Analysis of Telematics Data of Combine Harvesters and Evaluation of Potential to Reduce Environmental Pollution

Abstract

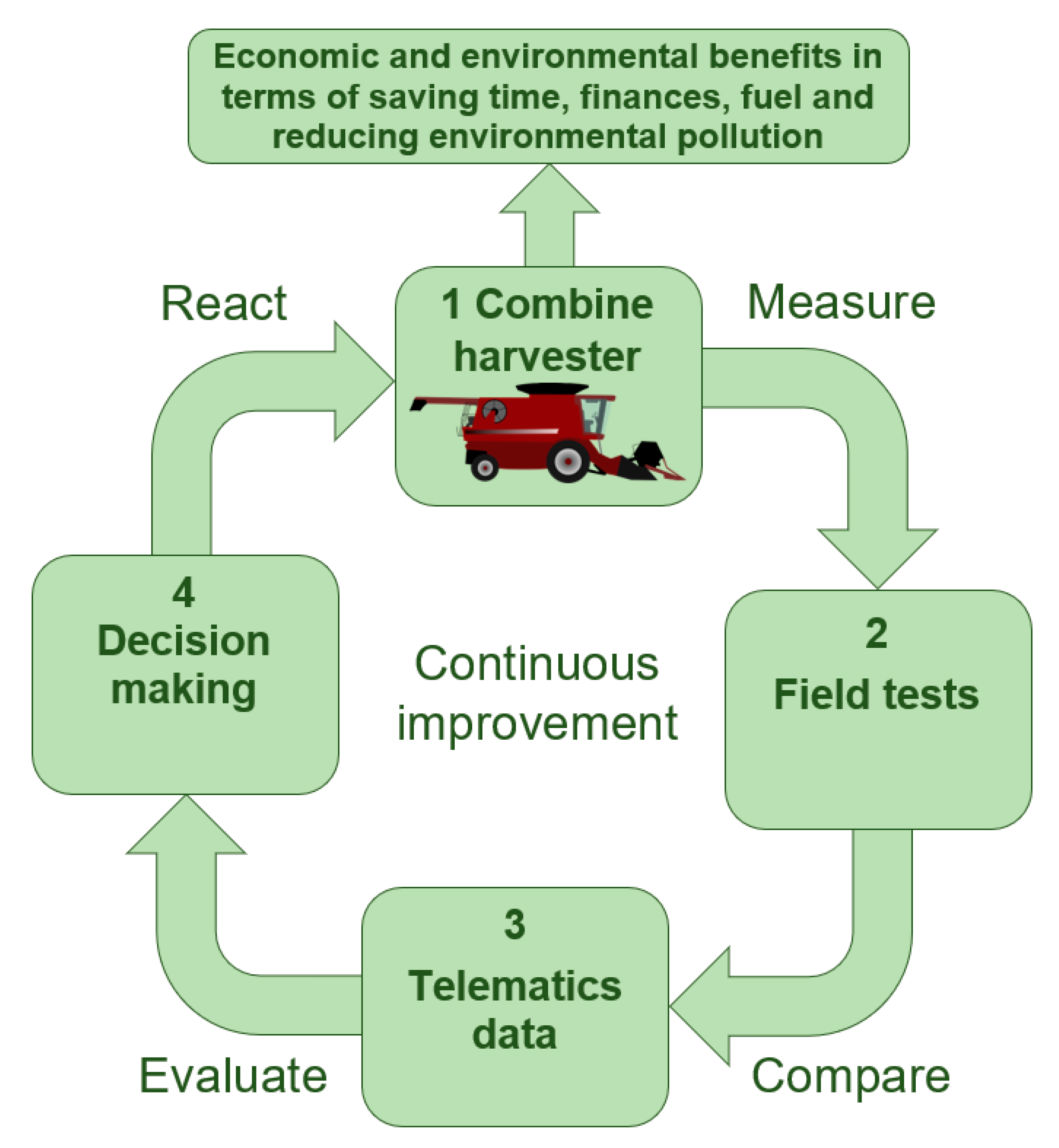

1. Introduction

2. Data and Methods

2.1. Evaluation of Telematics Data

2.2. Test Field and CH Specifications

2.3. Methodology of GWP Calculation

