Assessment of Chemical Fiber Air Filter for General Ventilation

Abstract

:1. Introduction

2. Materials and Methods

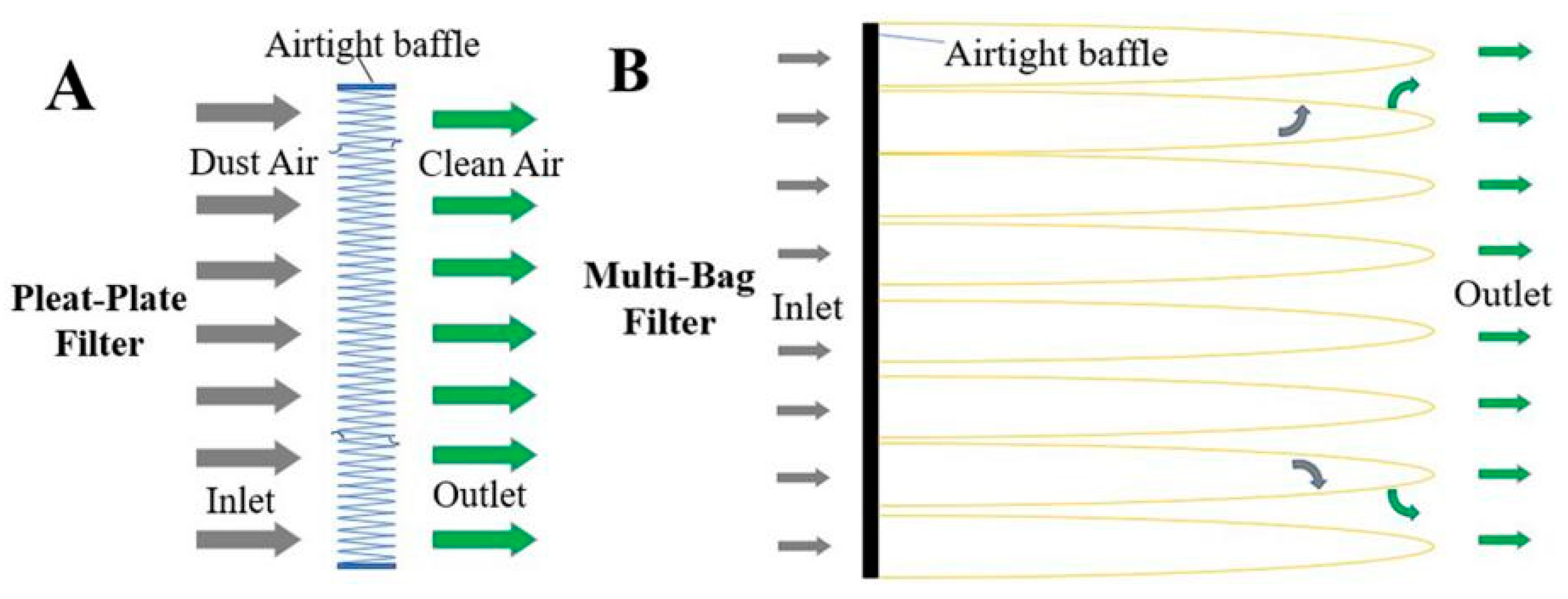

2.1. Selection of the Tested Air Filter

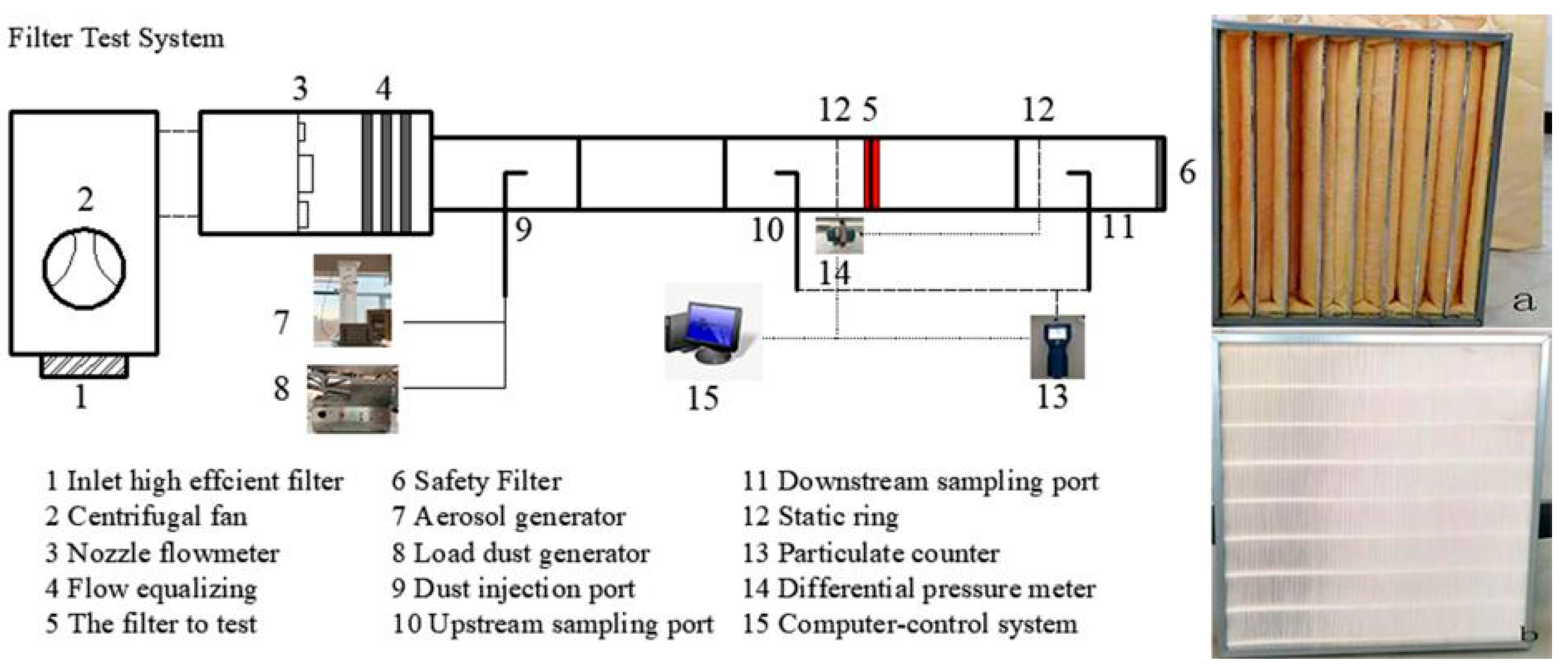

2.2. Performance Testing System

2.3. Experiments of Test Dust Capacity

2.4. Performance Evaluation

