A Novel Method of Using Vision System and Fuzzy Logic for Quality Estimation of Resistance Spot Welding

Abstract

1. Introduction

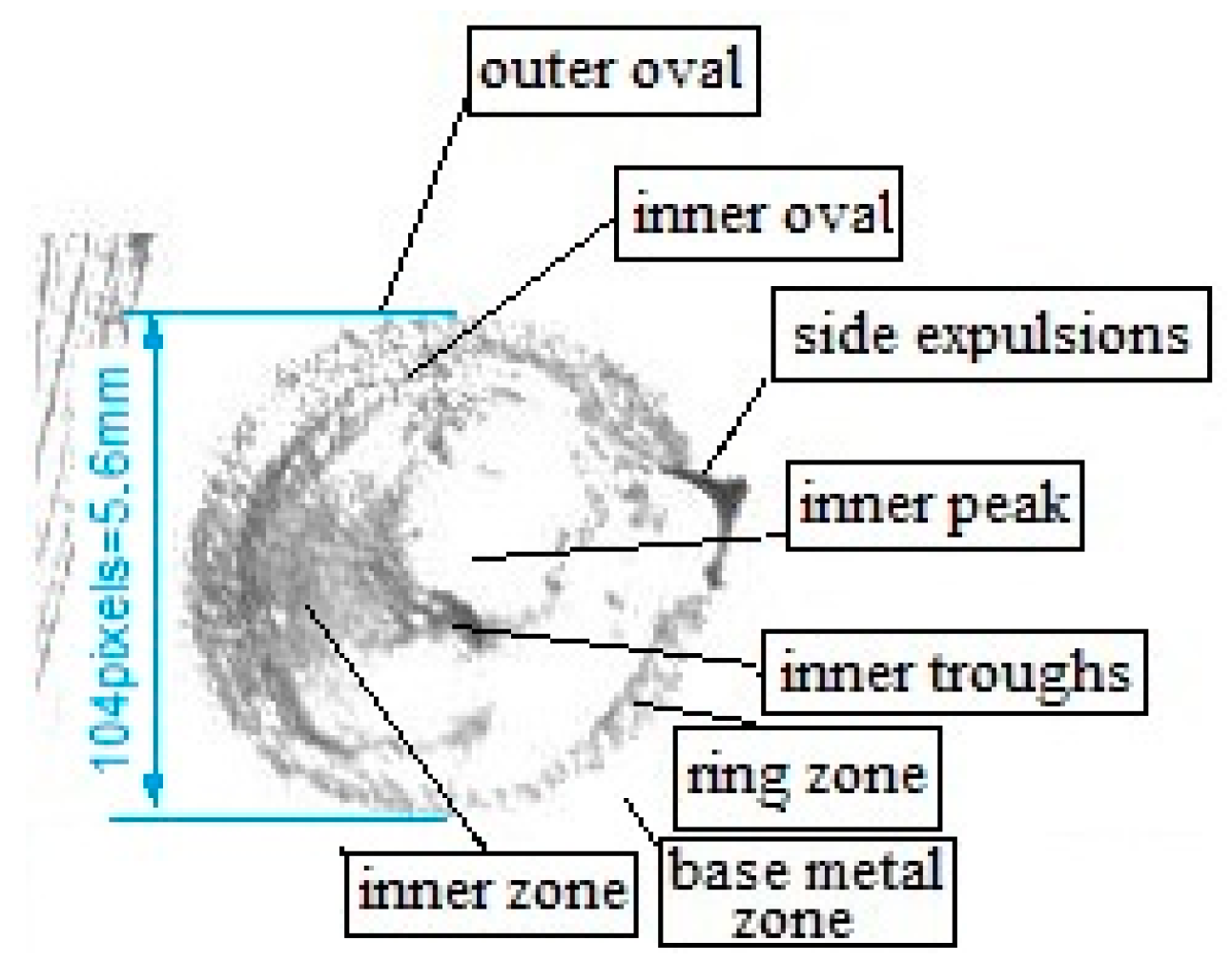

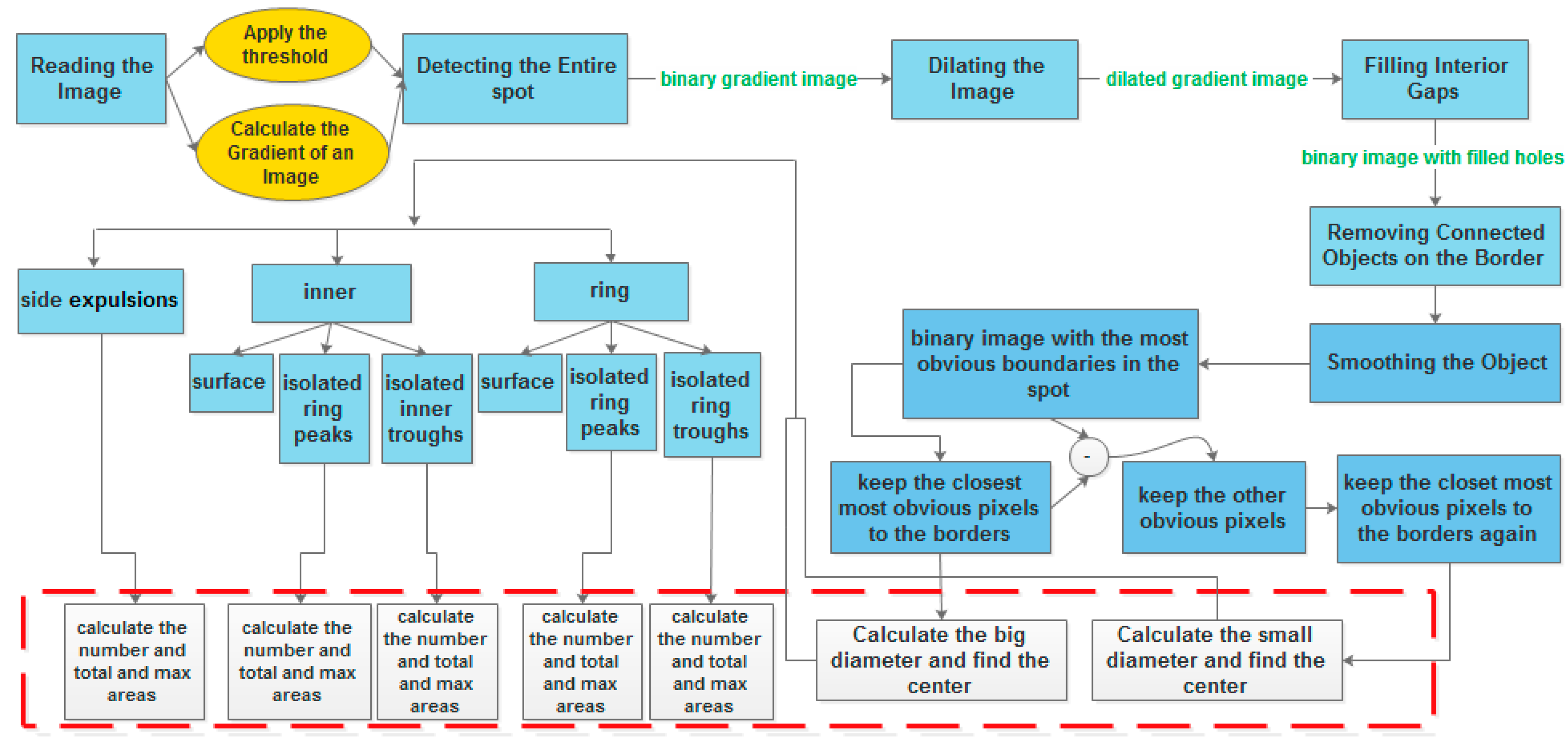

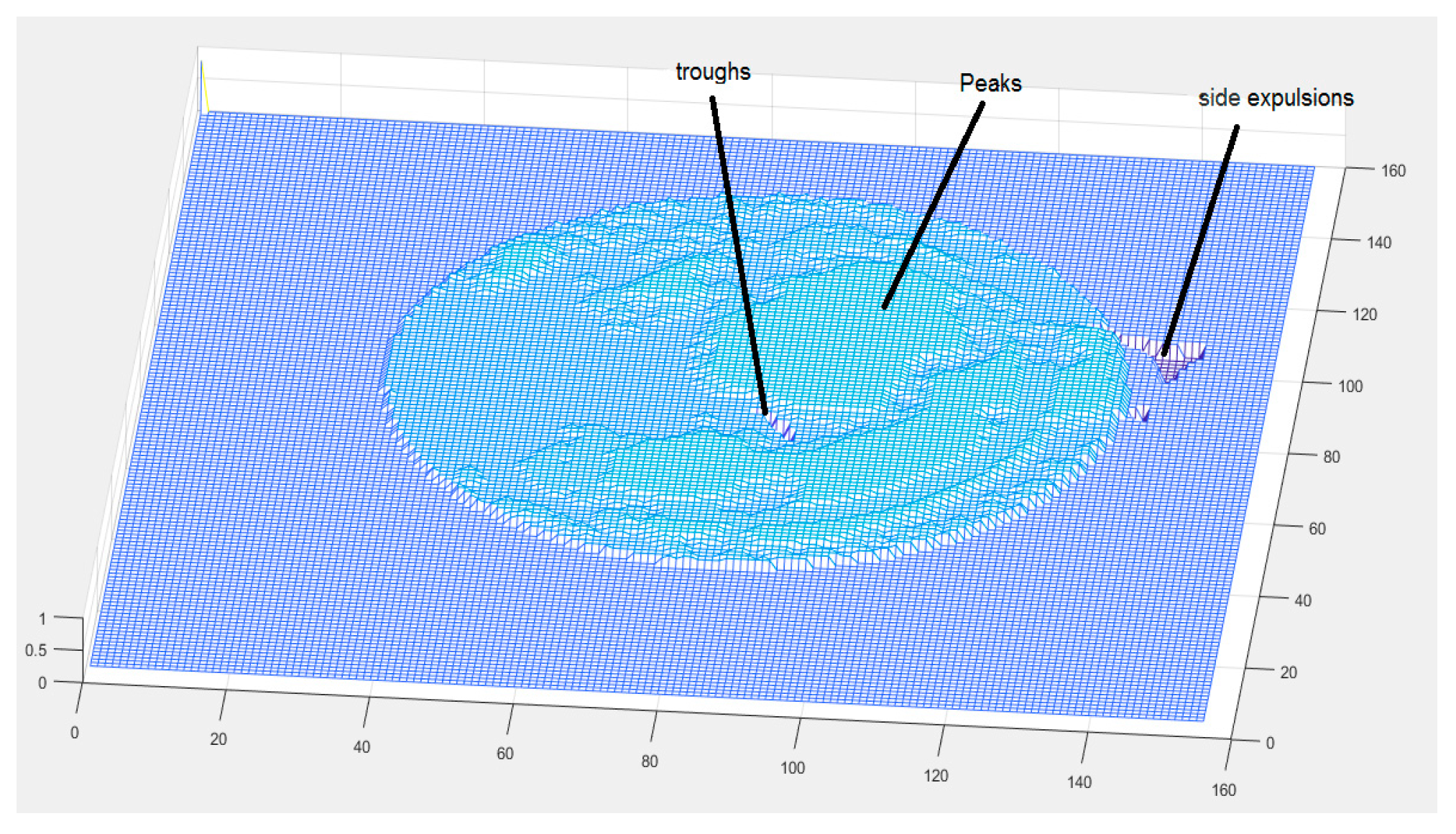

- The number and areas of all side expulsions.