2.4. Statistical Analysis

3. Results and Discussion

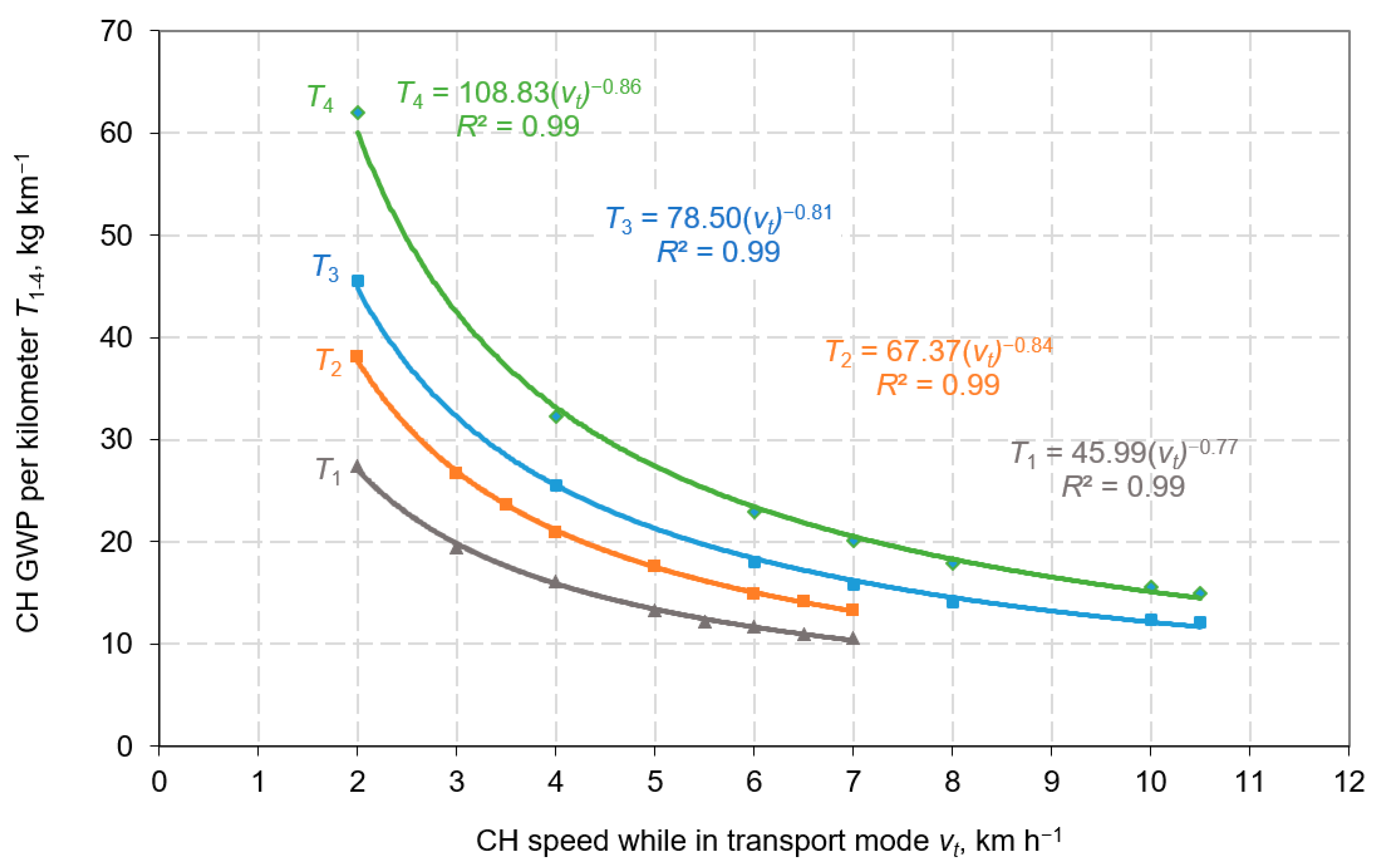

- The transport mode tests need to be extended to evaluate the CH’s travel in the field (low speed) and on public roads separately (high speed), and then establish separate recommendations for low and high speeds.