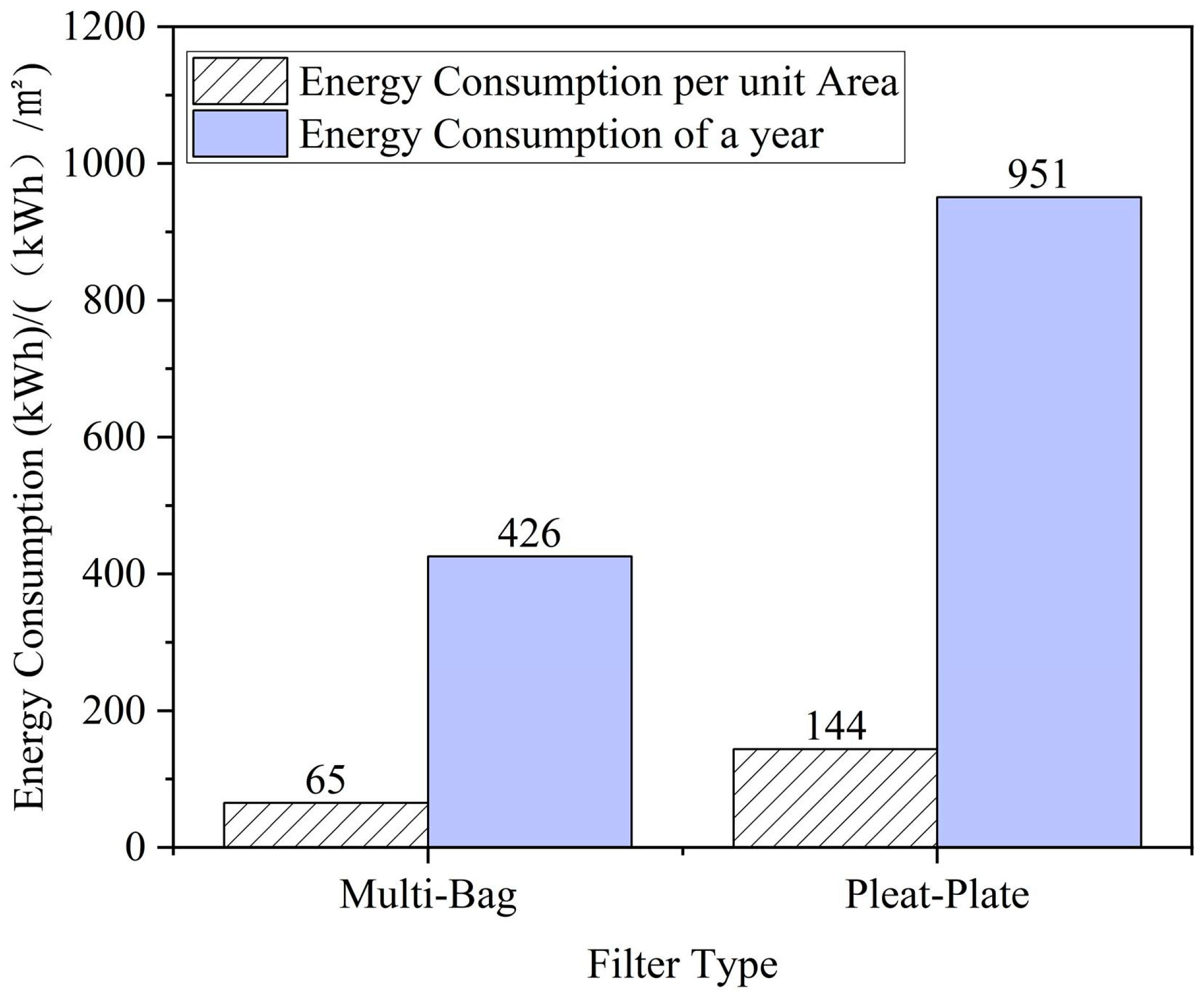

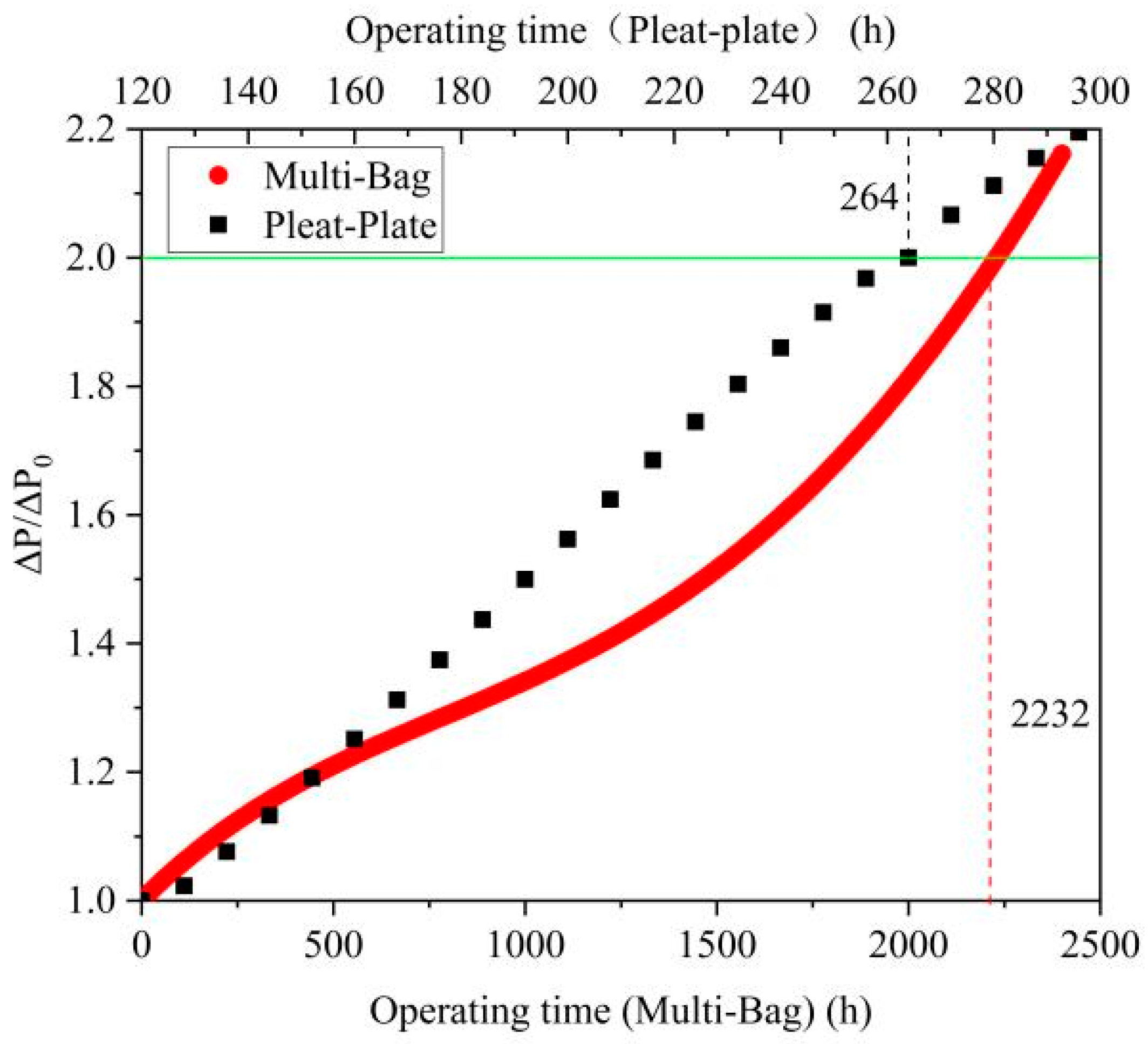

3. Results and Discussion

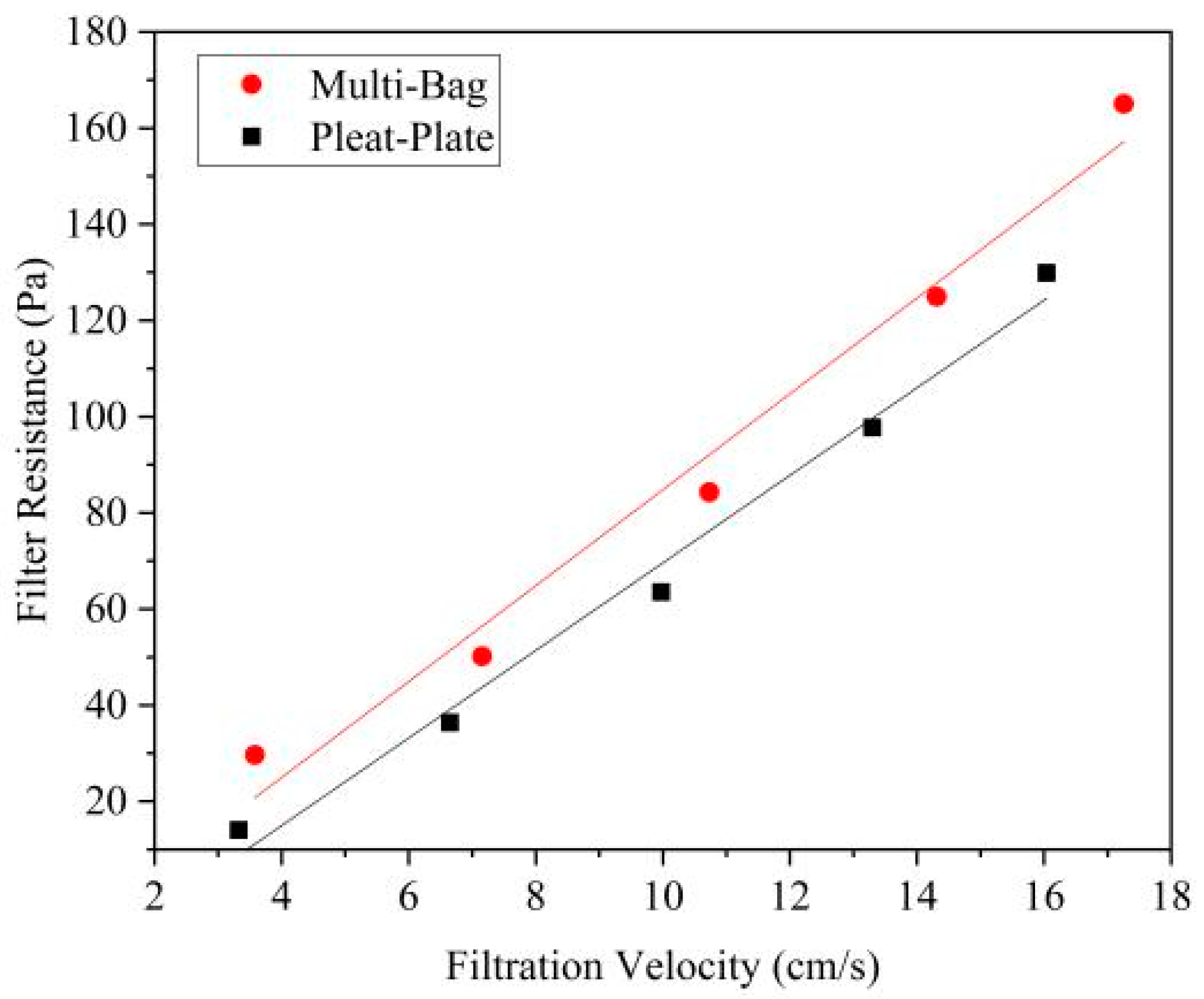

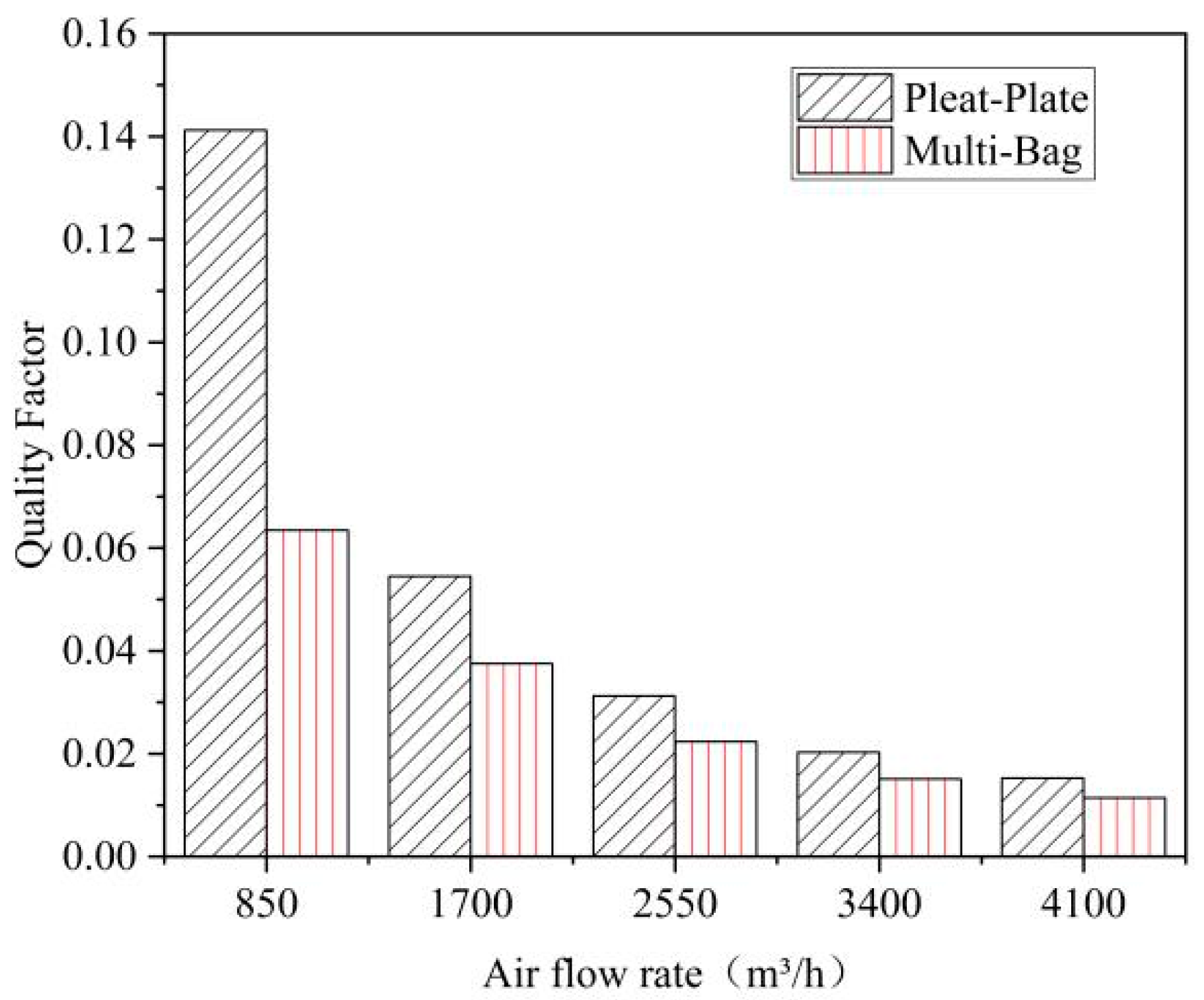

3.1. Performance of the Selected Air Filters

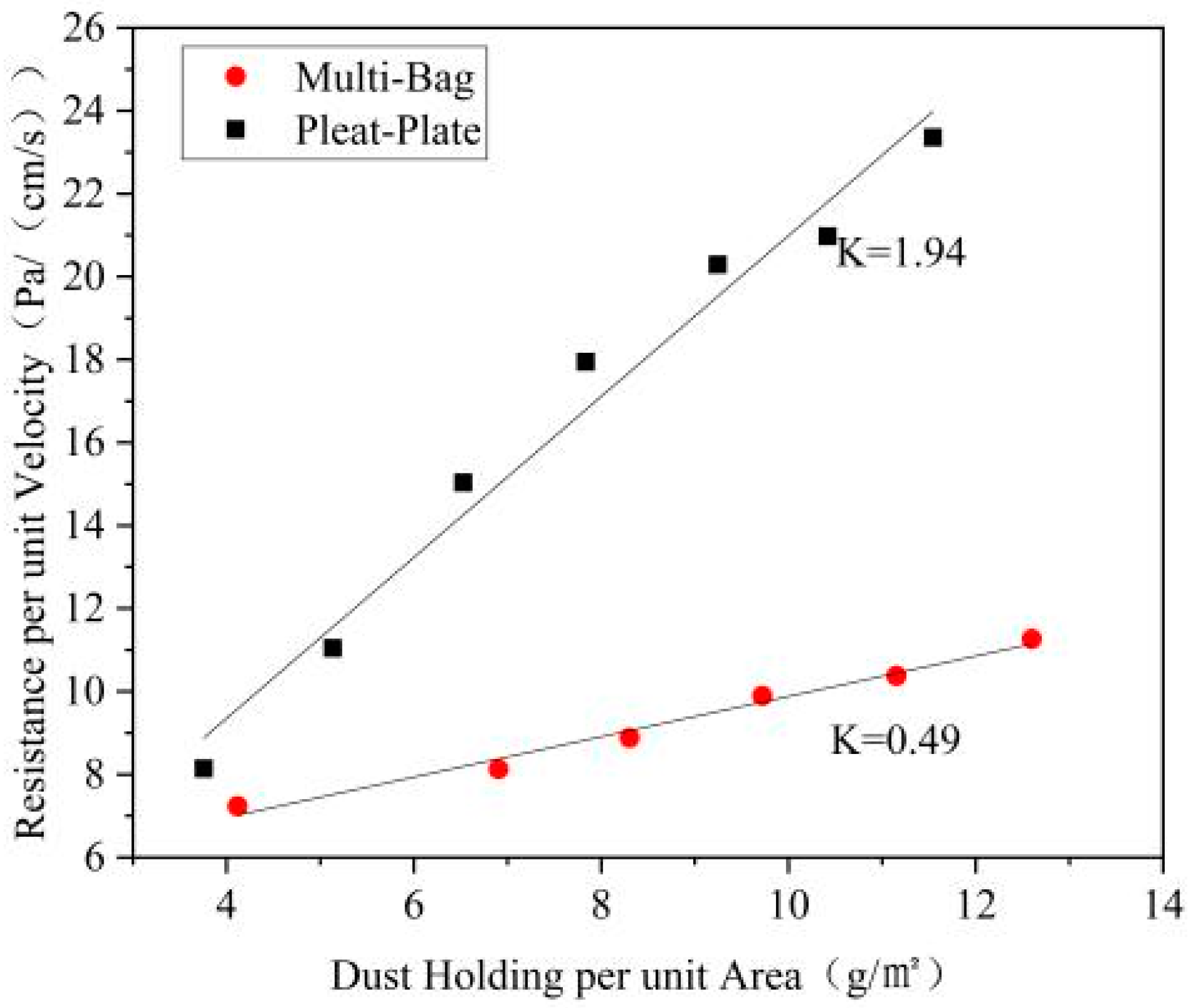

3.2. Relationship between Construction and Performance

