Abstract

In this study, the concept of symmetry is introduced by finding the optimal state of a power system. An electric vehicle type load is present, where the supply stores’ electrical energy causes an imbalance in the system. The optimal conditions are related by adjusting the voltage of the bus location. The key variables are the load voltage deviation (LVD), the variation of the load and the power, and the sizing of the distributed photovoltaic (DPV), which are added to the system for power stability. Here, a method to optimize the fast-charging stations (FCSs) and DPV is presented using an optimization technique comparison. The system tests the distribution line according to the bus grouping in the IEEE 33 bus system. This research presents a hypothesis to solve the problem of the voltage level in the system using metaheuristic algorithms: the cuckoo search algorithm (CSA), genetic algorithm (GA), and simulated annealing algorithm (SAA) are used to determine the optimal position for DPV deployment in the grid with the FCSs. The LVD, computation time, and total power loss for each iteration are compared. The voltage dependence power flow is applied using the backward/forward sweep method (BFS). The LVD is applied to define the objective function of the optimization techniques. The simulation results show that the SAA showed the lowest mean computation time, followed by the GA and the CSA. A possible location of the DPV is bus no. 6 for FCSs with high penetration levels, and the best FCS locations can be found with the GA, with the best percentage of best hit counter on buses no. 2, 3, 13, 14, 28, 15, and 27. Therefore, FCSs can be managed and handled in optimal conditions, and this work supports future FCS expansion.

1. Introduction

Electric vehicles (EVs) have become of critical interest for use in travel and to transfer passengers. Carmakers or car manufacturers have developed EVs and production lines to meet the demand in many countries, with government support provided through policies on EVs. The EV yield has a good relationship with environmental impacts in terms of low air pollution [1] and low carbon emissions [2]. Significantly, the promotion of EVs aims to protect the environment in the long term. A classic car uses a combustion process with fuel and emits CO2 gas to the environment [3]. However, car users are now interested in new car technology, with many types of EV technology. Due to advanced power, electronic components, and material technology, more and more people are supporting EV growth. Grid management is a key factor in enhancing system stability and supporting the load change.

Traditional cars are increasingly being replaced by EVs [4,5]. The matter of charging poses an uncertainty that worries many people regarding the use of electric vehicles. As EVs are not electrical appliances that operate in the same place, when not moving, they can supply power for normal use. However, electric vehicles are, in general, moving. Therefore, electric cars should be able to be recharged anywhere after each use so that they can be used anywhere and anytime, with charger plugs included. Many researchers are interested in studying numerous experimental conditions: traction driving and control are popular for study, as presented in [6]. Battery technology is of vital importance to the sizing and driving distance of EVs, and the related research areas include lithium batteries, magnetic batteries, and solid-state batteries [7,8]. Therefore, battery development is challenging, and many research areas focus their effort on creating high power density and reducing the time for charging the battery. Additionally, the motor technology of EVs is a significant component of EVs with traction driving and is rated by the energy consumption of the batteries of the EVs [9]. Battery technology and motor technology are different research areas but are similarly studied if researchers are interested in condition-based material technology. In particular, there is growing interest in the impact of EVs in terms of dead batteries in planning and managing energy.

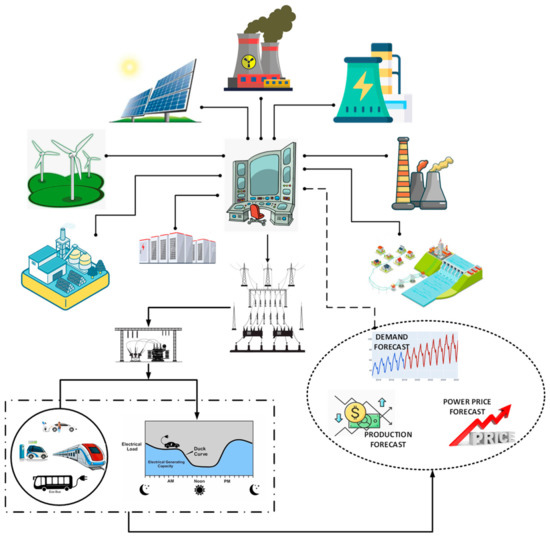

In addition, researchers have studied the effect of an electrical power system in terms of losses, voltage stability, power system oscillation, reduced energy demand response, and optimal charging stations [10,11,12]. As EVs have an impact on electric energy, optimum conditions and energy planning need to be simulated and considered to maintain the grid by adapting optimization techniques [13]. Therefore, energy management sources need to be studied along with the optimal FCSs for providing the energy of each source in the charging process of EVs. At present, photovoltaic (PV) power plants are of interest for providing energy [14]. PVs can be integrated into a radial distribution system (RDS) to reduce the total power loss of the electrical power system, as presented in [1,15]. The charger or equipment for charging the FCS is connected to an RDS using a step-down power transformer. It is applied to reduce the voltage level of the system from high to low. Meanwhile, the regular charge is connected with a power cable to a charger at home with slow-mode charging, as shown in Figure 1 [16].

