Fertilisation Potential of Combined Use of Wood Biomass Ash and Digestate in Maize Cultivation

Abstract

1. Introduction

2. Materials and Methods

2.1. Characteristics of the Experiment

2.2. Characteristics of the Soil

2.3. Characteristics of the Materials (WBA, ULD, SSD, SLD)

2.4. Analytical Analyses

2.5. Statistical Analyses

3. Results

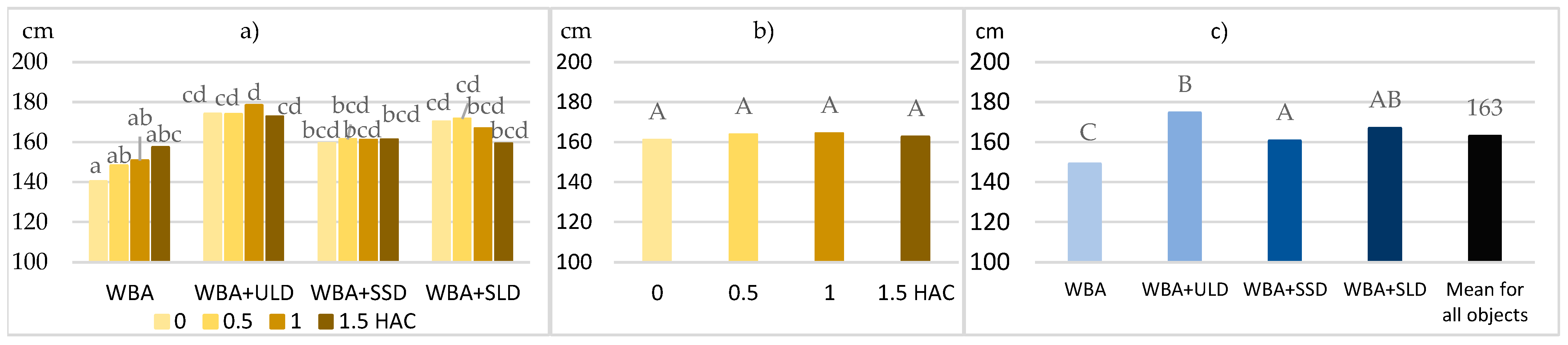

3.1. Yield, Plant Height and Leaf Greenness (SPAD) of Maize

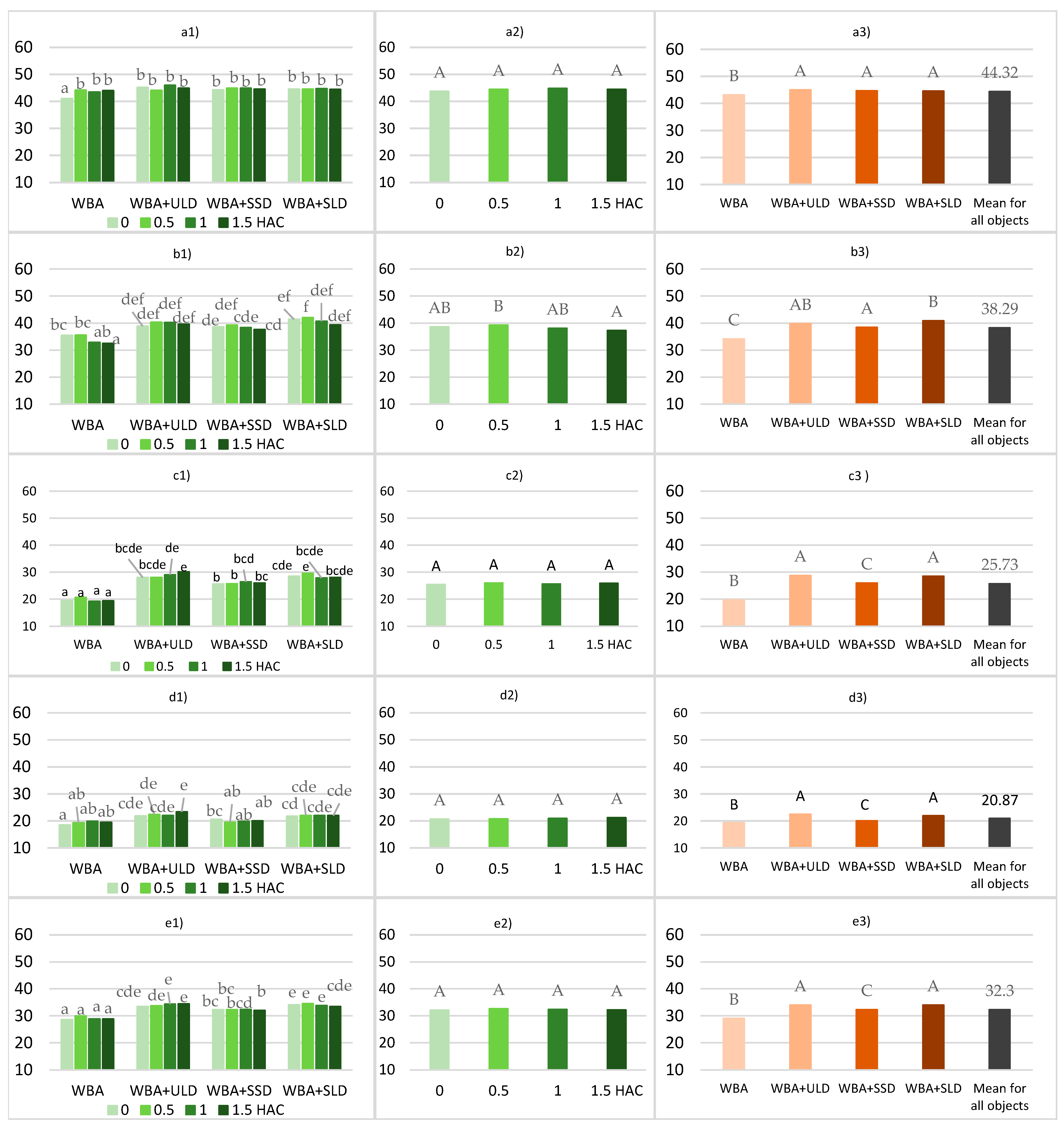

3.2. Dry Matter (DM) Content of Maize

3.3. Content and Uptake of Macronutrients (N, P, K, Mg, Ca and Na) by Maize Biomass

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| WBA | wood biomass ash |

| DG | digestate |

| DGs | digestates |

| ULD | unseparated liquid digestate |

| SSD | separated solid digestate |

| SLD | separated liquid digestate |

| DM | dry matter |

References

- Energy Policy of Poland Until 2040; Ministry of Climate and Environment: Warsaw, Poland, 2021; pp. 1–102. Available online: https://www.gov.pl/attachment/b1febd0c-e544-412d-a0d7-f6bff01707c1 (accessed on 28 July 2025).

- Pazalja, M.; Salihović, M.; Sulejmanović, J.; Smajović, A.; Begić, S.; Špirtović-Halilović, S.; Sher, F. Heavy metals content in ashes of wood pellets and the health risk assessment related to their presence in the environment. Sci. Rep. 2021, 11, 17952. [Google Scholar] [CrossRef] [PubMed]

- Odzijewicz, J.I.; Wołejko, E.; Wydro, U.; Wasil, M.; Jabłońska-Trypuć, A. Utilization of ashes from biomass combustion. Energies 2022, 15, 9653. [Google Scholar] [CrossRef]

- Ministry of Agriculture and Rural Development. Act on Fertilisers and Fertilisation of 10 July 2007. J. Laws 2007, 147, 1–45. [Google Scholar]

- Ministry of Agriculture and Rural Development. Regulation of the Minister of Agriculture and Rural Development of 18 June 2008 on the implementation of certain provisions of the Act on fertilisers and fertilisation. J. Laws 2008, 119, 1–6. [Google Scholar]

