Robust Adaptive Control of the Offshore Produced Water Treatment Process: An Improved Multivariable MRAC-Based Approach

Abstract

1. Introduction

1.1. Motivation

1.2. State of the Art

1.3. Contributions

- A novel control solution is presented for integrated hydrocyclone and TPGS systems, utilizing a robust MV-MRAC with respect to unknown disturbance.

- LDS decomposition is implemented in the proposed method to eliminate the constraint of a priori knowledge of the high-frequency gain matrix.

- To reach stable adaptive laws, the controller’s adaptive laws are formulated by considering augmented error, which encompasses parameters and tracking errors.

- A new multi-objective optimization problem is presented for optimizing the controller’s adaptation rates, which is solved using the TLBO algorithm.

2. Deoiling Process Model

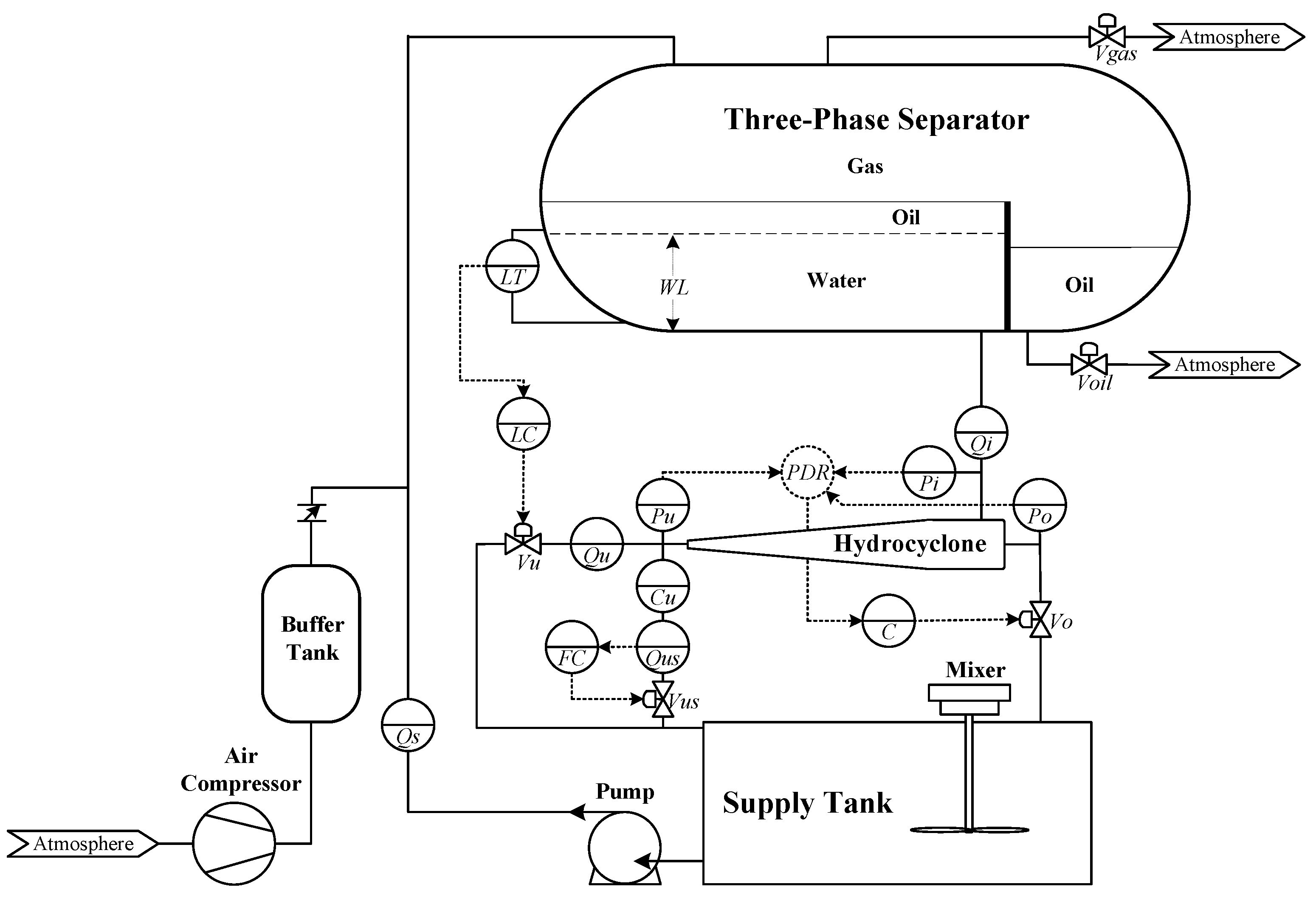

Considered Separation System

3. Prerequisites for Robust MV-MRAC Design

3.1. System Model

3.2. Modified Left Interactor and Reference Model

3.3. System Assumptions

- (A.1) is strictly proper and full rank, and its MLI matrix is also known, such that the reference model is selected as .

- (A.2) All transmission zeros of lie on the left of the imaginary axis, and the system is stabilizable and detectable.

- (A.3) All leading principal minors of the HFG matrix are nonzero with known signs.

- (A.4) An upper bound is known on observability index of . Transfer function models of the system from the control input and disturbance input are presented in their left coprime polynomial matrix decomposition, i.e., and , where , and are proper polynomial matrices.

- (A.5) The relative degree condition is established such that is proper.