Figure 1.

The impact of electric vehicles on the electric grid system.

The EV load is a key player in consuming energy from the grid. EV load modeling is defined in many load types, such as power constant (P), current constant (I), polynomial load or ZIP load, and voltage source converter modeling [17]. Large-scale FCSs are affected by the electrical power system in many ways, so the grid needs to be improved [18]. It can be adapted to solve the electrical power system’s problem, as revealed in many research areas. Genetic algorithms (GAs) are a popular OT that can be applied to determine optimal distributed generator (DG) placement [19,20]. Therefore, this paper aims to define the optimal conditions of FCSs and PVs by comparing the GA, CSA, and SAA methodology with the best number of models for calculation and time for computation. In the calculation part, the researcher uses the principle of symmetry to emphasize the diversity of methods for obtaining answers, but in the end, the end result is perfect symmetry.

The rest of this paper is organized as follows: Section 2 describes the optimization technique and power flow analysis of FCSs and the PV placement formula. Section 3 refers to the methodology of the OT adopted to find the optimal location for installing the distributed photovoltaic system (DPV) and the FCSs. Section 4 shows the simulation and results of the optimal FCSs and PV placement adapted from the OT by comparing the SA, GA, and CSA. Finally, Section 5 presents the conclusions.

2. Optimization Technique (OT) and Power Flow Analysis of FCSs and PV Placement Formula

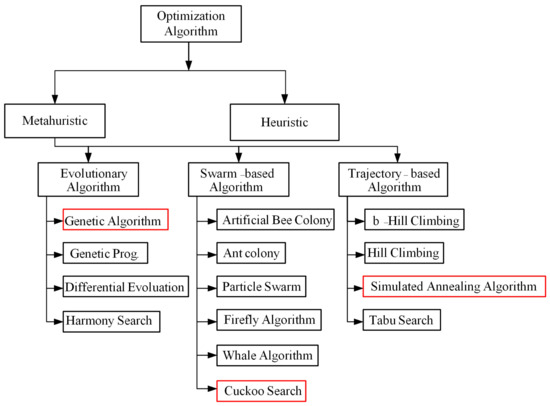

An optimization technique and a power flow analysis were used to solve the optimal condition. Therefore, this section is divided into two main parts addressing the optimization technique and the power flow analysis. The optimization technique was adapted to solve the optimal condition problem by defining the objective function. Load voltage deviation (LVD) is considered to represent the objective function for solving by using the OT [21]. Forward/backward sweep was used to solve the voltage dependence power flow for the FCS. There are many optimization methodologies and techniques used to solve problems, which can be divided into two types: single-objective optimization and multi-objective optimization [22]. Thus, the OT framework can be expanded, as shown in Figure 2. The objective of this work consists of metaheuristic and heuristic techniques. The metaheuristic swarm-based algorithm (SBA) from the objective was used to solve the proposed research. The artificial bee colony (ABC) and cuckoo search (CS) algorithms were adopted to compare the OTs with FCS and PV placement. ABC and CS can be described as follows.

Figure 2.

Review of the optimization algorithm techniques.

