Characteristics and Leak Localization of Transient Flow in Gas-Containing Water Pipelines

Abstract

1. Introduction

2. Transient Flow Model for Gas-Containing Water Pipelines Leakage

2.1. Computational Model

2.2. Unsteady Friction Model

2.3. Discrete Gas Cavity Model

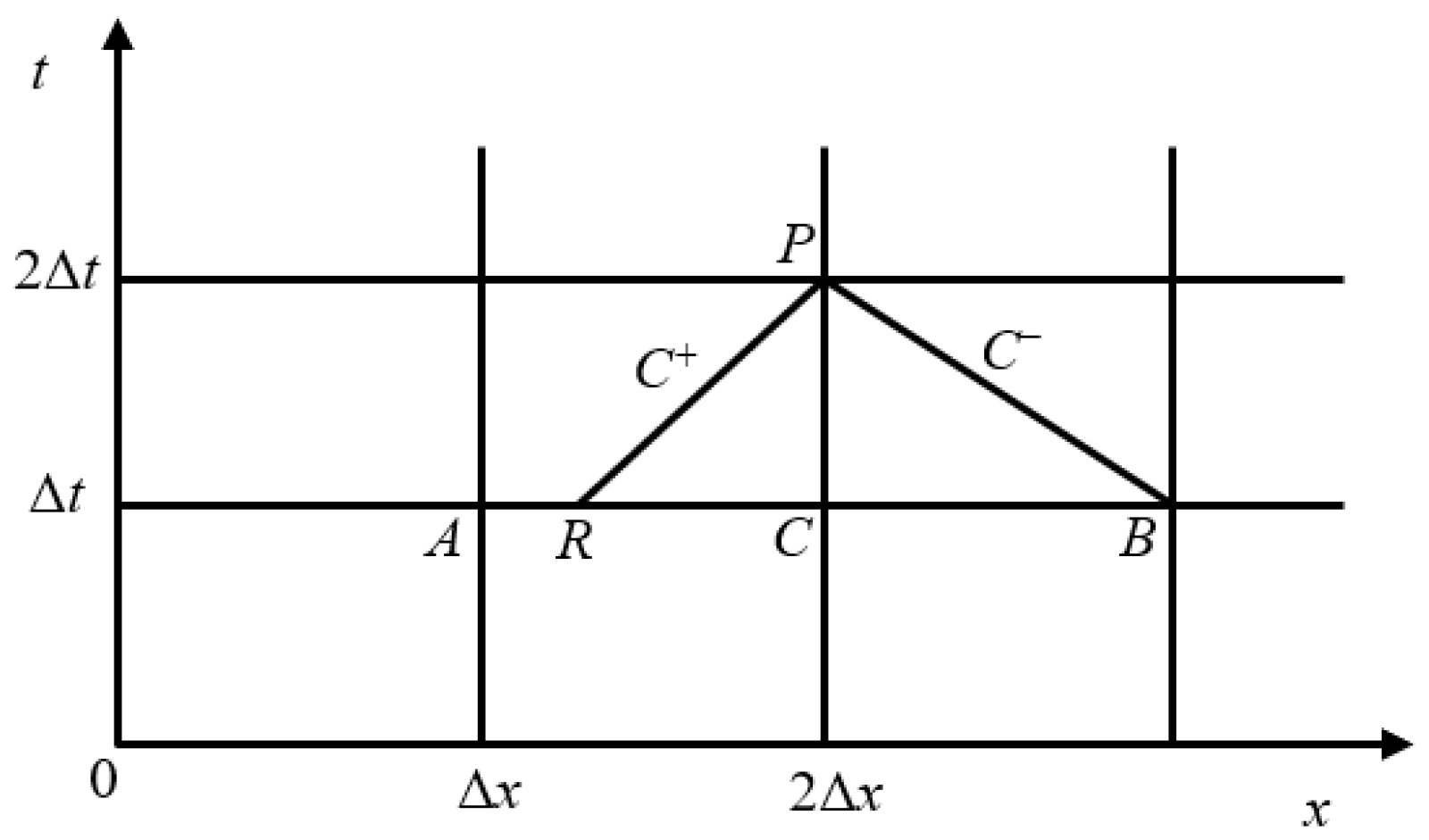

2.4. Calculation Method

2.4.1. Subsubsection

2.4.2. DGCM Model Solution Method

2.5. Boundary Conditions

2.5.1. Leakage Boundary Conditions

2.5.2. Upstream Reservoir Boundary Conditions

2.5.3. Downstream Valve Boundary Conditions

3. Result and Discussion

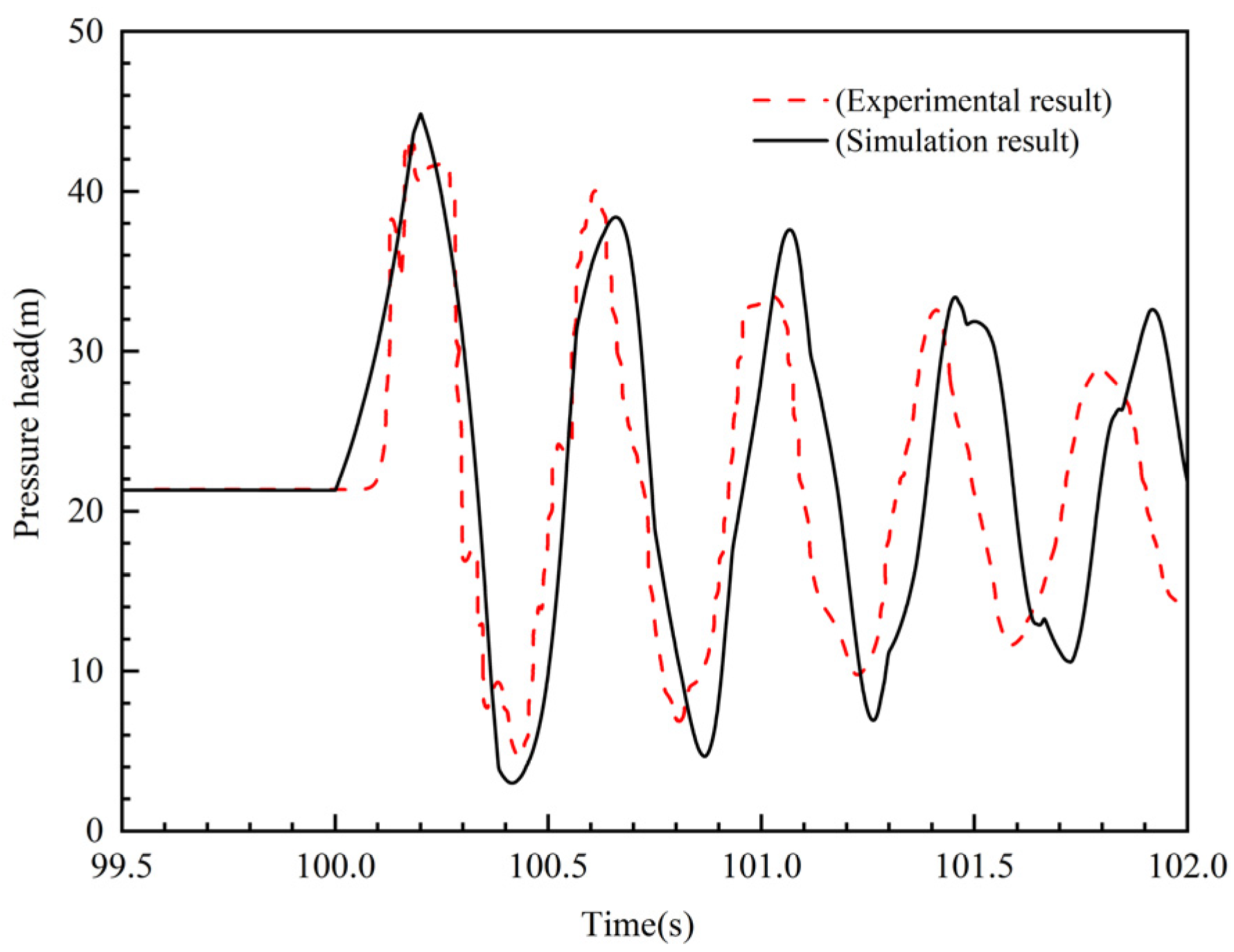

3.1. Subsection

3.2. Simulation Results and Analysis

3.2.1. The Impact of Valve Closing Time on End-of-Valve Pressure

