Response Surface Methodology Approach to Optimize Parameters for Coagulation Process Using Polyaluminum Chloride (PAC)

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental Instruments and Materials

2.2. Test Methods

2.3. Single-Factor Experiment Design

2.4. RSM Test Design

3. Results and Discussion

3.1. Analysis of Single-Factor Experiment

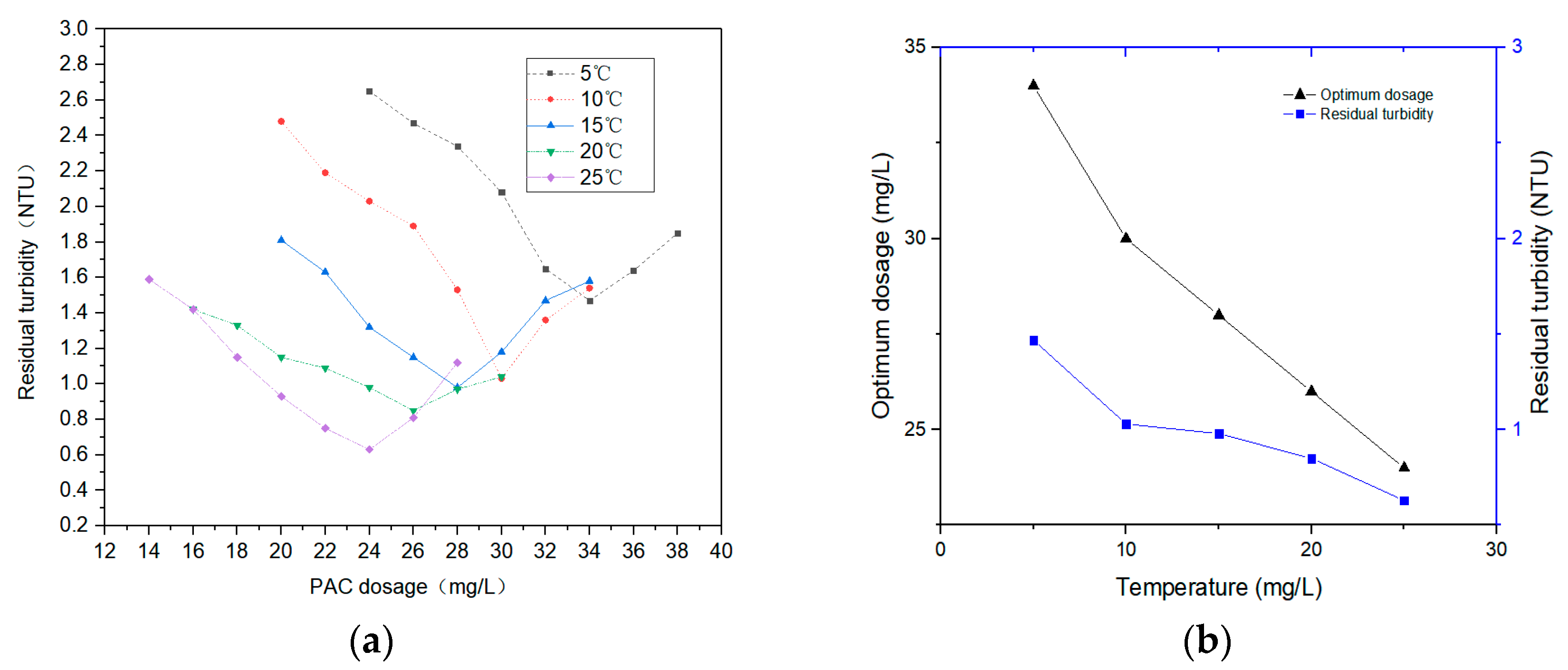

3.1.1. Influence of Temperature on Dosage of PAC

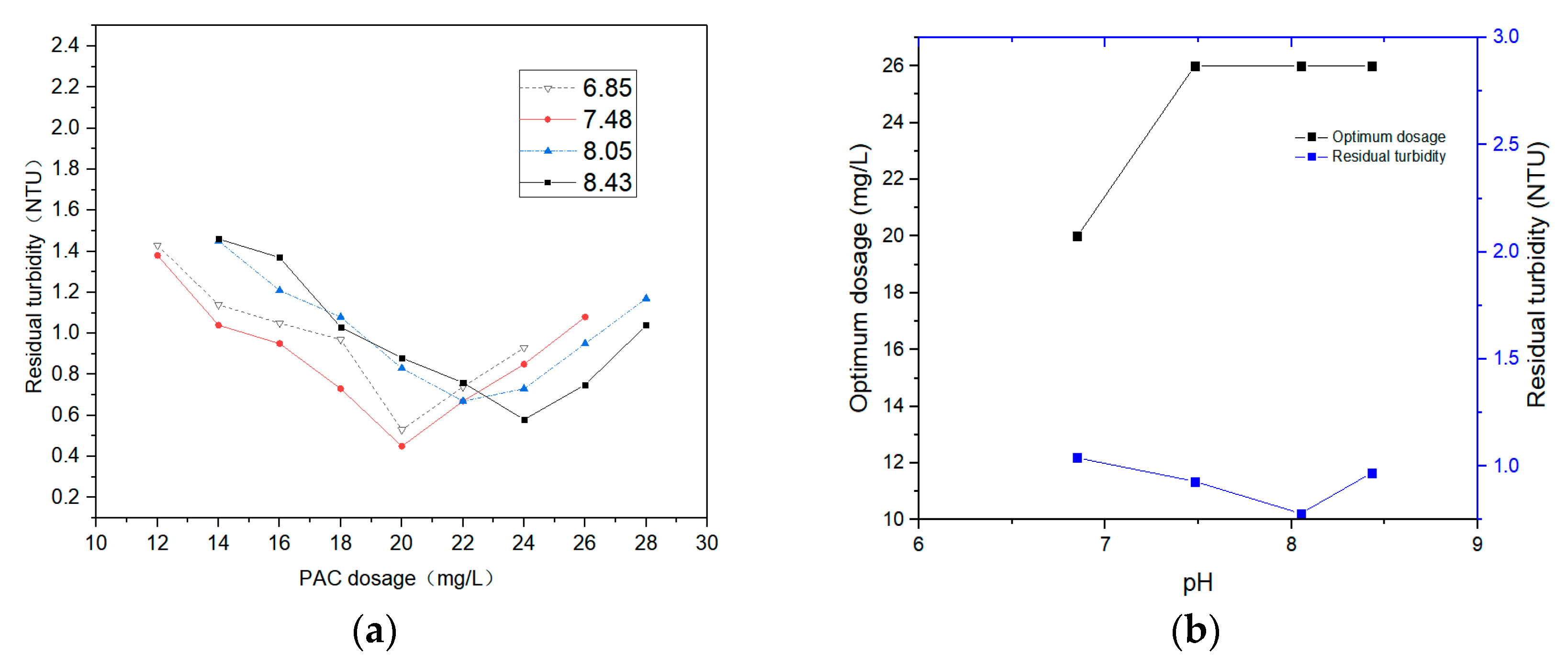

3.1.2. Influence of pH on Dosage of PAC

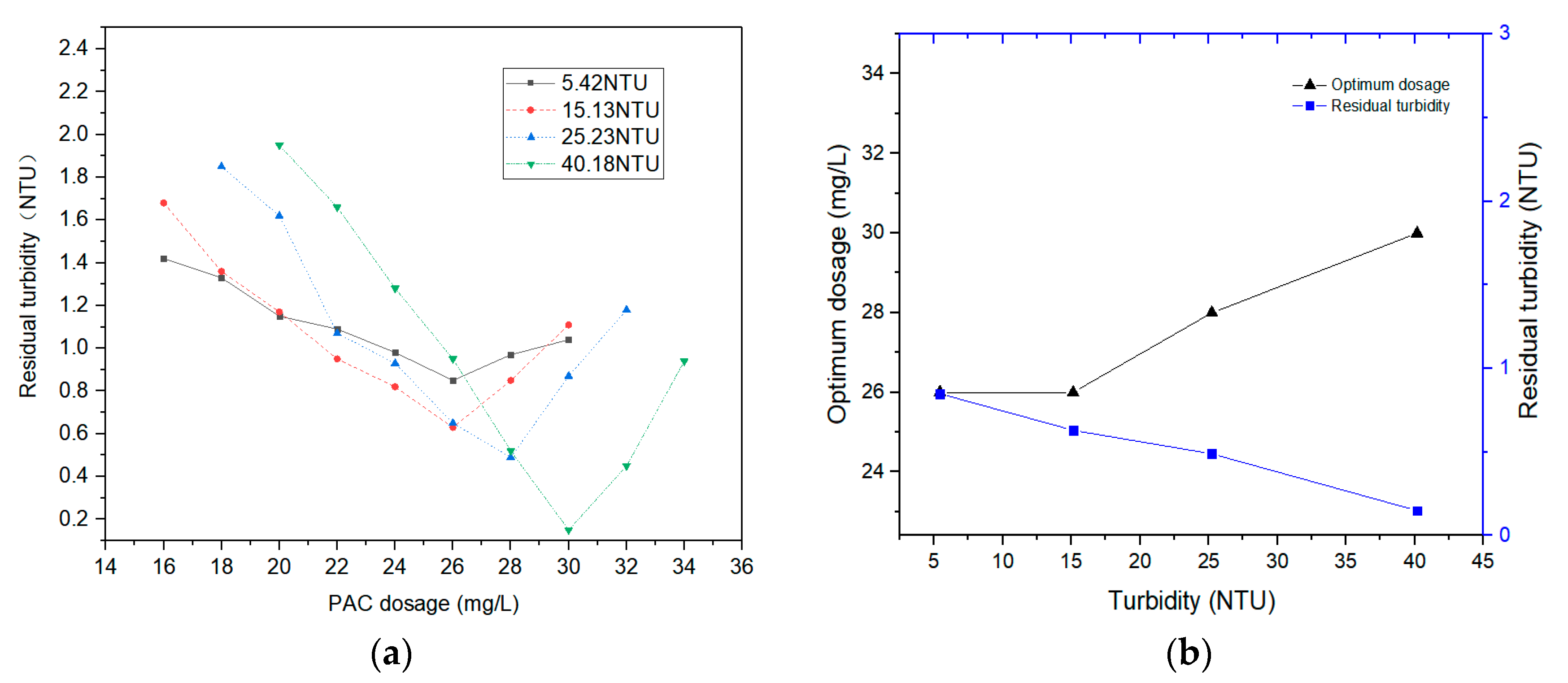