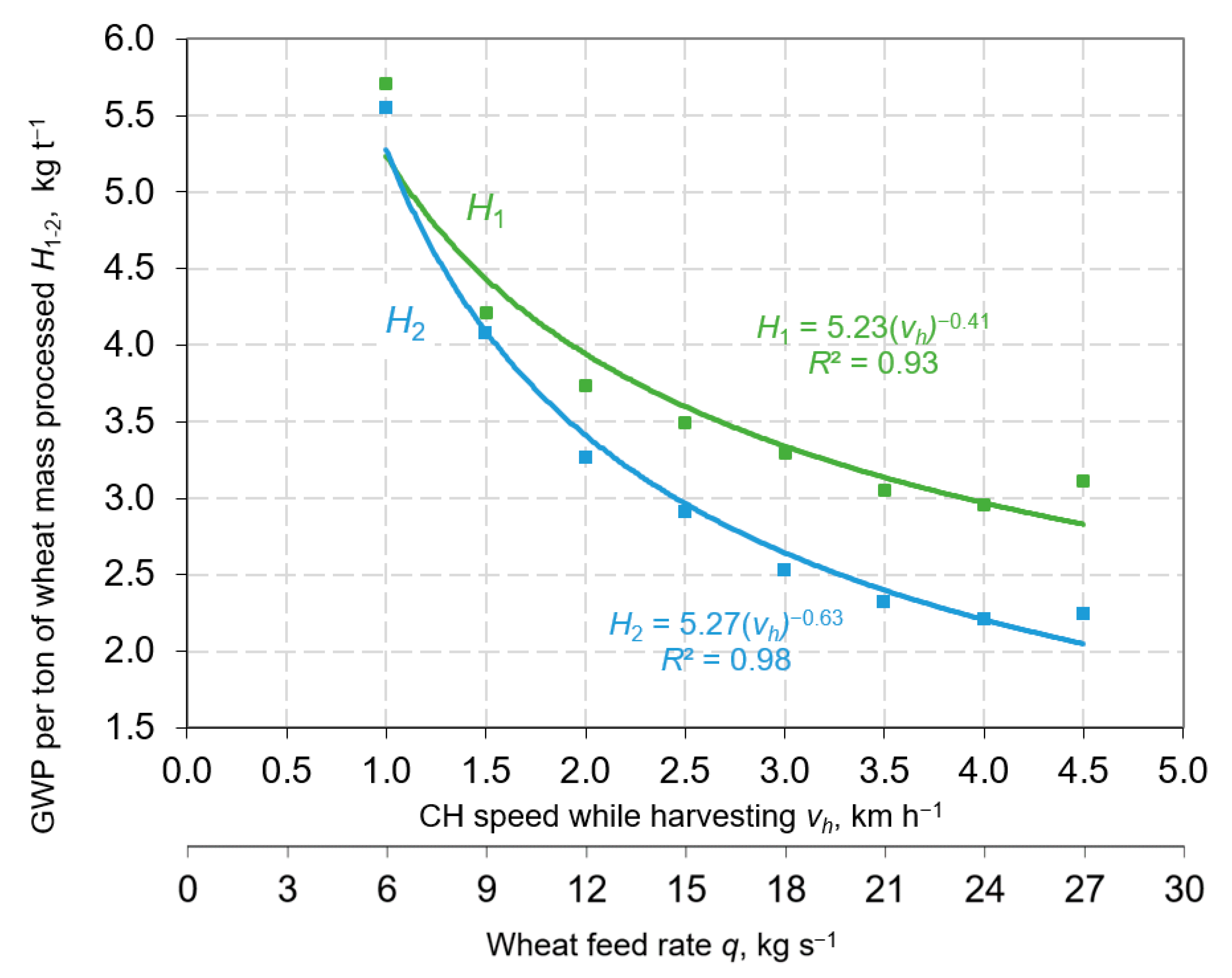

- To fully assess the impact of diesel fuel in the CH when harvesting winter wheat, it is necessary to evaluate the most suitable harvesting speed, wheat feed rate, grain damage, and grain separation losses [41,42,43]. Evaluating a minimum GWP per ton of the harvested wheat is not enough to assess the environmental impact and yield obtained.

- In order to establish general recommendations applicable to all CHs, analogous tests need to be performed on CHs with different engine powers. It would also be possible to compare the values obtained between different types of CHs (axial vs tangential threshing apparatus).

- An essential indicator of the CH’s efficiency is the technology of grain unloading from the grain tank [44,45]. The environmental impact during idle periods for a full and partially full grain tank and the unloading of grain while standing and harvesting should be investigated and assessed separately.

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ghiat, I.; Mahmood, F.; Govindan, R.; Al-Ansari, T. CO2 Utilisation in Agricultural Greenhouses: A Novel ‘Plant to Plant’ Approach Driven by Bioenergy with Carbon Capture Systems within the Energy, Water and Food Nexus. Energy Convers. Manag. 2021, 228, 113668. [Google Scholar] [CrossRef]

- Garnett, T. Where Are the Best Opportunities for Reducing Greenhouse Gas Emissions in the Food System (Including the Food Chain)? Food Policy 2011, 36, S23–S32. [Google Scholar] [CrossRef]

- Tang, Y.H.; Luan, X.B.; Sun, J.X.; Zhao, J.F.; Yin, Y.L.; Wang, Y.B.; Sun, S.K. Impact Assessment of Climate Change and Human Activities on GHG Emissions and Agricultural Water Use. Agric. For. Meteorol. 2021, 296, 108218. [Google Scholar] [CrossRef]

- Plath, E.; Rischen, T.; Mohr, T.; Fischer, K. Agriculture, Ecosystems and Environment Biodiversity in Agricultural Landscapes: Grassy Field Margins and Semi-Natural Fragments Both Foster Spider Diversity and Body Size. Agric. Ecosyst. Environ. 2021, 316, 107457. [Google Scholar] [CrossRef]

- de Nunzio, G.; Laraki, M.; Thibault, L. Road Traffic Dynamic Pollutant Emissions Estimation: From Macroscopic Road Information to Microscopic Environmental Impact. Atmosphere 2021, 12, 53. [Google Scholar] [CrossRef]

- OECD. Environment at a Glance 2020; OECD Publishing: Paris, France, 2020. [Google Scholar] [CrossRef]

- Hou, X.; Tian, J.; Song, C.; Wang, J.; Zhao, J.; Zhang, X. Emission Inventory Research of Typical Agricultural Machinery in Beijing, China. Atmos. Environ. 2019, 216, 116903. [Google Scholar] [CrossRef]

- Lovarelli, D.; Bacenetti, J. Exhaust Gases Emissions from Agricultural Tractors: State of the Art and Future Perspectives for Machinery Operators. Biosyst. Eng. 2019, 186, 204–213. [Google Scholar] [CrossRef]