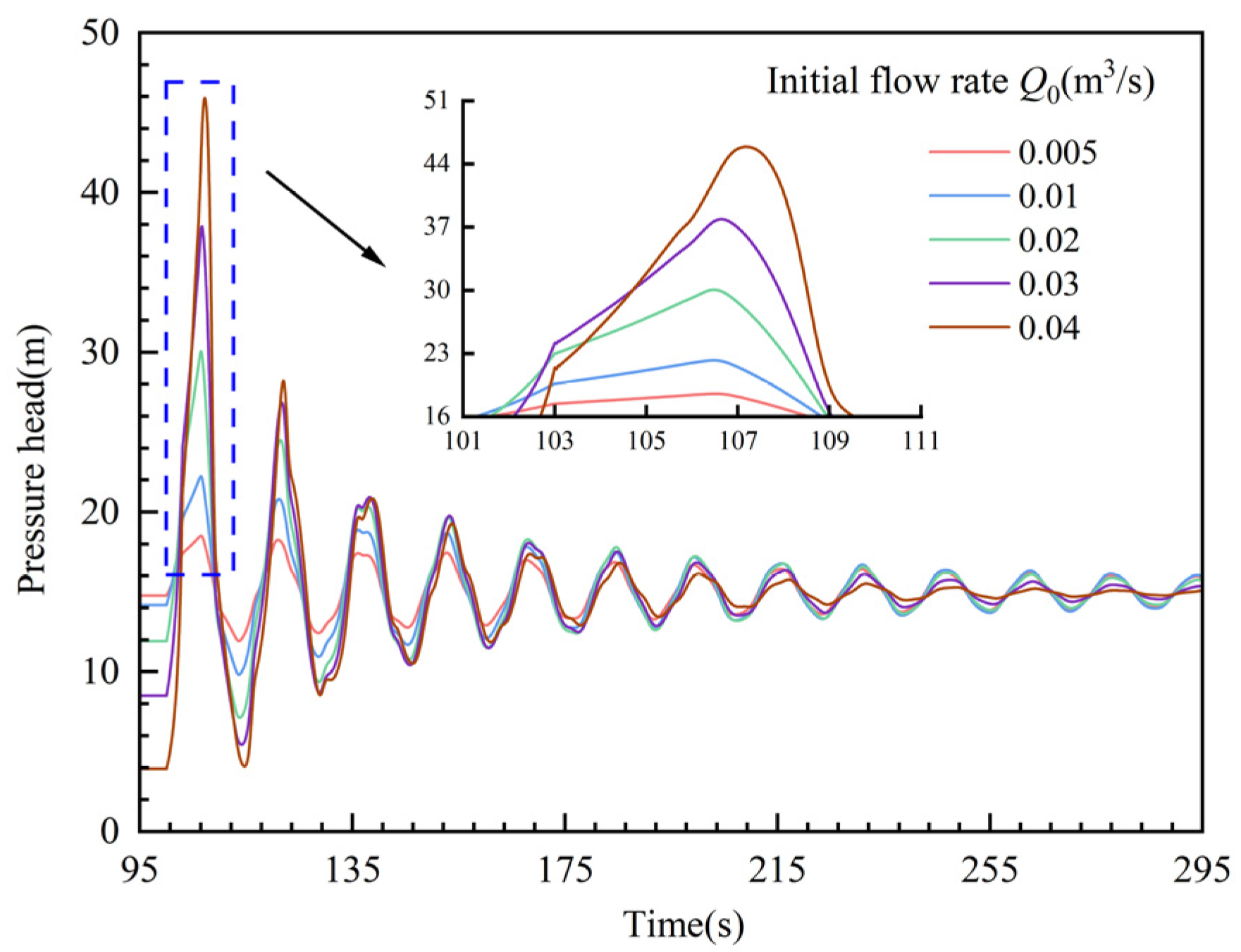

3.2.2. The Impact of Initial Flow Rate on End-of-Valve Pressure

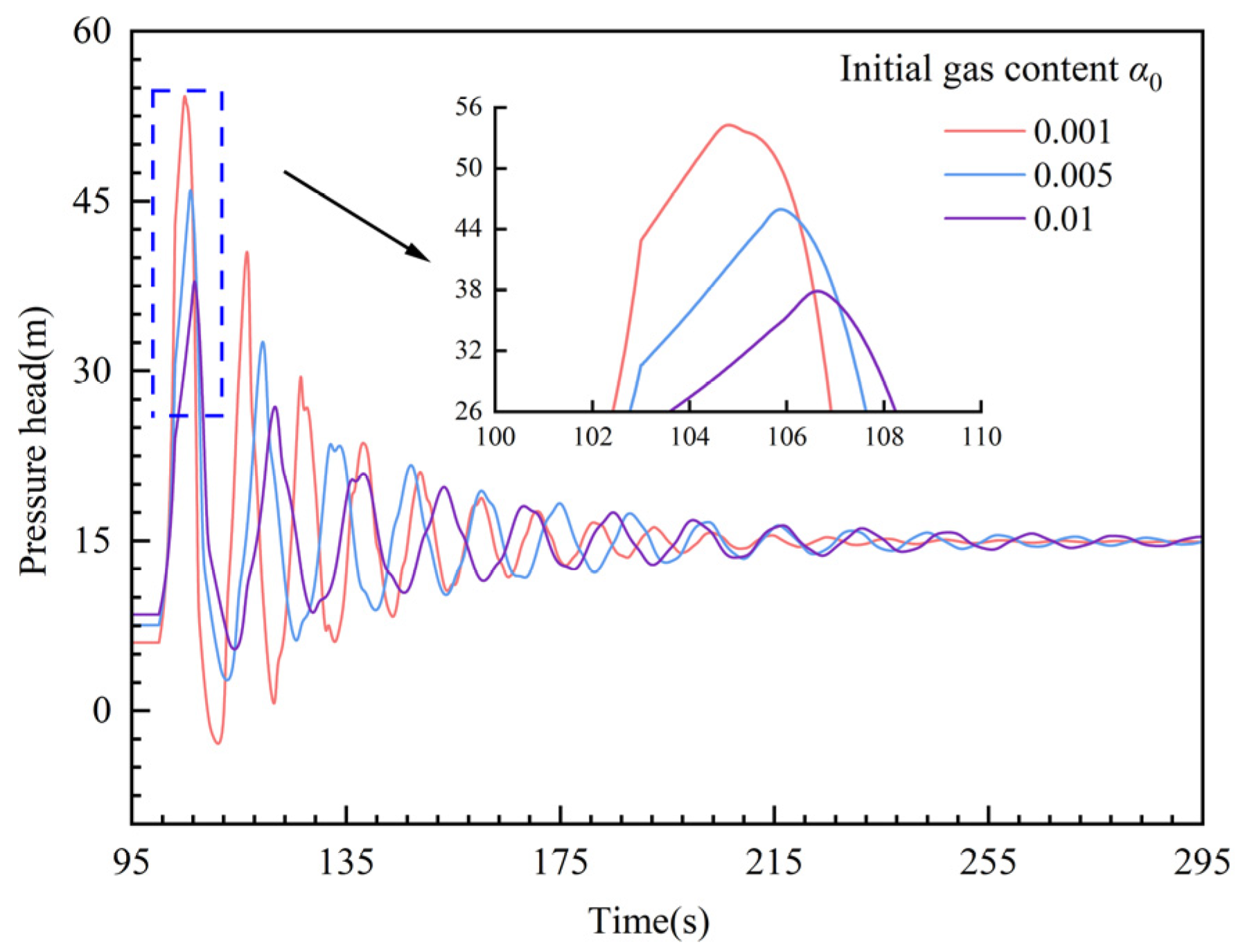

3.2.3. The Impact of Gas Content Rate on End-of-Valve Pressure

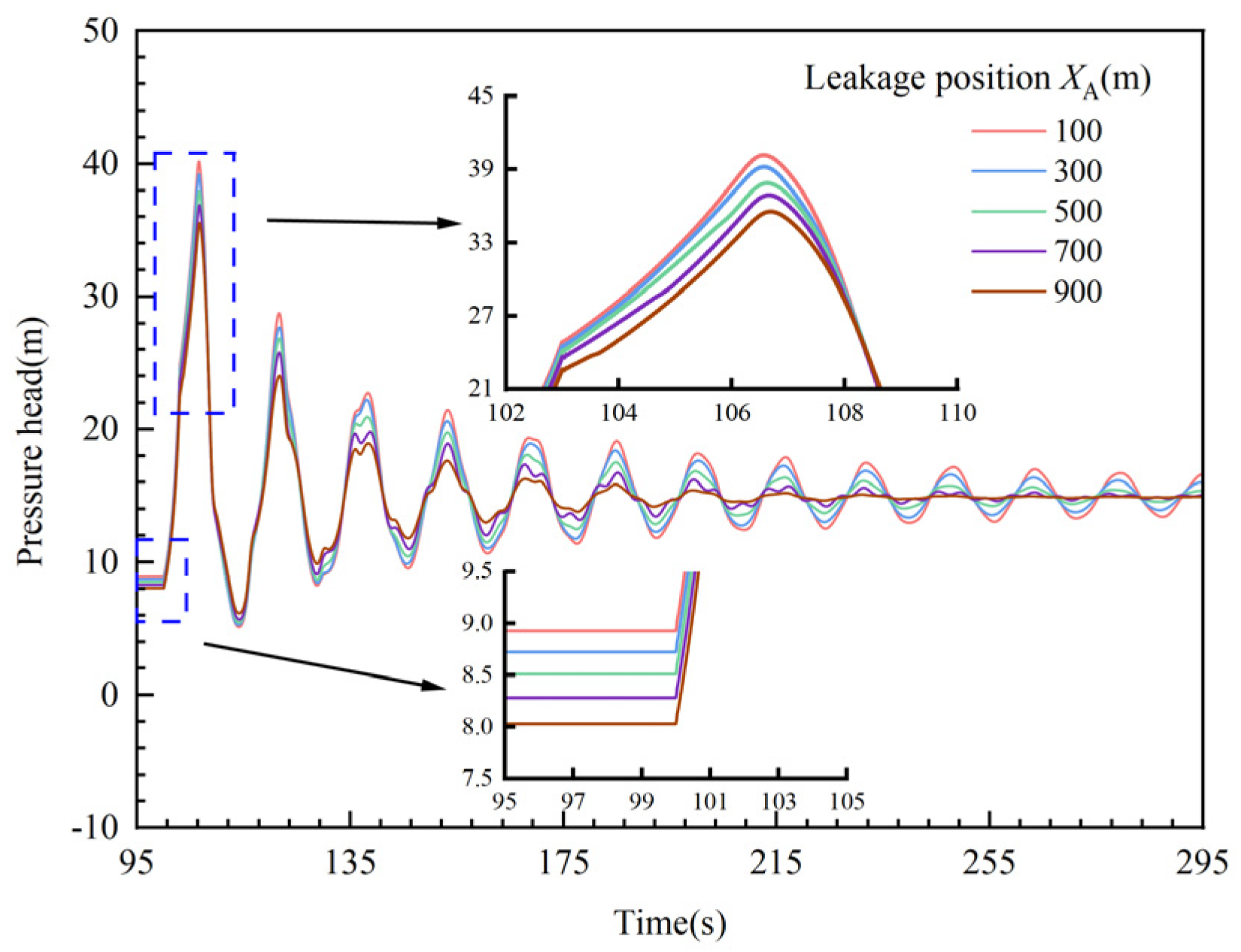

3.2.4. The Impact of Leak Location on End-of-Valve Pressure

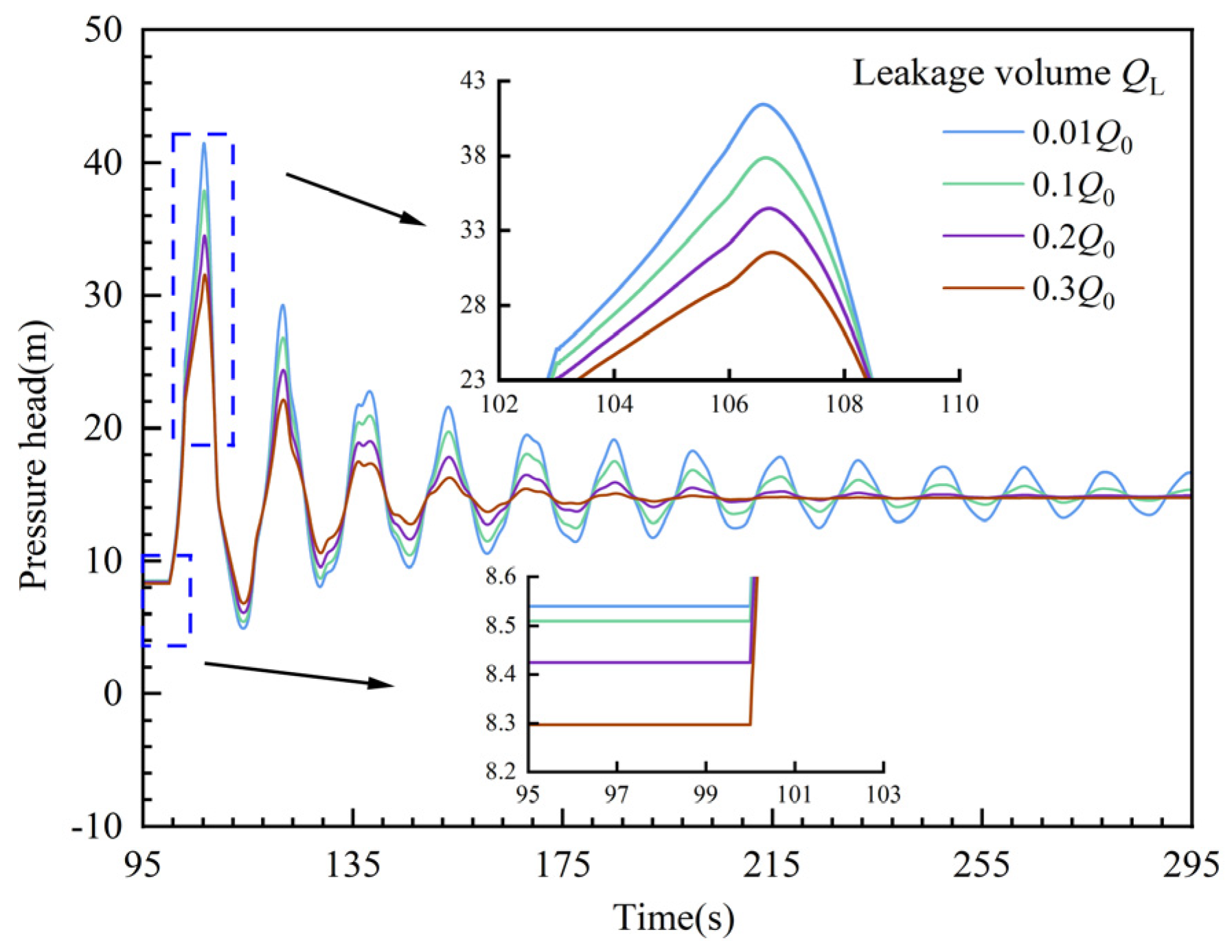

3.2.5. The Impact of Leakage Amount on End-of-Valve Pressure

4. Prediction of Leakage Location

4.1. Data Preprocessing

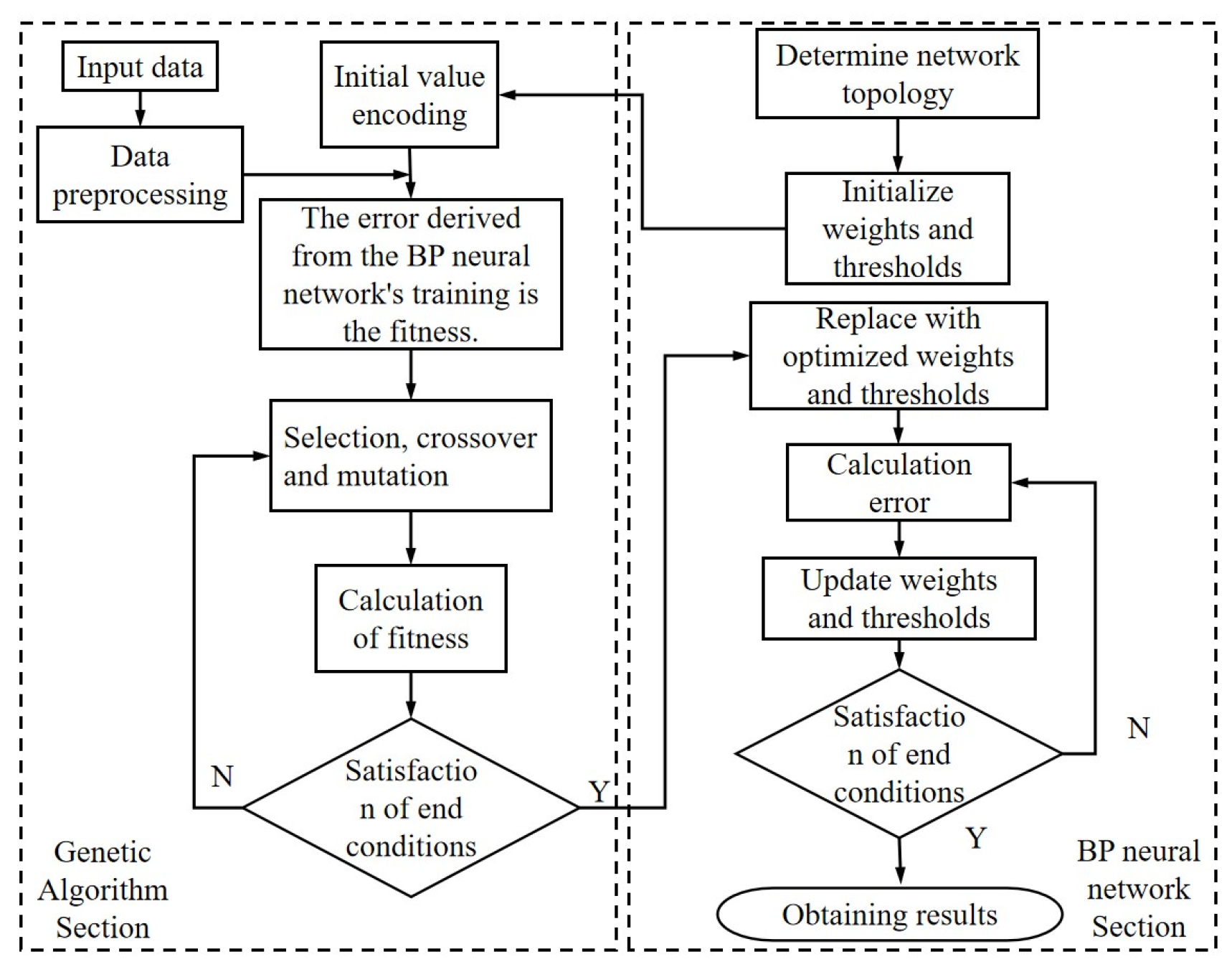

4.2. Neural Network Model

- Population Initialization. Before solving the problem, parameters need to be encoded to form the initial solutions of the population. Real-number encoding is used