3.1.3. Influence of Turbidity on Dosage of PAC

3.1.4. Influence of CODMn on the Dosage of PAC

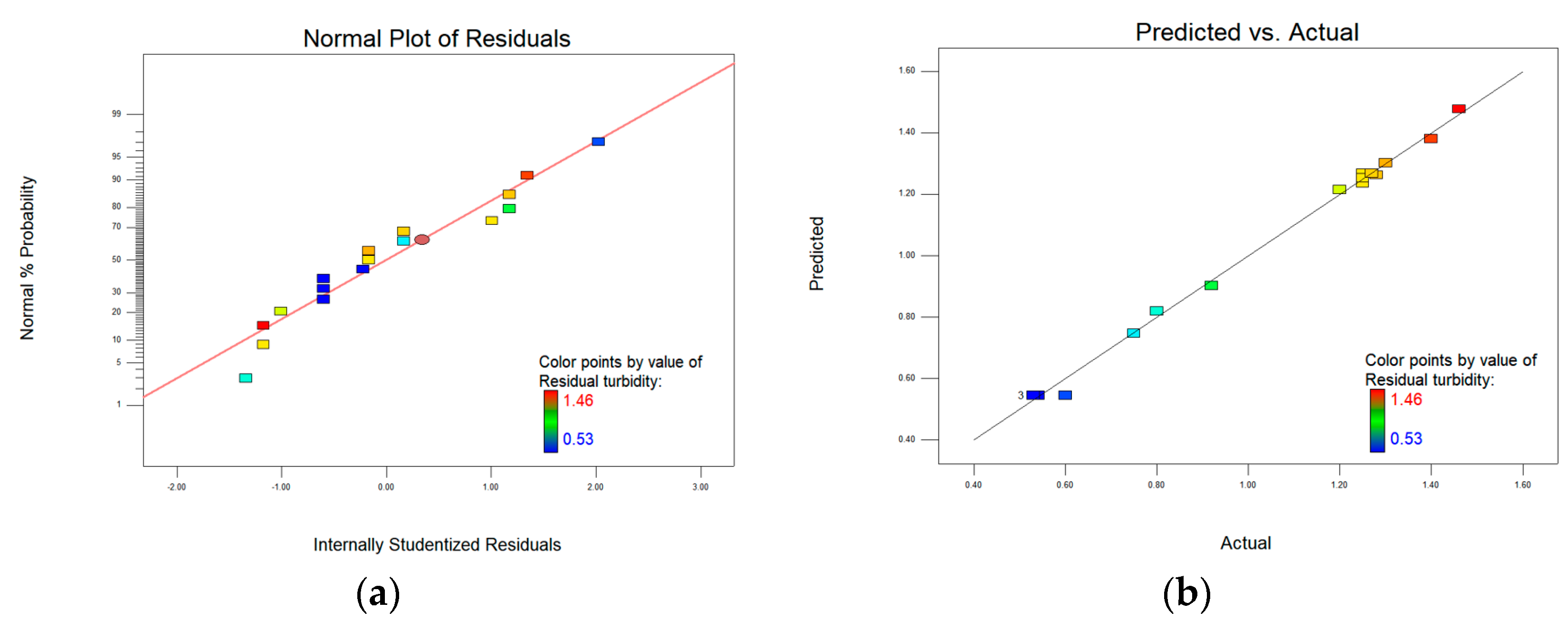

3.2. RSM Test Design Results and Analysis

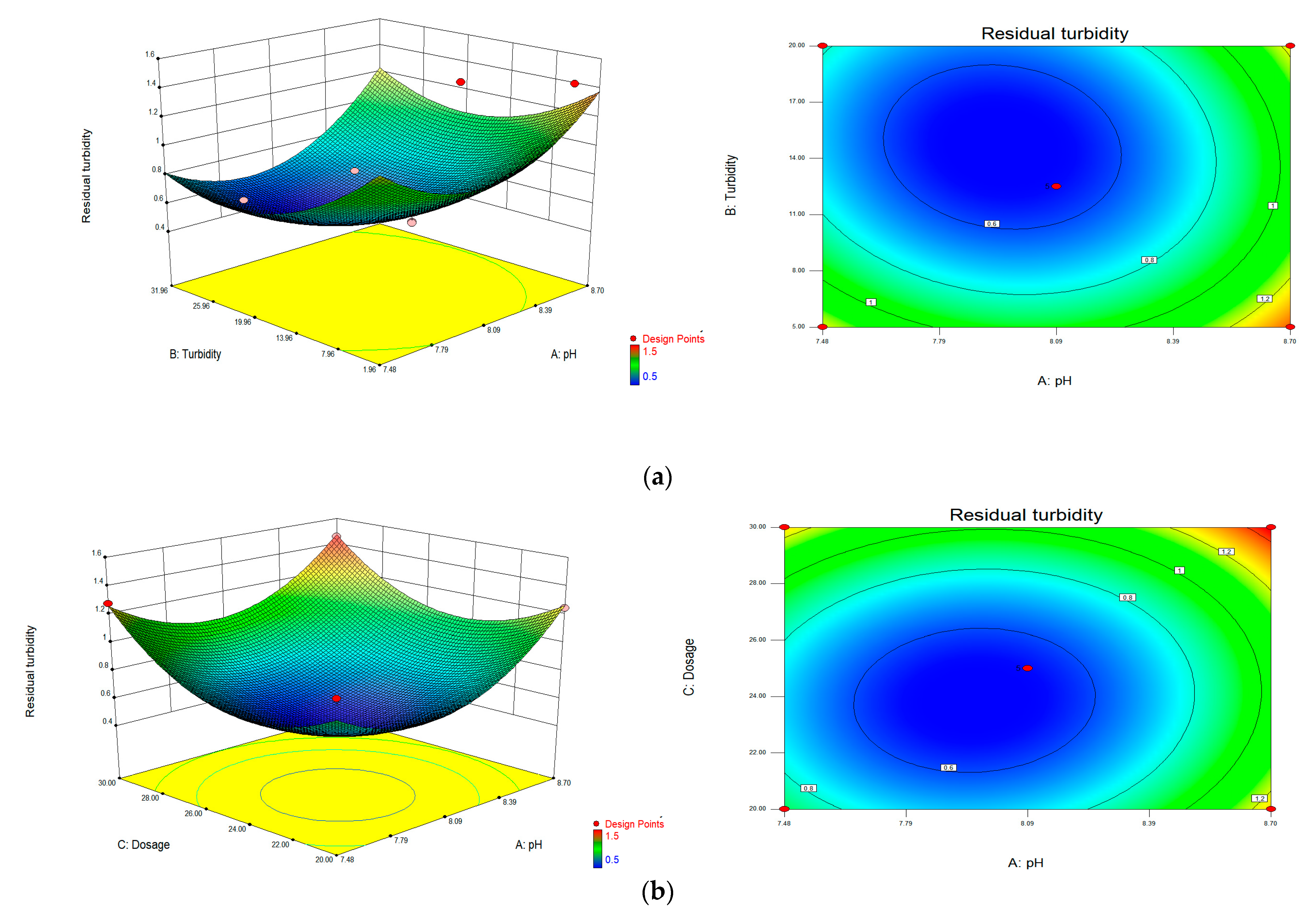

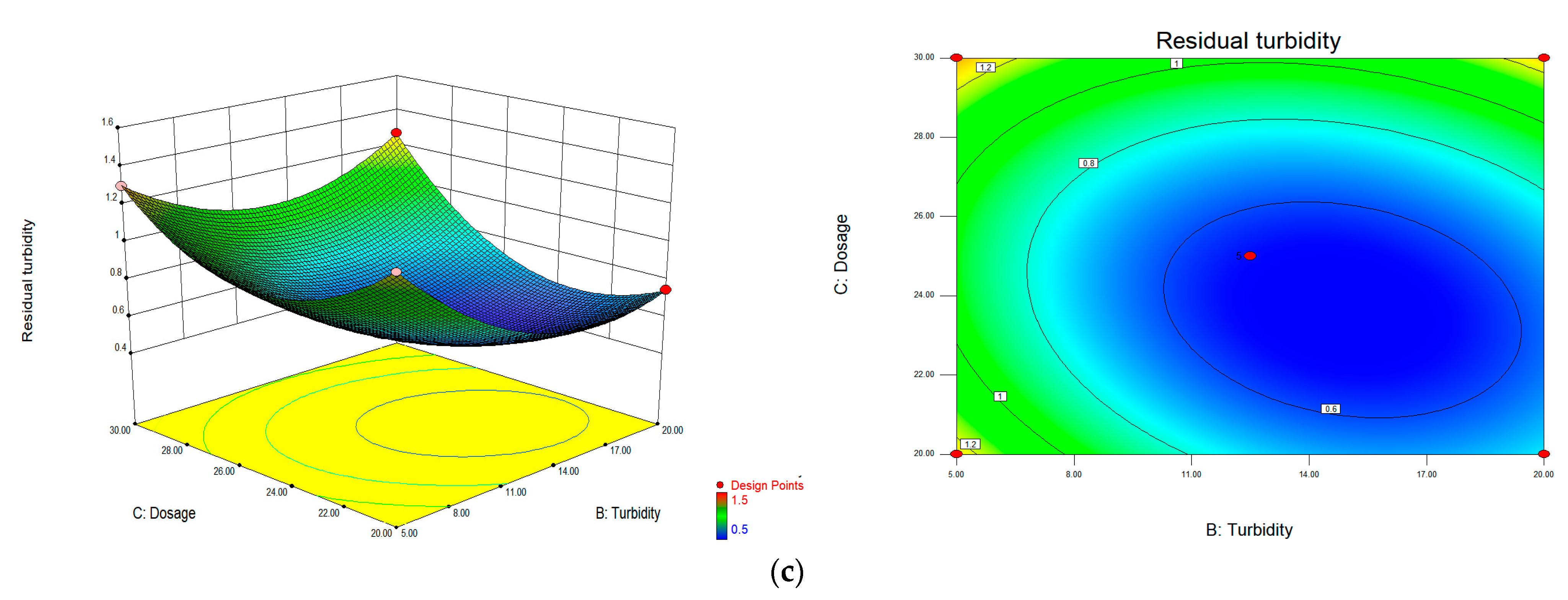

3.3. Response Surface Analysis

3.4. Model Validation by Experiments

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Skaf, D.W.; Punzi, V.L.; Rolle, J.T.; Cullen, E. Impact of Moringa oleifera extraction conditions on zeta potential and coagulation effectiveness. J. Environ. Chem. Eng. 2021, 9, 104687. [Google Scholar] [CrossRef]