- The number and areas of all the isolated peaks inside and outside the fusion zone.

- The number and areas of all the isolated troughs which refer to the existence of voids (blow holes), cracks, or pitting inside and outside the fusion zone.

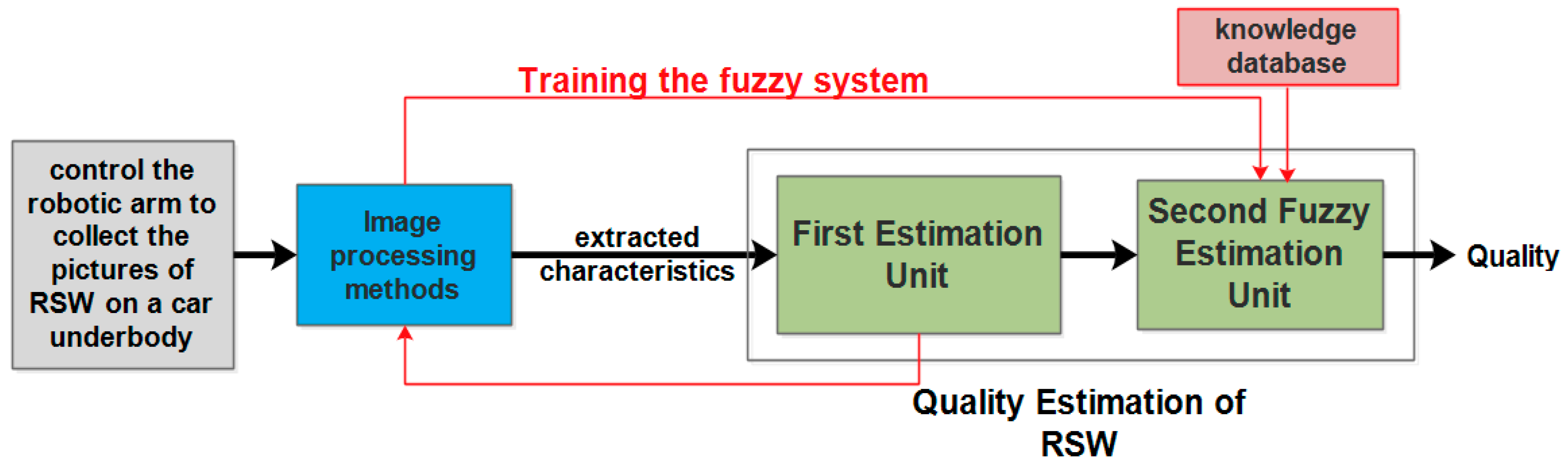

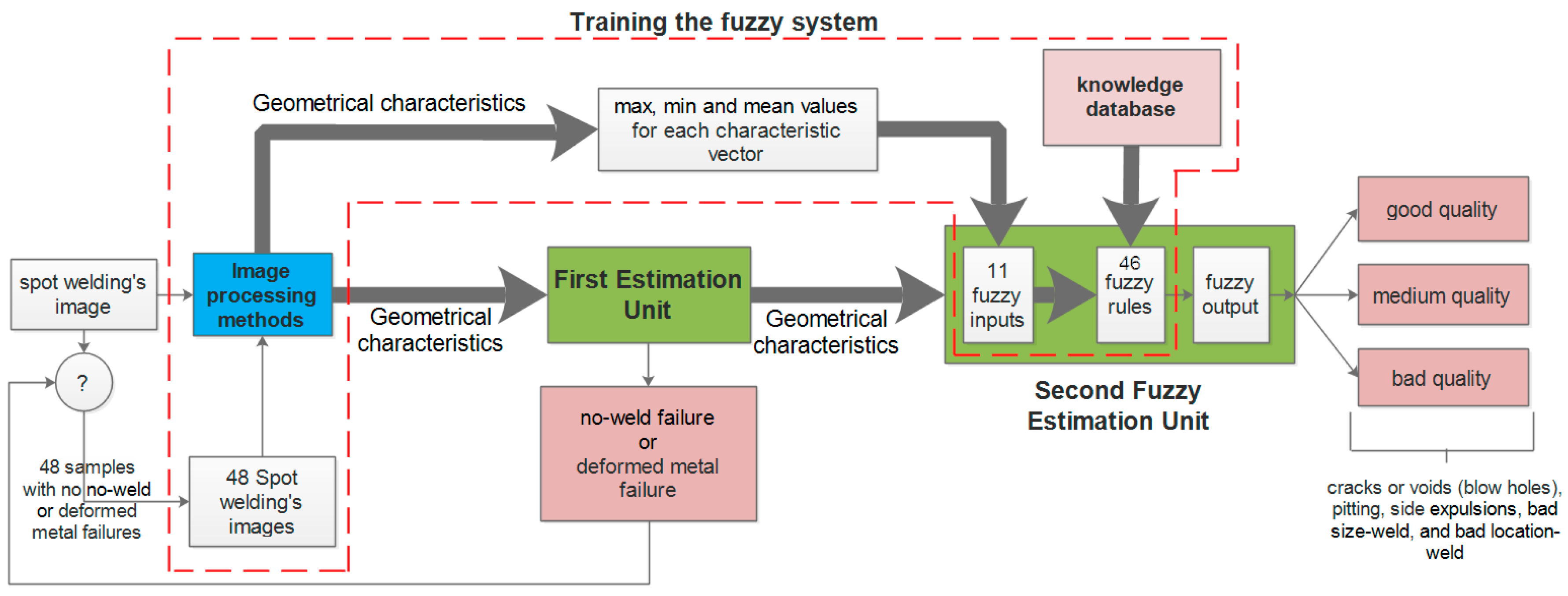

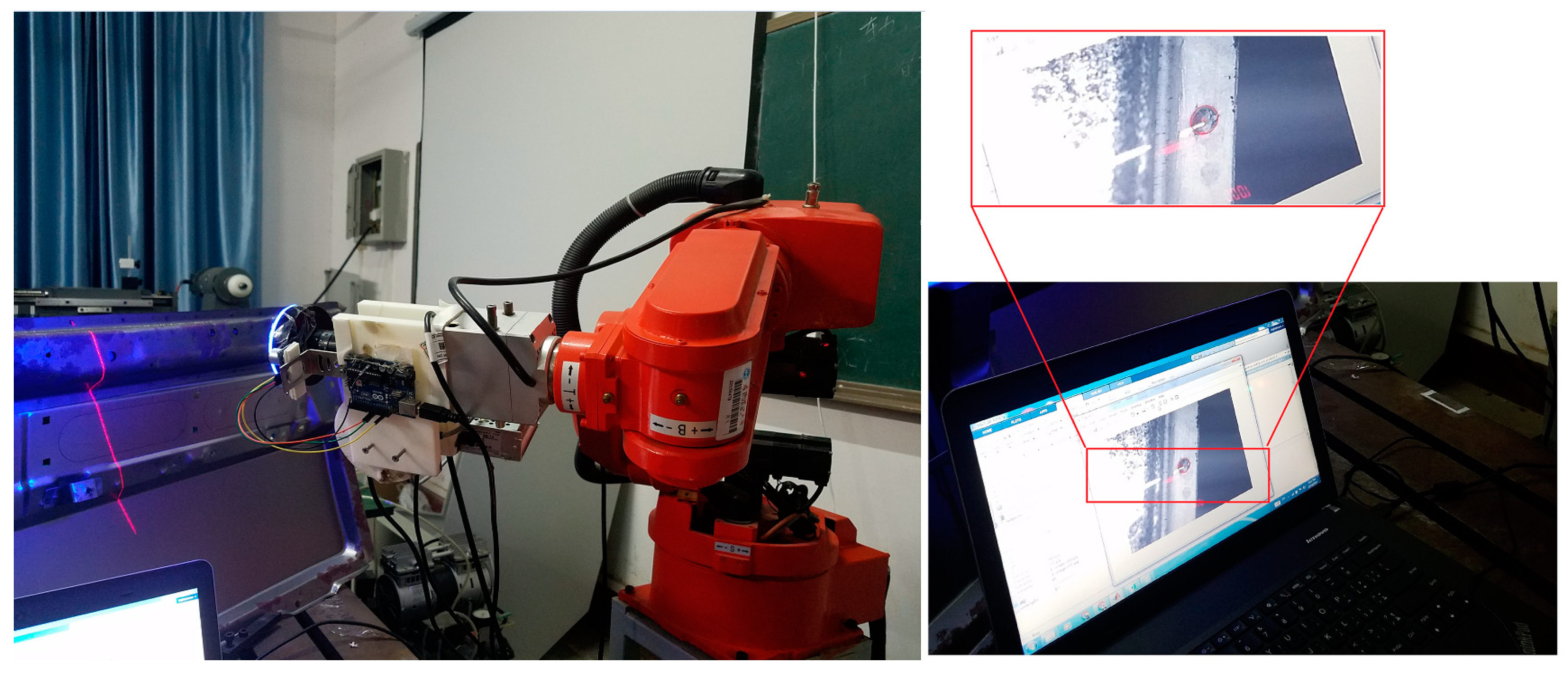

2. Resistance Spot Welding Quality Vision-Estimation System

2.1. System’s Structure

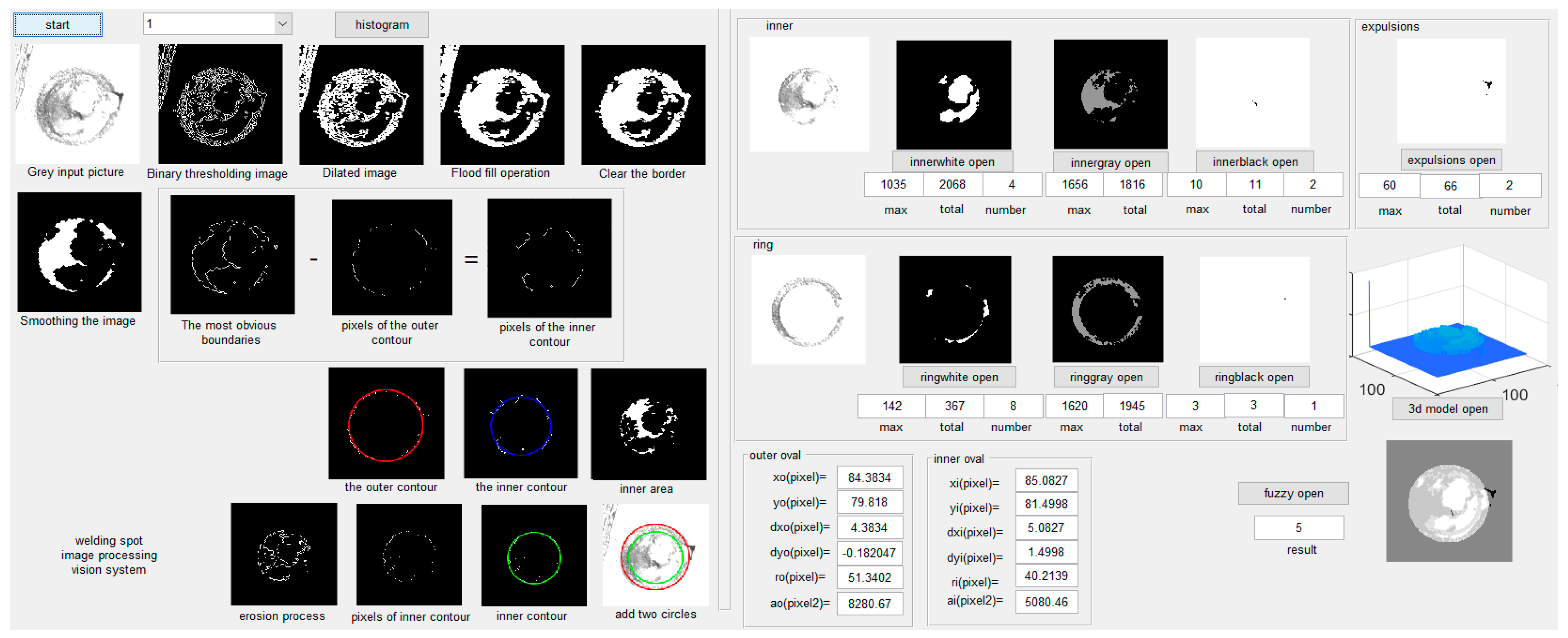

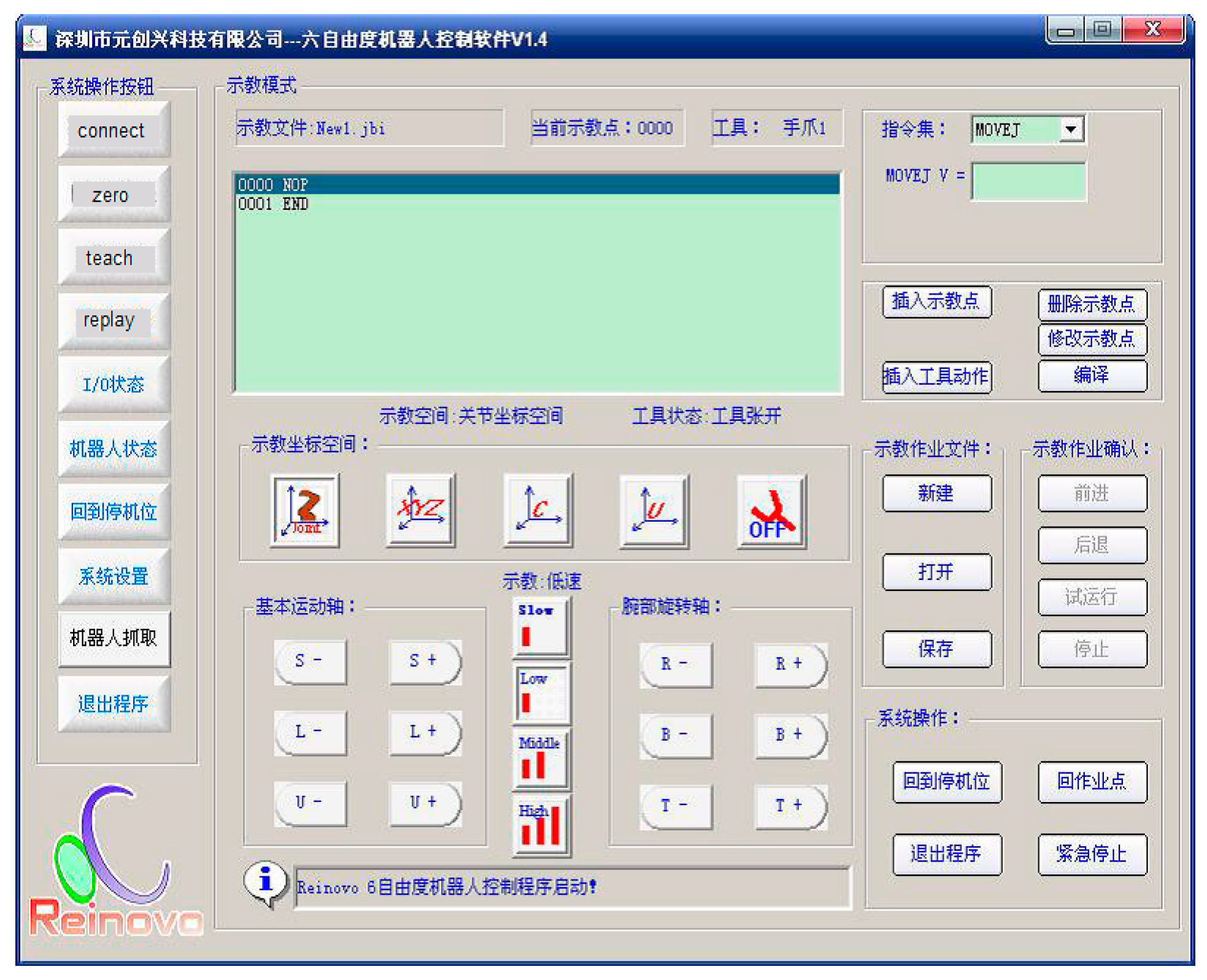

2.2. The System’s Software Interface

3. Image Processing System Methodology of Resistance Spot Welding

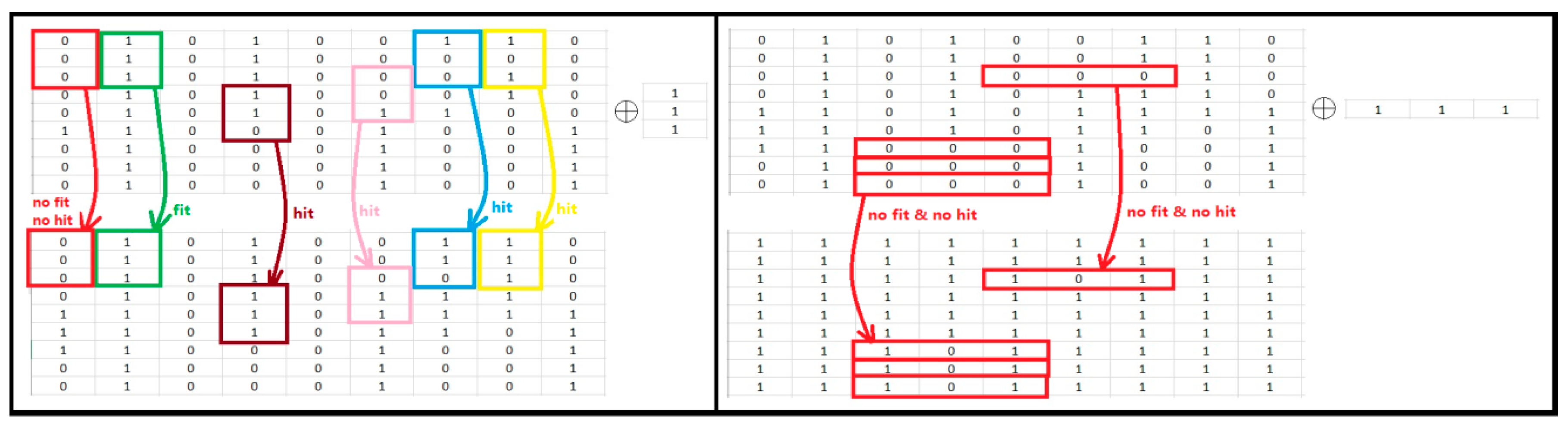

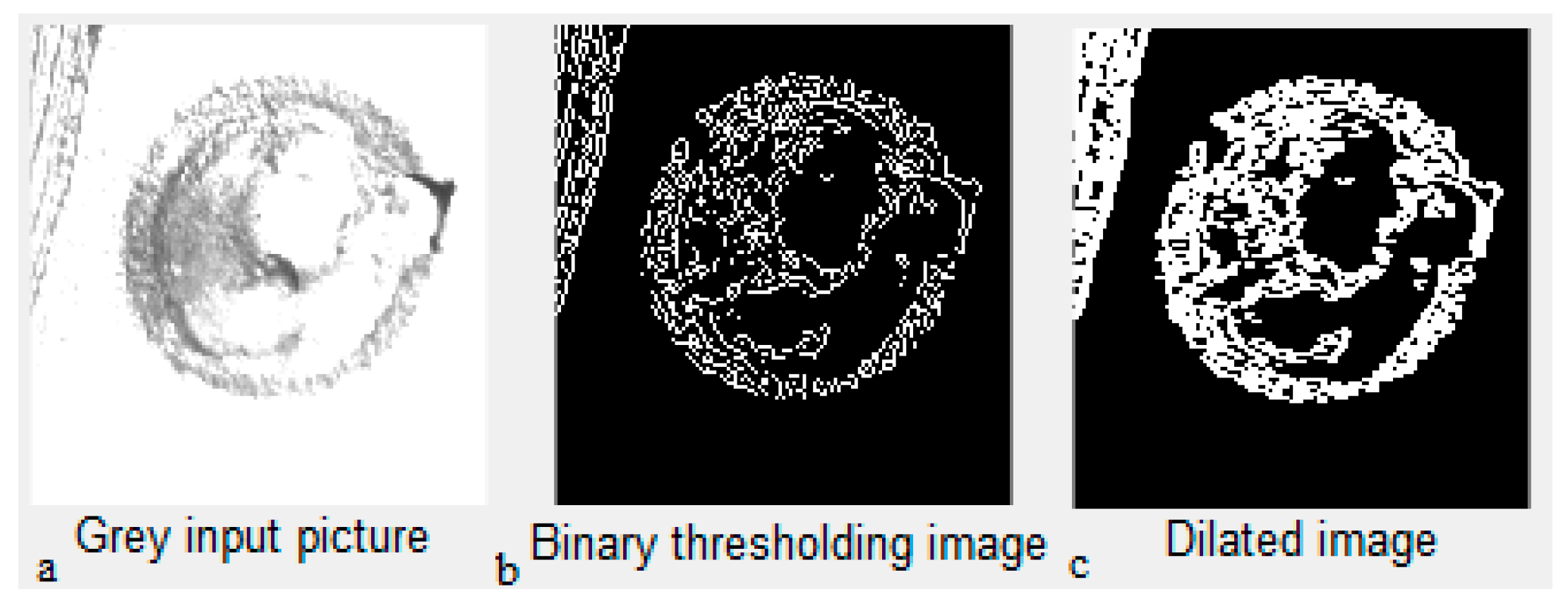

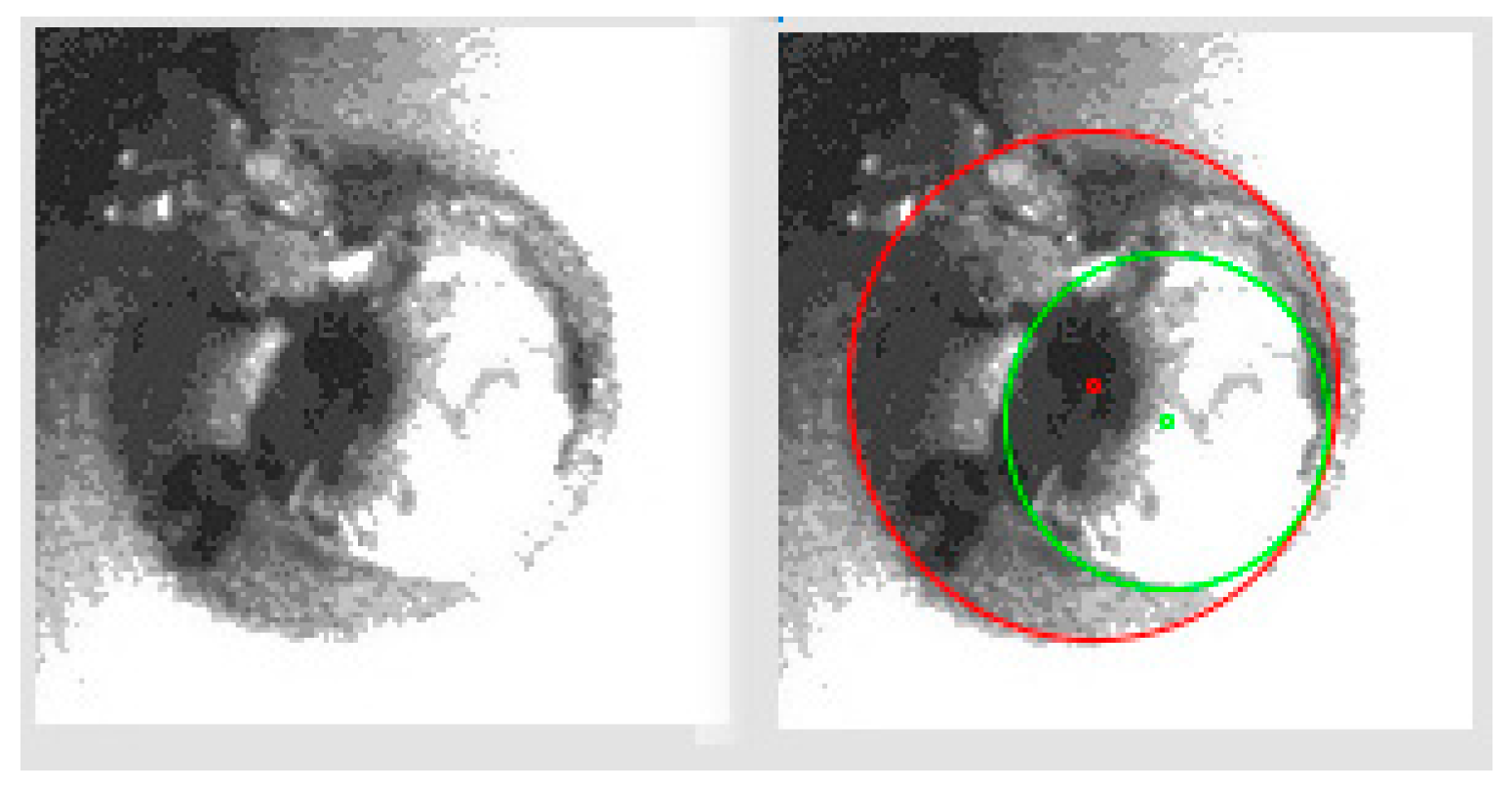

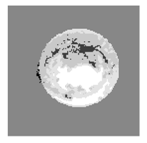

3.1. Segmentation Operation, Thresholding Process and Dilation Morphological Operation

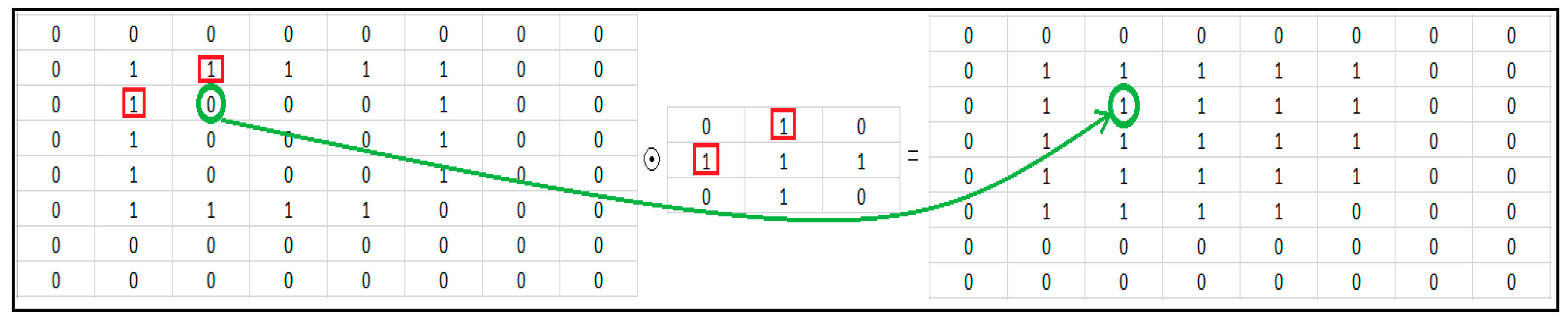

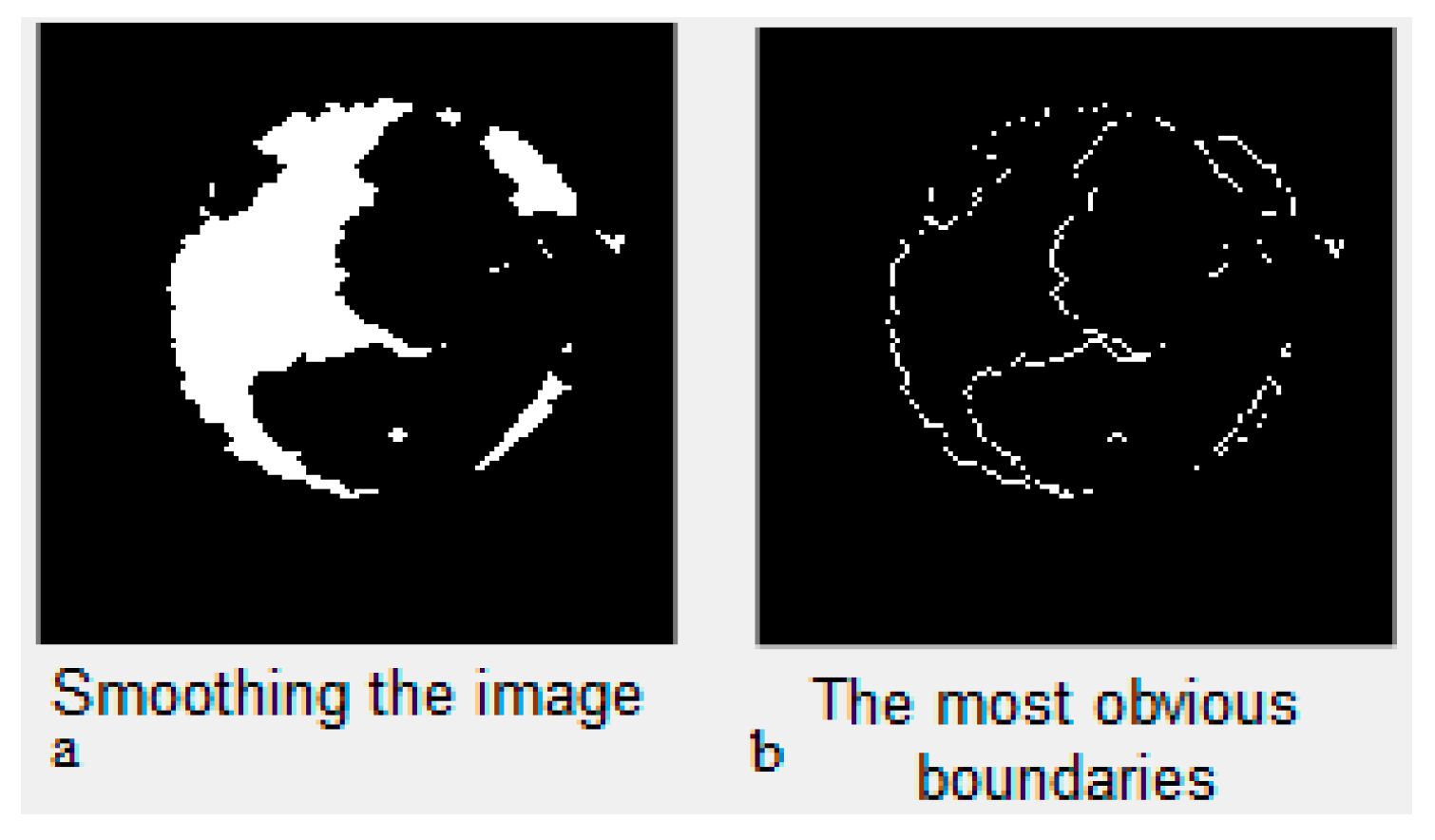

3.2. Flood-Fill Operation, Borders Clearance and Smoothing Operation