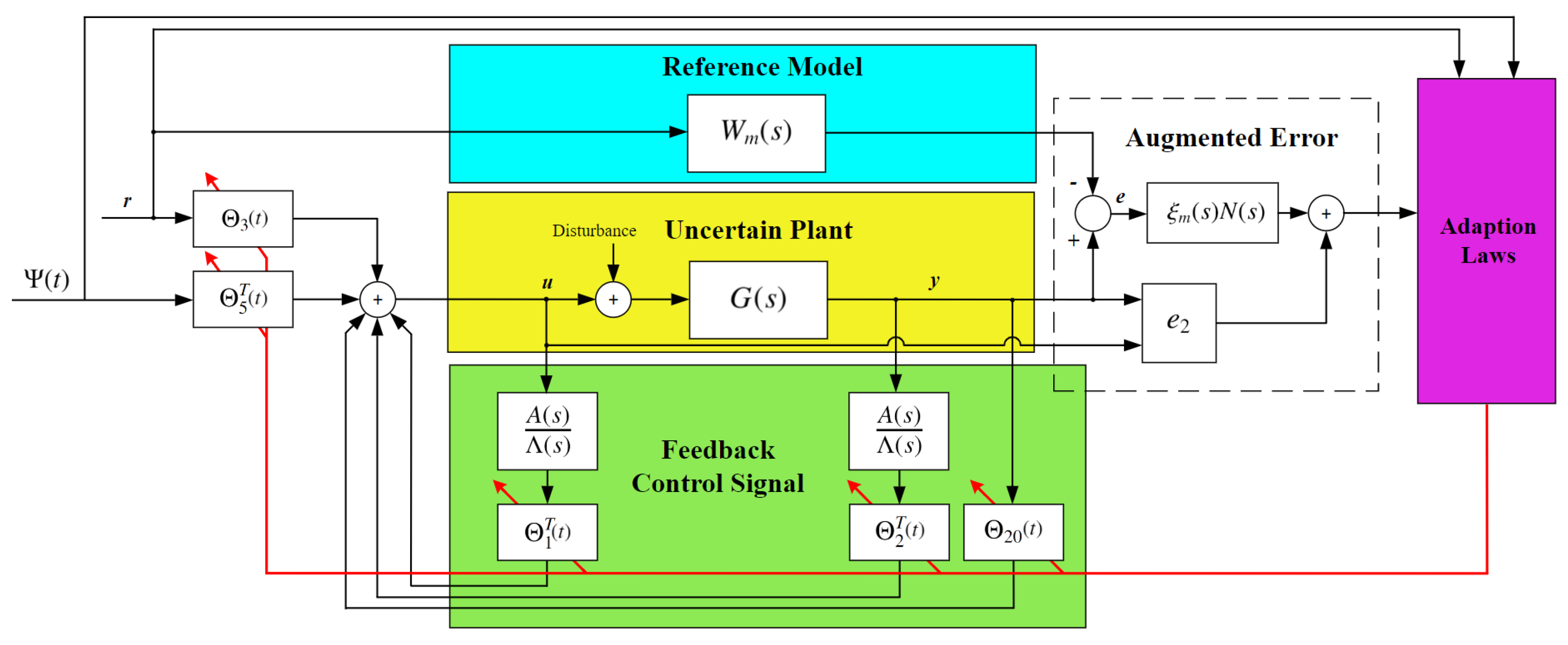

3.4. Output Feedback Control Structure

3.5. Plant Model Matching Condition

3.6. Linear Parametrization of

3.7. LDS Decomposition

4. Robust MRAC Design

4.1. Adaptive Law Design

4.2. Error Model

4.3. Adaptive Parameter Update Laws

4.4. Stability Analysis

4.5. Optimization of Adaptation Rates