to connect the weights and thresholds between the layers. Each individual is represented as a real number string, consisting of four parts: the weights connecting the input layer and hidden layer, the thresholds of the hidden layer, the weights connecting the hidden layer and output layer, and the thresholds of the output layer. The length of the encoding is calculated using the following formula:where l represents the encoding length. m is the number of nodes in the input layer of the BP neural network. sl is the number of neurons in the hidden layer. n is the number of nodes in the output layer.

- Fitness Function. The fitness function measures the quality of the individuals in the population by summing the absolute errors between the actual outputs and the desired outputs of the neural network. In this study, it refers to the difference between the true leakage location and the predicted value. A smaller error indicates a better fitness of the individual. The formula for the fitness function is as follows:where F represents the fitness value. n is the number of training samples. yi and represent the actual value and predicted value of the i-th node in the BP neural network.

- Selection Operation. The purpose of the selection operation is to increase the probability of selecting individuals with smaller errors. Since the fitness function indicates that a smaller fitness value corresponds to a smaller error, the reciprocal of the fitness value is used. The formula is as follows:where represents the fitness value of the i-th individual. k is a coefficient. is the probability of the individual being selected. n is the number of individuals in the population.

- Crossover Operation. The crossover operation involves performing position-based crossover between different chromosomes to achieve gene exchange, thereby forming new individuals. Since the individuals are encoded using real numbers, real-number crossover methods are used. The crossover operation between the -th chromosome and the -th chromosome at the -th position is performed as follows:where b is a random number within the interval [0, 1].