- da Silveira, F.; Ruppenthal, J.E.; Lermen, F.H.; Machado, F.M.; Amaral, F.G. Technologies Used in Agricultural Machinery Engines That Contribute to the Reduction of Atmospheric Emissions: A Patent Analysis in Brazil. World Pat. Inf. 2021, 64, 102023. [Google Scholar] [CrossRef]

- Resitoglu, I.A.; Keskin, A.; Özarslan, H.; Bulut, H. Selective Catalytic Reduction of NOx Emissions by Hydrocarbons over Ag–Pt/Al2O3 Catalyst in Diesel Engine. Int. J. Environ. Sci. Technol. 2019, 16, 6959–6966. [Google Scholar] [CrossRef]

- Helmers, E.; Leitão, J.; Tietge, U.; Butler, T. CO2-Equivalent Emissions from European Passenger Vehicles in the Years 1995–2015 Based on Real-World Use: Assessing the Climate Benefit of the European “Diesel Boom”. Atmos. Environ. 2019, 198, 122–132. [Google Scholar] [CrossRef]

- Fontaras, G.; Zacharof, N.G.; Ciuffo, B. Fuel Consumption and CO2 Emissions from Passenger Cars in Europe–Laboratory versus Real-World Emissions. Prog. Energy Combust. Sci. 2017, 60, 97–131. [Google Scholar] [CrossRef]

- Rimkus, A.; Stravinskas, S.; Matijošius, J. Comparative Study on the Energetic and Ecologic Parameters of Dual Fuels (Diesel-NG and HVO-Biogas) and Conventional Diesel Fuel in a CI Engine. Appl. Sci. 2020, 10, 359. [Google Scholar] [CrossRef]

- Rimkus, A.; Matijošius, J.; Manoj Rayapureddy, S. Research of Energy and Ecological Indicators of a Compression Ignition Engine Fuelled with Diesel, Biodiesel (RME-Based) and Isopropanol Fuel Blends. Energies 2020, 13, 2398. [Google Scholar] [CrossRef]

- Mohamed, M.; Tan, C.-K.; Fouda, A.; Gad, M.S.; Abu-Elyazeed, O.; Hashem, A.-F. Diesel Engine Performance, Emissions and Combustion Characteristics of Biodiesel and Its Blends Derived from Catalytic Pyrolysis of Waste Cooking Oil. Energies 2020, 13, 5708. [Google Scholar] [CrossRef]

- Warguła, Ł.; Kukla, M.; Lijewski, P.; Dobrzyński, M.; Markiewicz, F. Impact of Compressed Natural Gas (CNG) Fuel Systems in Small Engine Wood Chippers on Exhaust Emissions and Fuel Consumption. Energies 2020, 13, 6709. [Google Scholar] [CrossRef]

- Warguła, Ł.; Kukla, M.; Lijewski, P.; Dobrzyński, M.; Markiewicz, F. Influence of the Use of Liquefied Petroleum Gas (LPG) Systems in Woodchippers Powered by Small Engines on Exhaust Emissions and Operating Costs. Energies 2020, 13, 5773. [Google Scholar] [CrossRef]

- Rymaniak, Ł.; Lijewski, P.; Kamińska, M.; Fuć, P.; Kurc, B.; Siedlecki, M.; Kalociński, T.; Jagielski, A. The Role of Real Power Output from Farm Tractor Engines in Determining Their Environmental Performance in Actual Operating Conditions. Comput. Electron. Agric. 2020, 173, 105405. [Google Scholar] [CrossRef]

- Warguła, Ł.; Krawiec, P.; Walus, K.J.; Kukla, M. Fuel Consumption Test Results for a Self-Adaptive, Maintenance-Freewood Chipper Drive Control System. Appl. Sci. 2020, 10, 2727. [Google Scholar] [CrossRef]

- Warguła, Ł.; Kukla, M.; Lijewski, P.; Dobrzynski, M.; Markiewicz, F. Influence of Innovative Woodchipper Speed Control Systems on Exhaust Gas Emissions and Fuel Consumption in Urban Areas. Energies 2020, 13, 3330. [Google Scholar] [CrossRef]

- Molari, G.; Mattetti, M.; Lenzini, N.; Fiorati, S. An Updated Methodology to Analyse the Idling of Agricultural Tractors. Biosyst. Eng. 2019, 187, 160–170. [Google Scholar] [CrossRef]

- Wargula, L.; Kukla, M.; Krawiec, P.; Wieczorek, B. Impact of Number of Operators and Distance to Branch Piles on Woodchipper Operation. Forests 2020, 11, 598. [Google Scholar] [CrossRef]

- Perozzi, D.; Mattetti, M.; Molari, G.; Sereni, E. Methodology to Analyse Farm Tractor Idling Time. Biosyst. Eng. 2016, 148, 81–89. [Google Scholar] [CrossRef]

- Lijewski, P.; Szymlet, N.; Fuć, P.; Domowicz, A.; Rymaniak, Ł. The Effect of Start-Stop Systems on Scooter Exhaust Emissions. Transp. Res. Part D: Transp. Environ. 2021, 91. [Google Scholar] [CrossRef]