5. Results and Analysis

5.1. Validation of Design Assumptions

5.2. Design Components

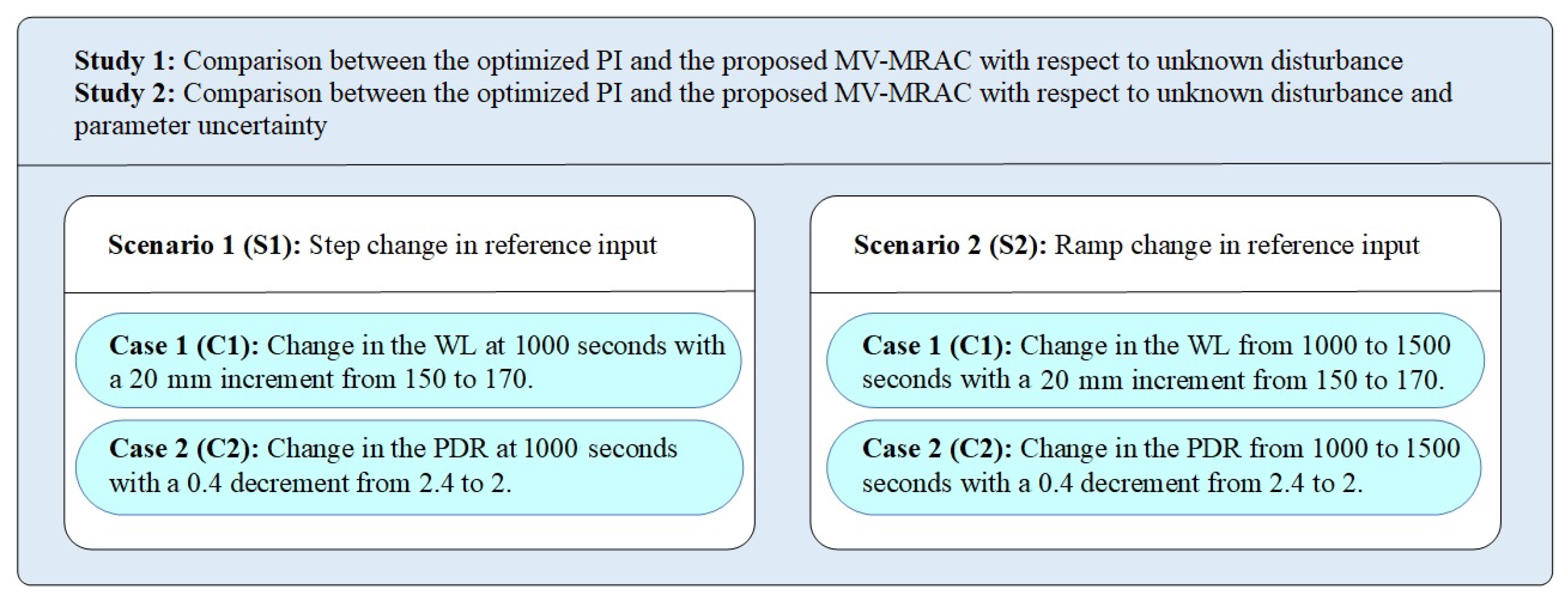

5.3. Simulation Scenarios

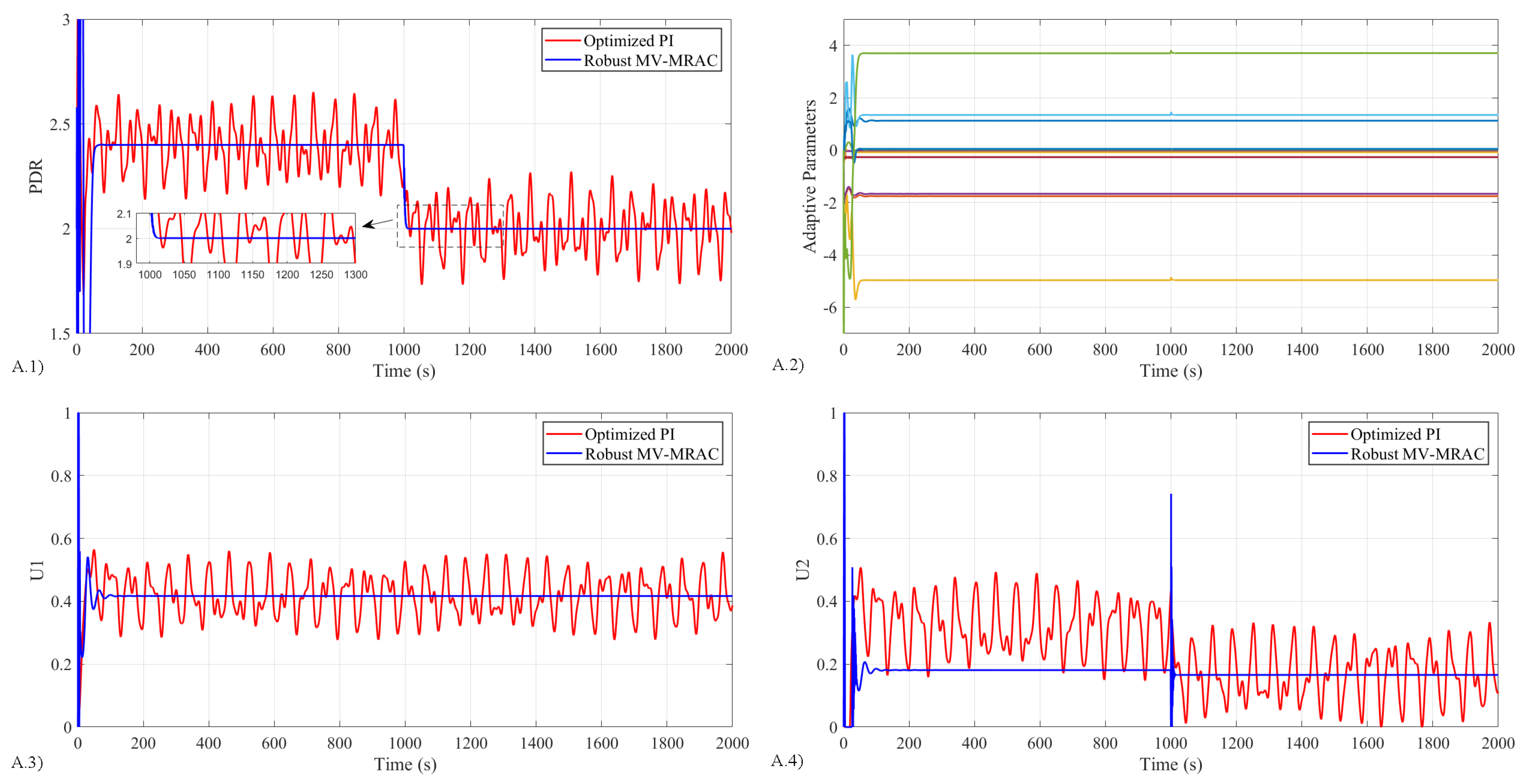

- Study 1 analyzes the closed-loop system in the presence of unknown system disturbances to examine both desired asymptotic output tracking and disturbance rejection.