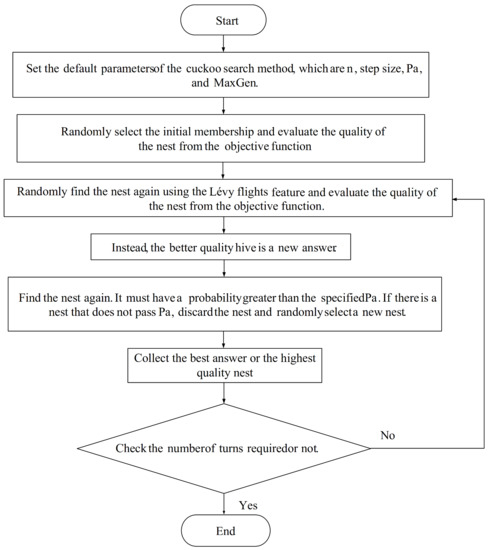

2.1. Cuckoo Search Algorithm (CSA)

In 2009, Xin She Ying and Susah Deb developed the cuckoo search method. It was developed from the spawning behavior (NE) of the cuckoo. It spawns in the nest of other birds of the same species, which may lay several eggs in one place simultaneously after laying the eggs. The cuckoo makes its egg (λ) as similar as possible to the nest, trying to avoid the nest owner finding any foreign eggs, sometimes called an alien egg. If the owner finds the egg, there are two options: destroy foreign eggs by throwing away the cuckoo eggs, or the nest birds leave the nest (Pa) to build a new nest [23]. In nature, creatures can seek nourishment in an arbitrary or quasi-random way. By and large, an animal’s nourishment-seeking method is a successful arbitrary walk since the other move is based on the current area’s state and the likelihood of moving to the following area. The chosen heading depends verifiably on a likelihood, which can be numerically demonstrated. Later considerations have appeared, where numerous creatures’ and insects’ flight behavior has illustrated the normal characteristics of Le’vy flights. In the next random location selection, until the answer population can be represented by Equations (1) and (2).

where

represents a constant in the range of 1 to 2.

represents the step size of the scale of the problem, defined by the value of 1.

represents the gamma function, which comes as an extension of the complex factorial function.

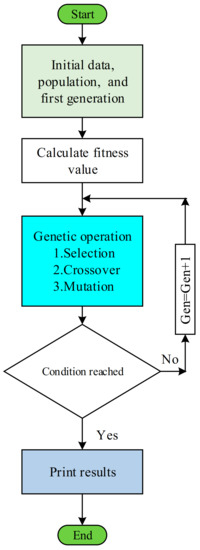

2.2. Genetic Algorithm (GA)

The GA is an optimization tool following the heuristic method based on the evolution algorithm. The GA was presented by Goldberg (1989) and developed by applying it to the problems of search, optimization, and machine learning as improvements in basic techniques and knowledge-based techniques [20,24]. The GA aims to follow natural evolution to select a specific number of chromosomes and adapt genetic algorithm operation. The chromosomes characterized represent the solution to the problem, and performance is evaluated using the fitness function presented in Figure 3. Therefore, GA operation is used to find a new population based on a random selection from the chromosomes of the previous population. The GA operation is divided into the section process, crossover process, and mutation process. The GA process is expressed in Figure 4.

Figure 3.

Cuckoo search algorithm flowchart.

Figure 4.

Genetic algorithm flowchart.

2.3. Simulated Annealing Algorithm (SAA)

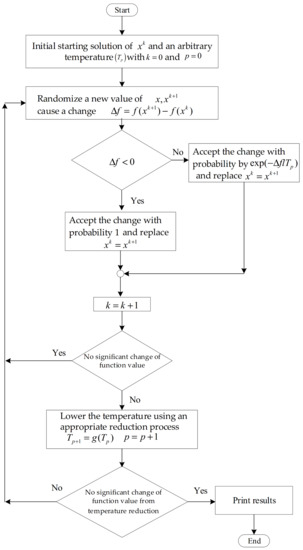

The SAA represents the use of a metallurgical structure from annealing. A metal is allowed to cool slowly enough in order to be able to find the minimum energy state for the system. The minimum energy state can be adapted by cooling the metal to find the global optima by relating non-linear functions. Here, the slow cooling process was implemented using the Boltzmann probability distribution of energy states with a prominent part in thermodynamics [25]. The Boltzmann probability distribution was applied to reflect the cooling process, where the energy level changes to a cooling state as per Equation (3).

where is the probability of the energy state , is Boltzmann’s constant, and is the temperature.

The SAA can be presented as the steps in searching for the answers, as shown in Figure 5.

Figure 5.

Simulated annealing algorithm (SAA).

2.4. Fast-Charging Station Load (FCS) Modeling

FCS modeling is presented by using a group of EVs’ load, and the FCS represents the voltage-dependent characteristics of the EVs [26]. Therefore, the FCS is divided into three parts: an AC-to-DC converter, a buck converter, and a battery for energy storage. FCS modeling can be expressed by active power and reactive power as Equations (4) and (5).

where is a power constant equal to 0.93, α is the voltage-dependent part and is equal to 0.07, α is an exponential index of EVs and is equal to −3.107, is the power factor of the FCSs and is equal to 0.97, and is the real power consumption of the FCSs at nominal voltage .

2.5. Load Voltage Deviation (LVD)

Generally, the power consumption process from each piece of equipment has a direct impact on the RDS. LVD is a pivotal issue to evaluate in the RDS. Here, the bus voltage magnitude was measured to indicate the level of burden of the loads in the electrical power system [27]. The minimized value of the LVD is presented to minimize the load voltage bus’ values, described by Equation (6).

Therefore, the reference voltage magnitude is defined as 1 p.u. and maintained to manage the grid loads. The LVD improved the electrical power system nearly to zero value.