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Koutrakis, P.; Briggs, S.; Leaderer, B. Source Apportionment of Indoor Aerosols in Suffolk and Onondaga Counties, New York. Environ. Sci. Technol. 1992, 26, 521–527. [Google Scholar] [CrossRef]

- Kakkar, P.; Jaffery, F.; Viswanathan, P.N. Specific Molecular Probes for Mechanistic Studies in Toxicology and Molecular Epidemiology for Risk Assessment. J. Environ. Sci. Health 1996, 14, 105–137. [Google Scholar] [CrossRef]

- Li, S.; Hu, S.; Xie, B.; Jin, H.; Xin, J. Influence of pleat geometry on the filtration and cleaning characteristics of filter media. Sep. Purif. Technol. 2010, 210, 38–47. [Google Scholar] [CrossRef]

- Qian, F.; Huang, N.; Zhu, X.; Lu, J. Numerical Study of the Gas-Solid Flow Characteristic of Fibrous Media Based on SEM Using CFD-DEM. Powder Technol. 2013, 249, 63–70. [Google Scholar] [CrossRef]

- Qian, F.; Huang, N.; Lu, J.; Han, Y. CFD-DEM Simulation of the Filtration Performance for Fibrous Media Based on the Mimic Structure. Comput. Chem. Eng. 2014, 71, 478–488. [Google Scholar] [CrossRef]

- Shu, Z.; Qian, F.; Fang, C. Numerical Simulation of Particle Spatial Distribution and Filtration Characteristic in the Pleated Filter Media Using OpenFOAM. Indoor Built Environ. 2020, 30, 1159–1172. [Google Scholar] [CrossRef]