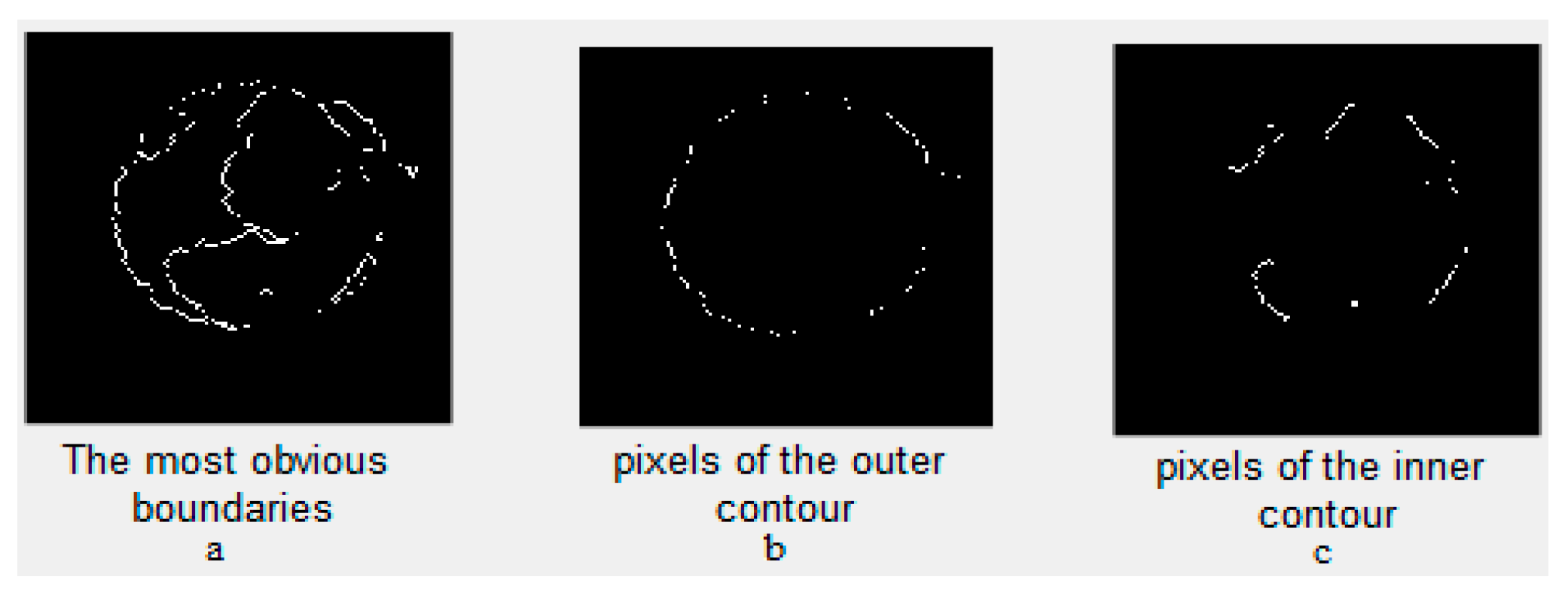

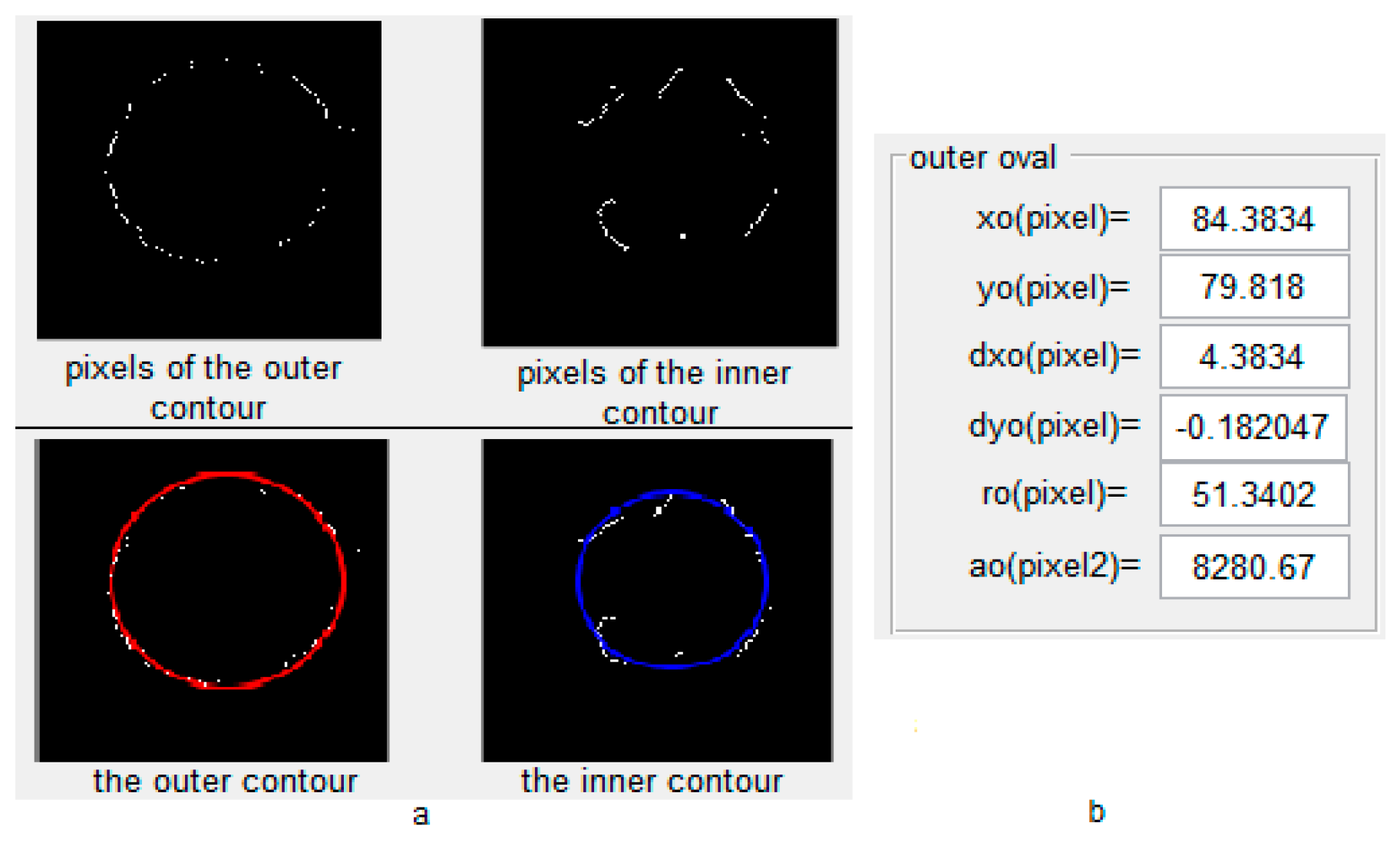

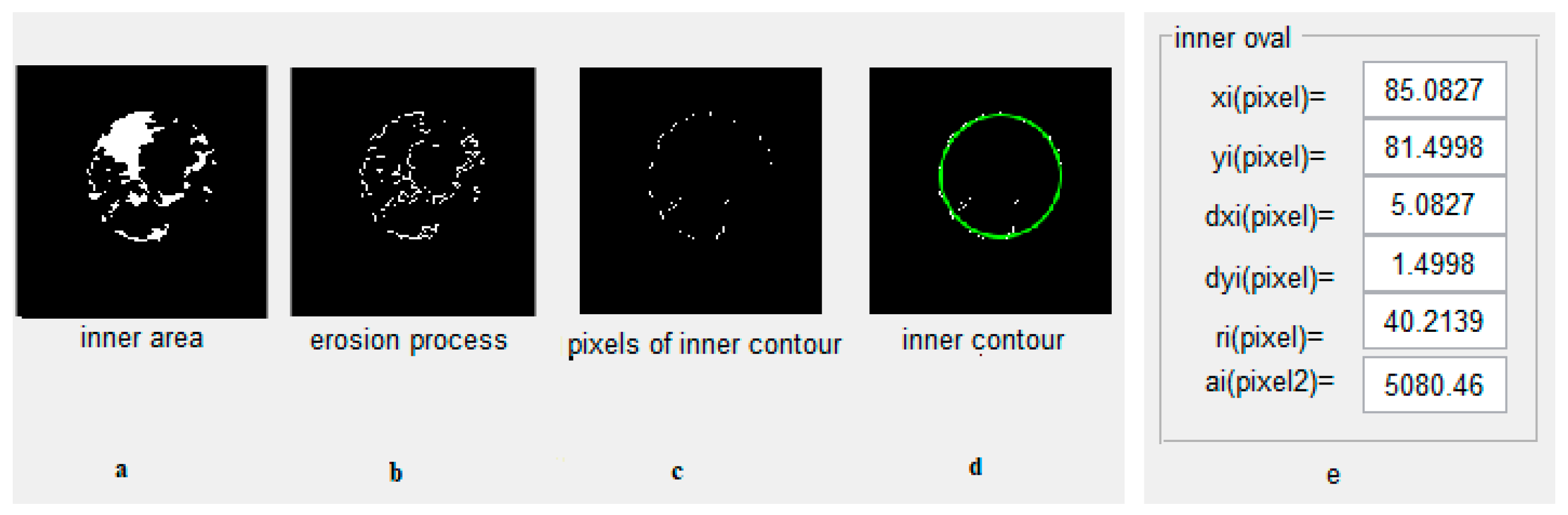

3.3. Contours Detection, Location Based Selection of Pixels Method and Least-Squares Fitting Curve Algorithm

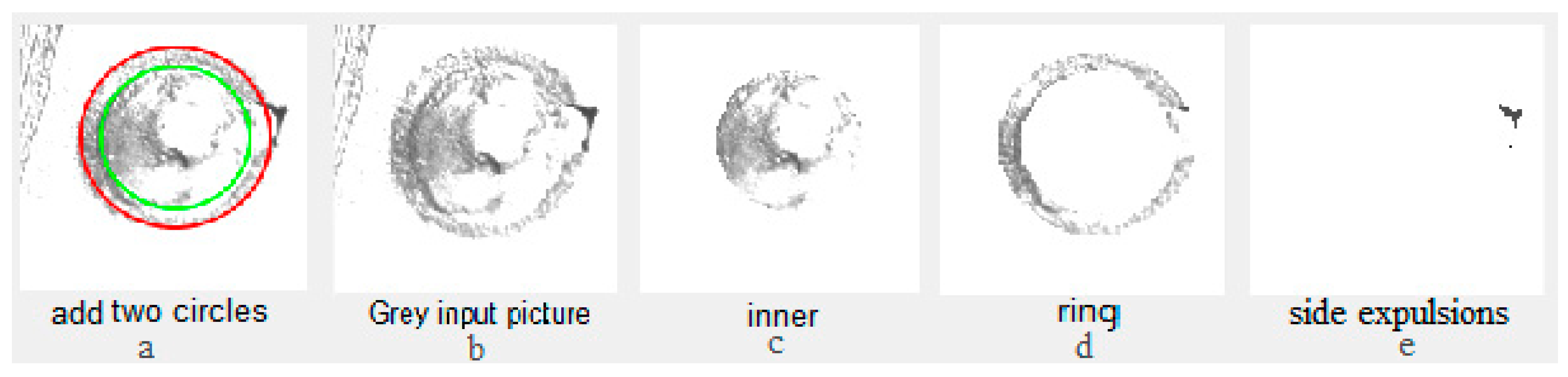

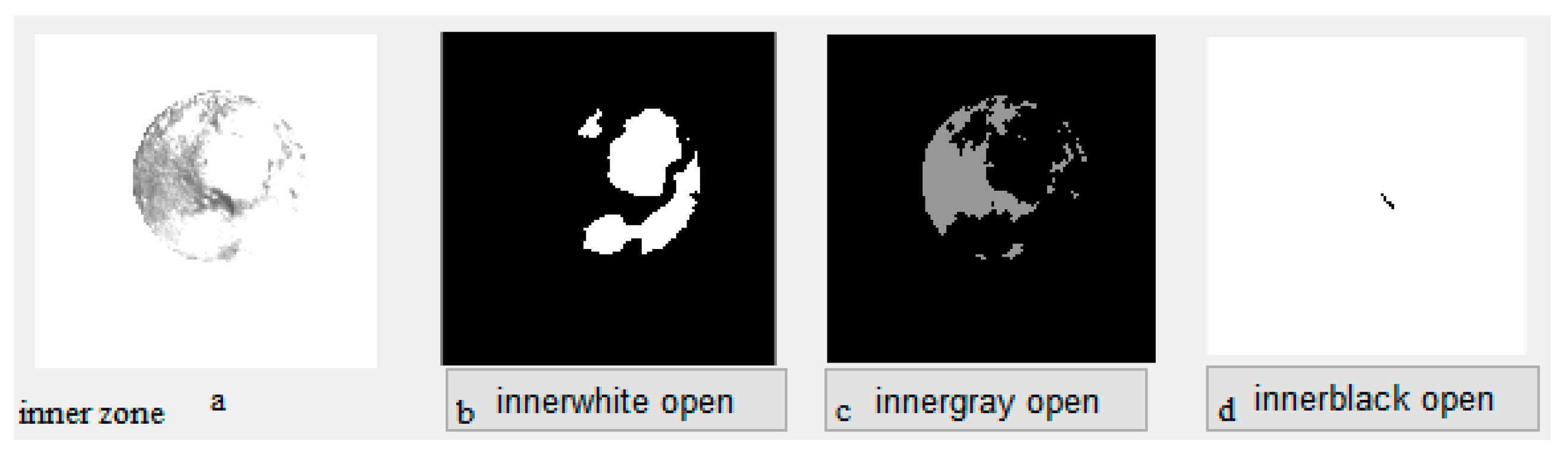

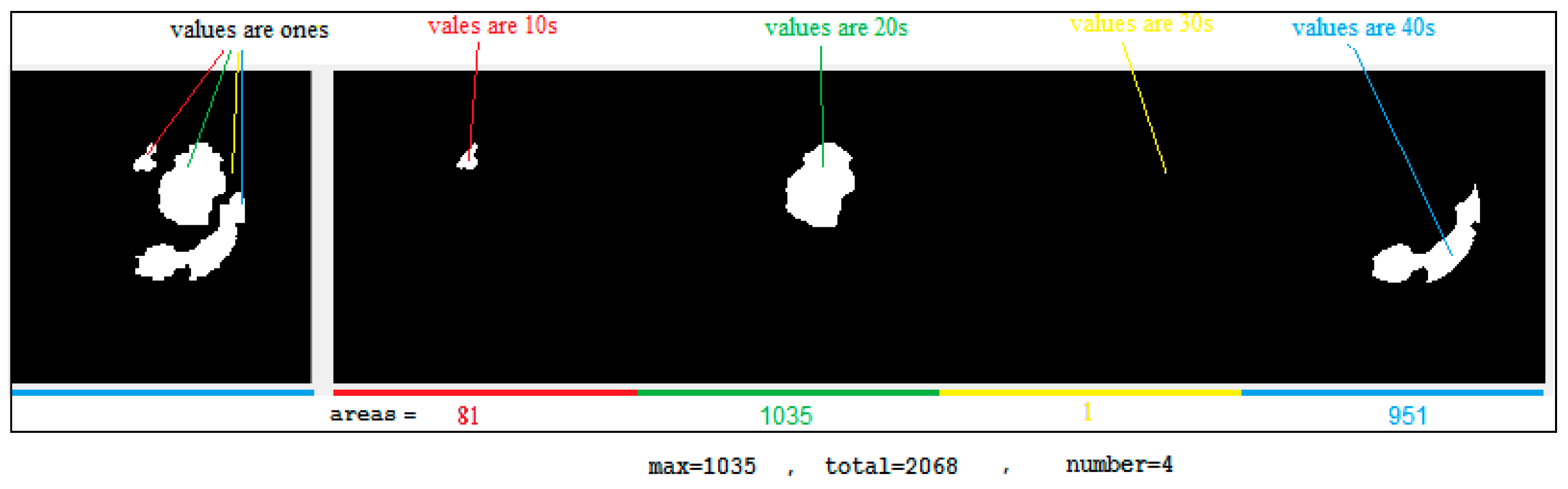

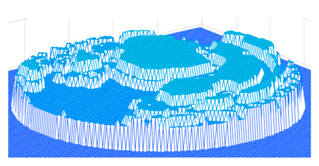

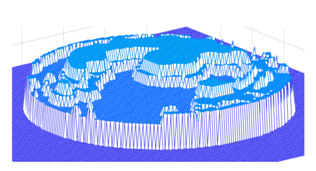

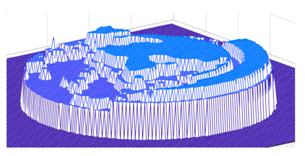

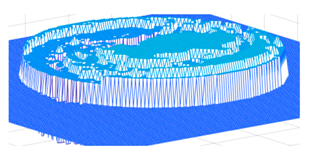

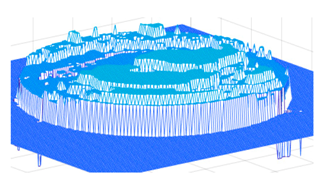

3.4. Zones Division, Value Based Selection of Pixels Method and 3D Model of the Weld Nugget

4. Quality Estimation of Resistance Spot Welding

4.1. The First Estimation Unit

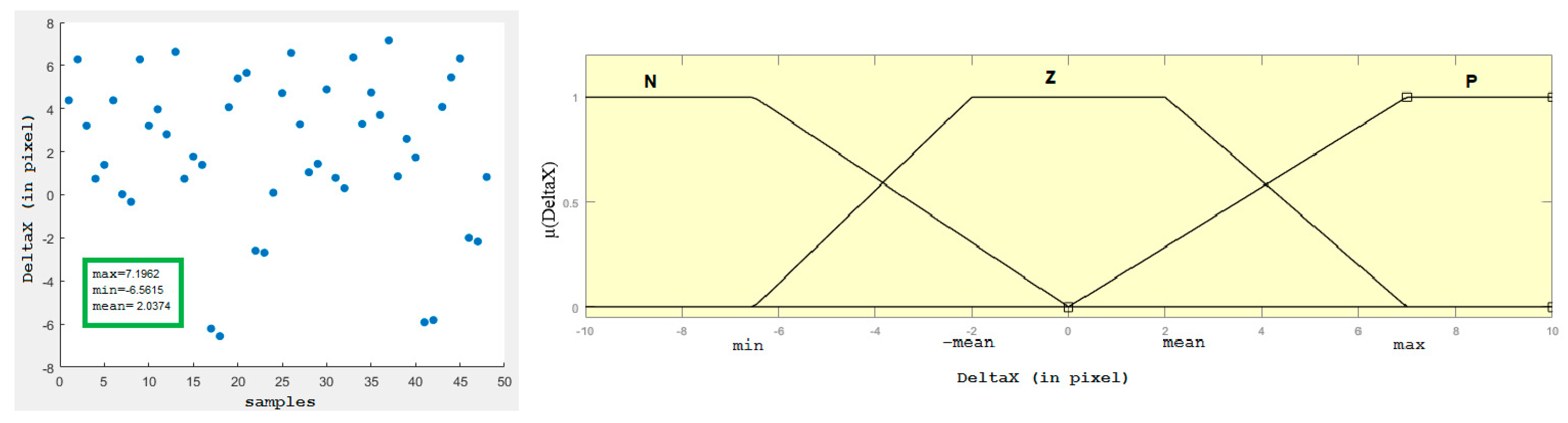

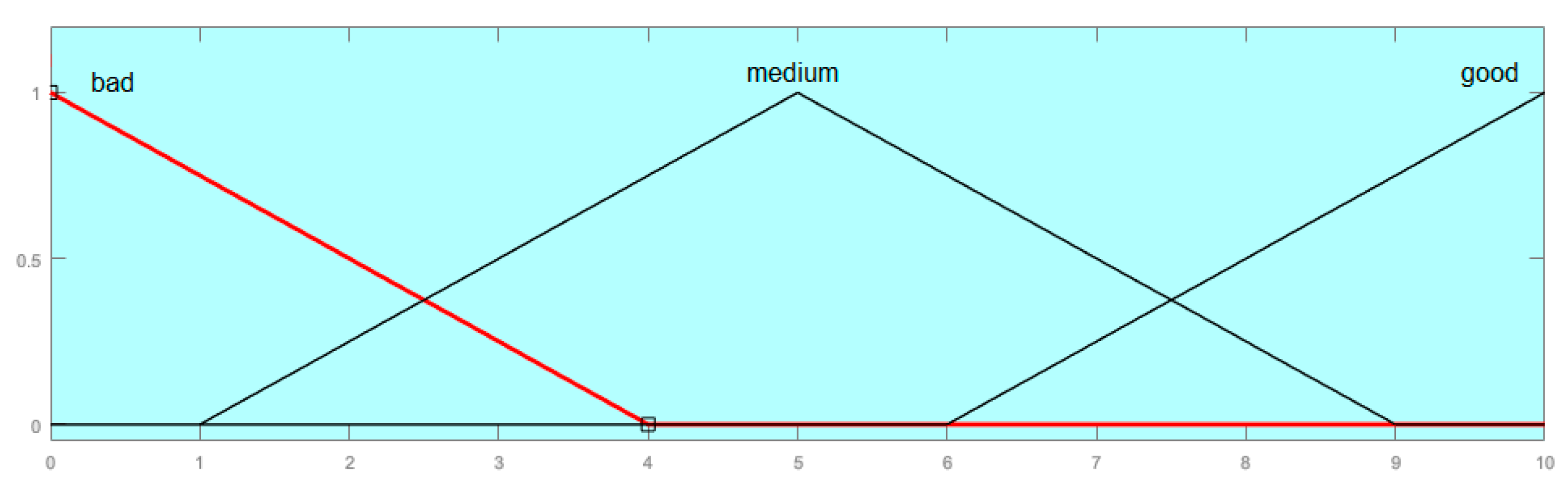

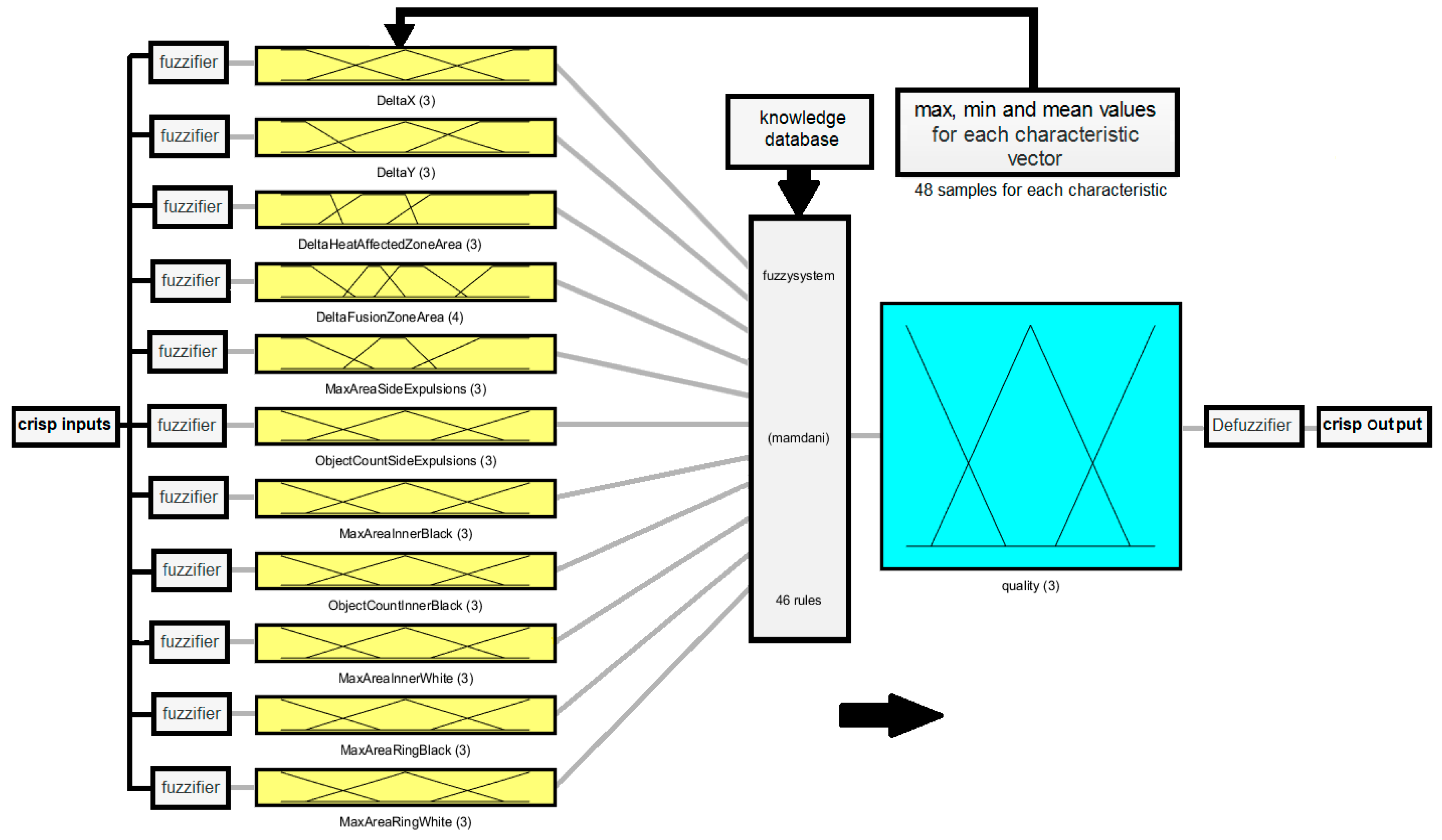

4.2. The Second Fuzzy Estimation Unit

- If [(deltaX is N) and (deltaY is N) and (DeltaHeatAffectedZoneArea is N) and (DeltaFusionZoneArea is N) and (MaxAreaSideExpulsions is B) and (ObjectCountSideExpulsions