- Mutation Operation. Select the -th individual’s -th gene for mutation. The operation method is as follows:where amax and amin represent the upper and lower bounds of the gene aij. g is the current iteration number. Gmax is the maximum number of evolutionary iterations. r is a random number within the interval [0, 1] and r2 is another random number.

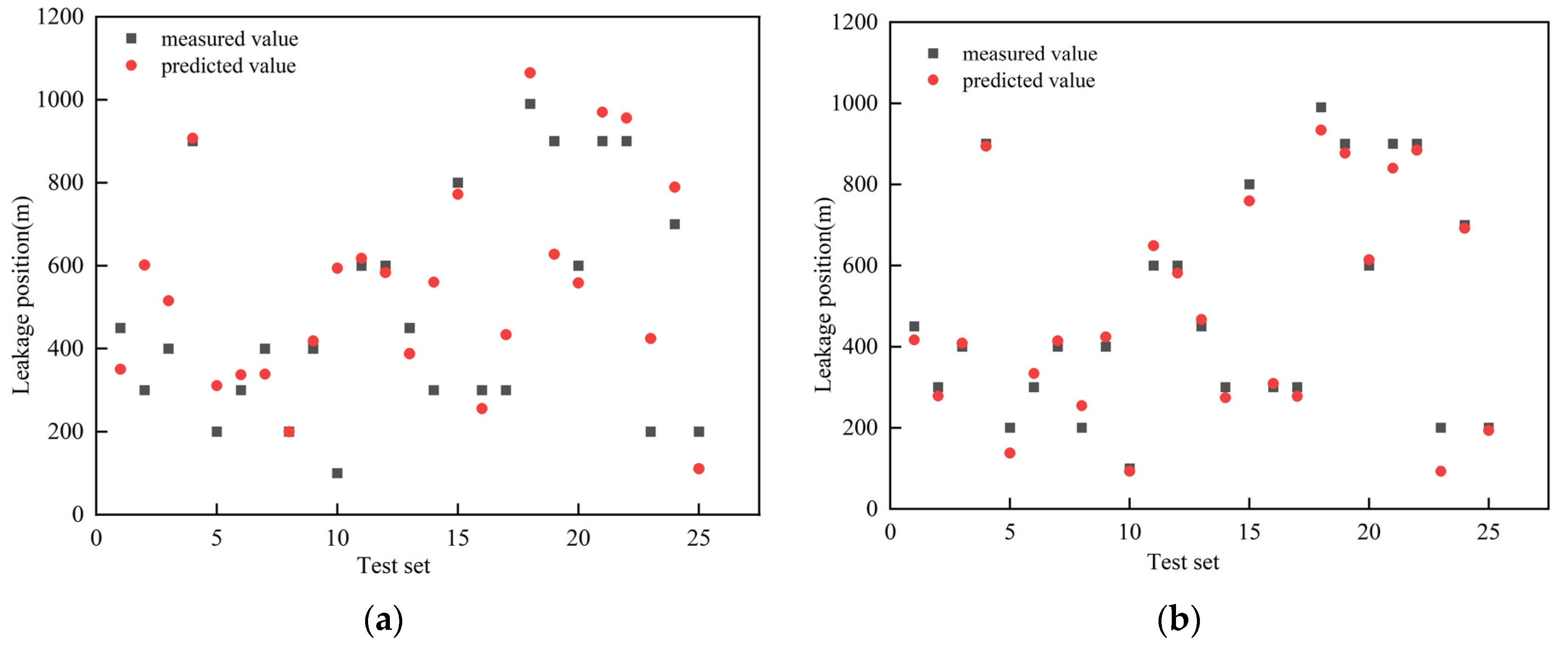

4.3. Leakage Location Prediction

5. Conclusions

- (1)

- Valve closing time has a significant impact on the end-of-valve pressure. When the valve closing time is increased from 1 s to 10 s, the pressure peak decreases from 42.67 m to 27.92 m, a reduction of 34.57%. Increasing the valve closing time also delays the arrival time of the pressure peak at the valve end.

