crystal; Publishing House of Tomsk State University: Tomsk, Russia, 2013. [Google Scholar]

- Dudarev, E.F.; Valiev, R.Z.; Kolobov, Y.R.; Lotkov, A.I.; Pushin, V.G.; Bakash, G.P.; Gunderov, D.V.; Dyupin, A.P.; Kuranova, N.N. On the nature of anomalously high plasticity of high-strength titanium nickelide alloys with shape memory effects: II. Mechanisms of plastic deformation upon isothermal loading. Phys. Met. Metallogr. 2009, 107, 298–311. [Google Scholar] [CrossRef]

- Yurko, G.A.; Barton, J.W.; Parr, J.G. The crystal structure of Ti2Ni. Acta Cryst. 1959, 12, 909–911. [Google Scholar] [CrossRef]

- Yurko, G.A.; Barton, J.W.; Parr, J.G. The crystal structure of Ti2Ni. (A correction). Acta Cryst. 1962, 15, 1309. [Google Scholar] [CrossRef]

- Kolosov, V.Y.; Tholen, A.R. Transmission electron microscopy studies of the specific structure of crystals formed by phase transition in iron oxide amorphous films. Acta Mater. 2000, 48, 1829–1840. [Google Scholar] [CrossRef]

- Burdett, J.K. Chemical Bonding in Solids; Oxford University Press: Oxford, UK, 1995. [Google Scholar]

- Lipson, H.; Parker, A.M.B. Structure of martensite. J. Iron Steel Inst. 1944, 149, 123–141. [Google Scholar]

- Surikova, N.S.; Klopotov, A.A.; Korznikova, E.A. Mechanisms of plastic deformation in microcrystalline and nanocrystalline TiNi-based alloys. Phys. Met. Metallogr. 2010, 110, 269–278. [Google Scholar] [CrossRef]

- Klopotov, A.A.; Yasenchuk, Y.F.; Abzaev, Y.A.; Dement’eva, M.G.; Kozlov, E.V.; Potekaev, A.I.; Solonitsyna, N.O. System Ni-Ti. Crystallogeometrical features. Russ. Phys. J. 2008, 51, 226–239. [Google Scholar] [CrossRef]

- Talis, A.; Kraposhin, V. Finite noncrystallographic groups, 11-vertex equi-edged triangulated clusters and polymorphic transformations in metals. Acta Cryst. 2014, A70, 616–625. [Google Scholar] [CrossRef]

- Kuraposhin, V.S.; Talis, A.L.; Demina, E.D.; Zaitsev, A.I. Crystal geometry mechanism of intergrowth of spinel and manganese sulfide into a complex nonmetallic inclusion. Met. Sci. Heat Treat. 2015, 57, 371–378. [Google Scholar] [CrossRef]

- Lipscomb, W.N. Framework rearrangement in boranes and carboranes. Science 1966, 153, 373–378. [Google Scholar] [CrossRef] [PubMed]

- Razorenov, S.V.; Garkushin, G.V.; Kanel, G.I.; Kashin, O.A.; Ratochka, I.V. Behavior of nickel-titanium shape memory alloys under shock-wave loading. Phys. Solid State 2011, 53, 768–773. [Google Scholar] [CrossRef]

- Slater, J.C.; Johnson, K.H. Self-consistent field Xα cluster method for polyatomic molecules and solids. Phys. Rev. B 1972, 5, 844–853. [Google Scholar] [CrossRef]

- Slater, J.C. Suggestions from solid-state theory regarding molecular calculations. J. Chem. Phys. 1965, 43, S228. [Google Scholar] [CrossRef]

- Hartree, D.R. The wave mechanics of an atom with a non-coulomb central field. Part I. Theory and methods. Math. Proc. Camb. Philos. Soc. 1928, 24, 89–110. [Google Scholar] [CrossRef]

- Hartree, D.R. The wave mechanics of an atom with a non-coulomb central field. Part II. Some results and discussion. Math. Proc. Camb. Philos. Soc. 1928, 24, 111–132. [Google Scholar] [CrossRef]

- Fock, V.A. Näherungsmethode zur Lösung des quantenmechanischen Mehrkörperproblems. Z. Phys. 1930, 61, 126–148. [Google Scholar] [CrossRef]