- Cao, B.; Wang, S.; Dong, W.; Zhu, J.; Qian, F.; Liu, J.; Han, Y. Investigation of the Filtration Performance for Fibrous Media: Coupling of a Semi-Analytical Model with CFD on Voronoi-Based Microstructure. Sep. Purif. Technol. 2020, 251, 117364. [Google Scholar] [CrossRef]

- Liu, J.; Ren, S.; Xu, L. Comparison Test of Filtration Performance of Class F7 Air Filters. Heat. Vent. Air Cond. 2014, 44, 71–75. [Google Scholar]

- Ma, H.; Shen, H.; Shui, T.; Li, Q.; Zhou, L. Experimental Study on Ultrafine Particle Removal Performance of Portable Air Cleaners with Different Filters in an Office Room. Int. J. Environ. Res. Public Health 2016, 13, 102. [Google Scholar] [CrossRef] [Green Version]

- Chen, D.; Pui, D.; Benjamin, L. Optimization of Pleated Filter Designs Using a Finite-Element Numerical Model. Aerosol Sci. Technol. 1995, 23, 579–590. [Google Scholar] [CrossRef]

- Thomas, C.; Thomas, S. The Influence of Pleat Geometry on the Pressure Drop in Deep-Pleated Cassette Filters. Filtr. Sep. 2002, 39, 49–54. [Google Scholar]

- Tronville, P.; Sala, R. Minimization of Resistance in Pleated-Media Air Filter Designs: Empirical and CFD Approaches. HVAC&R Res. 2003, 9, 95–106. [Google Scholar]

- Vinh, N.; Kim, H. Electrospinning Fabrication and Performance Evaluation of Polyacrylonitrile Nanofiber for Air Filter Applications. Appl. Sci. 2016, 6, 235. [Google Scholar] [CrossRef] [Green Version]

- Zhang, X.; Liu, J.; Liu, X.; Liu, C. Performance Optimization of Airliner Cabin Air Filters. Build. Environ. 2021, 187, 107392. [Google Scholar] [CrossRef]

- Xu, T.; Ming, S. Laboratory Evaluation of Fan-Filter Units’ Aerodynamic and Energy Performance. J. IEST 2004, 47, 116–120. [Google Scholar] [CrossRef] [Green Version]

- Park, W.; Hwang, S.; Roh, J. Comparison of the relative performance efficiencies of melt-blown and glass fiber filter media for managing fine particles. Aerosol Sci. Technol. 2018, 52, 451–458. [Google Scholar]

- CEN, BS EN 779-2012. Particulate Air Filters for General Ventilation-Determination of the Filtration Performances; European Committee for Standardization: Brussels, Belgium, 2012. [Google Scholar]

- ASHRAE, ASHRAE 52.2-2017. Method of Testing General Ventilation Air-Cleaning Devices for Removal Efficiency by Particle Size; American Society of Heating, Refrigerating and Air-Conditioning Engineer: Atlanta, GA, USA, 2017. [Google Scholar]

- Dhaniyala, S.; Benjamin, L. Investigations of Particle Penetration in Fibrous Filters: Part I. Experimental. J. IEST 1999, 42, 32–40. [Google Scholar] [CrossRef]

- EUROVENT. EUROVENT 4/21-2014, Calculation Method for the Energy Use Related to Air Filters in General Ventilation Systems; European Committee for Standardization: Brussels, Belgium, 2014; pp. 1–8. [Google Scholar]

- Cao, Q.; Xu, Q.; Liu, W.; Lin, C.; Wei, D.; Steven, B.; Sharon, N.; Chen, Q. In-flight monitoring of particle deposition in the environmental control systems of commercial airliners in China. Atmos. Environ. 2017, 154, 118–128. [Google Scholar] [CrossRef]

- Zhang, X.; Fan, Y.; Tian, G.; Wang, H.; Zhang, H.; Xie, W. Influence of fiber diameter on filtration performance of polyester fibers. Therm. Sci. 2019, 23, 2291–2296. [Google Scholar] [CrossRef]

- He, J.; Shen, H.; Wu, Y.; Fang, M. Experimental Study on Resistance Influencing Factors of Clean Filter Material Used in Air Purification. Adv. Mater. Res. 2012, 393–395, 1224–1230. [Google Scholar] [CrossRef]

- Sothen, R.; Tatarchuk, B. A Semi-Empirical Pressure Drop Model: Part II—Multi-Element Pleated Filter Banks. Hvac R Res. 2009, 15, 269–286. [Google Scholar] [CrossRef]

