A Monte-Carlo-Based Method for the Optimal Placement and Operation Scheduling of Sewer Mining Units in Urban Wastewater Networks

Abstract

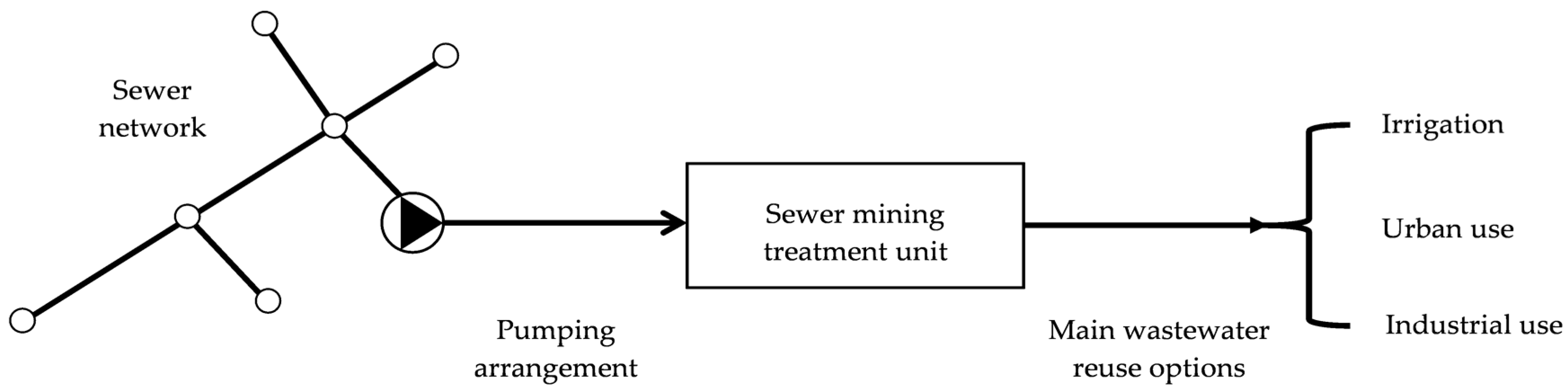

:1. Introduction

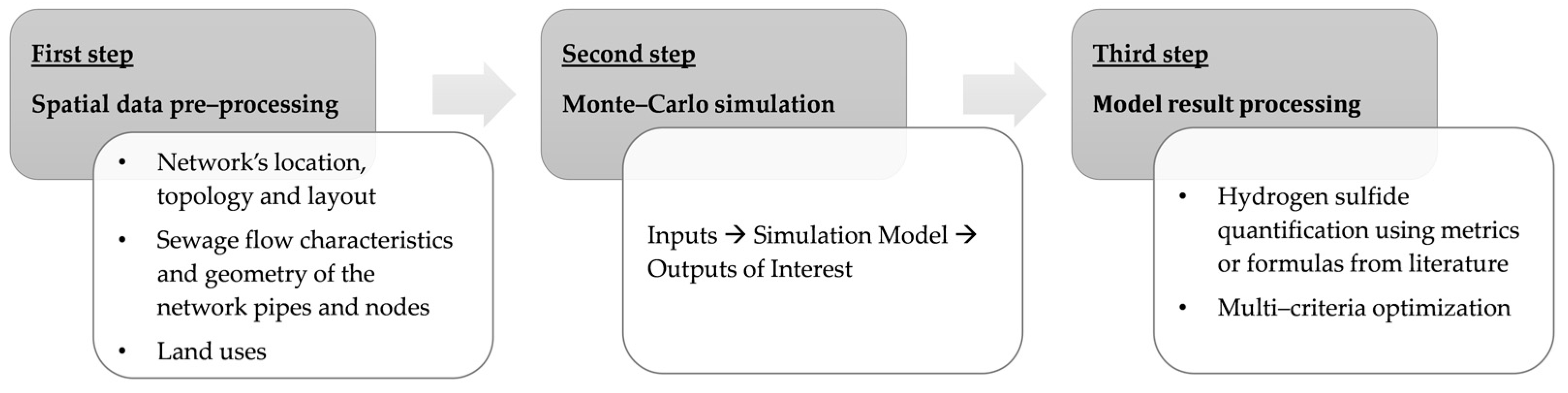

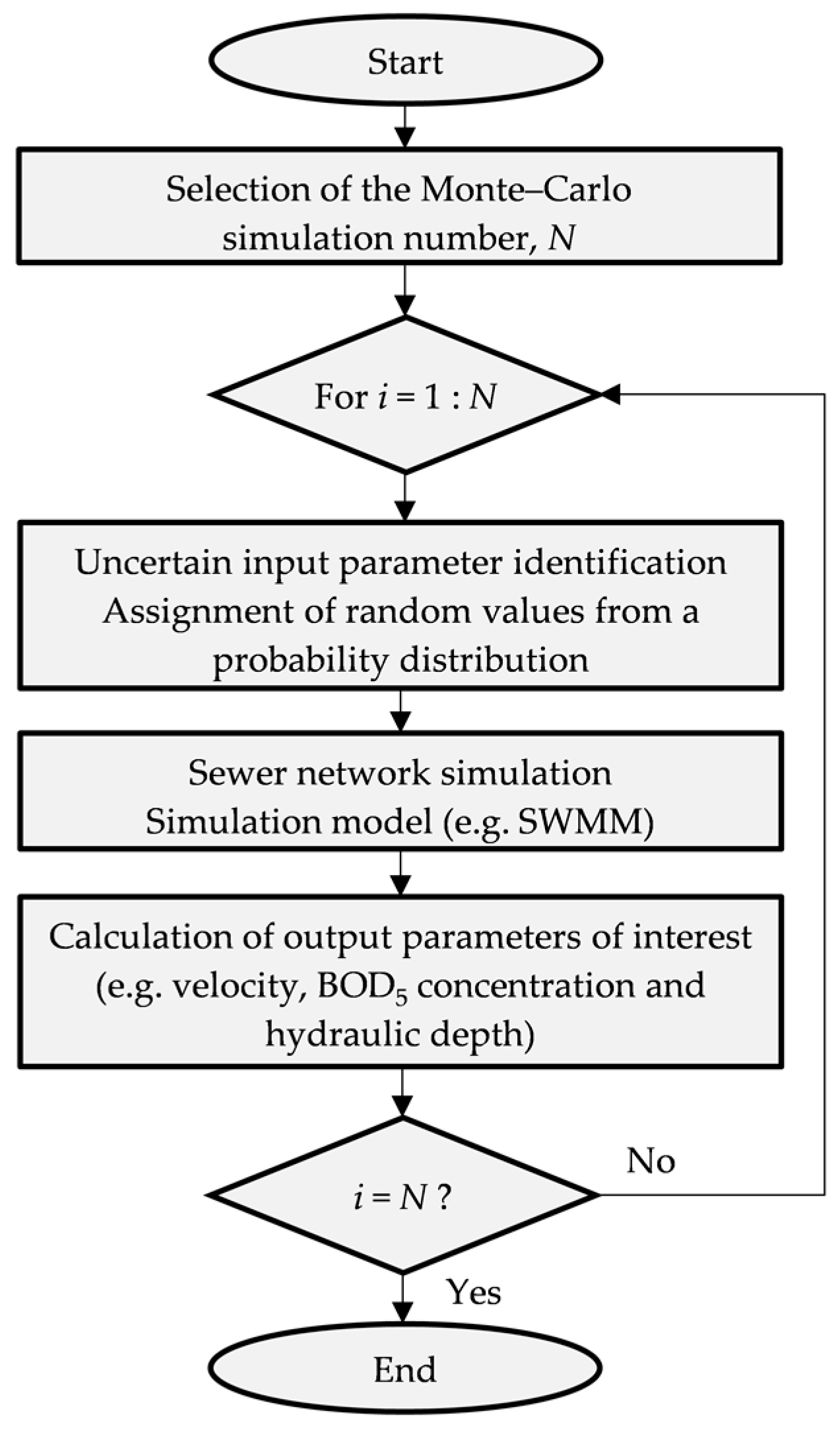

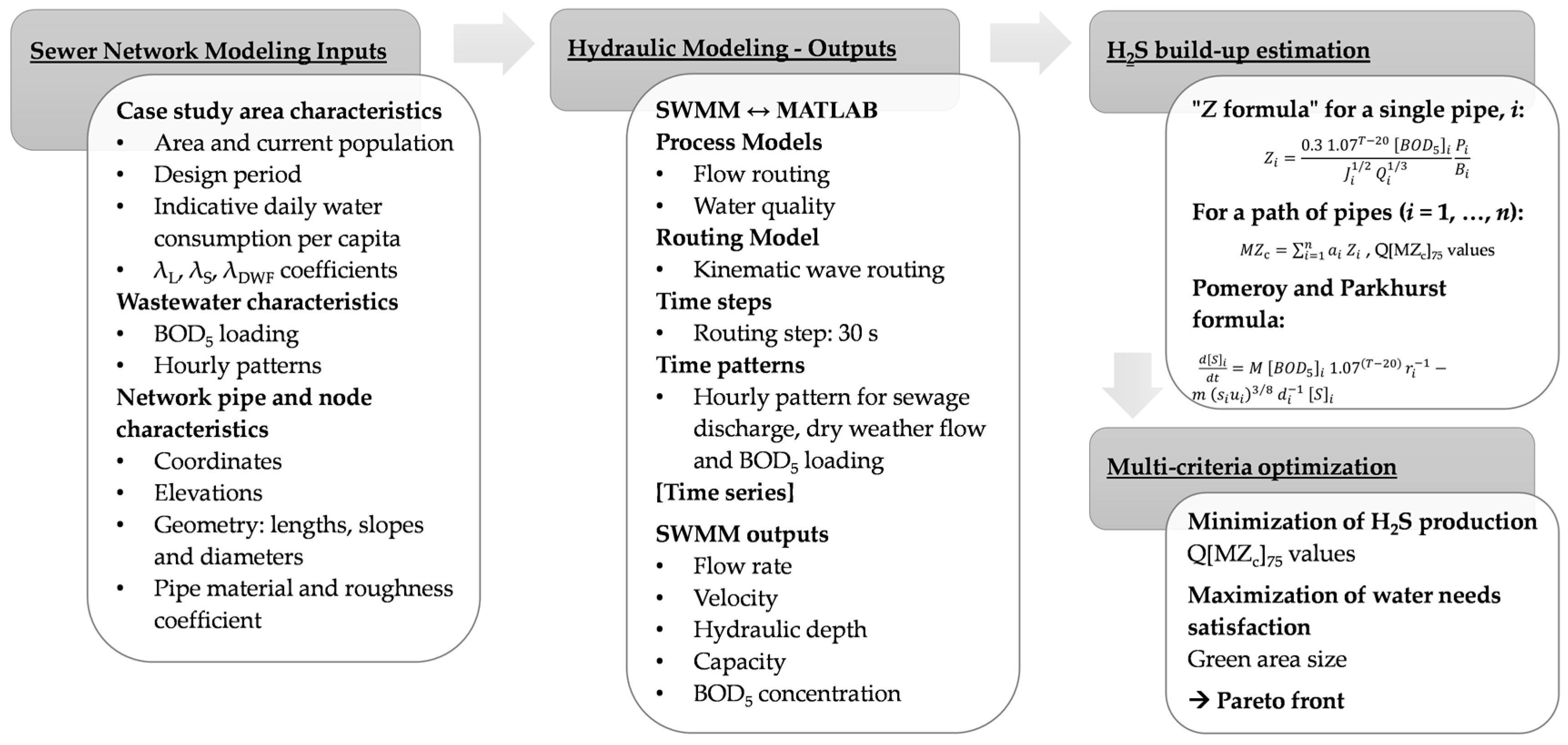

2. Materials and Methods

2.1. Methodology Description

2.2. The Storm Water Management Model (SWMM)

2.3. Design Discharge Calculation

2.4. Hydrogen Sulfide Build-Up Estimation

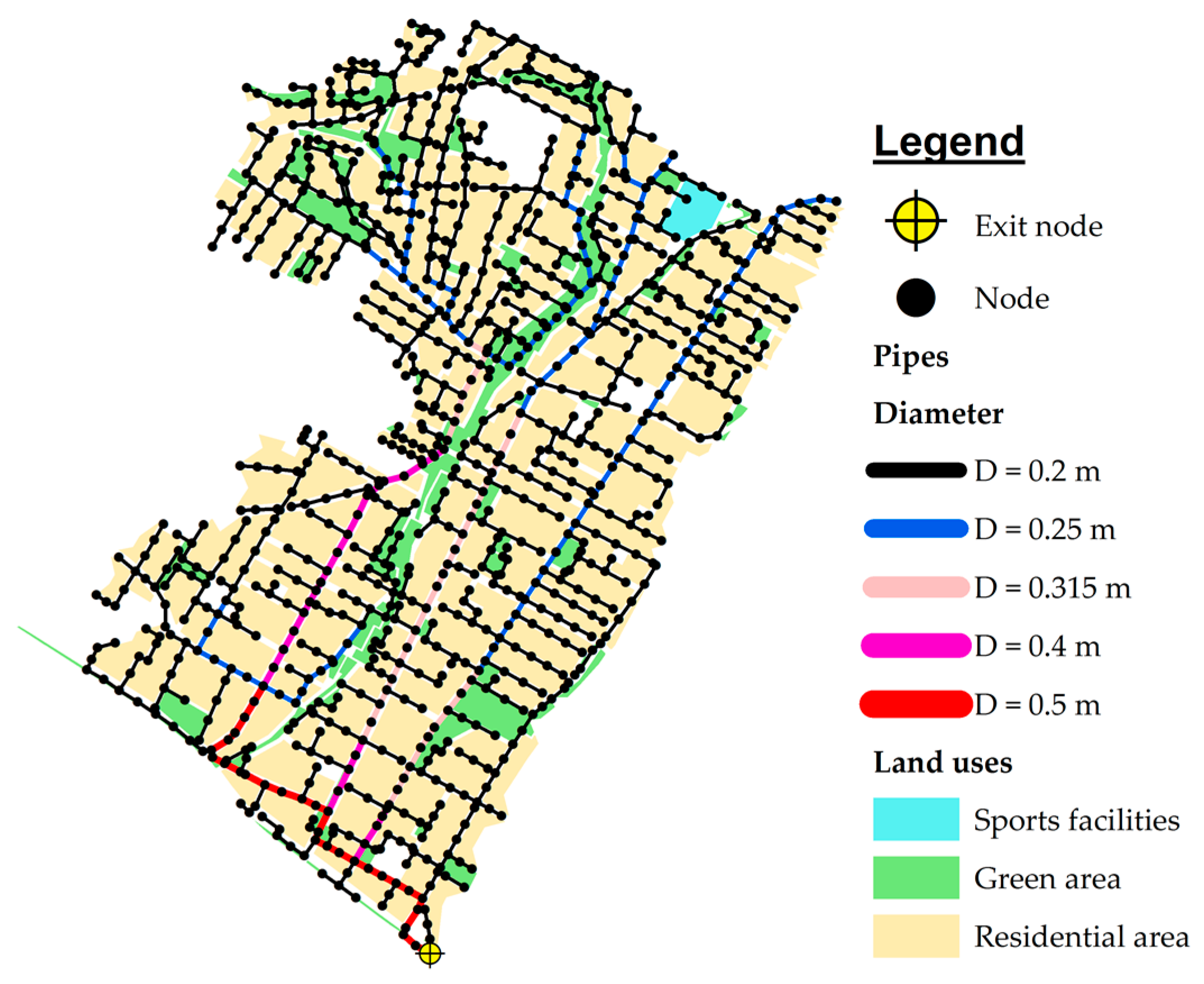

2.5. Case Study

2.5.1. Study Area

2.5.2. Implementation Details

3. Results

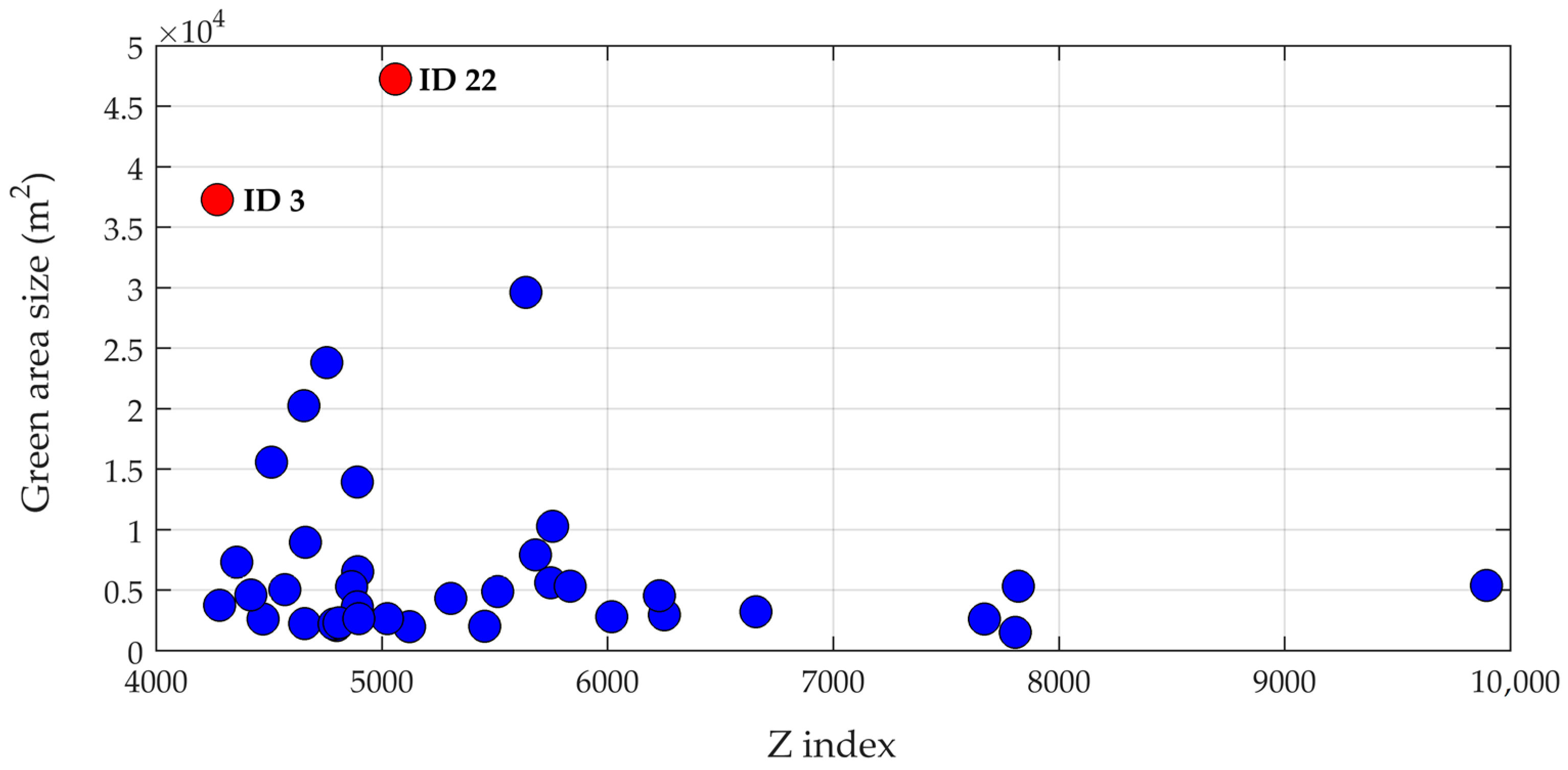

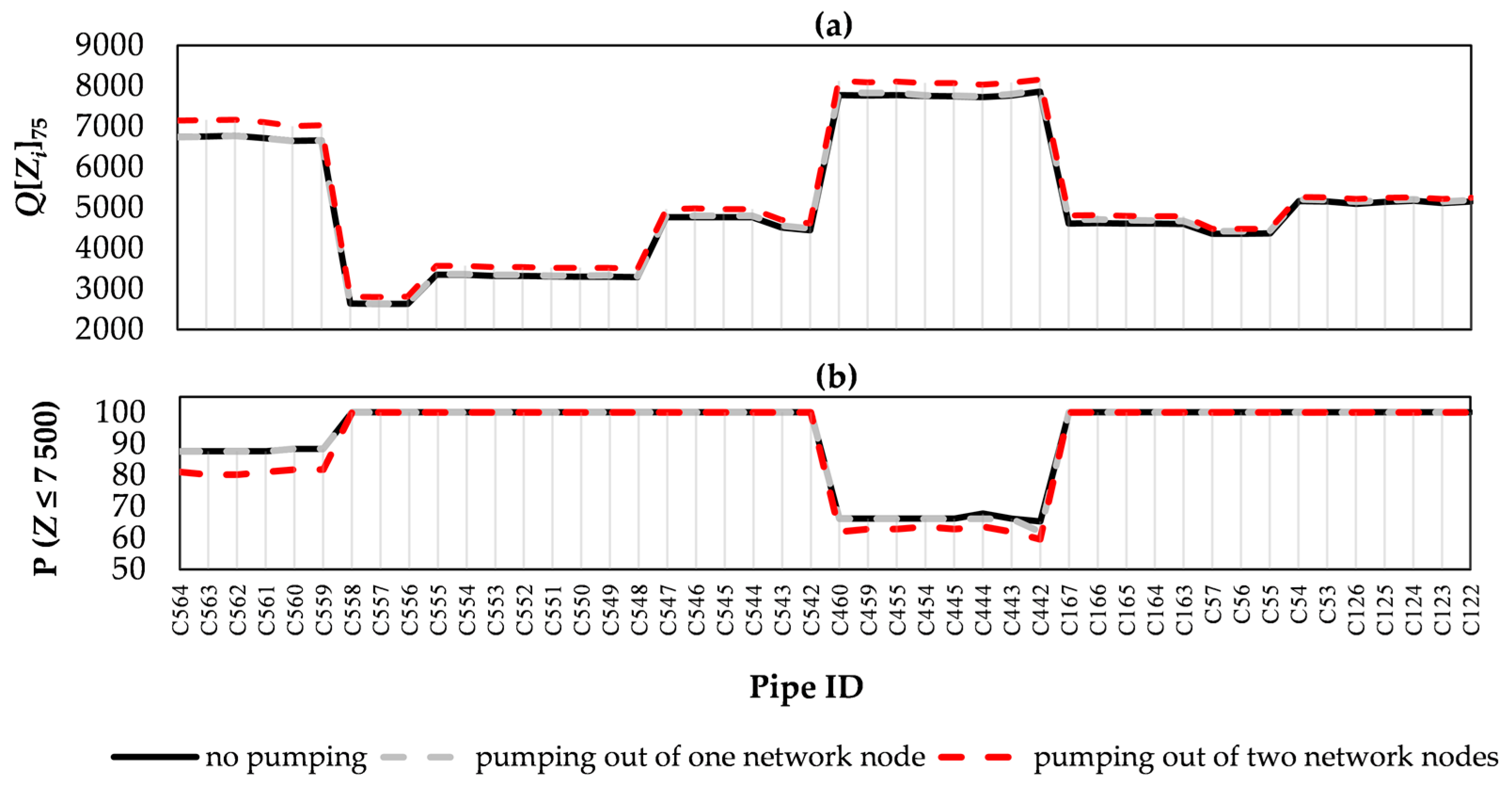

3.1. Identification of Locations for Optimal Sewer Mining Unit Placement

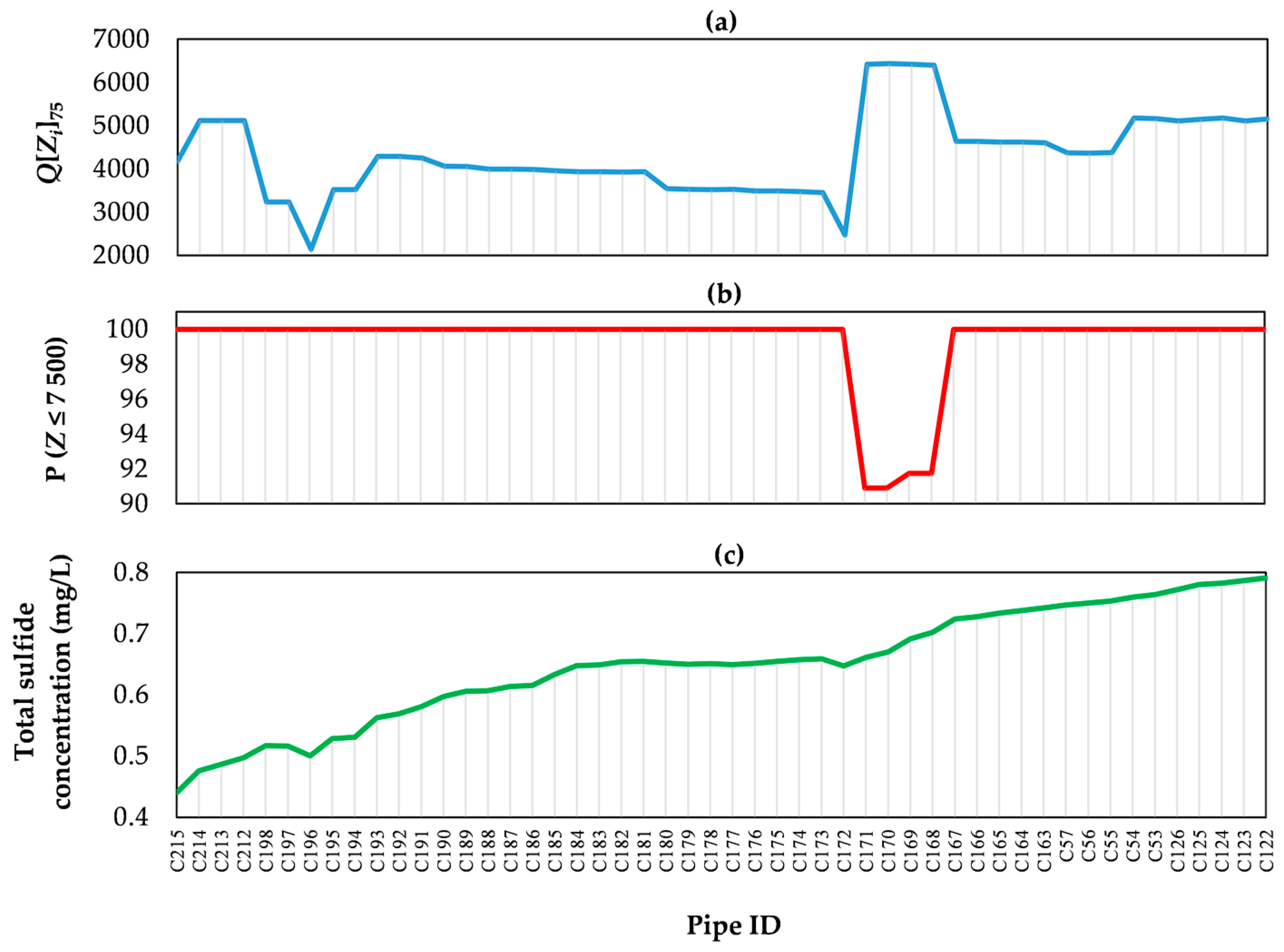

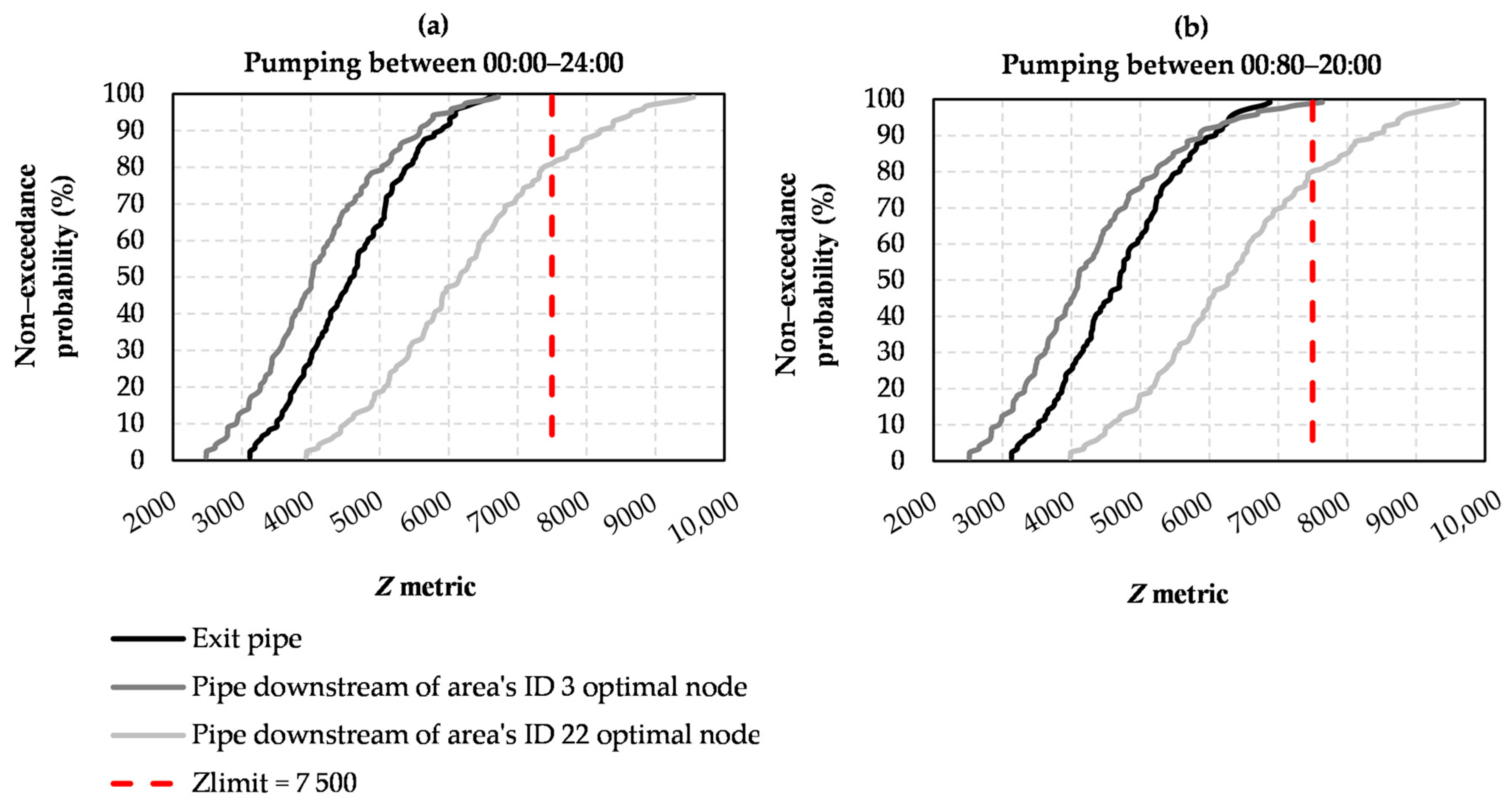