- Mueller, N.; Strauss, S.; Tumback, S.; Goh, G.-C.; Christ, A. Next Generation Engine Start/Stop Systems: “Free-Wheeling”. Sae Int. J. Eng. 2011, 4, 874–887. [Google Scholar] [CrossRef]

- Gutarevych, Y.; Mateichyk, V.; Matijošius, J.; Rimkus, A.; Gritsuk, I.; Syrota, O.; Shuba, Y. Improving Fuel Economy of Spark Ignition Engines Applying the Combined Method of Power Regulation. Energies 2020, 13, 1076. [Google Scholar] [CrossRef]

- Vopa, J.; Fridrichov, K.; Dlugo, J. Overview of the Potential and Limitations of Cylinder Deactivation. Renew. Sustain. Energy Rev. 2021, 146. [Google Scholar] [CrossRef]

- Cao, R.; Li, S.; Ji, Y.; Zhang, Z.; Xu, H.; Zhang, M.; Li, M.; Li, H. Task Assignment of Multiple Agricultural Machinery Cooperation Based on Improved Ant Colony Algorithm. Comput. Electron. Agric. 2021, 182, 105993. [Google Scholar] [CrossRef]

- Rodias, E.; Berruto, R.; Busato, P.; Bochtis, D.; Sørensen, C.G.; Zhou, K. Energy Savings from Optimised In-Field Route Planning for Agricultural Machinery. Sustainability 2017, 9, 1956. [Google Scholar] [CrossRef]

- Mattetti, M.; Maraldi, M.; Lenzini, N.; Fiorati, S.; Sereni, E.; Molari, G. Outlining the Mission Profile of Agricultural Tractors through CAN-BUS Data Analytics. Comput. Electron. Agric. 2021, 184, 106078. [Google Scholar] [CrossRef]

- Chinnasamy, C.; Tamilselvam, P.; Ranjith, R. Influence of Aluminum Oxide Nanoparticle with Different Particle Sizes on the Working Attributes of Diesel Engine Fueled with Blends of Diesel and Waste Plastic Oil. Environ. Sci. Pollut. Res. 2019, 26, 29962–29977. [Google Scholar] [CrossRef]

- Savickas, D.; Steponavičius, D.; Kliopova, I.; Saldukaitė, L. Combine Harvester Fuel Consumption and Air Pollution Reduction. Water Air Soil Pollut. 2020, 231, 1–11. [Google Scholar] [CrossRef]

- Venkatesan, V.; Nallusamy, N.; Nagapandiselvi, P. Performance and Emission Analysis on the Effect of Exhaust Gas Recirculation in a Tractor Diesel Engine Using Pine Oil and Soapnut Oil Methyl Ester. Fuel 2021, 290, 120077. [Google Scholar] [CrossRef]

- EMEP/EEA Air Pollutant Emission Inventory Guidebook; European Environment Agency: Copenhagen, Denmark, 2019; Available online: https://www.eea.europa.eu/publications/emep-eea-guidebook-2019 (accessed on 23 May 2021).

- Huang, R.; Liu, J.; He, X.; Xie, D.; Ni, J.; Xu, C.; Zhang, Y.; Ci, E.; Wang, Z.; Gao, M. Reduced Mineral Fertilization Coupled with Straw Return in Field Mesocosm Vegetable Cultivation Helps to Coordinate Greenhouse Gas Emissions and Vegetable Production. J. Soils Sediments 2020, 20, 1834–1845. [Google Scholar] [CrossRef]

- Jia, Q.; Zhang, H.; Wang, J.; Xiao, X.; Chang, S.; Zhang, C.; Liu, Y.; Hou, F. Planting Practices and Mulching Materials Improve Maize Net Ecosystem C Budget, Global Warming Potential and Production in Semi-Arid Regions. Soil Tillage Res. 2021, 207, 104850. [Google Scholar] [CrossRef]

- Kaur-Sidhu, M.; Ravindra, K.; Mor, S.; John, S. Emission Factors and Global Warming Potential of Various Solid Biomass Fuel-Cook Stove Combinations. Atmos. Pollut. Res. 2020, 11, 252–260. [Google Scholar] [CrossRef]

- Delchev, N.; Trendafilov, K.; Tihanov, G.; Stoyanov, Y. Grain Combines Productivity According to Various Unloading Methods–in the Field and at the Edge of the Field. Agric. Sci. Technol. 2016, 8, 221–226. [Google Scholar] [CrossRef]

- Špokas, L.; Steponavičius, D.; Butkus, V. Reduction of Fuel Consumption of Two Rotors Axial Flow Combine Harvester. J. Food Agric. Environ. 2014, 12, 329–333. [Google Scholar]

- Khoshnevisan, B.; Rafiee, S.; Omid, M.; Mousazadeh, H. Reduction of CO2 Emission by Improving Energy Use Efficiency of Greenhouse Cucumber Production Using DEA Approach. Energy 2013, 55, 676–682. [Google Scholar] [CrossRef]