- Ministry of Agriculture and Rural Development. Regulation of the Minister of Agriculture and Rural Development of 12 October 2023 on a detailed list of substrates that can be used in agricultural biogas plants. J. Laws 2023, 2230, 1–3. [Google Scholar]

- Ministry of Climate and Environment. Regulation of the Minister of Climate of 18 January 2020 on the waste catalogue. J. Laws 2020, 10, 1–48. [Google Scholar]

- Munawar, M.A.; Khoja, A.H.; Naqvi, S.R.; Mehran, M.T.; Hassan, M.; Liaquat, R.; Dawood, U.F. Challenges and opportunities in biomass ash management and its utilization in novel applications. Renew. Sustain. Energy Rev. 2021, 150, 111451. [Google Scholar] [CrossRef]

- Zając, G.; Szyszlak-Bargłowicz, J.; Gołębiowski, W.; Szczepanik, M. Chemical characteristics of biomass ashes. Energies 2018, 11, 2885. [Google Scholar] [CrossRef]

- Smol, M.; Szołdrowska, D. An analysis of the fertilizing potential of selected waste streams–municipial, industrial and agricultural. Miner. Resour. Manag. 2021, 37, 75–100. [Google Scholar] [CrossRef]

- Zając, G.; Szyszlak-Bargłowicz, J.; Szczepaniak, M. Influence of biomass incineration temperature on the content of selected heavy metals in the ash used for fertilizing purposes. Appl. Sci. 2019, 9, 1790. [Google Scholar] [CrossRef]

- Smołka-Danielowska, D.; Jabłońska, M. Chemical and mineral composition of ashes from wood biomass combustion in domestic wood fired furnaces. Int. J. Environ. Sci. Technol. 2022, 19, 5359–5372. [Google Scholar] [CrossRef]

- Demeyer, A.; Voundi Nkana, J.C.; Verloo, M.G. Characteristics of wood ash and influence on soil properties and nutrient uptake: An overview. Bioresour. Technol. 2001, 77, 287–295. [Google Scholar] [CrossRef]