2.6. Total Active Power Loss

The power flow of the electrical power system is delivered using transmission lines. Hence, the grid power flow effect is affected by system losses on the transmission lines related to the voltage magnitude and impedance. However, the system losses of the electrical power system can deviate due to many factors, such as the electrical power system’s topologies, load installed, and power generation. Therefore, the total power loss () of the grid is directly affected by the configuration of the transmission and the power consumption of loads. This is a significant problem of the grid that needs to be analyzed and managed in optimal conditions. The active power loss of the grid was computed using Equation (7), as follows [25]:

where and represent the active power and reactive power of the transmission line , respectively; is the resistance of transmission; is the total number of feeders or transmission lines; and is the voltage magnitude of the transmission .

2.7. Backward/Forward Sweep (BFS) Power Flow Analysis

BFS was used to find the RDS power flow, which defines the branch numbering process. The branch number is applied to arrange the transmission line’s order, connected with the node by specifying the layer. The number of the transmission line is applied and used to compute the power flow. Current flow can be calculated using the backward process, and the voltage bus is calculated in the forward sweep process. Therefore, the voltage mismatch used to iterate and approach stop criteria can be presented [28].

3. Methodology

The OT was adapted to find the optimal location for installing the distributed photovoltaic system (DPV) and the FCSs. The purpose of this paper is to compare the OT with the SAA, the GA, and the CSA. The evolutionary algorithm is represented by the GA, the swarm-based algorithm by the CSA, and the trajectory-based algorithm by the SAA. A laptop computer was used to solve the algorithms in metaheuristic problems. Thus, it was necessary to determine the capability of the processing machine, as shown in Table 1.

Table 1.

Processing equipment details.

A mathematical model was proposed to assess and test the electrical system’s reliability when a constant type of electric vehicle enters the system. The researchers selected the IEEE 33 radial distribution to test for a suitable value in installing an electric motor charging station and an alternative energy system to solve the voltage problem when the electric vehicle loads were installed in the system. This paper adapts the EV modeling by using the voltage dependence load and the voltage dependence power flow of the BFS. The optimization technique was applied to the objective function using the LVD described in Equation (8). The boundary of the voltage magnitude is defined by Equation (9). The possible PV positions can be explained by Equation (10).

where i is represented by the indices of bus no. i, and N is the total number of buses. The voltage magnitude of bus i is within the limit of Vmin and Vmax. However, the voltage magnitude of buses needs to be maintained at the limit of the boundary.

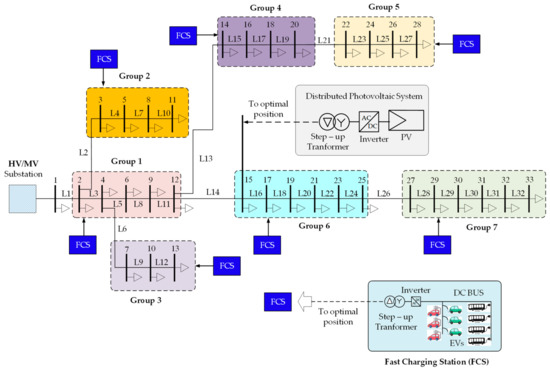

The IEEE 33 bus radial distribution network was selected to solve the OT for simulation studies. The metaheuristic methodology presents the FCS penetration and PV placement. This system is a 12.66 kV network with 33 buses and 4 laterals to divide the load flow into 7 groups, and it was used to test modeling performance, as shown in Figure 5.

Figure 6 shows the IEEE 33 bus test system and FCS groups, consisting of 33 connected loads with a total of 3.72 MW and 2.3 MVar. Additionally, the active power loss and reactive power loss were 211.1180 and 143.205 kV, respectively, measured at a 1.00 p.u. voltage reference. In this article, the impact of FCSs is analyzed in terms of the efficiency of the optimization model created for the 33-bus system tested. The obtained experimental results provide direction to determine the location of a PV installation for bus no. 2 to bus no. 33. Meanwhile, the FCSs can be indicated by using the possible position of the groups and the metaheuristic parameter for simulation, as shown in Table 1 and Figure 7.

Figure 6.

IEEE 33 bus test system and FCS groups.

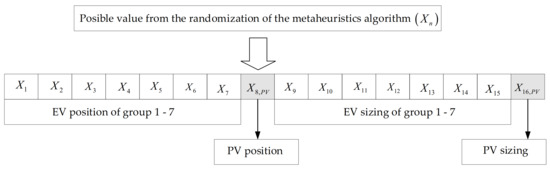

Figure 7.

Randomized values of FCSs and the PV for finding the optimal condition of the grid.