- Špokas, L.; Steponavičius, D.; Žebrauskas, G.; Čiplienė, A.; Bauša, L. Reduction in Adverse Environmental Impacts Associated with the Operation of Combine Harvesters during the Harvesting of Winter Oilseed Rape. J. Environ. Eng. Landsc. Manag. 2019, 27, 72–81. [Google Scholar] [CrossRef]

- Nik, M.A.E.; Khademolhosseini, N.; Abbaspour-Fard, M.H.; Mahdinia, A.; Alami-Saied, K. Optimum Utilisation of Low-Capacity Combine Harvesters in High-Yielding Wheat Farms Using Multi-Criteria Decision Making. Biosyst. Eng. 2009, 103, 382–388. [Google Scholar] [CrossRef]

- Mokhtor, S.A.; el Pebrian, D.; Johari, N.A.A. Actual Field Speed of Rice Combine Harvester and Its Influence on Grain Loss in Malaysian Paddy Field. J. Saudi Soc. Agric. Sci. 2020, 19, 422–425. [Google Scholar] [CrossRef]

- Tihanov, G. Examination of Impact of the Place for Unloading the Hopper of Grain Harvester Claas Lexion 780 onto Productivity at Harvesting Wheat and Sunflower. Appl. Res. Tech. Technol. Educ. 2020, 8. [Google Scholar] [CrossRef]

- Tihanov, G. A Study on the Hopper Unloading Duration of the Harvesting Machine at Different Technical Parameters. Agric. Sci. Technol. 2020, 12, 140–143. [Google Scholar] [CrossRef]

| Group of Indicators | Indicator | Indicator Name | Unit of Measurement |

|---|---|---|---|

| Time in different engine states | T1 | Idle with grain tank not full | h year−1 |

| T2 | Idle with grain tank full | ||

| T3 | Unloading not harvesting | ||

| T4 | Harvesting and unloading | ||

| T5 | Harvesting | ||

| T6 | Headland turn separator engaged | ||

| T7 | Transport below 16 km h−1 | ||

| T8 | Transport above 16 km h−1 | ||

| Consumed diesel fuel in different engine states | F1 | Idle with grain tank not full | L year−1 |

| F2 | Idle with grain tank full | ||

| F3 | Unloading not harvesting | ||

| F4 | Harvesting and unloading | ||

| F5 | Harvesting | ||

| F6 | Headland turn separator engaged | ||

| F7 | Transport below 16 km h−1 | ||

| F8 | Transport above 16 km h−1 |

| Indicator | Measurement Unit | Value |

|---|---|---|

| Year of manufacture | Year | 2017 |

| Engine emission level | - | Tier III B |

| Threshing-separation rotor length | m | 3.124 |

| Threshing-separation rotor diameter | m | 0.762 |

| Threshing area | m2 | 1.1 |

| Separation area | m2 | 1.54 |

| Grain tank capacity | l | 14,100 |

| Rated engine power ECE R120 | kW/hp | 405/543 |

| Engine operational hours during the 2019 field tests | h | 615 |

| GHG Emission Factors | ||

|---|---|---|

| CO2, kg t−1 | N2O, g t−1 | CH4, g t−1 |

| 3160 | 139 | 13 |

| Machine Utilization, h year−1 | |||||

| Idle | Harvesting | Transport | Idle + Transport | Total | |

| 1 Avg. | 45.1 ± 10.2 | 179.0 ± 23.9 | 33.7 ± 7.4 | 78.9 ± 16.0 | 257.8 ± 35.9 |

| 2 Min. | 19.3 | 112.5 | 17.1 | 36.4 | 152.0 |

| 3 Max. | 95.2 | 248.6 | 70.7 | 165.9 | 403.5 |

| Fuel Consumption, L year−1 | |||||

| Idle | Harvesting | Transport | Idle + Transport | Total | |

| 1 Avg. | 567.7 ± 138.7 | 13,467.4 ± 1963.6 | 1200.8 ± 375.0 | 1768.5 ± 476.7 | 15,235.9 ± 2232.5 |

| 2 Min. | 203.1 | 7312.5 | 424.2 | 627.3 | 8645.6 |

| 3 Max. | 1147.4 | 19,728.9 | 3130.9 | 4278.3 | 22,387.2 |

| Fuel Consumption, L h−1 | |||||

| Idle | Harvesting | Transport | Idle + Transport | Total | |

| 1 Avg. | 12.4 ± 0.8 | 75.0 ± 3.4 | 34.3 ± 3.6 | 21.8 ± 2.1 | 59.1 ± 2.8 |

| 2 Min. | 9.6 | 63.7 | 24.1 | 16.7 | 49.6 |

| 3 Max. | 14.6 | 82.6 | 44.3 | 29.1 | 66.6 |

| GWP, kg year−1 | |||||

| Idle | Harvesting | Transport | Idle + Transport | Total | |

| 1 Avg. | 1512.2 ± 369.3 | 35,875.2 ± 5230.7 | 3198.7 ± 998.9 | 4710.9 ± 1269.9 | 40,586.1 ± 5947.1 |