is B) and (MaxAreaInnerBlack is B) and (ObjectCountInnerBlack is B) and (MaxAreaInnerWhite is S) and (MaxAreaRingBlack is B) and (MaxAreaRingWhite is S)] then (quality is bad).

- If [(deltaX is P) and (deltaY is P) and (DeltaHeatAffectedZoneArea is P) and (DeltaFusionZoneArea is P) and (MaxAreaSideExpulsions is B) and (ObjectCountSideExpulsions is B) and (MaxAreaInnerBlack is B) and (ObjectCountInnerBlack is B) and (MaxAreaInnerWhite is S) and (MaxAreaRingBlack is B) and (MaxAreaRingWhite is S)] then (quality is bad).

- If [(deltaX is Z) and (deltaY is Z) and (DeltaHeatAffectedZoneArea is Z) and (DeltaFusionZoneArea is Z) and (MaxAreaSideExpulsions is S) and (ObjectCountSideExpulsions is S) and (MaxAreaInnerBlack is S) and (ObjectCountInnerBlack is S) and (MaxAreaInnerWhite is B) and (MaxAreaRingBlack is S) and (MaxAreaRingWhite is B)] then (quality is good).

5. Experimental Work

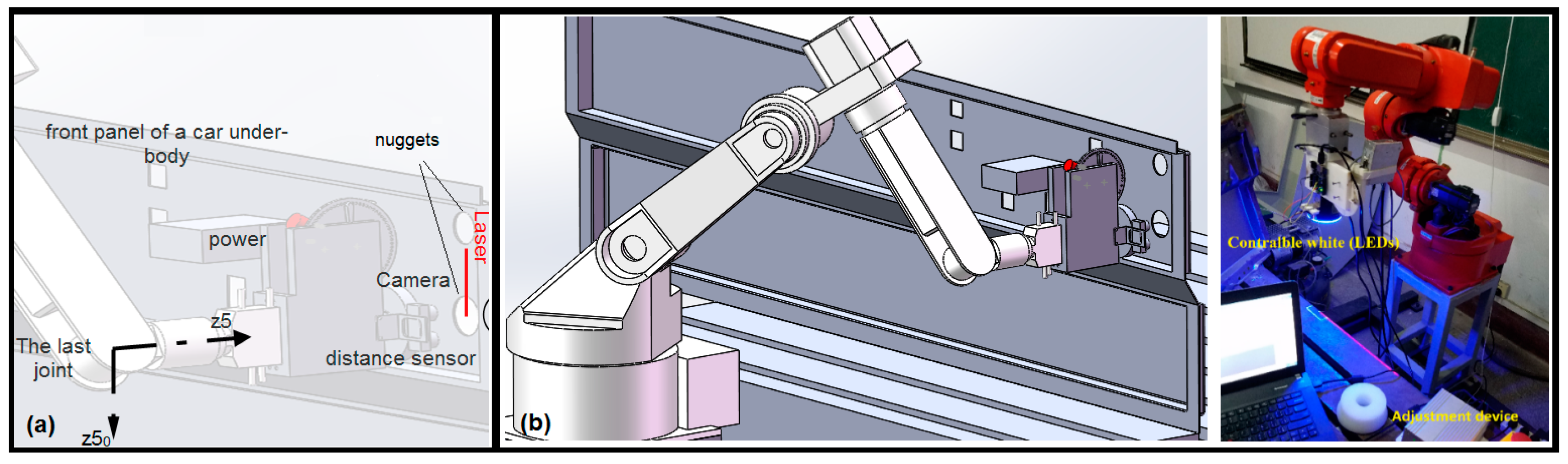

5.1. Collect the Pictures of the Weld Nuggets on a Car Underbody