3.2. Sewer Mining Implementation in the Sewer Network

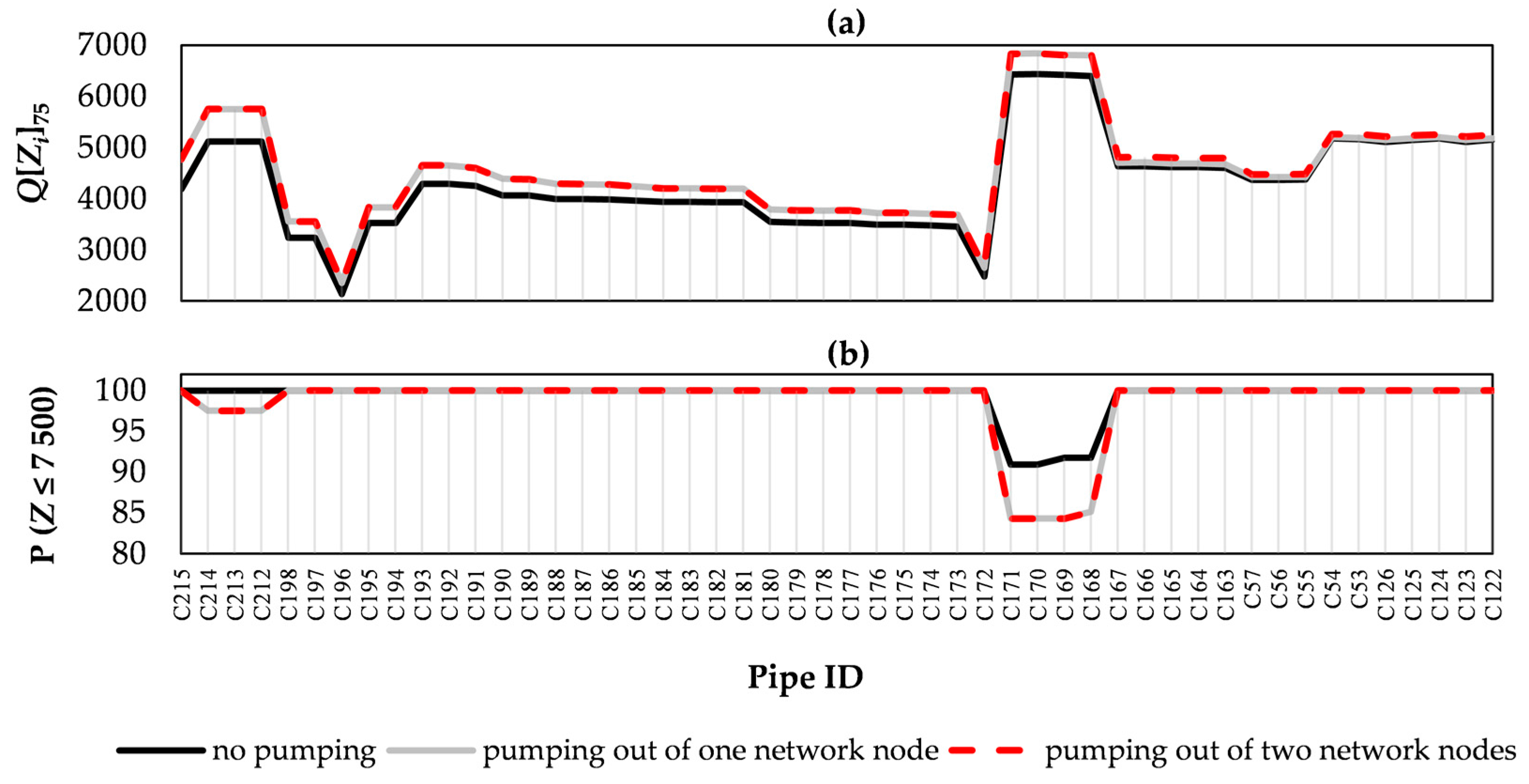

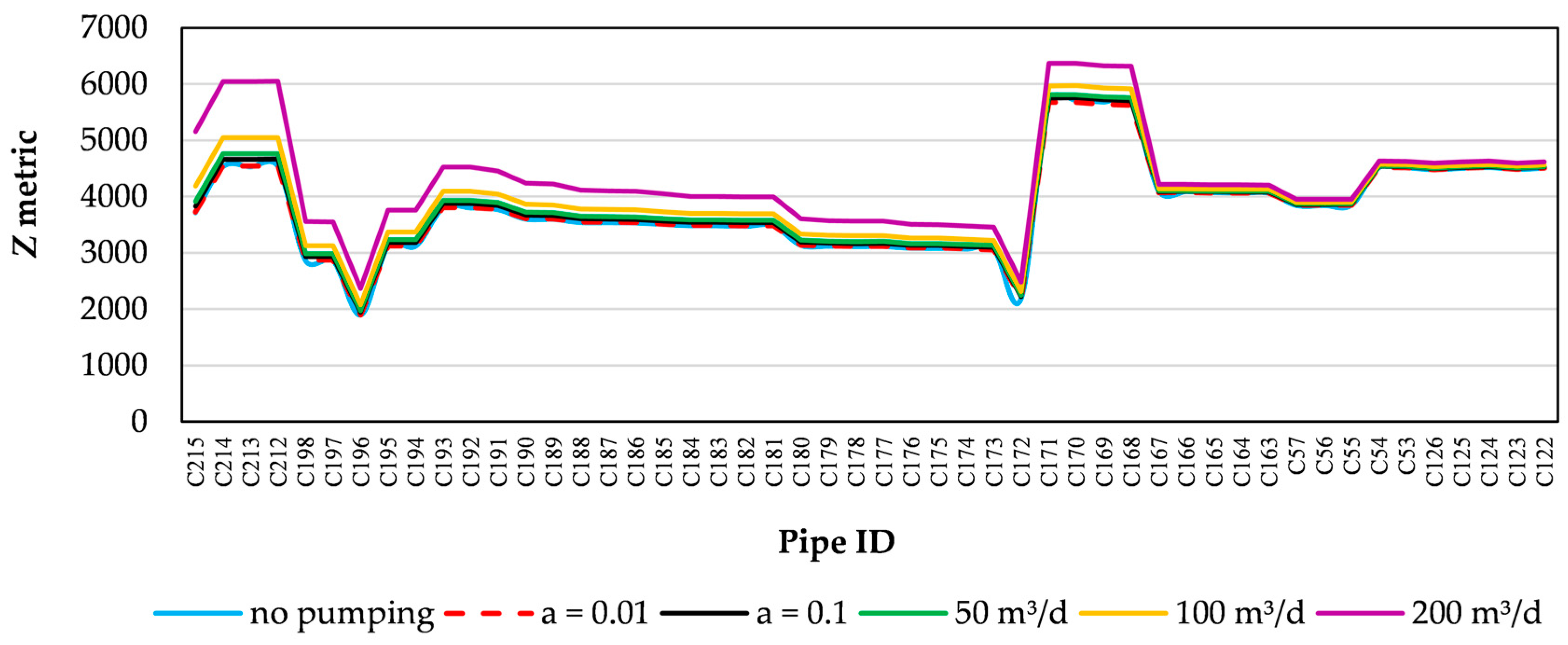

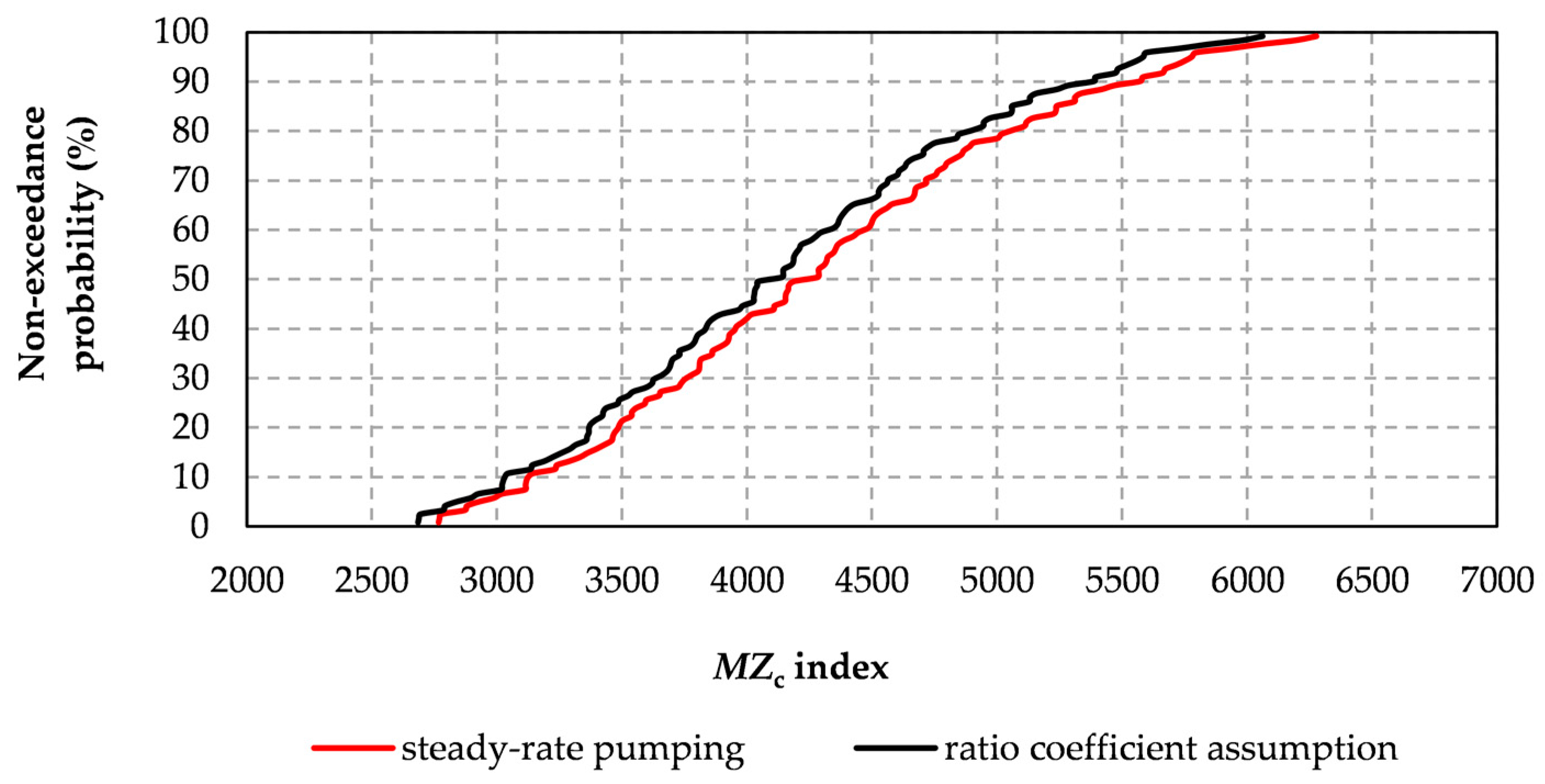

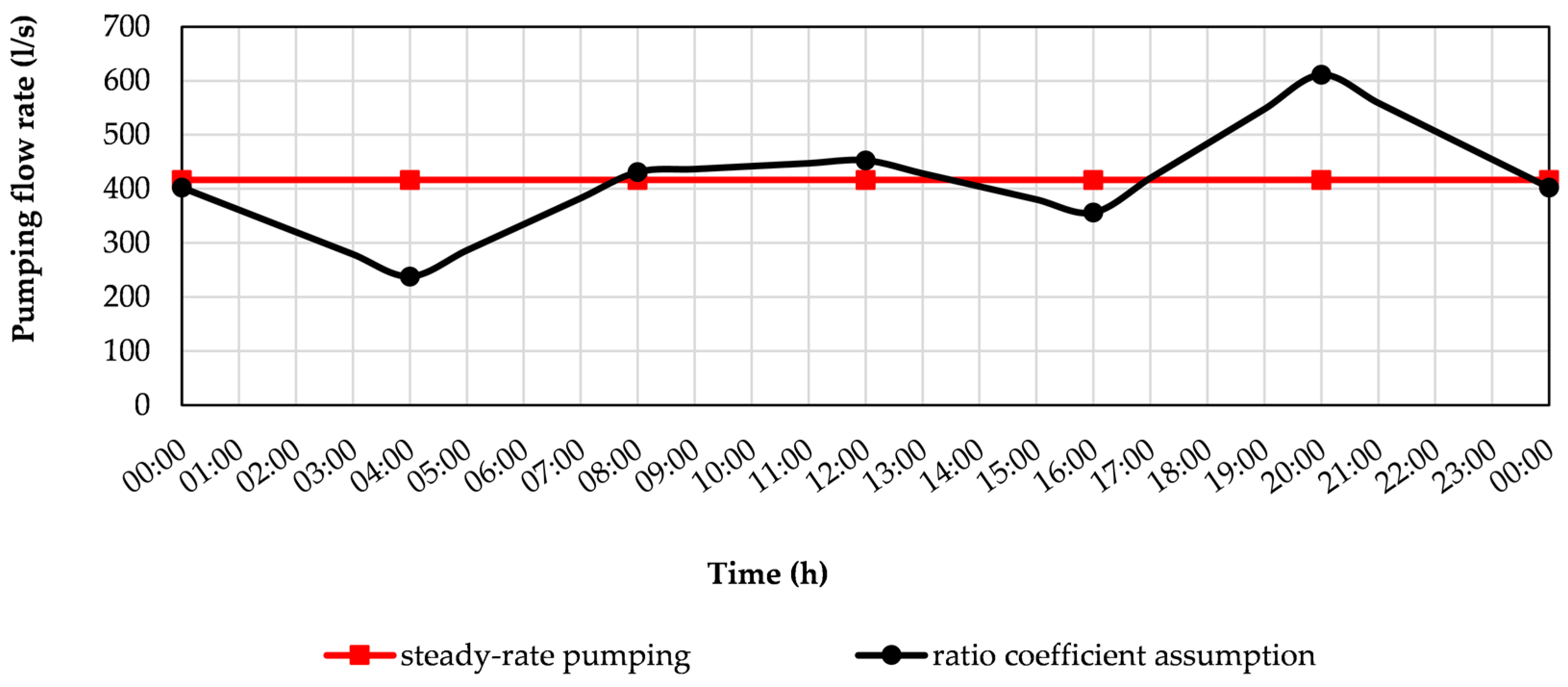

3.3. Optimal Pumping Scheduling

4. Discussion

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Angelakis, A.N.; Gikas, P. Water reuse: Overview of current practices and trends in the world with emphasis on eu states. Water Util. J. 2014, 8, 67–78. [Google Scholar]

- Reiter, P. Imperatives for Urban Water Professionals on the Pathway to 2050: Adapting to Rapidly Changing Conditions on a Crowder Planet; International Water Association (IWA): London, UK, 2010; pp. 6–8. [Google Scholar]

- Pereira, L.S.; Cordery, I.; Iacovides, I. Water scarcity concepts. In Coping with Water Scarcity; Springer: Dordrecht, The Netherlands, 2009; pp. 7–24. [Google Scholar]