- Füzesi, I.; Heil, B.; Kovács, G. Effects of wood ash on the chemical properties of soil and crop vitality in small plot experiments. Acta Silv. Lignaria Hung. 2015, 11, 55–64. [Google Scholar] [CrossRef]

- Varshney, A.; Dahiya, P.; Sharma, A.; Pandey, R.; Mohan, S. Fly ash application in soil for sustainable agriculture: An Indian overview. Energy Ecol. Environ. 2022, 7, 340–357. [Google Scholar] [CrossRef]

- Rolka, E.; Żołnowski, A.C.; Wyszkowski, M.; Zych, W.; Skorwider-Namiotko, A. Wood biomass ash (WBA) from the heat production process as a mineral amendment for improving selected soil properties. Energies 2023, 16, 5110. [Google Scholar] [CrossRef]

- Jian, C.; Hamamoto, T.; Inoue, C.; Chien, M.-F.; Naganuma, H.; Mori, T.; Sawada, A.; Hidaka, M.; Setoyama, H.; Makino, T. Effects of wood ash fertilizer on element dynamics in soil solution and crop uptake. Agronomy 2025, 15, 1097. [Google Scholar] [CrossRef]

- Kishor, P.; Ghosh, A.K.; Kumar, D. Use of fly ash in agriculture: A way to improve soil fertility and its productivity. Asian J. Agric. Res. 2010, 4, 1–14. [Google Scholar] [CrossRef]

- Basu, M.; Pande, M.; Bhadoria, P.B.S.; Mahapatra, S.C. Potential fly–ash utilization in agriculture: A global review. Prog. Nat. Sci. 2009, 19, 1173–1186. [Google Scholar] [CrossRef]

- Gill, K.S.; Malhi, S.S.; Lupwayi, N.Z. Wood ash improved soil properties and crop yield for nine years and saved fertilizer. J. Agric. Sci. 2015, 7, 72–83. [Google Scholar] [CrossRef]

- Ajala, R.; Awodun, M.; Oladele, S. Effects of wood ash biomass application on growth indices and chlorophyll content of maize and lima bean intercrop. Turk. JAF Sci. Technol. 2017, 5, 614–621. [Google Scholar] [CrossRef]

- Arshad, S.; Iqbal, M.Z.; Shafiq, M.; Athar, M.; Kabir, M.; Farooqui, Z.R. Azadirachta indica A. Juss: Wood ash affects seedling growth of mung bean Vigna radiata L. Eur. J. Agric. Food Sci. 2020, 2, 1–5. [Google Scholar] [CrossRef][Green Version]

- Arshad, S.; Iqbal, M.Z.; Shafiq, M.; Kabir, M.; Farooqui, Z.R. The effects of wood ash on seed germination and seedling growth of pulse crop Vigna radiata (L.) R. Wilczek. Biosci. Res. 2020, 17, 221–227. [Google Scholar][Green Version]

- Johansen, J.L.; Nielsen, M.L.; Vestergård, M.; Mortensen, L.H.; Cruz-Paredes, C.; Rønn, R.; Kjøller, R.; Hovmand, M.; Christensen, S.; Ekelund, F. The complexity of wood ash fertilization disentangled: Effects on soil pH, nutrient status, plant growth and cadmium accumulation. Environ. Exp. Bot. 2021, 185, 104424. [Google Scholar] [CrossRef]

- Romdhane, L.; Ebinezer, L.B.; Panozzo, A.; Barion, G.; Cortivo, C.D.; Radhouane, L.; Vamerali, T. Effects of soil amendment with wood ash on transpiration, growth, and metal uptake in two contrasting maize (Zea mays L.) hybrids to drought tolerance. Front. Plant Sci. 2021, 12, 661909. [Google Scholar] [CrossRef]

- Adeyemo, A.J.; Daramola, A.R.; Adejoro, S.A.; Ojeniyi, S.O. Application of urea and wood ssh on soil nutrient composition, growth and yield of okra under degraded humid tropical alfisol of South Western Nigeria. J. Hortic. Sci. Crop Res. 2022, 2, 101. [Google Scholar]

- Rolka, E.; Żołnowski, A.C.; Wyszkowski, M.; Skorwider-Namiotko, A. Determination of the possibilities of using woody biomass ash from thermal power plants in corn cultivation. Energies 2024, 17, 2783. [Google Scholar] [CrossRef]

- Couch, R.L.; Luckai, N.; Morris, D.; Diochon, A. Short–term effects of wood ash application on soil properties, growth, and foliar nutrition of Picea mariana and Picea glauca seedlings in a plantation trial. Can. J. Soil Sci. 2021, 101, 203–215. [Google Scholar] [CrossRef]