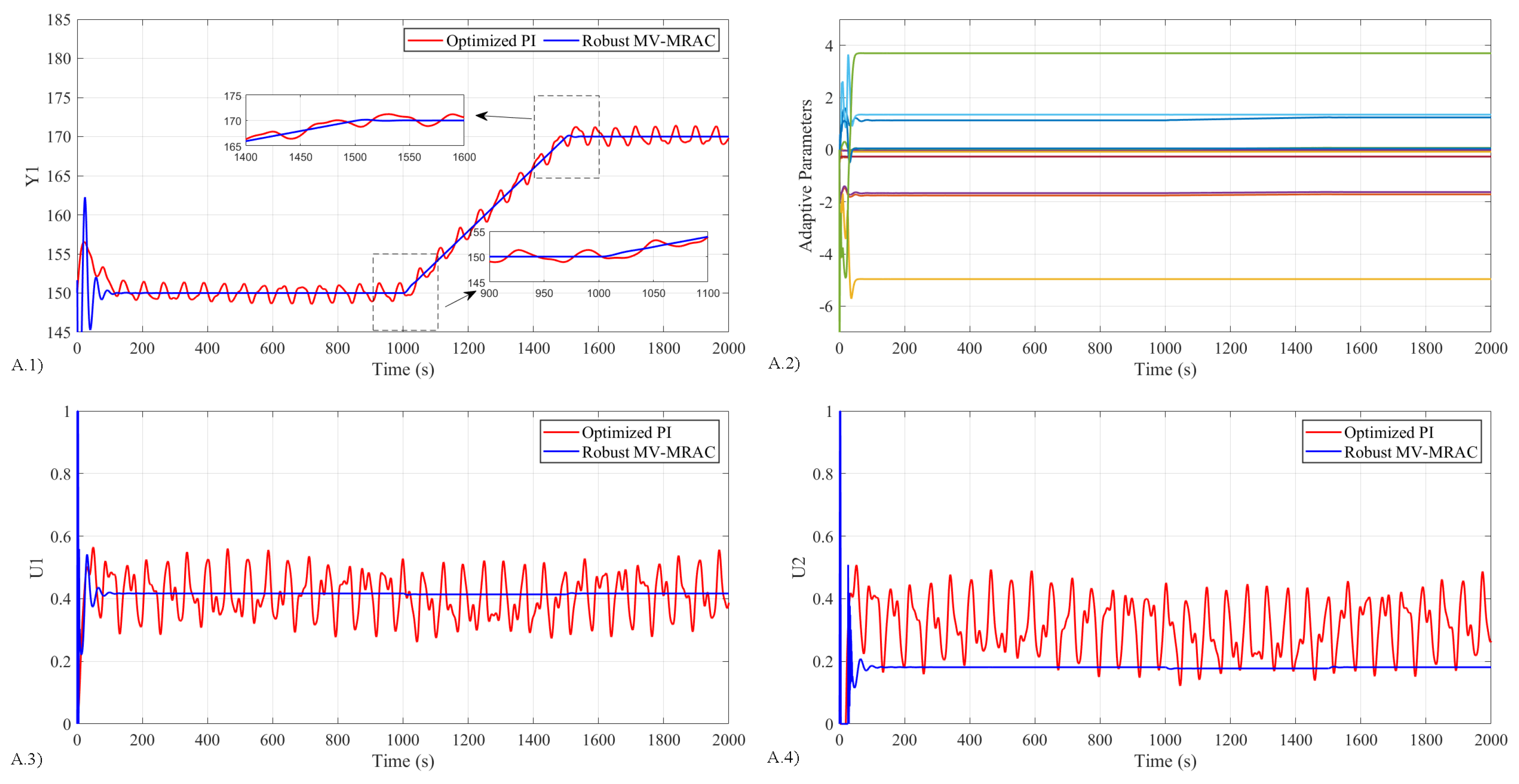

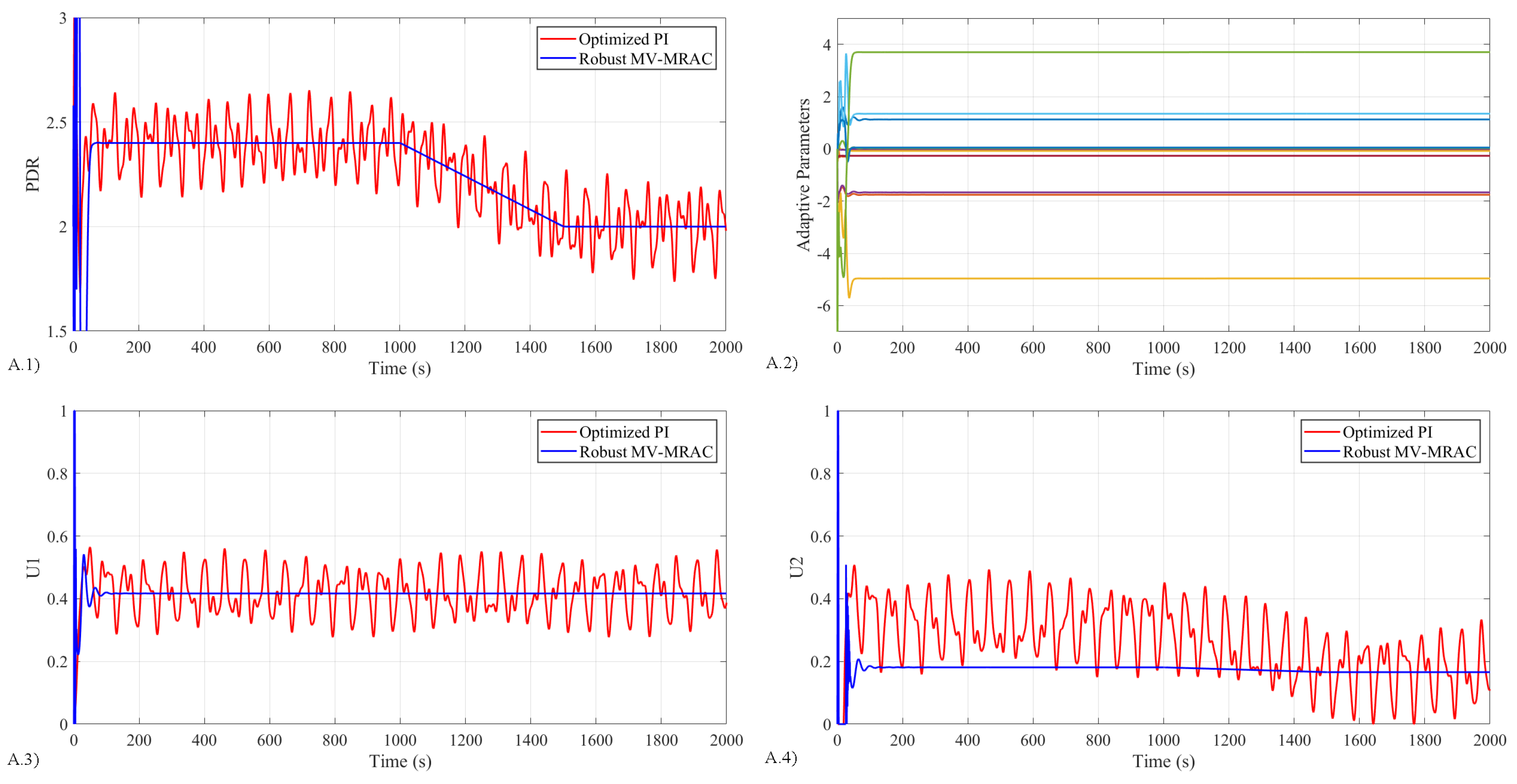

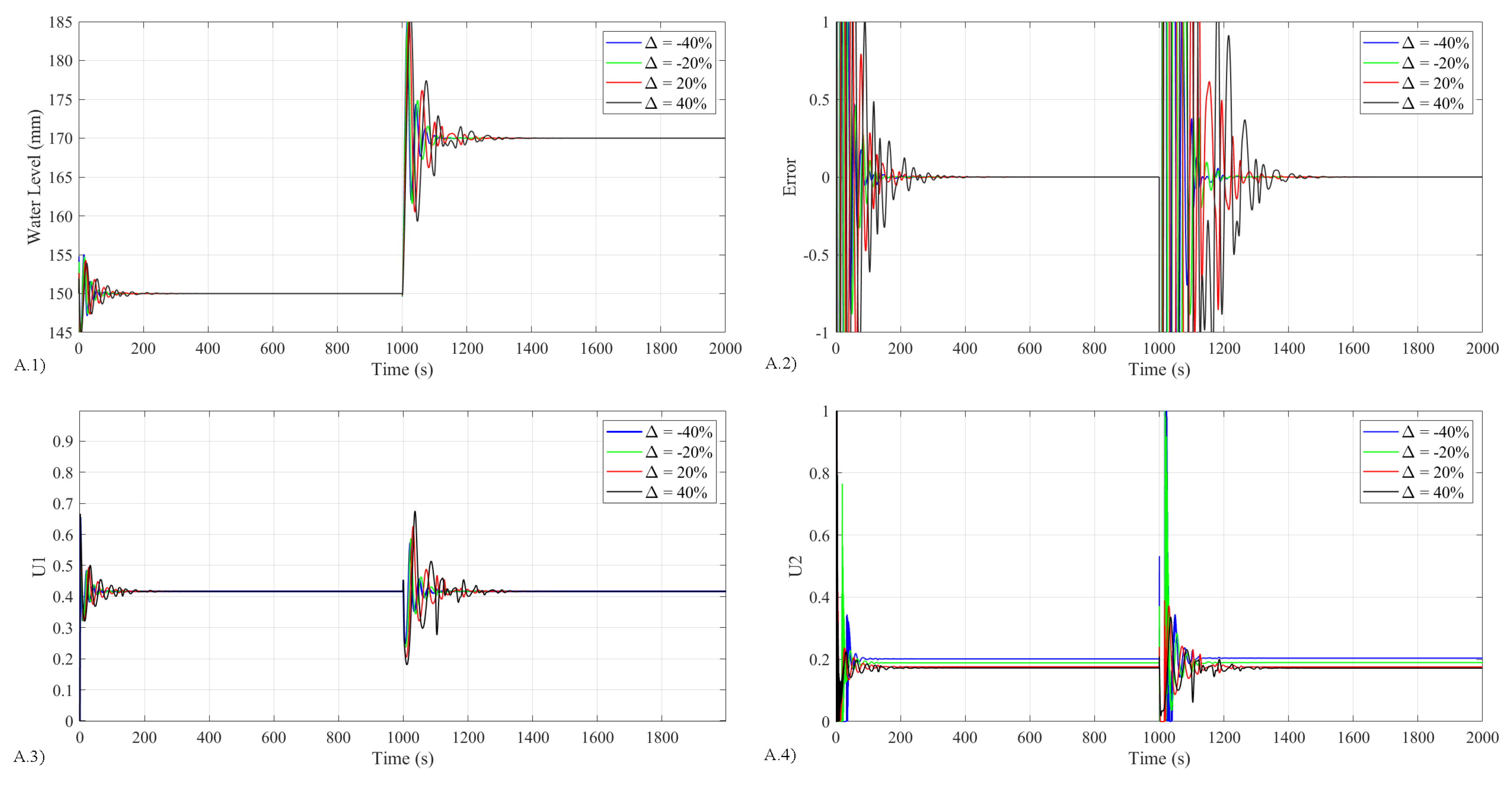