- Jiang, J.Q. The role of coagulation in water treatment. Curr. Opin. Chem. Eng. 2015, 8, 36–44. [Google Scholar] [CrossRef]

- Balbinoti, J.R.; Jorge, R.M.M.; Junior, R.E.D.S.; Balbinoti, T.C.V.; Coral, L.A.A.; Bossetti, F.J. Treatment of low-turbidity water by coagulation combining Moringa oleifera Lam and polyaluminium chloride (PAC). J. Environ. Chem. Eng. 2024, 12, 111624. [Google Scholar] [CrossRef]

- Takaara, T.; Sano, D.; Masago, Y.; Omura, T. Surface-retained organic matter of Microcystis aeruginosa inhibiting coagulation with polyaluminum chloride in drinking water treatment. Water Res. 2010, 44, 3781–3786. [Google Scholar] [CrossRef]

- Wang, Y.; Zhou, W.Z.; Gao, B.Y.; Xu, X.M.; Xu, G.Y. The effect of total hardness on the coagulation performance of aluminum salts with different Al species. Sep. Purif. Technol. 2009, 66, 457–462. [Google Scholar] [CrossRef]

- Tang, H.; Xiao, F.; Wang, D. Speciation, stability, and coagulation mechanisms of hydroxyl aluminum clusters formed by PACl and alum: A critical review. Adv. Colloid. Interf. Sci. 2015, 226, 78–85. [Google Scholar] [CrossRef]

- Prokopova, M.; Novotna, K.; Pivokonska, L.; Cermakova, L.; Cajthaml, T.; Pivokonsky, M. Coagulation of polyvinyl chloride microplastics by ferric and aluminium sulphate: Optimisation of reaction conditions and removal mechanisms. J. Environ. Chem. Eng. 2021, 9, 106465. [Google Scholar] [CrossRef]

- Ang, W.L.; Mohammad, A.W. State of the art and sustainability of natural coagulants in water and wastewater treatment. J. Clean. Prod. 2020, 262, 121267. [Google Scholar] [CrossRef]

- Rajendran, R.; Abirami, M.; Prabhavathi, P.; Premasudha, P.B.; Manikandan, K.A. African Journal of Biotechnology Biological treatment of drinking water by chitosan based. Nanocomposites 2015, 14, 930–936. [Google Scholar]

- Zhang, L.H.; Liu, X.L.; Zhang, M.S.; Wang, T.Z.; Tang, H.; Jia, Y.P. The effect of pH/PAC on the coagulation of anionic surfactant wastewater generated in the cosmetic production. J. Environ. Chem. Eng. 2023, 11, 109312. [Google Scholar] [CrossRef]

- Tomaszewska, M.; Mozia, S.; Morawski, A.W. Removal of organic matter by coagulation enhanced with adsorption on PAC. Desalination 2004, 161, 79–87. [Google Scholar] [CrossRef]

- Ng, M.; Liu, S.; Chow, C.W.K.; Chow, M.; Amal, R.; Lim, M. Understanding effects of water characteristics on natural organic matter treatability by PACl and a novel PACl-chitosan coagulants. J. Hazard. Mater. 2013, 263, 718–725. [Google Scholar] [CrossRef] [PubMed]

- Vishali, S.; Mullai, P.; Mahboob, S.; Al-Ghanim, K.; Sivasankar, A. Elucidation the influence of design variables on coagulation-flocculation mechanisms in the lab-scale bio-coagulation on toxic industrial effluent treatment. Environ. Res. 2022, 212, 113224. [Google Scholar] [CrossRef] [PubMed]

- Kakoi, B.; Wambua Kaluli, J.P.; Ndiba, G. Optimization of Maerua Decumbent bio-coagulant in paint industry wastewater treatment with response surface methodology. J. Clean. Prod. 2017, 164, 1124–1134. [Google Scholar] [CrossRef]

- Zhang, L.; Zeng, Y.; Cheng, Z. Removal of heavy metal ions using chitosan and modified chitosan: A review. J. Mol. Liq. 2016, 214, 175–191. [Google Scholar] [CrossRef]

- Khedmati, M.; Khodaii, A.; Haghshenas, H.F. A study on moisture susceptibility of stone matrix warm mix asphalt. Constr. Build. Mater. 2017, 144, 42–49. [Google Scholar] [CrossRef]

- Wang, J.P.; Chen, Y.Z.; Ge, X.W.; Yu, H.Q. Optimization of coagulation-flocculation process for a paper-recycling wastewater treatment using response surface methodology. Colloids Surf. A Physicochem. Eng. Aspects. 2007, 302, 204–210. [Google Scholar] [CrossRef]

- Pham, T.T.H.; Brar, S.K.; Tyagi, R.D.; Surampalli, R.Y. Ultrasonication of wastewater sludge-consequences on biodegradability and flowability. J. Hazard. Mater. 2009, 163, 891–898. [Google Scholar] [CrossRef]

