Preliminary Design and Experimental Study of a Steel-Batten Ribbed Cable Dome

Abstract

:1. Introduction

- The steel battens and bottom cable-strut system must be coordinated.

- The deformation mode of the SBRD should be investigated to ensure the stability of the entire structure in less-bracket consequent hoist-dragging construction.

- The stiffness and load-carrying capacity of the SBRD should be understood, and it should be ensured that the SBRD satisfies the practical requirements in actual projects.

2. Steel-Batten Ribbed Cable Dome (SBRD)

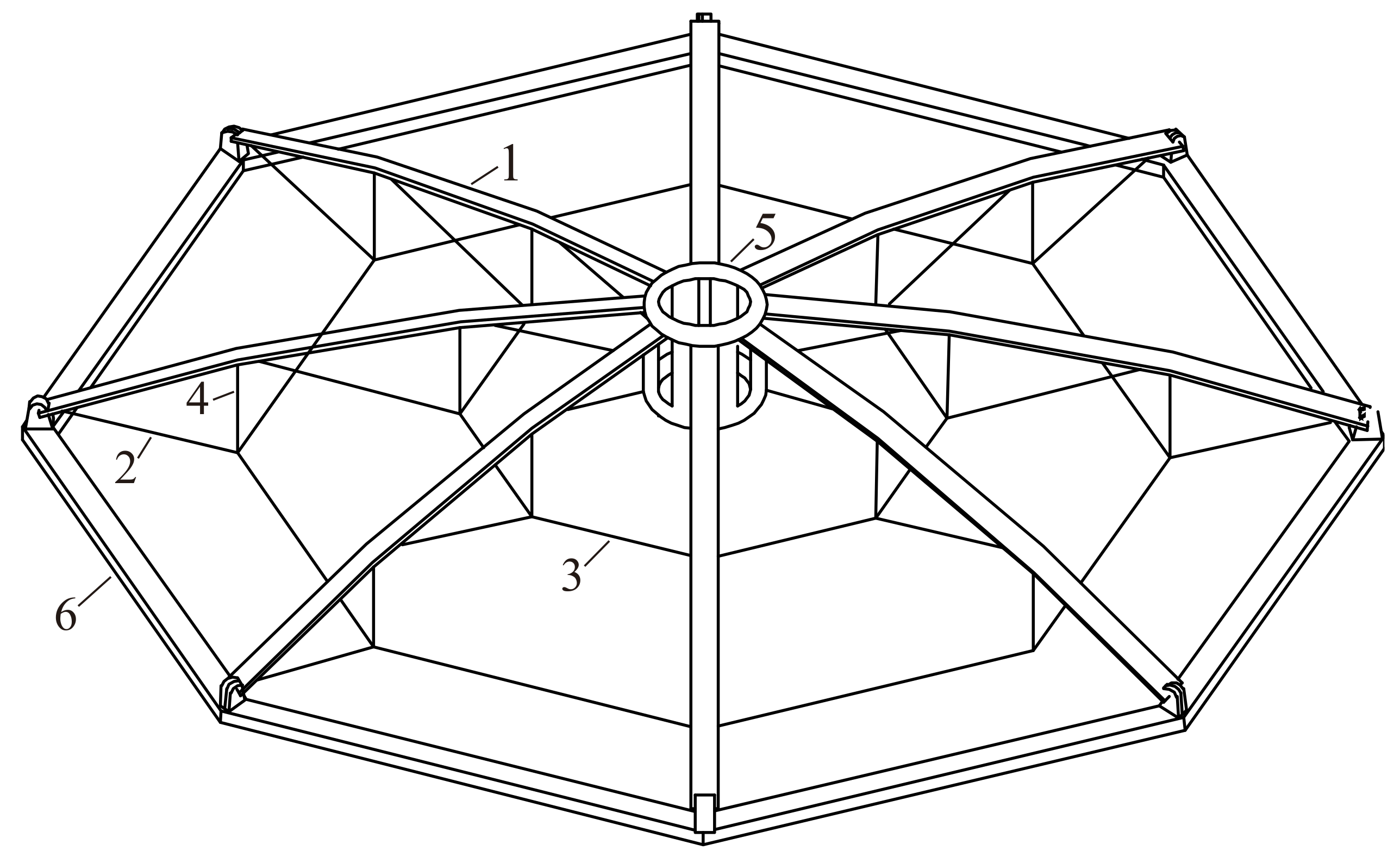

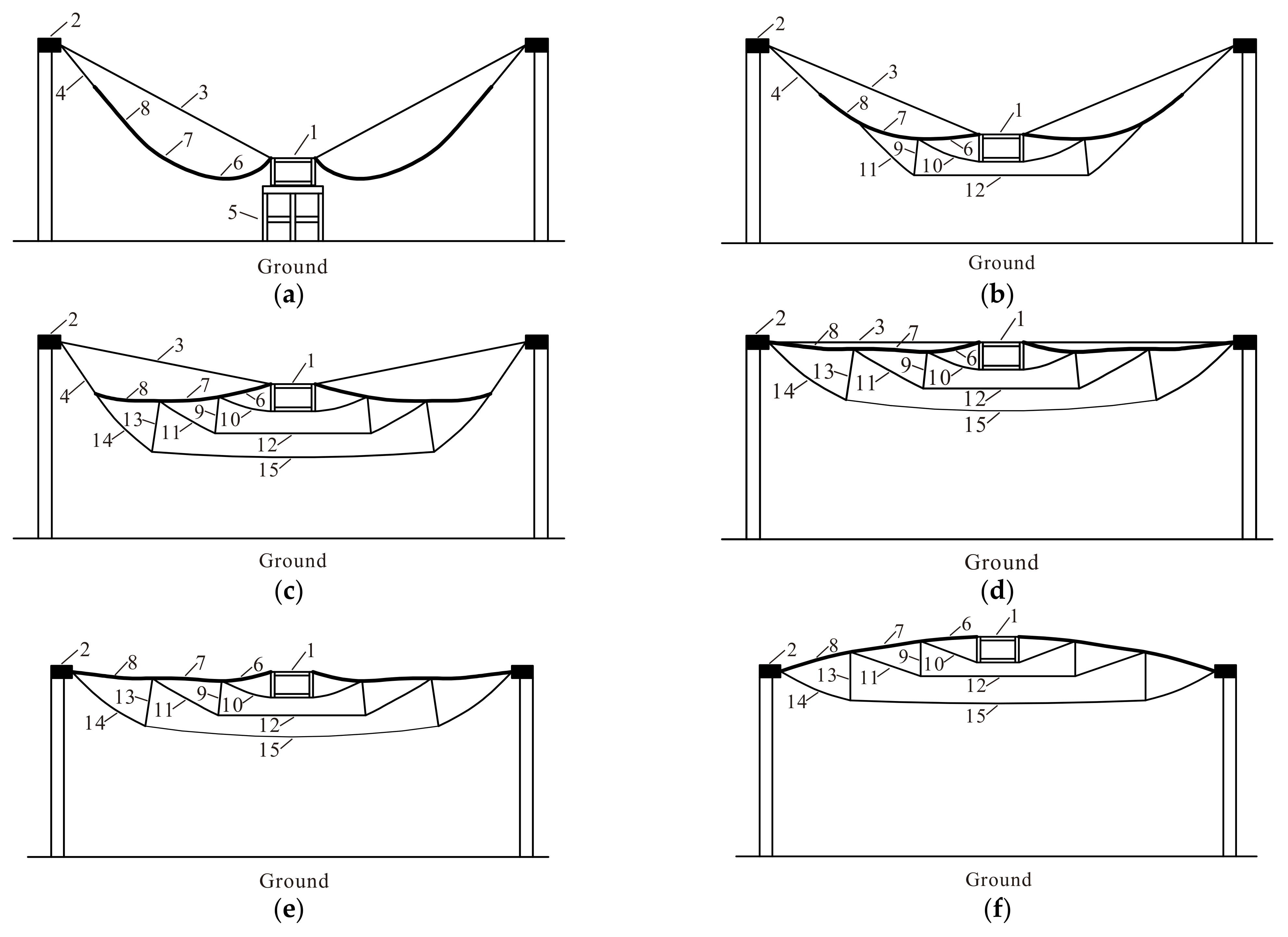

2.1. Structural Composition

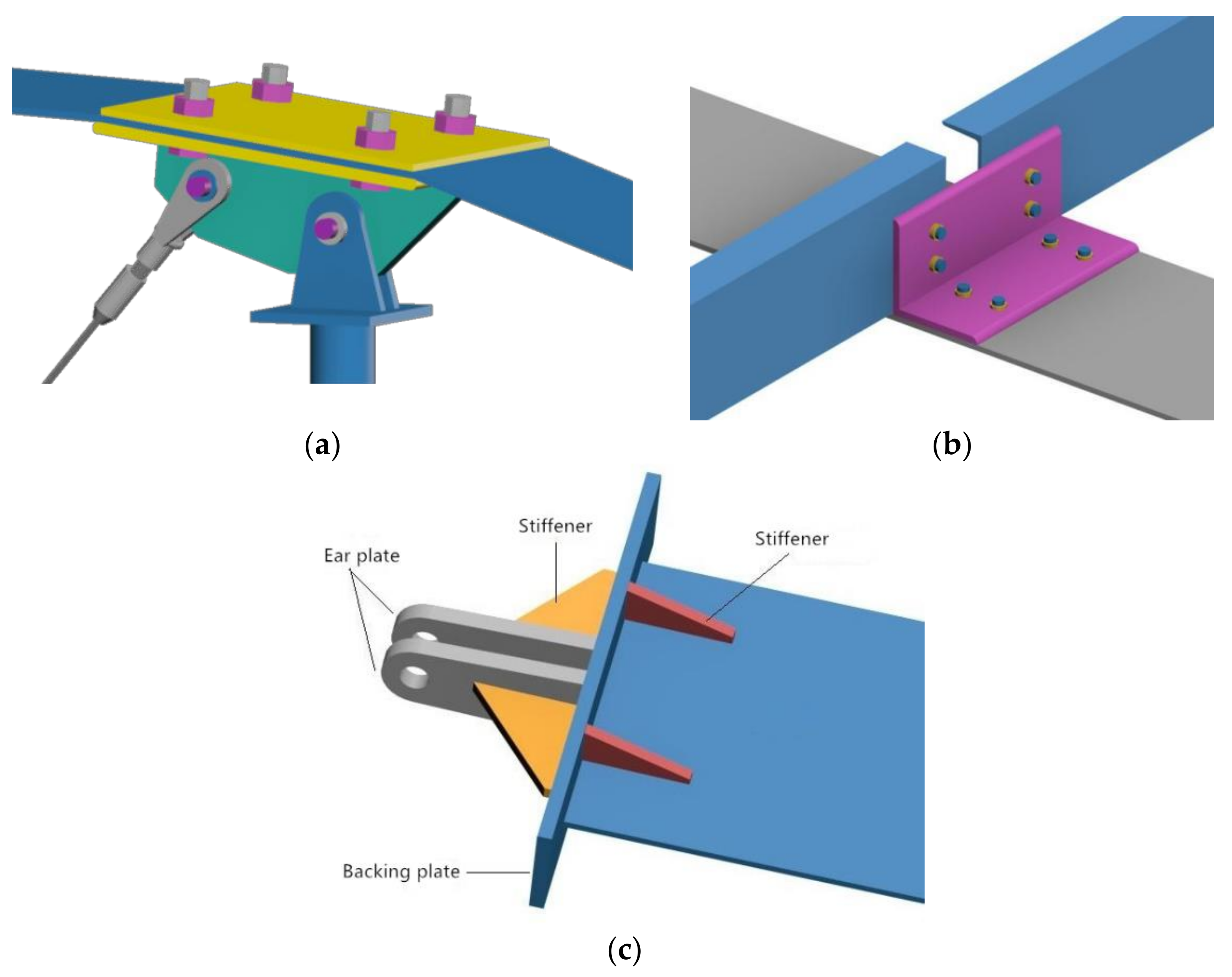

2.2. Connecting Joint

2.3. Advantages of the SBRD

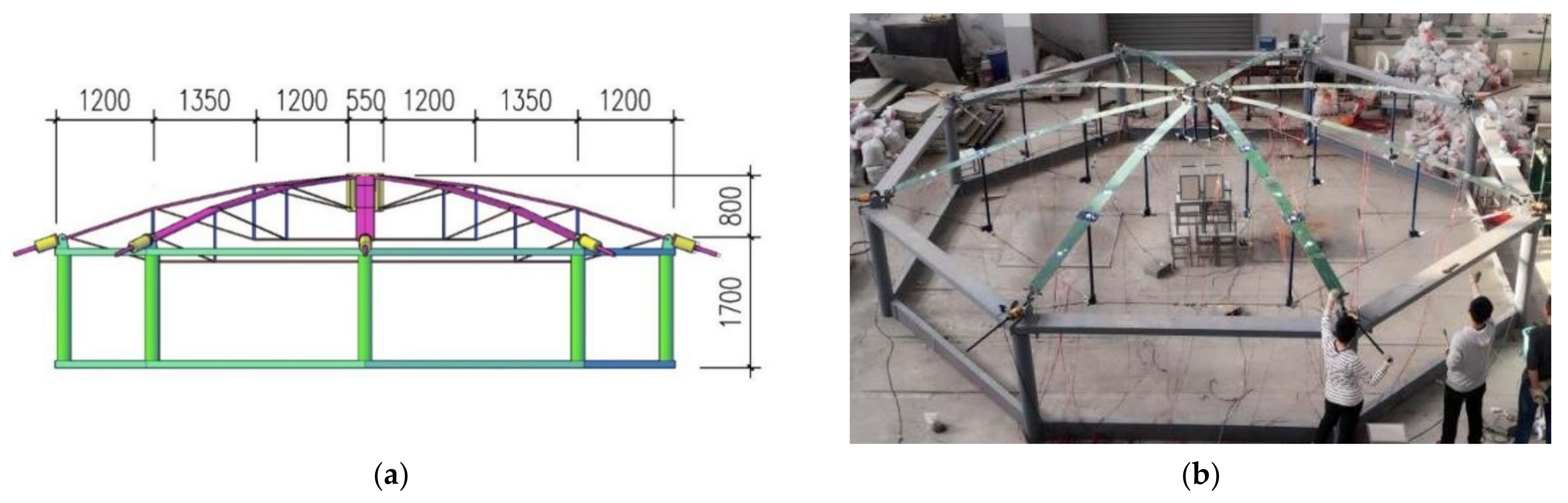

3. Design of the Test Model

3.1. Supporting System

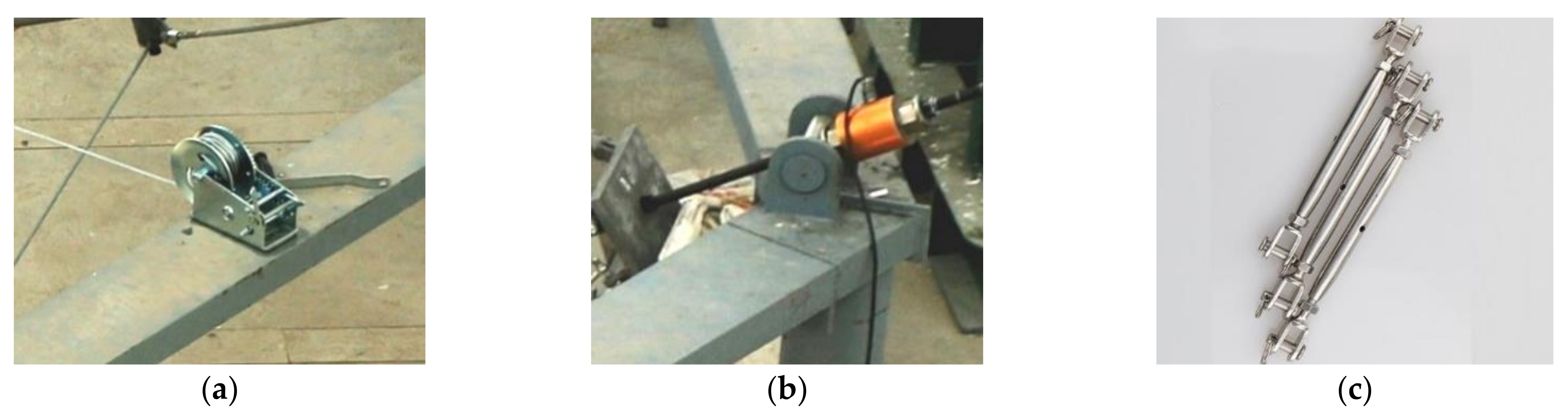

3.2. Structural Members and Joints

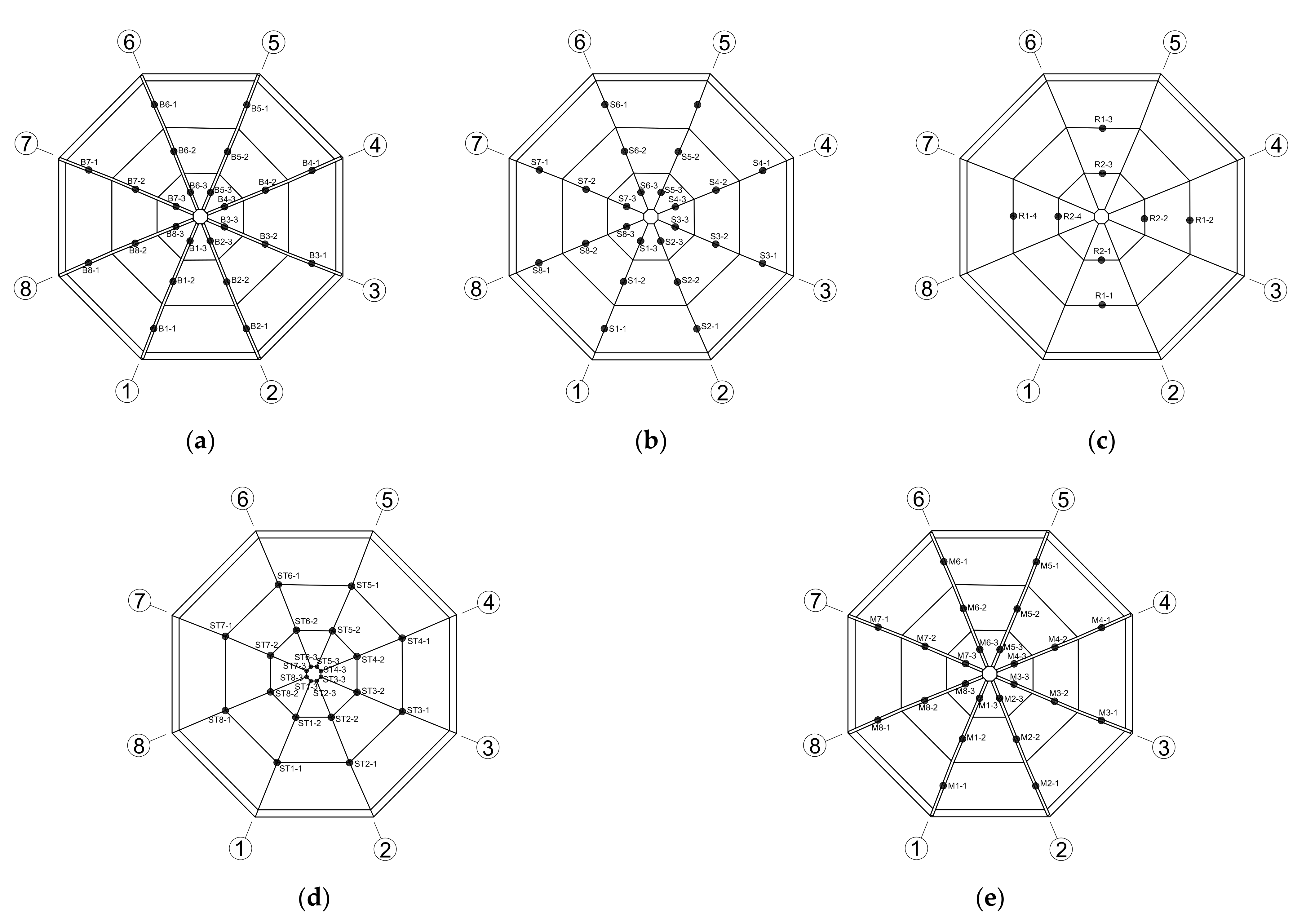

3.3. Measurement System and Measuring Point Arrangement

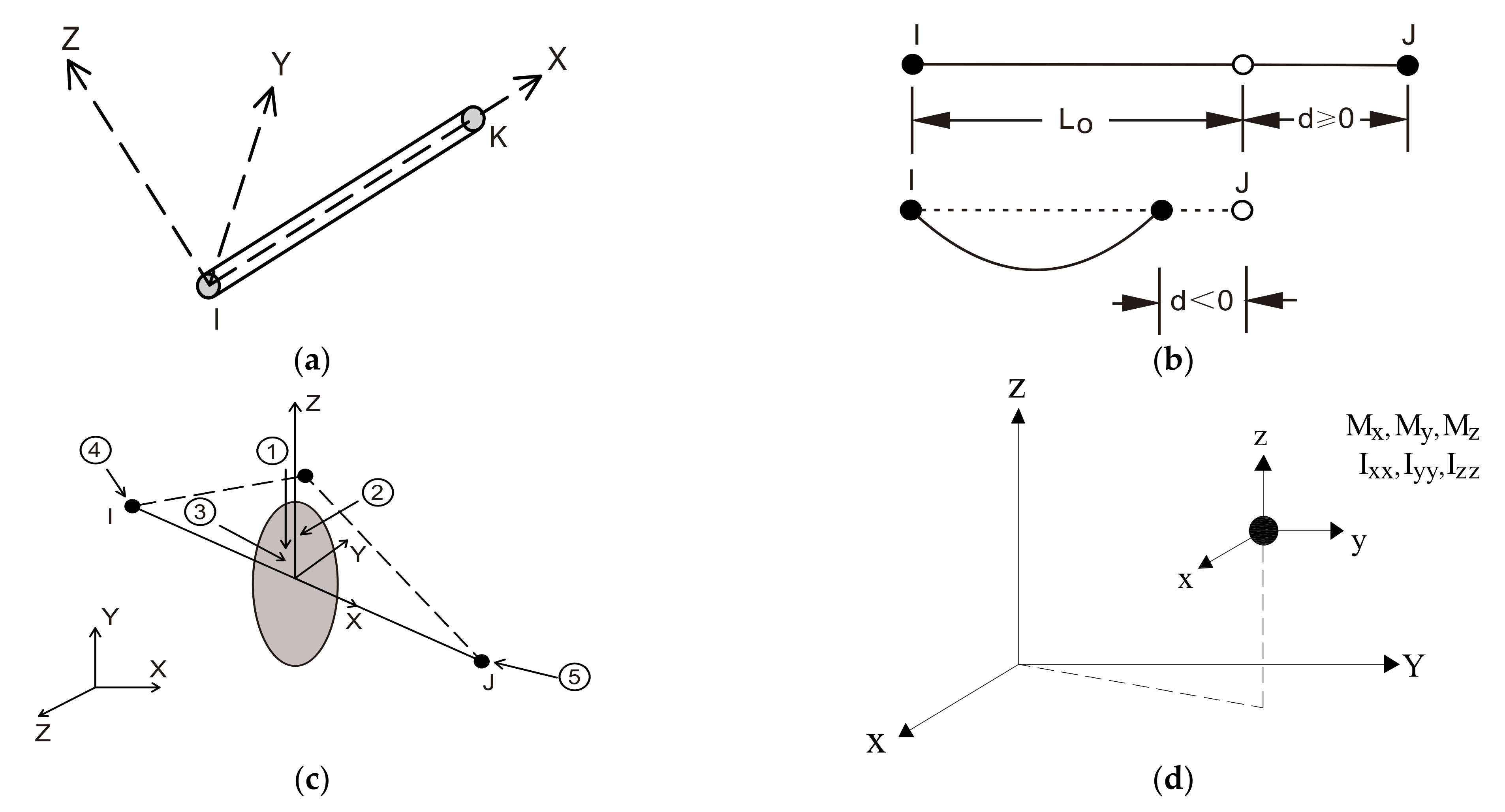

3.4. Finite Element Model

3.5. Calculation of the Initial Prestress

4. Test of the Construction Process

4.1. The ‘ω’ Shaped Less-Bracket Consequent Hoist-Dragging System for the SBRD

- (1)

- First, the outer compression beam, hoisting cables, steel battens, inner compression ring, hoisting cables, and dragging cables are assembled, and then the cables and struts are installed under the steel battens. After that, the ends of each component are hinged.

- (2)

- The outer compression beam is taken as the support to alternately lift and tract the steel batten grid. In each operation cycle, the lifting work should be taken before the hoist to maintain the ‘ω’ shape of the entire structure and to ensure the global stability of the structure during this process.

- (3)

- As the structure rises, the steel batten grid is gradually stretched until the end joints of the outer steel battens are connected with the outer compression beam.

- (4)

- The hoisting cables and dragging cables are removed. The outermost slanting cables are synchronously tensioned to build the prestress of the entire structure, and then a spatial structure with a certain rigidity that is able to withstand external loads is formed.

- (5)

- Finally, the total roof is divided into several units, according to the plane size, and then the rigid roofing plates are laid.