- The axis z5 of the 5th joint or the last joint, which is also the axis of the camera, must be perpendicular to the weld nugget’s surface.

- The best distance between the end effector and the nugget’s surface (d + s) is measured for the first nugget after considering the best clearance of the picture shown by the camera.

- The best value (30 cm) of s is measured by a light distance sensor, and has to be used for all the weld nuggets on the body.

5.2. Results

5.3. Discussion

6. Conclusions

- The extracted geometrical characteristics include:

- The weld nugget’s shape and center’s location.

- The smallest radius and the inner area of fusion zone of a weld nugget.

- The largest radius and the whole area of the heat-affected zone of a weld nugget.

- The number and areas of all side expulsions.

- The number and areas of all the isolated inner peaks

- The number and areas of all the isolated inner troughs which refer to the existence of voids (blow holes), cracks, or pitting inside and outside the fusion zone.

- The number and areas of all the isolated ring peaks.

- The number and areas of all the isolated ring troughs which refer to the existence of voids (blow holes), cracks, or pitting inside and outside the fusion zone.

- The topography of the weld nugget’s surface is concluded and shown as a 3D model.

- The results of the study concluded that the estimation of the 3D model of the weld nugget’s surface reaches a very high accuracy.

- The proposed system shows high accuracy in detecting different kinds of defects such as the deformed metal failure, the no-weld failure, the existence of side expulsions, cracks, voids (blow holes), pitting, bad size-weld, and bad location-weld.

- The execution time of the methods for each weld nugget is about 50 ms.

Author Contributions

Funding

Conflicts of Interest

References

- Tianhu, S. Application of welding technology in automotive manufacturing. Aeronaut. Manuf. Technol. 2004, 3, 24–27. [Google Scholar]

- Akkaş, N. Welding time effect on tensile-shear loading in resistance spot welding of SPA-H weathering steel sheets used in railway vehicles. Acta Phys. Pol. A 2017, 131, 52–54. [Google Scholar] [CrossRef]