- Adekayode, F.O.; Olojugba, M.R. The utilization of wood ash as manure to reduce the use of mineral fertilizer for improved performance of maize (Zea mays L.) as measured in the chlorophyll content and grain yield. J. Soil Sci. Environ. 2010, 1, 40–45. [Google Scholar]

- Pandey, V.C.; Singh, N. Impact of fly ash incorporation in soil systems. Agric. Ecosyst. Environ. 2010, 136, 16–27. [Google Scholar] [CrossRef]

- Szostek, M.; Szpunar-Krok, E.; Ilek, A. Chemical speciation of trace elements in soil fertilized with biomass combustion ash and their accumulation in winter oilseed rape plants. Agronomy 2023, 13, 942. [Google Scholar] [CrossRef]

- James, A.K.; Thring, R.W.; Helle, S.; Ghuman, H.S. Ash management review–applications of biomass bottom ash. Energies 2012, 5, 3856–3873. [Google Scholar] [CrossRef]

- Park, B.B.; Yanai, R.D.; Sahm, J.M.; Lee, D.K.; Abrahamson, L.P. Wood ash effects on plant and soil in a willow bioenergy plantation. Biomass Bioenergy 2005, 28, 355–365. [Google Scholar] [CrossRef]

- Iderawumi, A.M. Effects of ash on soil properties and yield of crops. Agric. Obs. 2020, 1, 61–66. [Google Scholar]

- Zuševica, A.; Adamovics, A.; Duminš, K.; Vendina, V.; Žigure, S.; Lazdina, D. Soil fertility improvement with mixtures of wood ash and biogas digestates enhances leaf photosynthesis and extends the growth period for deciduous trees. Plants 2023, 12, 1152. [Google Scholar] [CrossRef]

- Emma-Okafor, L.C.; Obijuru, E.E.; Nwokeji, I.M.; Echereobia, C.O.; Okoli, N.A. Effect of poultry manure and wood ash on the growth and yield of cucumber (Cucumis sativum L.) in Owerri Southeastern Nigeria. Net. J. Agric. Sci. 2022, 10, 49–53. [Google Scholar] [CrossRef]

- Simon, L.; Makadi, M.; Uri, Z.; Vigh, S.; Irinyine-Olah, K.; Vincze, G.; Toth, C. Phytoextraction of toxic elements and chlorophyll fluorescence in the leaves of energy willow (Salix sp.), treated with wastewater solids and wood ash. Agrochem. Soil Sci. 2022, 71, 77–99. [Google Scholar] [CrossRef]

- Abelenda, A.M.; Aiouache, F. Wood ash based treatment of anaerobic digestate: State–of–the–art and possibilities. Processes 2022, 10, 147. [Google Scholar] [CrossRef]

- Adamovics, A.; Poiša, L. The effect of digestate and wood ash mixtures on the productivity and yield quality of maize. Environ. Technol. Resour. 2024, 1, 15–18. [Google Scholar] [CrossRef]

- Rolka, E.; Wyszkowski, M.; Żołnowski, A.C.; Skorwider–Namiotko, A.; Szostek, R.; Wyżlic, K.; Borowski, M. Digestate from an agricultural biogas plant as a factor shaping soil properties. Agronomy 2024, 14, 1528. [Google Scholar] [CrossRef]

- Van Midden, C.; Harris, J.; Shaw, L.; Sizmur, T.; Pawlet, M. The impact of anaerobic digestate on soil life: A review. Appl. Soil Ecol. 2023, 191, 105066–105078. [Google Scholar] [CrossRef]

- Decision of the Minister of Agriculture and Rural Development No. 730/22 of 2 September 2022; Case number: DHR.ns.8100.42.2022.168; Ministry of Agriculture and Rural Development: Warsaw, Poland, 2022.

- Decision of the Minister of Agriculture and Rural Development No. 728/22 of 5 September 2022; Case number: DHR.ns.8100.46.2022.169; Ministry of Agriculture and Rural Development: Warsaw, Poland, 2022.

- Decision of the Minister of Agriculture and Rural Development No. 729/22 of 5 September 2022; Case number: DHR.ns.8100.43.2022.170; Ministry of Agriculture and Rural Development: Warsaw, Poland, 2022.

- Panalytical Malvern. Mastersizer 3000. Brochure. Available online: https://www.malvernpanalytical.com/en/assets/mastersizer%203000%20brochure%20(en)_tcm50-58994.pdf (accessed on 14 April 2023).