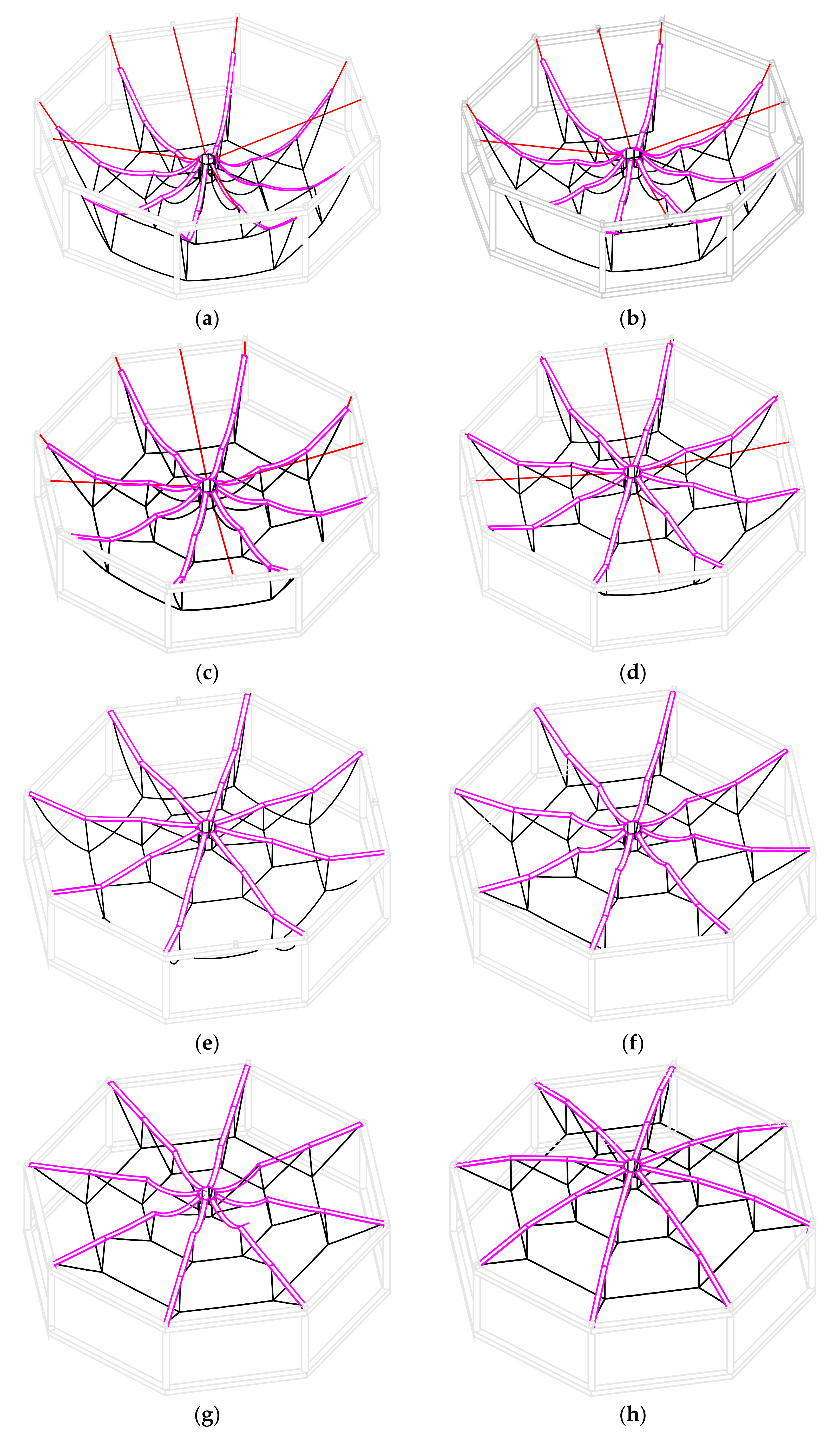

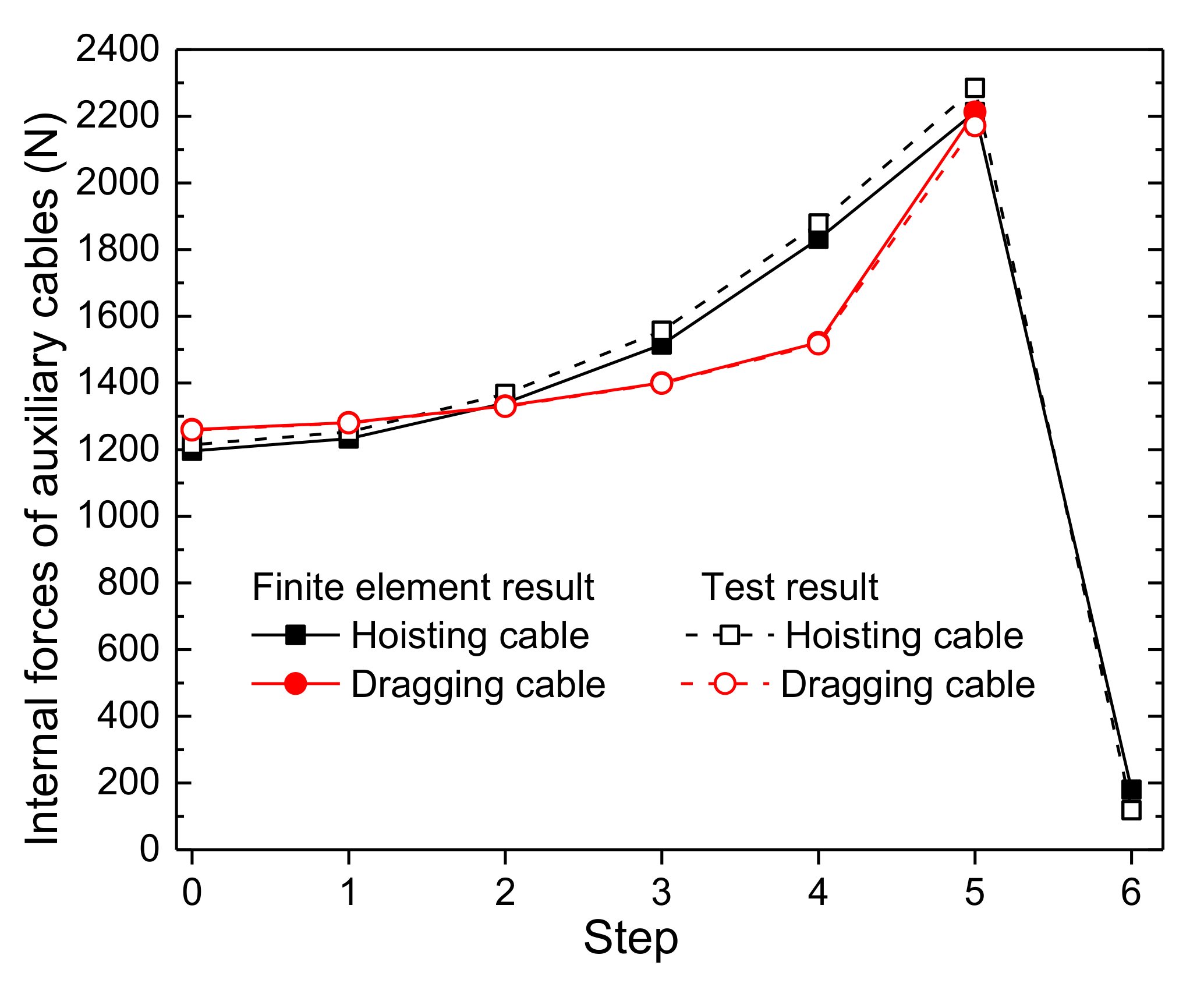

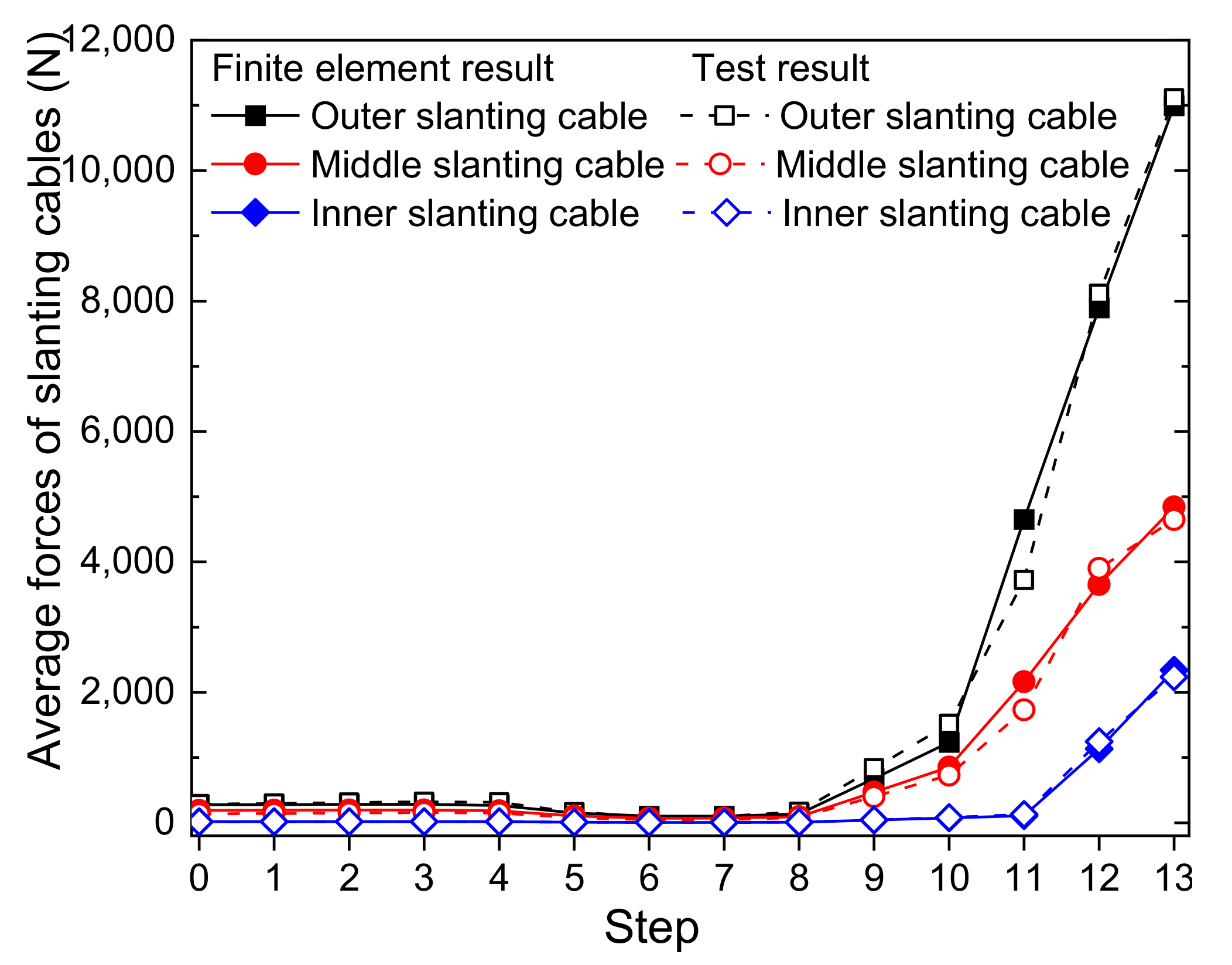

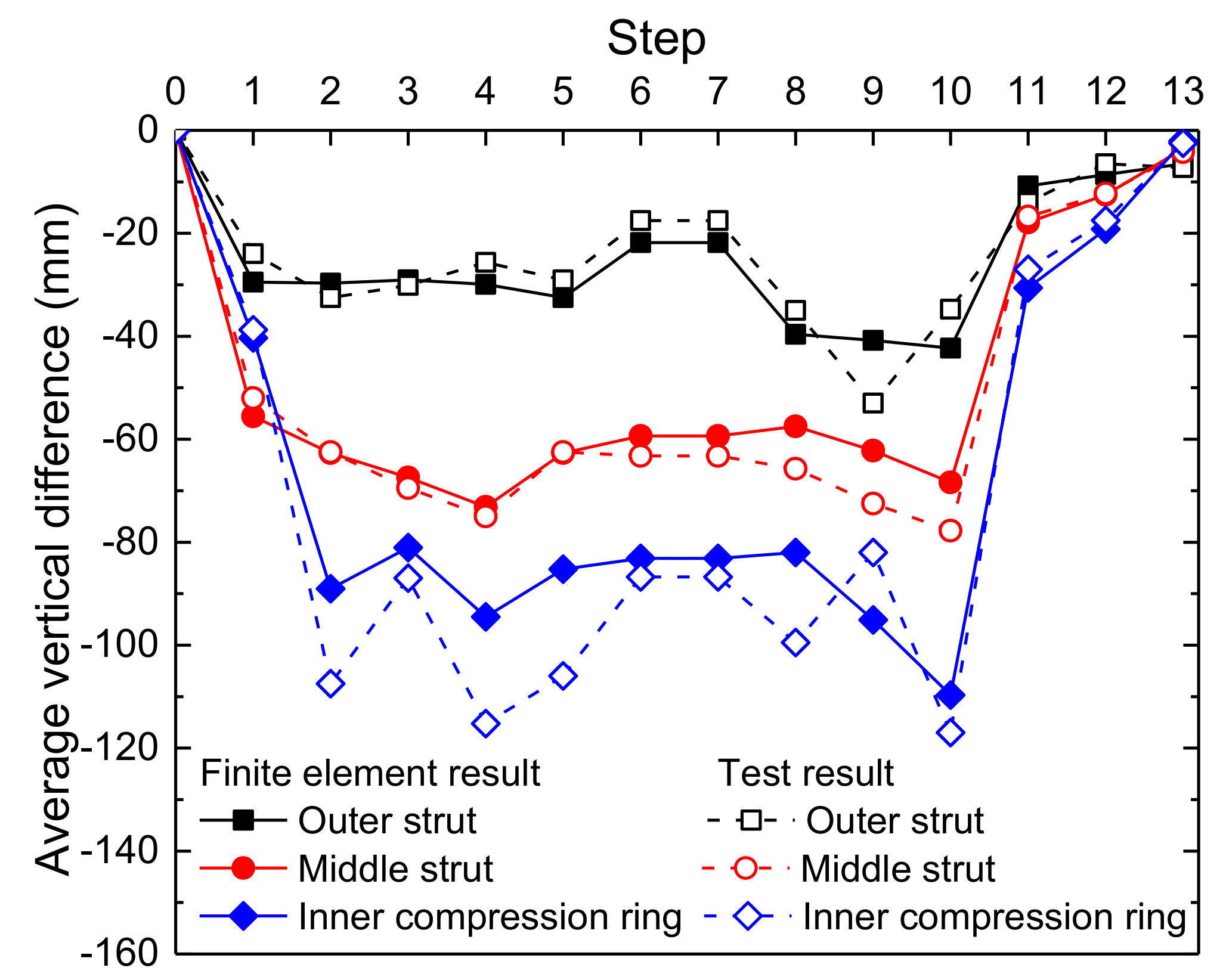

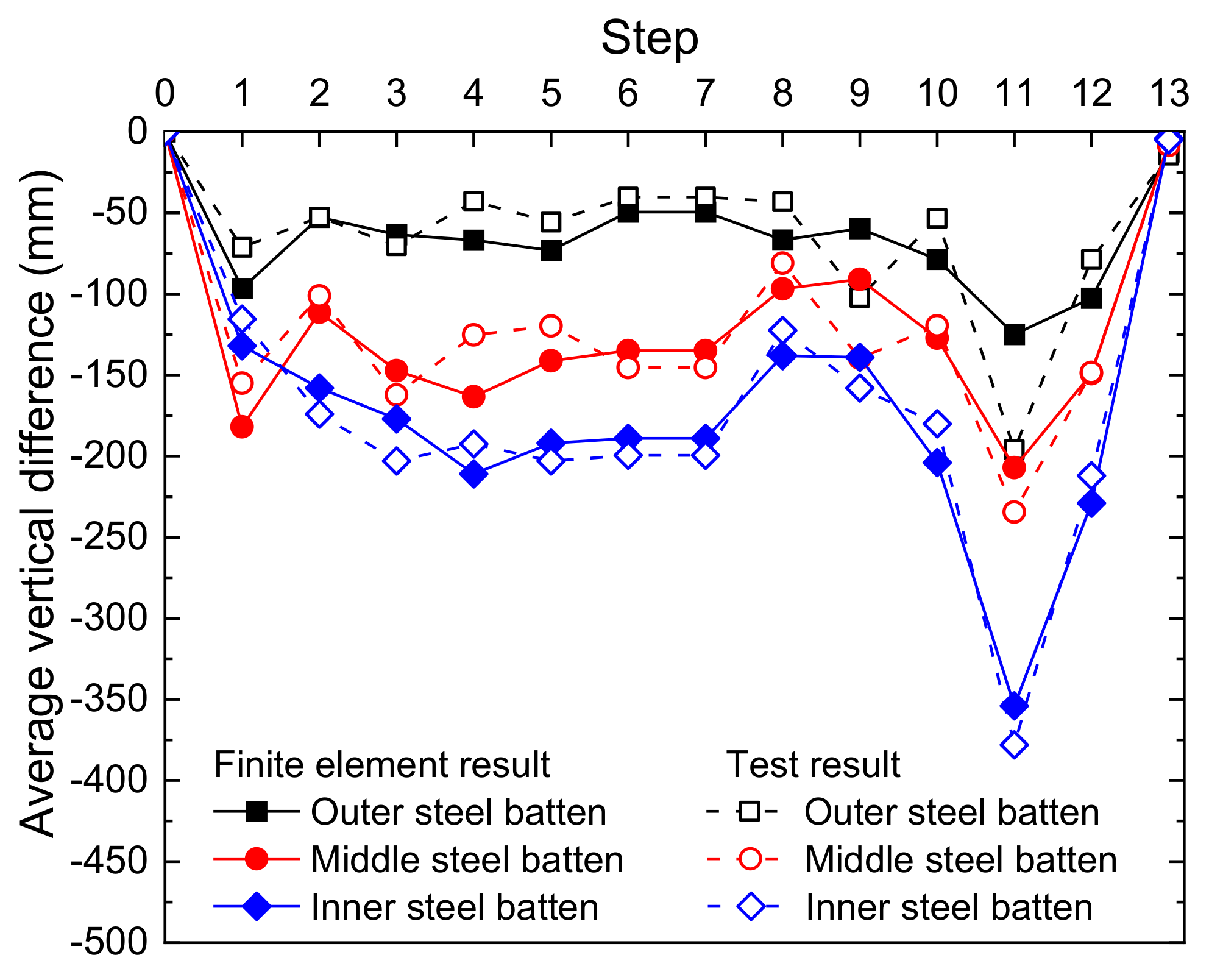

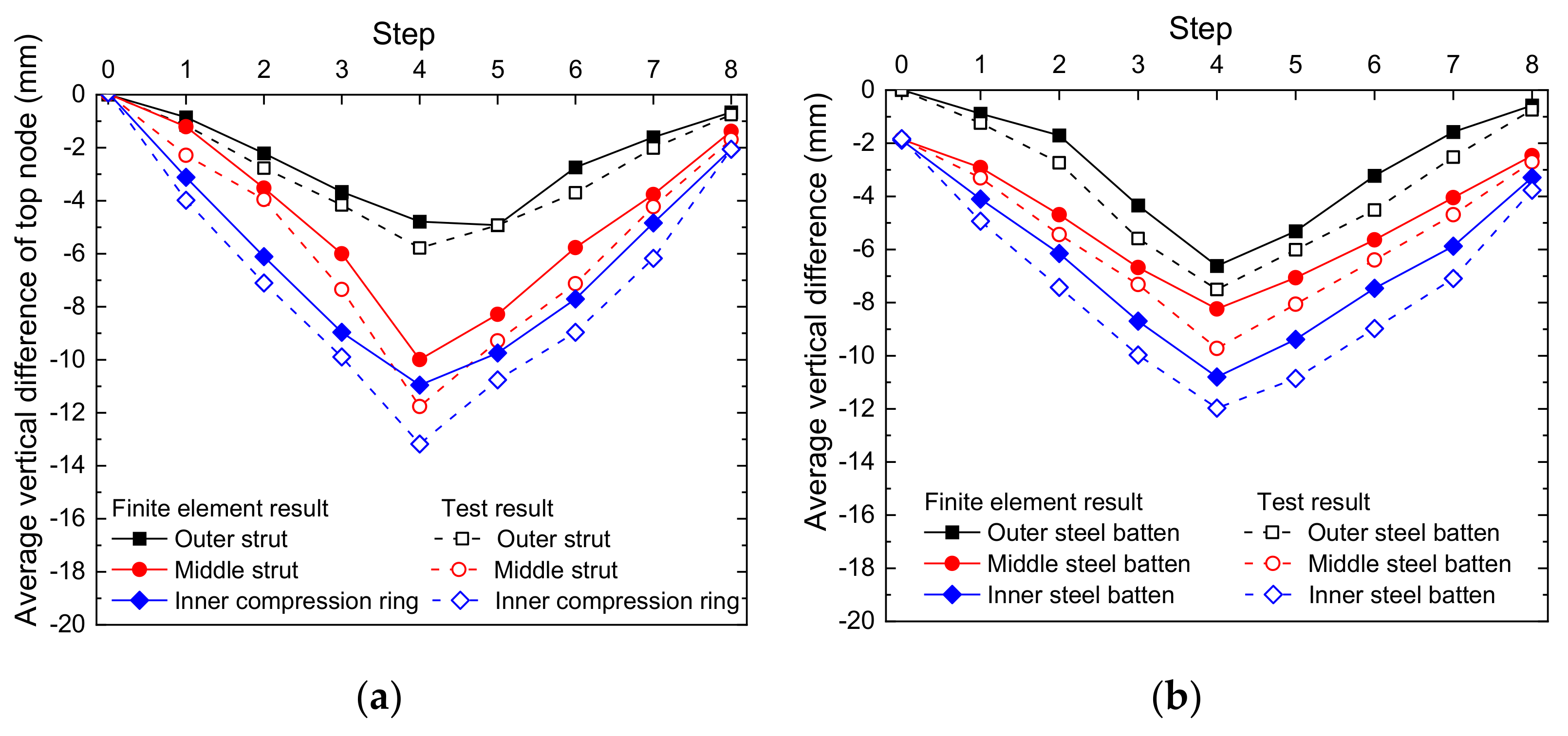