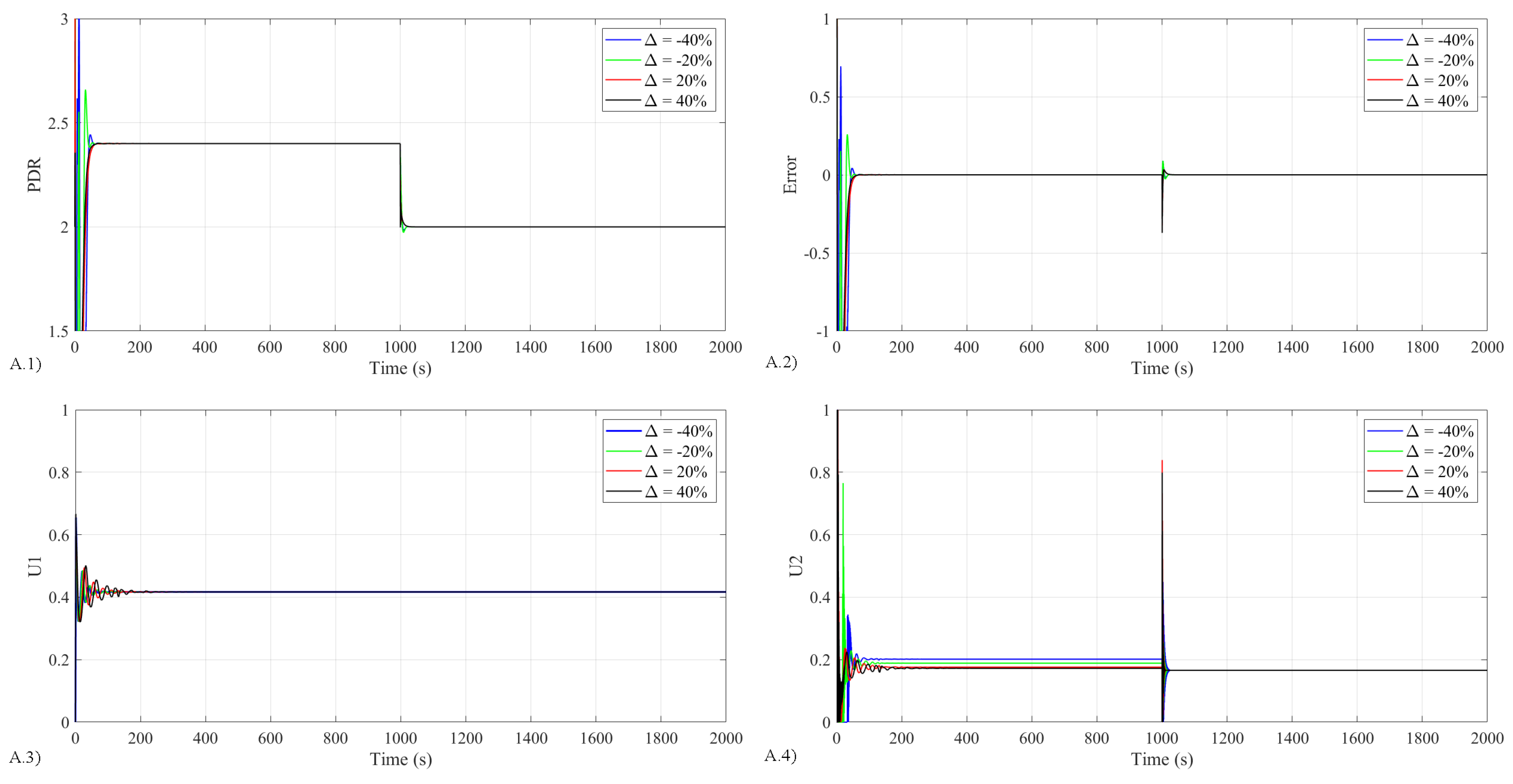

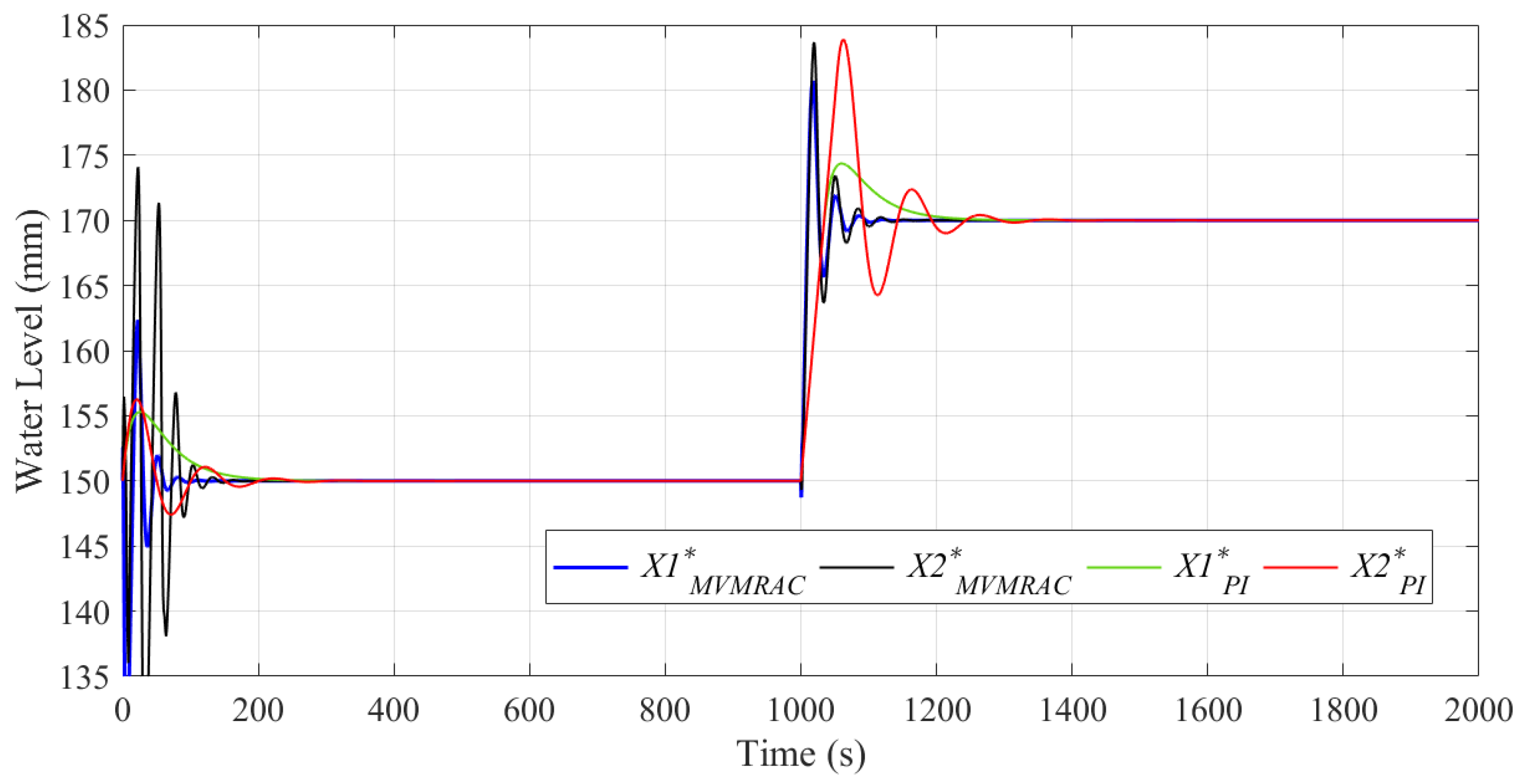

- Study 2 investigates the desired asymptotic output tracking and disturbance rejection of the closed-loop system in the presence of the system’s parameter uncertainty and unknown disturbance.