Figure 7 shows the randomized values of FCSs and the PV for finding the optimal condition of the electrical power system. The randomized value is defined using , and the PV is presented using . The possible values were used for the metaheuristic optimization process and the benchmarking of efficiency.

4. Simulation and Results

The optimal FCS and PV placements were adapted from the OT by comparing the SAA, GA, and CSA. The time and best generation for computing each iteration were considered. The LVD from the proposal revealed a different value from Table 2, but the two were similar. Therefore, the simulation was defined with a maximum iteration of 100 rounds and a population and search space equal to 100. It shows that it could be adjusted and iterations could be increased.

Table 2.

Parameters for configuration of optimization techniques.

Table 3 shows the comparison of time, LVD, PV site, PV sizing, and total loss between the SAA, GA, and CSA. The average value of computation time, presented in order from lowest to highest, was 8.85, 48.31, and 58.80 s for the SAA, GA, and CSA, respectively. The average LVD value, in order from low to high, was 0.024, 0.037, and 0.043 for the CSA, GA, and SAA, respectively. The average value of total power loss, in order from low to high, was 192.90, 263.52, and 334.22 kW for the CSA, GA, and SAA, respectively. The average PV sizing value, in order from high to low, was 1.192, 1.073, and 0.275 MW for the SAA, GA, and CSA, respectively. The lowest LVD value from the CSA is related to the low impact of the FCSs on the grid. Therefore, the penetration level of the FCSs to the grid needs to be managed in the optimal condition.

Table 3.

Comparison of time, LVD, PV site, PV sizing, and total loss between the SAA, GA, and CSA.

Table 4 compares the FCS position, best hit counter, and percent of best hit counter between the SAA, GA, and CSA, where 10 iterations generated the optimal position of the FCSs on the grid. The FCSs’ locations differed for each metaheuristic method. Both size and position are measured by indicating the best hit counter value and percent related to possible position accuracy with the objective function. The percentages of optimal FCS positions presented by the GA, SAA, and CSA were 85.71, 45.71, and 44.29%, respectively. Meanwhile, the optimal possible position of the PV was shown by bus no. 6, buses no. 6 and 9, and bus no. 6 in the SAA, GA, and CSA, respectively. Consequently, the optimal FCS and PV possible sizing and position are related by randomizing the value of the metaheuristic method. It can be revealed by the differing values of each generation, and the OT can be used to find the optimal condition from the objective function defined.

Table 4.

Comparison of FCS position, best hit counter, and percent of best hit counter between the SAA, GA, and the CSA algorithm.

Table 5 summarizes the maximum, minimum, and average values of the FCS sizing with the SAA, GA, and CSA. The FCS sizing results were obtained following 10 iterations of each metaheuristic methodology. The SAA, CSA, and GA presented average values of 482.44, 903.40, and 1192.44 kW, respectively. Therefore, the total FCS system affected the total power loss, and LVD can be moderated by installing the optimum PV. The low penetration level from the minimization of the FCSs is revealed by the closing values of 50 kW of each position, similar to that presented in [23], but the LVD and the PV position are different from the randomized FCSs and PV position.

Table 5.

Comparison of FCS sizing between the SAA, GA, and CSA.

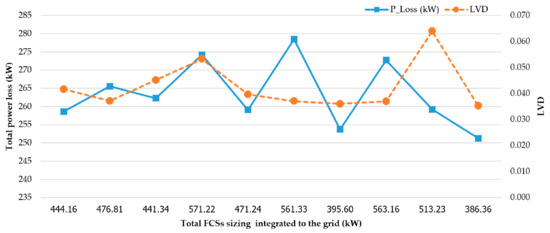

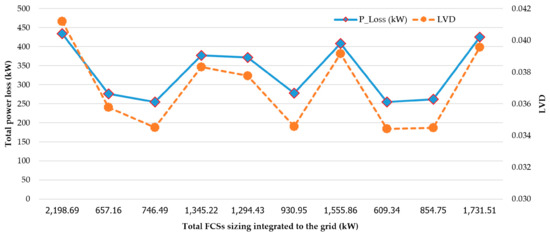

Figure 8 shows the comparison of the total FCS sizing against the total power loss and LVD of the SAA. The SAA can present the optimal FCSs and PV integrated into the grid. The SAA was simulated by increasing the sizing and position of the possible values of the FCSs and PV by reducing the minimum energy state. The high FCS penetration level was revealed by varying the LVD compared with the low penetration level of the FCSs. The SAA can find the optimal condition of the FCSs and PV installed using the metaheuristic process.

Figure 8.

Comparison of the total FCS sizing with the total power loss and LVD of the SAA.