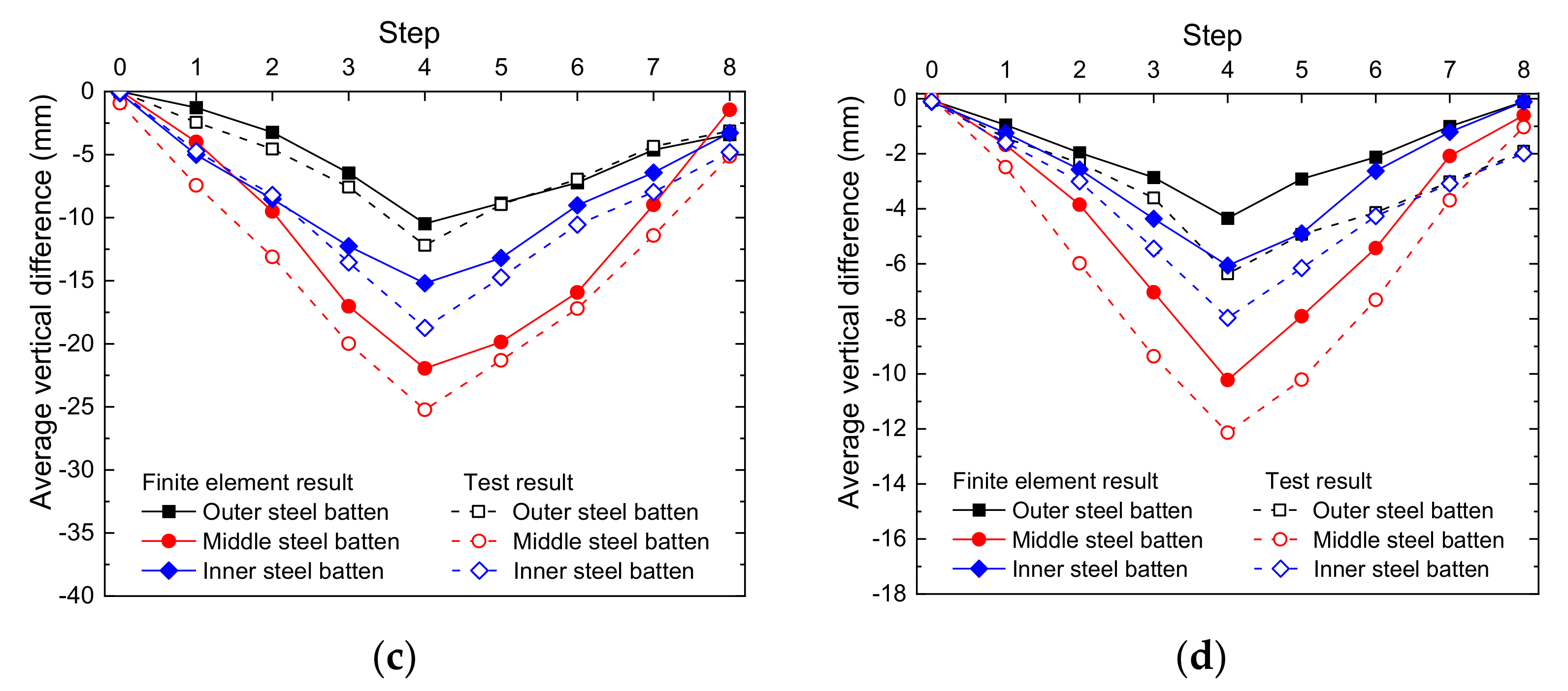

4.2. Results for ‘ω’ Shaped Less-Bracket Consequent Hoist-Dragging Construction

5. Test of Static Loading Performance

5.1. Summary of the Static Loading Test

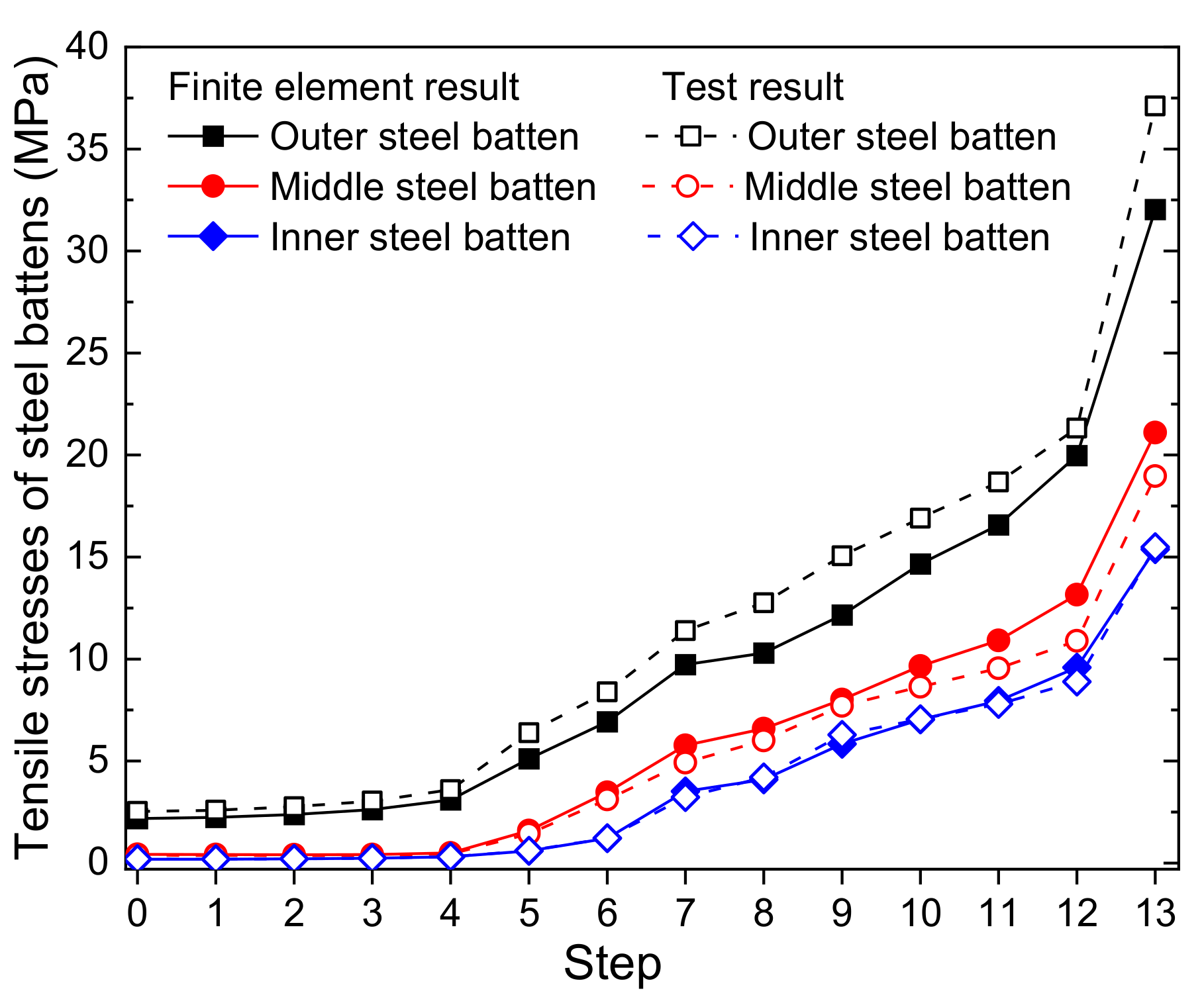

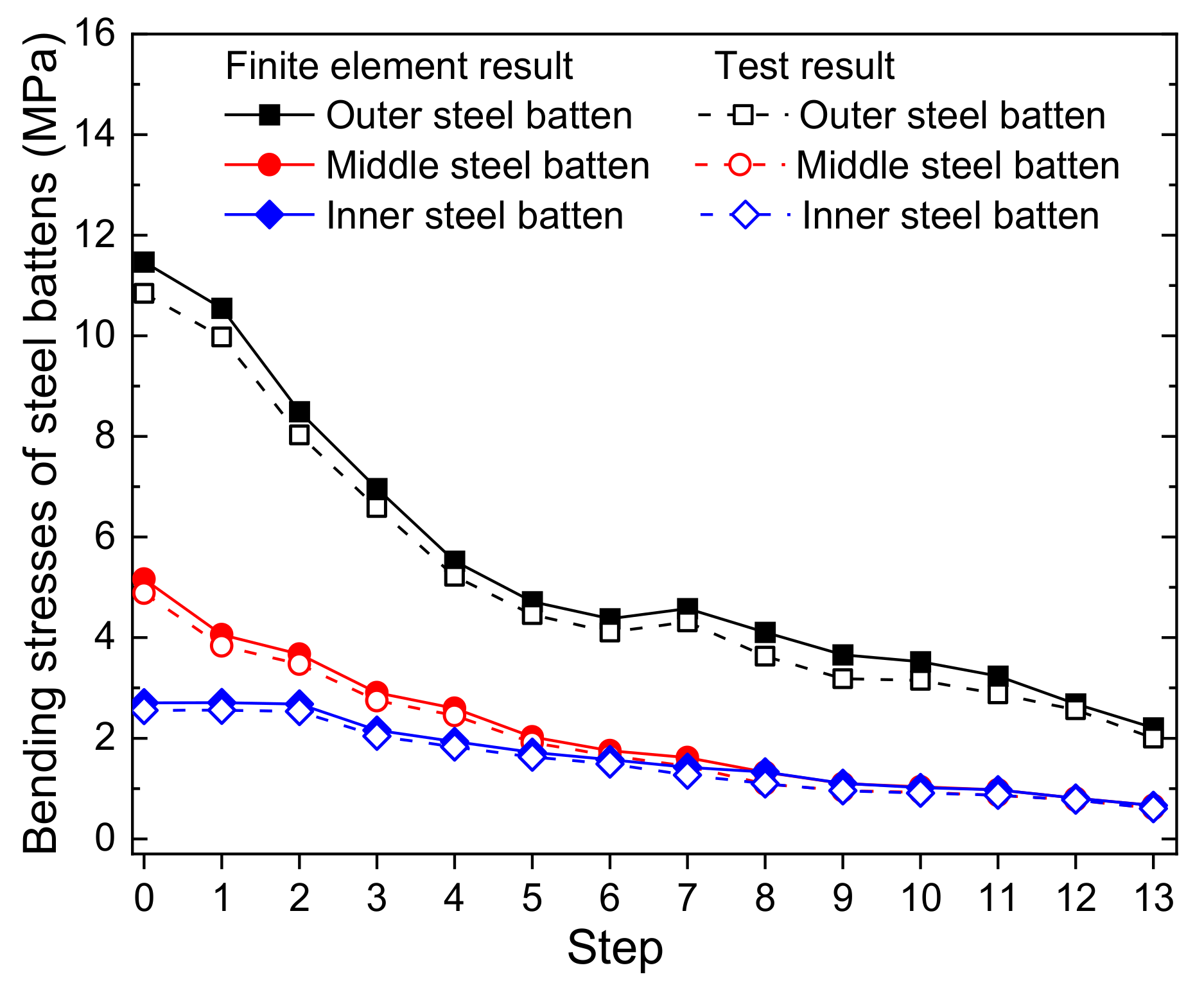