5.4. Simulation Results

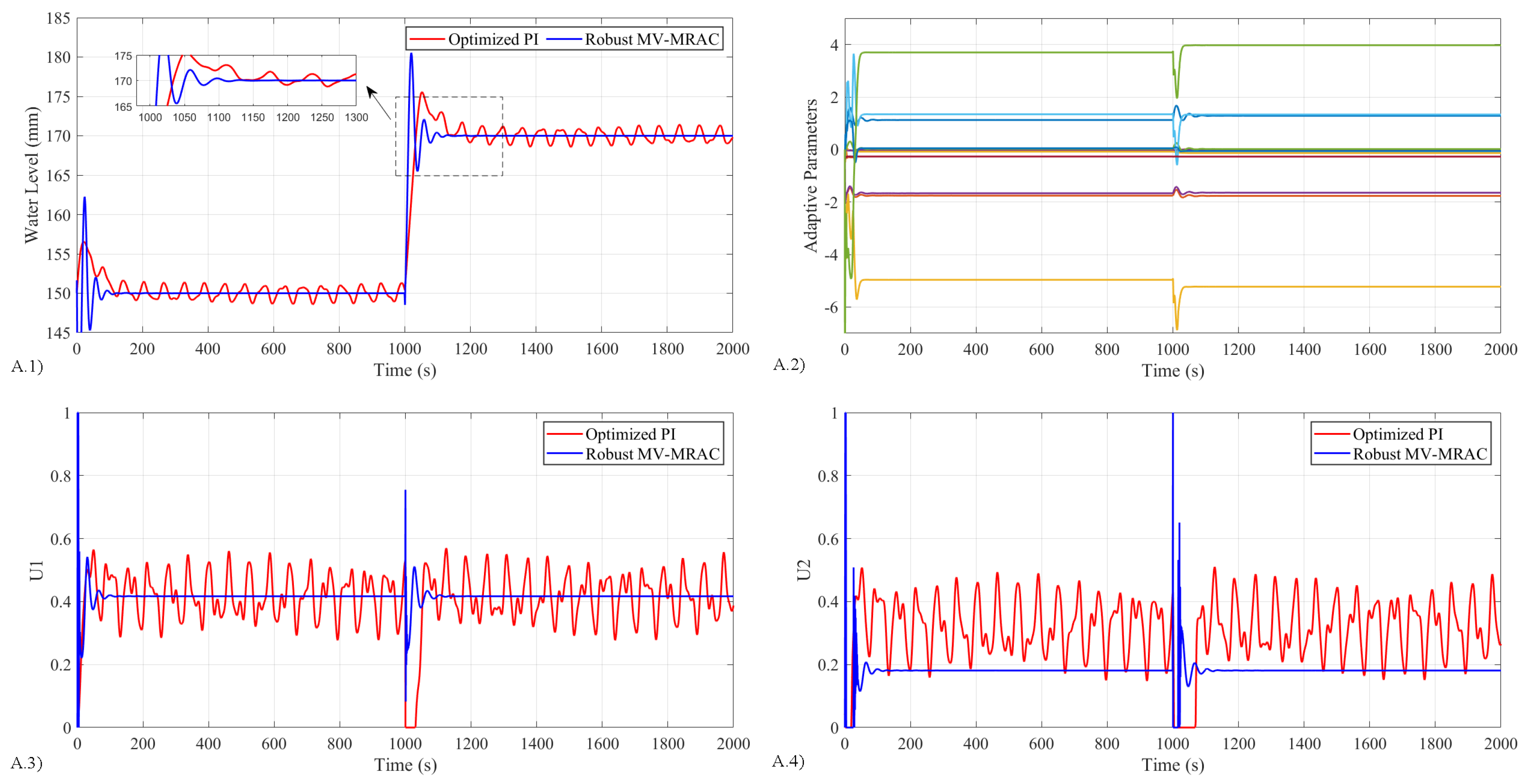

5.4.1. Results for Study 1

5.4.2. Results for Study 2

5.4.3. Results of the Adaptation Rate optimization

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

Appendix A.1. Model Development

References

- Durdevic, P.; Yang, Z. Application of H∞ Robust Control on a Scaled Offshore Oil and Gas De-Oiling Facility. Energies 2018, 11, 287. [Google Scholar] [CrossRef]

- Skogestad, S.; Postlethwaite, I. Multivariable Feedback Control: Analysis and Design; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2005. [Google Scholar]

- Hansen, L.; Durdevic, P.; Jepsen, K.L.; Yang, Z. Plant-wide Optimal Control of an Offshore De-oiling Process Using MPC Technique. IFAC-PapersOnLine 2018, 51, 144–150. [Google Scholar] [CrossRef]

- KG, M.V.; Holden, C.; Skogestad, S. A First-Principles Approach for Control-Oriented Modeling of De-oiling Hydrocyclones. Ind. Eng. Chem. Res. 2020, 59, 18937–18950. [Google Scholar] [CrossRef]

- Jespersen, S.; Yang, Z. Performance Evaluation of a De-oiling Process Controlled by PID, H∞ and MPC. In Proceedings of the IECON 2021—47th Annual Conference of the IEEE Industrial Electronics Society, Toronto, ON, Canada, 10 November 2021; pp. 1–6. [Google Scholar] [CrossRef]

- Tao, G. Adaptive Control Design and Analysis; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2003. [Google Scholar] [CrossRef]

- Pedersen, S. Plant-Wide Anti-Slug Control for Offshore Oil and Gas Processes. Ph.D. Thesis, Aalborg University, Aalborg, Denmark, 2016. [Google Scholar] [CrossRef]

- Jahanshahi, E.; Skogestad, S. Nonlinear control solutions to prevent slugging flow in offshore oil production. J. Process Control 2017, 54, 138–151. [Google Scholar] [CrossRef]

- Li, S.; Durdevic, P.; Yang, Z. Model-free H∞ tracking control for de-oiling hydrocyclone systems via off-policy reinforcement learning. Automatica 2021, 133, 109862. [Google Scholar] [CrossRef]

- Vallabhan KG, M.; Holden, C.; Skogestad, S. Deoiling Hydrocyclones: An Experimental Study of Novel Control Schemes. SPE Prod. Oper. 2022, 37, 462–474. [Google Scholar] [CrossRef]

- Diehl, F.C.; Almeida, C.S.; Anzai, T.K.; Gerevini, G.; Neto, S.S.; Von Meien, O.F.; Campos, M.C.; Farenzena, M.; Trierweiler, J.O. Oil production increase in unstable gas lift systems through nonlinear model predictive control. J. Process Control 2018, 69, 58–69. [Google Scholar] [CrossRef]

- Kashani, M.; Jespersen, S.; Yang, Z. Robust Multivariable Model Reference Adaptive State Feedback Output Tracking Control: An Offshore Produced Water Treatment Case Study. In Proceedings of the 2023 9th International Conference on Control, Decision and Information Technologies (CoDIT), Rome, Italy, 24 October 2023; pp. 2317–2324. [Google Scholar] [CrossRef]

- Song, G. A New Framework of Model Reference Adaptive Control Partial-State Feedback Designs and Applications. Ph.D. Thesis, University of Virginia, Charlottesville, VA, USA, 2019. [Google Scholar]

- Song, G.; Tao, G. Partial-state feedback multivariable MRAC and reduced-order designs. Automatica 2021, 129, 109622. [Google Scholar] [CrossRef]