- Karczewska, A.; Kabała, C. Methodology of Laboratory Analyzes of Soils and Plants; University of Life Sciences: Wrocław, Poland, 2008. [Google Scholar]

- Bremner, J.M. Nitrogen–Total. Methods of Soil Analysis. Part 3. In Chemical Methods; Sparks, D.L., Page, A.L., Helmke, P.A., Loeppert, R.H., Soltanpour, P.N., Tabatabai, M.A., Johnston, C.T., Sumner, M.E., Eds.; Soil Science Society of America: Madison, WI, USA, 1996; pp. 1087–1123. [Google Scholar]

- Ostrowska, A.; Gawliński, S.; Szczubiałka, Z. Methods of Analysis and Assessment of Soil and Plants Properties, 1st ed.; Institute of Environmental Protection: Warsaw, Poland, 1991. [Google Scholar]

- Egner, H.; Riehm, H.; Domingo, W.R. Untersuchungen Uber Die Chemische Bodenanalyse Als Grundlage Fur Die Beurteilung Des Nahrstoffzustandes Der Boden. II. Chemische Extraktionsmethoden Zur Phosphorund Kaliumbestimmung. K. Lantbrukshogskolans Ann. 1960, 26, 199–215. [Google Scholar]

- Panak, H. Methodological Guide for Agricultural Chemistry Exercises; Agricultural and Technical University in Olsztyn: Olsztyn, Poland, 1995. [Google Scholar]

- Microsoft. MS Excel® for Microsoft 365 MSO; Microsoft Corporation: Albuquerque, NM, USA, 2021. [Google Scholar]

- Burdzy, J. Statistical Tables; Lublin University of Technology Publishing House: Lublin, Poland, 1999. [Google Scholar]

- Tibco. Statistica Data Analysis Software System; Tibco Software Inc.: Palo Alto, CA, USA, 2021. [Google Scholar]

- Schiemenz, K.; Eichler-Löbermann, B. Biomass ashes and their phosphorus fertilizing effect on different crops. Nutr. Cycl. Agroecosyst. 2010, 87, 471–482. [Google Scholar] [CrossRef]

- De la Rosa, J.M.; Pérez-Dalí, S.M.; Campos, P.; Sánchez-Martín, Á.; González-Pérez, J.A.; Miller, A.Z. Suitability of volcanic ash, rice husk ash, green compost and biochar as amendments for a mediterranean alkaline soil. Agronomy 2023, 13, 1097. [Google Scholar] [CrossRef]

- Ike, M.; Kawagoe, H.; Oshita, K.; Takaoka, M. Detailed estimation of generated woody biomass ash for use as fertilizer material. Waste Manag. 2025, 195, 275–283. [Google Scholar] [CrossRef]

- Kovacevic, D.; Manojlovic, M.; Cabilovski, R.; Ilic, Z.S.; Petkovic, K.; Štrbac, M.; Vijuk, M. Digestate and manure use in Kohlrabi production: Impact on plant–available nutrients and heavy metals in soil, yield, and mineral composition. Agronomy 2022, 12, 871. [Google Scholar] [CrossRef]

- Adamovics, A.; Poiša, L. The effect of an innovative fertilizer of digestate and wood ash mixtures on winter garlic productivity. Environ. Technol. Resour. 2023, 1, 12–16. [Google Scholar] [CrossRef]

- Tymchuk, I.; Malovanyy, M.; Zhuk, V.; Kochubei, V.; Yatsukh, K.; Luchyt, L. Towards increasing the utilization of anaerobic digestate from biogas production in agrotechnologies. Ecol. Quest. 2023, 34, 1–18. [Google Scholar] [CrossRef]

- Çalik, B.; Sönmez, İ. The effects of liquid biogas digestate on yield and mineral nutrition of cucumber growing in greenhouse. HortiS 2024, 41, 28–35. [Google Scholar] [CrossRef]

- Koszel, M.; Parafiniuk, S.; Szparaga, A.; Bochniak, A.; Kocira, S.; Atanasov, A.Z.; Kovalyshyn, S. Impact of digestate application as a fertilizer on the yield and quality of winter rape seed. Agronomy 2020, 10, 878. [Google Scholar] [CrossRef]

- Witorożec-Piechnik, A.; Matyka, M.; Woźniak, M.; Oleszek, M. The effect of fertilization with the digestate on the quality and chemical composition of selected plants intended for biogas production. Pol. J. Agron. 2022, 48, 28–36. [Google Scholar] [CrossRef]

- Weimers, K.; Bergstrand, K.-J.; Hultberg, M.; Asp, H. Liquid anaerobic digestate as sole nutrient source in soilless horticulture–or spiked with mineral nutrients for improved plant growth. Front. Plant Sci. 2022, 13, 770179. [Google Scholar] [CrossRef]

- Szwed, M.; Koszel, M.; Przywara, A.; Kachel-Górecka, M. Impact of digestate fertilization on crop production–a comprehensive review. Adv. Sci. Technol. Res. J. 2024, 18, 347–353. [Google Scholar] [CrossRef]

- Kujawska, J.; Cel, W.; Kwiatkowski, C.A.; Harasim, E.; Zamorska, J. The effect of digestate from biogas plants alone and with the addition of biochar and zeolite on soil properties and sorghum yield. Bioresources 2025, 20, 5765–5789. [Google Scholar] [CrossRef]