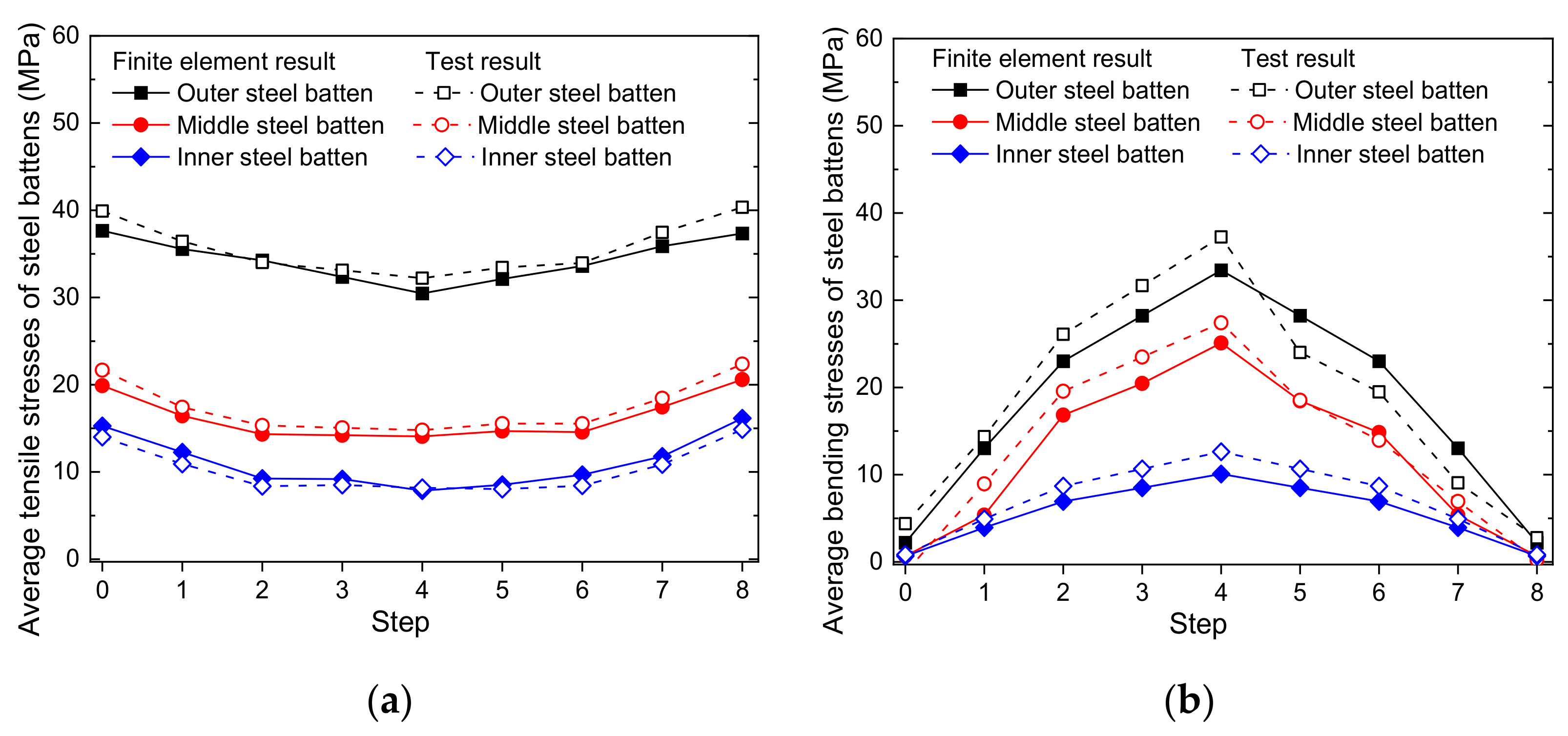

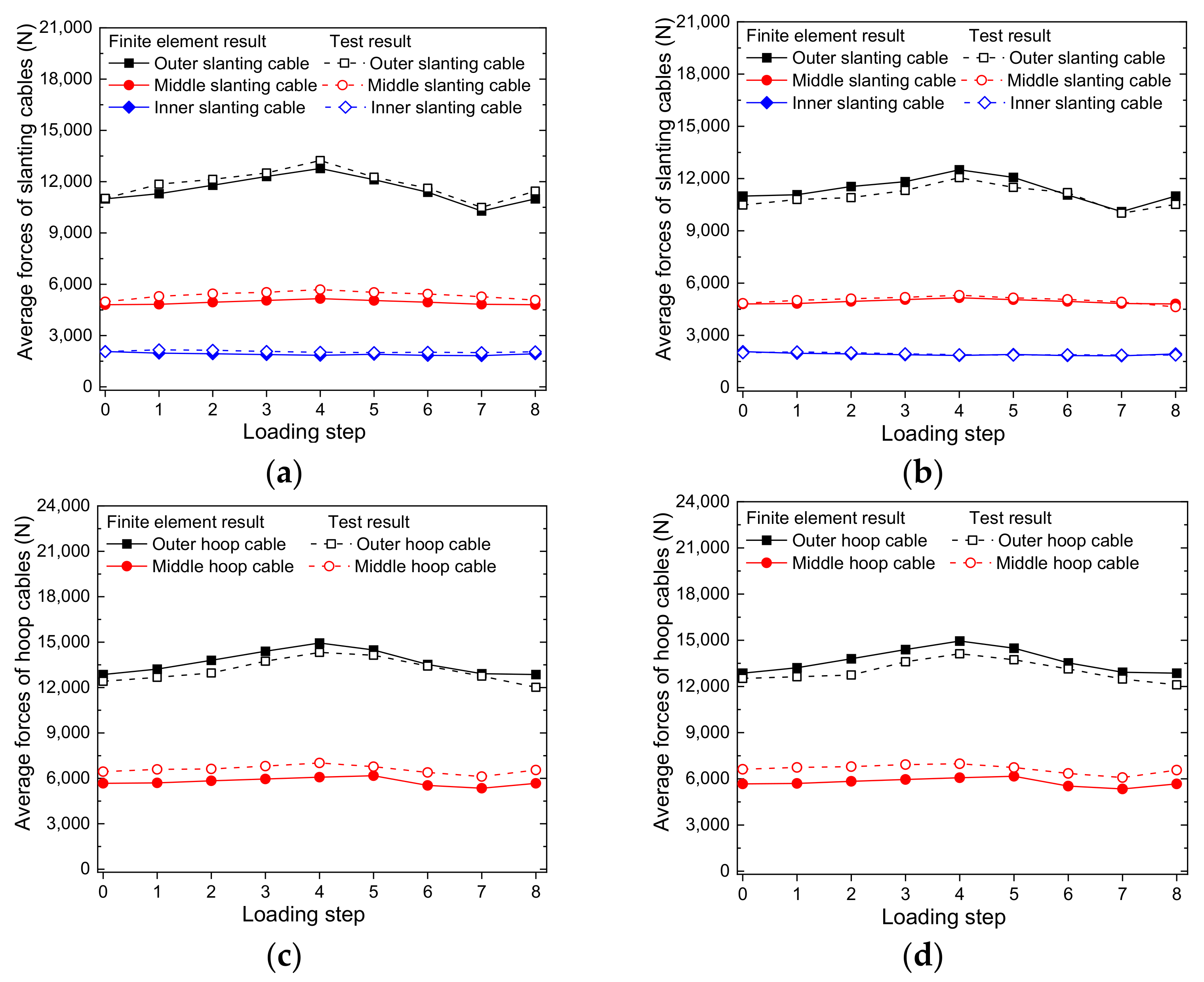

5.2. Results of Symmetric Uniform Loading

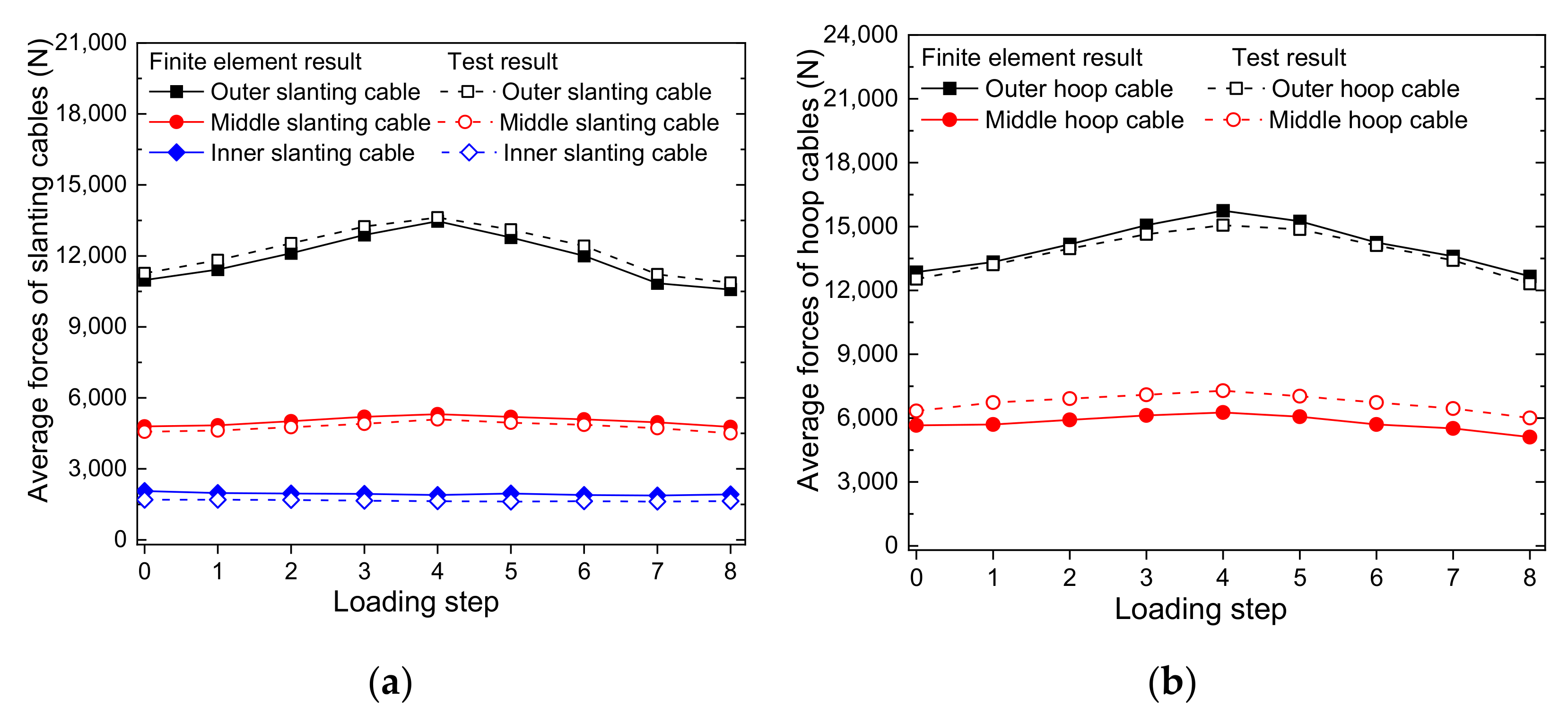

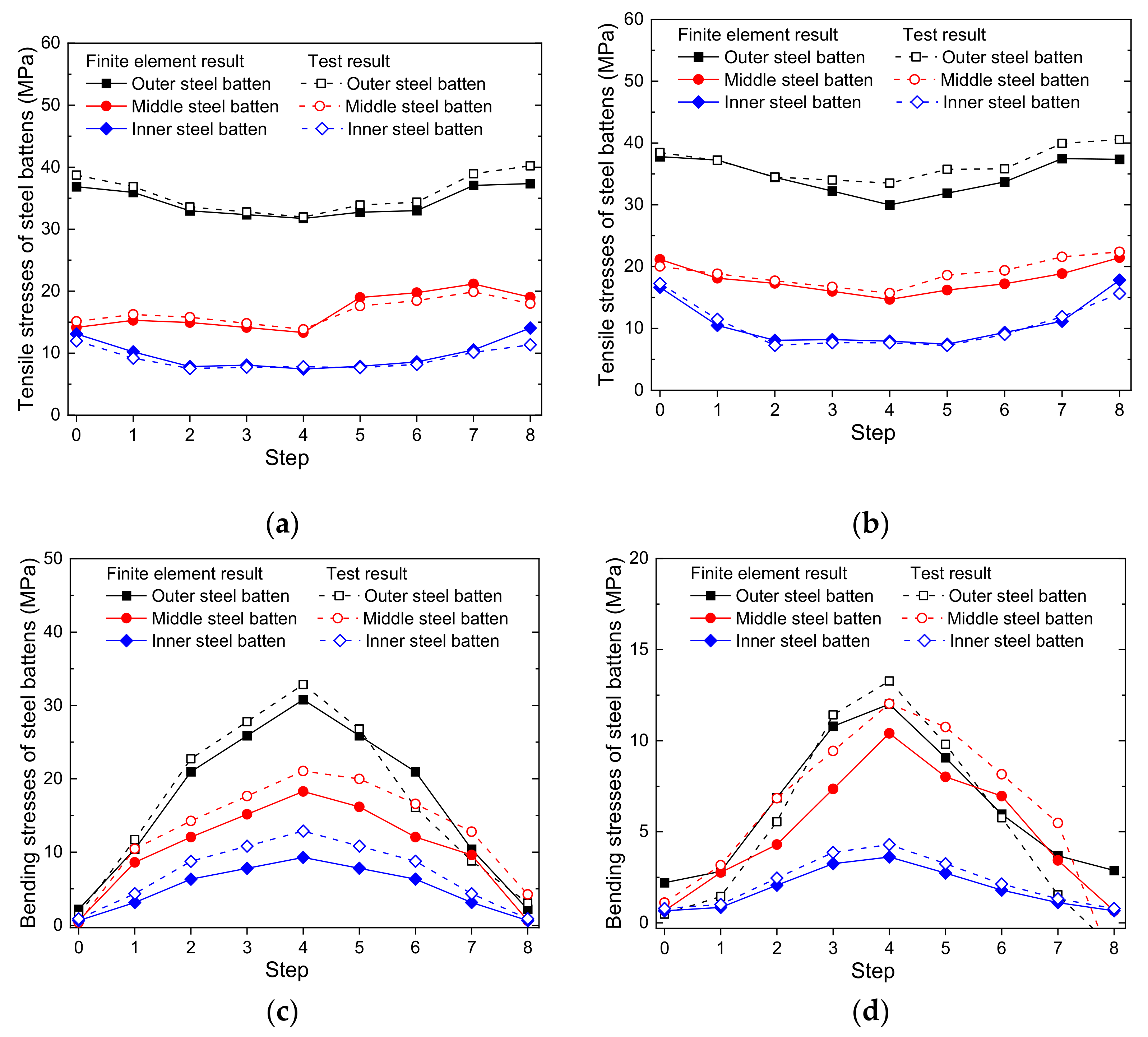

5.3. Results of Asymmetric Uniform Loading