- Asaithambi, P.; Beyene, D.; Aziz, A.R.A.; Alemayehu, E. Removal of pollutants with determination of power consumption from landfill leachate wastewater using an electrocoagulation process: Optimization using response surface methodology (RSM). Chem. Eng. Res. Des. 2023, 197, 669–684. [Google Scholar] [CrossRef]

- Ramirez, I.M.; Velasquez, M.T.O. Removal and transformation of recalcitrant organic matter from stabilized saline landfill leachates by coagulation–ozonation coupling processes. Water Res. 2004, 38, 2359–2367. [Google Scholar] [CrossRef]

- Zhang, X.; Han, H.; Chai, H.; Gao, P.; Wu, W.; Li, M.; Lv, Q.; Guo, X.; Meng, Q.; Liu, X.; et al. Pre-treatment of landfill leachate via coagulation-flocculation: Optimization of process parameters using response surface methodology (RSM). J. Water Process Eng. 2023, 54, 103937. [Google Scholar] [CrossRef]

- Zhou, G.Y.; Wang, Q.G.; Li, G.; Li, Q.S.; Xu, H.; Ye, Q.; Wang, Y.Q.; Shu, S.H.; Zhang, J. Removal of polystyrene and polyethylene microplastics using PAC and FeCl3 coagulation: Performance and mechanism. Sci. Total. Environ. 2021, 752, 141837. [Google Scholar] [CrossRef] [PubMed]

- Tatsi, A.A.; Zouboulis, A.I.; Matis, K.A.; Samaras, P. Coagulation–flocculation pretreatment of sanitary landfill leachates. Chemosphere 2003, 53, 737–744. [Google Scholar] [CrossRef]

- Amokrane, A.; Comel, C.; Veron, J. Landfill leachates pretreatment by coagulation–flocculation. Water Res. 1997, 31, 2775–2782. [Google Scholar] [CrossRef]

- Zhang, Z.; Jing, R.; He, S.; Qian, J.; Zhang, K.; Ma, G.L.; Chang, X.; Zhang, M.K.; Li, Y.T. Coagulation of low temperature and low turbidity water: Adjusting basicity of polyaluminum chloride (PAC) and using chitosan as coagulant aid. Sep. Purif. Technol. 2018, 206, 131–139. [Google Scholar] [CrossRef]

- Shen, X.; Gao, B.; Huang, X.; Bu, F.; Yue, Q.; Li, R.; Jin, B. Effect of the dosage ratio and the viscosity of PAC/PDMDAAC on coagulation performance and membrane fouling in a hybrid coagulation-ultrafiltration process. Chemosphere 2017, 173, 288–298. [Google Scholar] [CrossRef] [PubMed]

- Ali, I.; Burakova, I.; Galunin, E.; Burakov, A.; Mkrtchyan, E.; Melezhik, A.; Grachev, V. High-Speed and high-capacity removal of methyl orange and malachite green in water using newly developed mesoporous carbon: Kinetic and isotherm studies. ACS Omega 2019, 4, 19293–19306. [Google Scholar] [CrossRef] [PubMed]

- Witek-Krowiak, A.; Chojnacka, K.; Podstawczyk, D.; Dawiec, A.; Pokomeda, K. Application of response surface methodology and artificial neural network methods in modelling and optimization of biosorption process. Bioresour. Technol. 2014, 160, 150–160. [Google Scholar] [CrossRef] [PubMed]

- Dayarathne, H.N.P.; Angove, M.J.; Jeong, S.; Aryal, R.; Paudel, S.R.; Mainali, B. Effect of temperature on turbidity removal by coagulation: Sludge recirculation for rapid settling. J. Water Process Eng. 2022, 46, 102559. [Google Scholar] [CrossRef]

- Kim, G.; Ryu, J.; Ryu, T.; Kim, H.; Shin, J.; Cho, D.W. Effects of calcination temperature on the adsorption ability of polyaluminum chloride (PAC) sludge-derived granules for As(V). J. Water Process Eng. 2024, 57, 104688. [Google Scholar] [CrossRef]

- Cheng, W.P.; Chi, F.H.; Li, C.C.; Yu, R.F. A study on the removal of organic substances from low-turbidity and low-alkalinity water with metal-polysilicate coagulants. Colloid Surf. A 2008, 312, 238–244. [Google Scholar] [CrossRef]

- Yang, Z.L.; Gao, B.Y.; Cao, B.C.; Xu, W.Y.; Xu, Q.Y. Effect of OH−/Al3+ ratio on the coagulation behavior and residual aluminum speciation of polyaluminum chloride (PAC) in surface water treatment. Sep. Purif. Technol. 2011, 80, 59–66. [Google Scholar] [CrossRef]

- Canzares, P.; Jimenez, C.; Martinez, F.; Rodrigo, M.A. The pH as a key parameter in the choice between coagulation and electrocoagulation for the treatment of wastewaters. J. Hazard. Mater. 2009, 163, 158–164. [Google Scholar] [CrossRef]

- Huang, X.; Gao, B.Y.; Yue, Q.Y.; Wang, Y.; Li, Q.; Zhao, S.; Sun, S. Effect of dosing sequence and raw water pH on coagulation performance and flocs properties using dual-coagulation of polyaluminum chloride and compound bioflocculant in low temperature surface water treatment. Chem. Eng. J. 2013, 229, 477–483. [Google Scholar] [CrossRef]