- Pouranvari, M.; Marashi, S.P.H. Critical review of automotive steels spot welding: Process, structure and properties. Sci. Technol. Weld. Join. 2013, 18, 361–403. [Google Scholar] [CrossRef]

- Lan, Z.; Jianwei, Y.; Jing, C. Present status and trend analysis of quality monitor technique for resistance spot welding. J. Hubei Univ. Technol. 2008, 23, 38–45. [Google Scholar]

- Patange, S.; Anjaneyulu, T.; Reddy, G. Microprocessor-based resistance welding monitor. Weld. J. 1985, 25, 33–38. [Google Scholar]

- Dickinson, D.W.; Franklin, J.E.; Stanya, A. Characterization of spot welding behavior by dynamic electrical parameter monitoring. Weld. J. 1980, 59, 170–176. [Google Scholar]

- Gedeon, S.A.; Sorensen, C.D.; Ulrich, K.T.; Eagar, T.W. Measurement of dynamic electrical and mechanical properties of resistance spot welds. Weld. Res. Suppl. 1987, 66, 378–385. [Google Scholar]

- Hao, M.; Osman, K.A.; Boomer, D.R.; Newton, C.J. Developments in characterization of resistance spot welding of aluminum. Weld. J. 1996, 75, 1. [Google Scholar]