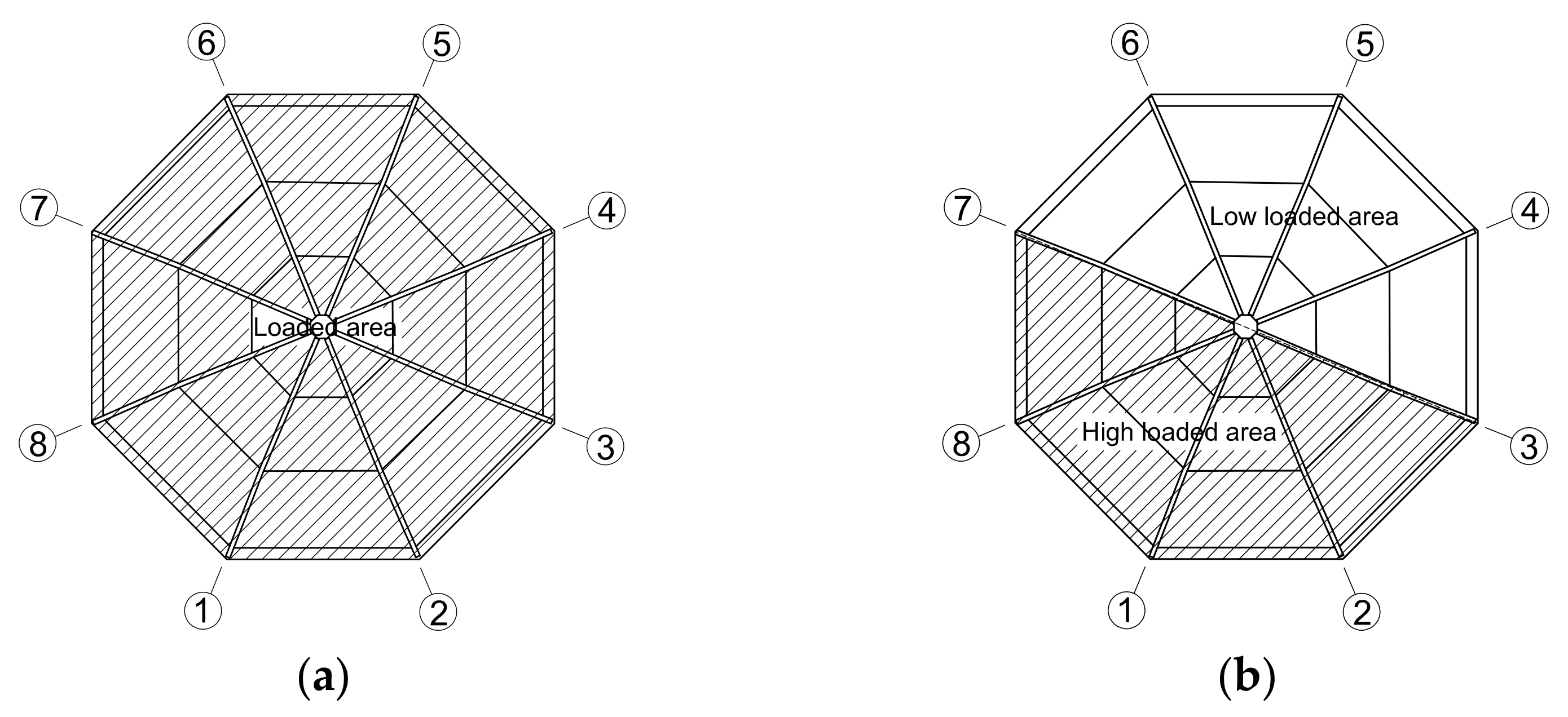

6. Conclusions

- By using the outer ring beam as the support and the tool cables as the traction equipment, the SBRD could be assembled within a limited horizontal area of the construction site at low altitude, and extended to cover the whole roofing area after alternately lifting the steel batten grid and tensioning the outer slanting cables. The scalability of SBRD is advantageous to shorten the construction period and improve the flexibility of installation and disassembly in actual engineering.