- (2)

- Initial flow rate, leakage amount, and gas content rate have a certain impact on the end-of-valve pressure. After valve closure, the larger the initial flow rate, the lower the gas content rate, and the smaller the leakage amount, the greater the pressure peak at the valve end. When the initial flow rate increases from 0.005 m3/s to 0.04 m3/s, the pressure peak rises from 18.52 m to 45.92 m, an increase of 147.95%. When the gas content rate increases from 0.001 to 0.01, the pressure peak decreases from 54.27 m to 37.89 m, a reduction of 30.18%. As the leakage rate increases from 0.01Q₀ to 0.3Q₀, the pressure peak decreases from 41.81 m to 31.57 m, a decrease of 24.55%.

- (3)

- The GA-BP neural network can accurately predict the leakage location. The prediction model constructed using the GA-BP neural network had a mean absolute percentage error (MAPE) of 7.72% when predicting experimental data, indicating good prediction performance. The GA-BP neural network model can effectively solve complex prediction problems influenced by multiple factors, providing a new feasible approach for predicting pipeline leakage locations.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Cao, H.; Nistor, I.; Mohareb, M. Effect of Boundary on Water Hammer Wave Attenuation and Shape. J. Hydraul. Eng. 2020, 146, 4020001. [Google Scholar] [CrossRef]

- Kim, S.; Lee, K.; Kim, K. Water hammer in the pump-rising pipeline system with an air chamber. J. Hydrodyn. Ser. B 2015, 26, 960–964. [Google Scholar] [CrossRef]

- Bergant, A.; Simpson, A.R.; Tijsseling, A.S. Water hammer with column separation: A historical review. J. Fluids Struct. 2006, 22, 135–171. [Google Scholar] [CrossRef]

- Bergant, A.; Tusseling, A.S.; Vitkovsky, J.P.; Covas, D.I.C.; Simpson, A.R.; Lambert, M.F. Parameters affecting water-hammer wave attenuation, shape and timing Part 1: Mathematical tools. J. Hydraul. Res. 2008, 46, 373–381. [Google Scholar] [CrossRef]

- Bergant, A.; Tijsseling, A.S.; Vitkovsy, J.P.; Covas, D.I.C.; Simpson, A.R.; Lambert, M.F. Parameters affecting water-hammer wave attenuation, shape and timing Part 2: Case studies. J. Hydraul. Res. 2008, 46, 382–391. [Google Scholar] [CrossRef]

- Wang, C.; Yang, J.; Nilsson, H. Simulation of Water Level Fluctuations in a Hydraulic System Using a Coupled Liquid-Gas Model. Water 2015, 7, 4446–4476. [Google Scholar] [CrossRef]

- Duan, H.; Ghidaoui, M.; Lee, P.J.; Tung, Y. Unsteady friction and visco-elasticity in pipe fluid transients. J. Hydraul. Res. 2010, 48, 354–362. [Google Scholar] [CrossRef]

- Zhou, L.; Wang, H.; Liu, D.; Ma, J.; Wang, P.; Xia, L. A second-order Finite Volume Method for pipe flow with water column separation. J. Hydro-Environ. Res. 2017, 17, 47–55. [Google Scholar] [CrossRef]

- Adamkowski, A.; Lewandowski, M. Investigation of Hydraulic Transients in a Pipeline with Column Separation. J. Hydraul. Eng. 2012, 138, 935–944. [Google Scholar] [CrossRef]

- Adamkowski, A.; Lewandowski, M. Consideration of the Cavitation Characteristics of Shut-off Valves in Numerical Modelling of Hydraulic Transients in Pipelines with Column Separation. Procedia Eng. 2014, 70, 1027–1036. [Google Scholar] [CrossRef][Green Version]

- Jiang, D.; Li, S.; Edge, K.A.; Zeng, W. Modeling and simulation of low pressure oil-hydraulic pipeline transients. Comput. Fluids 2012, 67, 79–86. [Google Scholar] [CrossRef]

- Warda, H.A.; Wahba, E.M.; El-Din, M.S. Computational Fluid Dynamics (CFD) simulation of liquid column separation in pipe transients. Alex. Eng. J. 2020, 59, 3451–3462. [Google Scholar] [CrossRef]

- Mehmood, K.; Zhang, B.; Jalal, F.E.; Wan, W. Transient flow analysis for pumping system comprising pressure vessel using unsteady friction model. Int. J. Mech. Sci. 2023, 244, 108093. [Google Scholar] [CrossRef]

- Daude, F.; Galon, P.; Douillet-Grellier, T. 1D/3D Finite-Volume coupling in conjunction with beam/shell elements coupling for fast transients in pipelines with fluid–structure interaction. J. Fluids Struct. 2021, 101, 103219. [Google Scholar] [CrossRef]

- Srinivasan, S.; O’Malley, D.; Hyman, J.D.; Karra, S.; Viswanathan, H.S.; Srinivasan, G. Transient flow modeling in fractured media using graphs. Phys. Rev. E 2020, 102, 052310. [Google Scholar] [CrossRef]