- Wen, L.; Tao, G.; Liu, Y. Multivariable adaptive output rejection of unmatched input disturbances. Int. J. Adapt. Control Signal Process. 2016, 30, 1203–1227. [Google Scholar] [CrossRef]

- Selfridge, J.M.; Tao, G. Multivariable output feedback MRAC for a quadrotor UAV. In Proceedings of the 2016 American Control Conference (ACC), Boston, MA, USA, 1 August 2016; pp. 492–499. [Google Scholar] [CrossRef]

- Bagherpoor, H.; Salmasi, F.R. Robust model reference adaptive output feedback tracking for uncertain linear systems with actuator fault based on reinforced dead-zone modification. ISA Trans. 2015, 57, 51–56. [Google Scholar] [CrossRef] [PubMed]

- Hua, C.C.; Leng, J.; Guan, X.P. Decentralized MRAC for large-scale interconnected systems with time-varying delays and applications to chemical reactor systems. J. Process Control 2012, 22, 1985–1996. [Google Scholar] [CrossRef]

- Narendra, K.S.; Annaswamy, A.M. Stable Adaptive Systems; Dover Publications: Mineola, NY, USA, 2012; Available online: https://books.google.co.uk/books?id=CRJhmsAHCUcC (accessed on 22 February 2024).

- Guo, J.; Liu, Y.; Tao, G. A multivariable MRAC design using state feedback for linearized aircraft models with damage. In Proceedings of the 2010 American Control Conference, Baltimore, MD, USA, 30 June–2 July 2010; pp. 2095–2100. [Google Scholar] [CrossRef]

- Lan, W.; Chen, B.M.; Ding, Z. Adaptive estimation and rejection of unknown sinusoidal disturbances through measurement feedback for a class of non-minimum phase non-linear MIMO systems. Int. J. Adapt. Control Signal Process. 2006, 20, 77–97. [Google Scholar] [CrossRef]

- Wolovich, W.A.; Falb, P.L. Invariants and Canonical Forms under Dynamic Compensation. SIAM J. Control Optim. 1976, 14, 996–1008. [Google Scholar] [CrossRef]

- Wang, C.; Wen, C.; Zhang, X.; Huang, J. Output-feedback adaptive control for a class of MIMO nonlinear systems with actuator and sensor faults. J. Frankl. Inst. 2020, 357, 7962–7982. [Google Scholar] [CrossRef]

- Liu, Y.; Tao, G. An Adaptive Disturbance Rejection Algorithm for MIMO Systems with An Aircraft Flight Control Application. In AIAA Guidance, Navigation and Control Conference and Exhibit; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2007. [Google Scholar] [CrossRef]

- Rao, R.; Savsani, V.; Vakharia, D. Teaching—Learning-based optimization: A novel method for constrained mechanical design optimization problems. Comput.-Aided Des. 2011, 43, 303–315. [Google Scholar] [CrossRef]

- Yang, Z.; Juhl, M.; Løhndorf, B. On the innovation of level control of an offshore three-phase separator. In Proceedings of the 2010 IEEE International Conference on Mechatronics and Automation, Xi’an, China, 7 October 2010; pp. 1348–1353. [Google Scholar] [CrossRef]

| S1-C1 | S1-C2 | |||

|---|---|---|---|---|

| Optimized-PI | MV-MRAC | Optimized-PI | MV-MRAC | |

| 1.1930 | 0.3159 | 1.0293 | 0.1301 | |

| 1.1726 | 0.3470 | 0.9734 | 0.1321 | |

| 1.1514 | 0.4653 | 0.8117 | 0.1478 | |

| 1.1899 | 0.5906 | 0.7031 | 0.1622 | |

| S2-C1 | S2-C2 | |||

|---|---|---|---|---|

| Optimized-PI | MV-MRAC | Optimized-PI | MV-MRAC | |

| 1.0353 | 0.3250 | 1.0293 | 0.3128 | |

| 0.9803 | 0.2003 | 0.9734 | 0.2874 | |

| 0.8222 | 0.2843 | 0.8117 | 0.2714 | |

| 0.7184 | 0.3049 | 0.7031 | 0.2904 | |

| S1-C1 | S1-C2 | |||

|---|---|---|---|---|

| Optimized-PI | MV-MRAC | Optimized-PI | MV-MRAC | |

| Mean | 1.167 | 0.431 | 0.876 | 0.137 |

| Standard Deviation | 0.040 | 0.052 | 0.070 | 0.016 |

| Standard Error of the Mean | 0.009 | 0.012 | 0.016 | 0.004 |

| 95% Confidence Interval | (1.14, 1.18) | (0.40, 0.45) | (0.84, 0.91) | (0.13, 0.14) |

| S2-C1 | S2-C2 | |||

|---|---|---|---|---|

| Optimized-PI | MV-MRAC | Optimized-PI | MV-MRAC | |

| Mean | 0.879 | 0.278 | 0.880 | 0.291 |

| Standard Deviation | 0.070 | 0.025 | 0.073 | 0.015 |

| Standard Error of the Mean | 0.016 | 0.006 | 0.016 | 0.003 |

| 95% Confidence Interval | (0.84, 0.91) | (0.26, 0.29) | (0.84, 0.91) | (0.28, 0.29) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kashani, M.; Jespersen, S.; Yang, Z. Robust Adaptive Control of the Offshore Produced Water Treatment Process: An Improved Multivariable MRAC-Based Approach. Water 2024, 16, 899. https://doi.org/10.3390/w16060899

Kashani M, Jespersen S, Yang Z. Robust Adaptive Control of the Offshore Produced Water Treatment Process: An Improved Multivariable MRAC-Based Approach. Water. 2024; 16(6):899. https://doi.org/10.3390/w16060899

Chicago/Turabian StyleKashani, Mahsa, Stefan Jespersen, and Zhenyu Yang. 2024. "Robust Adaptive Control of the Offshore Produced Water Treatment Process: An Improved Multivariable MRAC-Based Approach" Water 16, no. 6: 899. https://doi.org/10.3390/w16060899

APA StyleKashani, M., Jespersen, S., & Yang, Z. (2024). Robust Adaptive Control of the Offshore Produced Water Treatment Process: An Improved Multivariable MRAC-Based Approach. Water, 16(6), 899. https://doi.org/10.3390/w16060899