- Park, S.; Joe, Y.; Shim, J.; Park, H.; Shin, W. Non-Uniform Filtration Velocity of Process Gas Passing through a Long Bag Filter. J. Hazard. Mater. 2019, 365, 440–447. [Google Scholar] [CrossRef] [PubMed]

- Chen, C.; Huang, S.; Chiang, C.; Hsiao, T.; Chen, C. Filter Quality of Pleated Filter Cartridges. Ann. Occup. Hyg. 2008, 52, 207–212. [Google Scholar] [PubMed] [Green Version]

- Feng, Z.; Cao, S. A newly developed electrostatic enhanced pleated air filters towards the improvement of energy and filtration efficiency. Sustain. Cities Soc. 2019, 49, 101569. [Google Scholar] [CrossRef]

- Saleh, A.; Tafreshi, H.; Pourdeyhimi, B. Service life of circular pleated filters vs. that of their flat counterpart. Sep. Purif. Technol. 2015, 156, 881–888. [Google Scholar] [CrossRef]

- Sae-Lim, W.; Tanthapanichakoon, W.; Kanaoka, C. Structural Improvement to Quadruple Service Life of a High-Efficiency Electret Filter. Sci. Technol. Adv. Mater. 2005, 6, 307–311. [Google Scholar] [CrossRef]

- Saleh, A.; Fotovati, S.; Tafreshi, H.; Pourdeyhimi, B. Modeling Service Life of Pleated Filters Exposed to Poly-Dispersed Aerosols. Powder Technol. 2014, 266, 79–89. [Google Scholar] [CrossRef]

- Théron, F.; Aurélie, J.; Laurence, L. Numerical and Experimental Investigations of the Influence of the Pleat Geometry on the Pressure Drop and Velocity Field of a Pleated Fibrous Filter. Sep. Purif. Technol. 2017, 182, 69–77. [Google Scholar] [CrossRef] [Green Version]

- Fotovati, S.; Hosseini, S.; Tafreshi, H.; Pourdeyhimi, B. Modeling Instantaneous Pressure Drop of Pleated Thin Filter Media during Dust Loading. Chem. Eng. Sci. 2011, 66, 4036–4046. [Google Scholar] [CrossRef]

- Fotovati, S.; Tafreshi, H.; Pourdeyhimi, B. A Macroscale Model for Simulating Pressure Drop and Collection Efficiency of Pleated Filters over Time. Sep. Purif. Technol. 2012, 98, 344–355. [Google Scholar] [CrossRef]

- Wang, H.; Wang, K.; He, Y.; Zheng, C. Simulation of Filtration Process for Multi-Fiber Filter Using the Lattice-Boltzmann Two-Phase Flow Model. J. Aerosol Sci. 2013, 66, 164–178. [Google Scholar] [CrossRef]

- Kasper, G.; Schollmeier, S.; Meyer, J. Structure and density of deposits formed on filter fibers by inertial particle deposition and bounce. J. Aerosol Sci. 2010, 41, 1167–1182. [Google Scholar] [CrossRef]

- Hasolli, N.; Park, Y.; Rhee, Y. Filtration Performance Evaluation of Depth Filter Media Cartridges as Function of Layer Structure and Pleat Count. Powder Technol. 2013, 237, 24–31. [Google Scholar] [CrossRef]

- Thomas, D.; Pacault, S.; Charvet, A. Composite fibrous filters for nano-aerosol filtration: Pressure drop and efficiency model. Sep. Purif. Technol. 2019, 215, 557–564. [Google Scholar] [CrossRef]

| Model | Structure | Filtration Area, m2 | Size (L × W × D), mm |

|---|---|---|---|

| D-F8 | Multi-Bag | 6.6 | 592 × 592 × 650 |

| B-F8 | Pleat–plate | 7.1 | 592 × 592 × 46 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Y.; Chai, P.; Wang, Y.; Cheng, Z. Assessment of Chemical Fiber Air Filter for General Ventilation. Atmosphere 2021, 12, 1636. https://doi.org/10.3390/atmos12121636

Li Y, Chai P, Wang Y, Cheng Z. Assessment of Chemical Fiber Air Filter for General Ventilation. Atmosphere. 2021; 12(12):1636. https://doi.org/10.3390/atmos12121636

Chicago/Turabian StyleLi, Yanju, Pengchang Chai, Yu Wang, and Zelin Cheng. 2021. "Assessment of Chemical Fiber Air Filter for General Ventilation" Atmosphere 12, no. 12: 1636. https://doi.org/10.3390/atmos12121636

APA StyleLi, Y., Chai, P., Wang, Y., & Cheng, Z. (2021). Assessment of Chemical Fiber Air Filter for General Ventilation. Atmosphere, 12(12), 1636. https://doi.org/10.3390/atmos12121636