- Yan, M.; Tian, H.; Song, S.; Tan, H.T.W.; Lee, J.T.E.; Zhang, J.; Sharma, P.; Tiong, Y.W.; Tong, Y.W. Effects of digestate–encapsulated biochar on plant growth, soil microbiome and nitrogen leaching. J. Environ. Manag. 2023, 334, 117481. [Google Scholar] [CrossRef] [PubMed]

- Abelenda, A.M.; Semple, K.T.; Lag-Brotons, A.J.; Herbert, B.M.J.; Aggidis, G.; Aiouache, F. Effects of wood ash-based alkaline treatment on nitrogen, carbon, and phosphorus availability in food waste and agro–industrial waste digestates. Waste Biomass Valorization 2021, 12, 3355–3370. [Google Scholar] [CrossRef]

- Adamovičs, A.; Poiša, L. The effects of digestate and wood ash mixtures on the productivity and yield quality of winter wheat. Environ. Technol. Resour. 2025, 1, 17–21. [Google Scholar] [CrossRef]

| Parameter | Unit | WBA | ULD | SSD | SLD |

|---|---|---|---|---|---|

| Dry mas | % | 60.28 ± 0.646 | 5.509 ± 0.239 | 24.56 ± 0.619 | 5.238 ± 0.044 |

| Soil reaction (pHKCl) | −log10(H+) | 11.97 ± 0.090 | 7.477 ± 0.034 | 9.527 ± 0.025 | 7.487 ± 0.026 |

| Electrical conductivity (EC) | mS cm−1 | 10.49 ± 0.225 | 29.13 ± 1.040 | 25.15 ± 1.105 | 28.87 ± 0.943 |

| Hydrolytic acidity (HAC) | mmol kg−1 | 600.0 ± 4.082 | 285.0 ± 8.500 | 116.3 ± 3.750 | 300.0 ± 5.000 |

| Total carbon (TC) | g kg−1 | 231.7 ± 8.333 | 20.95 ± 0.119 | 39.05 ± 1.338 | 19.51 ± 0.579 |

| Total nitrogen (Ntot) | g kg−1 | 3.550 ± 0.330 | 2.800 ± 0.114 | 5.833 ± 0.175 | 2.473 ± 0.175 |

| C/N | ratio | 65.27 ± 7.175 | 7.496 ± 0.349 | 6.700 ± 0.306 | 7.943 ± 0.781 |

| Phosphorus (Ptot) | g kg−1 | 10.51 ± 0.327 | 2.108 ± 0.164 | 13.36 ± 0.488 | 2.053 ± 0.073 |

| Potassium (Ktot) | g kg−1 | 33.41 ± 0.127 | 8.558 ± 0.062 | 7.722 ± 0.209 | 8.359 ± 0.129 |

| Magnesium (Mgtot) | g kg−1 | 10.31 ± 0.051 | 0.384 ± 0.002 | 0.482 ± 0.002 | 0.368 ± 0.005 |

| Calcium (Catot) | g kg−1 | 168.9 ± 0.514 | 2.368 ± 0.102 | 4.772 ± 0.022 | 2.138 ± 0.228 |

| Sodium (Natot) | g kg−1 | 2.180 ± 0.024 | 3.409 ± 0.071 | 3.245 ± 0.096 | 3.507 ± 0.120 |

| Alkalinity (%CaO) | (%CaO) | 26.93 ± 0.876 | - | - | - |

| WBA Doses of HAC | WBA | WBA + ULD | WBA + SSD | WBA + SLD | Mean for Doses |

|---|---|---|---|---|---|

| 0 | 498.2 ± 25.60 a | 716.8 ± 26.49 c | 604.9 ± 16.00 b | 719.6 ± 8.79 cd | 634.9 ± 93.76 A |

| 0.5 | 478.7 ± 14.03 a | 694.5 ± 46.06 c | 607.7 ± 24.87 b | 706.8 ± 3.87 c | 621.9 ± 95.07 A |

| 1.0 | 469.0 ± 11.03 a | 691.8 ± 15.31 c | 617.5 ± 9.75 b | 757.8 ± 13.15 d | 634.0 ± 108.2 A |

| 1.5 | 478.7 ± 11.67 a | 700.7 ± 18.25 c | 631.9 ± 3.27 b | 734.0 ± 5.45 cd | 636.3 ± 98.84 A |

| Mean for series | 481.1 ± 19.75 A | 701.0 ± 30.69 C | 615.5 ± 18.89 B | 729.6 ± 20.78 D | 631.8 ± 99.28 |

| r | −0.386 n.s. | −0.185 n.s. | 0.537 n.s. | 0.506 n.s. | 0.000 n.s. |

| WBA Doses of HAC | WBA | WBA + ULD | WBA + SSD | WBA + SLD | Mean for Doses |

|---|---|---|---|---|---|

| 0 | 20.44 ± 0.619 c | 20.61 ± 0.936 c | 21.06 ± 0.891 c | 20.60 ± 0.642 c | 20.68 ± 0.818 A |

| 0.5 | 19.58 ± 0.846 bc | 21.27 ± 1.243 c | 20.80 ± 1.340 c | 21.44 ± 0.244 c | 20.77 ± 1.249 A |