Figure 9 shows the comparison of the total FCS sizing against the total power loss and LVD of the GA. The GA presented the impact of the FCSs integrated into the grid by increasing the total power loss when there was a high penetration level of the FCSs. Meanwhile, the LVD was revealed by computing the LVD value and the level of FCS integration. The GA can show the high penetration of the FCSs and PV installed that affected the LVD and the total power loss of the grid.

Figure 9.

Comparison of the total FCS sizing with the total power loss and LVD of the GA.

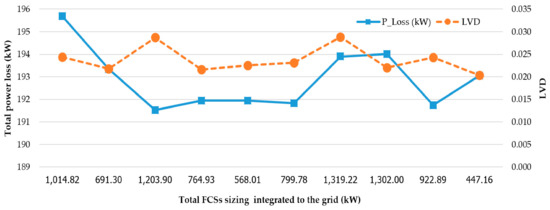

Figure 10 shows the comparison of the total FCS sizing against the total power loss and LVD of the CSA. The CSA presented the impact of the FCSs integrated into the grid by increasing the total power loss with a high penetration level of the FCSs. Meanwhile, the LVD was revealed by the low varying value related to PV sizing and installation position.

Figure 10.

Comparison of the total FCS sizing with the total power loss and LVD of the CSA.

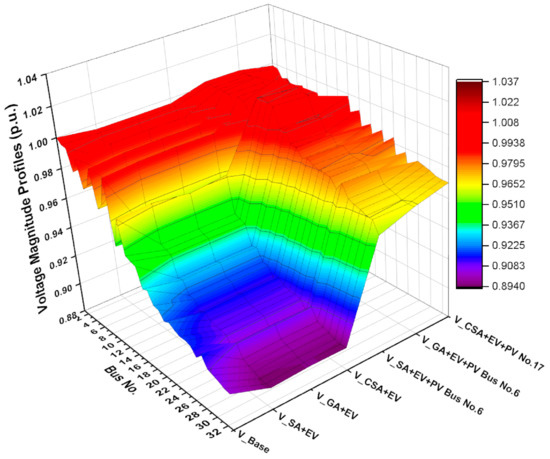

Figure 11 shows the voltage profile with a connected FCS at each location. The PV installation into the grid affected the voltage magnitude profile of the electrical power system. The FCSs were integrated into the grid at optimal sizing and locations related to the objective function’s minimized value. The LVD was defined by the objective function. Therefore, the optimal positions of the FCSs and PV are presented by the voltage magnitude contour. It presents the base case (V_base); the optimal condition when installing FCSs with the SAA (V_SA + EV), GA (V_GA + EV), and CSA (V_CSA + EV); and the optimal condition when installing FCSs and the PV with the SAA (V_SA + EV + PV No. 6), GA (V_GA + EV + PV No. 6), and CSA (V_CSA + EV + PV No. 17). The voltage magnitude contours were selected by the minimum value of LVD in Table 3, with values of 0.035, 0.035, and 0.020 for the SAA, GA, and CSA, respectively. The reduced voltage magnitude profiles, when connected by FCSs, are shown in the voltage magnitude contour of V_SA + EV, V_GA + EV, and V_CSA + EV. Meanwhile, the results show that the PV can improve the voltage magnitude profiles and can be used to reduce the impact of FCS penetration into the grid. However, the high penetration level of the FCSs is directly affected by the grid, which can be managed in optimal conditions. Significantly, the variation in the FCS sizing and installation position was revealed by the difference caused by the random metaheuristic process generation.

Figure 11.

Comparison between before and after PV installation for FCSs by minimizing the LVD from each case.

However, the optimal position of FCSs could be selected by the GA with the high percentage of the best hit counter of 85.71%, shown on buses no. 2, 3, 13, 14, 28, 15, and 27. The total power loss of 227.73 kW of the GA is presented by minimizing the objective function. Thus, the position and size of the PV are bus no. 6 and 1.083 kW, respectively.

5. Conclusions

The symmetry of the grid was achieved by applying the optimal management condition related to the optimal values of the FCSs and DPV installed. This work adapted metaheuristic methods to solve the problems of the FCSs and DPV. The metaheuristic methods used were the SAA, GA, and CSA, representing evolutionary, swarm-based, and trajectory-based algorithms, respectively. The LVD was selected as the objective function for finding the problem of the optimal FCSs and DPV. The comparison results of the optimization technique (OT) showed that the lowest average value of the LVD of 0.024 was presented by the CSA. The lowest average value of the total power loss of 192.90 kW was also presented by the CSA. Meanwhile, the highest average value of the PV sizing of 1.192 MW was given by the SAA. The simulation results showed that the average value of the computation time, from low to high, was 8.85, 48.31, and 58.80 s for the SAA, GA, and CSA, respectively. The installed FCSs and DPV revealed the impact of the LVD and the total power loss of the grid. A possible position of the DPV is at bus no. 6 for a high penetration level of the FCSs. Meanwhile, a low penetration level of the FCSs could be possible at bus no. 15. Thus, the penetration level of the FCSs integrated into the grid is important for managing the optimal condition to reduce grid impact. The SAA, GA, and CSA are limited in their adaptation to solve the problem from the benchmarking results. Additionally, accuracy and time computation need to be improved. Therefore, the metaheuristic method can be considered for this purpose to solve problems in the future and can be selected to solve the problem of the OT. As the answers are varied and comprise different solutions, pre-solving and trial and error may be needed to find the problem, which needs to be taken into account in the future.