| 2 Min. | 541.1 | 19,479.4 | 1130.1 | 1671.1 | 23,030.6 |

| 3 Max. | 3056.6 | 52,554.9 | 8340.1 | 11,396.7 | 59,636.2 |

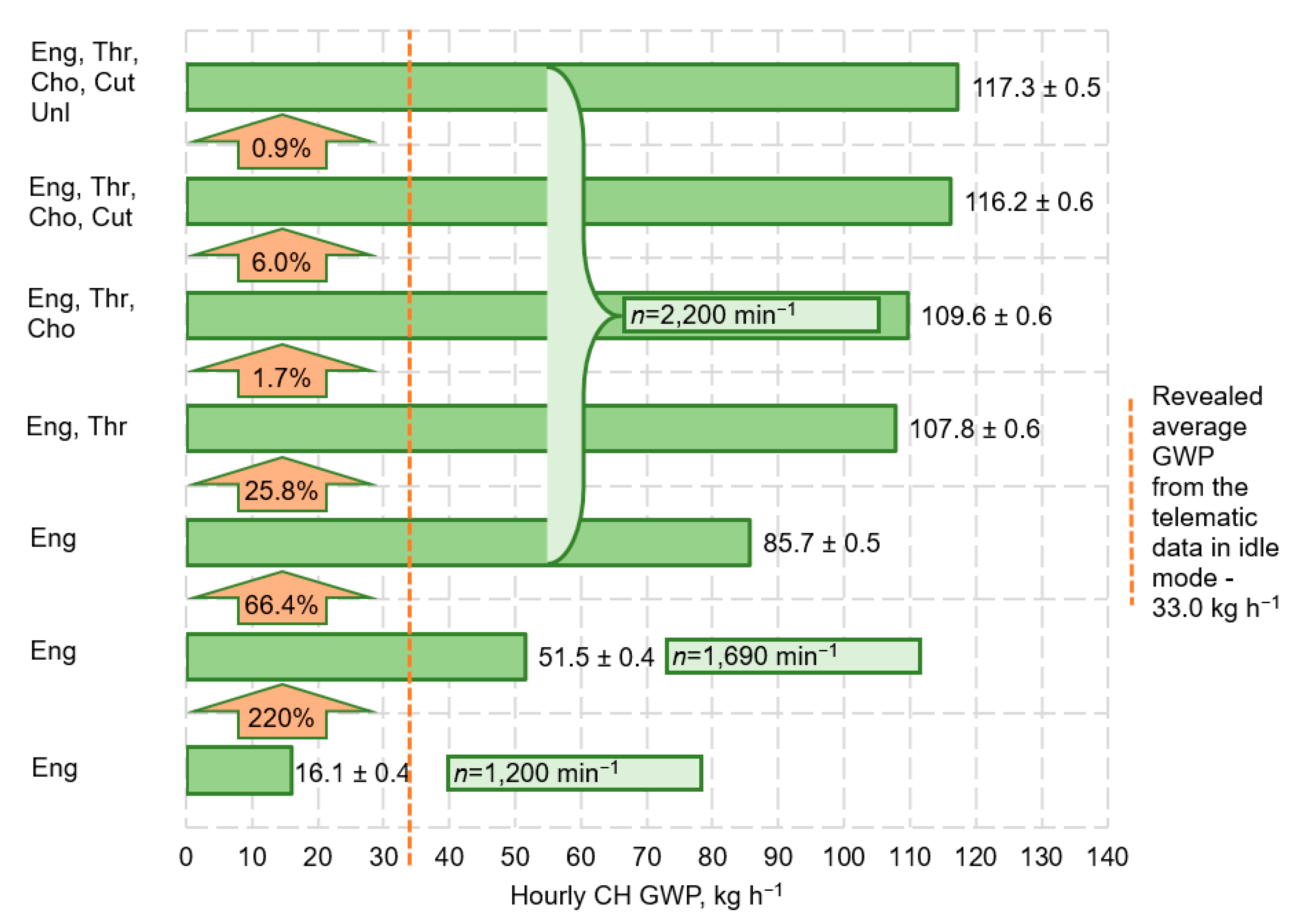

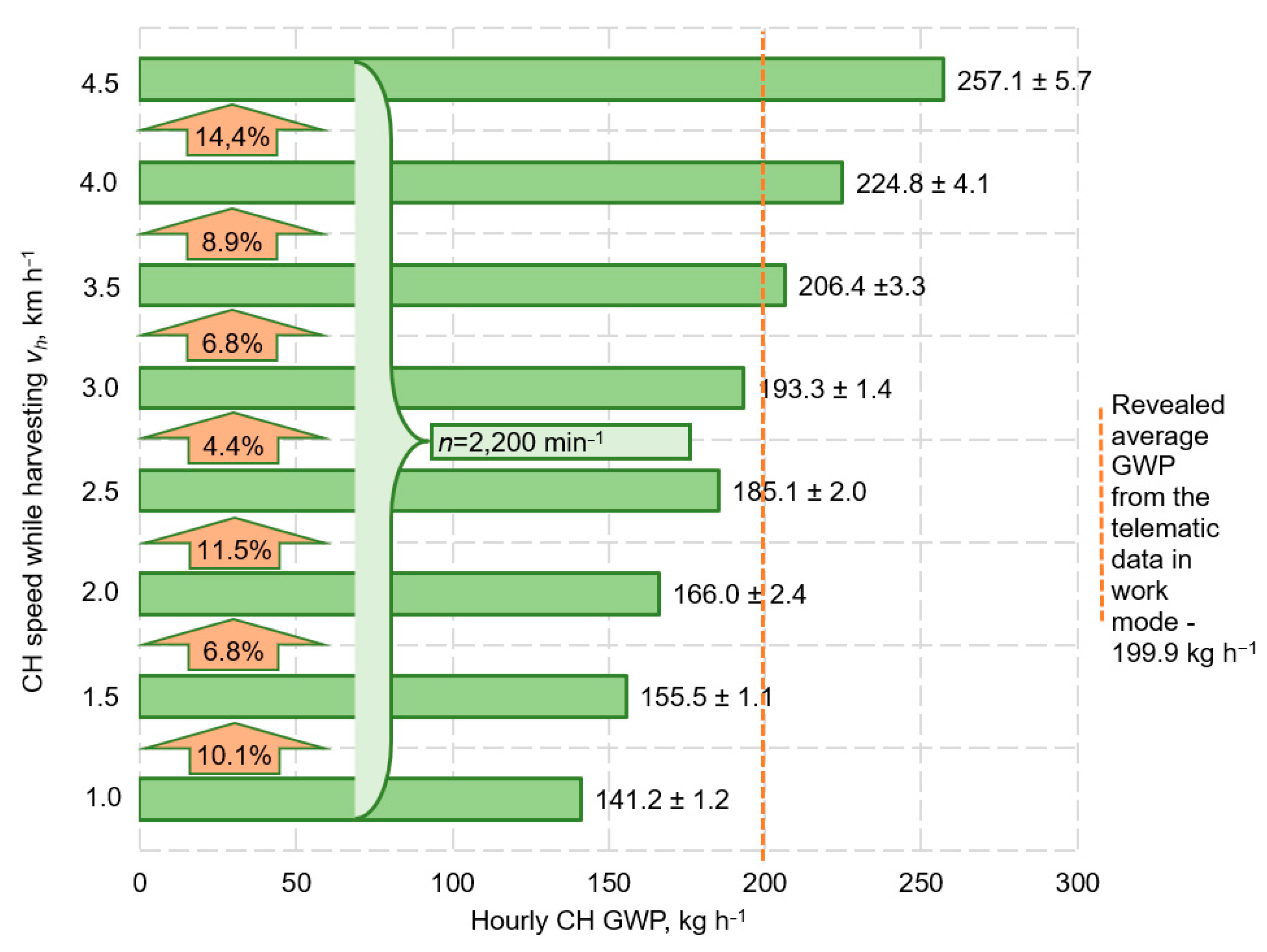

| GWP, kg h−1 | |||||

| Idle | Harvesting | Transport | Idle + Transport | Total | |

| 1 Avg. | 33.0 ± 2.1 | 199.9 ± 9.0 | 91.3 ± 9.5 | 58.1 ± 5.5 | 157.3 ± 7.5 |

| 2 Min. | 25.6 | 169.7 | 64.2 | 44.6 | 132.0 |

| 3 Max. | 39.0 | 220.0 | 118.0 | 77.6 | 177.3 |

| Idle with Grain Tank Not Full, h year−1 | Idle with Grain Tank Full, h year−1 | Unloading Not Harvesting, h year−1 | Harvesting and Unloading, h year−1 | |

|---|---|---|---|---|

| 1 Avg. | 43.4 ± 10.2 | 1.7 ± 0.9 | 7.4 ± 2.5 | 6.6 ± 1.9 |

| 2 Min. | 18.3 | 0.0 | 0.6 | 2.2 |

| 3 Max. | 95.2 | 5.0 | 17.5 | 10.4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Savickas, D.; Steponavičius, D.; Domeika, R. Analysis of Telematics Data of Combine Harvesters and Evaluation of Potential to Reduce Environmental Pollution. Atmosphere 2021, 12, 674. https://doi.org/10.3390/atmos12060674

Savickas D, Steponavičius D, Domeika R. Analysis of Telematics Data of Combine Harvesters and Evaluation of Potential to Reduce Environmental Pollution. Atmosphere. 2021; 12(6):674. https://doi.org/10.3390/atmos12060674

Chicago/Turabian StyleSavickas, Dainius, Dainius Steponavičius, and Rolandas Domeika. 2021. "Analysis of Telematics Data of Combine Harvesters and Evaluation of Potential to Reduce Environmental Pollution" Atmosphere 12, no. 6: 674. https://doi.org/10.3390/atmos12060674

APA StyleSavickas, D., Steponavičius, D., & Domeika, R. (2021). Analysis of Telematics Data of Combine Harvesters and Evaluation of Potential to Reduce Environmental Pollution. Atmosphere, 12(6), 674. https://doi.org/10.3390/atmos12060674