| 1.0 | 17.69 ± 1.150 a | 21.03 ± 0.150 c | 20.93 ± 0.809 c | 20.22 ± 0.718 c | 19.97 ± 1.569 A |

| 1.5 | 18.04 ± 0.715 ab | 21.43 ± 0.473 c | 21.09 ± 0.461 c | 20.68 ± 0.242 c | 20.31 ± 1.428 A |

| Mean for series | 18.94 ± 1.411 B | 21.08 ± 0.873 A | 20.97 ± 0.937 A | 20.73 ± 0.675 A | 20.43 ± 1.335 |

| r | −0.720 ** | 0.286 n.s. | 0.027 n.s. | −0.157 n.s. | 0.000 n.s. |

| WBA Doses of HAC | WBA | WBA + ULD | WBA + SSD | WBA + SLD | Mean for Doses |

|---|---|---|---|---|---|

| Nitrogen (N) | |||||

| 0 | 5.413 ± 0.476 abcd | 6.160 ± 0.229 de | 4.947 ± 0.132 ab | 5.040 ± 0.457 ab | 5.390 ± 0.595 A |

| 0.5 | 5.507 ± 0.660 abcd | 6.067 ± 0.476 de | 5.133 ± 0.132 ab | 5.693 ± 0.264 bcde | 5.600 ± 0.548 AB |

| 1.0 | 6.067 ± 0.132 de | 5.880 ± 0.229 cde | 4.853 ± 0.132 a | 5.227 ± 0.132 abc | 5.507 ± 0.515 AB |

| 1.5 | 7.280 ± 0.396 f | 6.347 ± 0.264 e | 4.760 ± 0.229 a | 4.853 ± 0.132 a | 5.810 ± 1.091 B |

| Mean for series | 6.067 ± 0.873 B | 6.113 ± 0.358 B | 4.923 ± 0.213 A | 5.203 ± 0.419 A | 5.577 ± 0.743 |

| r | 0.789 ** | 0.116 n.s. | −0.442 n.s. | −0.274 n.s. | 0.176 n.s. |

| Phosphorus (P) | |||||

| 0 | 4.225 ± 0.116 c | 4.133 ± 0.448 c | 4.217 ± 0.242 c | 3.622 ± 0.315 abc | 4.049 ± 0.394 C |

| 0.5 | 3.702 ± 0.238 abc | 3.869 ± 0.127 abc | 3.616 ± 0.125 abc | 3.538 ± 0.420 abc | 3.681 ± 0.285 AB |

| 1.0 | 3.794 ± 0.214 abc | 4.125 ± 0.536 c | 3.793 ± 0.568 abc | 3.535 ± 0.357 abc | 3.812 ± 0.489 BC |

| 1.5 | 4.039 ± 0.360 bc | 3.189 ± 0.121 a | 3.362 ± 0.123 ab | 3.282 ± 0.007 a | 3.468 ± 0.390 A |

| Mean for series | 3.940 ± 0.322 B | 3.829 ± 0.526 AB | 3.747 ± 0.447 AB | 3.494 ± 0.342 A | 3.753 ± 0.449 |

| r | −0.161 n.s. | −0.547 n.s. | −0.597 n.s. | −0.334 n.s. | −0.402 ** |

| Potassium (K) | |||||

| 0 | 16.00 ± 0.633 a | 18.83 ± 0.821 bcd | 16.39 ± 1.337 ab | 20.97 ± 1.323 defg | 18.05 ± 2.277 B |

| 0.5 | 19.89 ± 0.327 cde | 20.88 ± 1.762 defg | 17.22 ± 1.379 abc | 22.51 ± 1.417 efgh | 20.12 ± 2.338 C |

| 1.0 | 23.01 ± 2.070 fghi | 24.12 ± 1.399 hi | 18.98 ± 0.873 bcd | 23.78 ± 1.018 ghi | 22.48 ± 2.497 A |

| 1.5 | 25.56 ± 1.298 i | 23.41 ± 1.680 ghi | 20.26 ± 0.294 def | 24.57 ± 1.231 hi | 23.45 ± 2.345 A |

| Mean for series | 21.11 ± 3.791 A | 21.81 ± 2.561 AB | 18.21 ± 1.846 C | 22.96 ± 1.852 B | 21.02 ± 3.164 |

| r | 0.938 ** | 0.742 ** | 0.810 ** | 0.728 ** | 0.656 ** |

| Magnesium (Mg) | |||||

| 0 | 0.627 ± 0.088 a | 0.809 ± 0.029 bcde | 0.718 ± 0.028 abc | 0.716 ± 0.037 ab | 0.718 ± 0.083 C |

| 0.5 | 0.767 ± 0.110 bcde | 0.834 ± 0.024 bcde | 0.807 ± 0.064 bcde | 0.788 ± 0.030 bcde | 0.799 ± 0.071 A |