- Brown, J.D.; Rodd, M.G.; Williams, N.T. Application of artificial intelligence techniques to resistance spot welding. Ironmak. Steelmak. 1998, 25, 199–204. [Google Scholar]

- Dilthey, U.; Dickersbach, J. Application of neural networks for quality evaluation of resistance spot welds. ISIJ Int. 1999, 39, 10. [Google Scholar] [CrossRef][Green Version]

- Cho, Y.; Rhee, S. Quality estimation of resistance spot welding by using pattern recognition with neural networks. IEEE Trans. Instrum. Meas. 2004, 53, 330–334. [Google Scholar] [CrossRef]

- Hwang, I.; Yun, H.; Yoon, J.; Kang, M.; Kim, D.; Kim, Y.M. Prediction of resistance spot weld quality of 780 MPa grade steel using adaptive resonance theory artificial neural networks. Metals 2018, 8, 453. [Google Scholar] [CrossRef]

- Athi, N.; Wylie, S.R.; Cullen, J.D.; Al-Shamma’a, A.I.; Sun, T. Ultrasonic non-destructive evaluation for spot welding in the automotive industry. In Proceedings of the IEEE Sensors, Christchurch, New Zealand, 25–28 October 2009; pp. 1518–1523. [Google Scholar]

- Liu, J.; Xu, G.; Ren, L.; Qian, Z.; Ren, L. Defect intelligent identification in resistance spot welding ultrasonic detection based on wavelet packet and neural network. Int. J. Adv. Manuf. Technol. 2017, 90, 2581–2588. [Google Scholar] [CrossRef]

- Podržaj, P.; Polajnar, I.; Diaci, J.; Kariž, Z. Estimating the strength of resistance spot welds based on sonic emission. Sci. Technol. Weld. Join. 2005, 10, 399–405. [Google Scholar] [CrossRef]

- Tsukada, K.; Yoshioka, M.; Kiwa, T.; Hirano, Y. A magnetic flux leakage method using a magnetoresistive sensor for nondestructive evaluation of spot welds. NDT E Int. 2011, 44, 101–105. [Google Scholar] [CrossRef]

- Harada, D.; Sakai, K.; Kiwa, T.; Tsukada, K. Analysis of the internal structure of a spot-weld by magnetic measurement. In Proceedings of the Singapore International NDT Conference & Exhibition, Singapore, 19–20 July 2013. [Google Scholar]

- Tsukada, K.; Miyake, K.; Harada, D.; Sakai, K.; Kiwa, T. Magnetic nondestructive test for resistance spot welds using magnetic flux penetration and eddy current methods. J. Nondestruct. Eval. 2013, 32, 286–293. [Google Scholar] [CrossRef]

- Abdulhadi, A.; Gdeisat, M.; Burton, D.; Lilley, F. Assessing the quality of spot welding electrode tips using image processing techniques. Proc. World Congr. Eng. 2011, 2, 4–9. [Google Scholar]

- Simončič, S.; Podržaj, P. Image-based electrode tip displacement in resistance spot welding. Meas. Sci. Technol. 2012, 23, 6. [Google Scholar] [CrossRef]

- Podržaj, P.; Simončič, S. A machine vision-based electrode displacement measurement. Weld. World. 2014, 58, 93–99. [Google Scholar] [CrossRef]

- Simončič, S.; Podržaj, P. Resistance spot weld strength estimation based on electrode tip displacement/velocity curve obtained by image processing. Sci. Technol. Weld. Join. 2014, 19, 468–475. [Google Scholar] [CrossRef]

- Ruisz, J.; Biber, J.; Loipetsberger, M. Quality evaluation in resistance spot welding by analysing the weld fingerprint on metal bands by computer vision. Int. J. Adv. Manuf. Technol. 2007, 33, 952–960. [Google Scholar] [CrossRef]

- Yang, O.; Li, Y. Quality evaluation and automatic classification in resistance spot welding by analyzing the weld image on metal bands by computer vision. Int. J. Signal Process. Image Process. Pattern Recognit. 2015, 8, 301–314. [Google Scholar]

- Zhanfeng, H.; Pei, W.; Jing, X.; Jingyu, H. Application of fractal theory in examination of resistance spot welding quality. Mater. Sci. Technol. 2010, 17, 422–424. [Google Scholar]

- Ye, S.; Guo, Z.; Zheng, P.; Wang, L.; Lin, C. A vision inspection system for the defects of resistance spot welding based on neural network. In International Conference on Computer Vision Systems; Lecture Notes in Computer Science; Springer: Cham, Switzerland, 2017; pp. 161–168. [Google Scholar]

- Yang, Y.; Zheng, P.; He, H.; Zheng, T.; Wang, L.; He, S. An evaluation method of acceptable and failed spot welding products based on image classification with transfer learning technique. In Proceedings of the 2nd International Conference on Computer Science and Application Engineering (CSAE2018), Hohhot, China, 22–24 October 2018. [Google Scholar]

- Chen, J.; Feng, Z. IR-based spot weld NDT in automotive applications. Proc. SPIE 2015, 9485, 948513. [Google Scholar]

- Chen, J.; Feng, Z. Online resistance spot weld NDE using infrared thermography. Proc. SPIE 2017, 10169, 101690K. [Google Scholar]

- Božanić, D.; Pamučar, D.; Bojanić, D. Modification of the analytic hierarchy process (AHP) method using fuzzy logic: Fuzzy AHP approach as a support to the decision making process concerning engagement of the group for additional hindering. Serbian J. Manag. 2015, 10, 151–171. [Google Scholar] [CrossRef]

- Pamučar, D.; Božanić, D.; Lukovac, V.; Komazec, N. Normalized weighted geometric bonferroni mean operator of interval rough numbers—Application in interval rough dematel-copras. Facta Univ. Ser. Mech. Eng. 2018, 16, 171. [Google Scholar] [CrossRef]

- Pamučar, D.; Stević, Ž.; Sremac, S. A new model for determiningweight coefficients of criteria in MCDM models: Full consistency method (FUCOM). Symmetry 2018, 10, 393. [Google Scholar] [CrossRef]

- Pratt, V. Direct least-squares fitting of algebraic surfaces. ACM SIGGRAPH Comput. Graph. 2005, 21, 145–152. [Google Scholar] [CrossRef]

| Weld No. | Input | Weld Nugget Features Extractions | Output | |||||

|---|---|---|---|---|---|---|---|---|

| Gray Image | Contours Detection | (xo,yo) | Segmented Areas | (M,T,N) M = Max T = Total N = Number | 3D Model and Digital Image of the Surface | Quality | ||

| (dxo,dyo) | ||||||||

| (xi,yi) | ||||||||

| (dxi,dyi) | ||||||||

| (ro,ri) | ||||||||

| 1 |  |  | (84,80) | Inner white | (1035,2068,4) |  |  | 5.3 |

| (4,0) | Inner black | (10,11,2) | ||||||

| (85,81) | Ring white | (142,367,8) | ||||||

| (5,1) | Ring black | (3,3,1) | ||||||

| (51,40) | Side expulsions | (60,66,2) | ||||||

| 2 |  |  | (86,81) | Inner white | (3502,3503,2) |  |  | 8.7 |

| (6,1) | Inner black | (0,0,0) | ||||||

| (84,80) | Ring white | (479,490,2) | ||||||

| (4,0) | Ring black | (0,0,0) | ||||||

| (51,40) | Side expulsions | (0,0,0) | ||||||

| 3 |  |  | (83,85) | Inner white | (1766,1766,1) |  |  | 8 |

| (3,5) | Inner black | (0,0,0) | ||||||

| (81,85) | Ring white | (218,316,5) | ||||||

| (1,5) | Ring black | (4,4,1) | ||||||

| (51,39) | Side expulsions | (5,6,2) | ||||||

| 4 |  |  | (81,80) | Inner white | (1864,1864,1) |  |  | 8.2 |

| (1,0) | Inner black | (0,0,0) | ||||||

| (81,81) | Ring white | (357,434,2) | ||||||

| (1,1) | Ring black | (6,15,6) | ||||||

| (52,40) | Side expulsions | (4,4,1) | ||||||

| 5 |  |  | (81,85) | Inner white | (1407,1595,5) |  |  | 8.3 |

| (1,5) | Inner black | (11,11,1) | ||||||

| (84,85) | Ring white | (3,3,1) | ||||||

| (4,5) | Ring black | (0,0,0) | ||||||

| (51,42) | Side expulsions | (0,0,0) | ||||||

| 6 |  |  | (84,86) | Inner white | (1396,1415,3) |  |  | 5 |

| (4,6) | Inner black | (0,0,0) | ||||||

| (85,85) | Ring white | (645,735,3) | ||||||

| (5,5) | Ring black | (0,0,0) | ||||||

| (47,34) | Side expulsions | (0,0,0) | ||||||

| 7 |  |  | (77,86) | Inner white | (1273,1294,5) |  |  | 5 |

| (−3,6) | Inner black | (265,402,17) | ||||||

| (76,84) | Ring white | (447,457,4) | ||||||

| (−4,4) | Ring black | (27,97,22) | ||||||

| (48,35) | Side expulsions | (24,34,6) | ||||||

| 8 |  |  | (80,86) | Inner white | (1049,1793,4) |  |  | 4 |

| (0,6) | Inner black | (77,237,18) | ||||||

| (80,86) | Ring white | (278,396,9) | ||||||

| (0,6) | Ring black | (65,132,12) | ||||||

| (54,42) | Side expulsions | (17,42,8) | ||||||

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alghannam, E.; Lu, H.; Ma, M.; Cheng, Q.; Gonzalez, A.A.; Zang, Y.; Li, S. A Novel Method of Using Vision System and Fuzzy Logic for Quality Estimation of Resistance Spot Welding. Symmetry 2019, 11, 990. https://doi.org/10.3390/sym11080990

Alghannam E, Lu H, Ma M, Cheng Q, Gonzalez AA, Zang Y, Li S. A Novel Method of Using Vision System and Fuzzy Logic for Quality Estimation of Resistance Spot Welding. Symmetry. 2019; 11(8):990. https://doi.org/10.3390/sym11080990

Chicago/Turabian StyleAlghannam, Essa, Hong Lu, Mingtian Ma, Qian Cheng, Andres A. Gonzalez, Yue Zang, and Shuo Li. 2019. "A Novel Method of Using Vision System and Fuzzy Logic for Quality Estimation of Resistance Spot Welding" Symmetry 11, no. 8: 990. https://doi.org/10.3390/sym11080990

APA StyleAlghannam, E., Lu, H., Ma, M., Cheng, Q., Gonzalez, A. A., Zang, Y., & Li, S. (2019). A Novel Method of Using Vision System and Fuzzy Logic for Quality Estimation of Resistance Spot Welding. Symmetry, 11(8), 990. https://doi.org/10.3390/sym11080990