- Klein, R.J.T.; Midgley, G.F.; Preston, B.L.; Alam, M.; Berkhout, F.G.H.; Dow, K.; Shaw, M.R. Adaptation opportunities, constraints, and limits. In Climate Change 2014: Impacts, Adaptation, and Vulnerability; Cambridge University Press: Cambridge, UK, 2014; pp. 899–943. [Google Scholar]

- Bates, B.C.; Kundzewicz, Z.W.; Wu, S.; Palutikof, J.P.E. Climate Change and Water. Technical Paper of the Intergovernmental Panel on Climate Change; IPCC Secretariat: Geneva, Switzerland, 2008; p. 210. [Google Scholar]

- Anderson, J. The environmental benefits of water recycling and reuse. Water Sci. Technol. 2003, 3, 1–10. [Google Scholar]

- Metcalf & Eddy Inc.; Asano, T.; Burton, F.; Leverenz, H.; Tsuchihashi, R.; Tchobanoglous, G. Water Reuse: Issues, Technologies, and Applications; Mc-Graw Hill: NewYork, NY, USA, 2007; p. 1503. [Google Scholar]

- Crites, R.; Tchobanoglous, G. Small and Decentralized Wastewater Management Systems, 1st ed.; WCB/McGraw-Hill: New York, NY, USA, 1998; p. 1084. [Google Scholar]

- Gikas, P.; Tchobanoglous, G. The role of satellite and decentralized strategies in water resources management. J. Environ. Manag. 2009, 90, 144–152. [Google Scholar] [CrossRef] [PubMed]

- Sharma, A.K.; Tjandraatmadja, G.; Cook, S.; Gardner, T. Decentralised systems—Definition and drivers in the current context. Water Sci. Technol. 2013, 67, 2091–2101. [Google Scholar] [CrossRef] [PubMed]

- EPA. Decentralized Wastewater Treatment: A Sensible Solution. Available online: https://www.epa.gov/sites/production/files/2015-06/documents/mou-intro-paper-081712-pdf-adobe-acrobat-pro.pdf (accessed on 20 January 2018).

- Makropoulos, C.K.; Butler, D. Distributed water infrastructure for sustainable communities. Water Resour. Manag. 2010, 24, 2795–2816. [Google Scholar] [CrossRef]