- Vunain, E.; Masoamphambe, E.F.; Mpeketula, P.; Monjerezi, M.G.; Etale, M.A. Evaluation of coagulating efficiency and water borne pathogens reduction capacity of Moringa oleifera seed powder for treatment of domestic wastewater from Zomba, Malawi. J. Environ. Chem. Eng. 2019, 7, 103118. [Google Scholar] [CrossRef]

- Campinas, M.; Silva, C.; Viegas, R.M.C.; Coelho, R.; Lucas, H.; Rosa, M.J. To what extent may pharmaceuticals and pesticides be removed by PAC conventional addition to low-turbidity surface waters and what are the potential bottlenecks? J. Water Process Eng. 2021, 40, 101833. [Google Scholar] [CrossRef]

- Ozbey-Unal, B.; Balcik-Canbolat, C.; Dizge, N.; Keskinler, B. Treatability studies on optimizing coagulant type and dosage in combined coagulation/membrane processes for table olive processing wastewater. J. Water Process Eng. 2018, 26, 301–307. [Google Scholar] [CrossRef]

- Wu, K.; Wang, H.; Liu, R.; Zhao, X.; Liu, H.; Qu, J. Arsenic removal from a high-arsenic wastewater using in situ formed Fe-Mn binary oxide combined with coagulation by poly-aluminum chloride. J. Hazard. Mater. 2011, 185, 990–995. [Google Scholar] [CrossRef]

- Shabanizadeh, H.; Taahacijeloudar, M. A sustainable approach for industrial wastewater treatment using pomegranate seeds in flocculation-coagulation process: Optimization of COD and turbidity removal by response surface methodology (RSM). J. Water Process Eng. 2023, 53, 103651. [Google Scholar] [CrossRef]

- Karyab, H.; Ghasemi, M.; Ghotbinia, F.; Nazeri, N. Efficiency of chitosan nanoparticle with polyaluminum chloride in dye removal from aqueous solutions: Optimization through response surface methodology (RSM) and central composite design (CCD). Int. J. Biol. Macromol. 2023, 249, 125977. [Google Scholar] [CrossRef]

- Adelodun, B.; Ajibade, F.O.; Ogunshina, M.S.; Choi, K.S. Dosage and settling time course optimization of Moringa oleifera in municipal wastewater treatment using response surface methodology. Desalin. Water Treat. 2019, 167, 45–56. [Google Scholar] [CrossRef]

- Wang, J.P.; Chen, Y.Z.; Wang, Y.; Yuan, S.J.; Yu, H.Q. Optimization of the Coagulation-flocculation process for pulp mill wastewater treatment using a combination of uniform design and response surface methodology. Water Res. 2011, 45, 5633–5640. [Google Scholar] [CrossRef] [PubMed]

- Saxena, K.; Brighu, U.; Choudhary, A. Coagulation of humic acid and kaolin at alkaline pH: Complex mechanisms and effect of fluctuating organics and turbidity. J. Water Process Eng. 2019, 31, 100875. [Google Scholar] [CrossRef]

- Bouyakhsass, R.; Souabi, S.; Rifi, S.K.; Taleb, A.; Pala, A.; Madinzi, A. Optimization of coagulation-flocculation for landfill leachate treatment: An experimental design approach using response surface methodology. Environ. Nanotechnol. Monit. Manag. 2023, 20, 100841. [Google Scholar] [CrossRef]

- Ghafari, S.; Aziz, H.A.; Isa, M.H.; Zinatizadeh, A.A. Application of response surface methodology (RSM) to optimize coagulation–flocculation treatment of leachate using poly-aluminum chloride (PAC) and alum. J. Hazard. Mater. 2009, 163, 650–656. [Google Scholar] [CrossRef] [PubMed]

- Trinh, T.K.; Kang, L.S. Response surface methodological approach to optimize the coagulation-flocculation process in drinking water treatment. Chem. Eng. Res. Des. 2011, 89, 1126–1135. [Google Scholar] [CrossRef]

- Singh, S.S.; Dikshit, A.K. Optimization of the parameters for decolourization by Aspergillus niger of anaerobically digested distillery spentwash pretreated with polyaluminium chloride. J. Hazard. Mater. 2010, 176, 864–869. [Google Scholar] [CrossRef]

| Index | Unit | Number Range |

|---|---|---|

| Density (20 °C) | g/cm3 | ≥1.24 |

| pH (1% water solution) | ≥3.5–5.0 | |

| Al2O3 | mg/L | ≥10.0 |

| Basicity | % | 50.0–85.0 |

| Stage | Revolution Range (rpm) | Reaction Time (min) | Reference |

|---|---|---|---|

| The first coagulation stage (rapid mixing) | 80–200 | 1–5 | [19,20,21,22,23,24,25,26] |

| The second coagulation stage (slow mixing) | 25–70 | 9–50 | |

| Sedimentation stage | 0 | 20 |

| Test Index | Test Method | Equipment Information |

|---|---|---|

| turbidity | Light scattering method | Turbidimeter model—Hach 2100N (Hach Company, Loveland, CO, USA) |

| pH | Glass electrode method | pH meter—PHS-2F (Shanghai Leici Co., Ltd. Shanghai, China) |