Author Contributions

Conceptualization, K.Y. and K.B.; methodology, K.Y.; software, K.Y.; validation, Y.K. and P.P.; formal analysis, K.Y.; investigation, Y.K. and P.P.; writing—original draft preparation, K.Y.; writing—review and editing, Y.K., P.P. and K.B.; visualization, K.B.; supervision, K.B. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Kijewska, A.; Bluszcz, A. Analysis of greenhouse gas emissions in the European Union member states with the use of an agglomeration algorithm. J. Sustain. Min. 2016, 15, 133–142. [Google Scholar] [CrossRef]

- Yong, J.Y.; Ramachandaramurthy, V.K.; Tan, K.M.; Mithulananthan, N. A review on the state-of-the-art technologies of the electric vehicle, its impacts and prospects. Renew. Sustain. Energy Rev. 2015, 49, 365–385. [Google Scholar] [CrossRef]

- Li, Z.; Khajepour, A.; Song, J. A comprehensive review of the key technologies for pure electric vehicles. Energy 2019, 182, 824–839. [Google Scholar] [CrossRef]

- World Energy Council. World Energy Scenarios: Global Transport Scenarios 2050. Available online: https://www.worldenergy.ch/file/Publikationen/Aktuell/Global_Transport_Scenarios_2050.pdf (accessed on 31 October 2021).

- Rubino, L.; Capasso, C.; Veneri, O. Review on plug-in electric vehicle charging architectures integrated with distributed energy sources for sustainable mobility. Appl. Energy 2017, 207, 438–464. [Google Scholar] [CrossRef]

- Shaukat, N.; Khan, B.; Ali, S.M.; Mehmood, C.A.; Khan, J.; Farid, U.; Majid, M.; Anwar, S.M. A survey on electric vehicle transportation within a smart grid system. Renew. Sustain. Energy Rev. 2018, 81, 1329–1349. [Google Scholar] [CrossRef]

- Tomaszewska, A.; Chu, Z.; Feng, X.; O’Kane, S.; Liu, X.; Chen, J.; Ji, C.; Endler, E.; Li, R.; Liu, L.; et al. Lithiumion battery fast charging: A review. Transportation 2019, 1, 100011. [Google Scholar]

- Du, J.; Liu, Y.; Mo, X.; Li, Y.; Li, J.; Wu, X.; Ouyang, M. Impact of high-power charging on the durability and safety of lithium batteries used in long-range battery electric vehicles. Appl. Energy 2019, 255, 113793. [Google Scholar] [CrossRef]

- Lulhe, A.M.; Date, T.N. A technology review paper for drives used in the electrical vehicle (EV) & hybrid electrical vehicles (HEV). In Proceedings of the 2015 International Conference on Control, Instrumentation, Communication and Computational Technologies (ICCICCT), Kumaracoil, India, 18–19 December 2015; pp. 632–636. [Google Scholar]

- Deb, S.; Tammi, K.; Kalita, K.; Mahanta, P. Impact of Electric Vehicle Charging Station Load on Distribution Network. Energies 2018, 11, 178. [Google Scholar] [CrossRef] [Green Version]

- Clement-Nyns, K.; Haesen, E.; Driesen, J. The Impact of Charging Plug-In Hybrid Electric Vehicles on a Residential Distribution Grid. IEEE Trans. Power Syst. 2010, 25, 371–380. [Google Scholar] [CrossRef] [Green Version]

- Dharmakeerthi, C.H.; Mithulananthan, N.; Saha, T.K. Impact of electric vehicle fast-charging on power system voltage stability. Int. J. Electr. Power Energy Syst. 2014, 57, 241–249. [Google Scholar] [CrossRef]

- Farkoush, S.G.; Kim, C.H.; Rhee, S.B. THD Reduction of Distribution System Based on ASRFC and HVC Method for SVC under EV Charger Condition for Power Factor Improvement. Symmetry 2016, 8, 156. [Google Scholar] [CrossRef]