- Barwon Water. Barwon Water Sewer Mining Guidelines. Available online: https://www.barwonwater.vic.gov.au/vdl/A2413187/Sewer%20Mining%20Guidelines.pdf (accessed on 25 November 2017).

- Marleni, N.; Gray, S.; Sharma, A.; Burn, S.; Muttil, N. Modeling the effects of sewer mining on odour and corrosion in sewer systems. In Proceedings of the 20th International Congress on Modelling and Simulation, Adelaide, Australia, 1–6 December 2013. [Google Scholar]

- Ødegaard, H. Description of an Alternative Urban Water Management System and Its Inherent Technologies; Rapport Nr. 1; Smart Water Cluster: Trondheim, Norway, 2012. [Google Scholar]

- Sydney Water. Sewer Mining: How to Set up a Sewer Mining Scheme. Available online: https://www.sydneywater.com.au/web/groups/publicwebcontent/documents/document/zgrf/mdu0/~edisp/dd_054030.pdf (accessed on 25 November 2017).

- Makropoulos, C.; Rozos, E.; Tsoukalas, I.; Plevri, A.; Karakatsanis, G.; Karagiannidis, L.; Makri, E.; Lioumis, C.; Noutsopoulos, C.; Mamais, D.; et al. Sewer-mining: A water reuse option supporting circular economy, public service provision and entrepreneurship. J. Environ. Manag. 2017. [Google Scholar] [CrossRef] [PubMed]

- Zern, B. From Waste to Resource; WaterHub at Emory University: Atlanta, GA, USA, 2016. [Google Scholar]

- Applied CleanTech. Leading the Sewage Mining Revolution: Presenting a Sustainable, Efficient and Environmentally-Friendly Approach to Wastewater Treatment. Available online: http://www.appliedcleantech.com/files/content/SRS_Brochure.pdf (accessed on 28 November 2017).

- Makropoulos, C.; Tsoukalas, I. Sewer mining for urban re-use enabled by advanced monitoring infrastructure (ami). Presented at the Water Reuse Conference, Barcelona, Spain, 13–14 June 2016. [Google Scholar]

- Haworth, D. A green wicket at the ‘g’—An overview of the mcg water recycling facility. In 76th Annual WIOA Victorian Water Industry Operations Conference and Exhibition Bendigo Exhibition Centre, Bendigo, Australia 3–5 September 2013; Bendigo Exhibition Centre: Bendigo, Australia, 2013; p. 7. [Google Scholar]

- Water Environment Research Foundation (WERF). When to Consider Distributed Systems in an Urban and Suburban Context. Case Study: Pennant Hills Golf Club. Available online: http://www.werf.org/i/c/Decentralizedproject/When_to_Consider_Dis.aspx (accessed on 9 December 2017).

- Dahl, K.; Kirkby, R. Sewer Mining as an Alternative Water Source—The Pennant Hills Experience. Available online: https://www.agcsa.com.au/sites/default/files/uploaded-content/website-content/atm-journal/Water%20Management%20-%20Sewer%20Mining%2C%20the%20Pennant%20Hills%20Experience.pdf (accessed on 8 December 2017).