| CODMn | Spectrophotometric method | Digester—DRB200 (Hach Company, Loveland, CO, USA) |

| Factor | Code | Level | ||

|---|---|---|---|---|

| −1 | 0 | 1 | ||

| pH | A | 7.48 | 8.09 | 8.7 |

| Turbidity (NTU) | B | 5 | 12.5 | 20 |

| Dosage (mg/L) | C | 20 | 25 | 30 |

| Test Number | Parameter 1—pH | Parameter 2—Turbidity (NTU) | Parameter 3—Dosage (mg/L) | Response Value—Residual Turbidity (NTU) |

|---|---|---|---|---|

| 1 | 8.7 | 5 | 25 | 1.4 |

| 2 | 8.09 | 12.5 | 25 | 0.53 |

| 3 | 8.09 | 12.5 | 25 | 0.54 |

| 4 | 8.7 | 12.5 | 20 | 1.25 |

| 5 | 8.09 | 12.5 | 25 | 0.53 |

| 6 | 8.09 | 12.5 | 25 | 0.6 |

| 7 | 7.48 | 5 | 25 | 1.2 |

| 8 | 8.09 | 20 | 20 | 0.75 |

| 9 | 8.09 | 5 | 30 | 1.3 |

| 10 | 8.7 | 12.5 | 30 | 1.46 |

| 11 | 8.09 | 12.5 | 25 | 0.53 |

| 12 | 8.09 | 20 | 30 | 1.27 |

| 13 | 8.09 | 5 | 20 | 1.25 |

| 14 | 7.48 | 20 | 25 | 0.8 |

| 15 | 8.7 | 20 | 25 | 1.25 |

| 16 | 7.48 | 12.5 | 30 | 1.28 |

| 17 | 7.48 | 12.5 | 20 | 0.92 |

| Sum of | Mean | F | p Value | |||

|---|---|---|---|---|---|---|

| Source | Squares | Df | Square | Value | Prob > F | |

| Model | 1.98 | 9 | 0.22 | 247.12 | <0.0001 * | significant |

| A—pH | 0.17 | 1 | 0.17 | 189.29 | <0.0001 * | |

| B—Turbidity | 0.15 | 1 | 0.15 | 164.08 | <0.0001 * | |

| C—Dosage | 0.16 | 1 | 0.16 | 182.82 | <0.0001 * | |

| AB | 0.016 | 1 | 0.016 | 17.58 | 0.0041 * | |

| AC | 5.63 × 10−3 | 1 | 5.625 × 10−3 | 6.33 | 0.04 * | |

| BC | 0.055 | 1 | 0.0055 | 62.15 | 0.0001 * | |

| A2 | 0.52 | 1 | 0.52 | 582.96 | <0.0001 * | |

| B2 | 0.3 | 1 | 0.30 | 334.65 | <0.0001 * | |

| C2 | 0.46 | 1 | 0.46 | 518.37 | <0.0001 * | |

| Residual | 6.22 × 10−3 | 7 | 8.886 × 10−4 | |||

| Lack of fit | 2.50 × 10−3 | 3 | 8.333 × 10−4 | 0.9 | 0.5166 | not significant |

| Pure error | 3.72 × 10−3 | 4 | 9.300 × 10−4 | |||

| Cor total | 1.98 | 16 |

| No. | Experimental Design | Factors | Optimization | Removal Efficiencies | Reference |

|---|---|---|---|---|---|

| 1 | Single-variable experiments | PAC concentration, pH | multi-response | 91.38% COD, 92.41% turbidity | [10] |

| 2 | Single-variable experiments | Different PAC types, doses, contact times | multi-response | 65–79% total pharmaceuticals, 73–83% total-pesticides, | [36] |

| 3 | Single-variable experiments | pH | multi-response | 99% UV254, 81–89% CODMn | [11] |

| 4 | Central composite design | PAC dosage, pH | multi-response | 43.1% COD, 94.0% turbidity, 90.7% color, 0.1% TSS | [45] |

| 5 | Box–Behnken design | KH2PO4, Glucose, pH | single-response | 86.8% decolorization | [47] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ji, X.; Li, Z.; Wang, M.; Yuan, Z.; Jin, L. Response Surface Methodology Approach to Optimize Parameters for Coagulation Process Using Polyaluminum Chloride (PAC). Water 2024, 16, 1470. https://doi.org/10.3390/w16111470

Ji X, Li Z, Wang M, Yuan Z, Jin L. Response Surface Methodology Approach to Optimize Parameters for Coagulation Process Using Polyaluminum Chloride (PAC). Water. 2024; 16(11):1470. https://doi.org/10.3390/w16111470

Chicago/Turabian StyleJi, Xuemei, Zhihua Li, Mingsen Wang, Zhigang Yuan, and Li Jin. 2024. "Response Surface Methodology Approach to Optimize Parameters for Coagulation Process Using Polyaluminum Chloride (PAC)" Water 16, no. 11: 1470. https://doi.org/10.3390/w16111470

APA StyleJi, X., Li, Z., Wang, M., Yuan, Z., & Jin, L. (2024). Response Surface Methodology Approach to Optimize Parameters for Coagulation Process Using Polyaluminum Chloride (PAC). Water, 16(11), 1470. https://doi.org/10.3390/w16111470