- Kim, M.; Kim, J.; Bae, S. Design of a Sustainable and Efficient Transportation Station (SETS) Based on Renewable Sources and Efficient Electric Drives. Symmetry 2016, 8, 146. [Google Scholar] [CrossRef] [Green Version]

- Prabpal, P.; Kongjeen, Y.; Bhumkittipich, K. Optimal Battery Energy Storage System Based on VAR Control Strategies Using Particle Swarm Optimization for Power Distribution System. Symmetry 2021, 13, 1692. [Google Scholar] [CrossRef]

- Kongjeen, Y.; Bhumkittipich, K.; Mithulananthan, N.; Amiri, I.S.; Yupapin, P. A modified backward and forward sweep method for microgrid load flow analysis under different electric vehicle load mathematical models. Electr. Power Syst. Res. 2019, 168, 46–54. [Google Scholar] [CrossRef]

- Nizam, M.; Wicaksono, F.X.R. Design and Optimization of Solar, Wind, and Distributed Energy Resource (DER) Hybrid Power Plant for Electric Vehicle (EV) Charging Station in Rural Area. In Proceedings of the 5th International Conference on Electric Vehicular Technology (ICEVT), Surakarta, Indonesia, 30–31 October 2018; pp. 41–45. [Google Scholar]

- Ahmadi, L.; Croiset, E.; Elkamel, A.; Douglas, P.; Unbangluang, W.; Entchev, E. Impact of PHEVs Penetration on Ontario’s Electricity Grid and Environmental Considerations. Energies 2012, 5, 5019. [Google Scholar] [CrossRef]

- Shukla, A.; Verma, K.; Kumar, R. Voltage-dependent modeling of fast-charging electric vehicle load considering battery characteristics. IET Electr. Syst. Transp. 2018, 8, 221–230. [Google Scholar] [CrossRef]

- Mohan, B.; Ramesh, M.V. Optimal DG placement under Standard Market Design using GA. In Proceedings of the 2012 International Conference on Emerging Trends in Electrical Engineering and Energy Management (ICETEEEM), Tamil Nadu, India, 13–15 December 2012; pp. 148–153. [Google Scholar]

- Shaheen, A.M.; Spea, S.R.; Farrag, S.M.; Abido, M.A. A review of meta-heuristic algorithms for reactive power planning problem. Ain Shams Eng. J. 2018, 9, 215–231. [Google Scholar] [CrossRef] [Green Version]

- Abdmouleh, Z.; Gastli, A.; Ben-Brahim, L.; Haouari, M.; Al-Emadi, N.A. Review of optimization techniques applied for the integration of distributed generation from renewable energy sources. Renew. Energy 2017, 113, 266–280. [Google Scholar] [CrossRef]

- Zexi, D.; Feidan, H. Cuckoo search algorithm for solving numerical integration. In Proceedings of the IEEE International Conference on Cyber Technology in Automation, Control, and Intelligent Systems (CYBER), Shenyang, China, 8–12 June 2015; pp. 1508–1512. [Google Scholar]

- Wang, X.; Gao, X.; Wang, Z.; Ma, C.; Song, Z. A Combined Model Based on EOBL-CSSA-LSSVM for Power Load Forecasting. Symmetry 2021, 13, 1579. [Google Scholar] [CrossRef]

- El-Naggar, K.M.; AlRashidi, M.R.; AlHajri, M.F.; Al-Othman, A.K. Simulated Annealing algorithm for photovoltaic parameters identification. Solar Energy 2012, 86, 266–274. [Google Scholar] [CrossRef]

- Dharmakeerthi, C.H.; Mithulananthan, N.; Atputharajah, A. Development of dynamic EV load model for power system oscillatory stability studies. In Proceedings of the 2014 Australasian Universities Power Engineering Conference (AUPEC), Perth, Australia, 28 September–1 October 2014; pp. 1–6. [Google Scholar]

- Kongjeen, Y.; Yenchamchalit, K.; Bhumkittipich, K. Optimal Sizing and Placement of Solar Powered Charging Station under EV loads Penetration using Artificial Bee Colony Technique. In Proceedings of the The 2018 International Power Electronics Conference (IPEC2018), TOKI MESSE Niigata Convention Center Japan, Niigata, Japan, 20–24 May 2018. [Google Scholar]

- Kongjeen, Y.; Bhumkittipich, K. Modeling of electric vehicle loads for power flow analysis, based on PSAT. In Proceedings of the 2016 13th International Conference on Electrical Engineering/Electronics, Computer, Telecommunications and Information Technology (ECTI-CON), Mai, Thailand, 28 June–1 July 2016; pp. 1–6. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).