| 1.0 | 0.882 ± 0.013 ef | 0.840 ± 0.015 bcde | 0.750 ± 0.038 bcd | 0.794 ± 0.012 bcde | 0.817 ± 0.054 AB |

| 1.5 | 0.979 ± 0.064 f | 0.851 ± 0.047 de | 0.769 ± 0.014 bcde | 0.845 ± 0.088 cde | 0.861 ± 0.096 B |

| Mean for series | 0.814 ± 0.153 AB | 0.833 ± 0.035 B | 0.761 ± 0.051 A | 0.786 ± 0.068 AB | 0.798 ± 0.093 |

| r | 0.857 ** | 0.427 n.s. | 0.209 n.s. | 0.643 * | 0.537 ** |

| Calcium (Ca) | |||||

| 0 | 0.591 ± 0.013 ab | 0.641 ± 0.034 abcd | 0.577 ± 0.010 a | 0.632 ± 0.026 abc | 0.610 ± 0.035 A |

| 0.5 | 0.674 ± 0.018 abcde | 0.694 ± 0.006 bcdef | 0.593 ± 0.018 ab | 0.680 ± 0.060 abcde | 0.660 ± 0.051 B |

| 1.0 | 0.725 ± 0.021 cdef | 0.709 ± 0.077 cdef | 0.694 ± 0.021 bcdef | 0.743 ± 0.057 def | 0.718 ± 0.054 C |

| 1.5 | 0.944 ± 0.070 g | 0.790 ± 0.044 f | 0.745 ± 0.073 def | 0.776 ± 0.064 ef | 0.814 ± 0.100 D |

| Mean for series | 0.847 ± 0.136 A | 0.742 ± 0.072 A | 0.775 ± 0.080 B | 0.686 ± 0.078 A | 0.763 ± 0.100 |

| r | 0.734 ** | 0.708 ** | 0.652 * | 0.707 ** | 0.700 ** |

| Sodium (Na) | |||||

| 0 | 0.847 ± 0.008 c | 0.986 ± 0.030 d | 0.656 ± 0.002 a | 1.055 ± 0.042 e | 0.886 ± 0.155 A |

| 0.5 | 0.851 ± 0.015 c | 0.982 ± 0.030 d | 0.657 ± 0.022 a | 1.067 ± 0.027 e | 0.889 ± 0.156 A |

| 1.0 | 0.855 ± 0.006 c | 0.954 ± 0.007 d | 0.712 ± 0.014 b | 0.976 ± 0.007 d | 0.874 ± 0.105 A |

| 1.5 | 0.878 ± 0.016 c | 0.946 ± 0.025 d | 0.713 ± 0.006 b | 0.964 ± 0.022 d | 0.875 ± 0.101 A |

| Mean for series | 0.858 ± 0.017 B | 0.967 ± 0.030 C | 0.684 ± 0.031 A | 1.015 ± 0.054 D | 0.881 ±0.132 |

| r | 0.636 * | −0.540 n.s. | 0.816 ** | −0.762 ** | −0.040 n.s. |

| Elements | Nitrogen (N) | Phosphorus (P) | Potassium (K) | Magnesium (Mg) | Calcium (Ca) |

|---|---|---|---|---|---|

| Phosphorus (P) | 0.235 n.s. | ||||

| Potassium (K) | 0.388 ** | −0.276 n.s. | |||

| Magnesium (Mg) | 0.672 ** | −0.086 n.s. | 0.595 ** | ||

| Calcium (Ca) | 0.494 ** | −0.246 n.s. | 0.759 ** | 0.647 ** | |

| Sodium (Na) | 0.308 * | −0.120 n.s. | 0.532 ** | 0.143 n.s. | 0.206 n.s. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rolka, E.; Wyszkowski, M.; Skorwider-Namiotko, A.; Szostek, R. Fertilisation Potential of Combined Use of Wood Biomass Ash and Digestate in Maize Cultivation. Agronomy 2025, 15, 1968. https://doi.org/10.3390/agronomy15081968

Rolka E, Wyszkowski M, Skorwider-Namiotko A, Szostek R. Fertilisation Potential of Combined Use of Wood Biomass Ash and Digestate in Maize Cultivation. Agronomy. 2025; 15(8):1968. https://doi.org/10.3390/agronomy15081968

Chicago/Turabian StyleRolka, Elżbieta, Mirosław Wyszkowski, Anna Skorwider-Namiotko, and Radosław Szostek. 2025. "Fertilisation Potential of Combined Use of Wood Biomass Ash and Digestate in Maize Cultivation" Agronomy 15, no. 8: 1968. https://doi.org/10.3390/agronomy15081968

APA StyleRolka, E., Wyszkowski, M., Skorwider-Namiotko, A., & Szostek, R. (2025). Fertilisation Potential of Combined Use of Wood Biomass Ash and Digestate in Maize Cultivation. Agronomy, 15(8), 1968. https://doi.org/10.3390/agronomy15081968