- McFallan, S.; Logan, I. Barriers and Drivers of New Public-Private Infrastructure: Sewer Mining; CRC Construction Innovation: Brisbane, Australia, 15 July 2008; p. 44. [Google Scholar]

- Rossman, L. Storm Water Management Model User’s Manual Version 5.1; EPA/600/R-14/413 (NTIS EPA/600/R-14/413b); US EPA Office of Research and Development: Washington, DC, USA, 2015; p. 353.

- Rossman, L.; Huber, W. Storm Water Management Model Reference Manual Volume i—Hydrology; EPA/600/R-15/162A; US EPA Office of Research and Development: Washington, DC, USA, 2016; p. 233.

- Marleni, N.; Park, K.; Lee, T.; Navaratna, D.; Shu, L.; Jegatheesan, V.; Pham, N.; Feliciano, A. A methodology for simulating hydrogen sulphide generation in sewer network using epa swmm. Desalin. Water Treat. 2014, 54, 1308–1317. [Google Scholar] [CrossRef]

- Miller, J.E. Basic Concepts of Kinematic-Wave Models; U.S. Geological Survey Professional Paper 1302; United States Department of the Interior: Washington, DC, USA, 1984; p. 36.

- Rossman, L. Storm Water Management Model Quality Assurance Report: Dynamic Wave Flow Routing; EPA/600/R-06/097; U.S. Environmental Protection Agency: Washington, DC, USA, 2006; p. 115.

- Psarrou, E.; Tsoukalas, I.; Makropoulos, C. A decision support tool for optimal placement of sewer mining units: Coupling swmm 5.1 and monte-carlo simulation. In Proceedings of the 15th International Conference on Environmental Science and Technology, Rhodes, Greece, 31 August–2 September 2017. [Google Scholar]

- Tsoukalas, I.K.; Makropoulos, C.K.; Michas, S.N. A monte-carlo based method for the identification of potential sewer mining locations. In Proceedings of the 13th IWA Specialized Conference on Small Water and Wastewater Systems, Athens, Greece, 14–16 September 2016. [Google Scholar]

- Tsoukalas, I.K.; Makropoulos, C.K.; Michas, S.N. Identification of potential sewer mining locations: A monte-carlo based approach. Water Sci. Technol. 2017, 76, 3351–3357. [Google Scholar] [CrossRef] [PubMed]

- Pomeroy, R. The Problem of Hydrogen Sulphide in Sewers, 2nd ed.; Boon, A.G., Ed.; Clay Pipe Development Association: London, UK, 1990; p. 24. [Google Scholar]

- Hvitved-Jacobsen, T.; Vollertsen, J.; Nielsen, A.H. Sewer Processes: Microbial and Chemical Process Engineering of Sewer Networks, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2013; p. 395. [Google Scholar]

- Boon, A.G.; Lister, A.R. Formation of sulphide in rising main sewers and its prevention by injection of oxygen. Prog. Wat. Tech. 1975, 7, 289–300. [Google Scholar]

- Pomeroy, R. Generation and control of sulfide in filled pipes. Sewage Ind. Waste 1959, 31, 1082–1095. [Google Scholar]

- Thistlethwayte, D.K.B. Control of Sulphides in Sewerage Systems; Ann Arbor Science Publishers: Sydney, Australia, 1972; p. 173. [Google Scholar]

- Lahav, O.; Sagiv, A.; Friedler, E. A different approach for predicting H2S (g) emission rates in gravity sewers. Water Res. 2006, 40, 259–266. [Google Scholar] [CrossRef] [PubMed]

- Pomeroy, R.; Parkhurst, J. The forecasting of sulfide build-up rates in sewers. Program. Water Technol. 1977, 9, 621–628. [Google Scholar]

- Yongsiri, C.; Vollertsen, J.; Hvitved-Jacobsen, T. Influence of wastewater constituents on hydrogen sulfide emission in sewer networks. J. Environ. Eng. 2005, 131, 1676–1683. [Google Scholar] [CrossRef]

- Bielecki, R.; Schremmer, H. Biogene Schwefelsäure-Korrosion in Teilgefüllten Abwasserkanälen; Technichen Universität Braunschweig: Braunschweig, Germany, 1987. [Google Scholar]

- Metcalf & Eddy; Tchobanoglous, G. Wastewater Engineering: Collection and Pumping of Wastewater; McGraw-Hill: New York, NY, USA, 1981. [Google Scholar]

- Koutsoyannis, D. Design of Urban Sewer Networks, 4th ed.; National Technical University of Athens: Athens, Greece, 2011; p. 193. [Google Scholar]

- Metcalf & Eddy Inc.; Tchobanoglous, G.; Burton, F.L. Wastewater Engineering: Treatment, Disposal, and Reuse, 2nd ed.; McGraw-Hill: New York, NY, USA, 1979; p. 920. [Google Scholar]

- Plevri, A.; Mamais, D.; Noutsopoulos, C.; Makropoulos, C.; Andreadakis, A.; Rippis, K.; Smeti, E.; Lytras, E.; Lioumis, C. Promoting on-site urban wastewater reuse through mbr-ro treatment. In Proceedings of the 13th IWA Specialized Conference on Small Water and Wastewater Systems, Athens, Greece, 14–16 September 2016. [Google Scholar]

- Tsoukalas, I.; Kossieris, P.; Efstratiadis, A.; Makropoulos, C. Surrogate-enhanced evolutionary annealing simplex algorithm for effective and efficient optimization of water resources problems on a budget. Environ. Modell. Softw. 2016, 77, 122–142. [Google Scholar] [CrossRef]

- Razavi, S.; Tolson, B.A.; Matott, L.S.; Thomson, N.R.; MacLean, A.; Seglenieks, F.R. Reducing the computational cost of automatic calibration through model preemption. Water Resour. Res. 2010, 46, 2387–2392. [Google Scholar] [CrossRef]

- Razavi, S.; Tolson, B.A.; Burn, D.H. Review of surrogate modeling in water resources. Water Resour. Res. 2012, 48. [Google Scholar] [CrossRef]

| Pumping Scheduling Approach | Minimum H2S Production | Moderate H2S Production | Maximum H2S Production |

|---|---|---|---|

| Steady-rate pumping | 2487.44 | 3811.27 | 5574.80 |

| Assumption of ratio coefficient a | 2487.30 | 3807.18 | 5570.05 |

| Genetic algorithm optimization | 2483.11 | 3790.36 | 5534.58 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Psarrou, E.; Tsoukalas, I.; Makropoulos, C. A Monte-Carlo-Based Method for the Optimal Placement and Operation Scheduling of Sewer Mining Units in Urban Wastewater Networks. Water 2018, 10, 200. https://doi.org/10.3390/w10020200

Psarrou E, Tsoukalas I, Makropoulos C. A Monte-Carlo-Based Method for the Optimal Placement and Operation Scheduling of Sewer Mining Units in Urban Wastewater Networks. Water. 2018; 10(2):200. https://doi.org/10.3390/w10020200

Chicago/Turabian StylePsarrou, Eleftheria, Ioannis Tsoukalas, and Christos Makropoulos. 2018. "A Monte-Carlo-Based Method for the Optimal Placement and Operation Scheduling of Sewer Mining Units in Urban Wastewater Networks" Water 10, no. 2: 200. https://doi.org/10.3390/w10020200

APA StylePsarrou, E., Tsoukalas, I., & Makropoulos, C. (2018). A Monte-Carlo-Based Method for the Optimal Placement and Operation Scheduling of Sewer Mining Units in Urban Wastewater Networks. Water, 10(2), 200. https://doi.org/10.3390/w10020200