- Pan, B.; Keramat, A.; Duan, H. Energy Analysis for Transient-Leak Interaction and Implication to Leak Detection in Water Pipeline Systems. J. Hydraul. Eng. 2023, 149, 04023031. [Google Scholar] [CrossRef]

- Mosaheb, M.; Zeidouni, M. Pressure Transient Analysis to Determine Anisotropic Fault Leakage Characteristics. J. Hydrol. Eng. 2020, 25, 04020046. [Google Scholar] [CrossRef]

- Fathi-Moghadam, M.; Kiani, S. Simulation of transient flow in viscoelastic pipe networks. J. Hydraul. Res. 2020, 58, 531–540. [Google Scholar] [CrossRef]

- Keramat, A.; Tijsseling, A.S.; Hou, Q.; Ahmadi, A. Fluid-structure interaction with pipe-wall viscoelasticity during water hammer. J. Fluids Struct. 2012, 28, 434–455. [Google Scholar] [CrossRef]

- Zhu, Y. Study on Steady-State Vibration and Transient Process in Water Conveyance Pipeline Based on Gas-Liquid Two-Phase Flow. Ph.D. Thesis, Harbin Institute of Technology, Harbin, China, 2018; p. 154. [Google Scholar]

- Medeiros, V.d.S.; dos Santos, M.D.; Brito, A.V. Case Study for Predicting Failures in Water Supply Networks Using Neural Networks. Water 2024, 16, 1455. [Google Scholar] [CrossRef]

- Gorenstein, A.; Kalech, M.; Hanusch, D.F.; Hassid, S. Pipe fault prediction for water transmission mains. Water 2020, 12, 2861. [Google Scholar] [CrossRef]

- Feng, G.; Zhang, K.; Wan, H.; Yao, W.; Zuo, Y.; Lin, J.; Liu, P.; Zhang, L.; Yang, Y.; Yao, J.; et al. Enhancing Oil–Water Flow Prediction in Heterogeneous Porous Media Using Machine Learning. Water 2024, 16, 1411. [Google Scholar] [CrossRef]

- Ye, J.; Do, N.C.; Zeng, W.; Lambert, M. Physics-informed neural networks for hydraulic transient analysis in pipeline systems. Water Res. 2022, 221, 118828. [Google Scholar] [CrossRef]

- Wang, W.; Sun, H.; Guo, J.; Lao, L.; Wu, S.; Zhang, J. Experimental study on water pipeline leak using In-Pipe acoustic signal analysis and artificial neural network prediction. Measurement 2021, 186, 110094. [Google Scholar] [CrossRef]

- Ribeiro, A.M.; Grossi, C.D.; Santos, B.F.; Santos, R.B.; Fileti, A.M.F. Leak Detection Modeling of a Pipeline Using Echo State Neural Networks. Comput. Aided Chem. Eng. 2018, 43, 1231–1236. [Google Scholar]

- Pérez-Pérez, E.J.; López-Estrada, F.R.; Valencia-Palomo, G.; Torres, L.; Puig, V.; Mina-Antonio, J.D. Leak diagnosis in pipelines using a combined artificial neural network approach. Control. Eng. Pract. 2021, 107, 104677. [Google Scholar] [CrossRef]

- Bohorquez, J.; Lambert, M.F.; Alexander, B.; Simpson, A.R.; Abbott, D. Stochastic Resonance Enhancement for Leak Detection in Pipelines Using Fluid Transients and Convolutional Neural Networks. J. Water Resour. Plan. Manag. 2022, 148, 04022001. [Google Scholar] [CrossRef]

- Liu, Z.; Yang, X.; Wu, M.; Mu, W.; Liu, G. Leveraging deep learning techniques for ship pipeline valve leak monitoring. Ocean. Eng. 2023, 288, 116167. [Google Scholar]

- Zhang, Y. Numerical Simulation and Experimental Research on Transient Characteristic and Leak Detection of Pressurized Pipeline. Ph.D. Thesis, Wuhan University, Wuhan, China, 2018; p. 144. [Google Scholar]

| Number of Neurons | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

|---|---|---|---|---|---|---|---|---|---|---|

| Correlation Coefficient | 0.8832 | 0.8910 | 0.9690 | 0.9626 | 0.9786 | 0.9440 | 0.9787 | 0.97840 | 0.9832 | 0.9779 |

| MAPE | 37.51% | 21.70% | 21.14% | 20.91% | 13.56% | 17.83% | 10.67% | 12.99% | 8.80% | 11.58% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Q.; Zhang, Z.; Huang, B.; Yu, Z.; Luo, X.; Yang, Z. Characteristics and Leak Localization of Transient Flow in Gas-Containing Water Pipelines. Water 2024, 16, 2459. https://doi.org/10.3390/w16172459

Zhang Q, Zhang Z, Huang B, Yu Z, Luo X, Yang Z. Characteristics and Leak Localization of Transient Flow in Gas-Containing Water Pipelines. Water. 2024; 16(17):2459. https://doi.org/10.3390/w16172459

Chicago/Turabian StyleZhang, Qiaoling, Zhen Zhang, Biyun Huang, Ziyuan Yu, Xingqi Luo, and Zhendong Yang. 2024. "Characteristics and Leak Localization of Transient Flow in Gas-Containing Water Pipelines" Water 16, no. 17: 2459. https://doi.org/10.3390/w16172459

APA StyleZhang, Q., Zhang, Z., Huang, B., Yu, Z., Luo, X., & Yang, Z. (2024). Characteristics and Leak Localization of Transient Flow in Gas-Containing Water Pipelines. Water, 16(17), 2459. https://doi.org/10.3390/w16172459