- In the early steps of hoist dragging, the structure establishes the prestress, accumulates stiffness, and finds its own internal force balance while the entire structure keeps the shape of a “ω” with both ends and midpoint sunken to guarantee that all the cables and struts remain suspended under the steel batten grid and to guarantee the stability of the overall configuration. As the internal force of the component increases in the following steps after demolishing the auxiliary cables, the outer slanting cables are tensioned, the prestress is gradually built, and the configuration of the entire structure changes from a “ω” shape to an “m” shape with both ends and midpoint exhibiting a convex structure. Finally, the structure reaches the molding state.

- With increasing symmetric uniform load, the tensile stresses of the steel battens and the internal forces of all the cables gradually decrease, while the bending stresses of the steel battens increase. However, the total stresses of the steel battens do not exceed their yield strength; in this case, the steel battens are in the elastic stage during the loading steps. The measured values are basically consistent with the finite element values, and the maximum error is within 16.1% for component forces and 16.8% for deformation results.

- The SBRD is sensitive to loading arrangements. Under an asymmetric uniform load, the high loaded area exhibits a downward deflection, while the low loaded area exhibits small upward displacements, which made the overall structure behave torsionally centered by the inner compression ring.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Guo, J.; Jiang, J. An algorithm for calculating the feasible pre-stress of cable-struts structure. Eng. Struct. 2016, 118, 228–239. [Google Scholar] [CrossRef]

- Yan, X.; Yang, Y.; Chen, Z.; Ma, Q. Mechanical properties of a hybrid cable dome under non-uniform snow distribution. J. Constr. Steel Res. 2019, 153, 519–532. [Google Scholar] [CrossRef]

- Deng, H.; Li, H.; Su, C.; Jiang, Y. Monitoring and Analyzing Displacement of Large-Span Spoke-Type Cable Structure Roof. J. Surv. Eng. 2017, 143, 06017001. [Google Scholar] [CrossRef]

- Fu, X.; Gao, Y.; Xiao, C.; Tian, C. Horizontal Skyscraper: Innovative Structural Design of Shenzhen VANKE Center. J. Struct. Eng. 2012, 138, 663–668. [Google Scholar] [CrossRef]

- Liu, F.; Wang, L.; Jin, D.; Wen, H. Equivalent continuum modeling of beam-like truss structures with flexible joints. Acta Mech. Sinica 2019, 35, 1067–1078. [Google Scholar] [CrossRef]

- Liu, F.; Wang, L.; Jin, D.; Liu, X.; Lu, P. Equivalent micropolar beam model for spatial vibration analysis of planar repetitive truss structure with flexible joints. Int. J. Mech. Sci. 2020, 165, 105202. [Google Scholar] [CrossRef]

- Shen, X.; Zhang, Q.; Lee, D.S.-H.; Cai, J.; Feng, J. Static Behavior of a Retractable Suspen-Dome Structure. Symmetry 2021, 13, 1105. [Google Scholar] [CrossRef]

- Guo, J.; Zhu, M. Negative Gaussian Curvature Cable Dome and Its Feasible Prestress Design. J. Aerospace Eng. 2016, 29, 04015077. [Google Scholar] [CrossRef]

- Wan, Z.; Cao, Z.; Sun, Y.; Fan, F. Pre-stressing method and structural behaviour of a Tensairity dome with multiple inflated cushions. Thin Walled Struct. 2018, 132, 585–595. [Google Scholar] [CrossRef]

- Sibley, M.; Peña-García, A. Flat Glass or Crystal Dome Aperture? A Year-Long Comparative Analysis of the Performance of Light Pipes in Real Residential Settings and Climatic Conditions. Sustainability 2020, 12, 3858. [Google Scholar] [CrossRef]

- Thuillier, S.; Zang, S.-L.; Troufflard, J.; Manach, P.-Y.; Jegat, A. Modeling Bake Hardening Effects in Steel Sheets—Application to Dent Resistance. Metals 2018, 8, 594. [Google Scholar] [CrossRef] [Green Version]

- Yu, F.; Leng, J. Multivariable interactions in simulation-based energy-saving glass roof designs. Sol. Energy 2020, 201, 760–772. [Google Scholar] [CrossRef]

- Krentowski, J. Steel roofing disaster and the effect of the failure of butt joints. Eng. Fail. Anal. 2014, 45, 245–251. [Google Scholar] [CrossRef]

- Zhao, Z.; Wu, J.; Liu, H.; Liang, B. Influence of Friction on Buckling and Dynamic Behavior of Suspen-Dome Structures. Struct. Eng. Int. 2019, 30, 262–269. [Google Scholar] [CrossRef]

- Ruan, Y.; Luo, B.; Ding, M.; Huang, L.; Guo, Z. Theoretical and Experimental Study on the Antisliding Performance of Casting Steel Cable Clamps. Adv. Civ. Eng. 2019, 2019, 1438754. [Google Scholar] [CrossRef]

- Ding, M.; Luo, B.; Pan, J.; Guo, Z. Experimental Study and Comparative Analysis of a Geiger-Type Ridge-Beam Cable Dome Structure. Int. J. Civ. Eng. 2018, 16, 1739–1755. [Google Scholar] [CrossRef]

- Wang, B.; Li, Y. A theoretical study of super-span latticed shells. J. Constr. Steel Res. 1999, 51, 287–296. [Google Scholar] [CrossRef]

- Luo, Y.; Shen, Y.; Xu, X. Construction Method for Cylindrical Latticed Shells Based on Expandable Mechanisms. J. Constr. Eng. Manag. 2007, 133, 912–915. [Google Scholar] [CrossRef]

| Type | Conventional Cable Dome | SBRD |

|---|---|---|

| Construction method | Non-bracket or less-bracket hoist-dragging construction and traditional methods | Non-bracket or less-bracket hoist-dragging construction and traditional methods |

| Roofing material | Only expensive flexible materials can be laid | Both expensive flexible materials and low-priced rigid roofs can be laid |

| Prestress establishment | Actively tension slanting cables or hoop cables | Actively tension slanting cables or hoop cables, and passively establish prestress in the steel battens |

| Mechanical behavior | Struts and inner compression ring in compression, others in tension | Steel battens in tension and bending, struts and inner compression ring in compression, others in tension |

| Component Name | Type | Density (×103 kg/m3) | Elastic Modulus (×1011 N/m2) | Specification (mm) |

|---|---|---|---|---|

| Steel batten | Q345 | 7.85 | 2.06 | 150 × 3 |

| Outer hoop cable | 1670 MPa | 7.85 | 1.60 | Φ7.7 |

| Inner hoop cable | 1670 MPa | 7.85 | 1.60 | Φ5 |

| Outer slanting cable | 1670 MPa | 7.85 | 1.60 | Φ5 |

| Middle slanting cable | 1670 MPa | 7.85 | 1.60 | Φ5 |

| Inner slanting cable | 1670 MPa | 7.85 | 1.60 | Φ5 |

| Outer strut | Q345 | 7.85 | 2.06 | Φ34 × 4 |

| Middle strut | Q345 | 7.85 | 2.06 | Φ34 × 4 |

| Inner compression ring | Q345 | 7.85 | 2.06 | Φ34 × 4 |

| Component No. | Specification | Initial Pretension Force/N |

|---|---|---|

| Outer steel batten | Beam188 | 14,418 |

| Middle steel batten | Beam188 | 9496 |

| Inner steel batten | Beam188 | 7376 |

| Outer hoop cable | Link8 | 12,861 |

| Inner hoop cable | Link8 | 5672 |

| Outer slanting cable | Link8 | 10,994 |

| Middle slanting cable | Link8 | 4842 |

| Inner slanting cable | Link8 | 2069 |

| Outer strut | Link8 | —— |

| Middle strut | Link8 | —— |

| Inner compression ring | Beam188 | —— |

| Connecting joint | Mass21 | —— |

| Step | Original Length (mm) | |||

|---|---|---|---|---|

| Hoisting Cables | Dragging Cables | Outer Slanting Cables | ||

| Initial stage | 0 | 4560 | 720 | +120 |

| Hoist-dragging | 1 | 4380 | 570 | +120 |

| 2 | 4200 | 420 | +120 | |

| 3 | 4020 | 270 | +120 | |

| 4 | 3840 | 120 | +120 | |

| 5 | 3750 | 50 | +120 | |

| 6 | 3725 | 0 | +120 | |

| Demolish the hoisting cables and dragging cables | 7 | - | - | +120 |

| Tension the outer slanting cables | 8 | - | - | +100 |

| 9 | - | - | +80 | |

| 10 | - | - | +60 | |

| 11 | - | - | +40 | |

| 12 | - | - | +20 | |

| 13 | - | - | 0 | |

| Loading Step | Outer Steel Batten | Middle Steel Batten | Inner Steel Batten |

|---|---|---|---|

| 1 | 740 | 470 | 200 |

| 2 | 1480 | 940 | 400 |

| 3 | 2220 | 1410 | 600 |

| 4 | 2960 | 1880 | 800 |

| Loading Step | Region | Outer Steel Batten | Middle Steel Batten | Inner Steel Batten |

|---|---|---|---|---|

| 1 | High loaded area | 740 | 470 | 200 |

| Low loaded area | 740 | 470 | 200 | |

| 2 | High loaded area | 1480 | 940 | 400 |

| Low loaded area | 740 | 470 | 200 | |

| 3 | High loaded area | 2220 | 1410 | 600 |

| Low loaded area | 740 | 470 | 200 | |

| 4 | High loaded area | 2960 | 1880 | 800 |

| Low loaded area | 740 | 470 | 200 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ding, M.; Shen, Y.; Wei, Y.; Luo, B.; Wang, L.; Zhang, N. Preliminary Design and Experimental Study of a Steel-Batten Ribbed Cable Dome. Symmetry 2021, 13, 2136. https://doi.org/10.3390/sym13112136

Ding M, Shen Y, Wei Y, Luo B, Wang L, Zhang N. Preliminary Design and Experimental Study of a Steel-Batten Ribbed Cable Dome. Symmetry. 2021; 13(11):2136. https://doi.org/10.3390/sym13112136

Chicago/Turabian StyleDing, Mingmin, Yuzhou Shen, Yang Wei, Bin Luo, Lulu Wang, and Ningyuan Zhang. 2021. "Preliminary Design and Experimental Study of a Steel-Batten Ribbed Cable Dome" Symmetry 13, no. 11: 2136. https://doi.org/10.3390/sym13112136

APA StyleDing, M., Shen, Y., Wei, Y., Luo, B., Wang, L., & Zhang, N. (2021). Preliminary Design and Experimental Study of a Steel-Batten Ribbed Cable Dome. Symmetry, 13(11), 2136. https://doi.org/10.3390/sym13112136