- Gunnarsson, O.; Lundqvist, B.I.; Wilkins, J.W. Contribution to the cohesive energy of simple metals: Spin-dependent effect. Phys. Rev. B 1974, 10, 1319–1327. [Google Scholar] [CrossRef]

| Line Num. | d, Å. | BCC, hkl | FCC, hkl | HCP, hkl | Ti2Ni, [45] hkl/(Δd, Å) |

|---|---|---|---|---|---|

| 1 | 6.16 | ½ ½ 0* | |||

| 2 | 5.02 | ½ 0 0* | |||

| 3 | 4.45 | 3/2 3/2 0* | |||

| 4 | 3.36 | 100* | |||

| 5 | 3.09 | 110* | |||

| 6 | 2.87 | 400/(−0.05) | |||

| 7 | 2.54 | 100 | 331/(+0.04) | ||

| 8 | 2.43 | 111 | |||

| 9 | 2.33 | 110 | 002 | 422/(−0.03) | |

| 10 | 2.21 | 101 | 511/(−0.04) | ||

| 11 | 2.10 | 200 | |||

| 12 | 1.93 | 531/(−0.03) | |||

| 13 | 1.86 | 442/(+0.02) | |||

| 14 | 1.67 | 200 | 622/(+0.03) | ||

| 15 | 1.59 | 551/(−0.01) | |||

| 16 | 1.47 | 220 | 110 | 553/(0.00) | |

| 17 | 1.43 | 800/(−0.02) | |||

| 18 | 1.33 | 211 | 103 | 660/(0.00) | |

| 19 | 1.28 | 311 | 200 | 662/(+0.01) | |

| 20 | 1.21 | 842/(+0.02) | |||

| 21 | 1.18 | 220 | 931/(0.00) | ||

| 22 | 1.03 | 11 1 1/(−0.01) |

| Line Num. | d, Å. | BCC, Hkl | FCC, hkl | HCP, hkl | Ni4Ti3 hkl/(Δd, Å) |

|---|---|---|---|---|---|

| 1 | 4.70 | ½ ½ 0* | ½ ½ ½* | 001* | |

| 2 | 3.62 | 3/2 ½ 2* | |||

| 3 | 2.78 | 1 ½ 0* | |||

| 4 | 2.55 | 100 | |||

| 5 | 2.37 | 110 | 111 | 002 | 131/(+0.01) |

| 6 | 2.05 | 200 | 122/(+0.04) | ||

| 7 | 1.80 | 312/(+0.04) | |||

| 8 | 1.69 | 200 | 211* | 102 | 232/(−0.02) |

| 9 | 1.53 | 210* | |||

| 10 | 1.46 | 220 | 422/(+0.02) | ||

| 11 | 1.38 | 211 | |||

| 12 | 1.31 | 103 | |||

| 13 | 1.25 | 311 | 201 | ||

| 14 | 1.22 | 220 | 222 | 004 | 532/(0.00) |

| 15 | 1.13 | ||||

| 16 | 1.02 | 310 | 400 | ||

| 17 | 0.99 | 222 | |||

| 18 | 0.95 | 331 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kveglis, L.I.; Noskov, F.M.; Volochaev, M.N.; Nyavro, A.V.; Filarowski, A. Magnetic Properties of Nickel-Titanium Alloy during Martensitic Transformations under Plastic and Elastic Deformation. Symmetry 2021, 13, 665. https://doi.org/10.3390/sym13040665

Kveglis LI, Noskov FM, Volochaev MN, Nyavro AV, Filarowski A. Magnetic Properties of Nickel-Titanium Alloy during Martensitic Transformations under Plastic and Elastic Deformation. Symmetry. 2021; 13(4):665. https://doi.org/10.3390/sym13040665

Chicago/Turabian StyleKveglis, Ludmila I., Fedor M. Noskov, Mikhail N. Volochaev, Alexander V. Nyavro, and Aleksander Filarowski. 2021. "Magnetic Properties of Nickel-Titanium Alloy during Martensitic Transformations under Plastic and Elastic Deformation" Symmetry 13, no. 4: 665. https://doi.org/10.3390/sym13040665

APA StyleKveglis, L. I., Noskov, F. M., Volochaev, M. N., Nyavro, A. V., & Filarowski, A. (2021). Magnetic Properties of Nickel-Titanium Alloy during Martensitic Transformations under Plastic and Elastic Deformation. Symmetry, 13(4), 665. https://doi.org/10.3390/sym13040665